Production line for light guide plates

A technology of light guide plate and production line, applied in the direction of light guide, optics, optical components, etc., can solve the problems of lengthy, unable to increase production, cumbersome process, etc., to achieve the effect of simple process, enhance industrial competitiveness, and increase output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a further understanding and understanding of the purpose, characteristics and effects of the present invention, please cooperate with the [simplified description of the drawings] to describe in detail as follows:

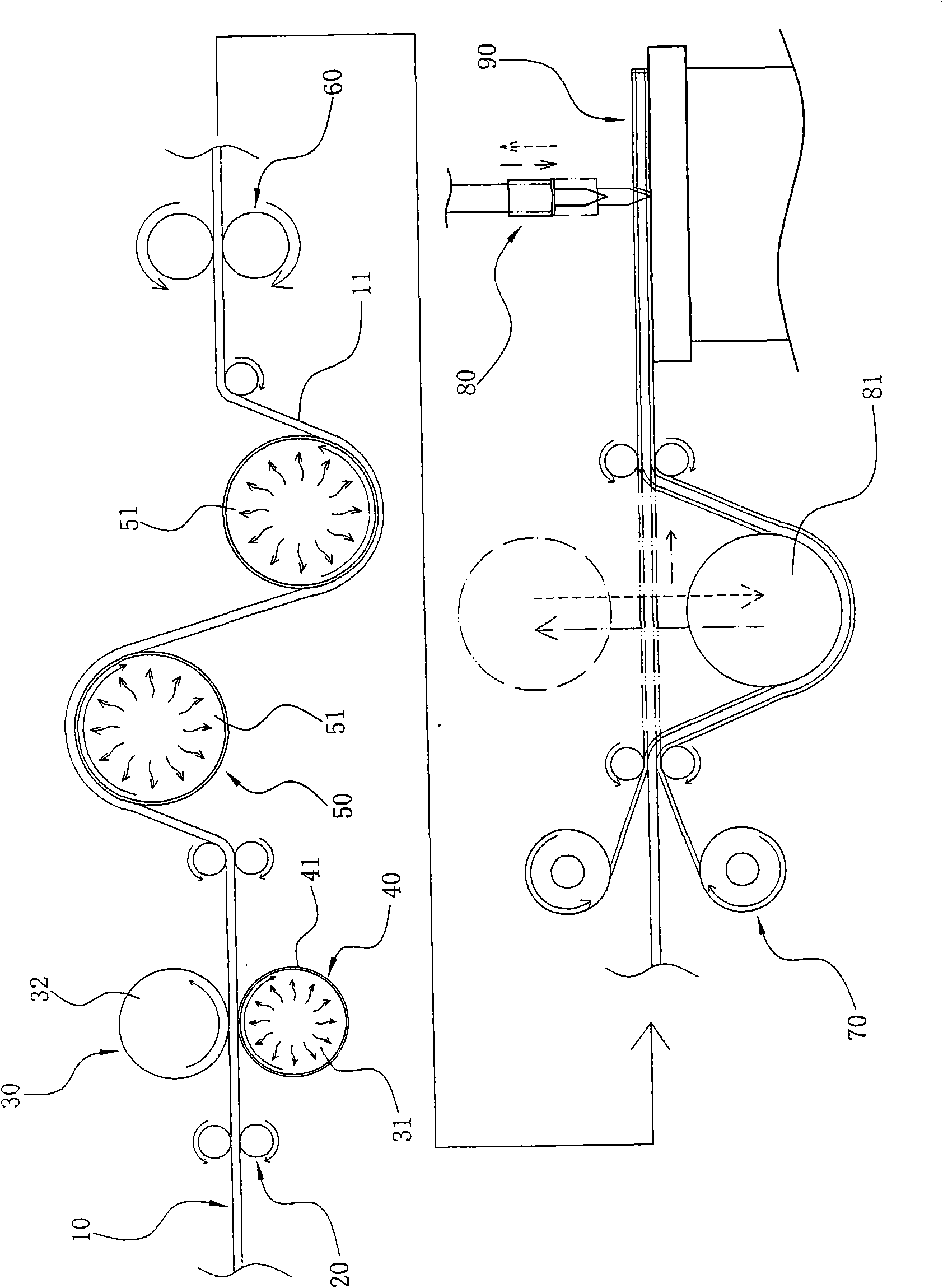

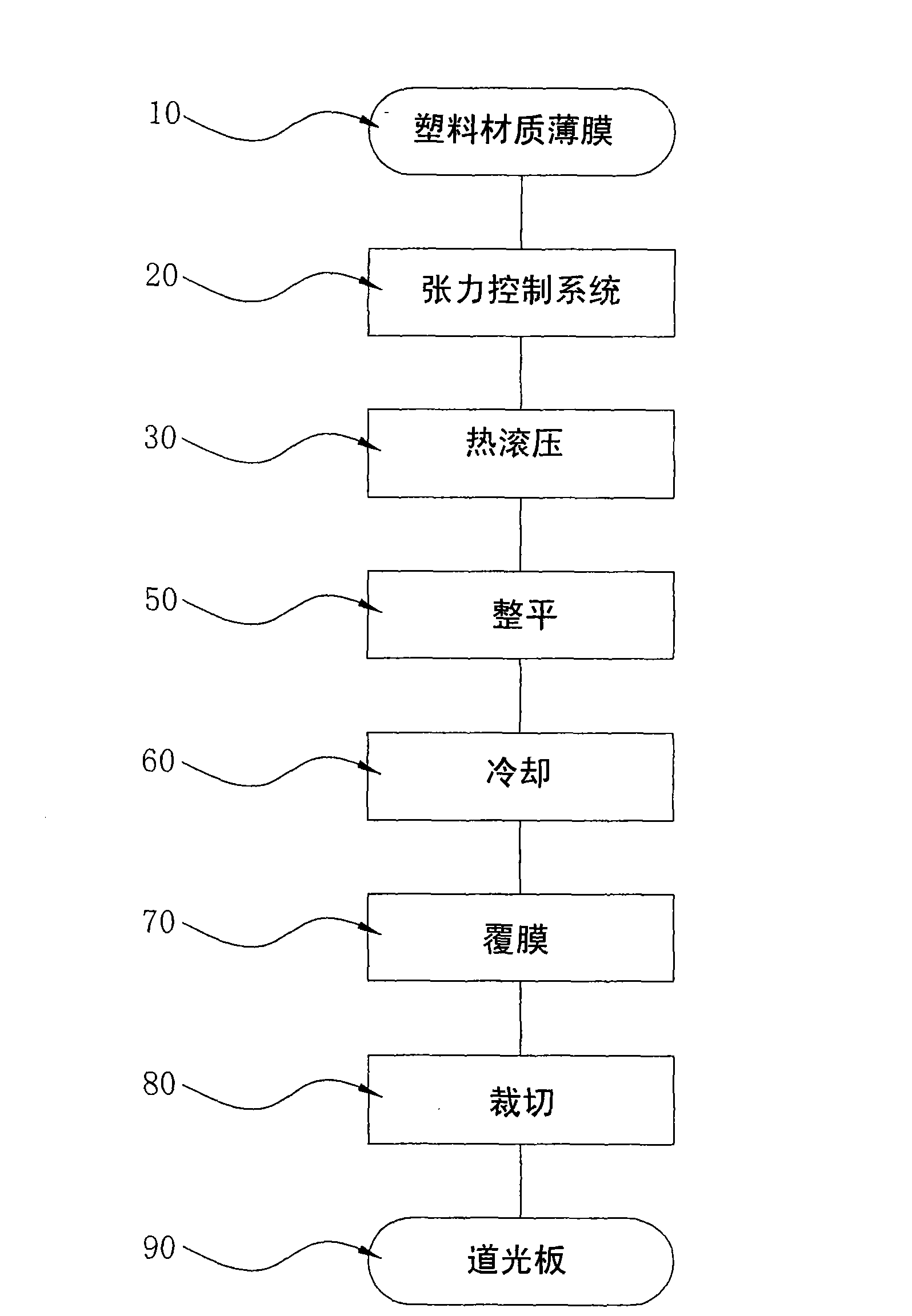

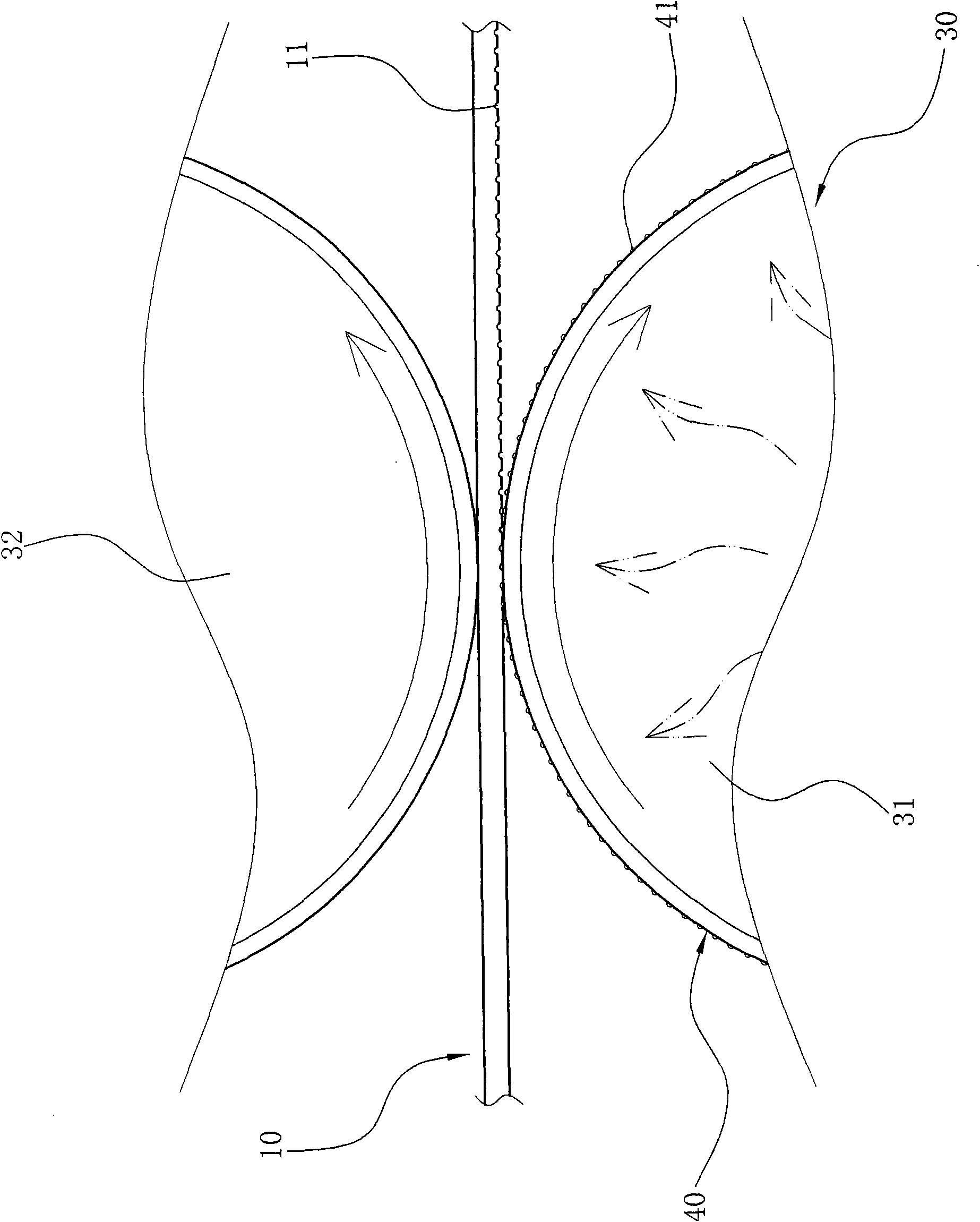

[0031] Usually according to the present invention, first by figure 1 match figure 2 As shown, the plastic material film (LightGuide Film) 10 is conveyed by the tension control system 20, and can run forward. During the running process, it passes through hot rolling 30, metal film 40, leveling 50, Cooling 60, coating 70, cutting 80 and other processes can complete the forming of the light guide plate 90; wherein,

[0032] The tension control system 20 is the conveying wheel, which is mainly used to drive the plastic material film 10 forward, so as to continue the processes of hot rolling 30, leveling 50, cooling 60, coating 70, cutting 80 into a consistent process flow line, and can be used to drive the output of the formed light guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com