Liquid crystal display panel repair method and repair system

A liquid crystal display panel and repair method technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of inability to achieve selective deposition of micro-regions, slow heating and cooling rates, structural damage, etc., to achieve environmental protection and manufacturing process Simple, Enhanced Restorative Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

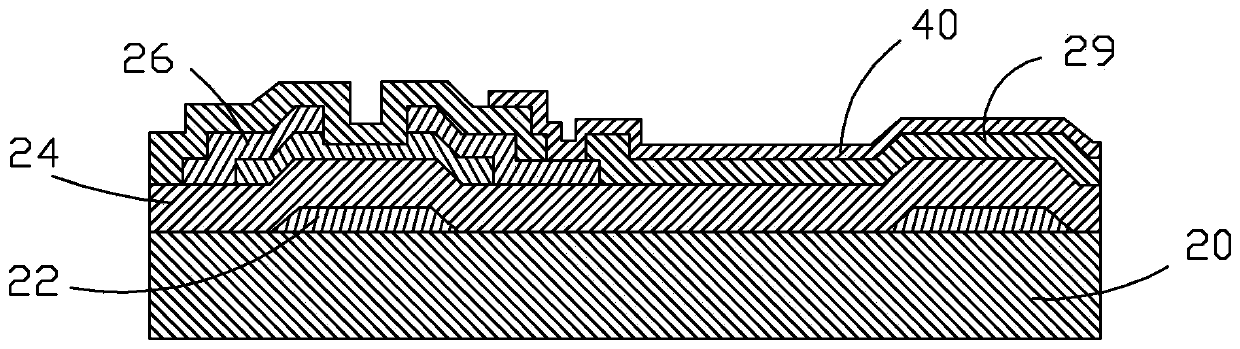

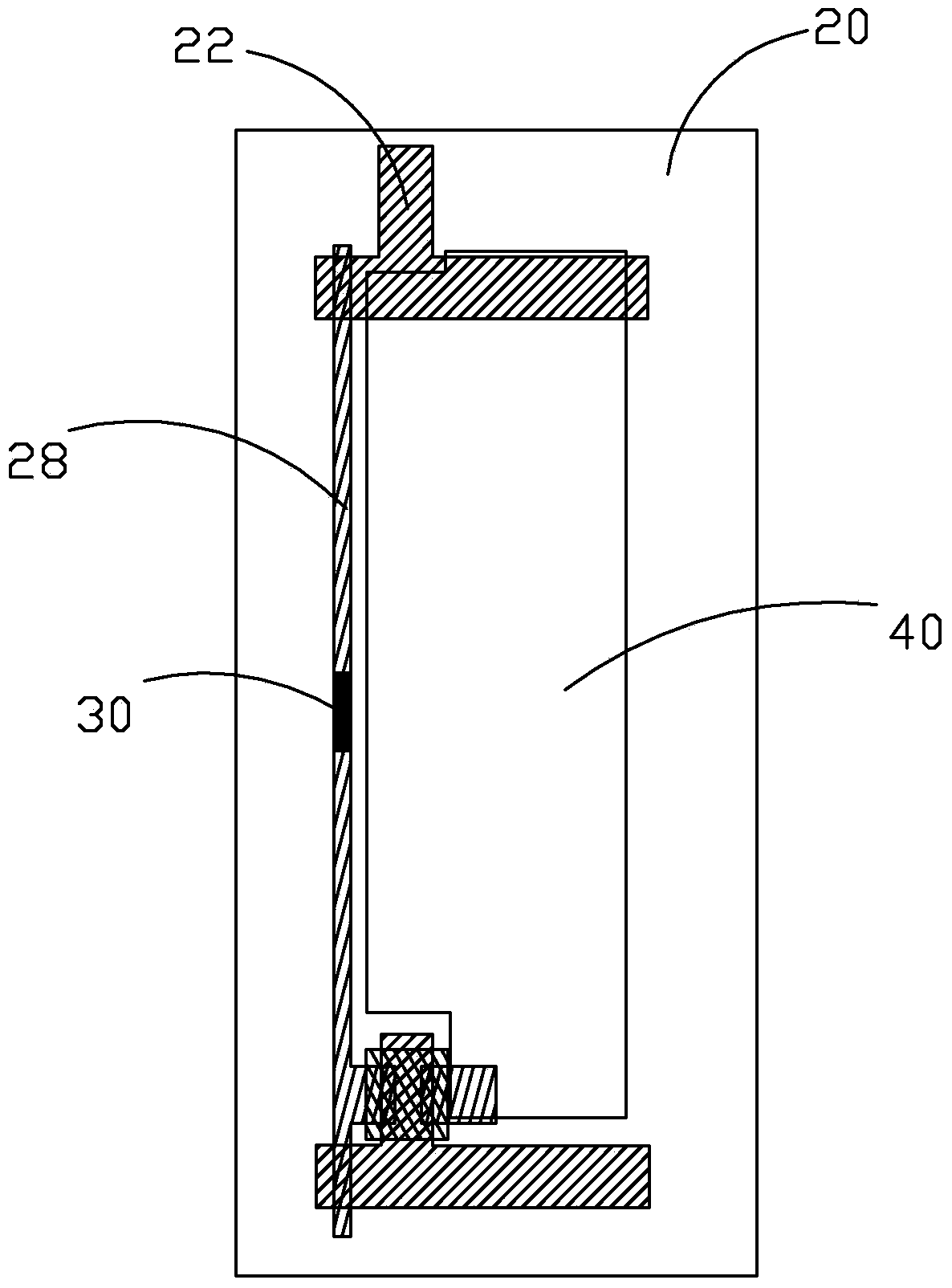

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

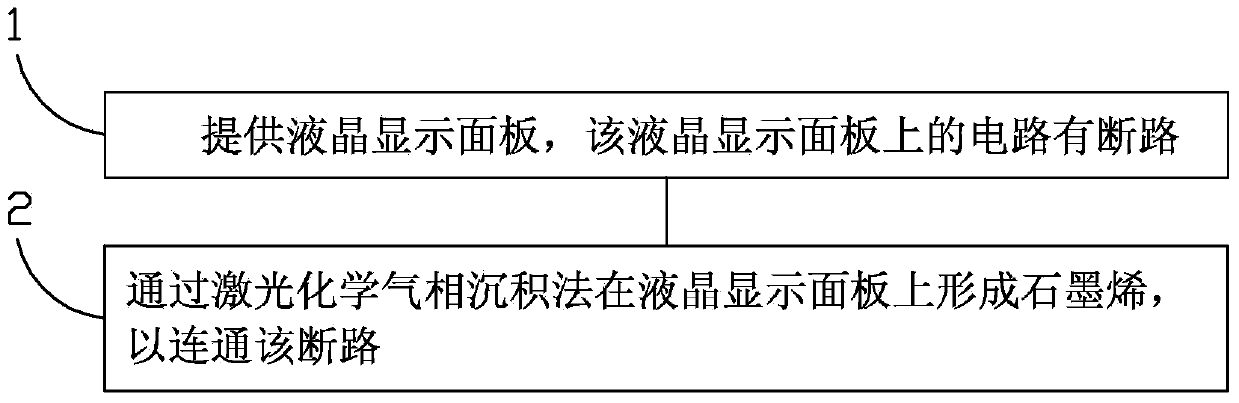

[0030] see figure 1 , the invention provides a repair method for a liquid crystal display panel, comprising the following steps:

[0031] Step 1. Provide a liquid crystal display panel, and the circuit on the liquid crystal display panel has an open circuit.

[0032] Step 2, forming graphene on the liquid crystal display panel by laser chemical vapor deposition to connect the open circuit.

[0033] In the present invention, graphene replaces the existing chromium or tungsten and deposits it at the open circuit position to repair defects. Since graphene has more excellent charge and heat transmission capabilities and excellent ductility, it solves the problem of chromium or tungsten repair due to thermal stress. Repair the defective defect, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com