Metal-resin complex and manufacturing method thereof

A manufacturing method and composite technology, applied in electrode manufacturing, metal layered products, chemical instruments and methods, etc., can solve the problems of uneven micropore size, weak connection strength, high cost, and achieve uniform micropore size and improve The connection strength, the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

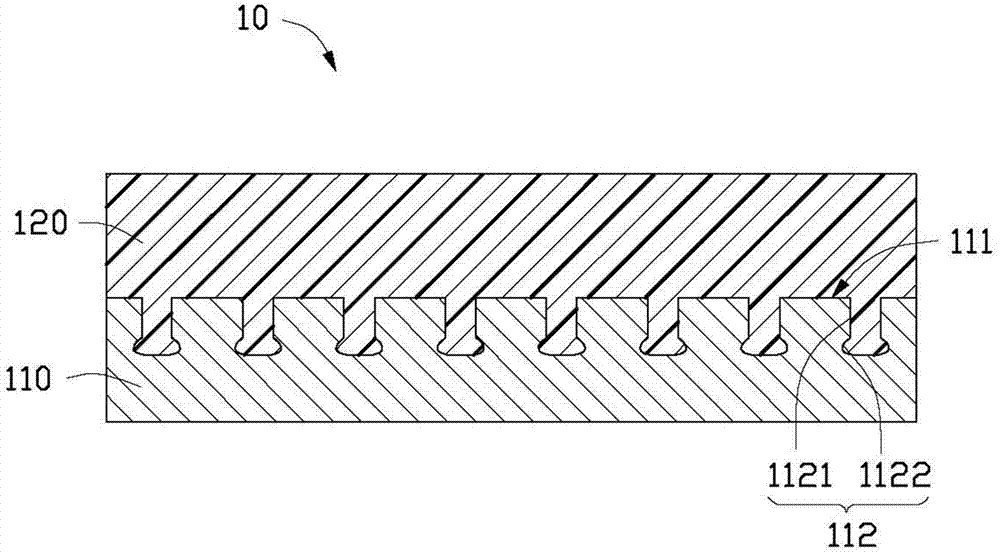

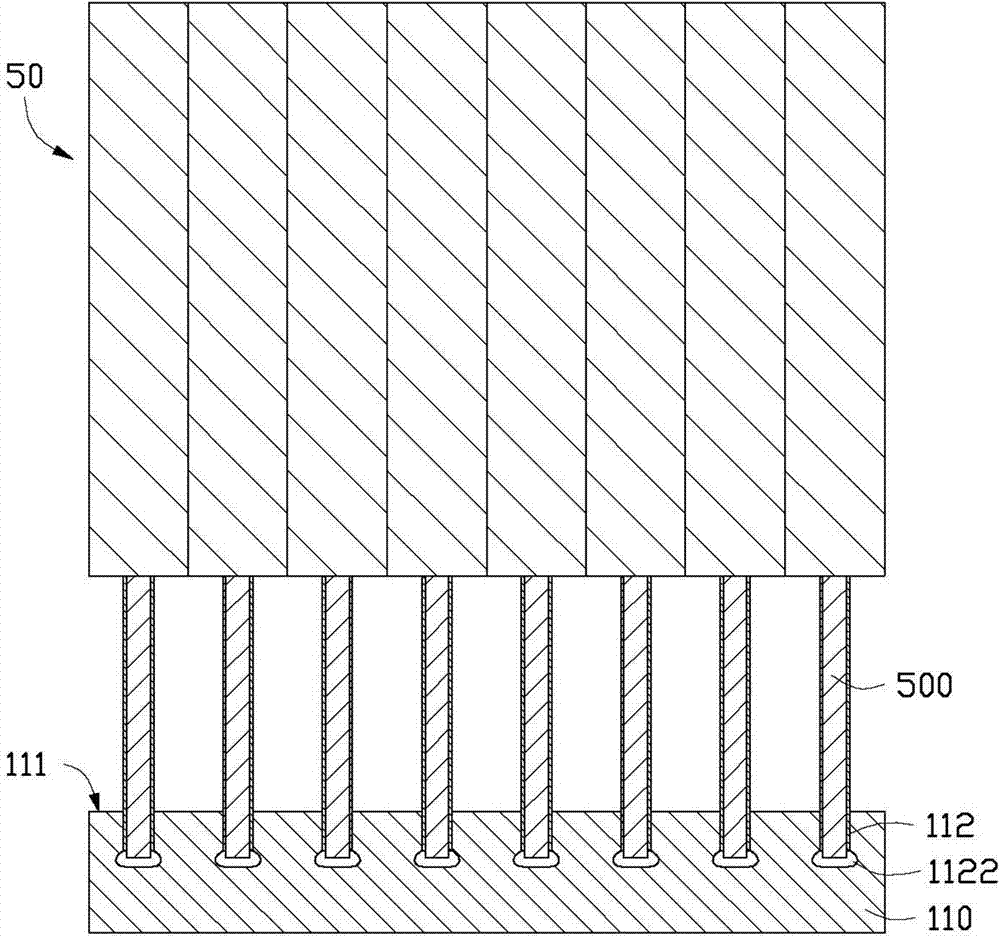

[0019] see figure 1 The metal-resin composite body 10 according to the first embodiment of the present invention includes a metal part 110 and a resin part 120 combined with the metal part 110 .

[0020] The material of the metal part 110 can be aluminum alloy, magnesium alloy, stainless steel, copper and copper alloy. The metal part 110 has a metal part surface 111 combined with a resin part 120 , and a plurality of micropores 112 are provided on the metal part surface 111 . The micropore 112 is substantially in a T-shaped structure, which includes a top 1121 and a bottom 1122 , and the bottom 1122 is located at an end of the top 1121 away from the end of the resin part 120 . The top 1121 communicates with the bottom 1122 , the aperture of the bottom 1122 is larger than the aperture of the top 1121 , and the bottom 1122 has rounded corners. In this embodiment, the top 1121 is positioned vertically relative to the metal member surface 111 . Preferably, the plurality of micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com