Patents

Literature

149results about How to "Simplify the process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

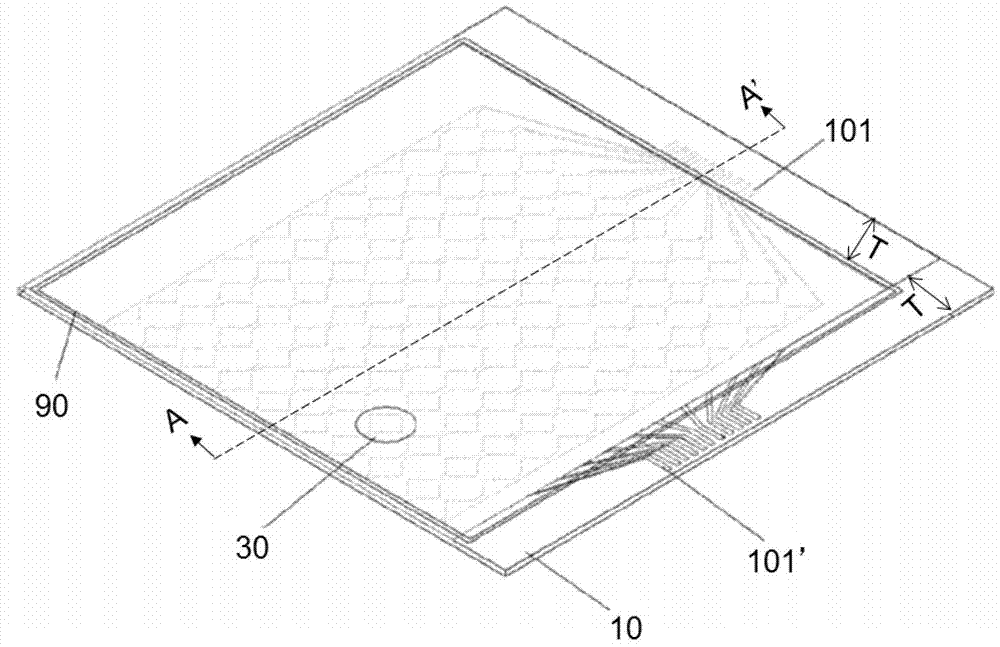

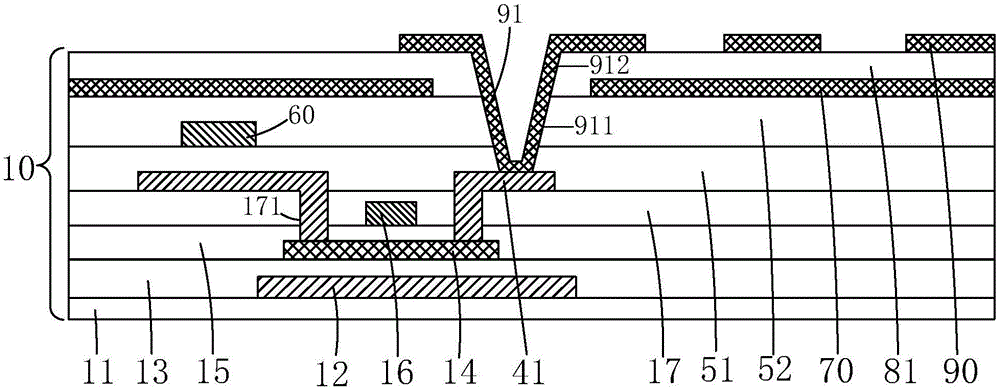

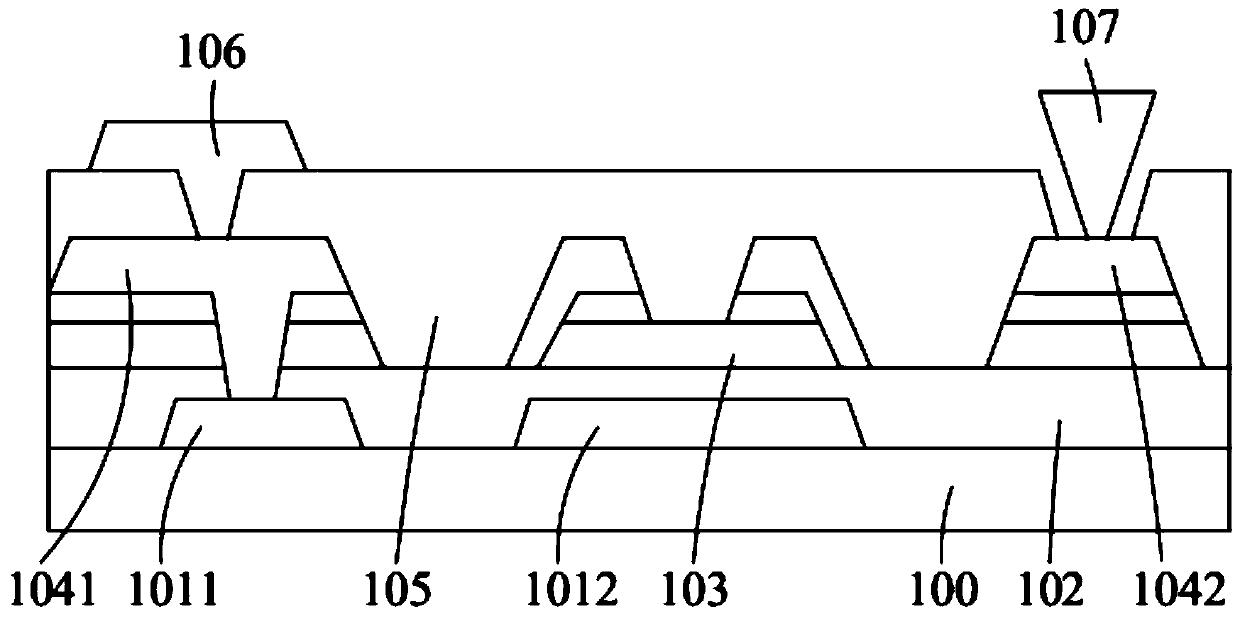

Display panel, manufacturing method of display panel and display device

ActiveCN107808896ASimplify the processHigh precisionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAnode

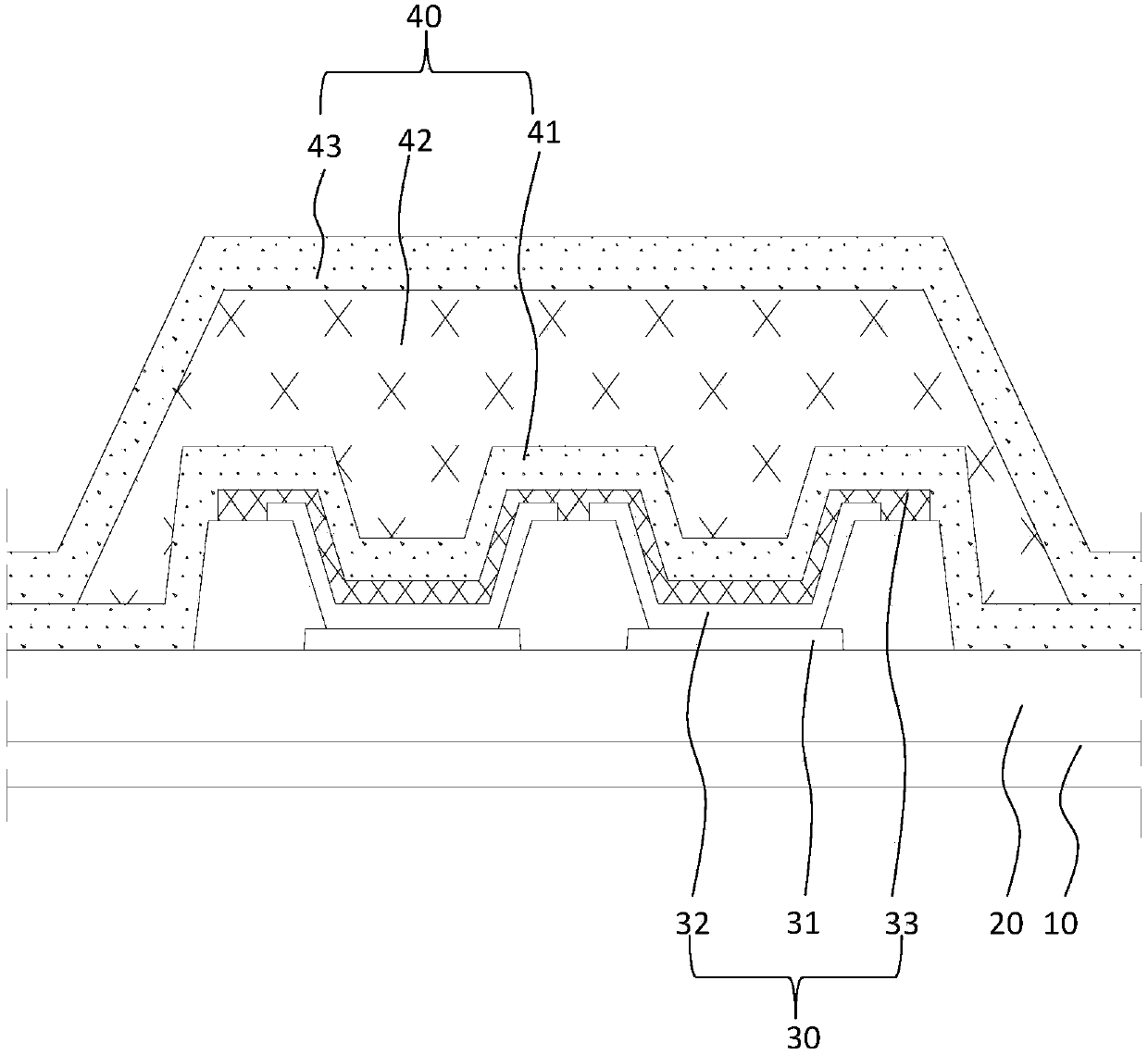

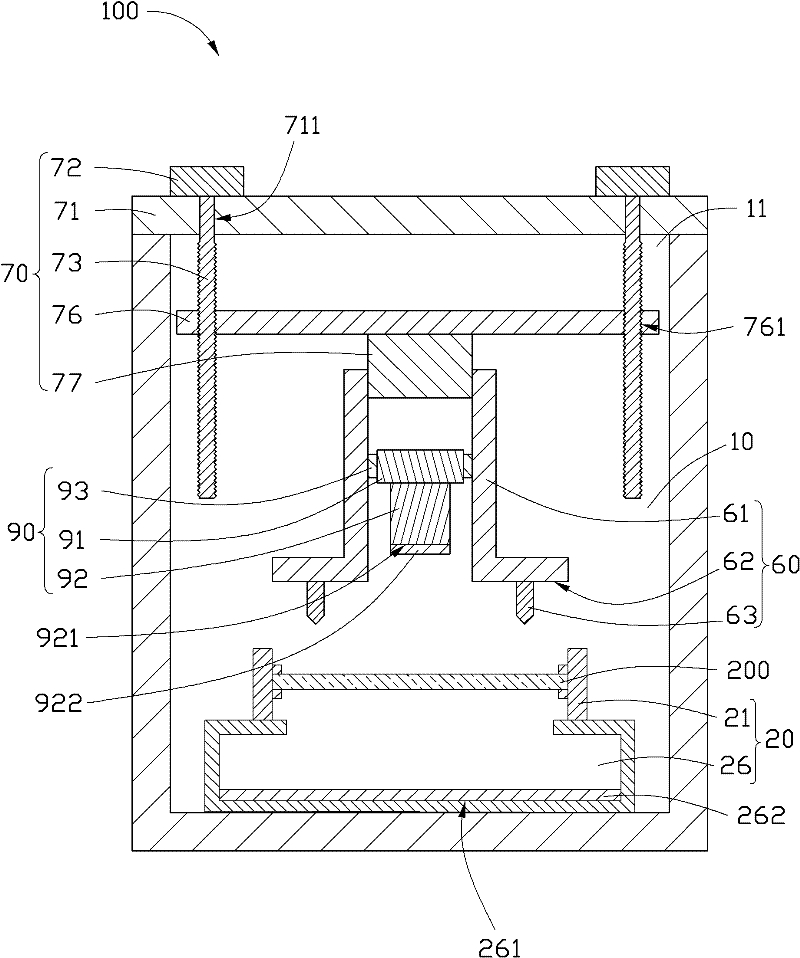

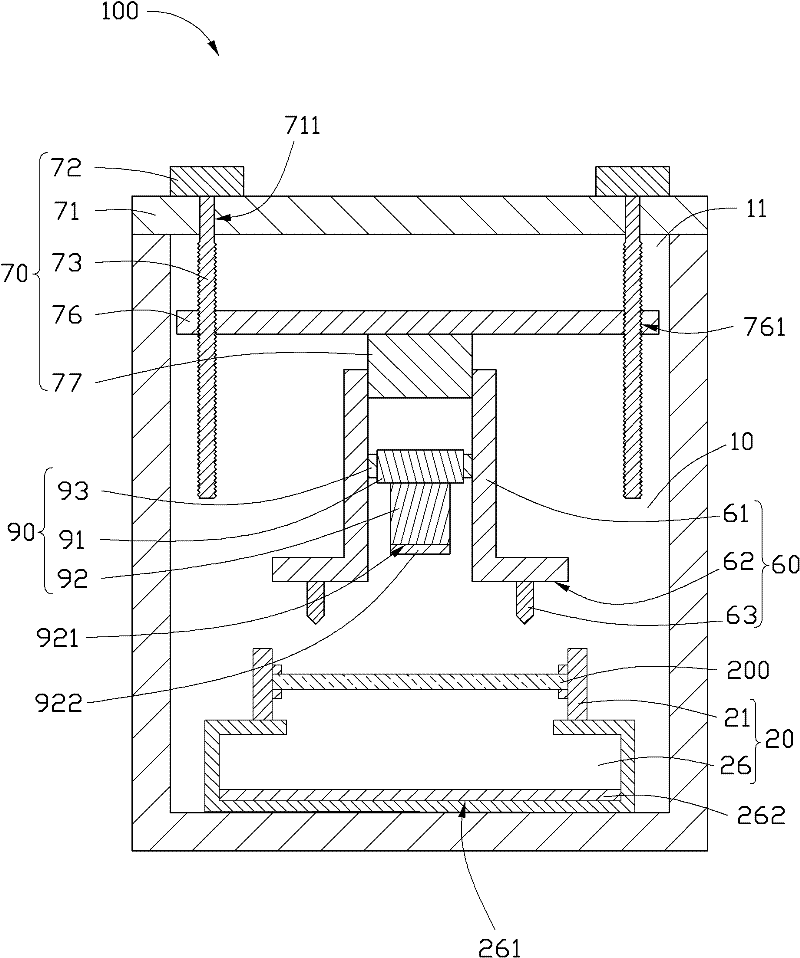

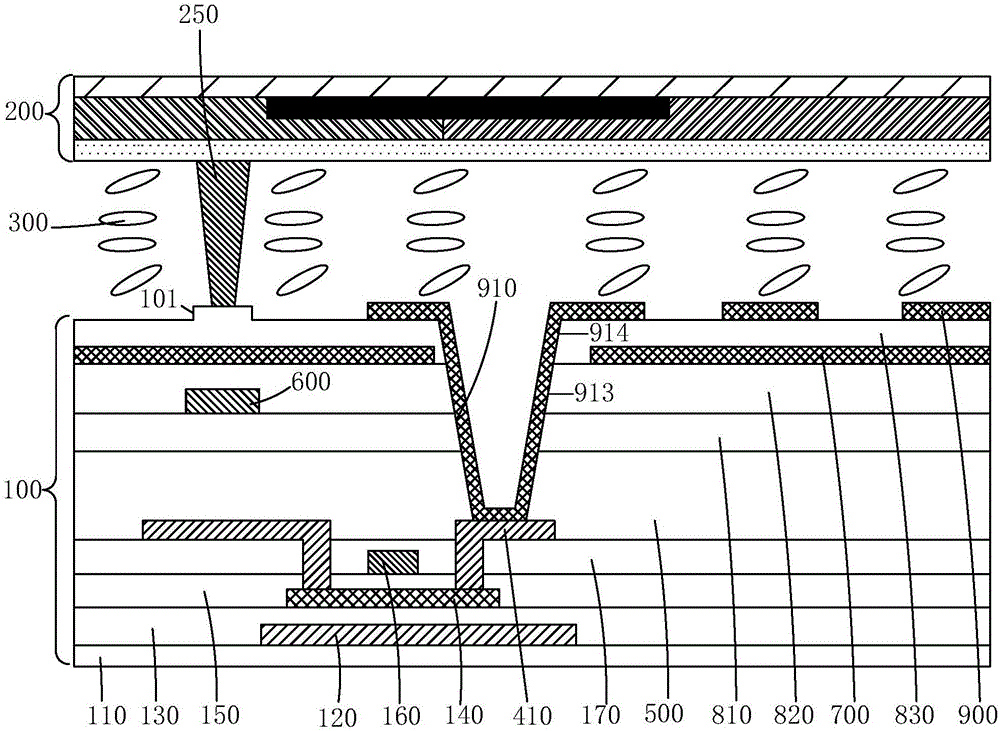

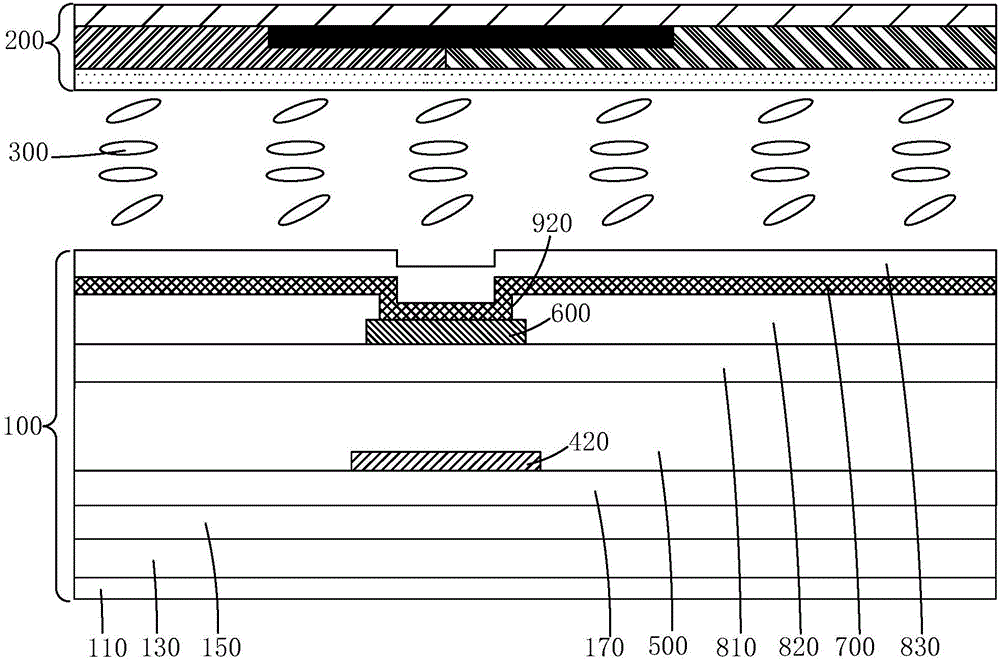

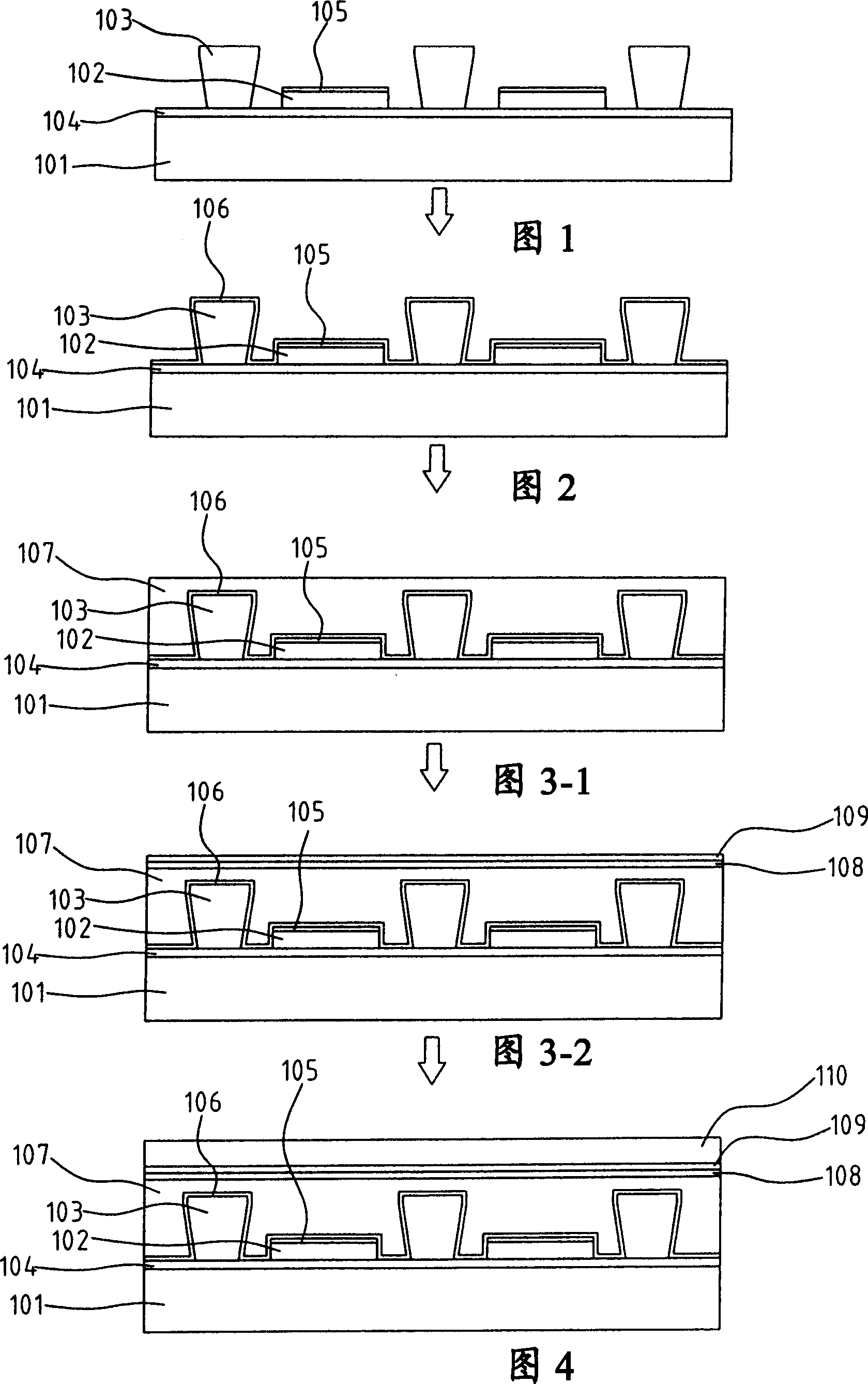

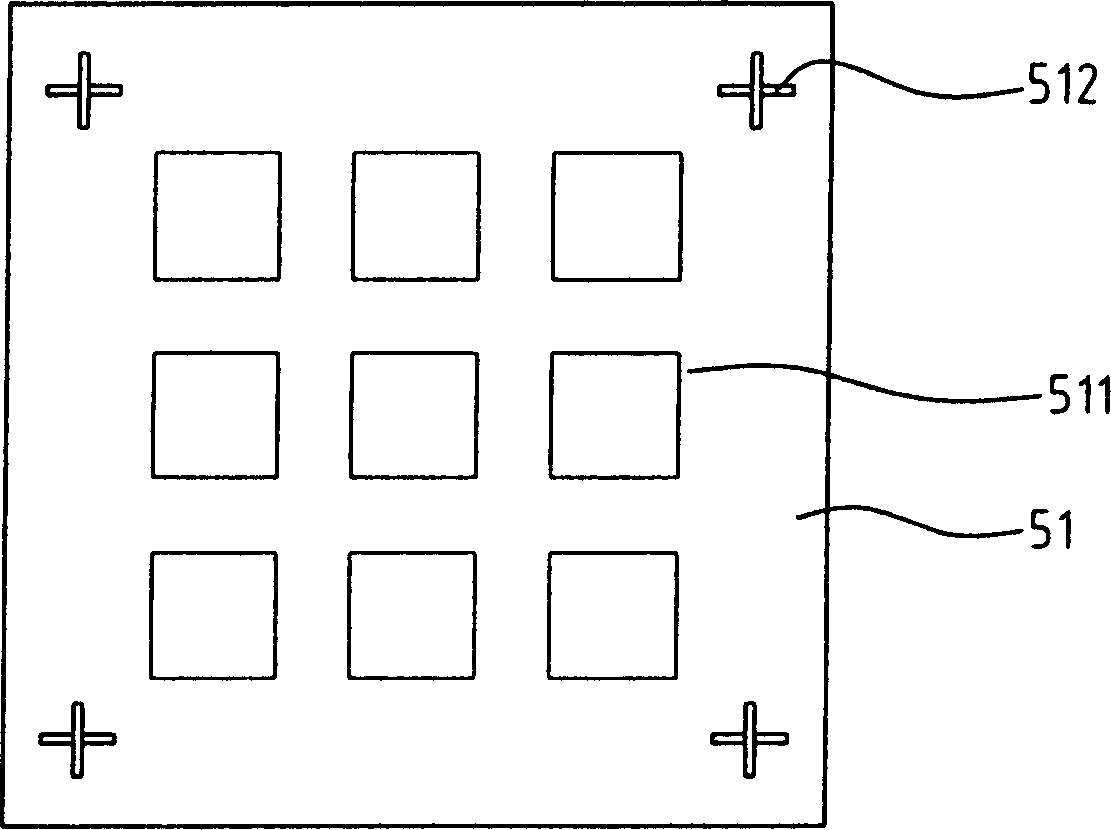

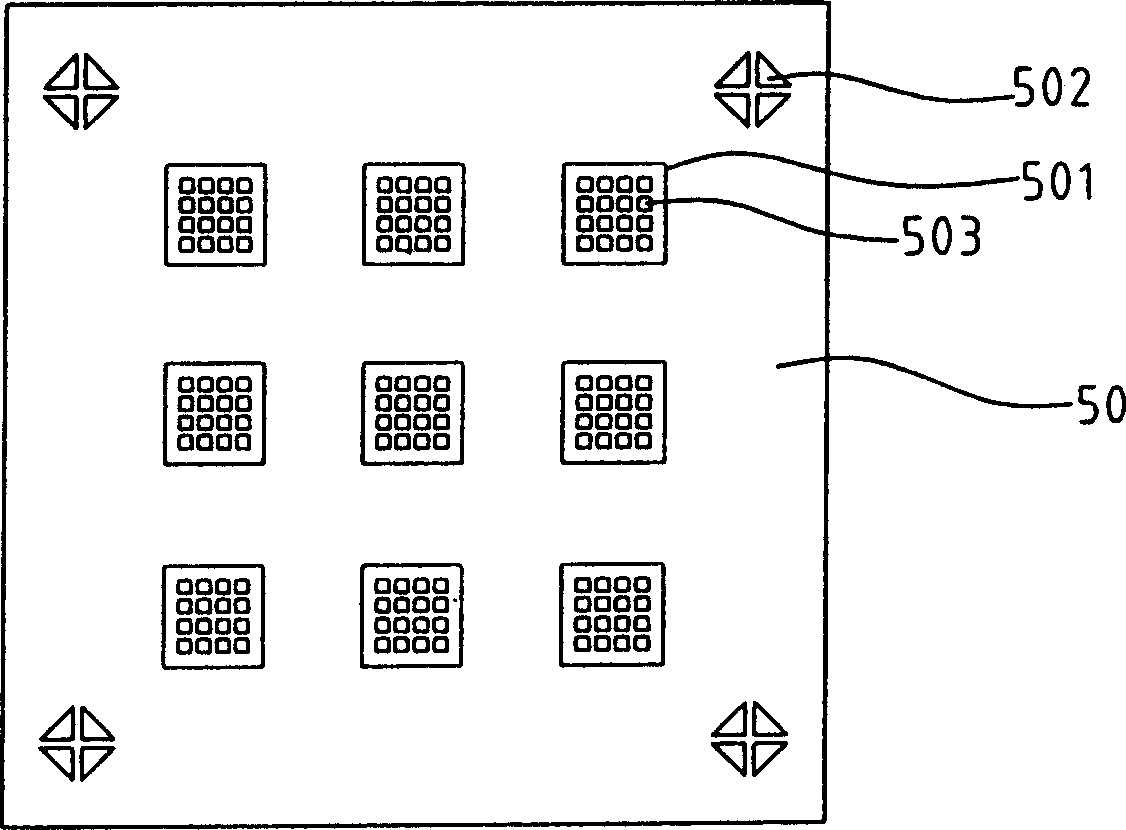

The invention provides a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a substrate; an array layer which is arranged on one side of the substrate; a luminescence functional layer which is arranged on one side away from the substrate of the array layer and comprises an anode layer, an organic light-emitting layer and a cathode layer which are arranged along the direction away from the substrate; and a thin film packaging layer which is arranged on one side away from the array layer of the luminescence functional layer and completelycovers the luminescence functional layer and comprises a first inorganic packaging layer, a first organic packaging layer and a second inorganic packaging layer which are arranged along the directionaway from the substrate, wherein the edges of the orthographic projection of the cathode layer, the first inorganic packaging layer and the first organic packaging layer on the display panel are overlapped, and the second inorganic packaging layer covers the luminescence functional layer, the first inorganic packaging layer and the first organic packaging layer. According to the display panel, the manufacturing process can be simplified and the accuracy of the cathode patterning technology can be enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

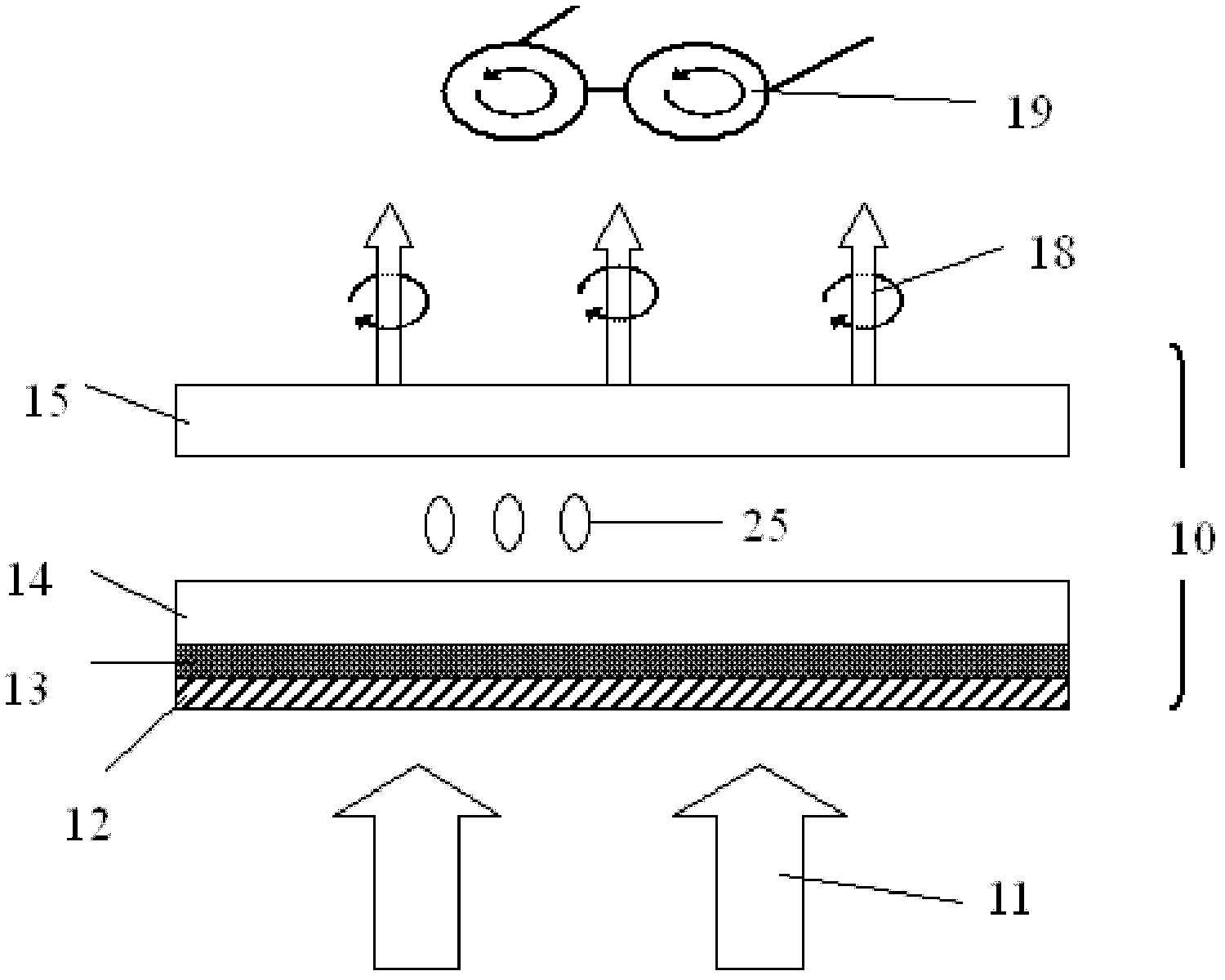

Anti-peep liquid crystal display

InactiveCN102360136AReduce processing costsSimplify the processNon-linear opticsOptical elementsPolarizerLiquid-crystal display

The invention discloses an anti-peep liquid crystal display. The liquid crystal display comprises a liquid crystal panel and circular polarized glasses matched with the liquid crystal panel, wherein the liquid crystal panel comprises a color film substrate and an array substrate which are arranged oppositely, and a liquid crystal layer arranged between the color film substrate and the array substrate; and a first 1 / 4 phase delay film and a first polarizer are arranged on the array substrate in turn. The liquid crystal display can prevent a picture on a display screen from being peeped by other people.

Owner:NANJING CEC PANDA LCD TECH

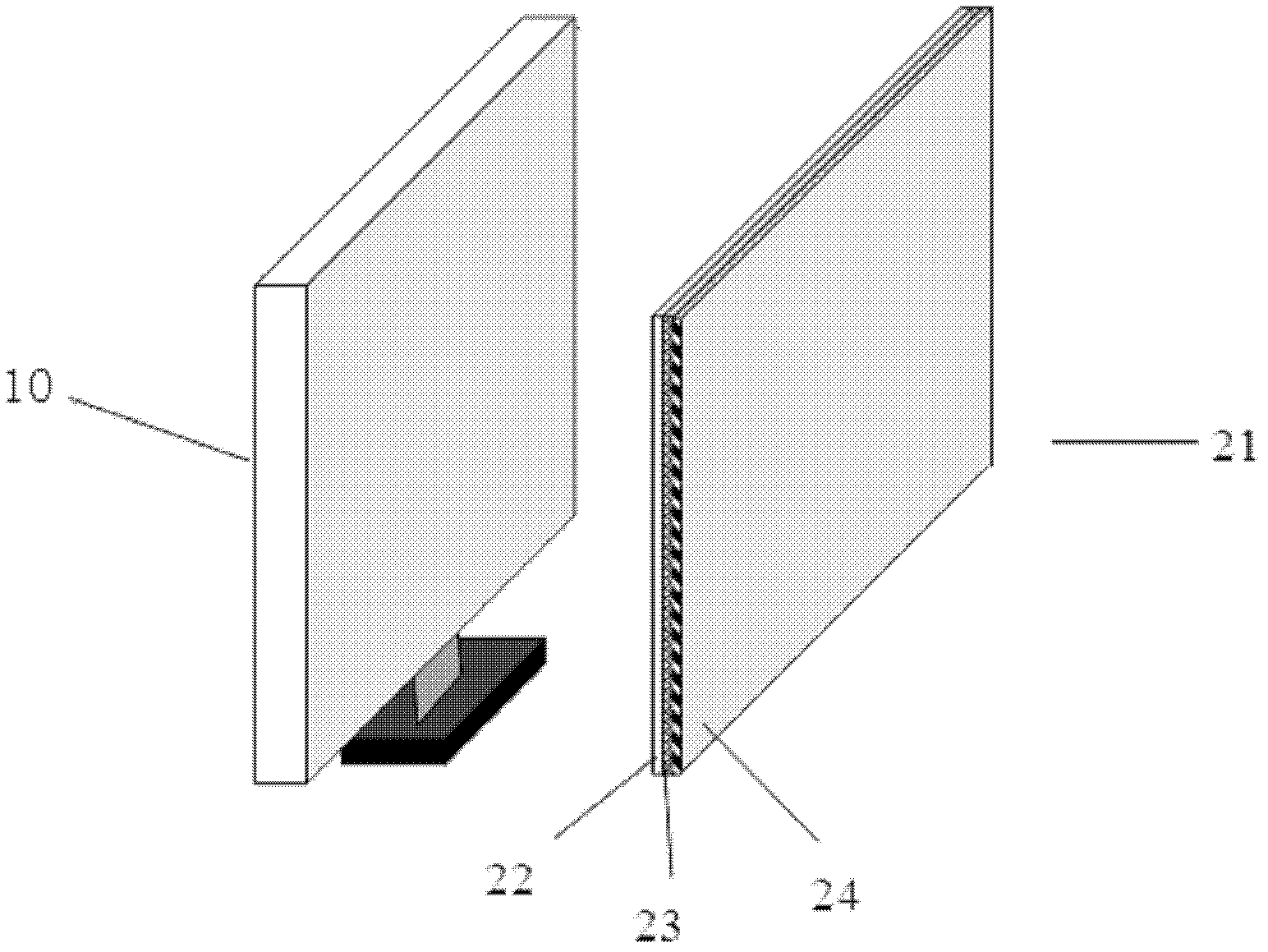

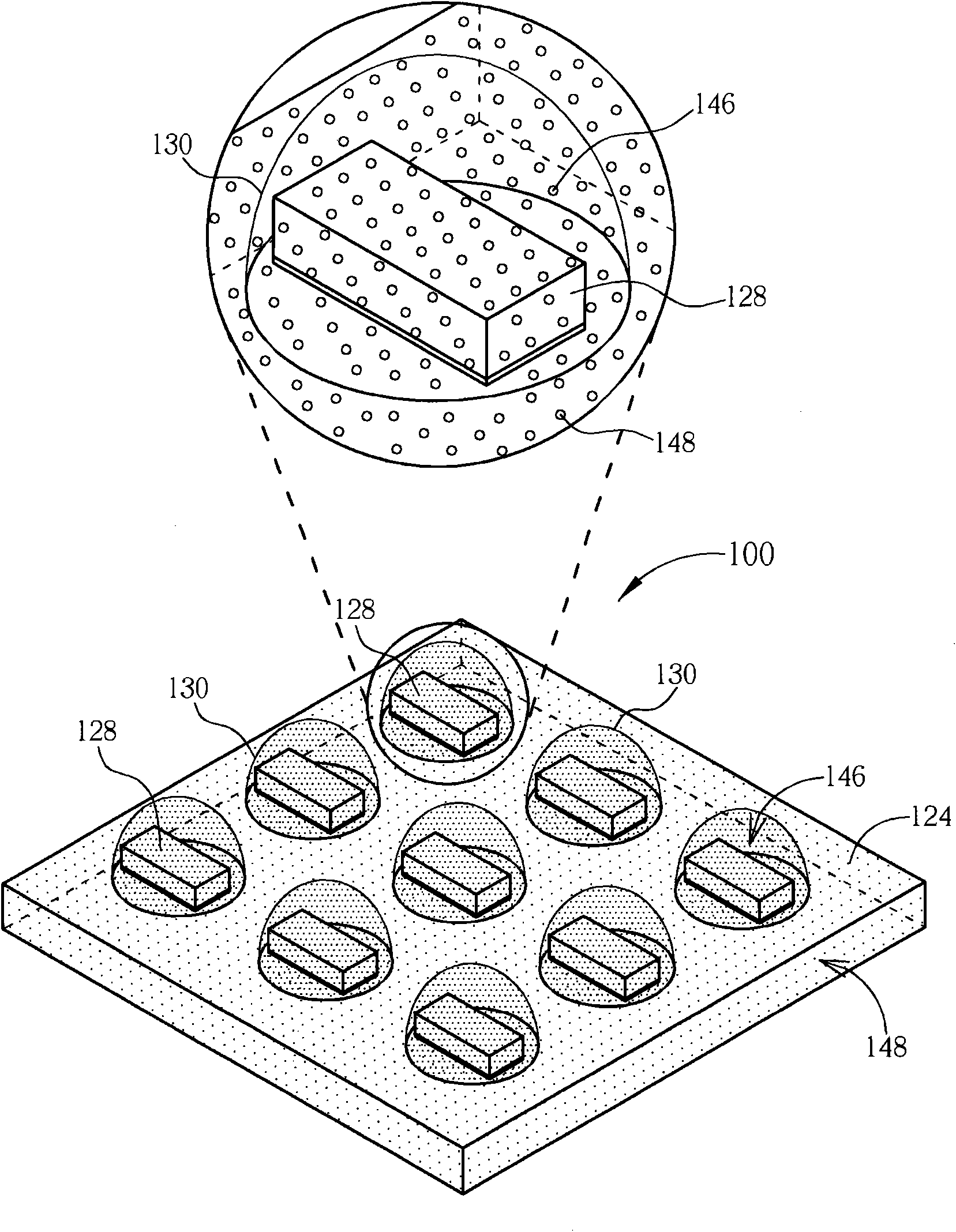

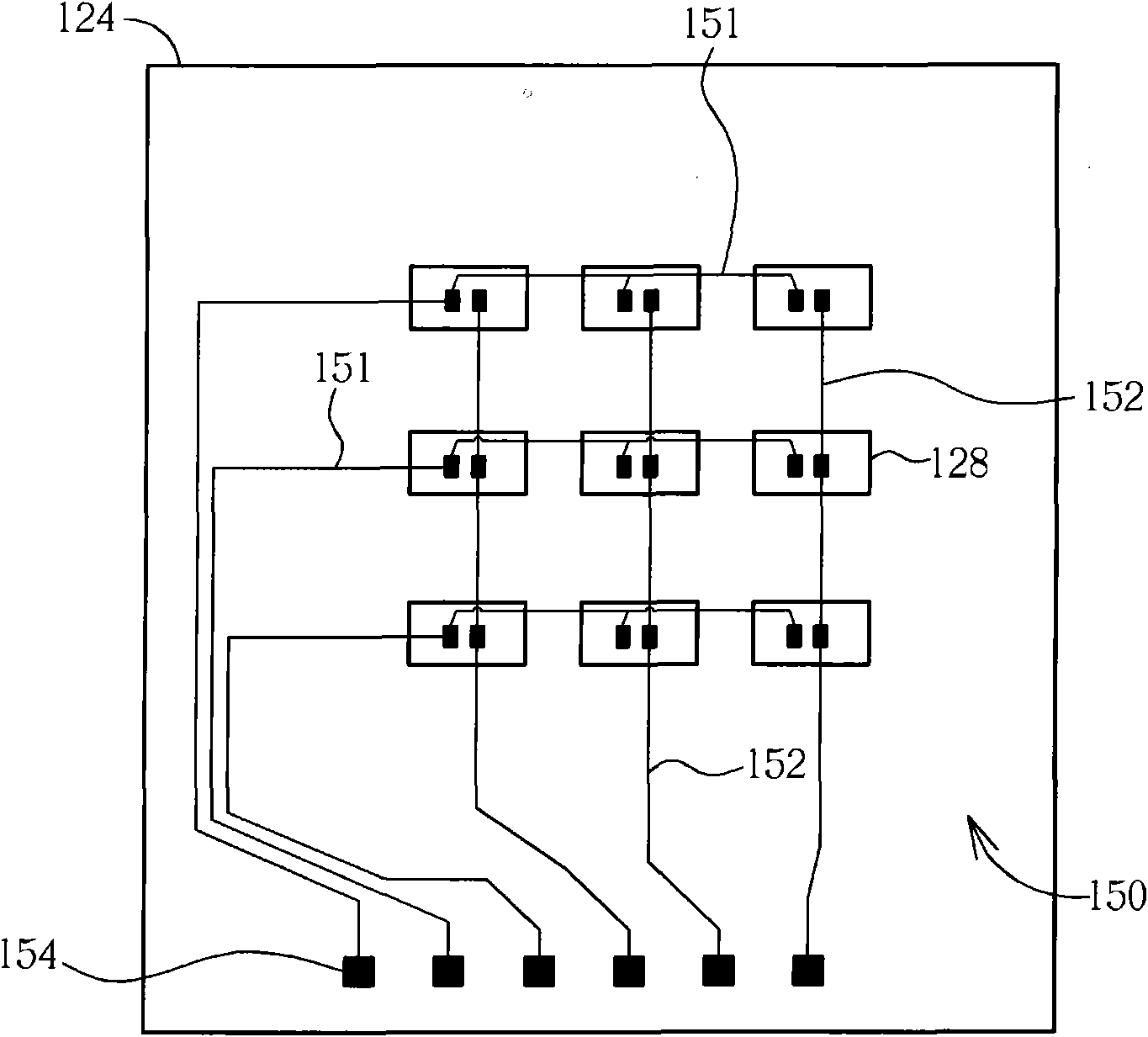

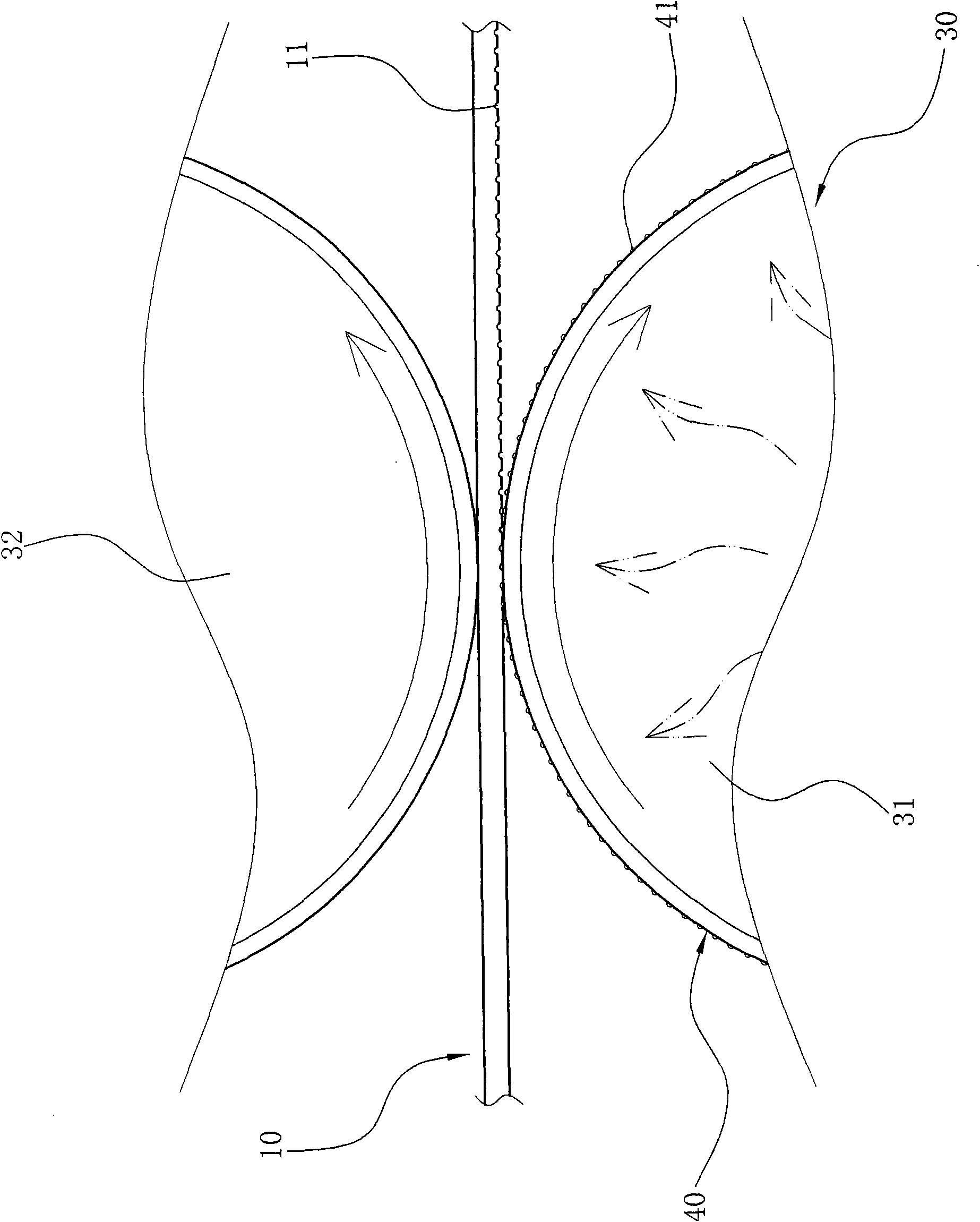

Light emitting diode device and packaging method therefore

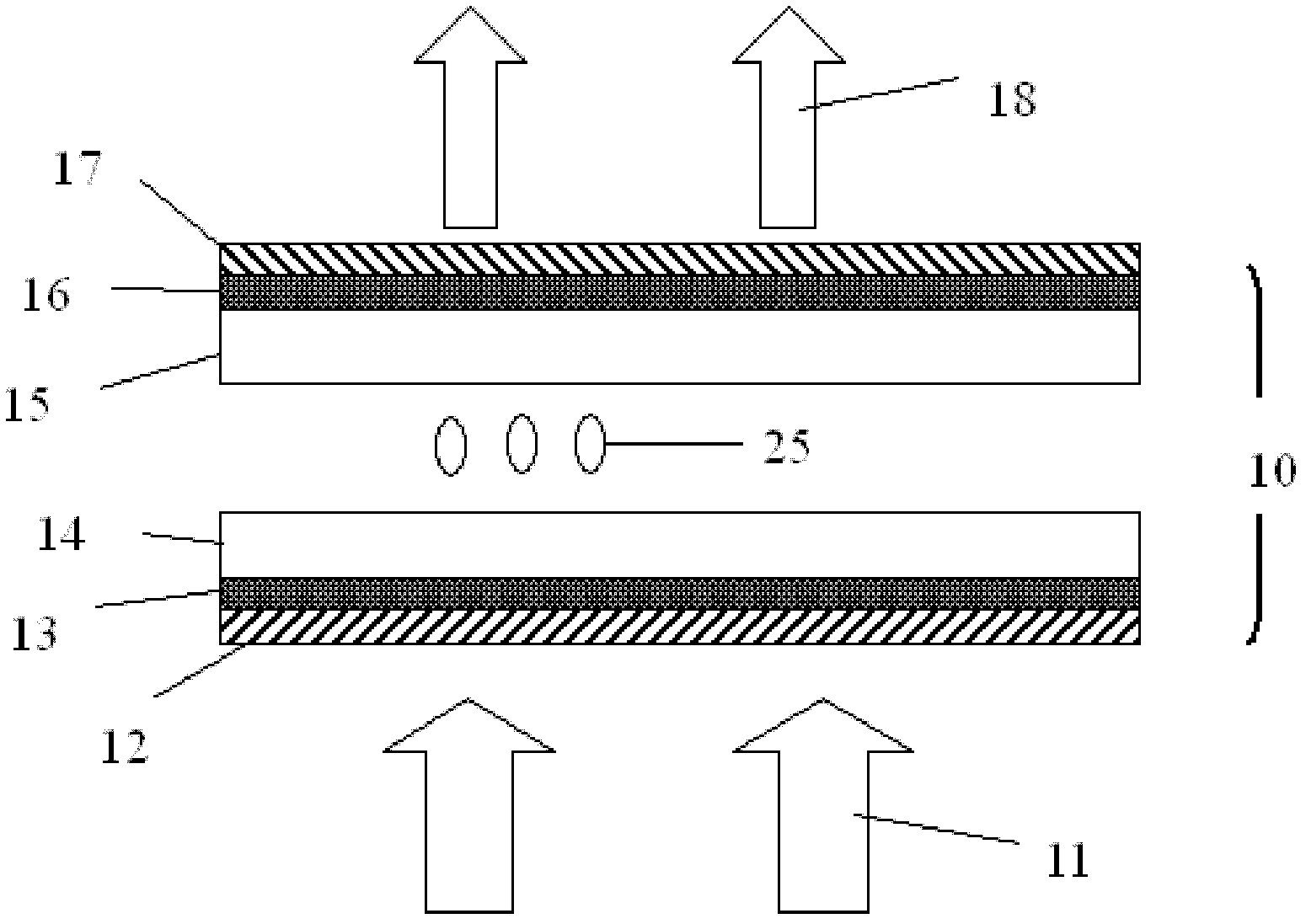

The invention provides a light emitting diode device which comprises a transparent base plate, a plurality of light emitting diode chips, a circuit and a transparent colloid, wherein the light emitting diode chips are fixedly connected to the transparent base plate; the circuit is formed on the transparent base plate and is electrically connected to the light emitting diode chips; and the transparent colloid is used for packaging the light emitting diode chips. The light emitting diode chips are used for generating light rays with at least one type of wavelength, and the light generated by the light emitting diode chips is respectively emitted to two opposite surfaces of the transparent base plate. The blue light chips are welded on the circuit of the transparent base plate, the fluorescence material is matched and coated, and the advantages of the base plate are utilized, therefore the double-surface white light emitting device packaged by the chips is manufactured.

Owner:EVERLIGHT ELECTRONICS

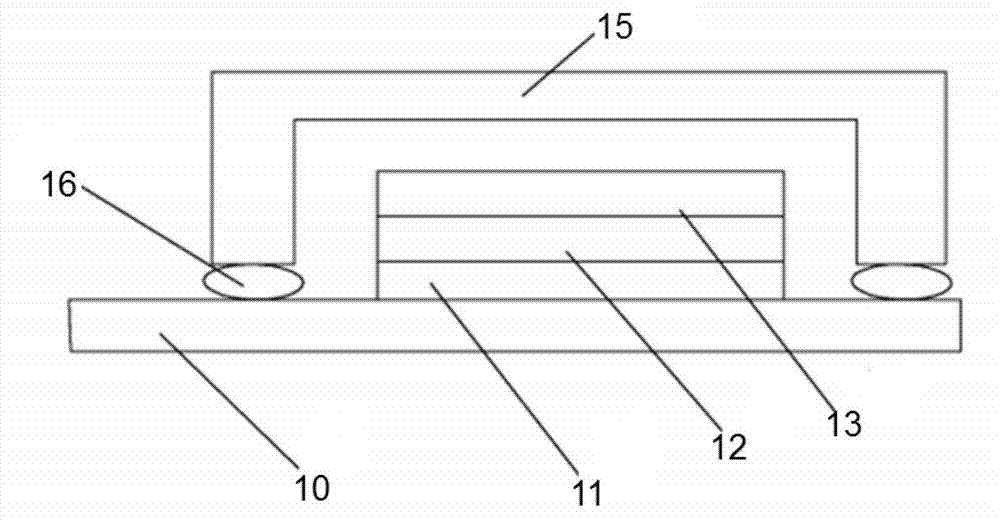

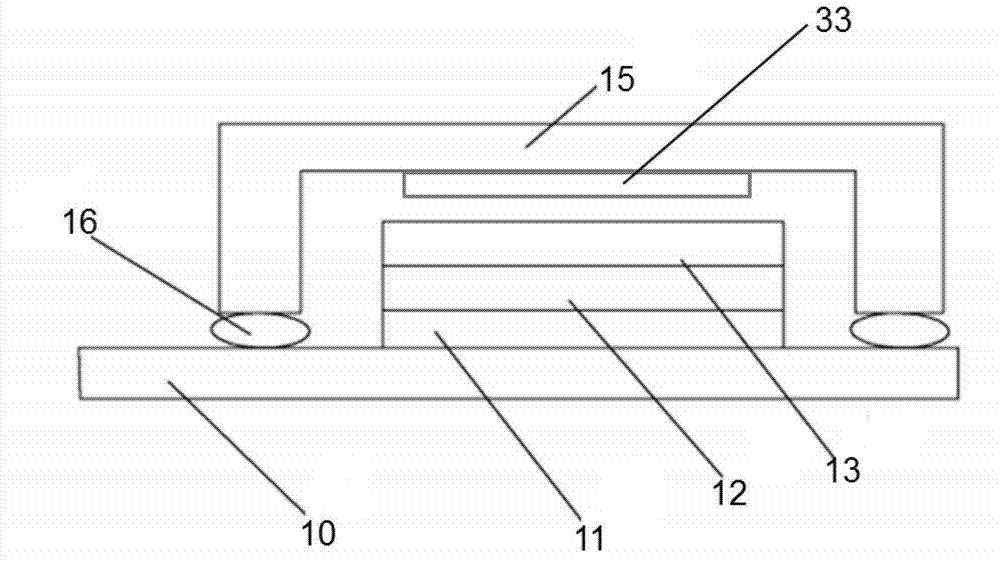

OLED (organic light-emitting diode) display

InactiveCN103050506AReduce thicknessSimplify the processSolid-state devicesInput/output processes for data processingControl functionIntegrated circuit

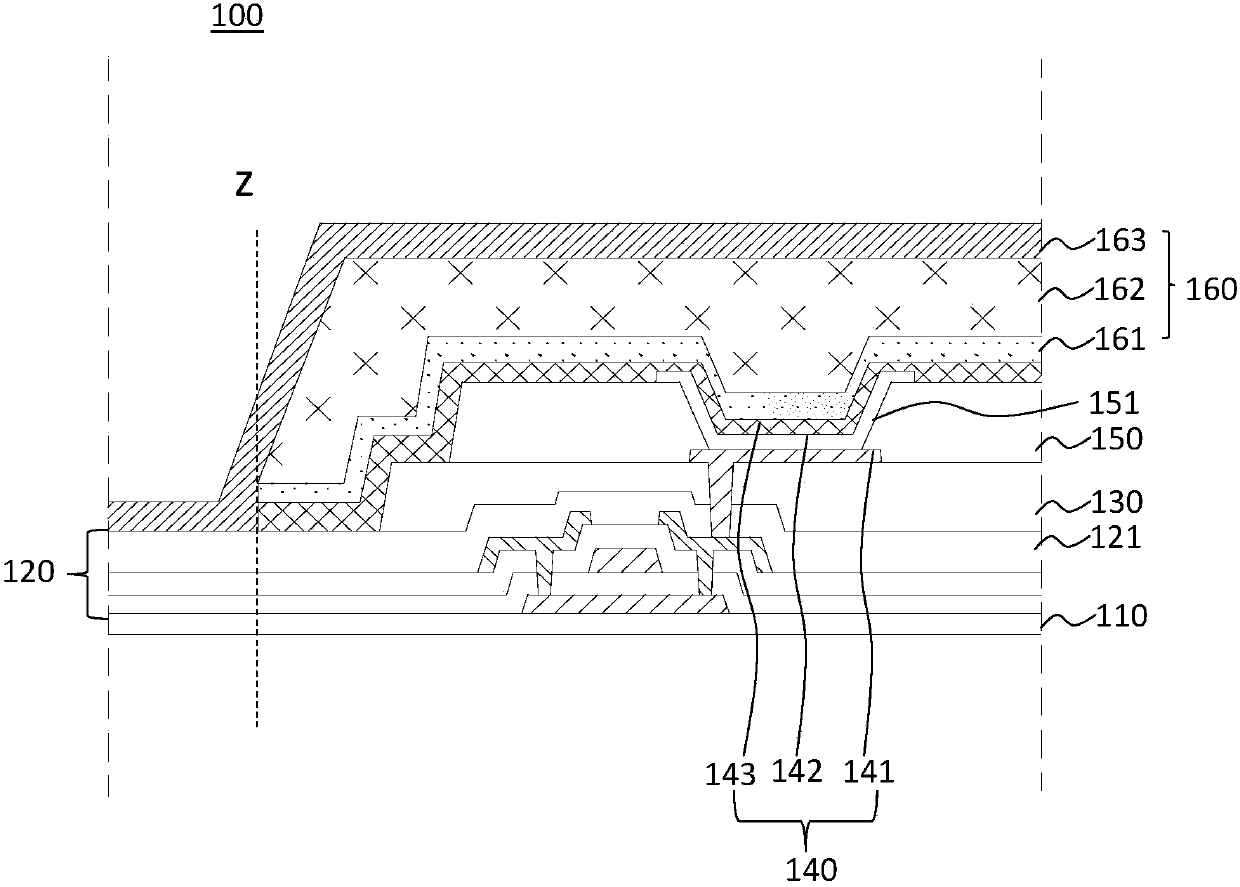

The invention discloses an OLED (organic light-emitting diode) display, which comprises a base plate, an isolation layer and a touch controlled functional layer, wherein an OLED light-emitting element is formed on the base plate. The OLED light-emitting element comprises an OLED displaying component, an organic light-emitting functional layer and an OLED anode; the isolation layer is formed on the OLED light-emitting element; the touch controlled functional layer is formed on the isolation layer, and the touch controlled functional layer is provided with a touch controlled electrode; and the touch controlled electrode and the OLED anode are respectively connected onto respective ICs (integrated circuits) to form a top light-emitting OLED display integrated with touch control. A shielding layer is arranged between the isolation layer and the touch controlled functional layer, an insulation layer is arranged on the shielding layer, and thus signal interference between the OLED light-emitting element and the touch controlled functional layer is prevented. As the OLED light-emitting element and the touch controlled functional layer are arranged on the same base plate, the thickness of the OLED display integrated with a touch control function in the prior art is reduced. The touch controlled electrode is connected onto the terminal part of the base plate and is further connected onto the respective IC through the terminal part, thus the manufacture process of the display is simplified.

Owner:NANJING CEC PANDA LCD TECH

Service data transmission and apparatus thereof

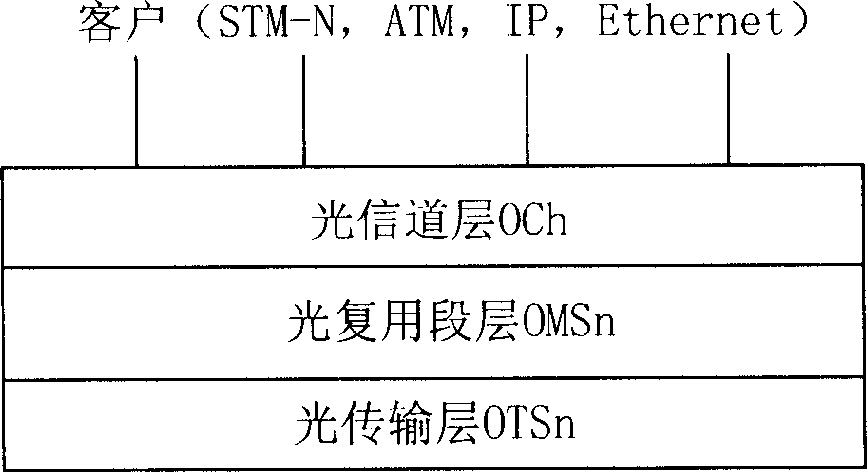

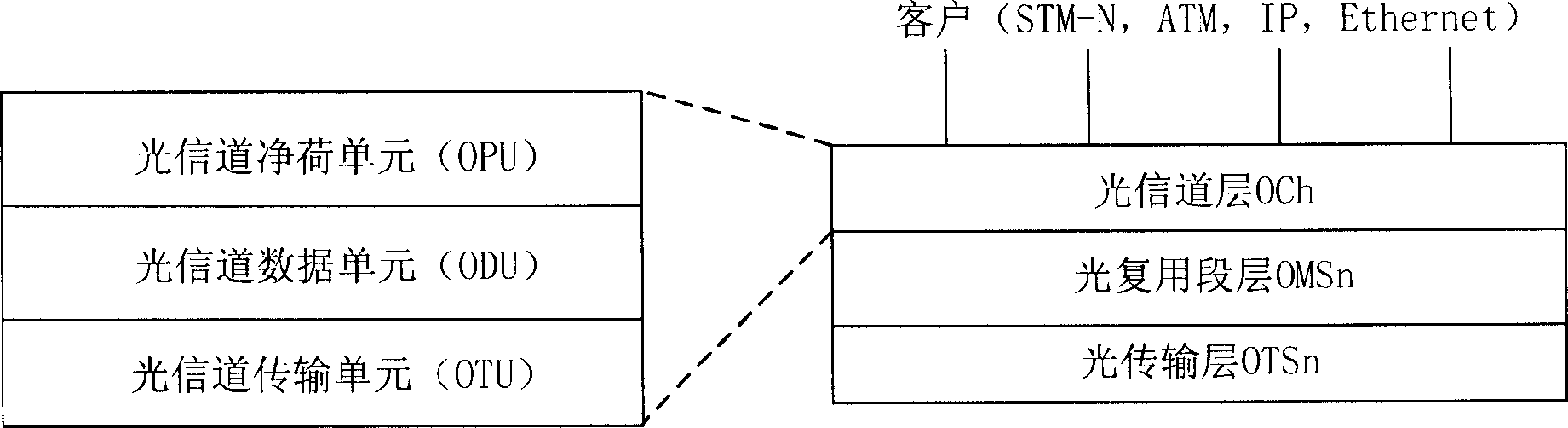

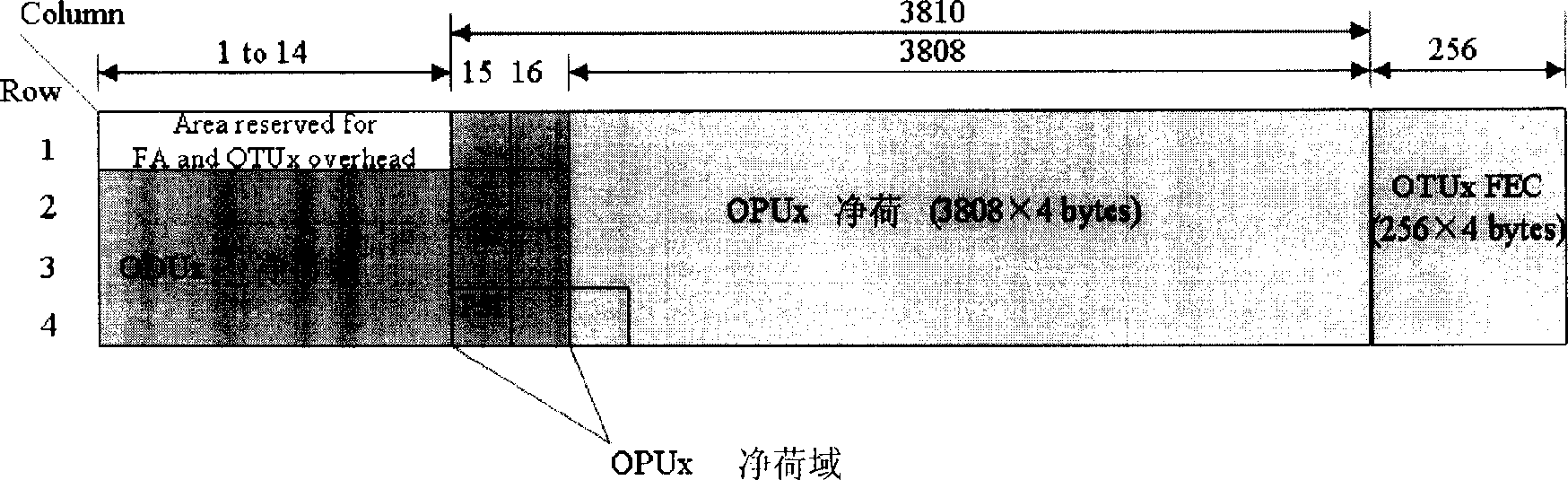

InactiveCN1747606ASimplify the processEasy to implementStar/tree networksElectromagnetic transmissionData transmissionBandwidth utilization

A service data transmission method for optical network includes such steps as determining the net load unit of optical channel adaptive to the total bandwidth of GE service data according to the number of GE service data channels to be transmitted, dividing the net load domain of said net load unit into the time slots relative to said number of data channels, packing the GE service data into frames, transmitting them over optical network, receiving them by receiver, decomposing to obtain frames, and unpacking the frames to obtain the GE service data. Its transmission device is also disclosed.

Owner:HUAWEI TECH CO LTD

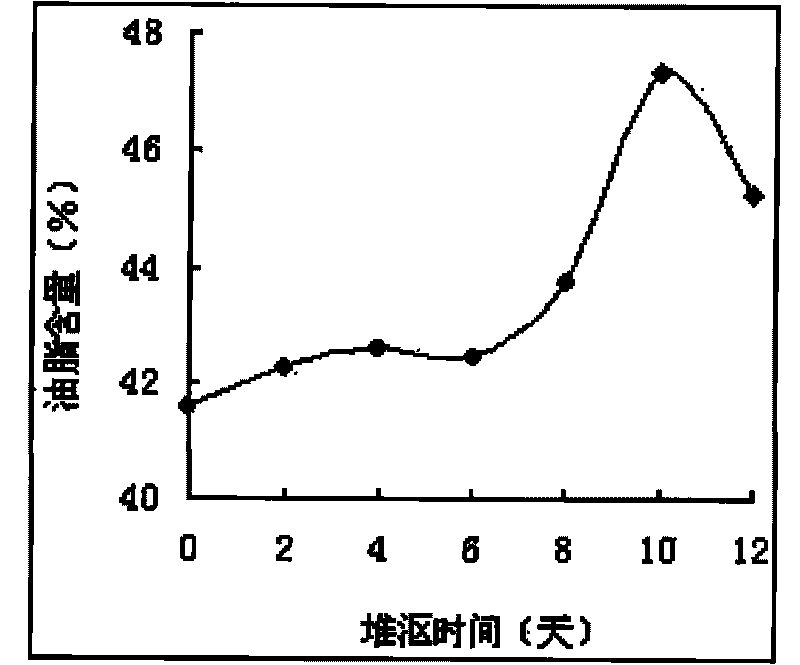

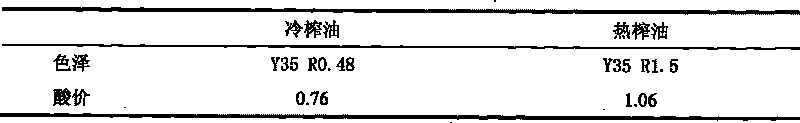

Method for preparing edible safflower tea oil

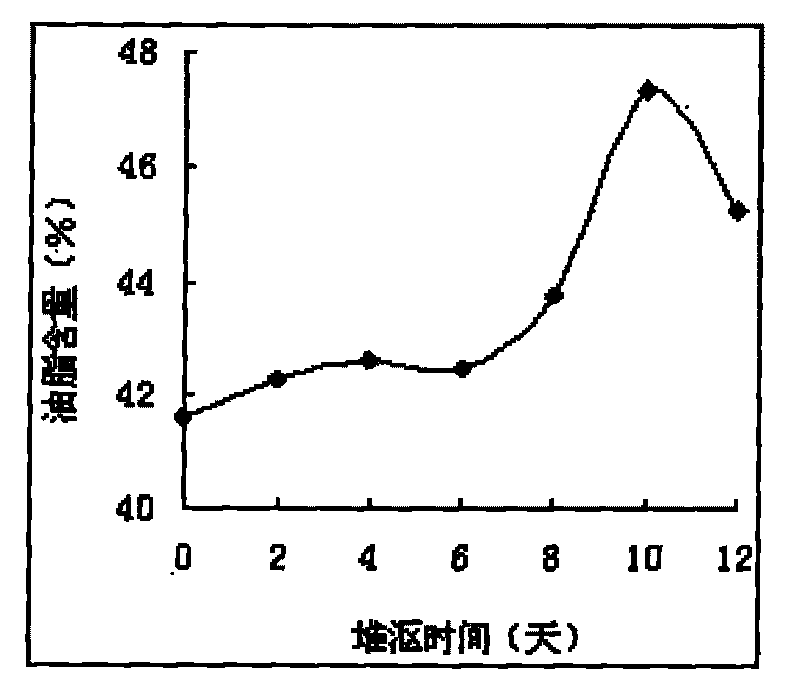

InactiveCN101692854AHigh oil contentQuality improvementEdible oils/fats production/working-upFlavorLoss rate

The invention discloses a method for preparing edible safflower tea oil, comprising the following steps: taking safflower tea seeds as raw materials; conducting stackretting, removal of the oil tea fruit shells, and taking-off of the tea seeds for low-temperature drying below safe moisture content on the harvested mature safflower oil tea fruits, and then cleaning stone, removing shells, separating kernels and shells, and crushing till the particle size is 20 to 60 meshes and adding water for tempering; adopting a cold pressing method for extracting the tea oil; and finally conducting simple refining processes such as filtration, wintering and the like so that the quality index can achieve national first-class edible tea oil standards. The method for preparing edible safflower tea oil hassimple and feasible process, easily-controlled production conditions, less refining processes, low refining loss rate, can keep various nutritional components in the safflower tea seeds from being destroyed, leads the finished tea oil to have light, clear and transparent color, aromatic natural flavor of the tea seeds, and is a nutritional and healthy tea oil.

Owner:SOUTH CHINA AGRI UNIV

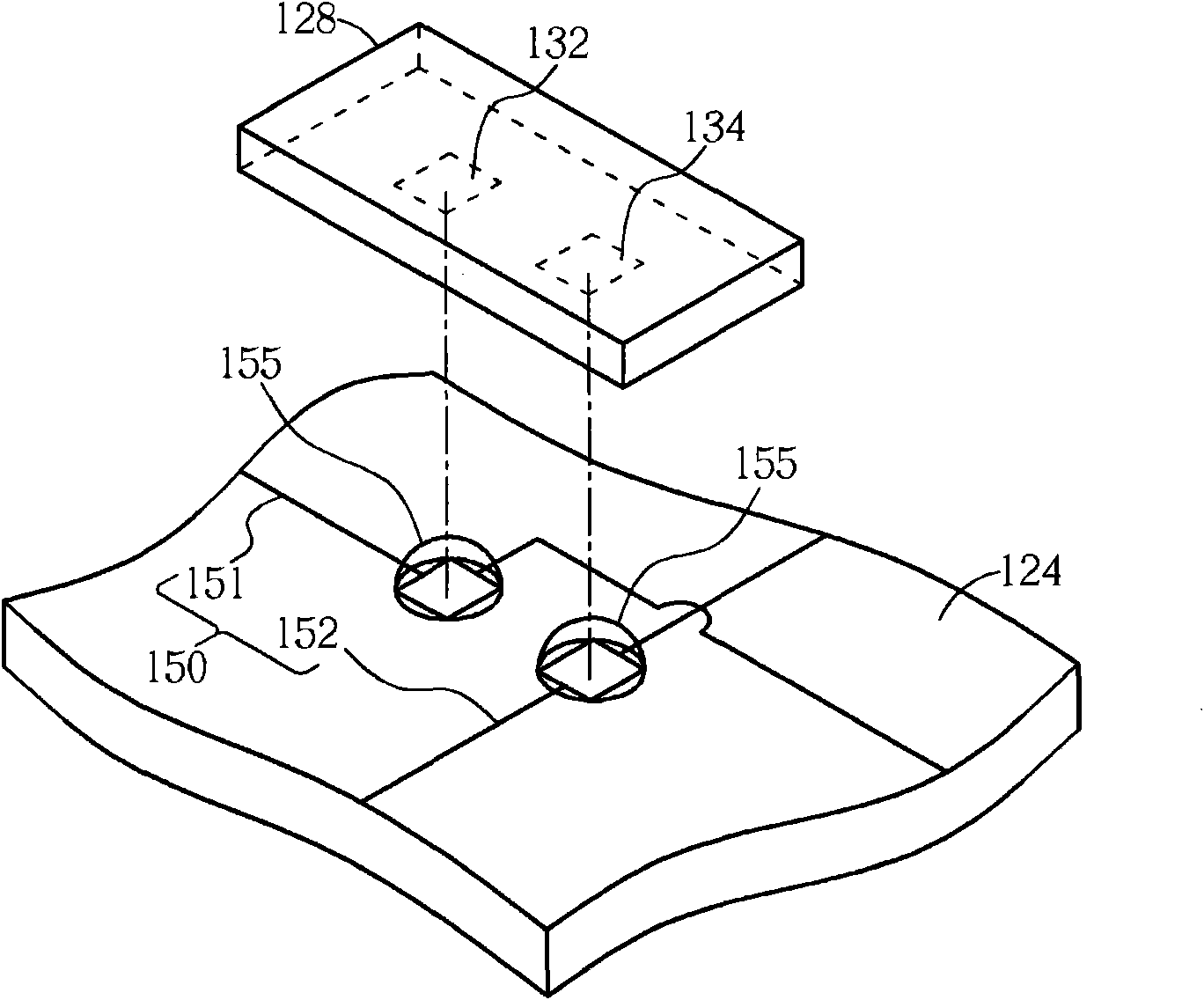

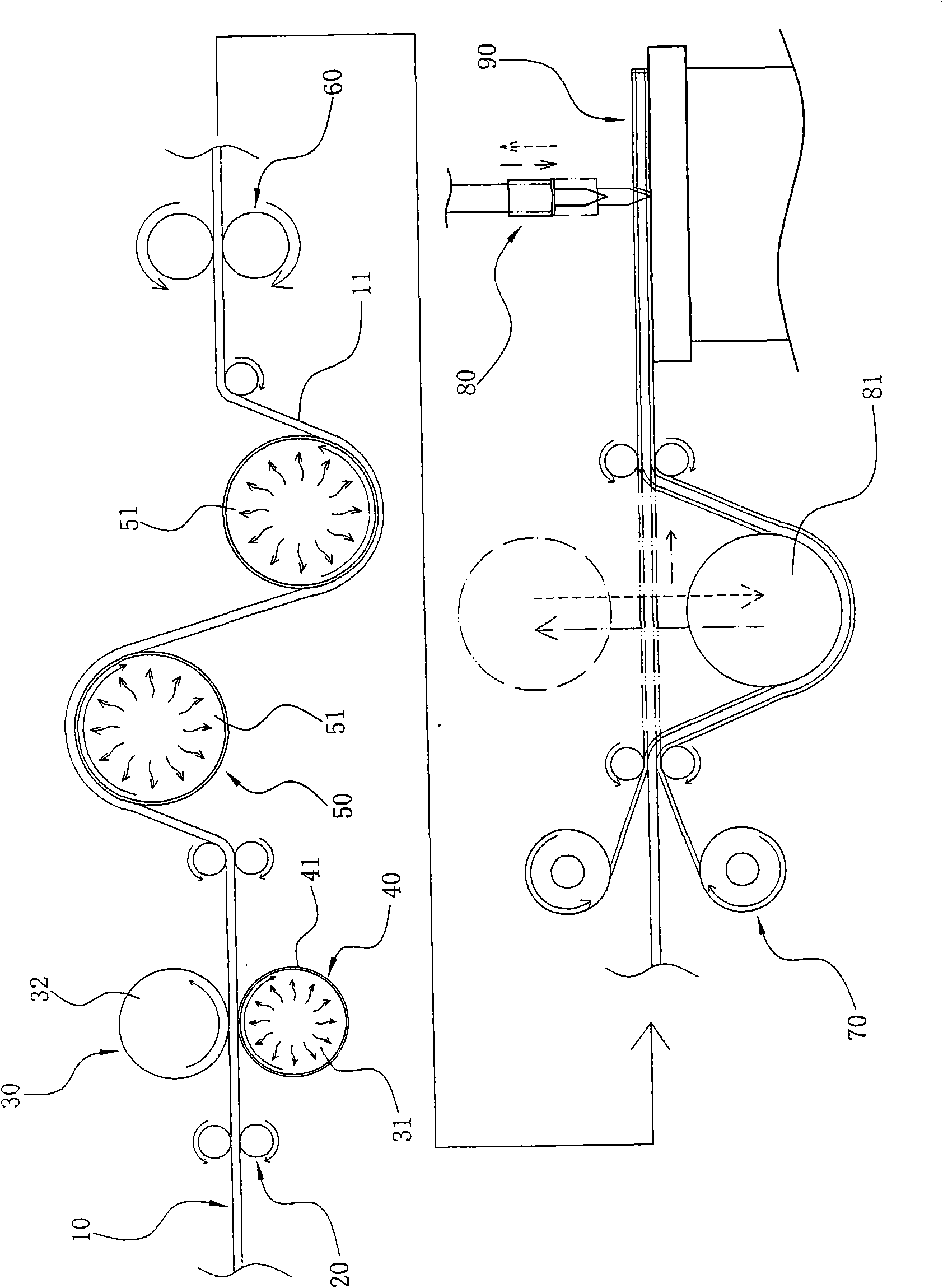

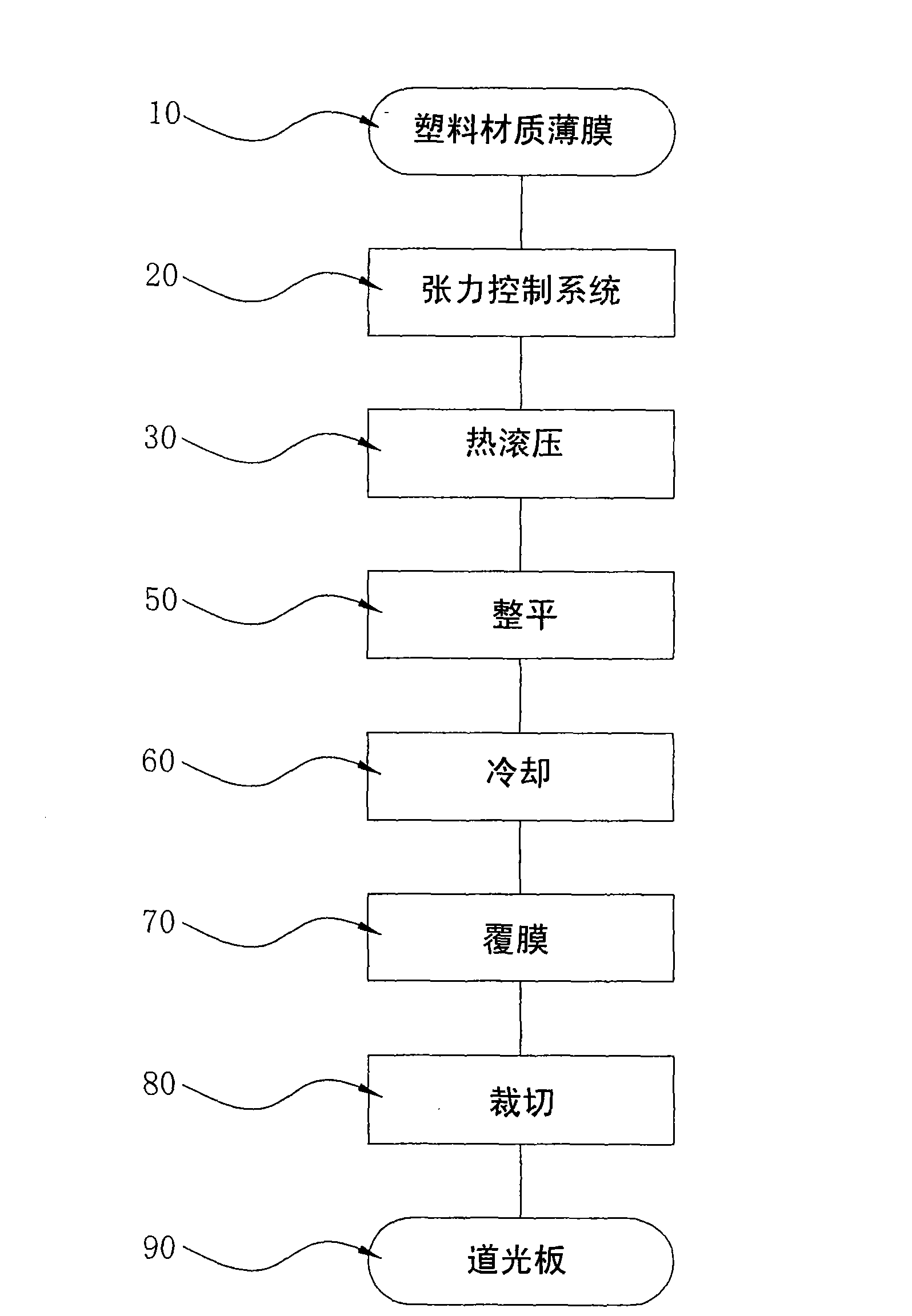

Production line for light guide plates

InactiveCN101526641ASimplify the processIncrease productionOptical light guidesPlastic filmEngineering

The invention relates to a production line for light guide plates. Plastic films of the light guide plates run forwards through the transportation of a tension control system, and are subjected to processing procedures such as hot rolling with metal films, leveling-up, cooling, film coating, cutting and the like in turn in the running process to complete the forming of the light guide plates.

Owner:洪文修

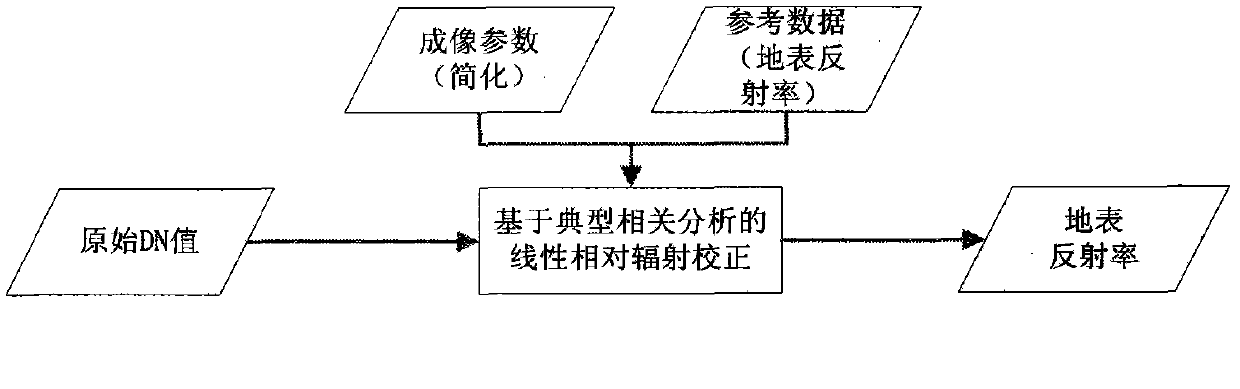

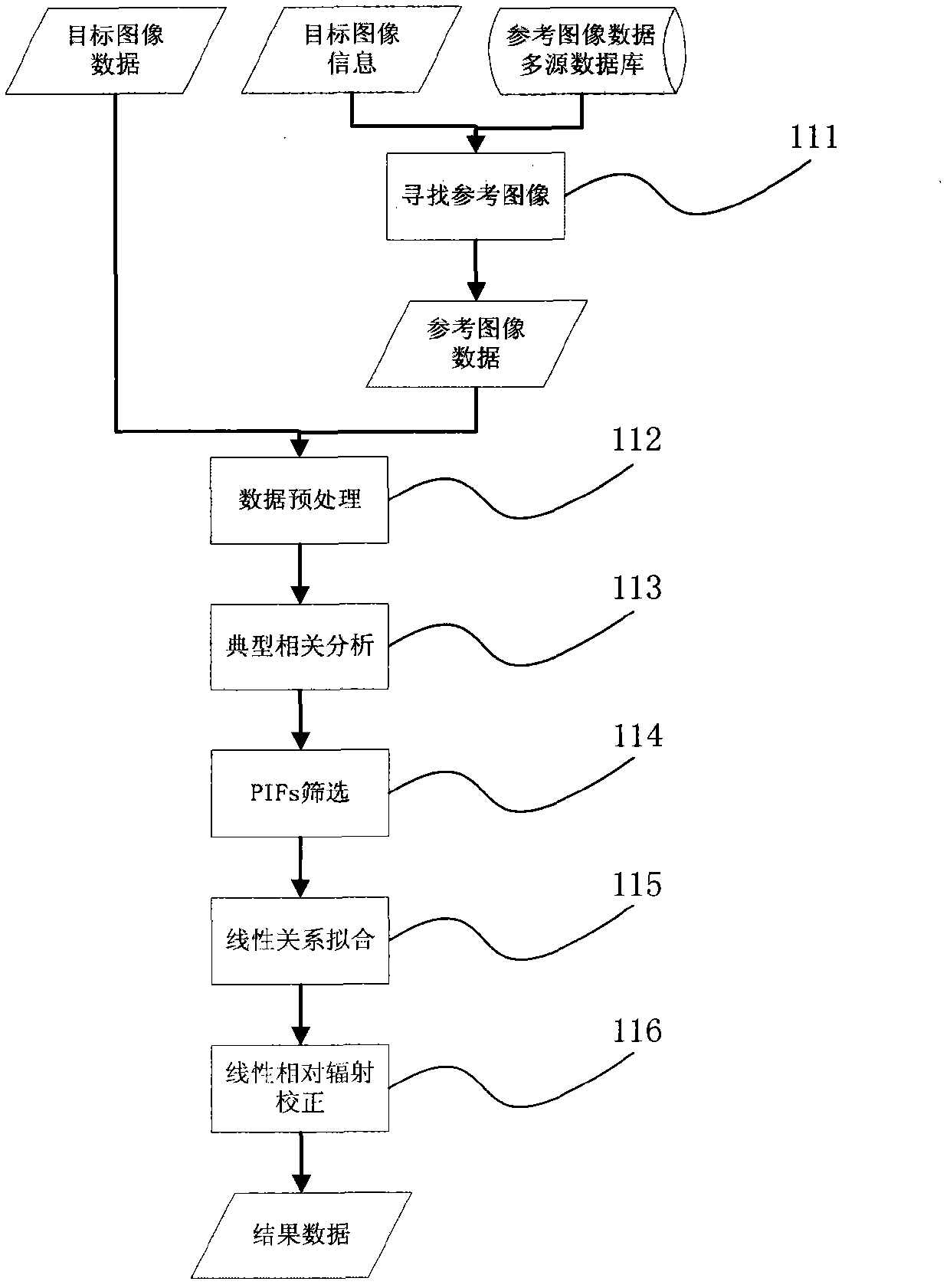

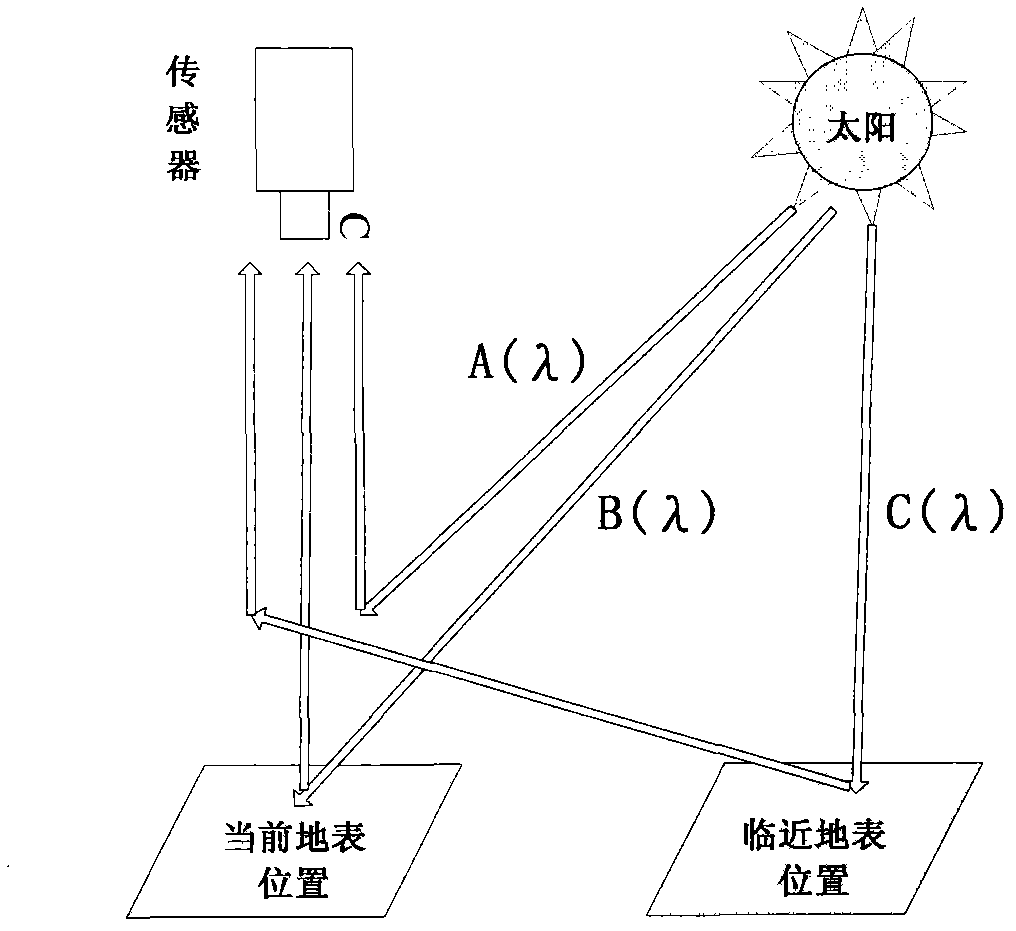

Relative radiometric correction method for automatically extracting pseudo-invariant features for remote sensing image

InactiveCN102565778ASimplify the processNo human interaction requiredWave based measurement systemsImage analysisRadiometric correctionSensing data

For multi-spectral space remote sensing data in a visible light and near-infrared range, the invention provides a relative radiometric correction technology for automatically extracting pseudo-invariant feature points for a remote sensing image. The technology mainly comprises the following steps of: for a target image with a digital number (DN) value, searching a matched reference image with surface reflectivity; pre-processing the two images; by using a canonical correlation analysis technology, searching a canonical correlation point set; screening the pseudo-invariant feature points in the canonical correlation point set; and by using the pseudo-invariant feature points, fitting a linear relation, and by using the linear relation, performing linear relative radiometric correction processing on the target image. By adoption of an algorithm, the DN value of the target image is directly converted into the surface reflectivity. The algorithm has the characteristics of simple processing flow, high processing speed and stability, and manual interaction is not required; moreover, the algorithm can be used for relative radiometric correction of the same sensors or different sensors and is particularly applicable to radiometric processing of remote sensing data, wherein the auxiliary information of the remote sensing data is lost or calibration accuracy is low, and absolute radiometric correction is not suitable for the remote sensing data.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

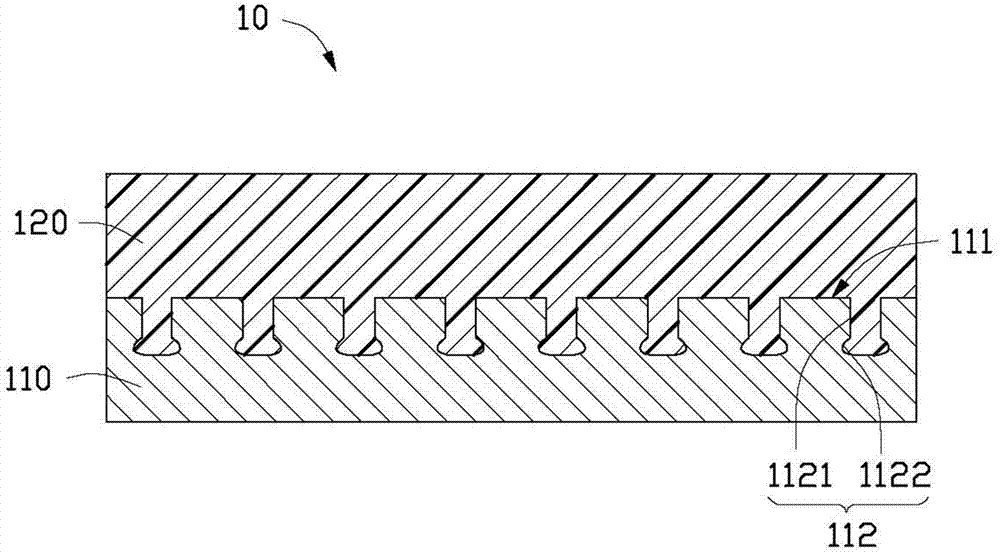

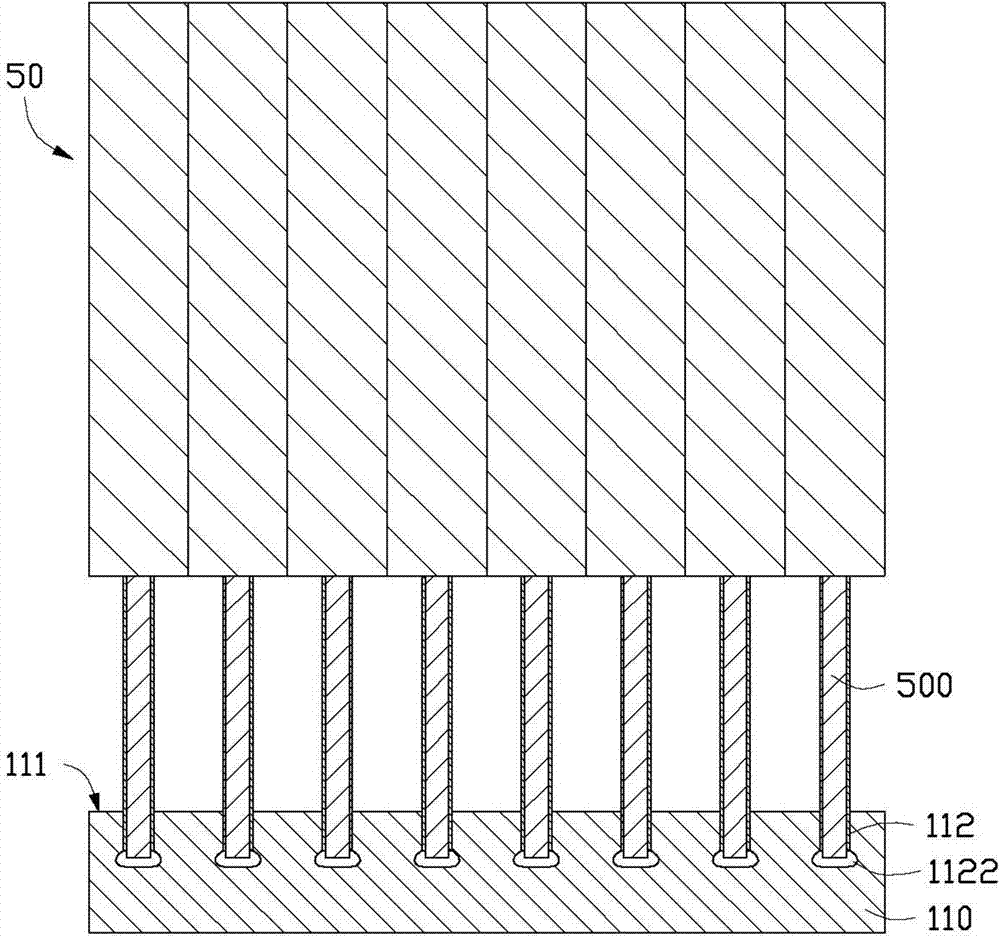

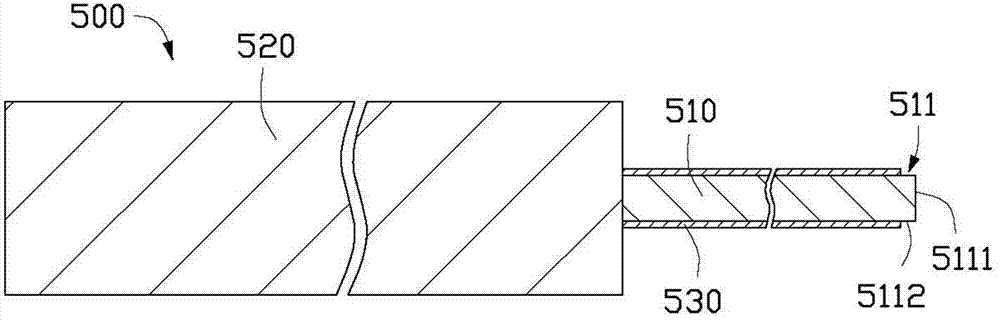

Metal-resin complex and manufacturing method thereof

ActiveCN104742308AImprove connection strengthSimplify the processMachining electrodesElectrical-based machining electrodesMetalMaterials science

A composite of metal and resin includes a metal piece and a resin piece combined with the metal piece. A surface of the metal piece defines a plurality of micropores including an upper portion and a lower portion, the upper portion is communicated with the lower portion, and an aperture of the lower portion is larger than an aperture of the upper portion. The lower portion includes an undercut portion. The resin piece is partially embedded into the lower portion and the upper portion of the micropores. A method of manufacturing the composite of metal and resin is also provided.

Owner:富联裕展科技(河南)有限公司

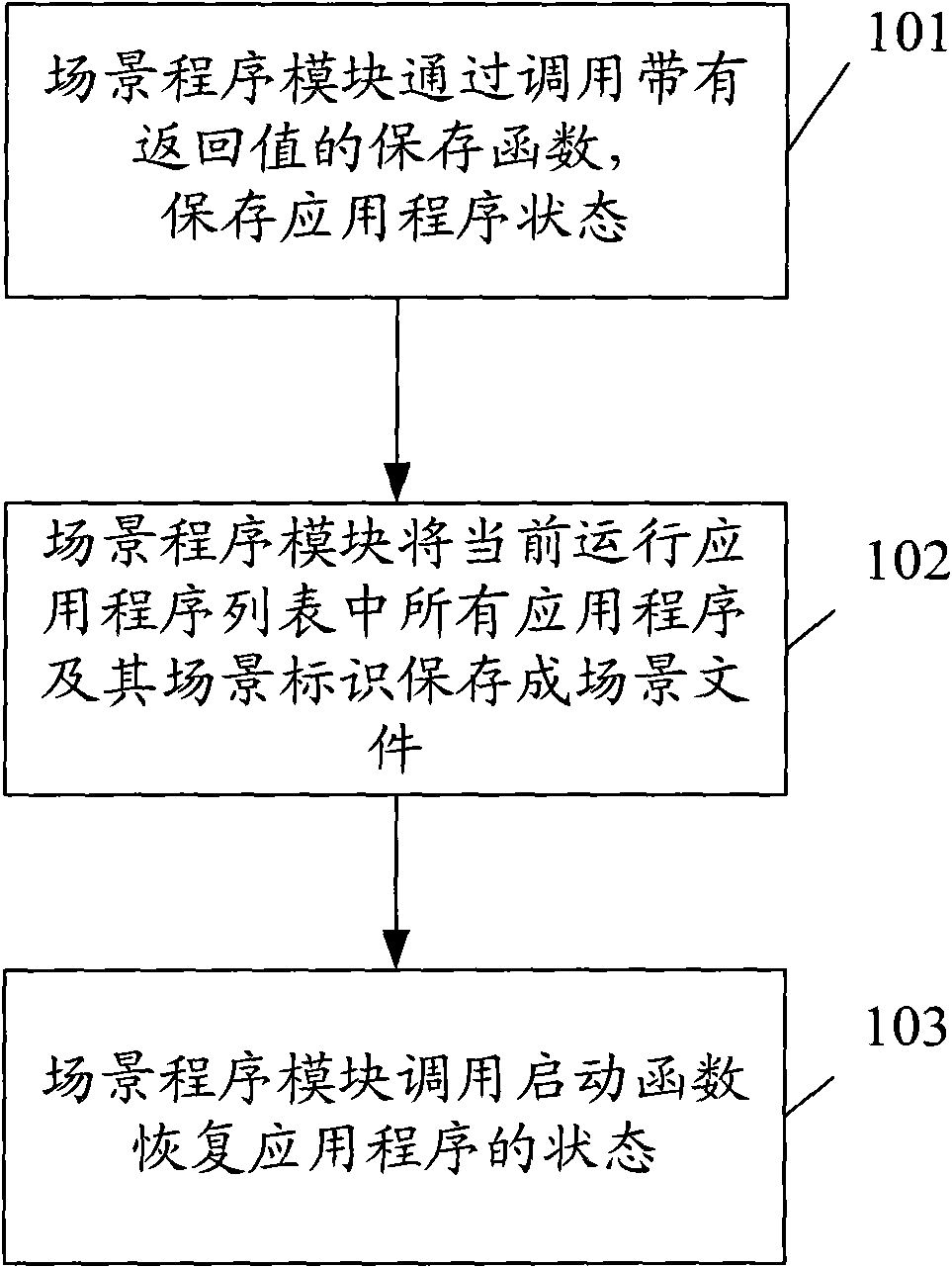

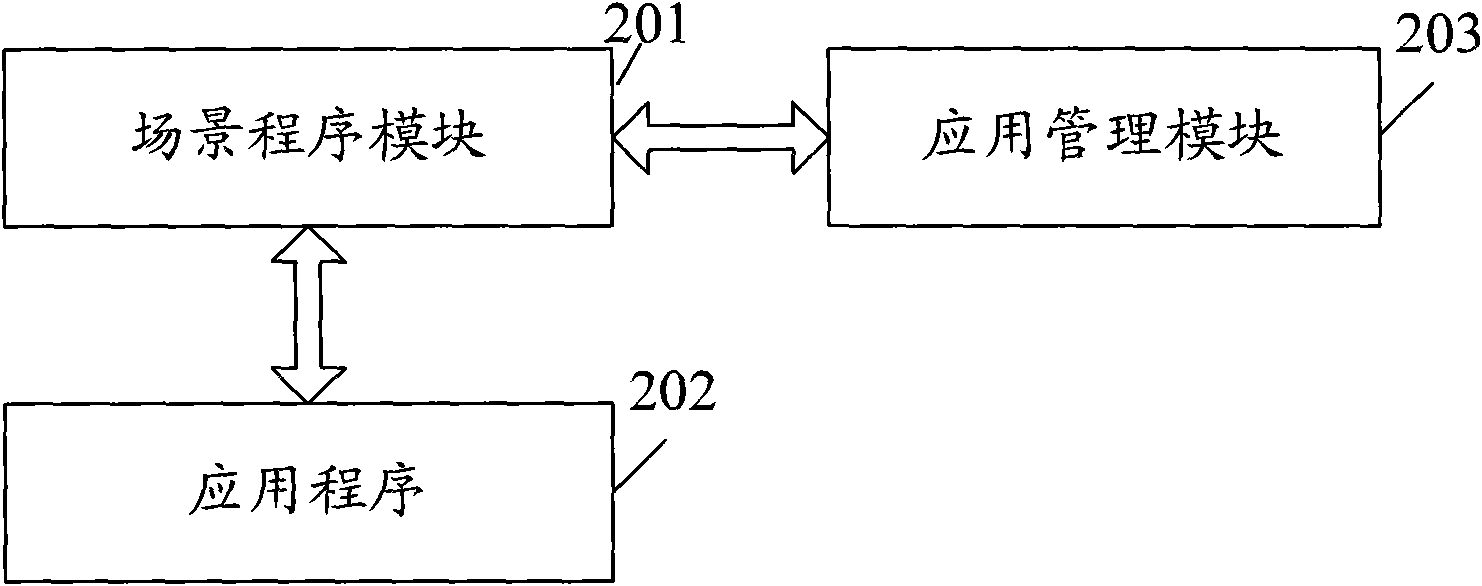

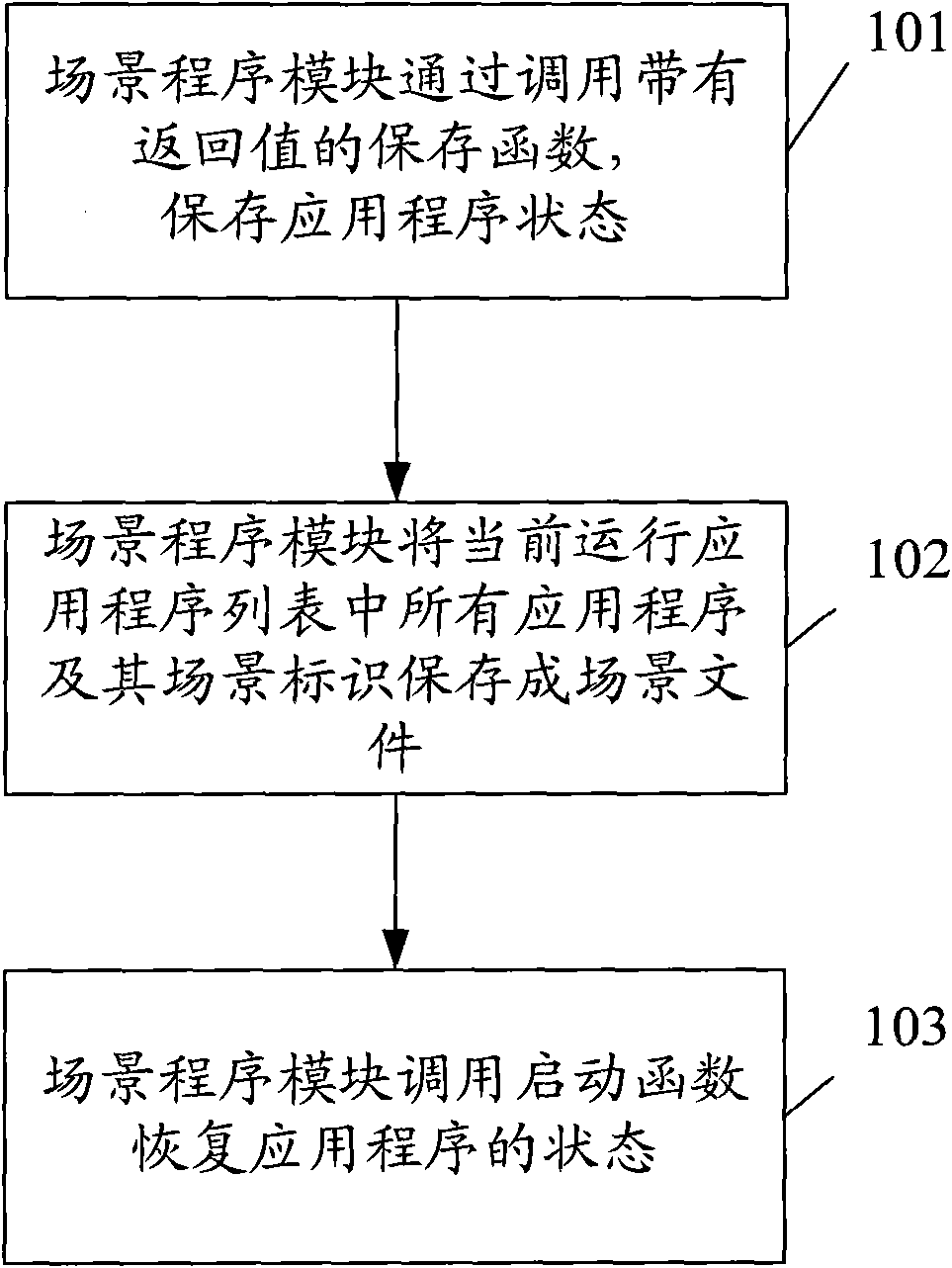

Management method and device for application program

InactiveCN101882092ASimplify the processImprove management efficiencyProgram initiation/switchingProgram saving/restoringApplication softwareApplication posture

The invention discloses a management method for an application program. A scene program module of a mobile terminal stores an application program state in a current running application program list through the application program, and recovers the application program state through the application program. The invention also provides a management device for the application program. The method and the device can store and recover the application programs in batch, and are favorable for promoting user experience.

Owner:林何枝

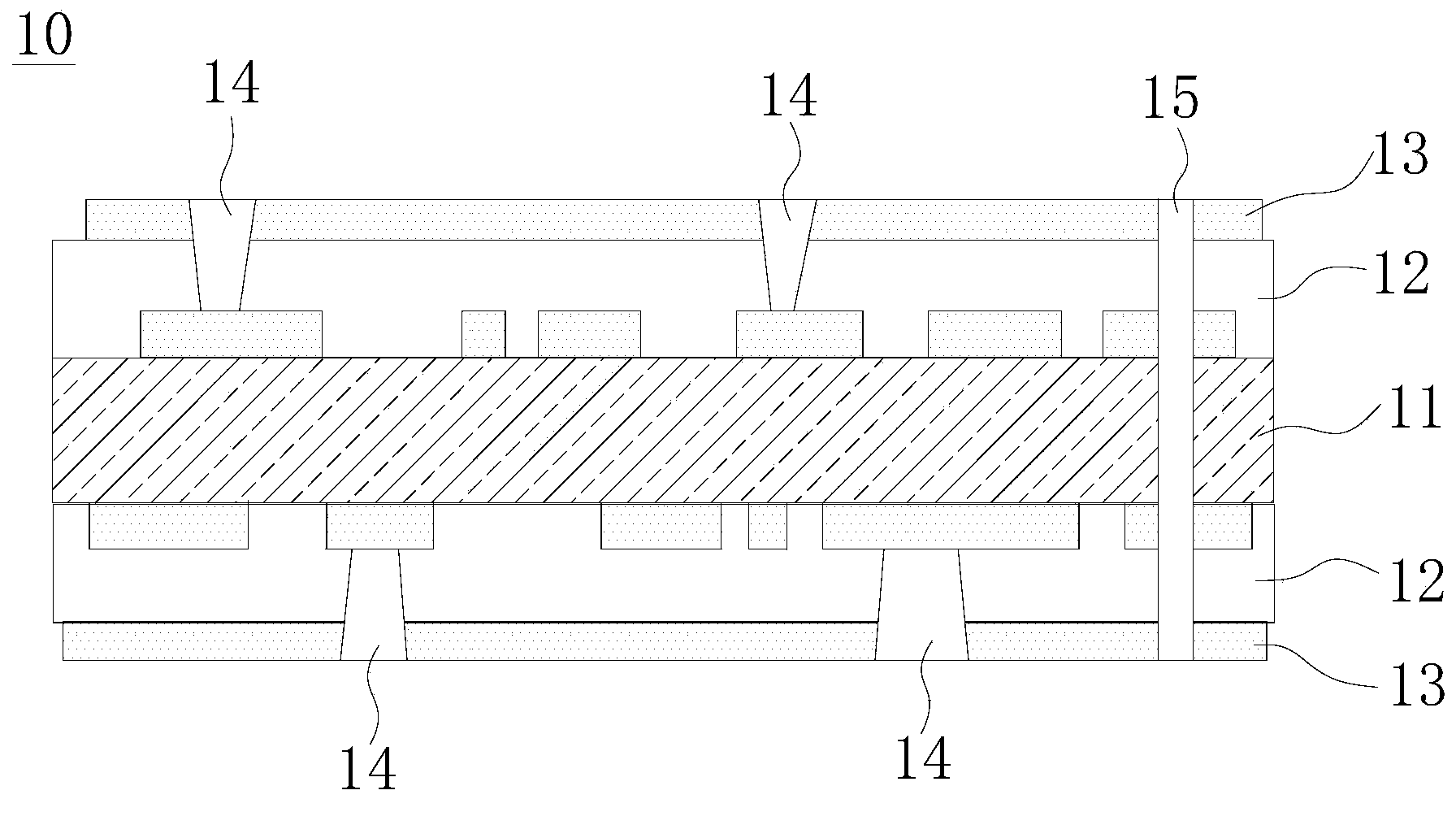

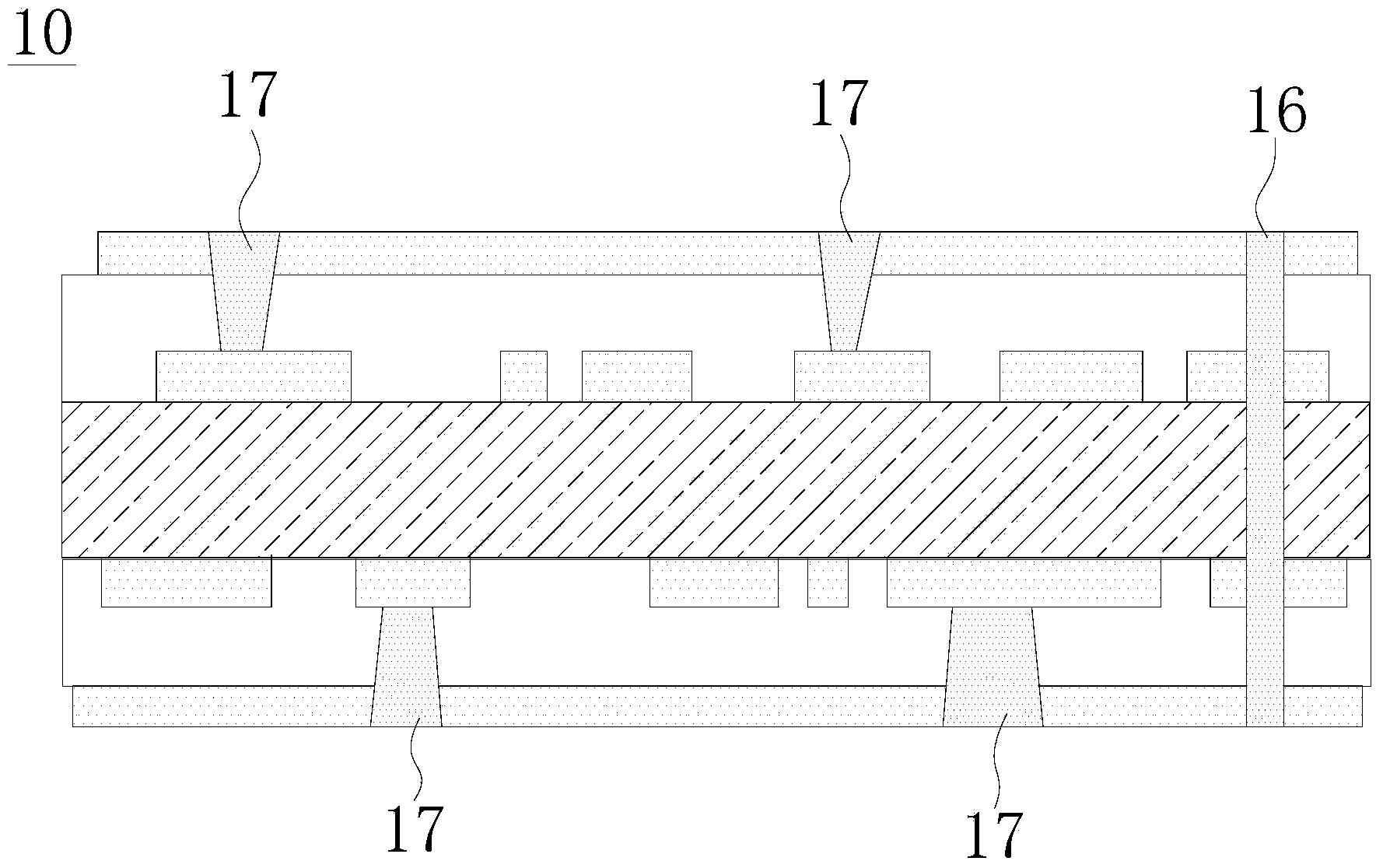

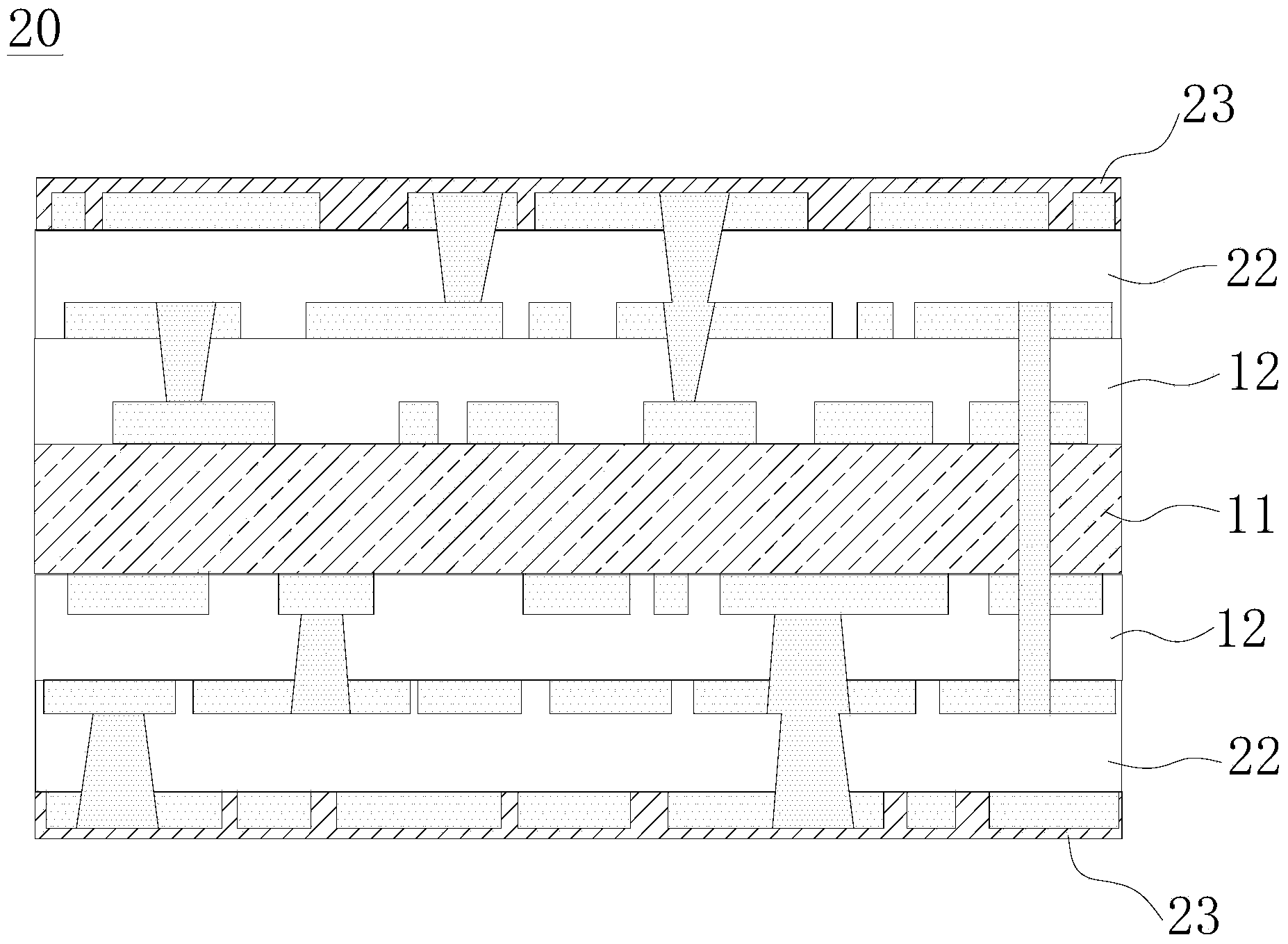

Method for manufacturing plated-through holes in HDI plate

InactiveCN104244613AImprove qualityFulfil requirementsPrinted element electric connection formationMicrometerEngineering

The invention relates to the technical field of circuit board production, in particular to a method for manufacturing plated-through holes in an HDI plate. After blind holes and through holes are drilled in multiple inner-layer plates, inner-layer copper deposition and whole-plate hole filling electroplating are conducted so that the blind holes and the through holes can be metallized at the same time. A horizontal copper deposition electroplating wire is used during inner-layer copper deposition, a perpendicular continuous electroplating wire is used during whole-plate hole filling electroplating, the blind holes and the through holes can be metallized at the same time when the horizontal copper deposition electroplating wire and the perpendicular continuous electroplating wire are used in cooperation, and therefore the technological process can be simplified, production efficiency can be improved, and production cost can be reduced. Specific electroplate liquid is used during whole-plate hole filling electroplating, and therefore the quality of the metallized blind holes and the metallized through holes can be remarkably improved, and the metallized blind holes are prevented from cavities, fractures, poor hole filling and the like, the thickness of hole wall copper layers of the metallized through holes is 25 micrometers or higher, the thickness of electroplated copper on the surfaces of the inner-layer plates ranges from 35 micrometers to 45 micrometers, the requirements of a client are completely met, and manufacturing of circuits in the later procedure is completely achieved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

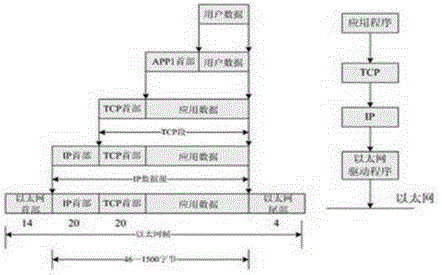

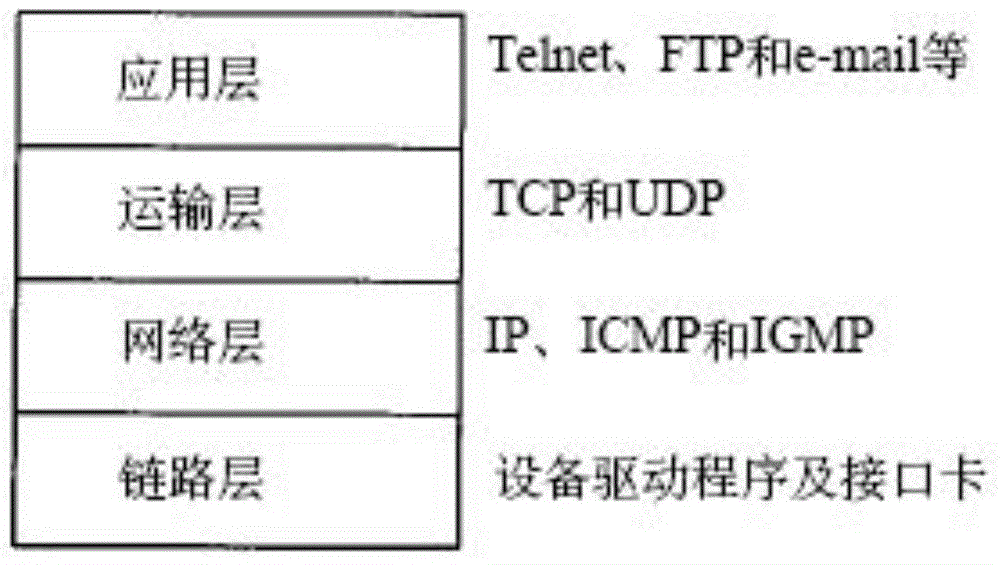

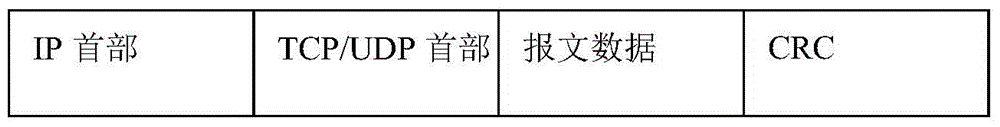

Ethernet IP message packaging method based on SDN and network isolation and DHCP implementing method based on SDN

ActiveCN104010049AImprove utilization efficiencySimplify the processData switching networksTransmission mediumMAC address

The invention provides an Ethernet IP message packaging method based on the SDN and a network isolation and DHCP implementing method based on the SDN. The technical problems that due to message layer two head packaging introduction, the transfer process is complex and the transmission efficiency is reduced are solved. The methods include the steps that firstly, an equipment physical layer obtains a physical signal from a transmission medium according to a frame gap and a guide frame, converts the physical signal into a bit and transfers the bit to a data link layer; secondly, the data link layer carries out prior processing work besides MAC address recognition and addressing; thirdly, a protocol stack recognition message is analyzed; fourthly, after being transferred out through a router, the message is transferred to the data link layer for carrying out other processing procedures besides Ethernet packaging and MAC addressing, and the message is sent to the physical layer to be processed according to the format of the message header; fifthly, the physical layer converts the bit of the data frame of the message into an optoelectronic signal in a prior mode and forwards the optoelectronic signal out.

Owner:EAYUN INC

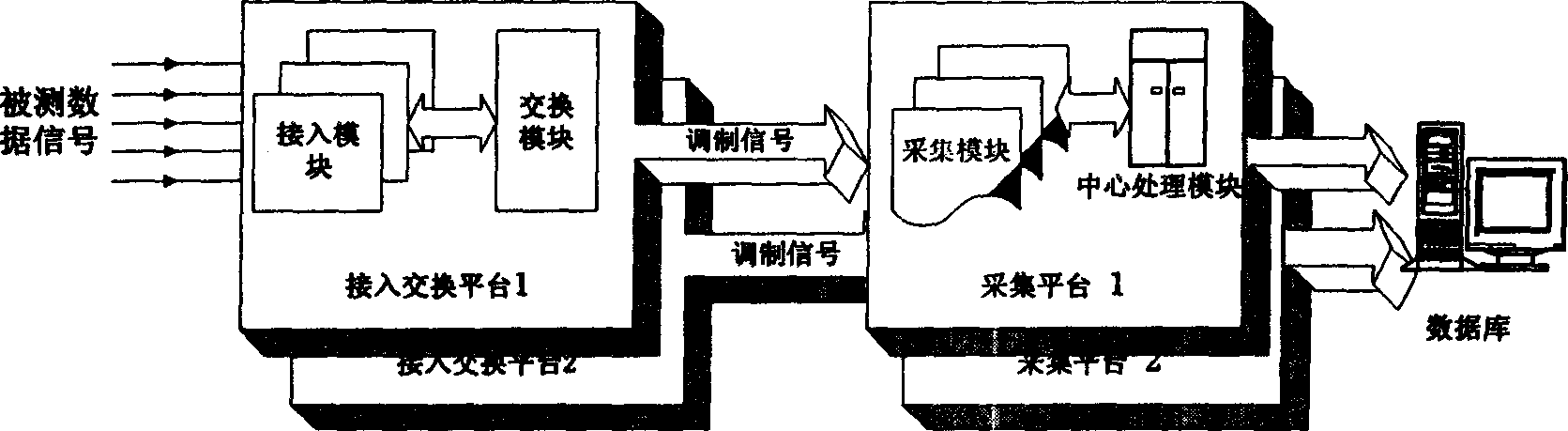

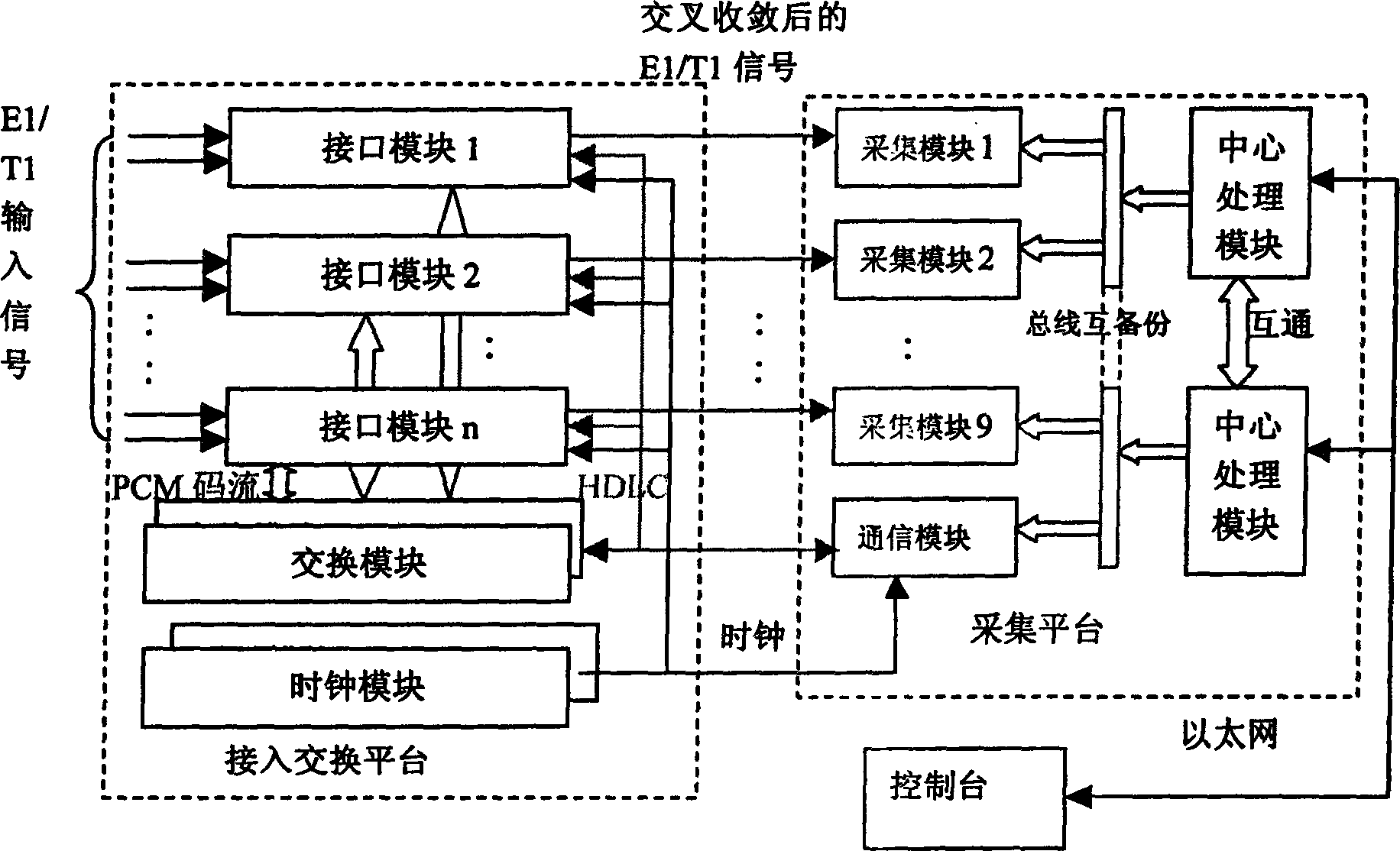

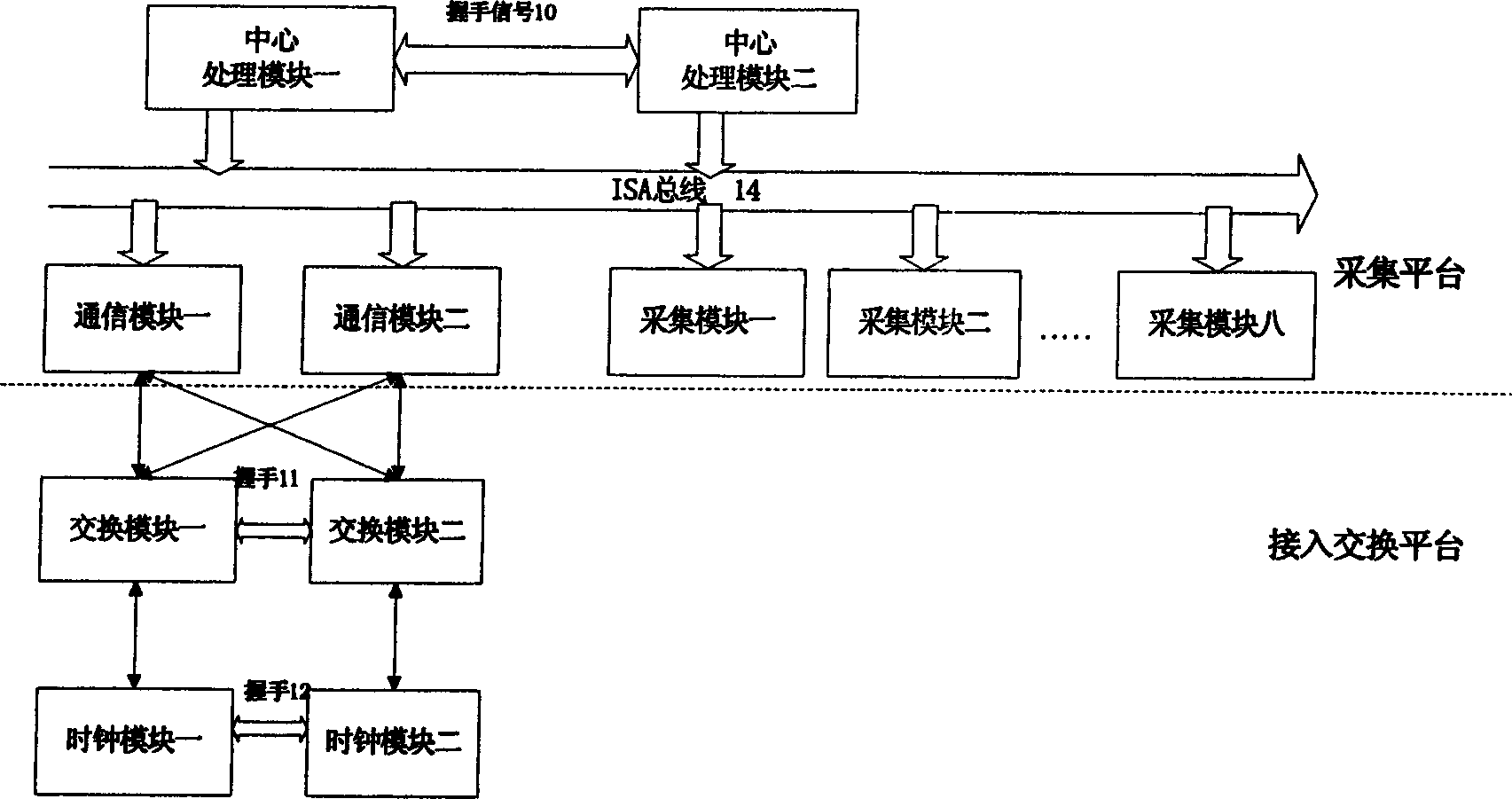

Centeralization type system of collecting communication data based on exchange platform

The system consists of an access switch platform and a collection platform. The access switch platform includes multi interface modules and a switch module, and its input signal is data link signal under tested, and its output signal is transmitted to the collection platform after making cross, convergence and recombination. The collection platform includes multi collection module and a CPU, and is used to receive the data from the switch platform or the data under test directly from outside. The collection modules above translate the data into a unified format, and sent it to the CPU in order to process the data and extract the valid message. The processed data is sent to a storage device.

Owner:ZTE CORP

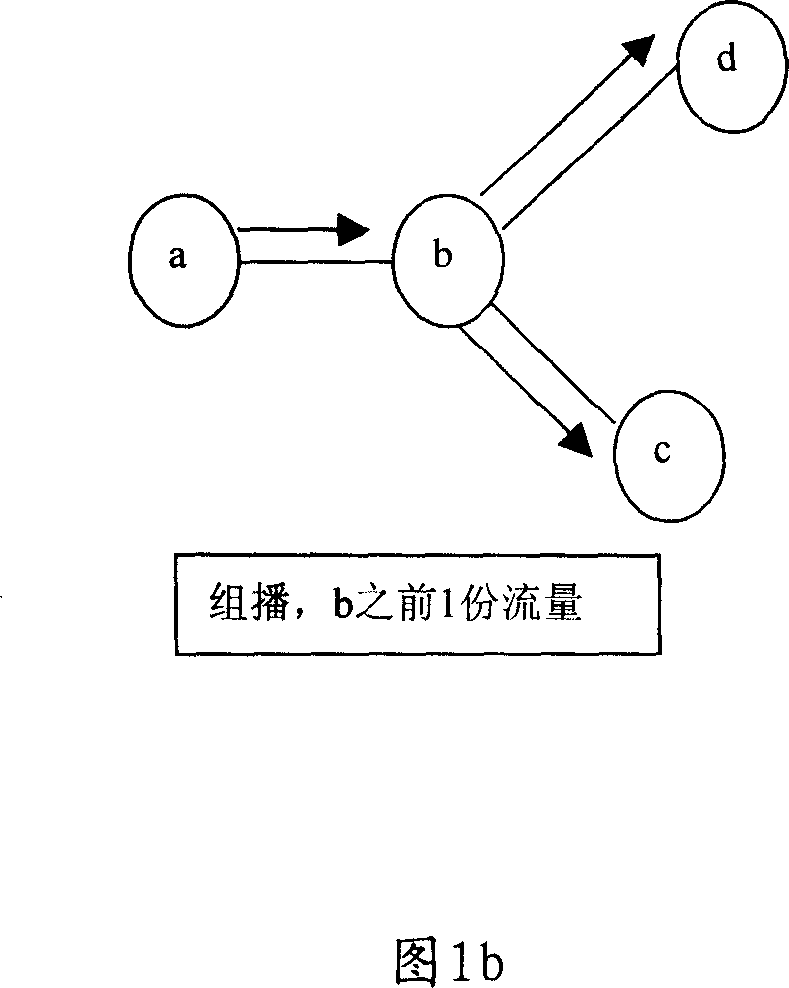

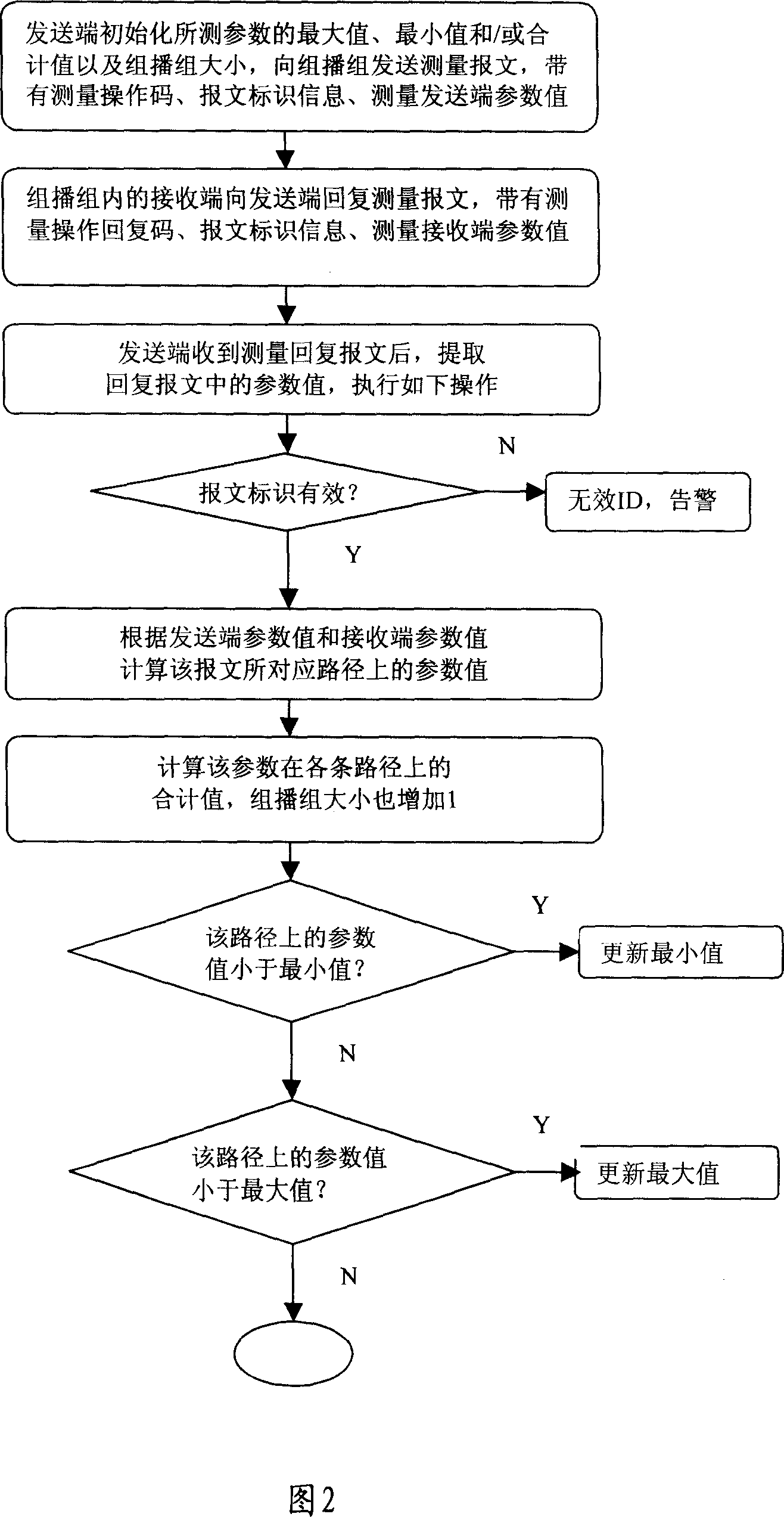

Implementation method for detecting multicast performance of Ethernet

InactiveCN1992651ASimplify the processComprehensive Network Performance EvaluationSpecial service provision for substationMulticastNetwork performance

This invention relates to a detecting network multicast performance method. The invention mainly includes: firstly, at the test starting point, construct and send the multicast performance measurement request packet with the identification information; then, at each node receiving the said multicast performance measurement request packet, respectively send the performance measurement response packet with the said identification information to the test starting point; finally, in the scheduled time, the test starting point receives the said performance measurement response packet, and according to the identification information, measure the multicast performance parameters. The invention makes small change to the OAM frame format defined in Y.17ethoam, and in the realization of the invention, the process in the sending point and the receiving point is rather simple, and based on the original unicast performance measurement calculation method, it processes the calculation method of multicast performance measurement. Therefore, the invention can be nice to achieve P2MP multicast performance parameter measurement in the Ethernet OAM, thereby assisting OAM to provide a more comprehensive network performance assessment.

Owner:HUAWEI TECH CO LTD

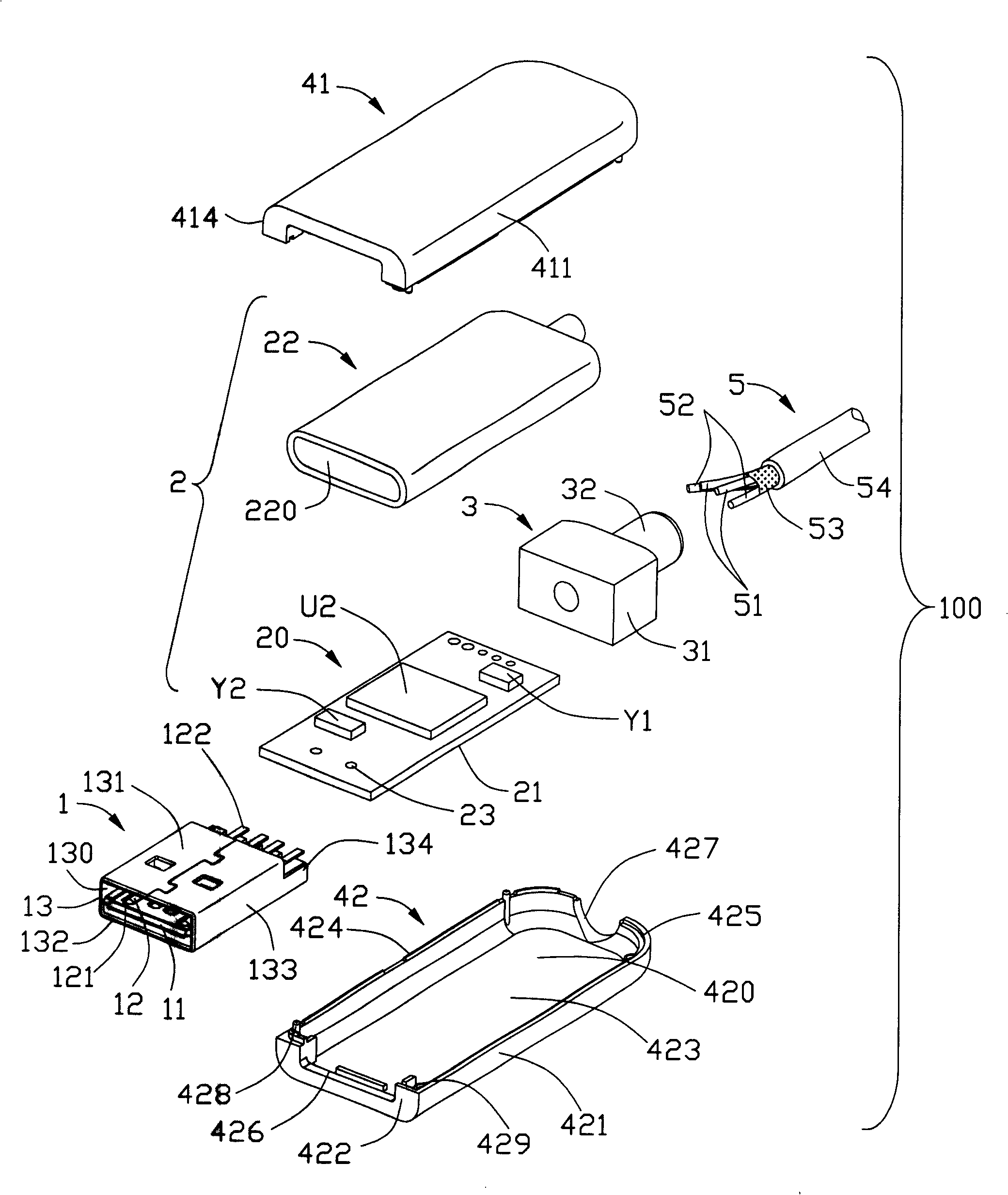

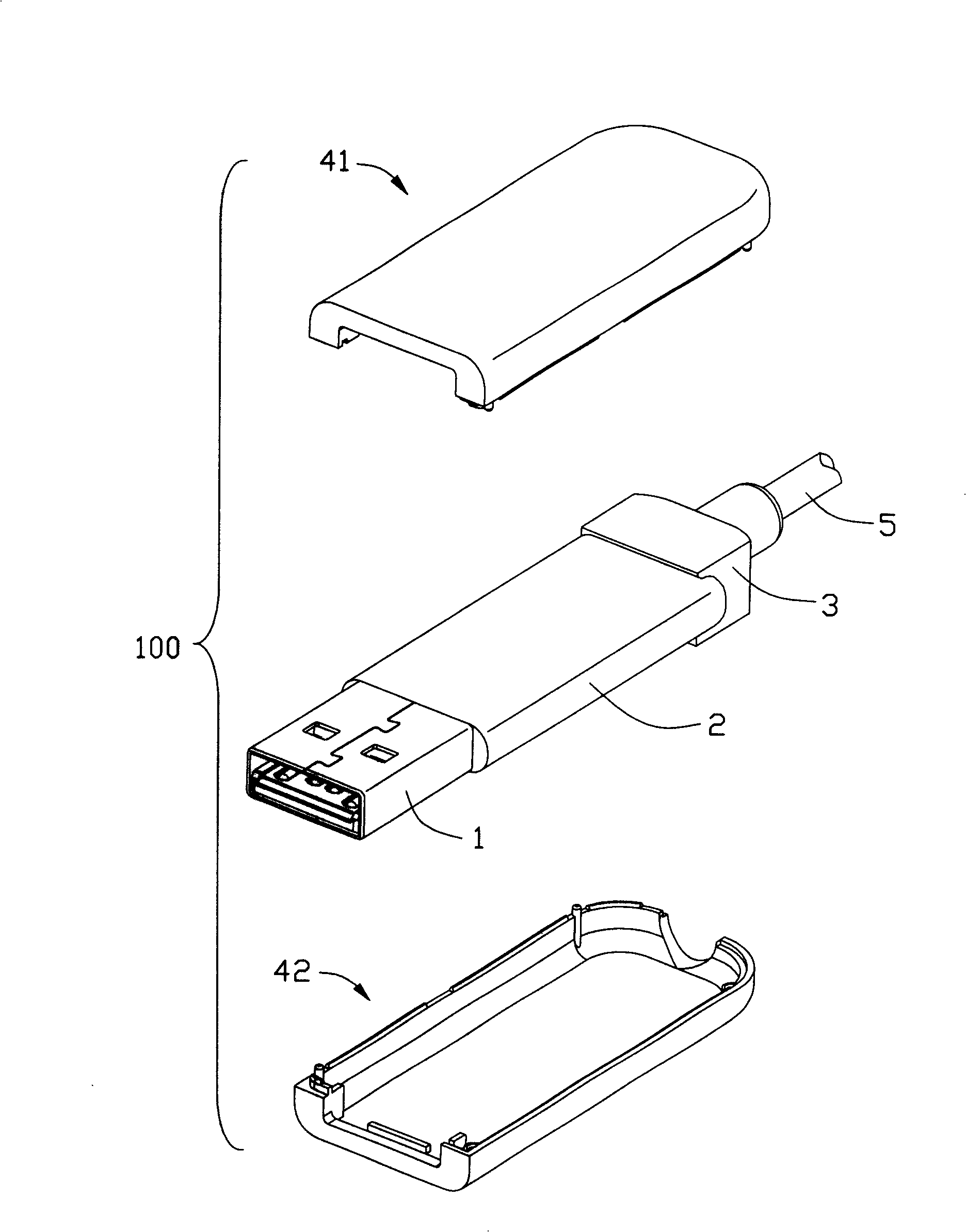

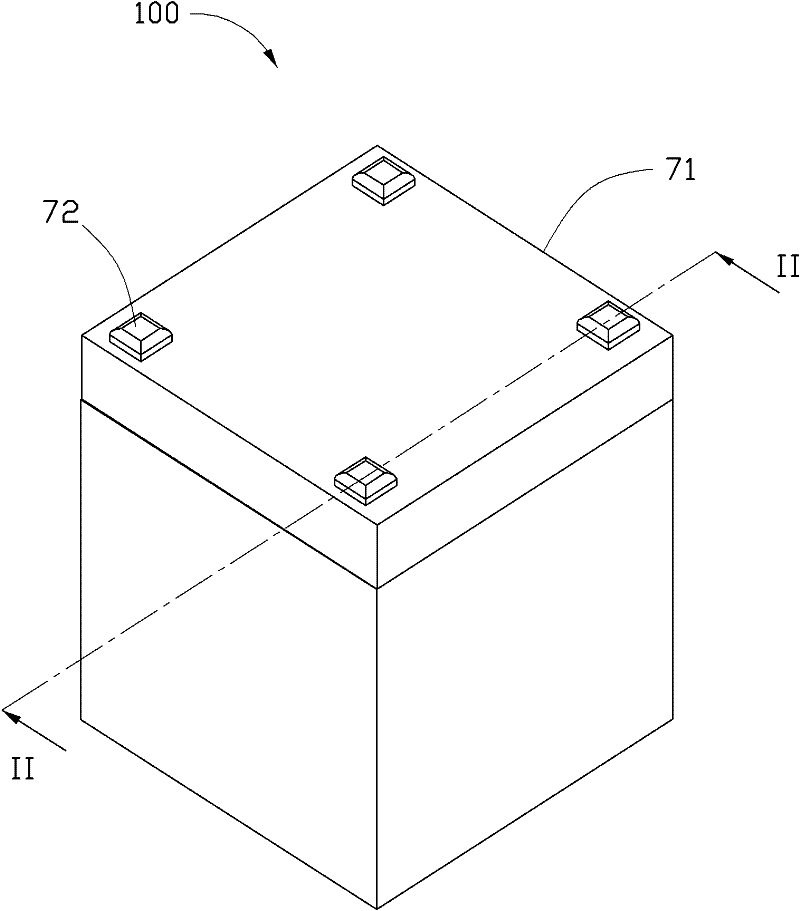

Cable connector assembly

InactiveCN101256545ASimplify the processSimple process and processRelieving strain on wire connectionCouplings bases/casesData transmissionEngineering

The invention discloses a cable connector assembly used for data transmission between two computers. The assembly comprises a first cable connector assembly (100) and a second cable connector assembly electrically connected with the first cable connector assembly. The first cable connector assembly (100) comprises a first USB electric connector (1), a USB transmission device (2) and a cable (5), the USB transmission control device (2) comprises a circuit board (21) and a USB transmission control chip (U2) mounted on the circuit board; the second cable connector assembly comprises a second USB electric connector. The first USB electric connector is welded with the circuit board of the USB transmission control device, and the second electric connector is connected with the USB transmission control device via a cable. The procedure and manufacture process of the cable connector assembly of the above structure are relatively simple so that manufacture cost is reduced efficiently.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

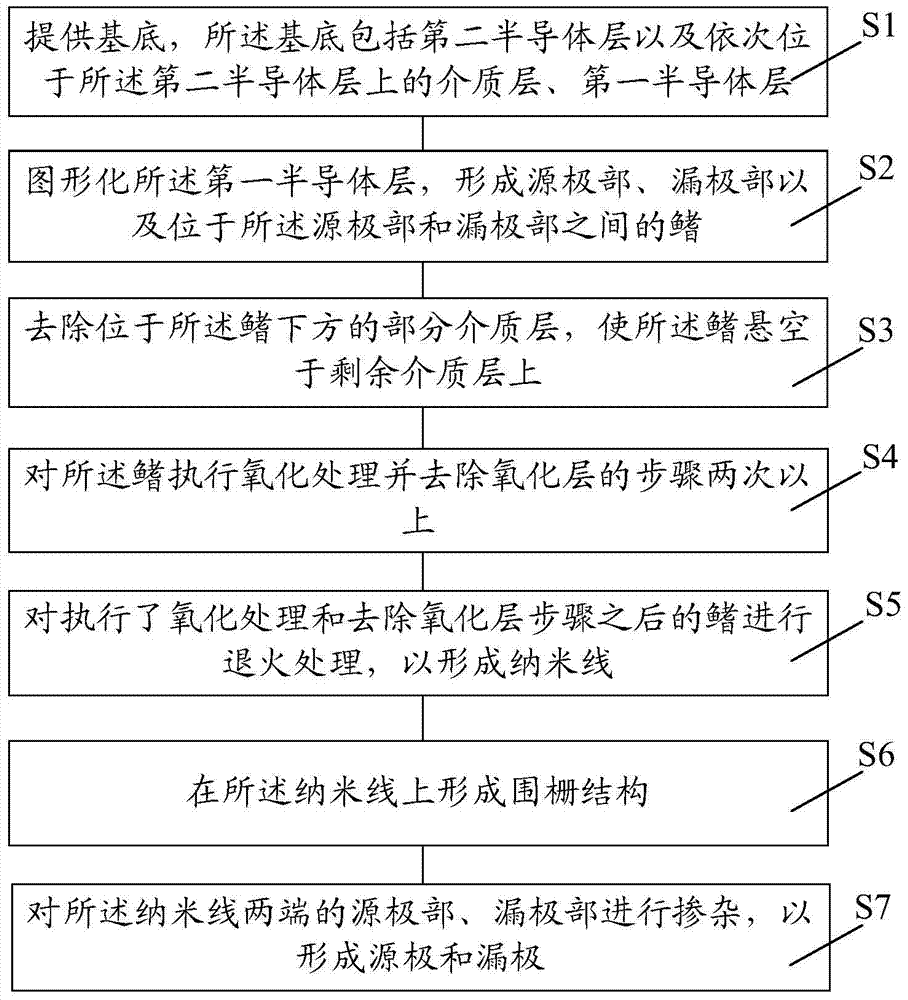

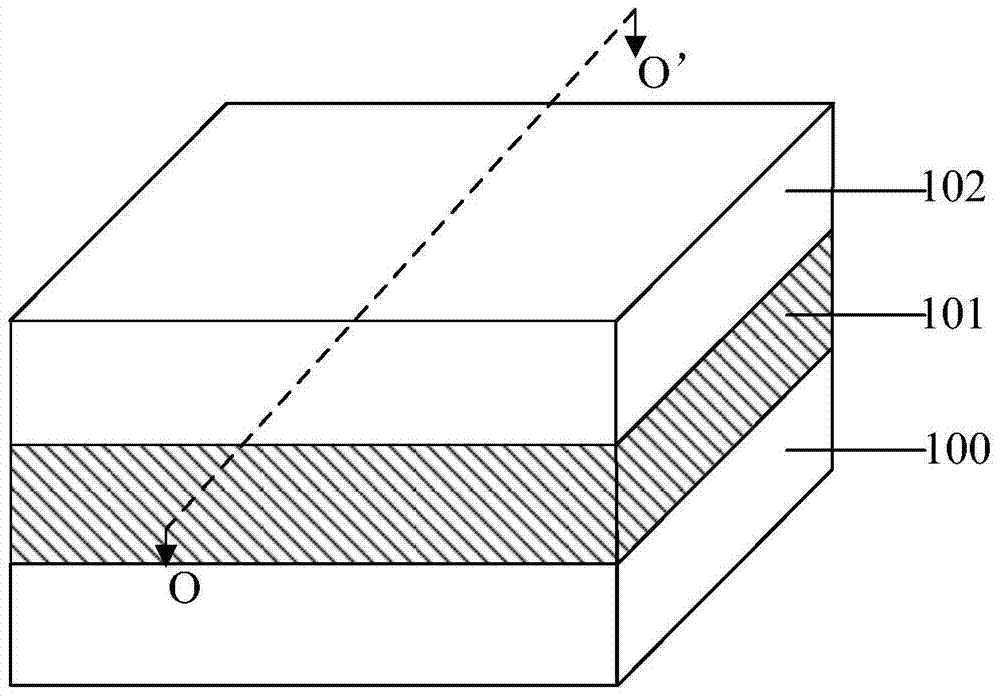

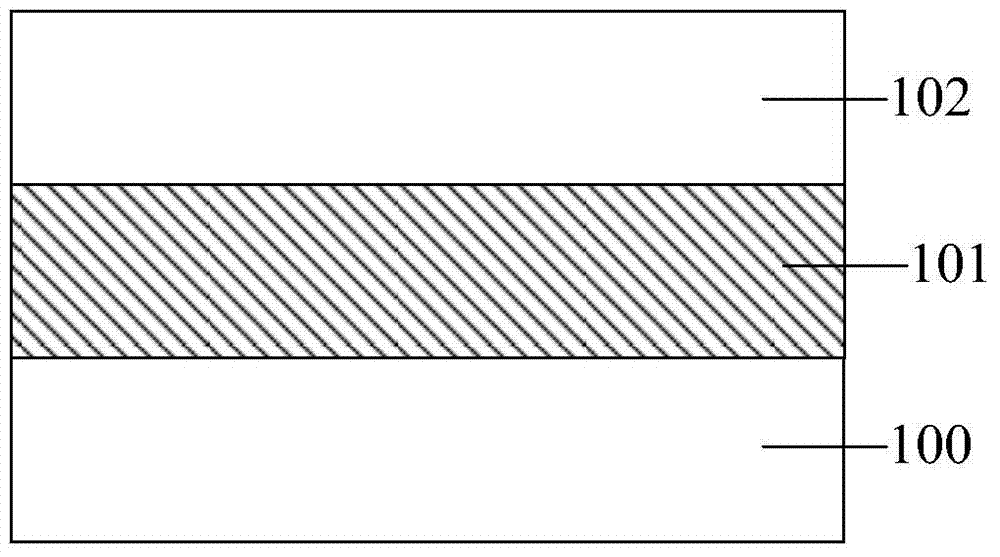

Transistor and manufacturing method thereof

InactiveCN104752200AGood compatibilitySimplify the processNanoinformaticsSemiconductor/solid-state device manufacturingNanometreEngineering

The invention provides a transistor and a manufacturing method thereof. The manufacturing method comprises the following steps: patterning a first semiconductor layer and forming a source part, a drain part and a fin between the source part and the drain part; removing part of a dielectric layer and making the fin suspended on the remaining dielectric layer; performing the step of oxidizing the fin and removing an oxide layer twice or more to form a nanowire; and forming a fence structure on the nanowire. The transistor comprises a substrate, a germanium nanowire, and a fence structure. The substrate comprises a silicon layer, and a dielectric layer and a germanium-silicon layer disposed on the silicon layer sequentially. A groove is formed in the germanium-silicon layer and part of the dielectric layer, and the parts of the first semiconductor layer at the two sides of the groove are respectively used as a source or a drain. The germanium nanowire is disposed between the source and the drain and is in contact with the source and the drain. The fence structure fills the groove and covers the nanowire. According to the invention, the carrier mobility of the channel region of the transistor can be improved, and the performance of the transistor can be optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

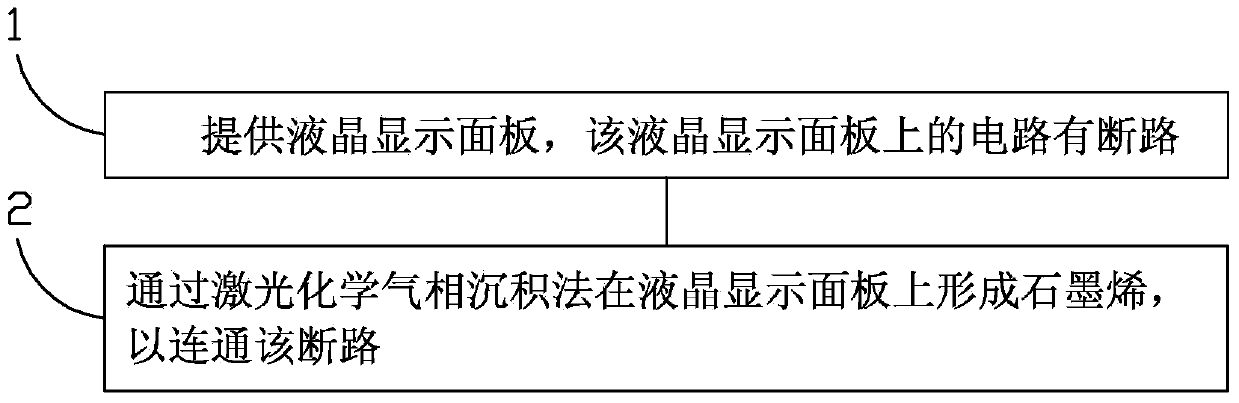

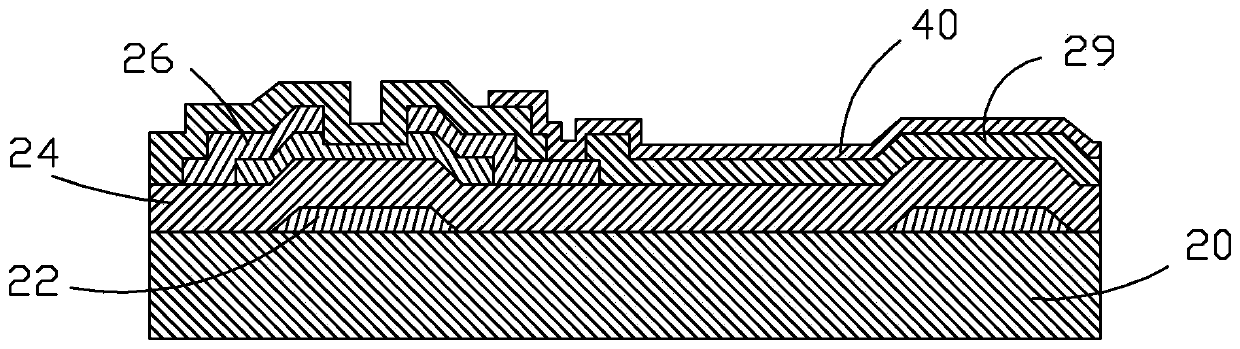

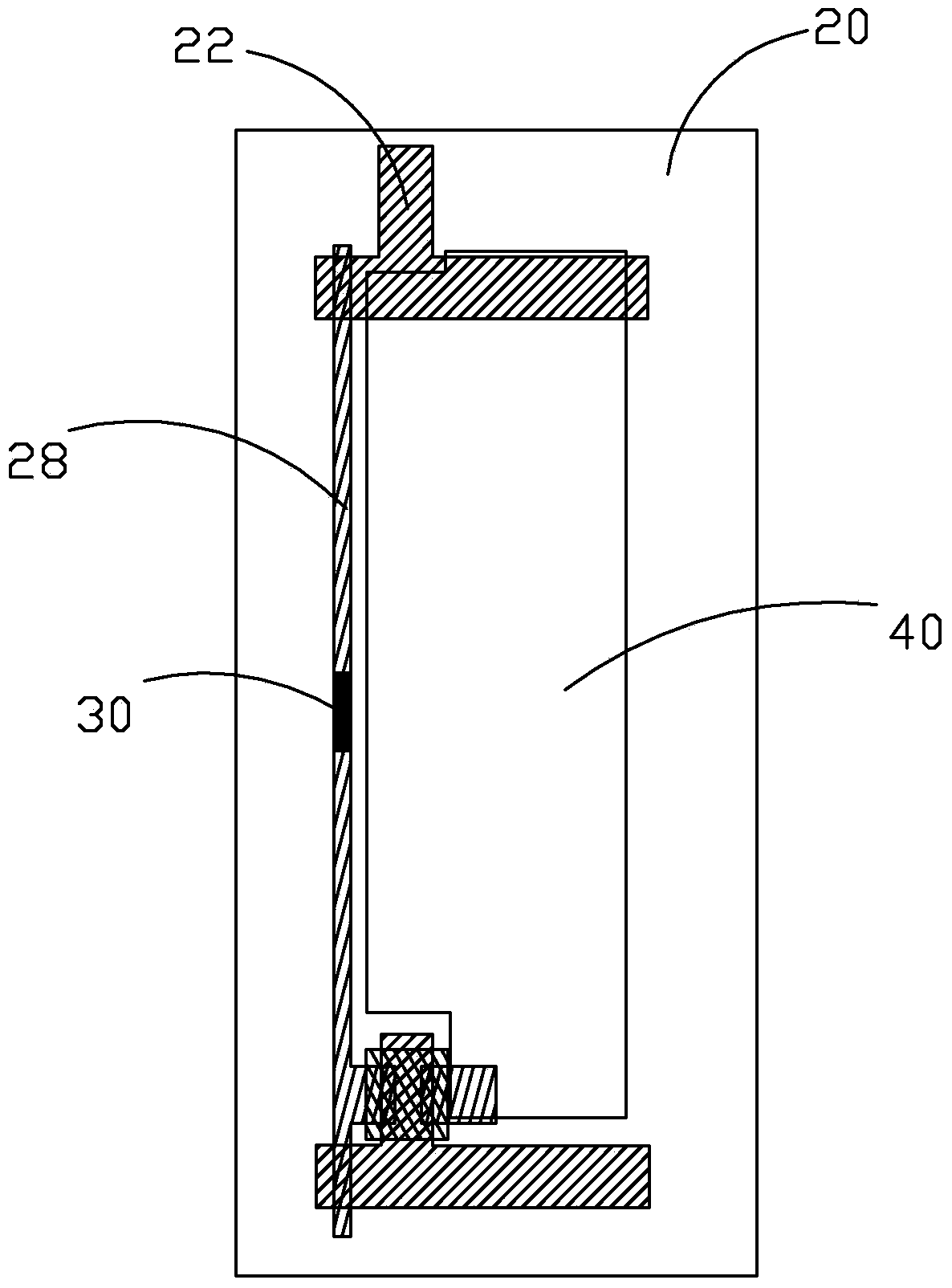

Liquid crystal display panel repair method and repair system

The invention provides a liquid crystal display panel repair method and repair system. The method includes the steps: firstly, providing a liquid crystal display panel with a broken circuit; secondly, forming graphene on the liquid crystal display panel by laser chemical vapor deposition to communicate the broken circuit. According to the liquid crystal display panel repair method and repair system, the graphene is formed at the broken circuit by laser chemical vapor deposition to repair the broken circuit, manufacture procedures are simple, repair effects are fine, common gases such as methane serve as carbon source gases, environmental protection is facilitated, the number of layers of the graphene can be controlled by controlling laser irradiation, the conductivity of the graphene is further controlled, and the repair effects are improved. Besides, the spot radius of laser can be adjusted, the resolution ratio of a graphene growth line can be controlled, a laser light path is adjusted, spots can be used for heating a broken circuit area according to a set path, and the needed graphene line or shape is deposited.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

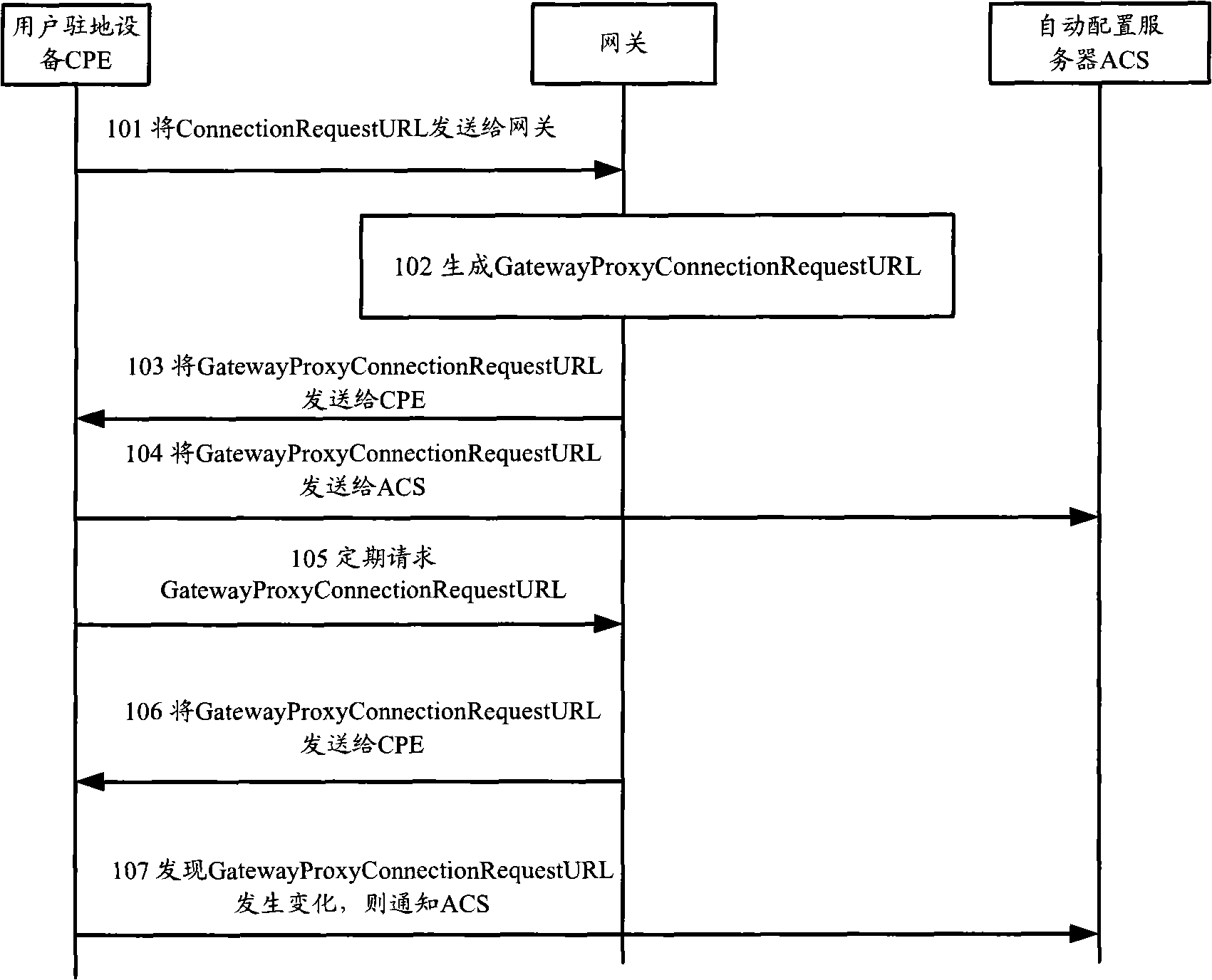

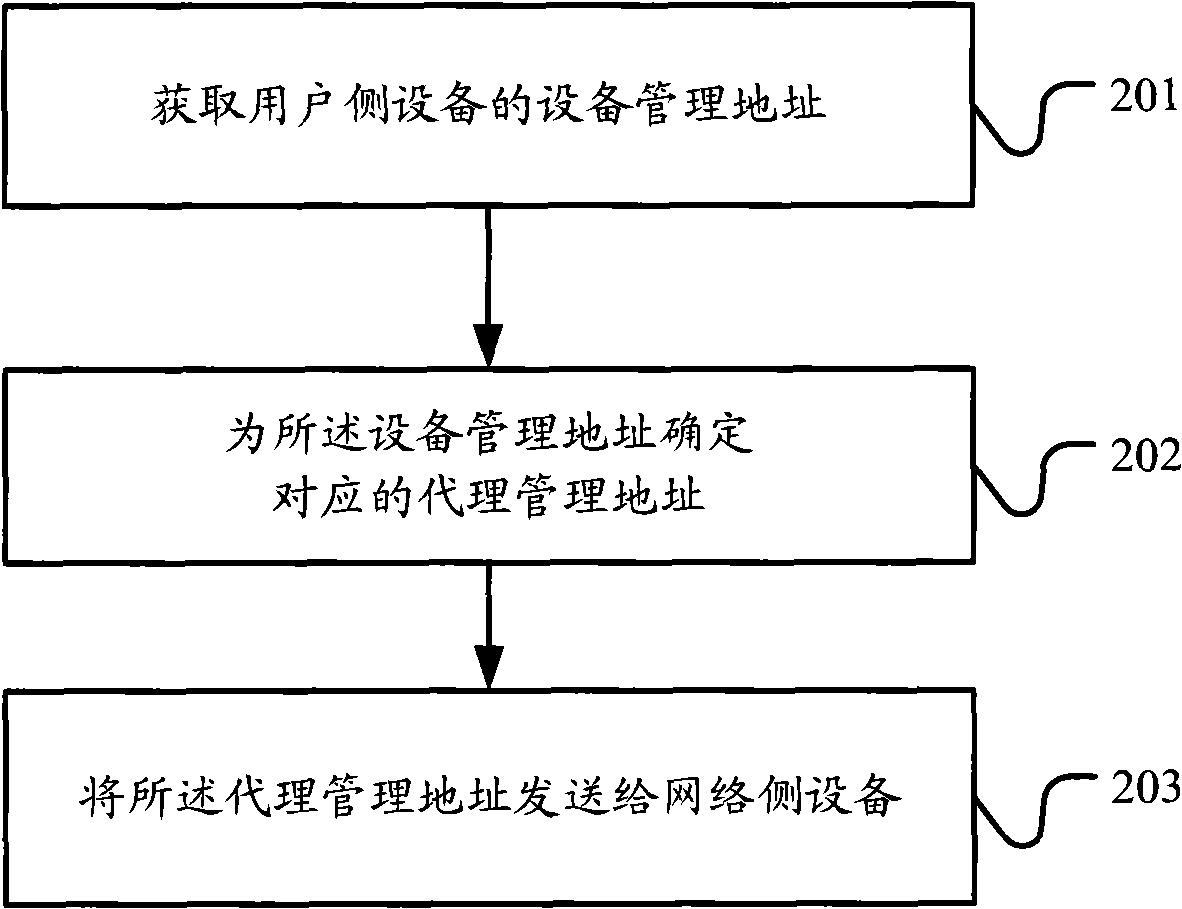

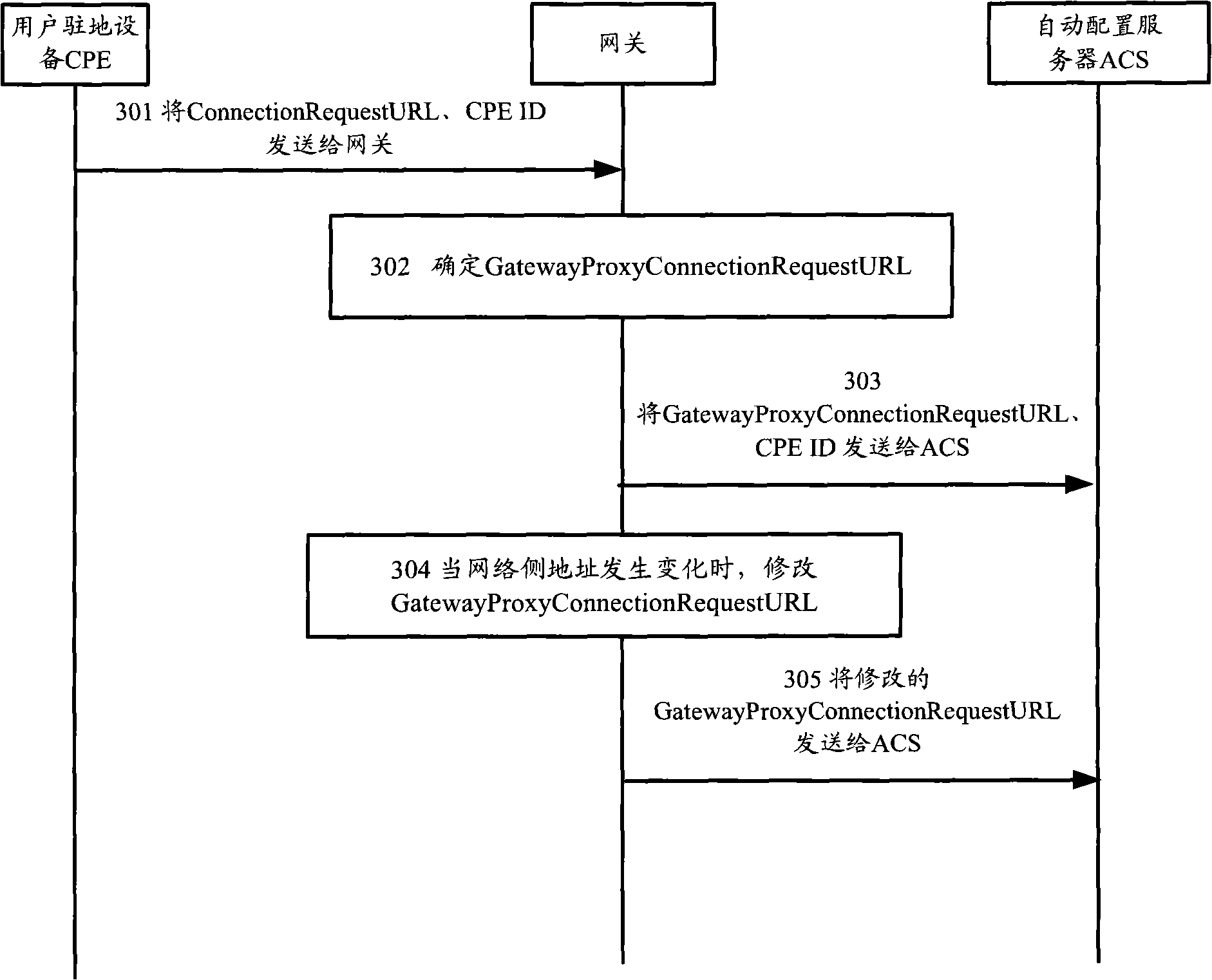

Information processing method, gateway and network system

InactiveCN101552802ASimplify the processReduce waste of resourcesNetwork connectionsNetworked systemManagement unit

The embodiment of the invention discloses an information processing method, a gateway and a network system. The method comprises the steps: obtaining an equipment management address of user side equipment; determining a corresponding acting management address for the equipment management address; and transmitting the acting management address to network side equipment. The embodiment of the invention provides the gateway which comprises an information obtaining unit used for obtaining the equipment management address of the user side equipment, a mapping unit used for determining the corresponding acting management unit for the equipment management address, and a transmitting unit used for transmitting the acting management address for the network side equipment. The embodiment of the invention also provides the network system. The technical scheme provided by the embodiment of the invention can simplify a processing process and reduce the resource waste of the user side equipment and the gateway.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

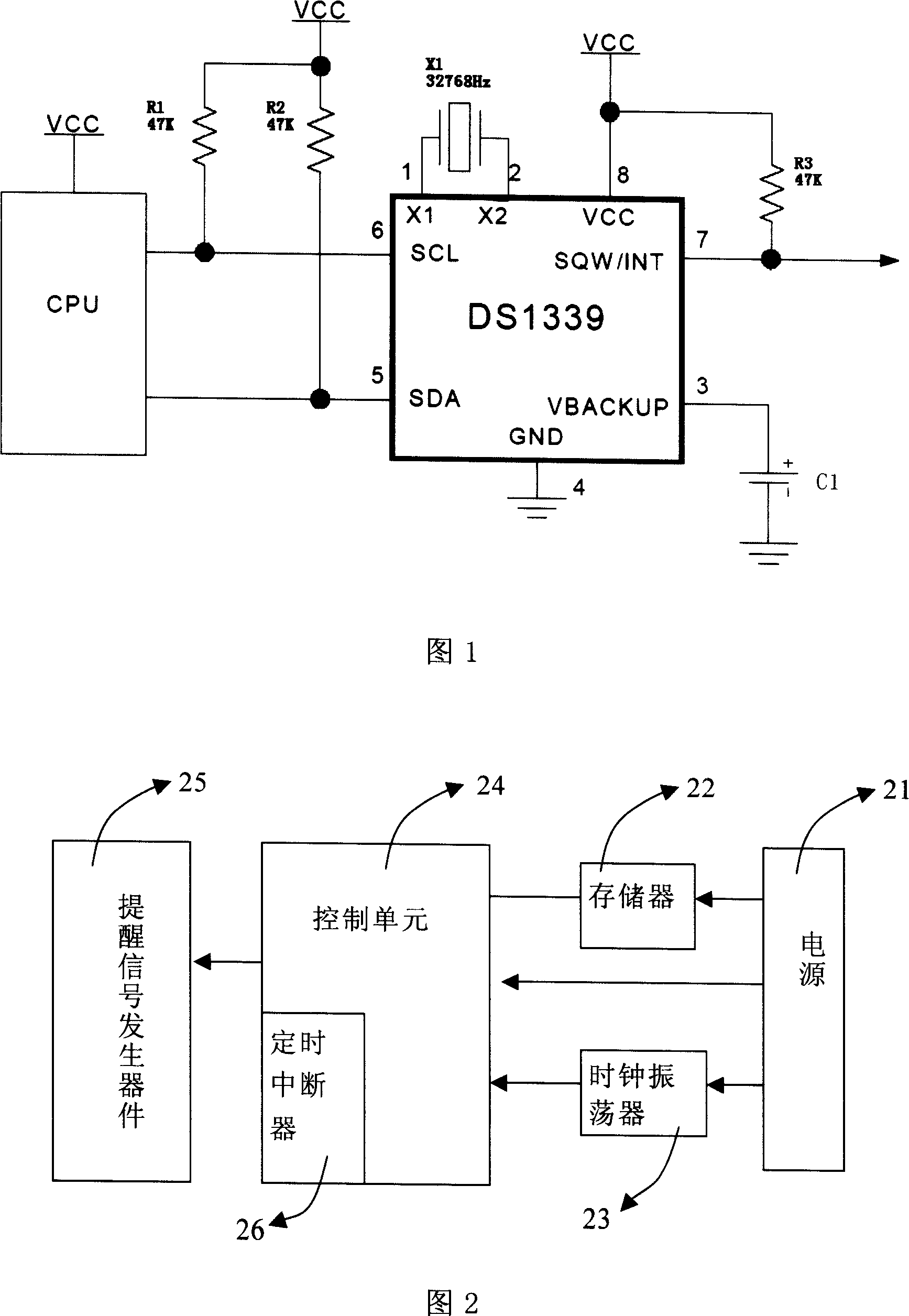

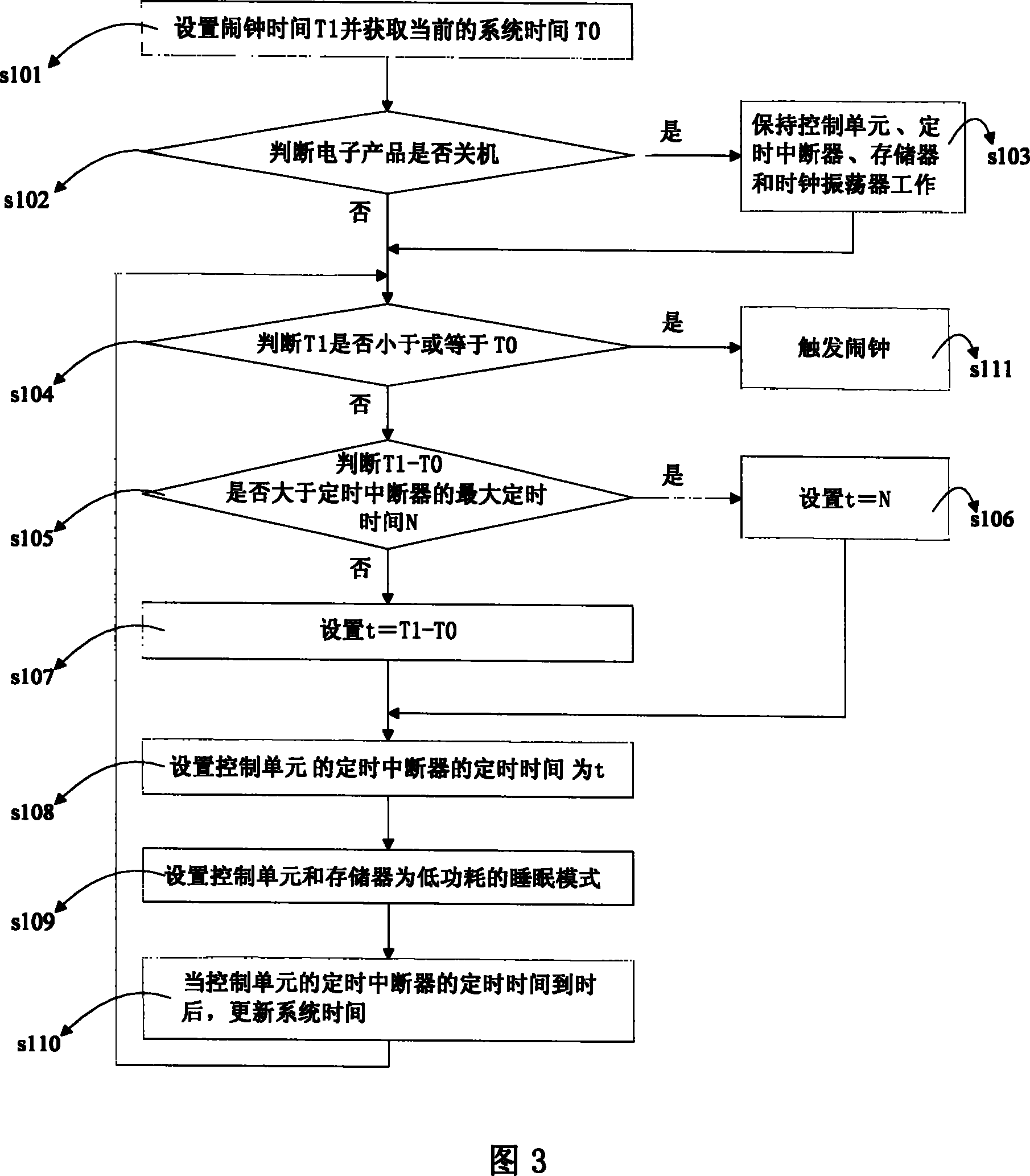

Device and method for realizing alarm clock function

A method for realizing alarm clock function includes setting a timing time of timing interruption unit by control unit according to alarm clock time, starting up timing by timing interruption unit and triggering up alarm clock when system time is on preset alarm clock time. The device used for realizing said method is also disclosed.

Owner:HUAWEI TECH CO LTD

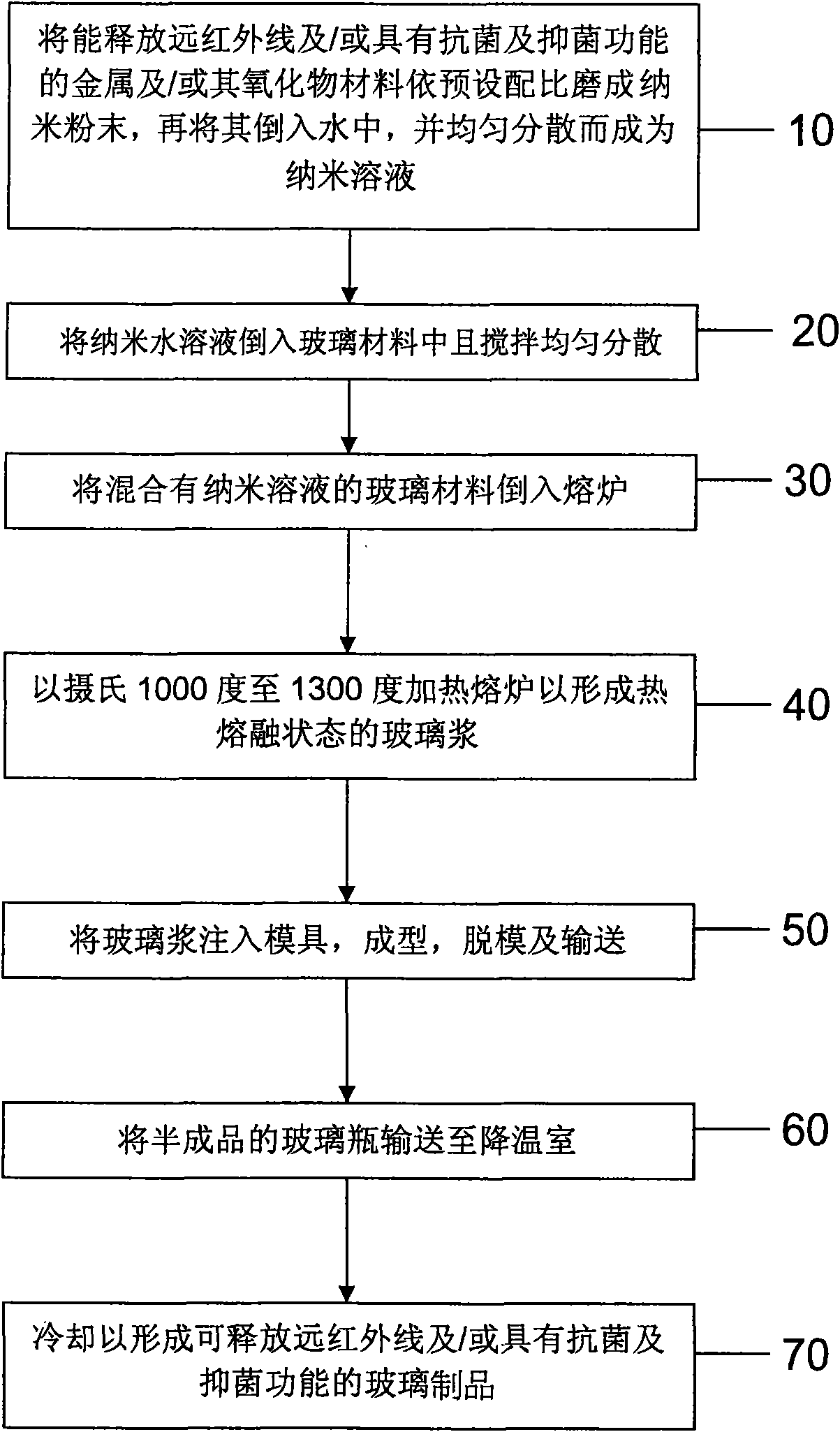

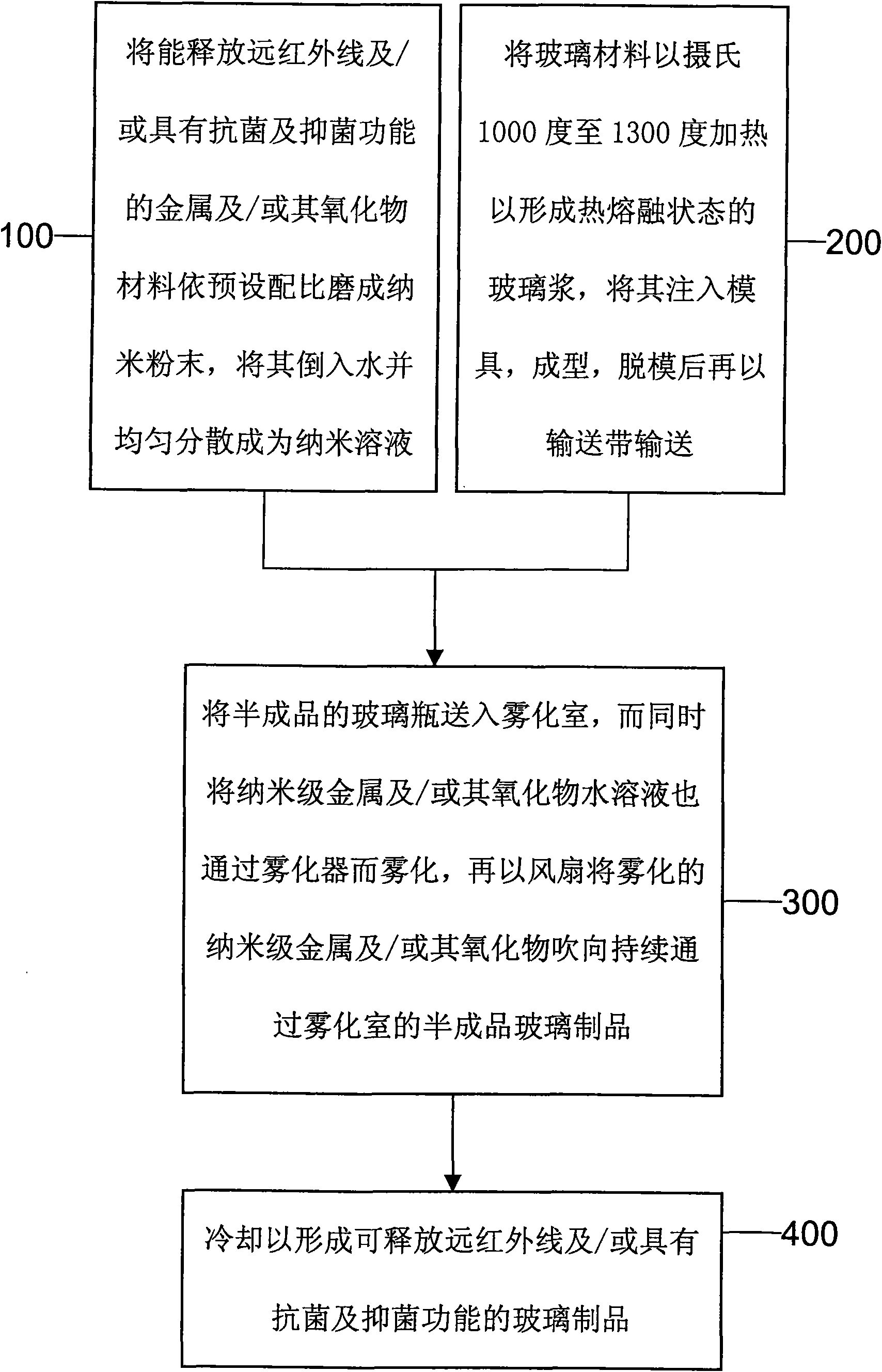

Method for manufacturing glass product

The invention relates to a method for manufacturing glass products, which comprises the following steps: grinding preset metal and / or oxide materials of the preset metal with a certain proportion into nanometer powder; pouring the nanometer powder into water solution and evenly dispersing the nanometer powder to form water solution of nano-scale metal and / or nano-scale metal oxide; pouring the water solution into glass materials and evenly mixing the mixture; pouring the glass materials mixed with the water solution of the nano-scale metal and / or the nano-scale metal oxide into a furnace and melting the glass materials through high-temperature heating to form glass paste of a hot melting state; injecting the glass paste into a mould to carry out molding and demoulding and conveying the obtained product to a cooling chamber through a conveying belt; and cooling the obtained product to room temperature to form glass products which can release far-infrared ray and / or have functions of antibacterium and bacteriostasis. The method can simply combine the nanometer metal or the nanometer metal oxide into a glass manufacture procedure so as to manufacture functional glass containing nanometer materials. The method is simple in manufacture procedure, does not need complex equipment and complex technology, reduces the production cost and is suitable to be applied to large-scale industry.

Owner:陈建仁

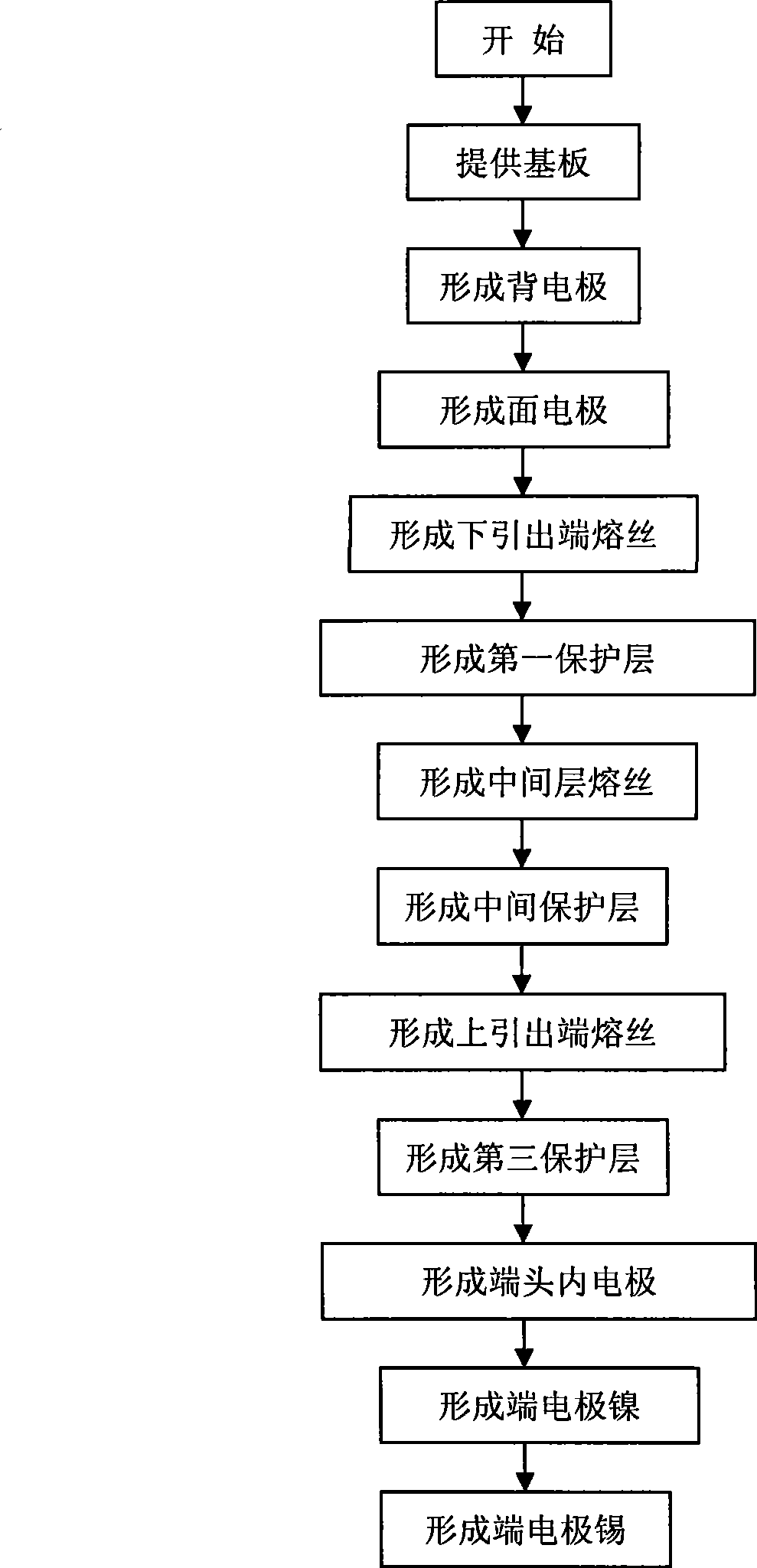

Multilayer tablet fuse and method of manufacturing the same

ActiveCN101441960ASimplify the processReduce equipment investmentFuse device manufactureElectrical and Electronics engineeringProduction cycle

The invention belongs to the field of fuse plug, and in particular relates to a multilayer SMD fuse and a preparation method thereof. The multi-layer SMD fuse consists of a ceramic substrate, a back electrode, face electrodes, fuse wires, protective layers and a metal end head, wherein the fuse wires are multilayer, fuse wires of adjacent layers are connected end to end, two end heads of connected fuse wires are connected with the face electrodes on two sides of the substrate respectively, and each layer of fuse wire is provided with a protective layer. When the fuse is prepared, except the uppermost protective layer, each protective layer does not cover the tail end of the fuse wire, so that the multilayer fuse wires are connected end to end to form a cascaded structure. Compared with the prior art, the invention has the advantages of simpler procedure, smaller equipment input, shorter production period and lower cost.

Owner:NANJING SART SCI & TECH DEV

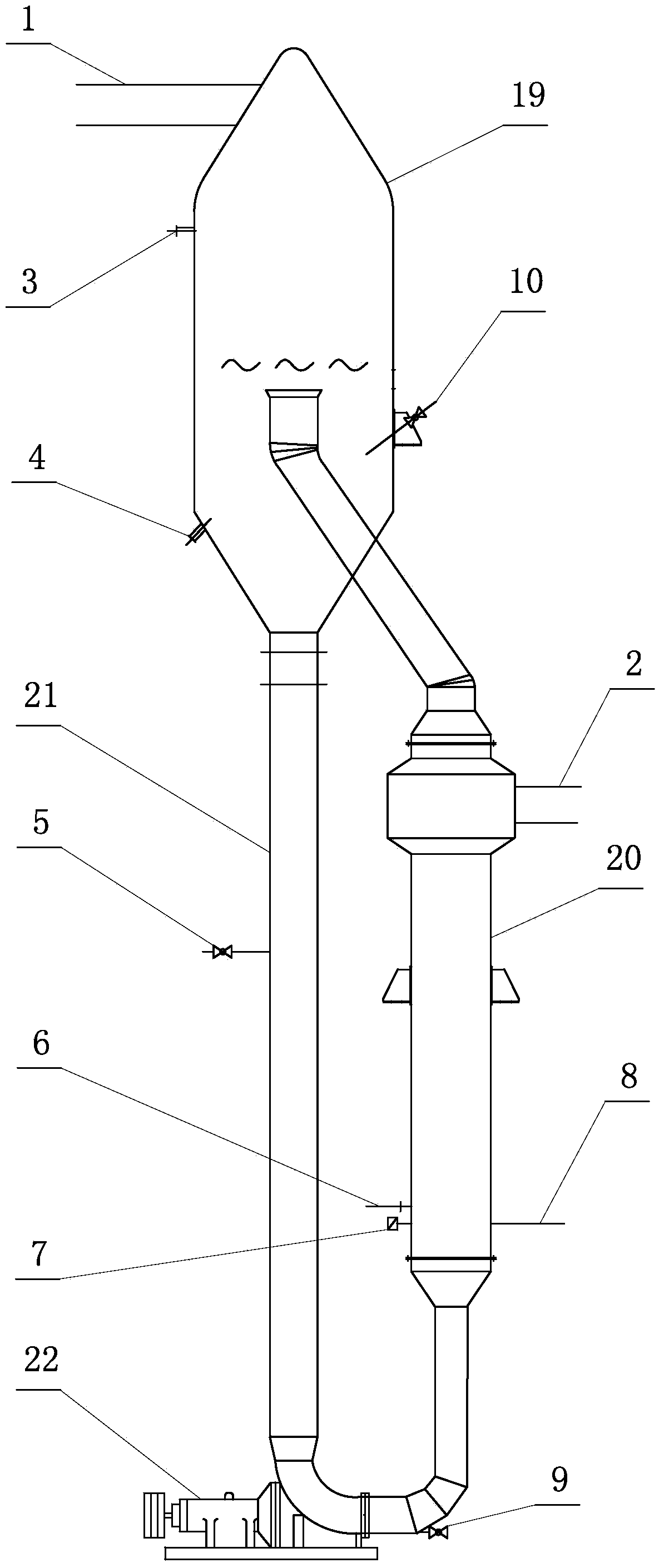

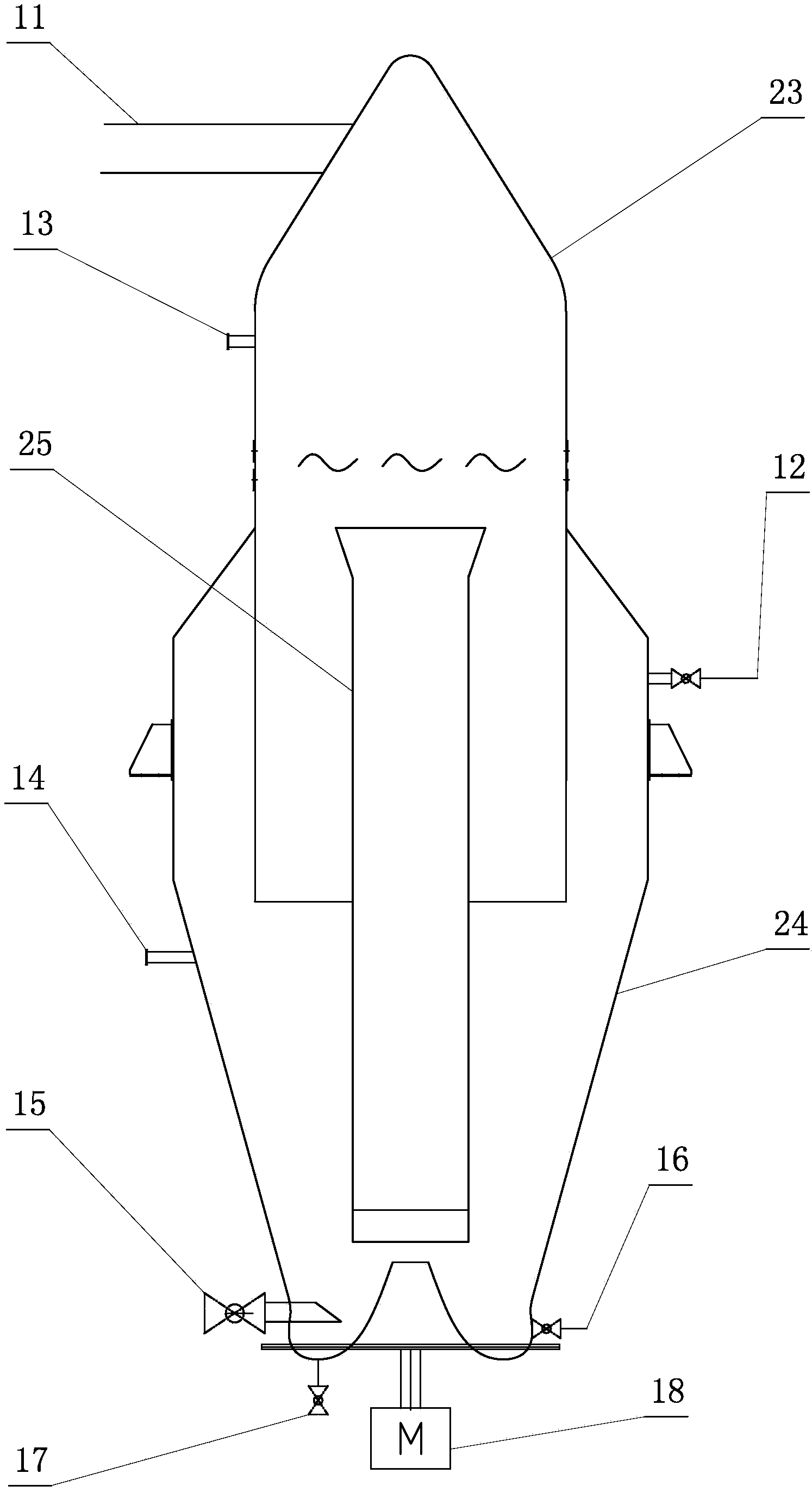

Device and method for treating high-concentration ammonia nitrogen wastewater

ActiveCN103833174ALow costSimplify the processMultistage water/sewage treatmentAmmonium halidesChemistryCounter flow

The invention relates to a device and a method for treating high-concentration ammonia nitrogen wastewater, which solve technical problems that an existing high-concentration ammonia nitrogen wastewater treatment method is high in cost, complex in treatment process, poor in treatment effect, and produces secondary pollution. The method comprises the following steps: firstly, adopting a quadruple-effect counter-flow evaporation process to separate out sodium chloride after settling and recycling the wastewater, and obtaining a sodium chloride product after centrifuging; and then, separating out ammonium chloride at a low temperature after adopting a two-stage flash evaporation process. The device and the method disclosed by the invention can be widely applied to treating high-concentration ammonia nitrogen wastewater.

Owner:山东众音化学科技有限公司

Glass processing device

InactiveCN102442768ASimplify the processIncrease productivityGlass severing apparatusGlass productionEngineeringCutting glass

A glass processing device is provided, which is used for cutting a glass substrate to form round glass sheets. The glass processing device comprises a working chamber, a loading device, a cutting device, a driving device and a jacking device which are received in the working chamber. The loading device comprises a holding part for holding the glass substrate. The cutting device comprises a hollow fixed shaft and at least one blade. A receiving chamber is formed in the fixed shaft. At least one blade is fixed on the end surface of the fixed shaft facing the loading device. The distance of at least one blade and axis of the fixed shaft is equal. The driving device drives the cutting device to move and rotate in the direction of the glass substrate in order to cut the glass substrate. The jacking device can be flexibly received in the receiving chamber. When at least one blade cuts the glass substrate, the jacking device can jack out the receiving chamber to push the cut glass sheets, so that the cut glass sheets separate from at least one blade. The glass processing device has simple process and can effectively improve production efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Array substrate and its manufacturing method and In Cell touch control display panel

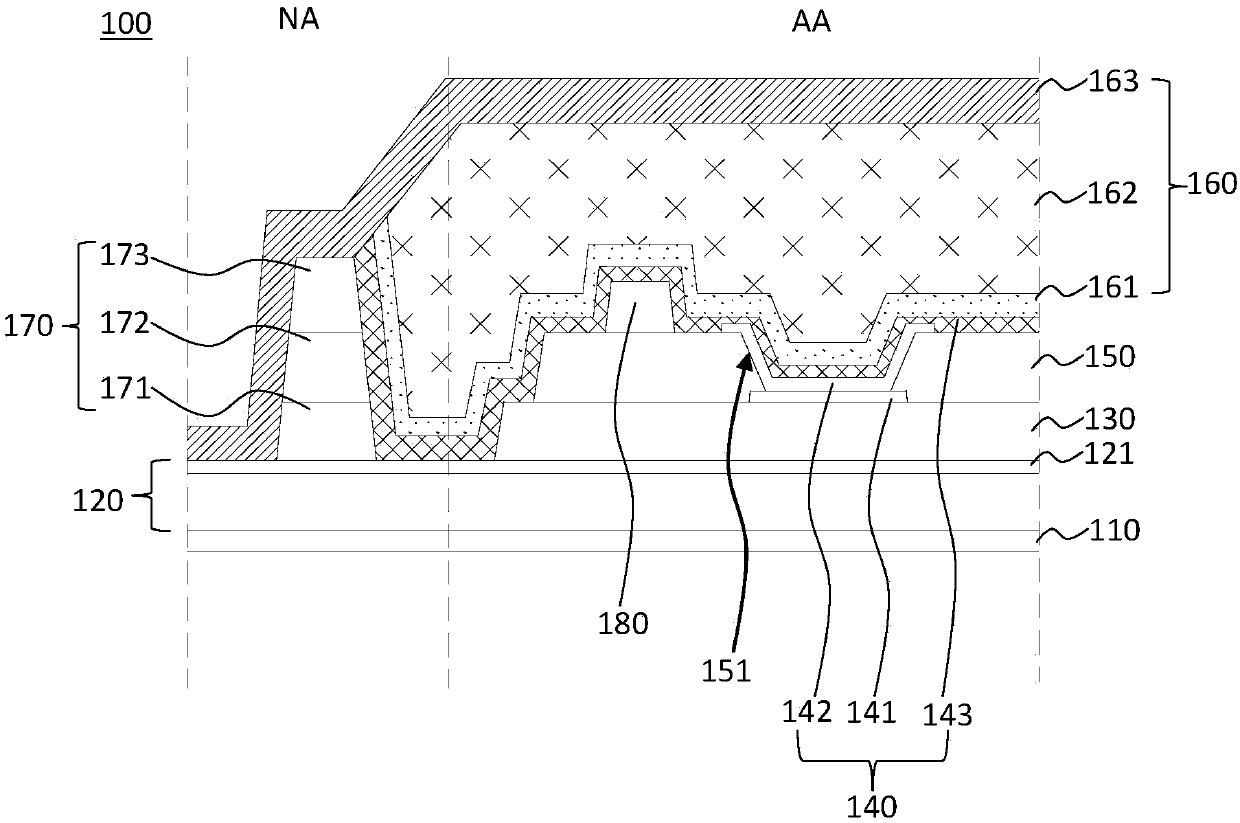

InactiveCN106773221AImprove display qualitySimplify the processNon-linear opticsInput/output processes for data processingData linesControl signal

The invention provides an array substrate and its manufacturing method and an In Cell touch control display panel. According to the array substrate, a first flat layer, a touch control signal layer, a second flat layer, a common electrode, a passivation layer and a pixel electrode are sequentially formed on a source / drain electrode, a data line and a third insulating layer, in the structure, the touch control signal layer is located below the second flat layer, the situation that bulges form in the region, corresponding to the touch control signal layer, on the surface of the array substrate does not occur, the surface of the array substrate is relatively flat, the situation that sliding of a spacer causes the collapse of a liquid crystal box or the scratch of an alignment film can be avoided, and the displaying quality is improved; at the same time, three passivation layers in an existing array substrate are reduced to one passivation layer, the manufacture procedure is thus simplified, and the manufacturing cost is reduced. According to the manufacturing method of the array substrate, the surface of the prepared array substrate is flat, the manufacture procedure is simple, and the manufacturing cost is low. The In Cell touch control display panel is good in displaying quality and low in production cost.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

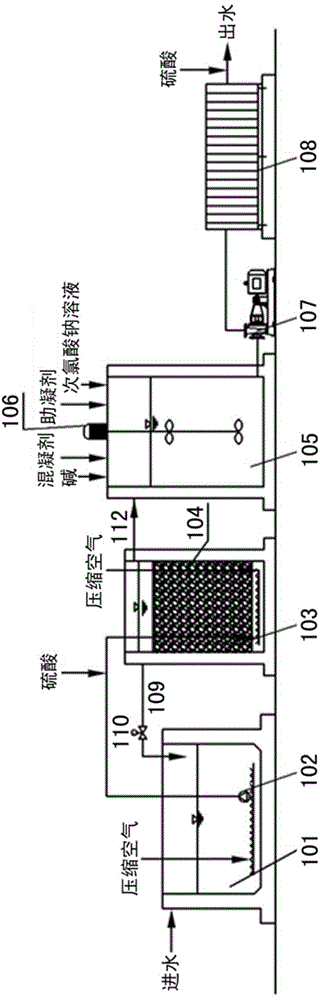

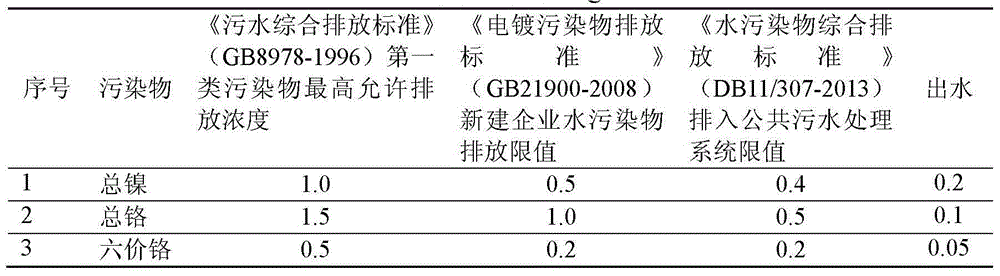

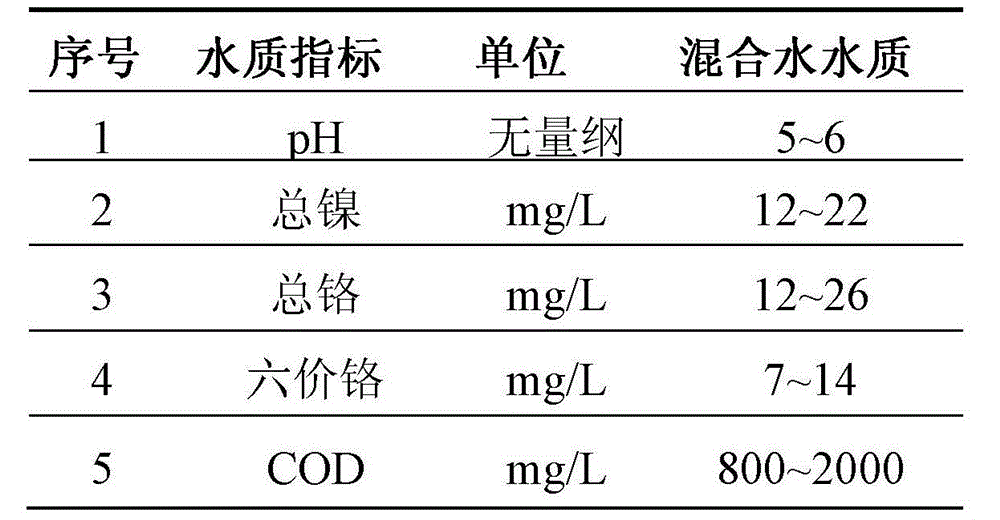

Treatment method and treatment device of electroplating mixed water

ActiveCN104529017ASimplify the processReduce engineering investment and operating costsWaste water treatment from metallurgical processMultistage water/sewage treatmentIonPollutant

The invention relates to a treatment method of electroplating mixed water. The method comprises the following steps: (1) collecting the electroplating mixed water in a water collecting tank, adjusting the pH value to be 2 to 3, hoisting the electroplating mixed water from the water collecting tank into a micro-electrolytic reactor, carrying out the micro-electrolysis by virtue of iron-carbon filler, returning the electroplating mixed water to the water collecting tank from the micro-electrolytic reactor, circulating the electroplating mixed water until hexavalent chromium ions in the electroplating mixed water are reduced to trivalent chromium ions, and ending the circulation stage; (2) enabling the mixed water after the micro-electrolysis to enter a coagulation reactor, stirring the mixed water, adjusting the pH value to 10 to 12, and sequentially adding a coagulant, a coagulant aid and a sodium hypochlorite solution; (3) stopping stirring, standing and precipitating; (4) dehydrating the mud-water mixture in the coagulation reactor after the water quality is qualified, discharging the water, adjusting the pH value of the discharged water to 6 to 9, and externally transporting mud cakes. The invention also discloses a device for realizing the method. By adopting the treatment method and the treatment device, heavy metals and organic pollutants in the electroplating mixed water can be simultaneously and efficiently removed.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

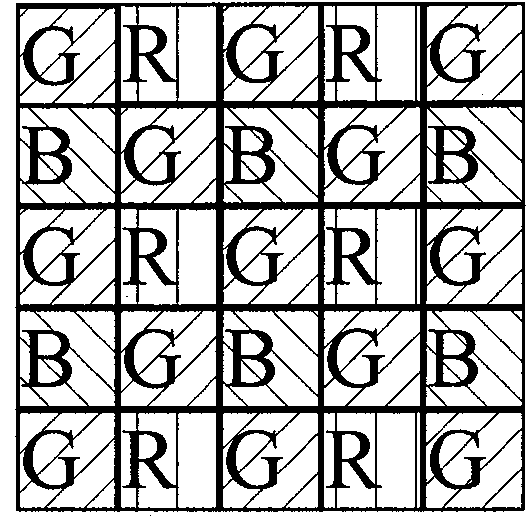

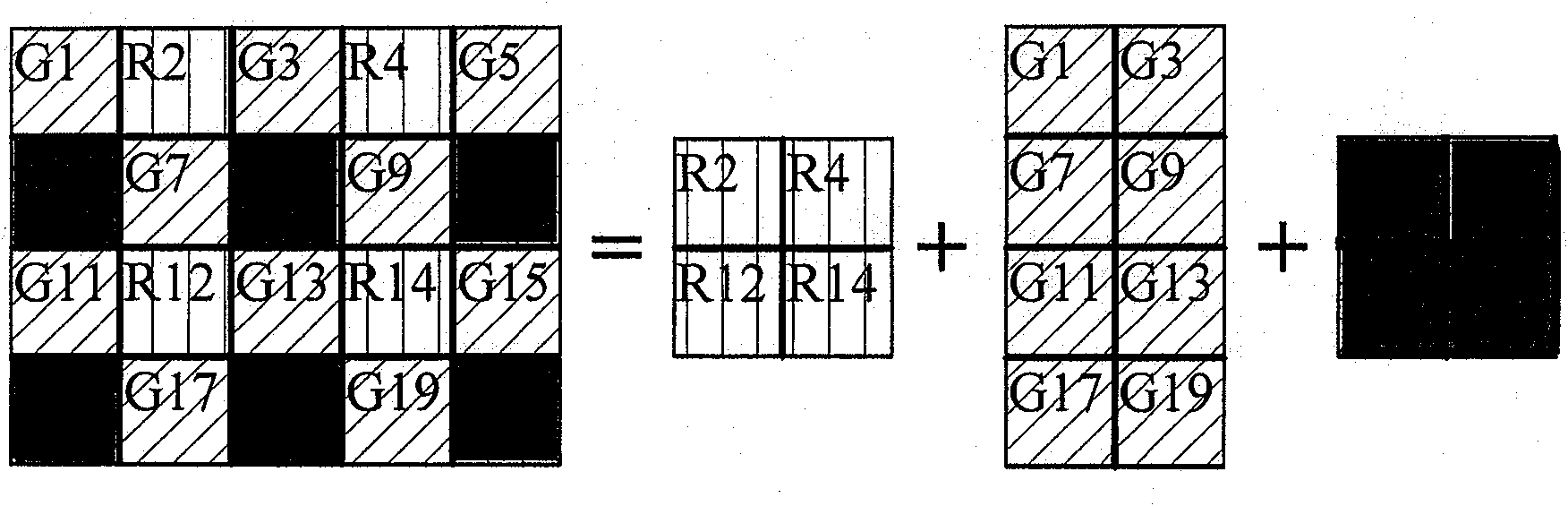

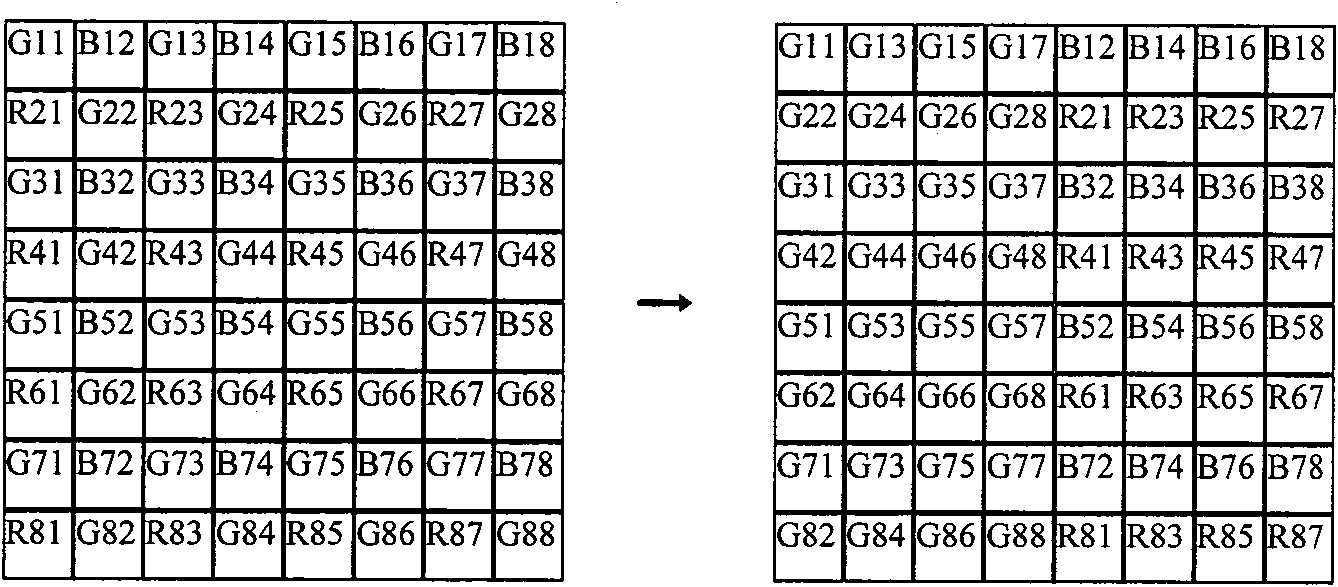

Lossless compression method applicable to Bayer image format

ActiveCN101902650ASimplify the processSave memory or register spacePicture signal generatorsPre treatmentDecomposition

The invention discloses a lossless compression method applicable to the Bayer image format, which comprises the following steps: carrying out correlation evaluation and calculation by separating a current pixel with the above part by a line of pixels and separating the current pixel with the left side by a column of pixels, adopting two storage lines of line 0 and line 1 to respectively store odd-numbered lines and even-numbered lines of pixel values, and using the line 0 to carry out the correlation evaluation if the current pixel is in the even-numbered line; using the line 1 to carry out the correlation evaluation if the current pixel is in the odd-numbered line; that is, giving corresponding values to variables of N1 and N2, then calculating L which is equal to min (N1, N2) and calculating H which is equal to ma multiplied by (N1, N2), and determining the encoding method according to the distribution position fallen by the current pixel value P. The lossless compression method does not need to carry out pre-treatment, can overcome the calculations of three-color channel decomposition or image structure conversion and the like, inherits the characteristics of fastness, high efficiency and capability of being applicable to physical realization with low power consumption and small area of the FELICS method, and has good compression effect.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

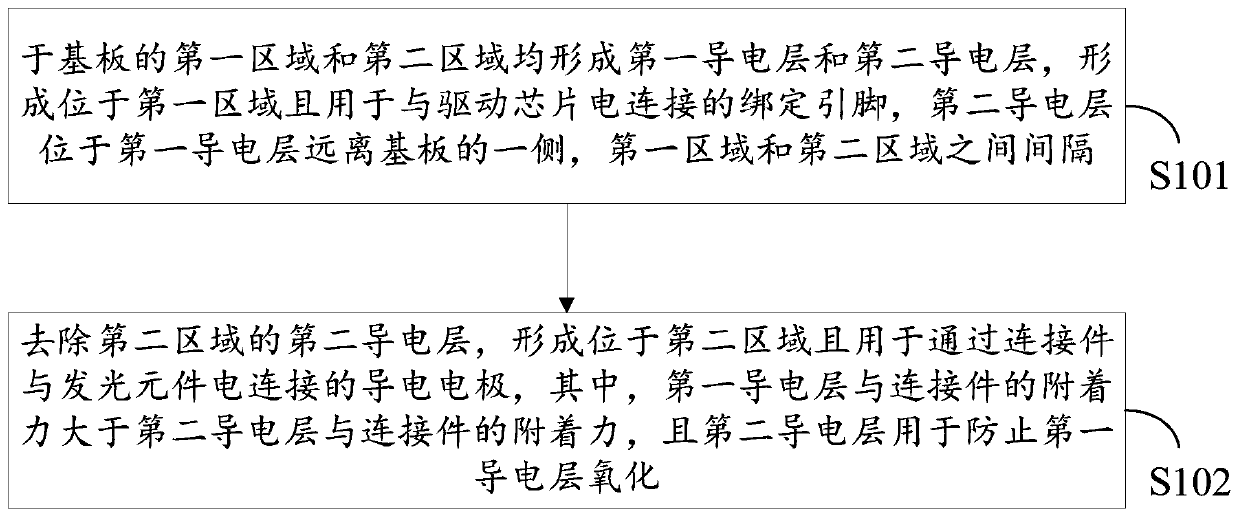

Array substrate, manufacturing method thereof and display device

PendingCN111477638ASimplify the processPrevent oxidationSolid-state devicesSemiconductor devicesPhysicsElectrically conductive

The invention provides an array substrate, a manufacturing method thereof and a display device. The manufacturing method comprises the steps of forming a first conducting layer and a second conductinglayer in a first area and a second area of a substrate, binding pins which are located in the first area and used for being electrically connected with a driving chip are formed, the second conducting layer is located on the side, away from the substrate, of the first conducting layer, and the first area and the second area are spaced; removing the second conductive layer in the second region, and forming a conductive electrode which is located in the second region and is used for being electrically connected with the light-emitting element through a connecting piece; wherein the adhesive force between the first conducting layer and the connecting piece is larger than that between the second conducting layer and the connecting piece, and the second conducting layer is used for preventingthe first conducting layer from being oxidized. The manufacturing method has the advantages that the manufacturing process is simplified, the oxidation resistance of the binding pin is improved, and the adhesive force between the connecting piece and the conductive electrode is improved, so that the light-emitting element is firmly fixed on the array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

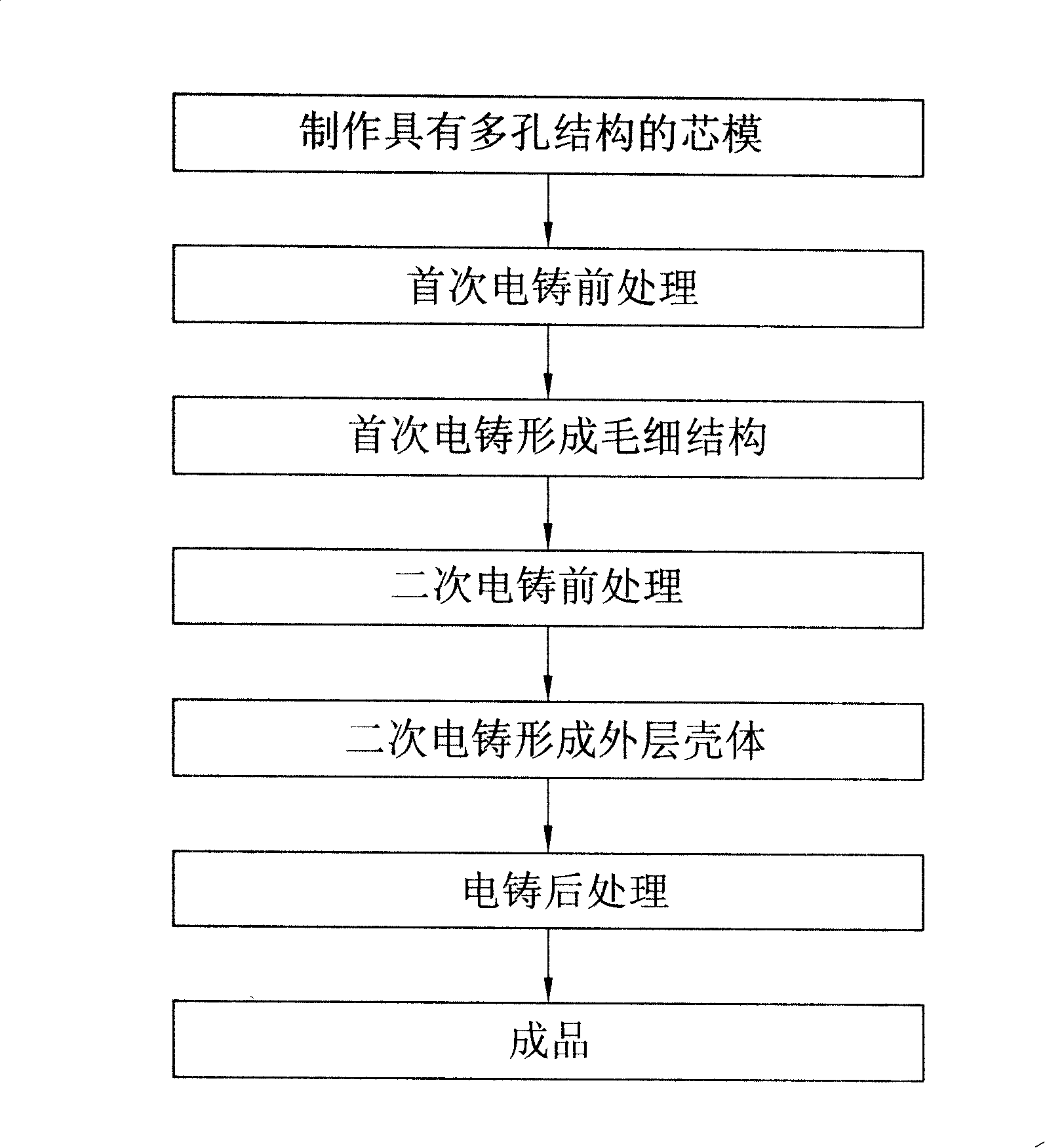

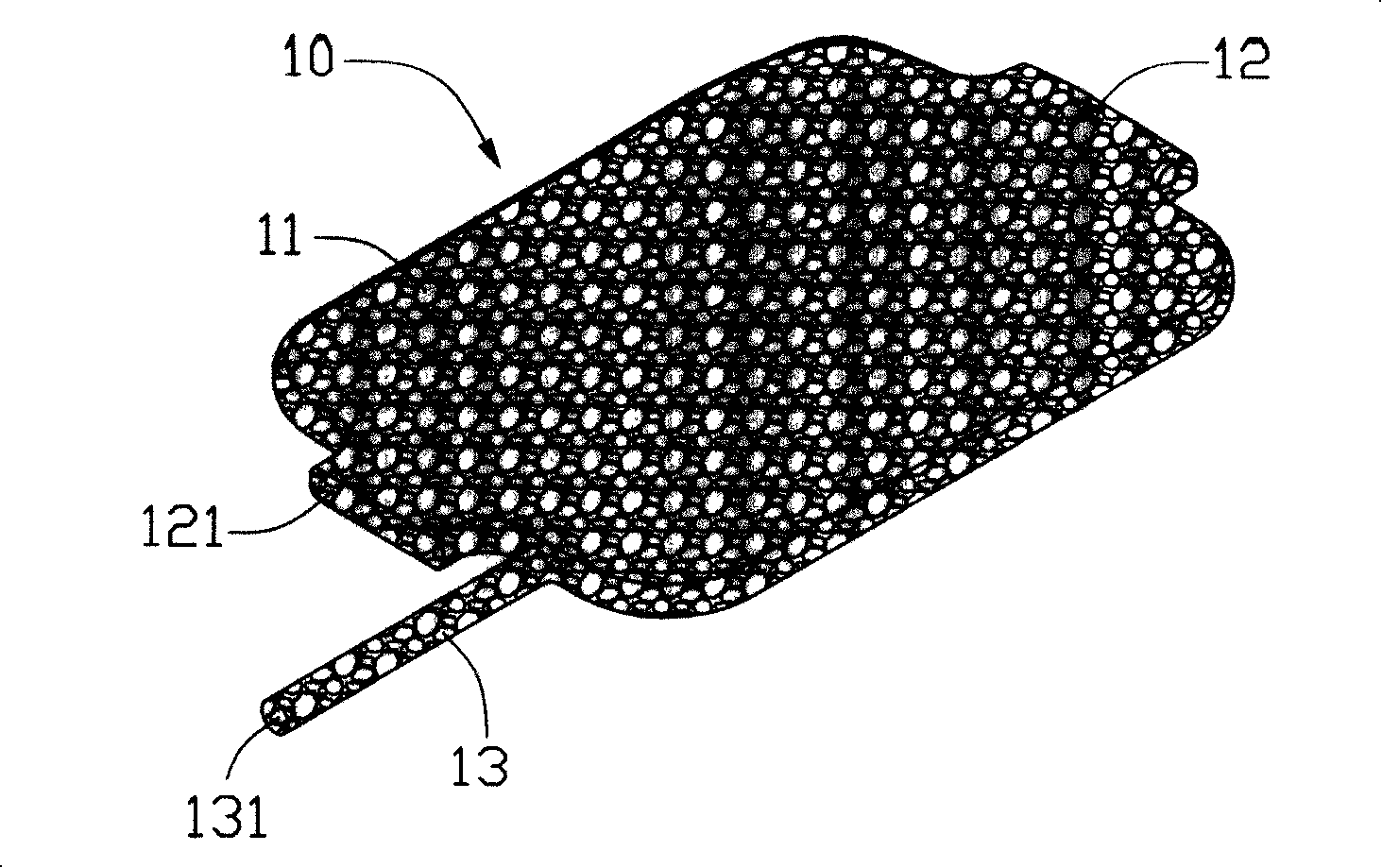

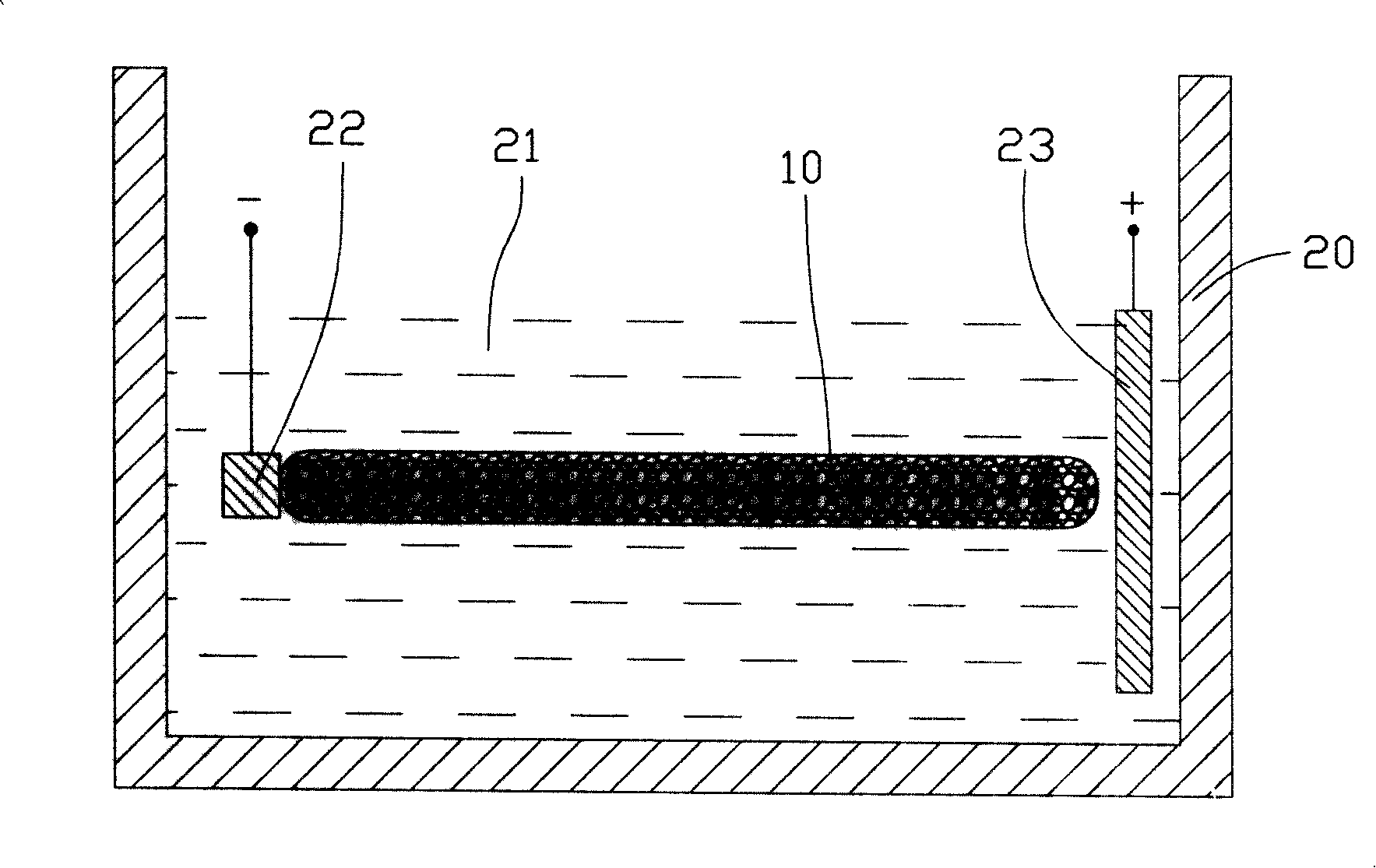

Method for manufacturing airtight cavity structure

InactiveCN101230472ASimplify the processGood capillary effectElectroforming processesMetalMaterials science

The invention relates to a method of manufacturing an airtight cavity structure and includes the following steps: firstly, a mandrel with a porous structure is manufactured, that is, a porous foam plastic framework is manufactured; secondly, an electric conduction treatment is conducted to the pore wall of the foam pore on the surface of the mandrel and at a predetermined depth under the surface of the mandrel; thirdly, the mandrel is electroformed for the first time and a first metal cast layer is formed on the surface of the mandrel and in the foam pore at the predetermined depth; fourthly, a surface polishing treatment is conducted to the mandrel electroformed for the first time to flatten and smooth the surface; fifthly, the mandrel is electroformed for the second time and a second metal cast layer is formed on the outer surface of the mandrel; sixthly, the mandrel is eliminated and a cavity body with the first metal cast layer as the capillary structure and the second metal cast layer as the shell body is obtained; and finally, an operating fluid is injected into the cavity body and an airtight cavity structure is thus obtained. The manufacturing method has simple manufacturing procedures and can mold an airtight cavity structure with preferable capillary effect.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

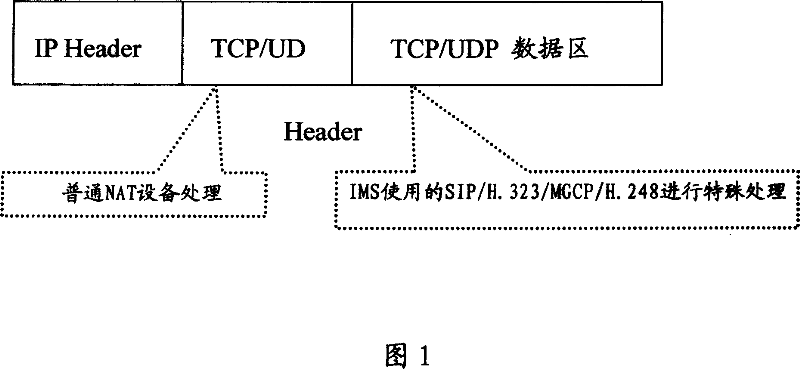

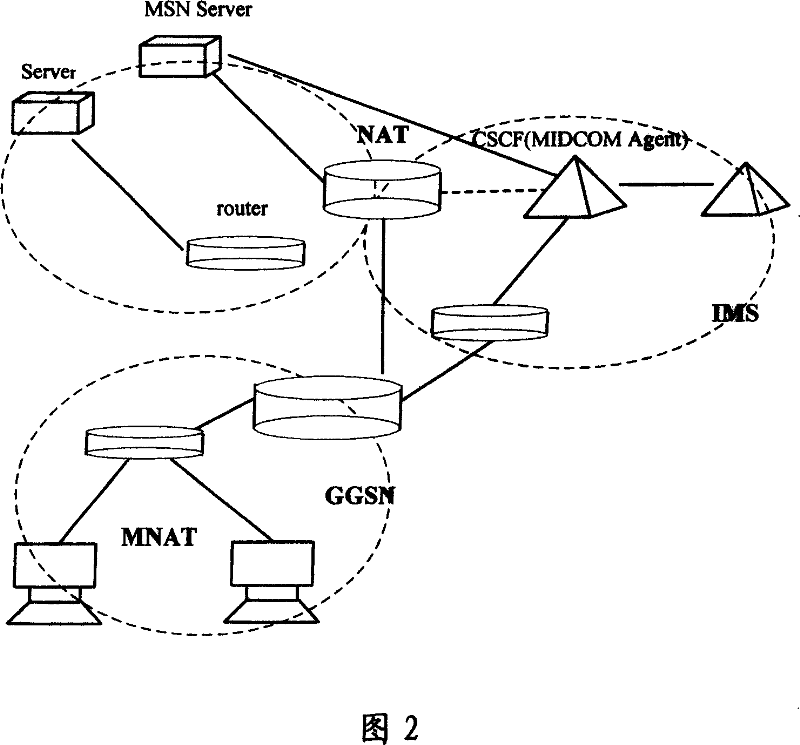

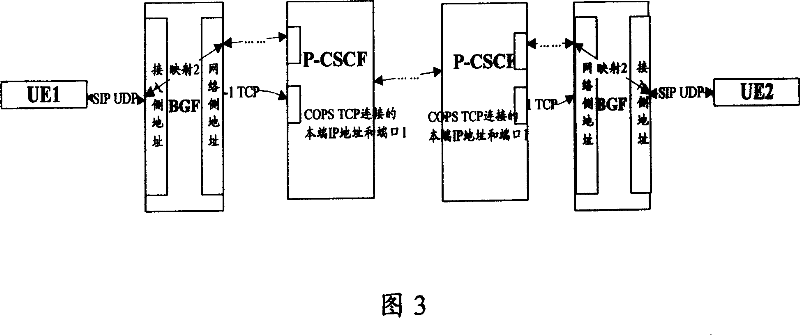

Process and system for media flow transverse network address conversion

InactiveCN101043475ASimplify the processImprove system efficiencyNetwork connectionsNetwork addressLogical address

The disclosed address conversion method for media flow crossing network comprises: it transmits user media flow to the BGF entity; the latter matches the media mapping relation binding with media mapping message according to mark and original address in media to determine the port, and transmits the media flow. It also discloses a network system for the address conversion.

Owner:HUAWEI TECH CO LTD

Passivation encapsulation method for organic electro luminescence elements and structure

InactiveCN1520235ASimplify the processReduce product weight and thicknessElectrical apparatusElectroluminescent light sourcesOrganic electroluminescenceCascading effects

Passivation structure is coated on surface of lamellar structured organic EL elements to isolate contact between organic material / pole material and outside surroundings in order to prolong lifetime of organic EL elements. When coating by vaporization on organic layer and pole layer is completed, inorganic material with gas barrier property is coated on surface of element selectively at same time in order to protect cathode in primary. Then, following steps are carried out: high molecular passivation material coated on element through spray coating or printing method directly; heat cure or ultraviolet cure; filling up surface of element by using macromolecule layer to even the surface and eliminating cascade effect of gap between element and rib so as to reach compactness of passivation structure. Finally, encapsulation material seals passivation surface in order to provide final protection.

Owner:WINTEK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com