Method for manufacturing glass product

A technology of glass products and glass slurry, which is applied in the field of glass manufacturing, can solve problems such as high difficulty, high cost of manufacturing methods, and complicated manufacturing processes, and achieve the effects of reducing production costs, being suitable for large-scale industrial applications, and simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

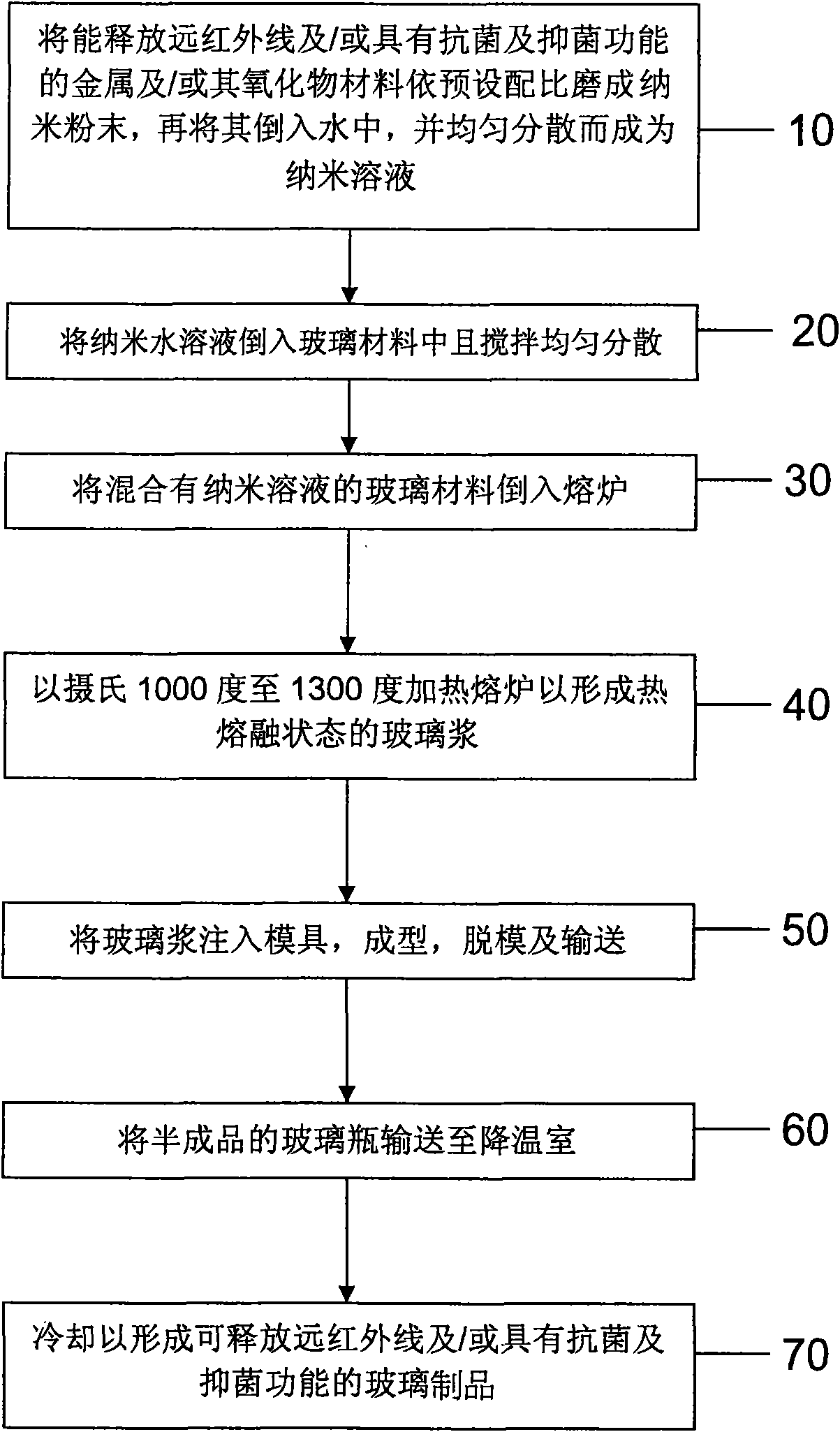

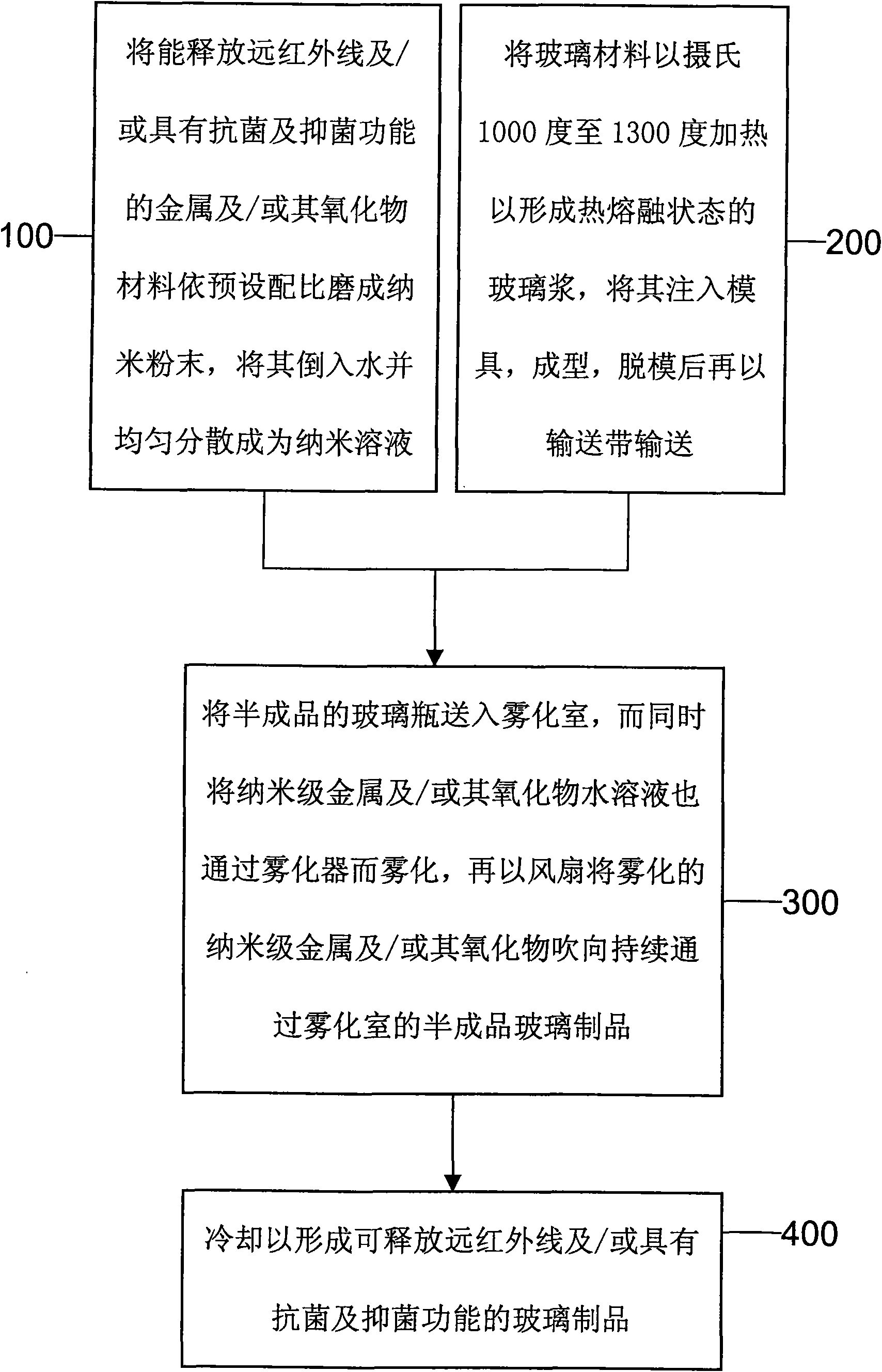

[0014] First please refer to figure 1 , which shows the process flow of the first embodiment of the glass product manufacturing method according to the present invention.

[0015] First in step 10, metals and / or their oxide materials that can release far-infrared rays and / or have antibacterial and antibacterial functions, including: silver (Ag), zinc oxide (ZnO), magnesium oxide (MgO), sodium oxide (Na 2 O), potassium oxide (K 2 O), tantalum oxide (Ta 2 o 5 ), neodymium oxide (Nb 2 o 5 ), silicon dioxide (SiO 2 ), titanium dioxide (TiO 2 ), zirconium dioxide (ZrO 2 ), germanium dioxide (GeO 2 ), aluminum oxide (Al 2 o 3 ), ferric oxide (Fe 2 o 3 ), bamboo charcoal (C), medical stone, serpentine, granite, and silicon ore, etc., all or part of which are ground into nano-sized powder according to the preset ratio, poured into the aqueous solution and made uniform Dispersed in an aqueous solution to become an aqueous solution of nanoscale metals and / or their oxides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com