Treatment method and treatment device of electroplating mixed water

A treatment method and mixed water technology, which are applied in water/sewage treatment, metallurgical wastewater treatment, neutralization water/sewage treatment, etc., can solve the problem of increasing the complexity of electroplating mixed water treatment process, large amount of sludge, increasing operating costs, etc. problems, to achieve the effect of saving engineering investment and operating costs, high operating stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

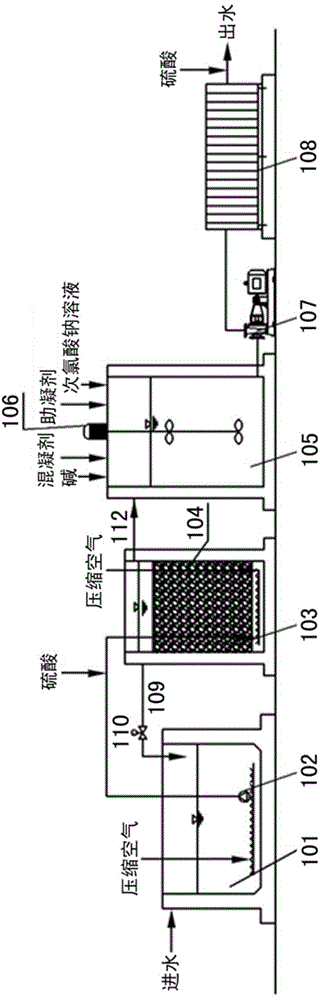

Method used

Image

Examples

Embodiment

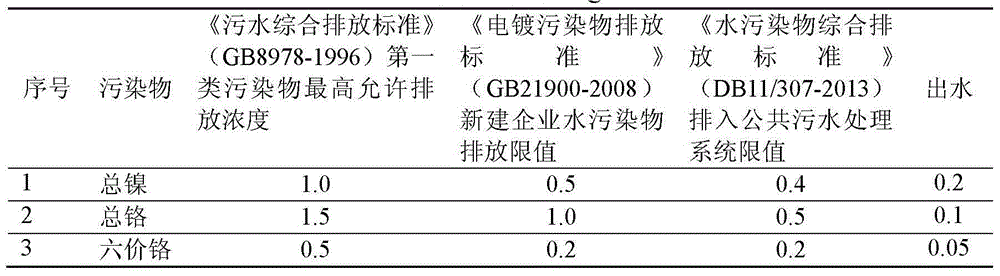

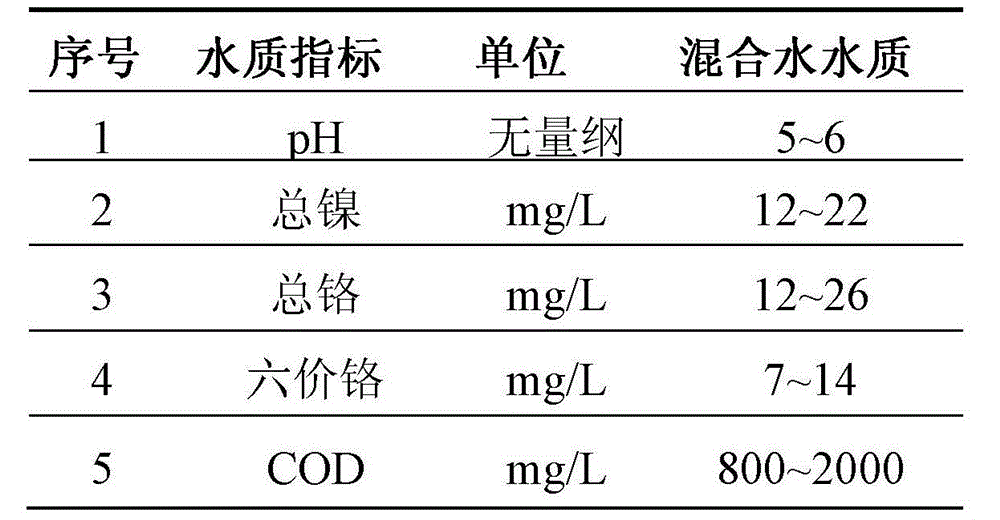

[0044] The electroplating mixed water in the electroplating production workshop of a factory includes electroplating wastewater and organic wastewater. The electroplating wastewater mainly comes from the wastewater generated during nickel plating and chrome plating in the electroplating workshop and flushing wastewater. The main heavy metal ions contained in it are Ni 2+ 、Cr 6+ and Cr 3+ ; The organic wastewater comes from the wastewater formed by adding ammonium dichromate solution, complexing agent, thickener, etc. during the cleaning process of the cleaning workshop, and its heavy metal ions mainly contain Cr 6+ and Cr 3+ . The treatment water volume of electroplating mixed water is 20m 3 / d, the main pollutants are heavy metals (nickel, chromium) and organic pollutants (COD). After treatment, the effluent is discharged into the local sewage treatment plant. The raw water quality is shown in Table 2.

[0045] Before the transformation, the electroplating mixed water us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com