Method for manufacturing airtight cavity structure

A manufacturing method and air-tightness technology, applied in electrolysis process, electroforming and other directions, can solve the problems of inability to form, small capillary size, complicated manufacturing process, etc., and achieve the effect of simple process and good capillary effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

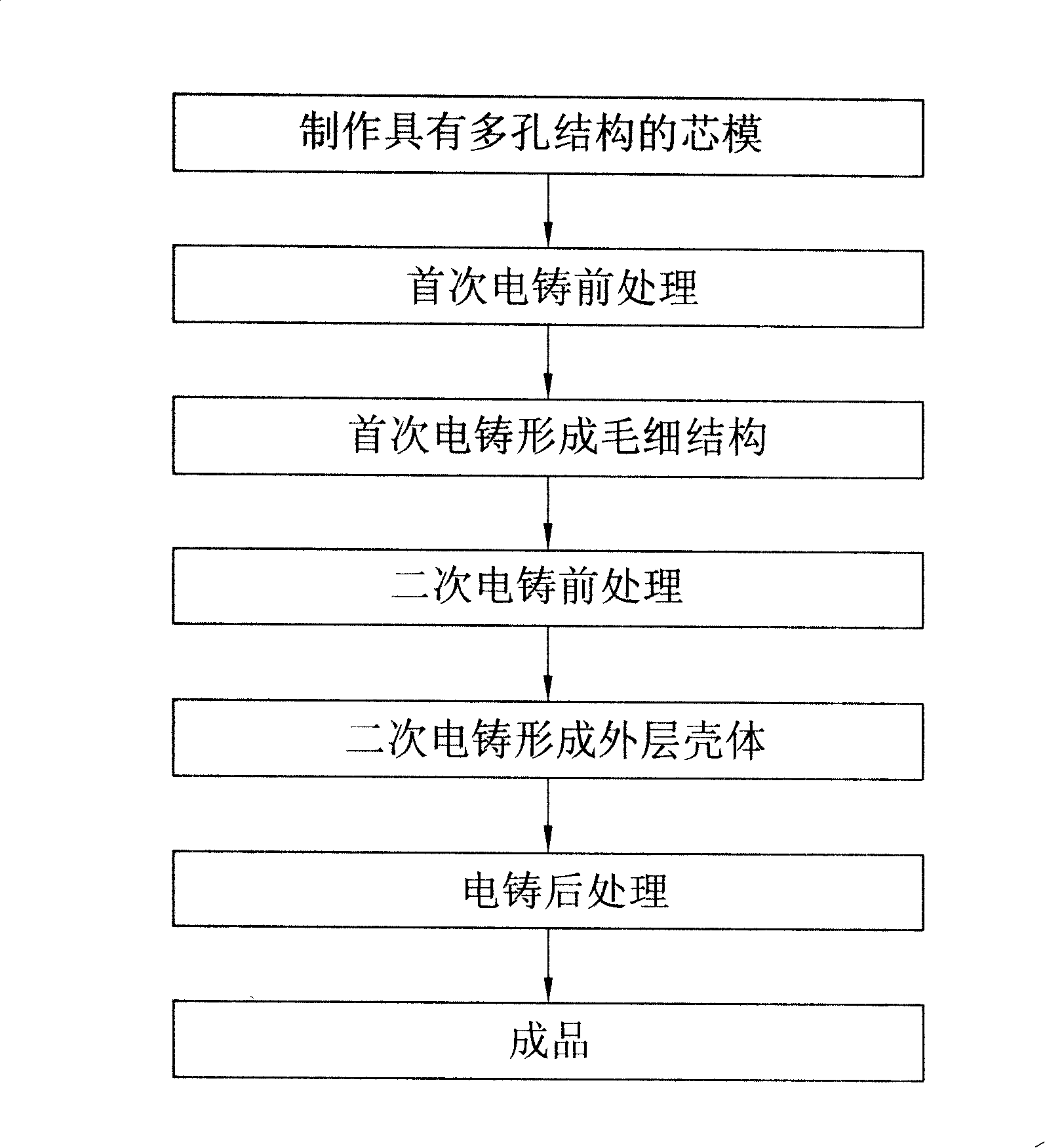

[0014] figure 1 Shown is a schematic flow chart of the manufacturing method of the airtight cavity structure of the present invention, which includes the following main steps: making a core mold with a porous structure → first electroforming pretreatment → first electroforming to form a capillary structure → before secondary electroforming Processing → secondary electroforming to form the outer shell → post-electroforming processing → finished product.

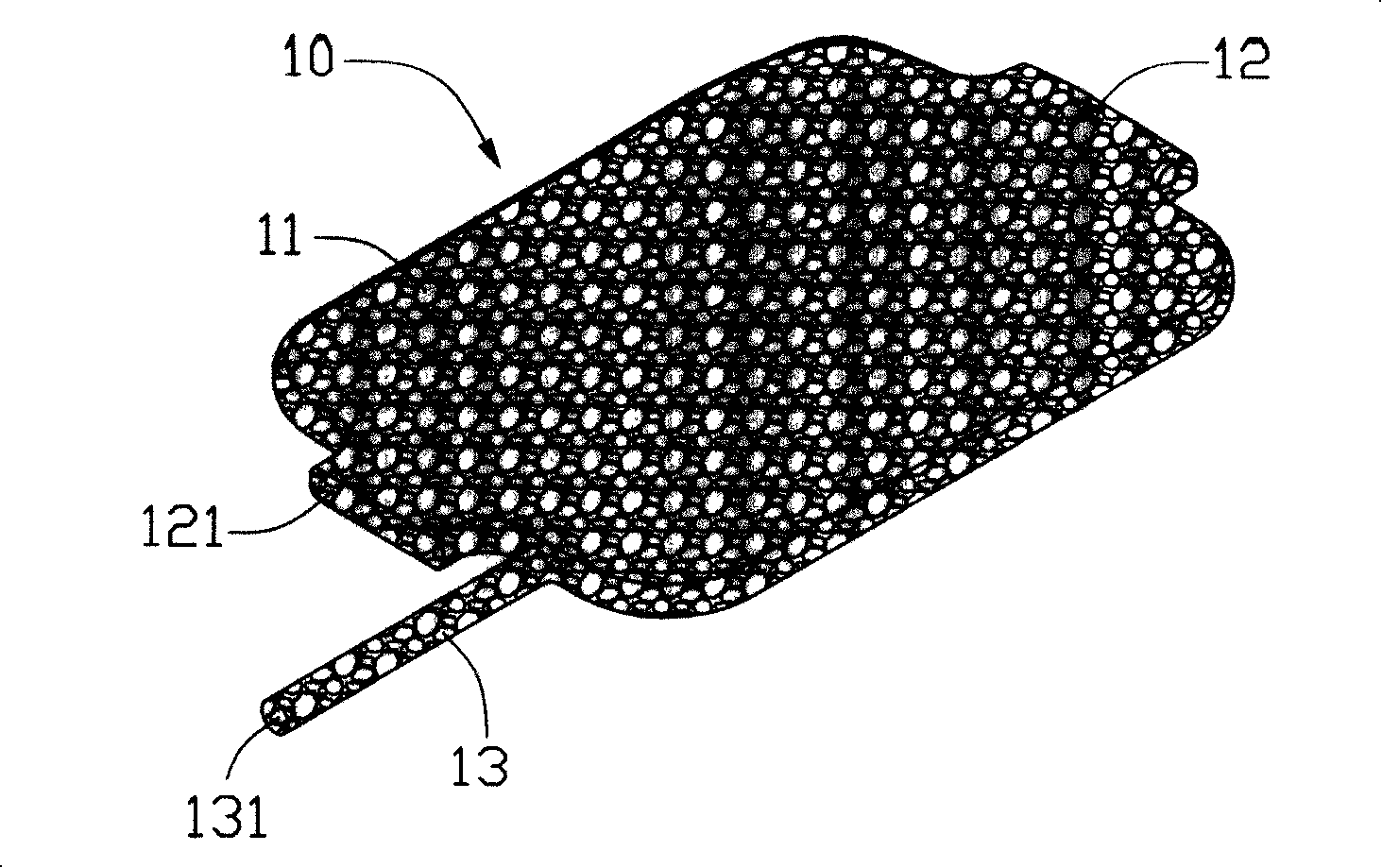

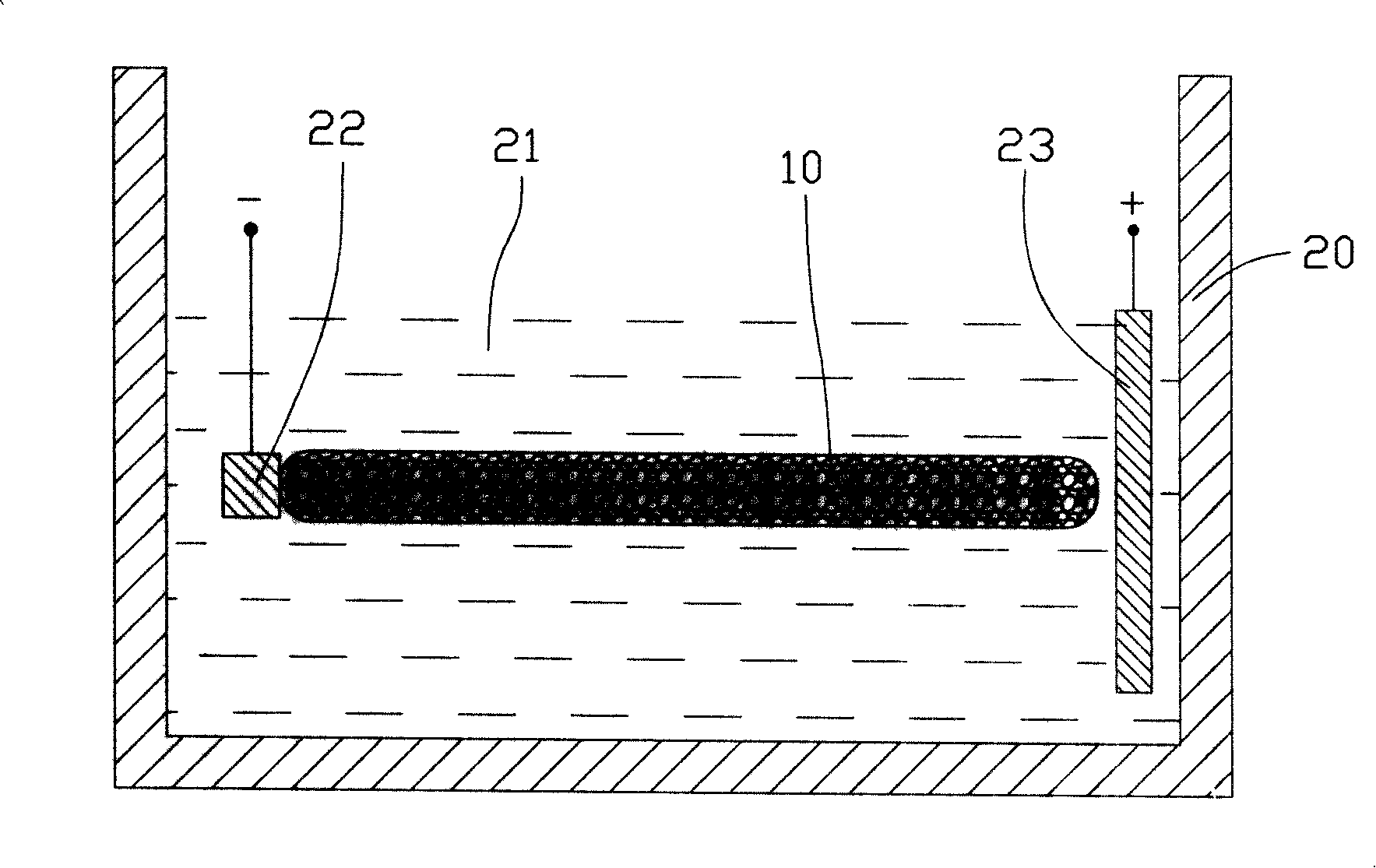

[0015] For brevity and convenience of description, the following Figure 4 and Figure 5 The airtight cavity structure 30 shown in is a representative example to illustrate the above manufacturing method. Figure 4 and Figure 5 It is a schematic diagram before the airtight cavity structure 30 is not filled with working liquid and not subjected to sealing treatment. The airtight cavity structure 30 includes a housing 31, a cavity 32 is formed in the housing 31, a porous capillary structure 33 is arranged on the entire inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com