Online high manganese steel toughening heat treatment method

A heat treatment method and technology for high manganese steel, applied in heat treatment equipment, heat treatment process control, manufacturing tools and other directions, can solve the problems of increasing the production difficulty and production cost of high manganese steel, difficult transportation and hoisting, waste of water resources, etc. Production line, simplified production process, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

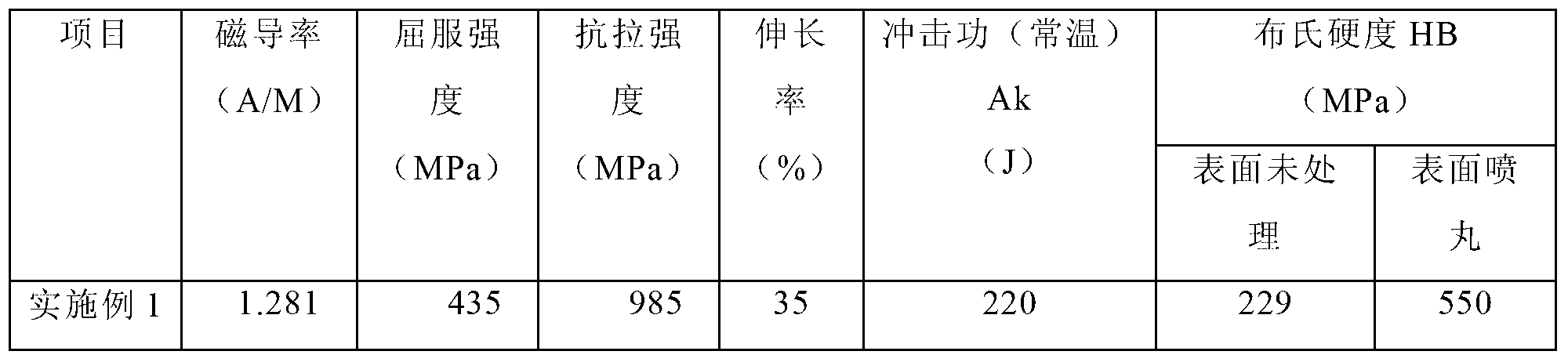

Embodiment 1

[0018] In this example, it is intended to perform online heat treatment on a high manganese steel plate with a thickness of 3 mm, a width of 1000 mm, and a weight of 15 tons after coiling. The high manganese steel consists of the following chemical components by weight: 1.1% carbon, 13% manganese, 0.3% silicon, no more than 0.03% phosphorus, no more than 0.005% sulfur, and the rest are iron and inevitable impurity elements.

[0019] The processing process is as follows:

[0020] It is measured that the temperature of the high manganese steel that leaves the finish rolling hole in the last pass is 955°C (finish rolling temperature), and the temperature when the steel plate begins to reach the water quenching device is 953°C (that is, the temperature at which heat treatment cooling starts), and the water quenching device senses the temperature of the steel plate When it arrives, spray water immediately for cooling. The time for the steel plate to pass through the entire water qu...

Embodiment 2

[0023] In this example, it is intended to perform online heat treatment on a high manganese steel plate with a thickness of 2 mm, a width of 1000 mm, and a weight of 10 tons after coiling. The high manganese steel consists of the following chemical components by weight: 1.1% carbon, 13% manganese, 0.3% silicon, no more than 0.03% phosphorus, no more than 0.005% sulfur, and the rest are iron and inevitable impurity elements.

[0024] The processing process is as follows:

[0025] It is measured that the temperature of the high manganese steel that exits the finish rolling hole in the last pass is 953°C (final rolling temperature), and the temperature when the steel plate reaches the water quenching device is 951°C (heat treatment start temperature). The water quenching device senses the arrival of the steel plate, Immediately carry out water spray cooling, the time for the steel plate to pass through the entire water quenching device is 15 seconds (cooling time), the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com