Patents

Literature

128results about How to "Shorten the production line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method

ActiveUS20110293906A1Uniform colorControlled colour variationIrregular area designLayered product treatmentSurface plateDry powder

A method for producing a panel is disclosed. The method includes the step of applying steam on a dry powder layer on a core. Thereafter is a heat and pressure applied to the powder layer in order to bond the powder together.

Owner:VÄLINGE INNOVATION AB

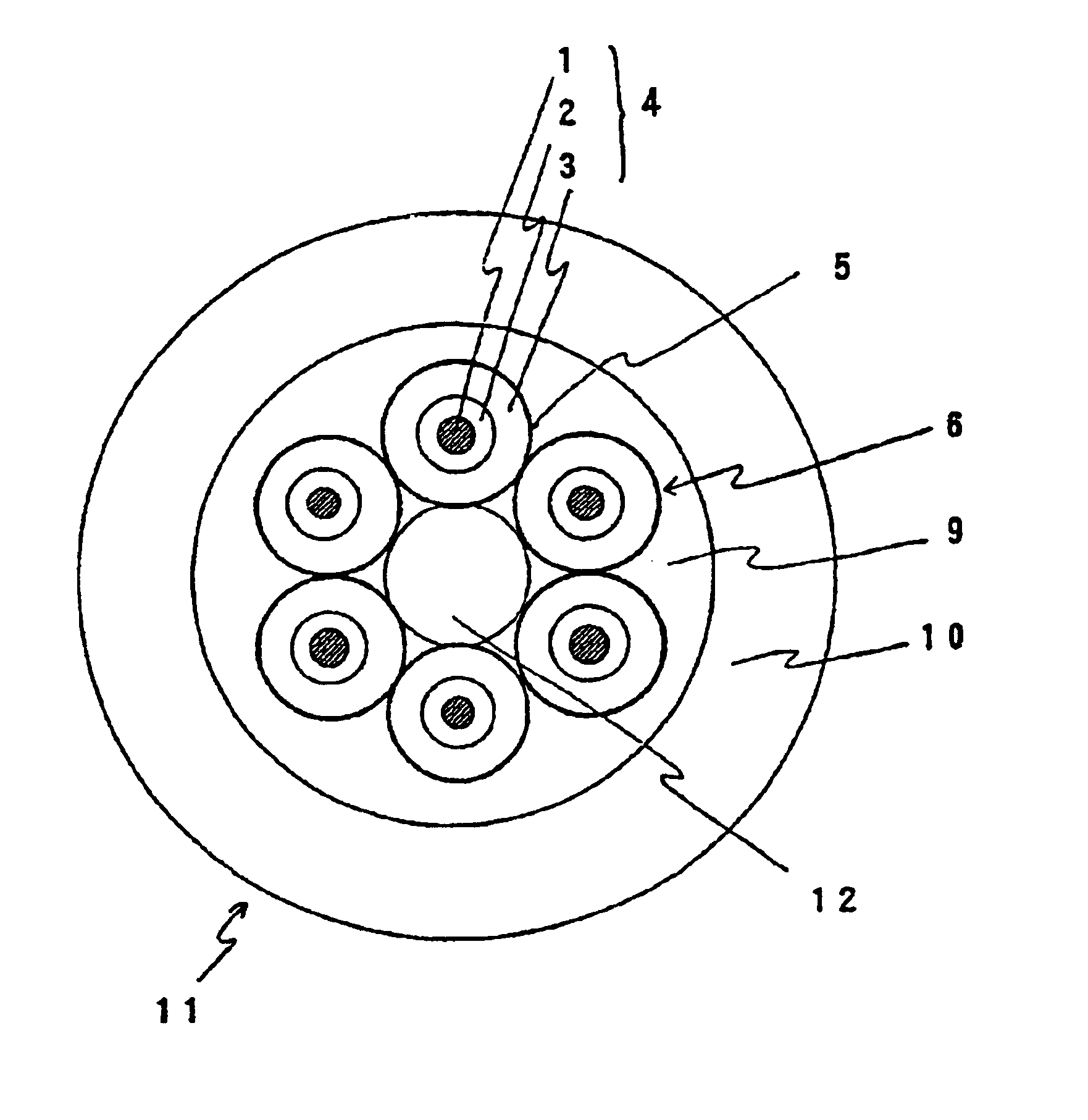

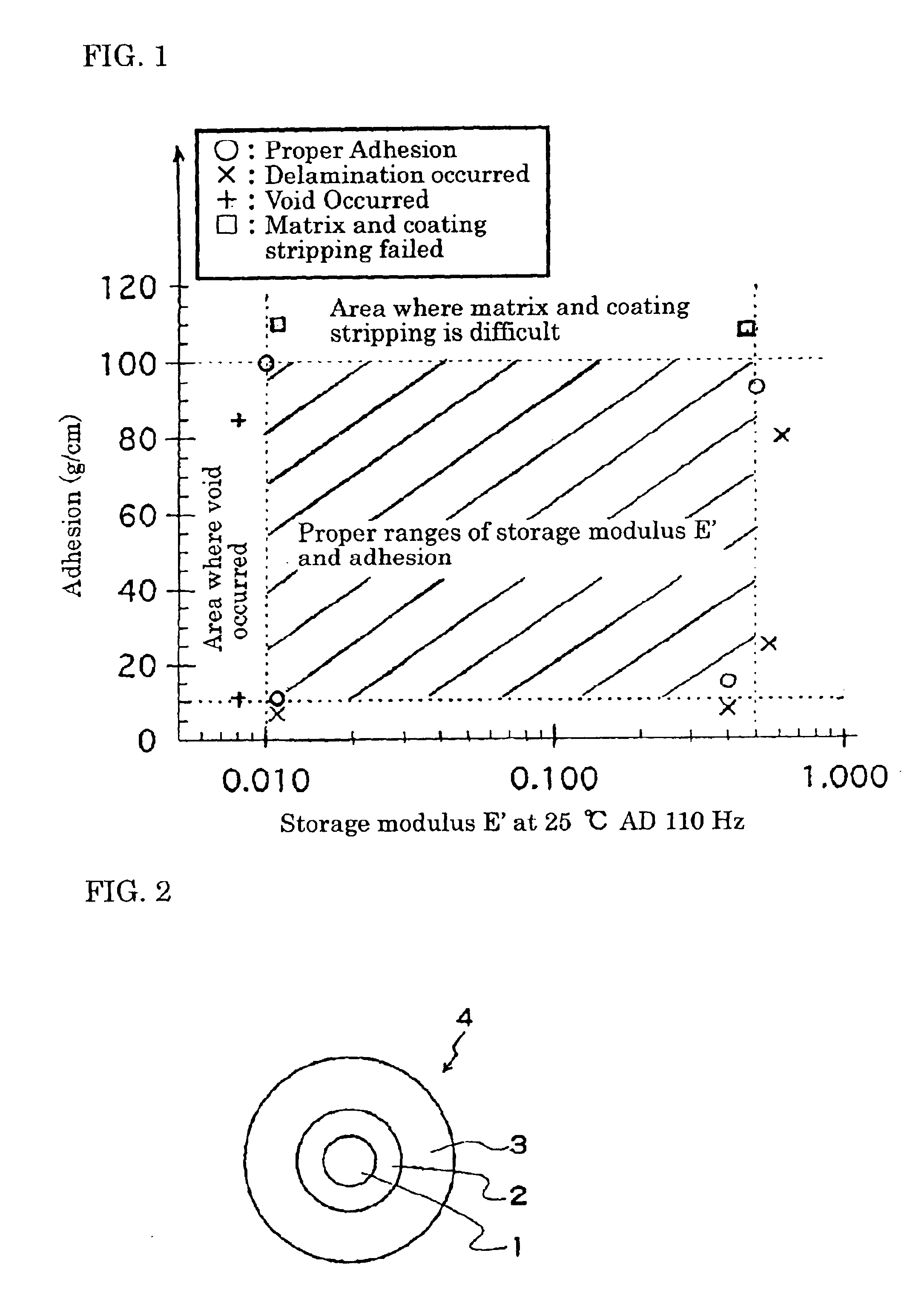

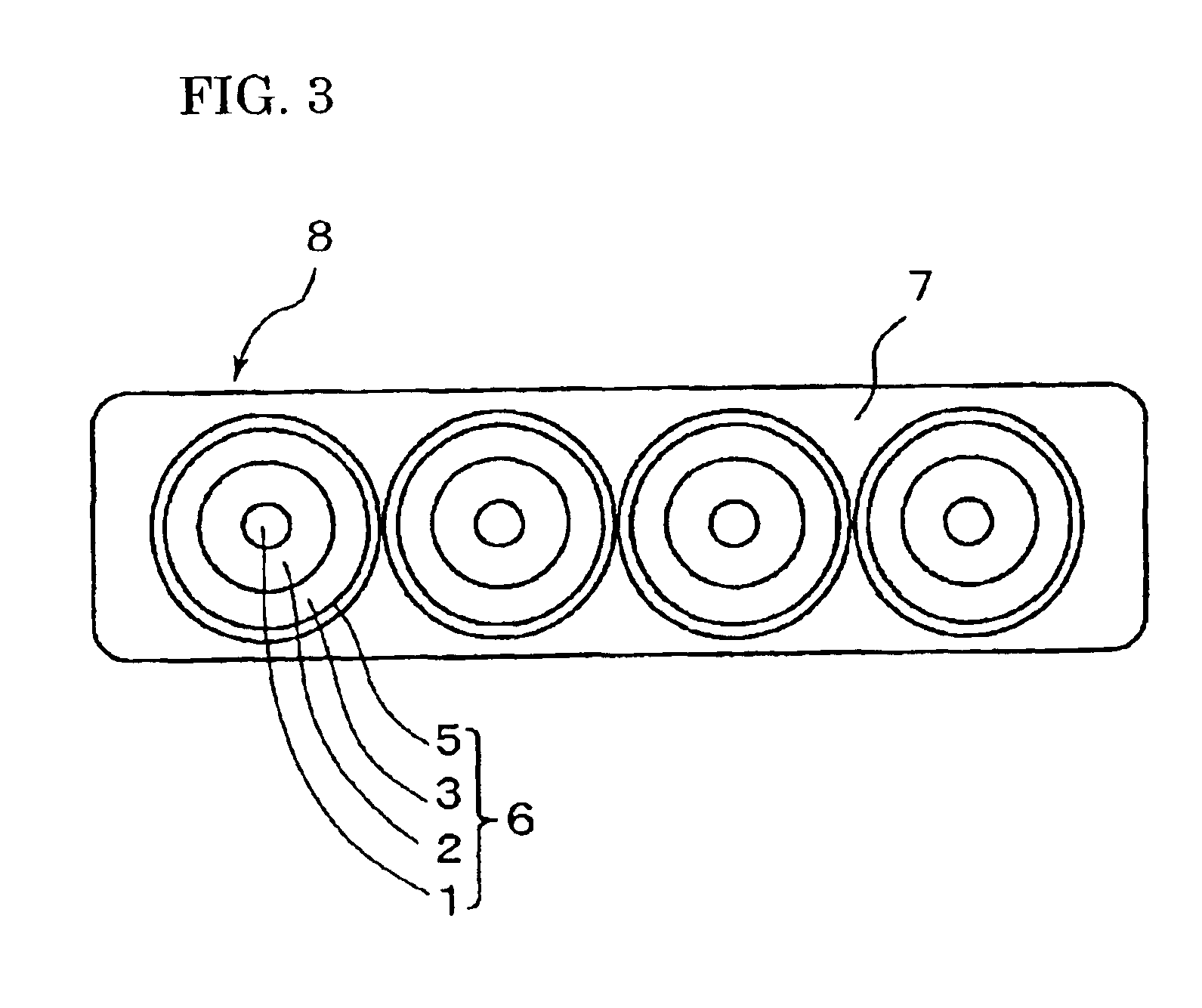

Coated optical fiber

InactiveUS6810188B1Shorten the production lineExcellent peelabilityGlass optical fibreOptical fibre with multilayer core/claddingOptoelectronicsPlastic optical fiber

A coated optical fiber is shown in which, by coating a glass optical fiber with a primary coating having a storage modulus E' of 0.01 kg / mm<2 >to 2.0 kg / mm<2 >at 25° and 110 Hz and an adhesion of 10 g / cm to 200 g / cm to the glass optical fiber, delamination at the interface between the glass optical fiber and the primary coating, and voids are prevented during and after the production, for example, on the line during drawing and winding. An optical fiber ribbon of the present invention, which is formed by collectively coating the coated optical fibers each including a primary coating with a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 10 g / cm to 100 g / m, has a high delamination resistance and a good collective strippability of coatings. In an optical fiber unit of the present invention which is formed by collectively coating the coated optical fibers having a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 100 g / cm to 200 g / cm, delamination and voids will not occur.

Owner:SUMITOMO ELECTRIC IND LTD

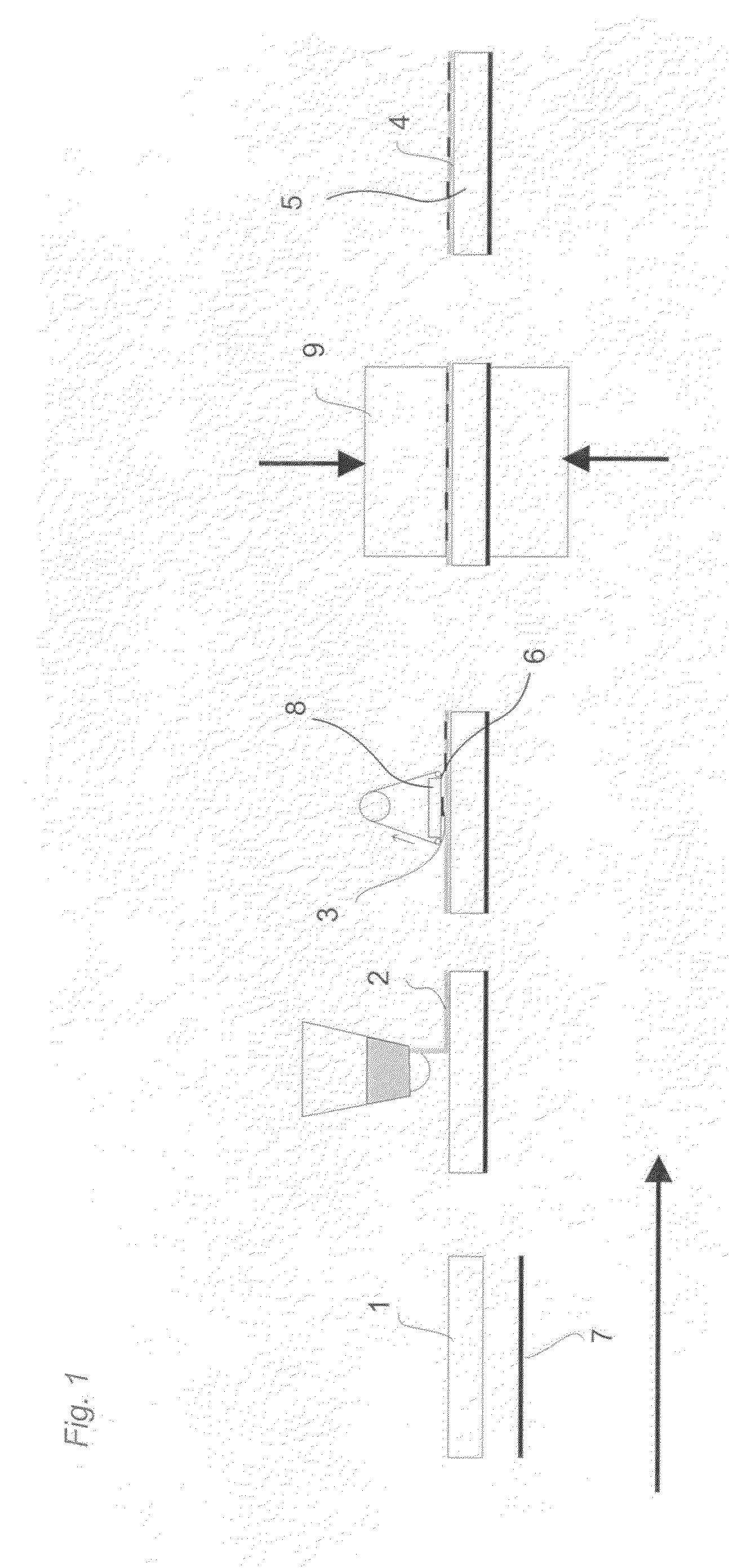

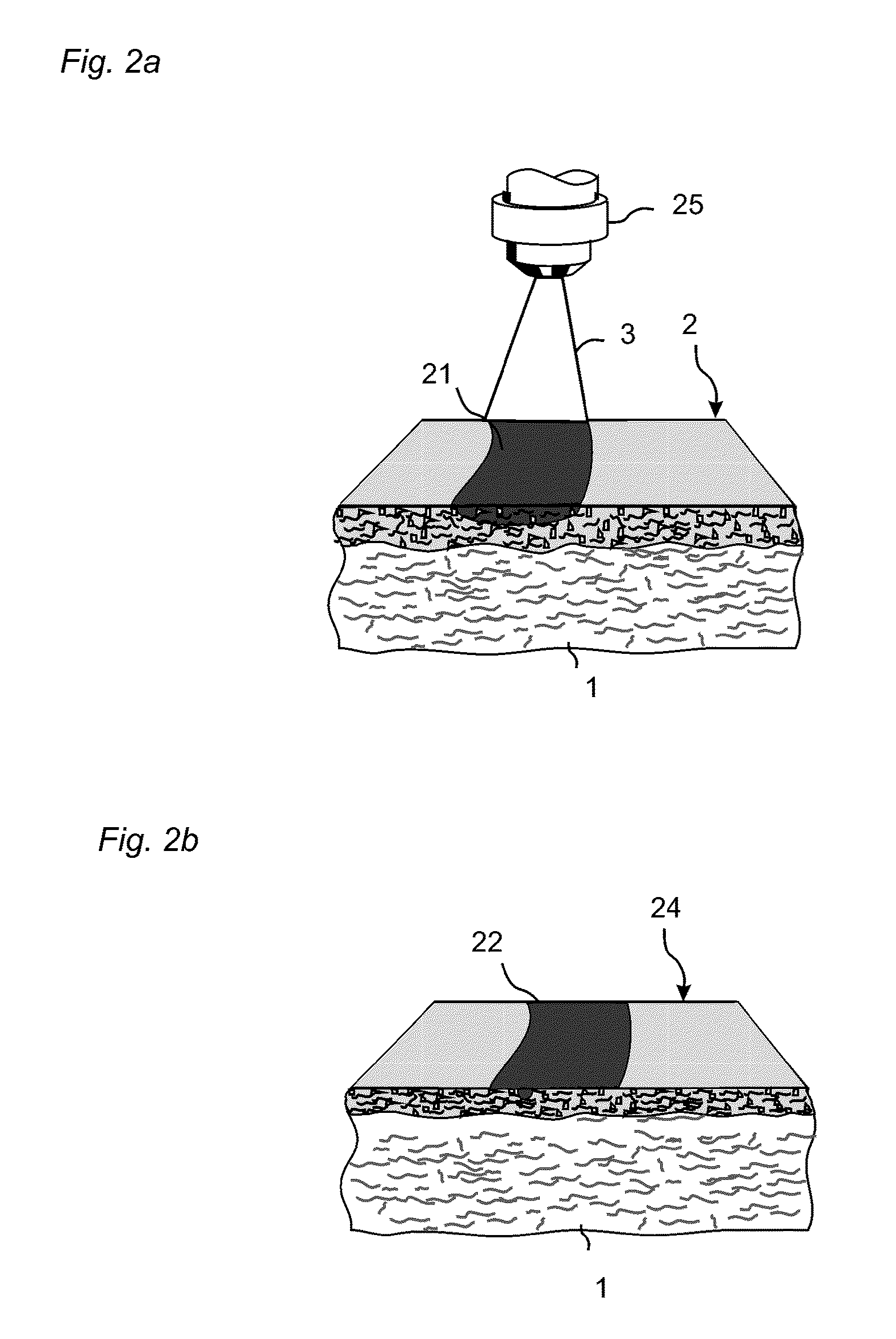

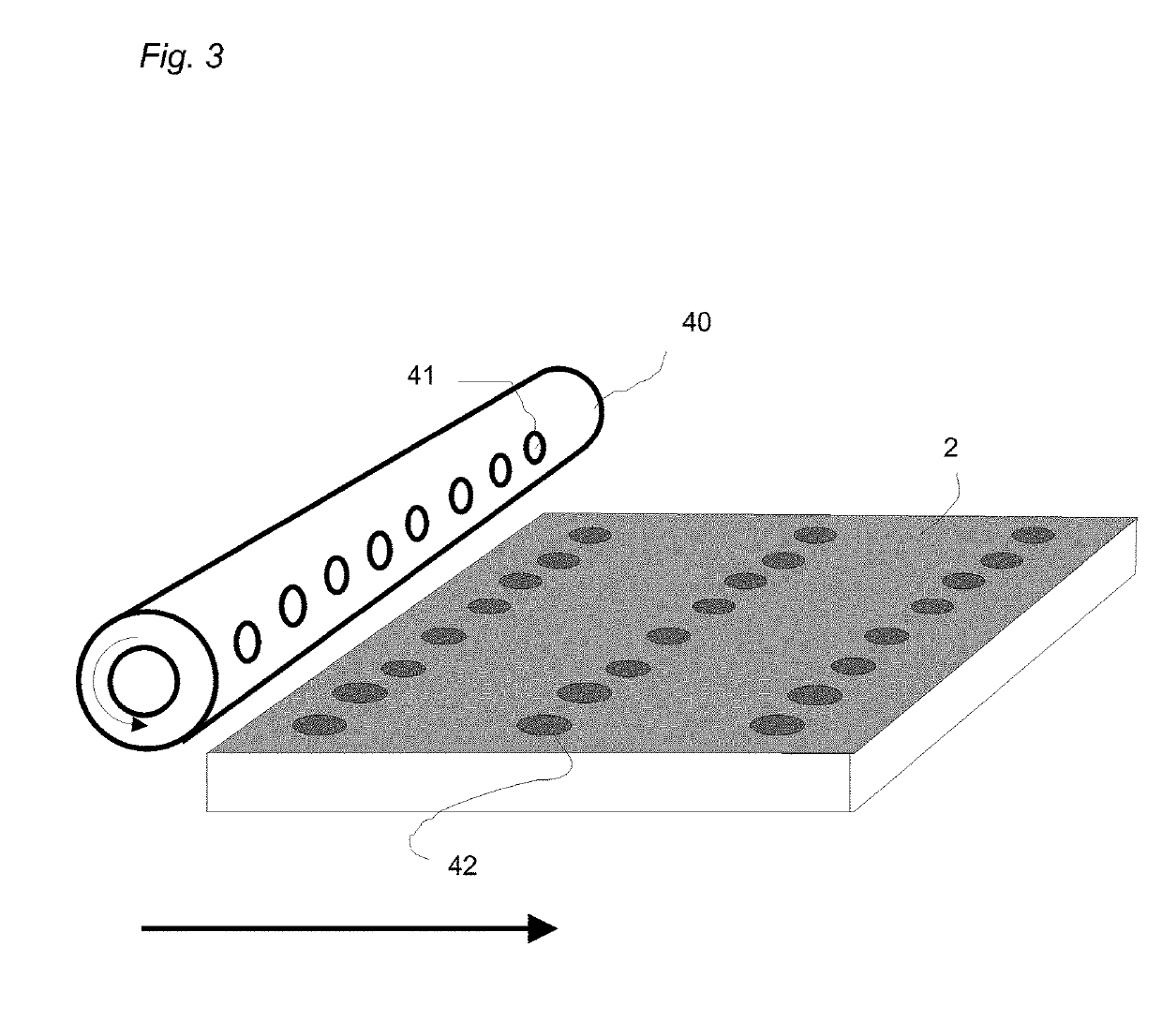

Method of manufacturing a panel

ActiveUS10315219B2Uniform colorAvoid color changesIrregular area designLayered product treatmentMaterials scienceDry powder

A method for producing a panel is disclosed. The method includes the step of applying steam on a dry powder layer on a core. Thereafter heat and pressure are applied to the powder layer in order to bond the powder together.

Owner:VÄLINGE INNOVATION AB

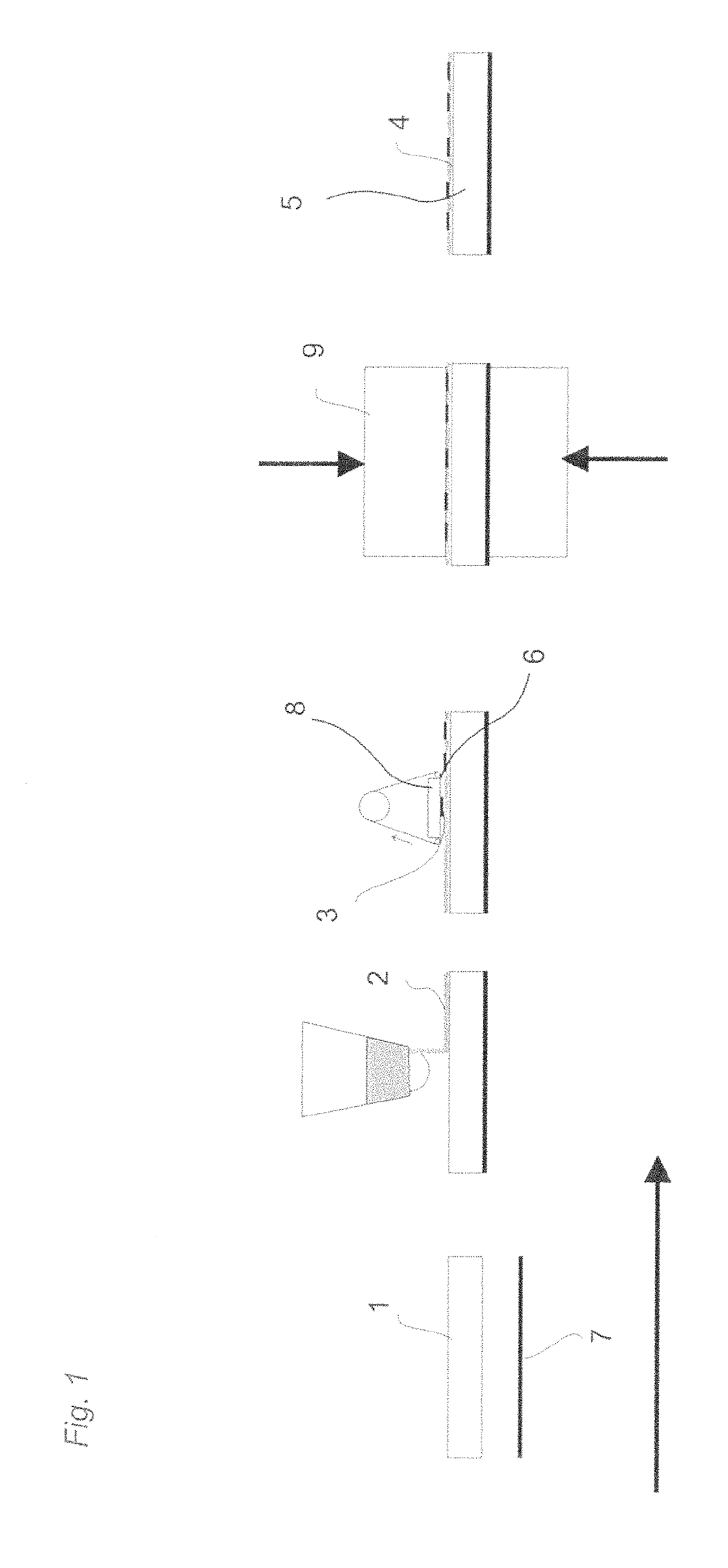

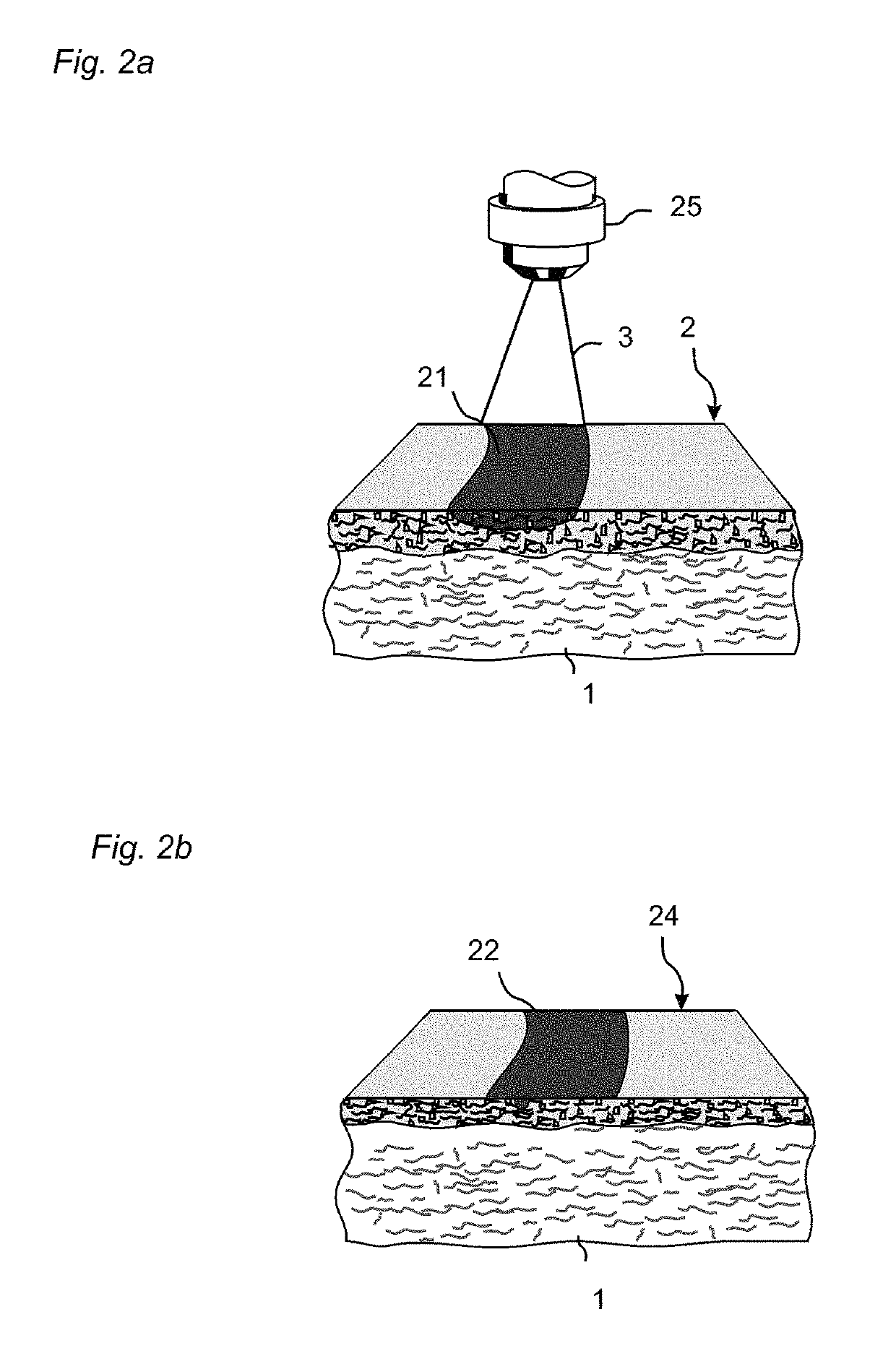

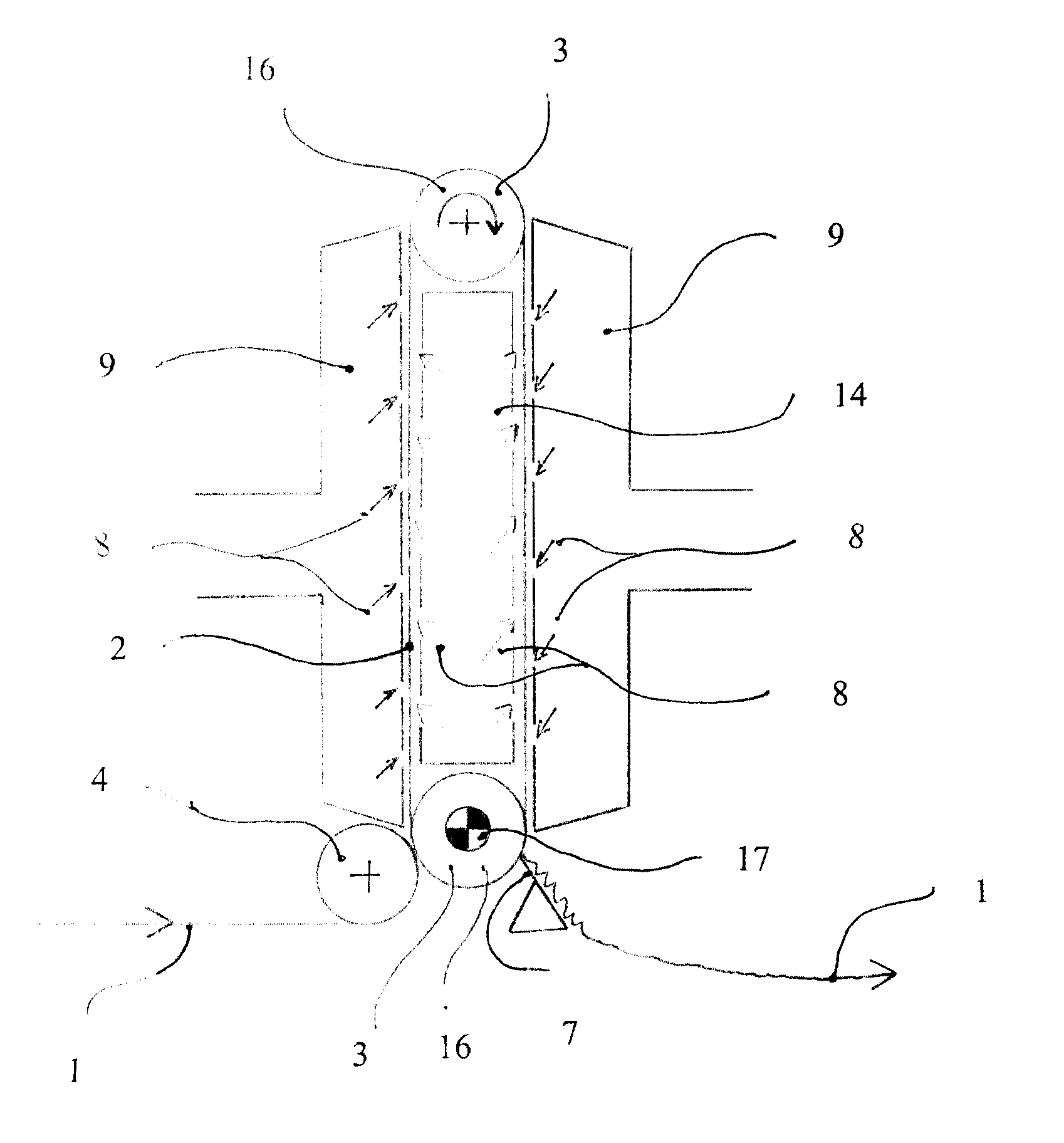

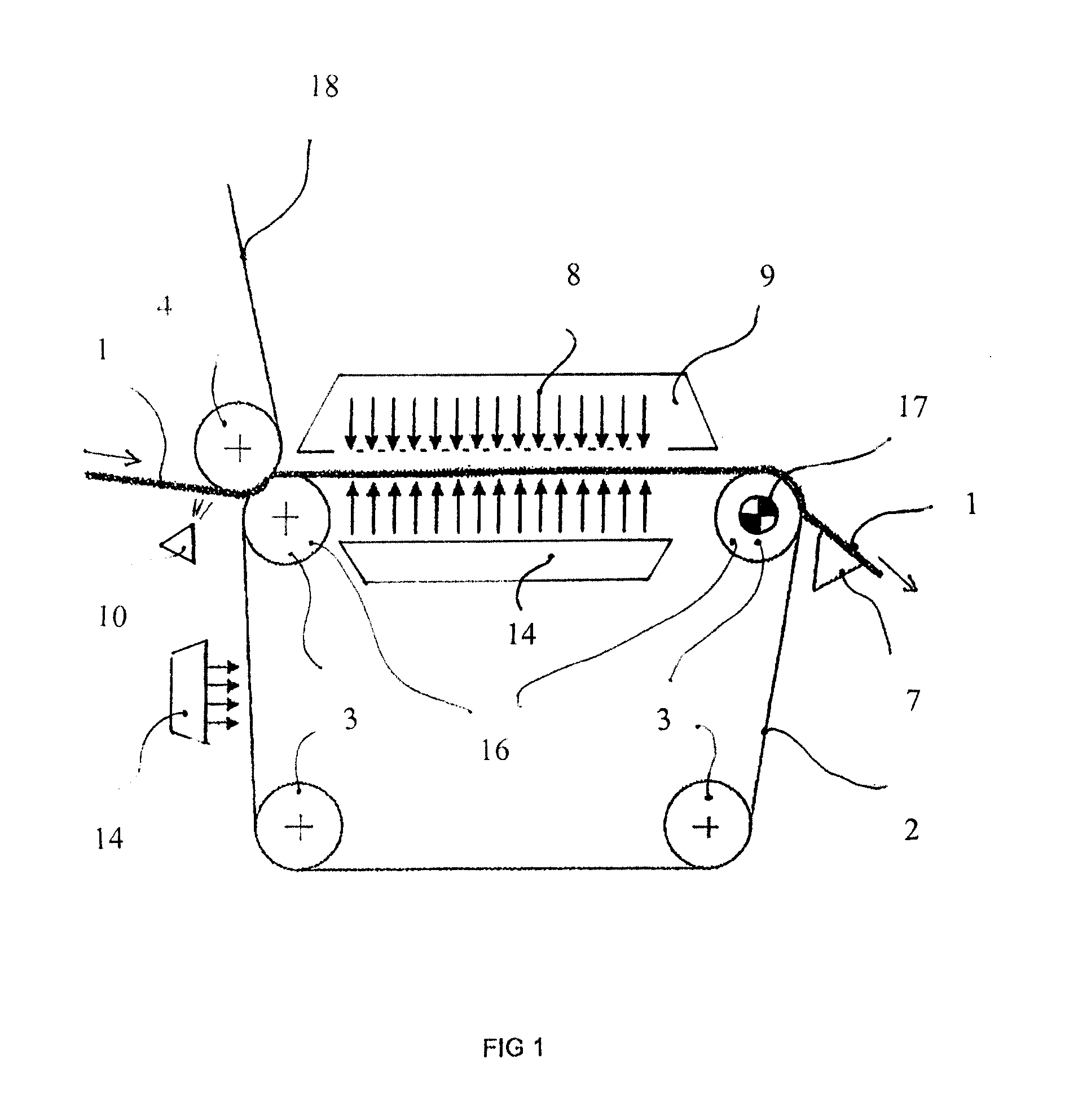

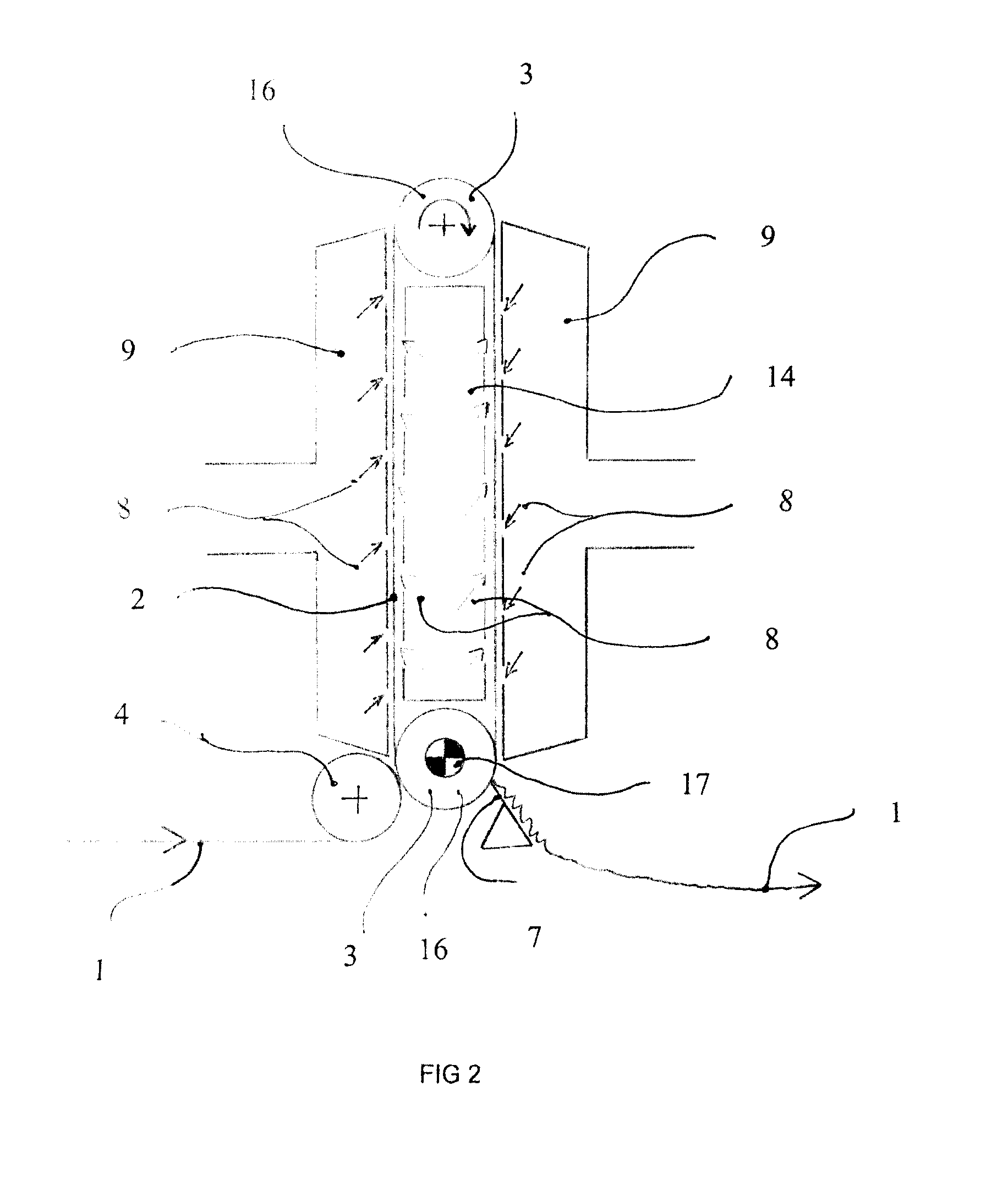

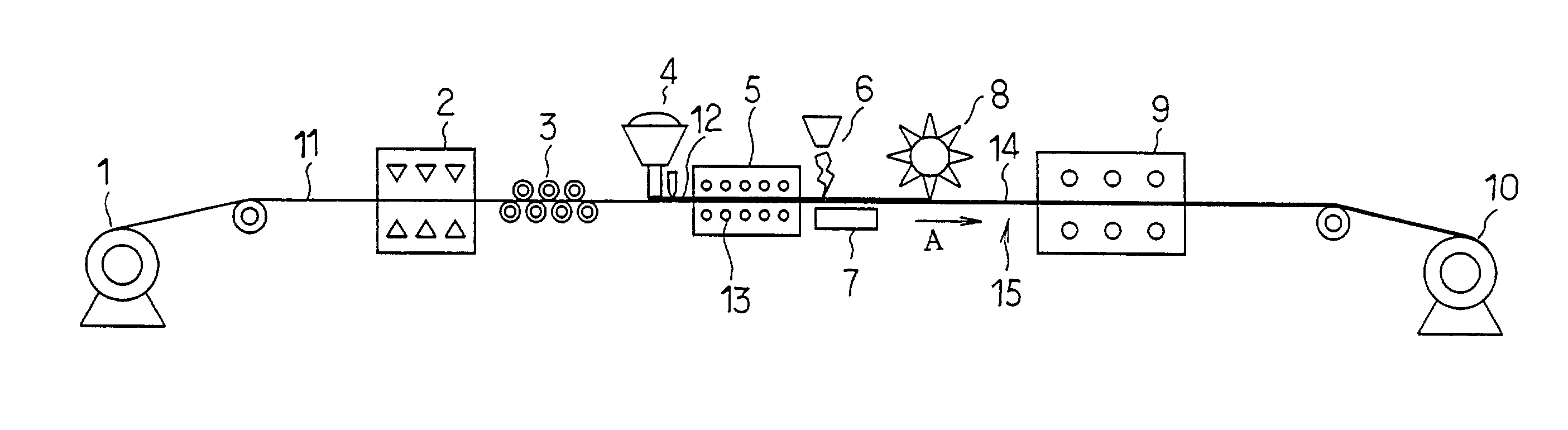

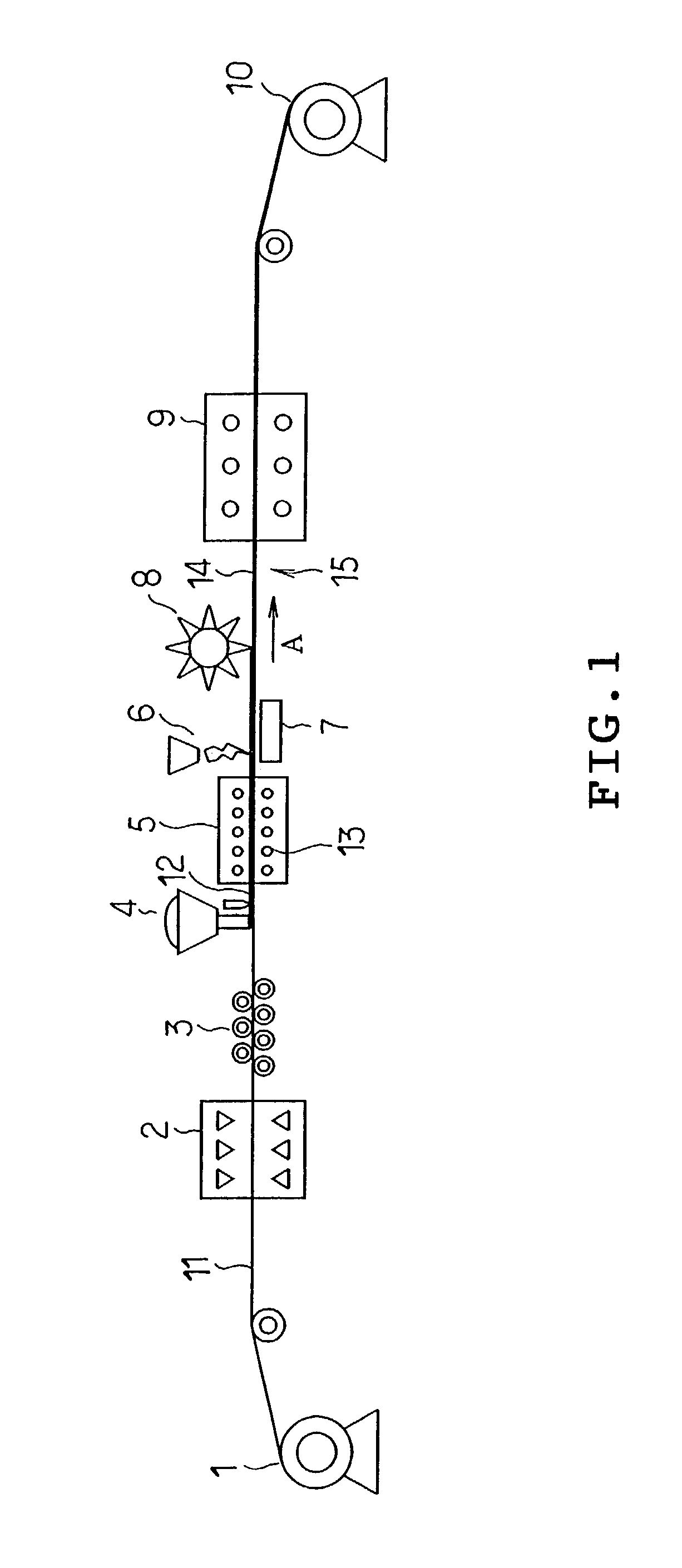

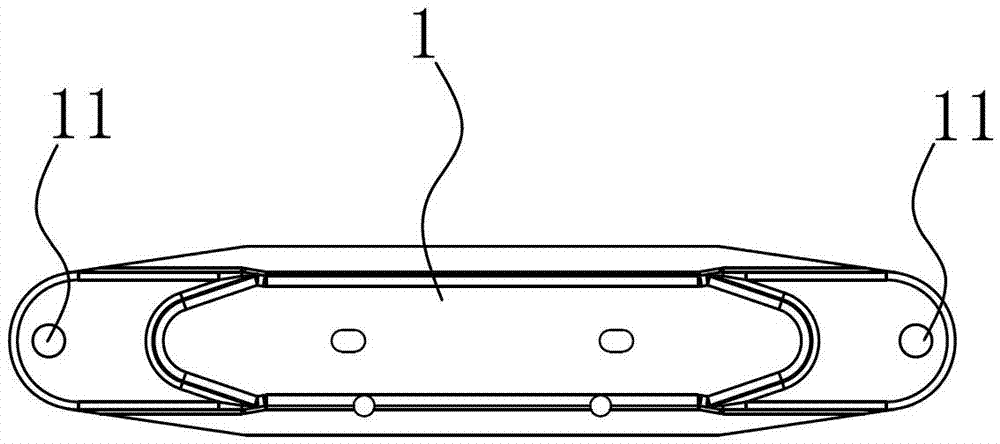

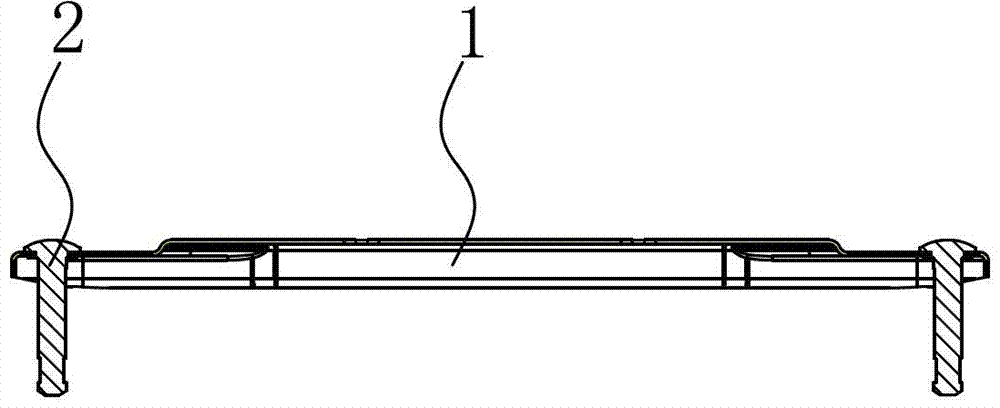

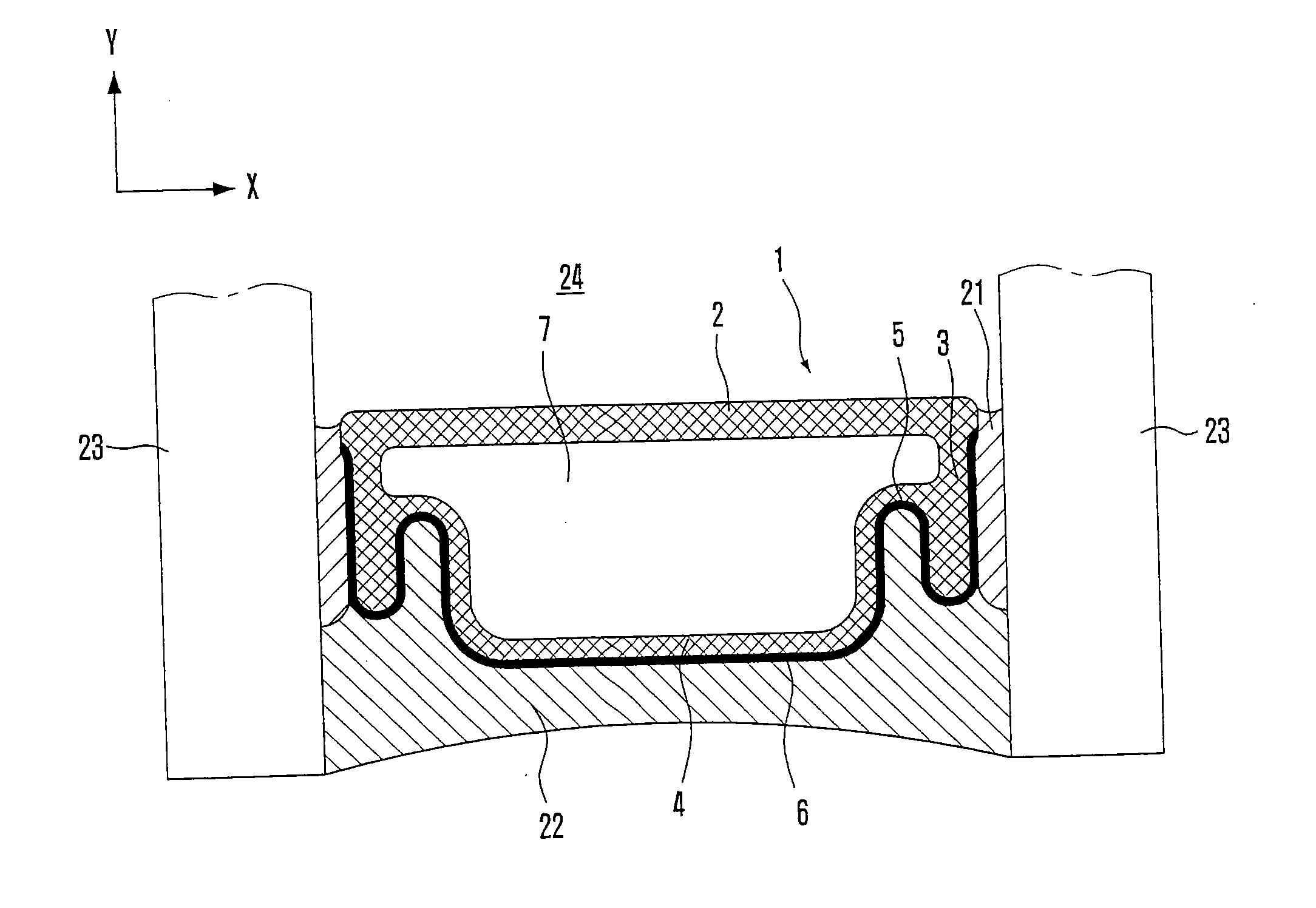

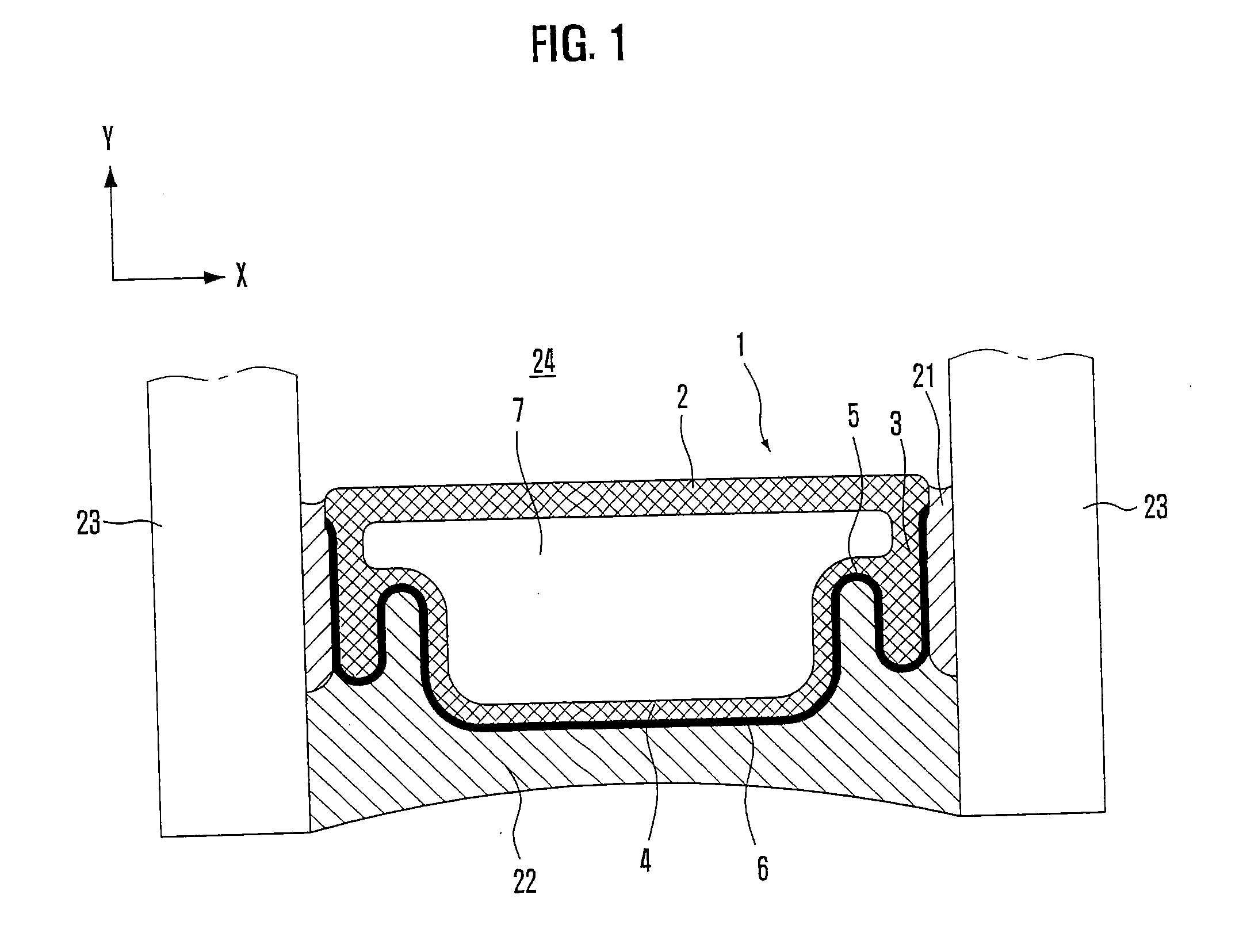

Device for drying and treating a tissue paper web

ActiveUS8486229B2Quality of the produced fiber productQuality of fiber productMechanical working/deformationDryer sectionFiberEngineering

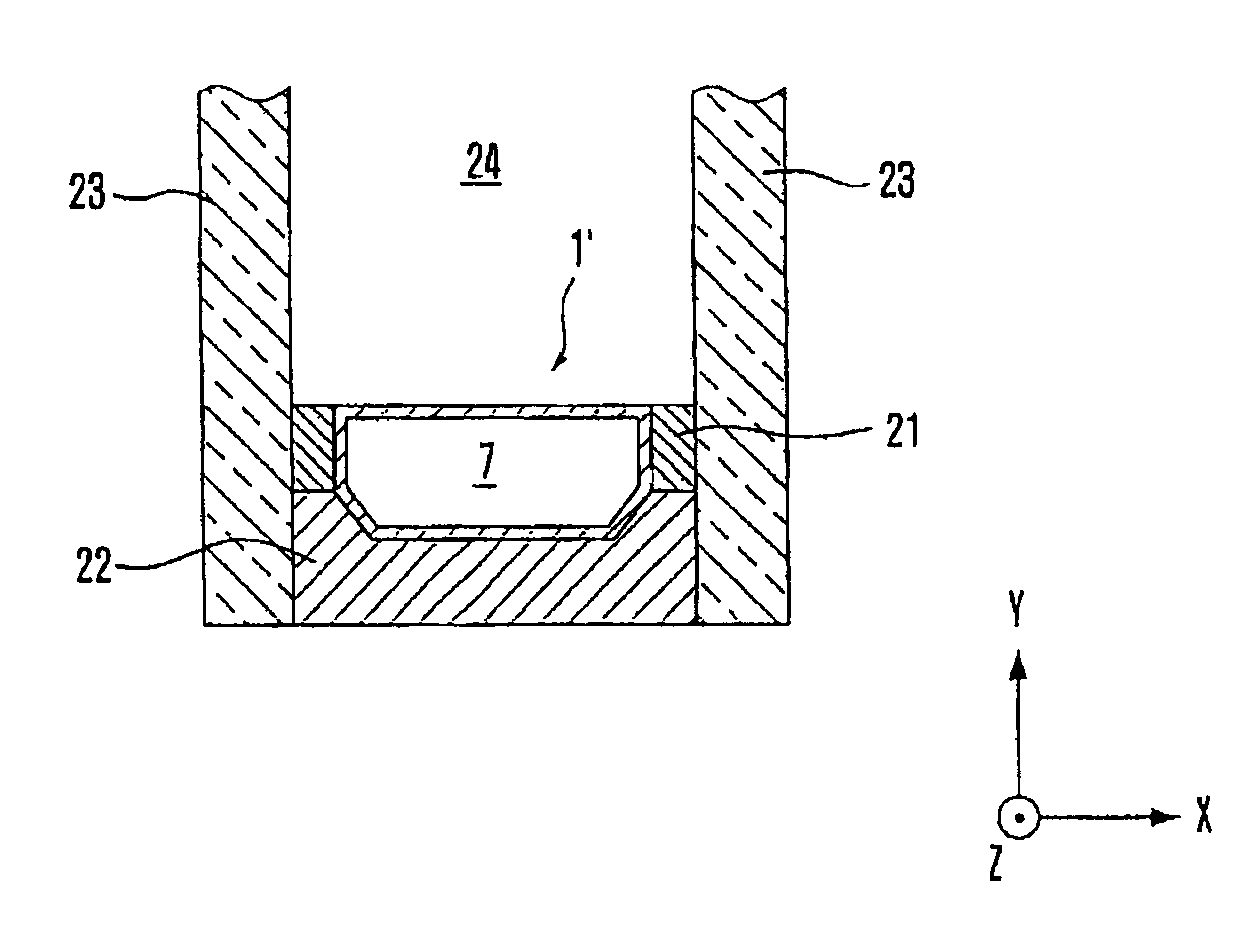

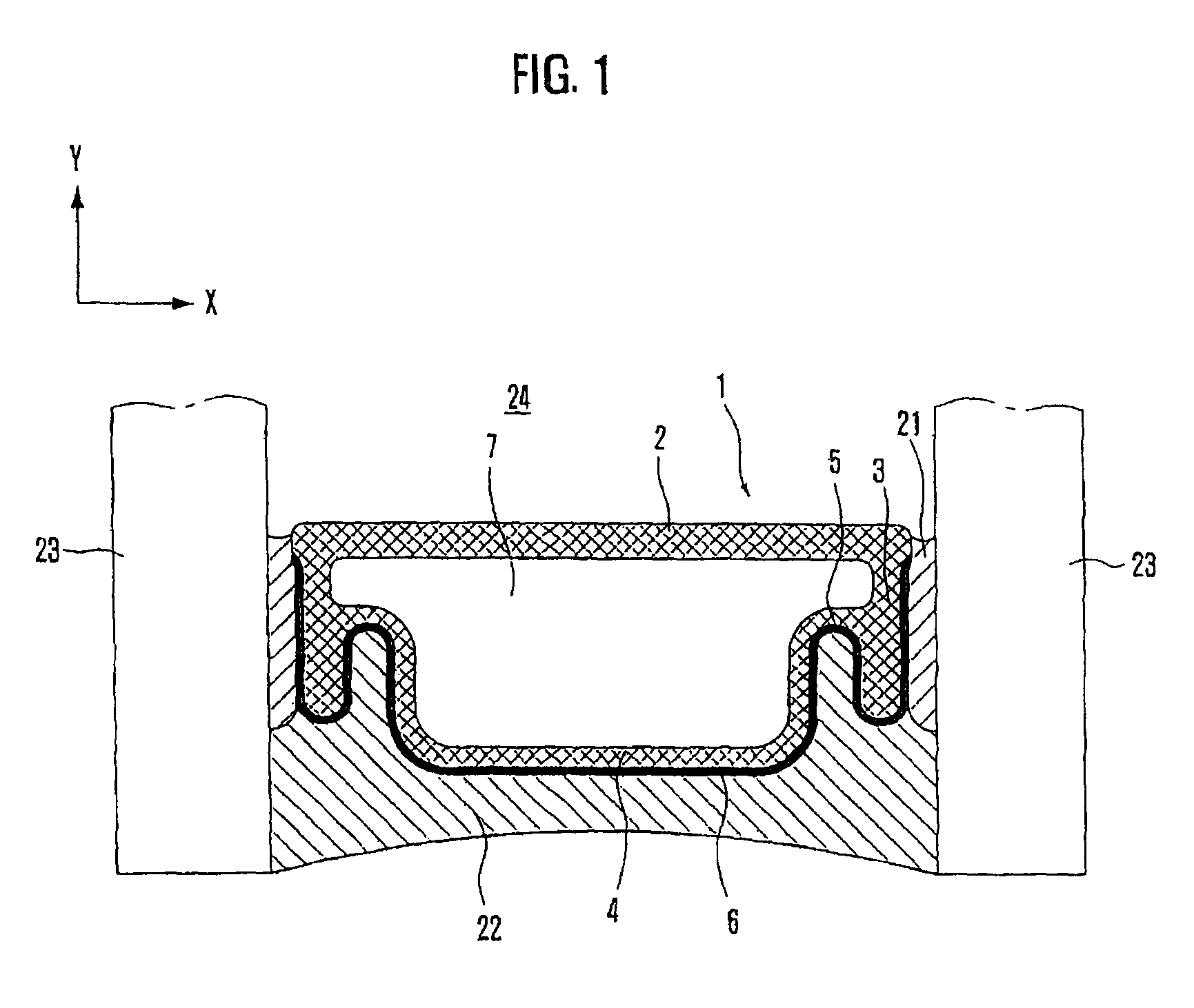

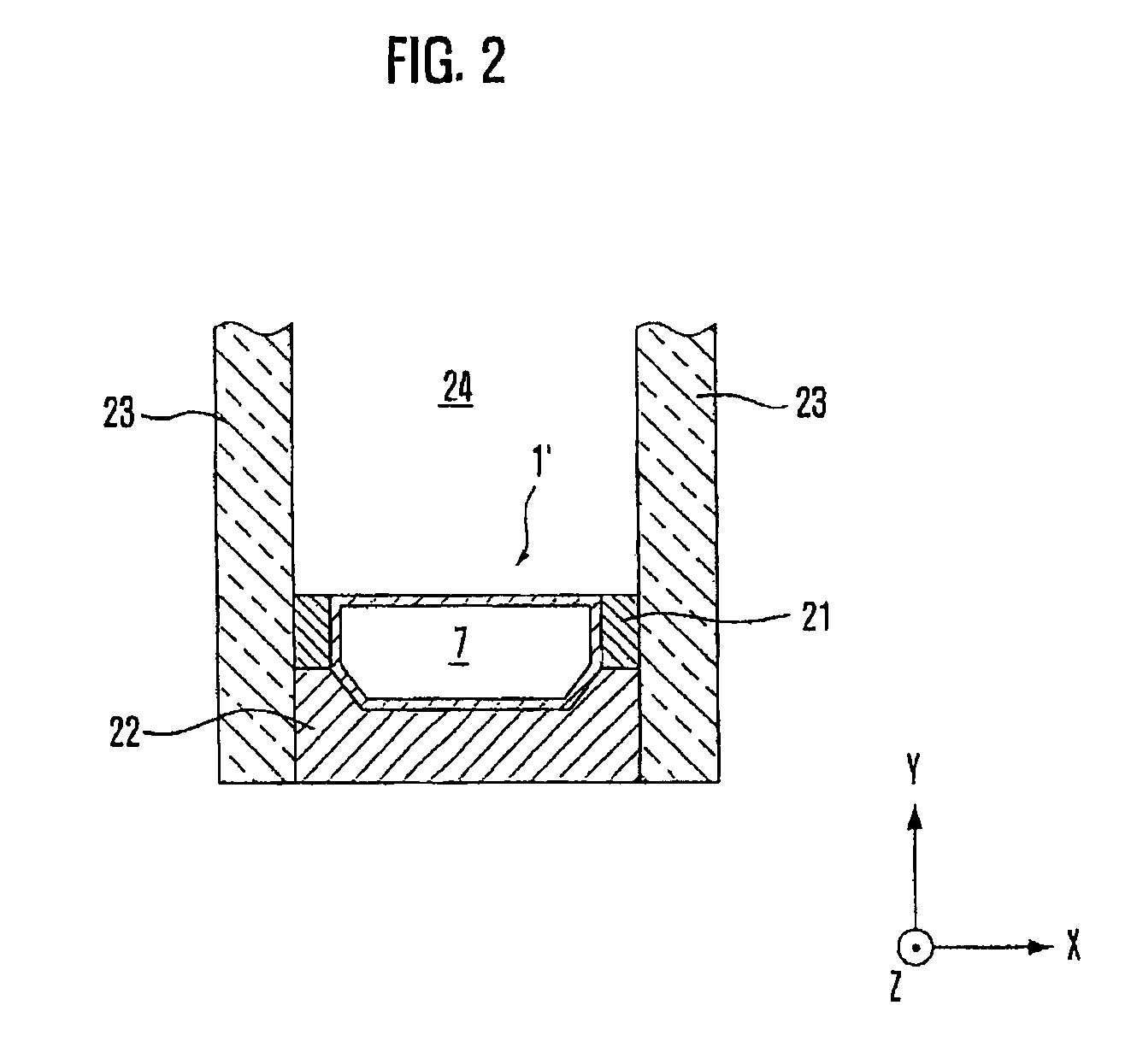

A device for drying and treating a fiber-based moving fiber web (1) in a machine intended for producing tissue paper includes a metal belt (2) which is arranged to support the fiber web (1) and to transfer the fiber web (1) in the machine direction and which metal belt (2) is arranged as a continuous rotating cycle, at least one roll (3) the shell of which is in contact with the metal belt (2) arranged to rotate around, which roll (3) is for supporting and / or controlling the metal belt (2), and at least one counter element (5) arranged to create a contact area outside the metal belt (2) between the metal belt (2) and the counter element (5) for a process zone (6), via which process zone (6) the fiber web (1) is arranged to travel when using the device.

Owner:VALMET TECH INC

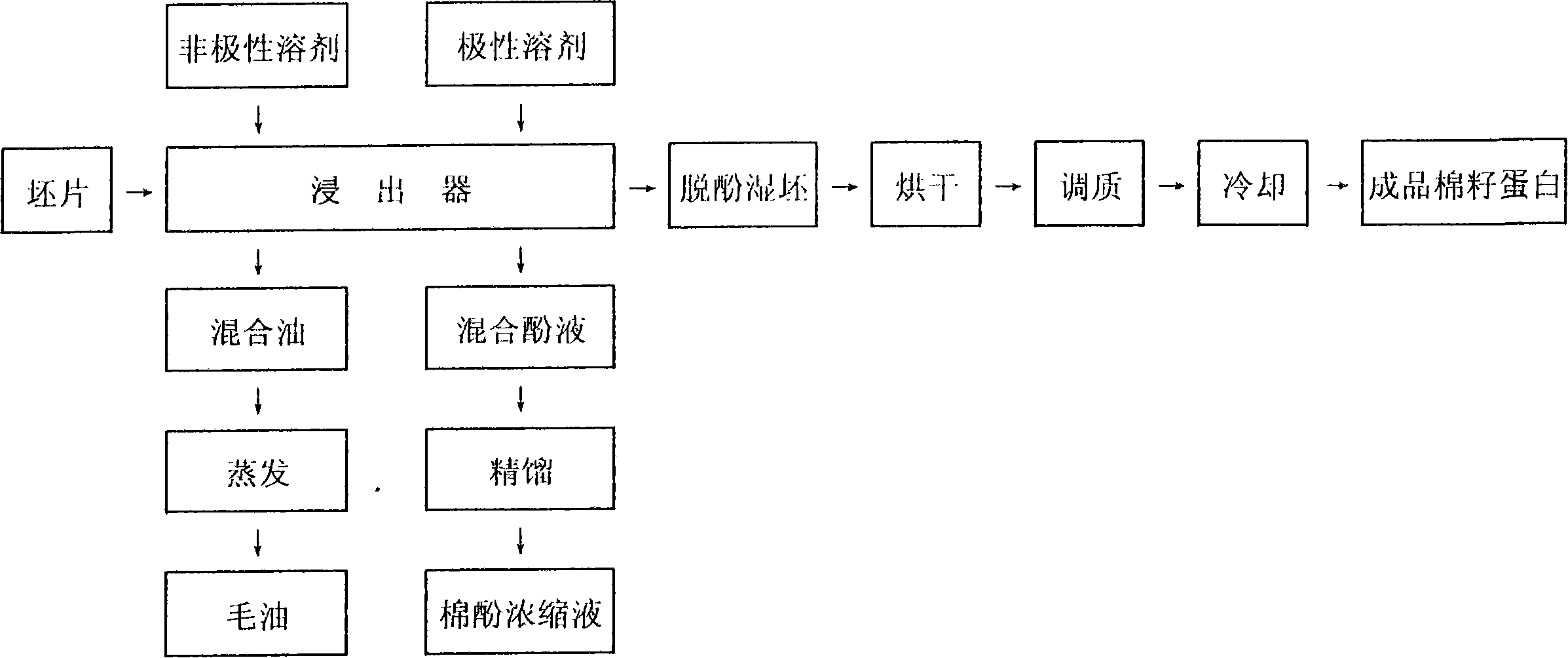

Extraction method for dephenolize cotton seed protein

InactiveCN101121744AShorten the production lineSmall footprintAnimal feeding stuffPeptide preparation methodsSolventChemistry

The invention discloses an extraction method of the dephenolized cottonseed protein, with the rough piece of the cotton kernel after doffing the cashmere, shelling, adjusting the quality, rolling and drying as the raw material; the polar and non-polar solvents are used as the extraction reagents; concentrated in a container, the raw material is continuously added and the two extraction reagents are continuously added in the divided steps; after the low-temperature extraction and separation, the mixed oil, mixed phenol solution and wet meal can be got; the mixed oil can be made into the rough cotton oil after the wholly negative-pressure evaporation and concentration; the mixed phenol solution can be made into the gossypol concentrated liquid after the vacuum distillation and concentration; the wet meal can be made into the dephenolized cottonseed protein after doffing the cashmere and adjusting the quality. The technological route of the invention is simple; the occupied area of the equipment is small; the one-time comprehensive investment is less; the running and leakage of the negative pressure in the whole system is less; the production cost is low; the product quality is guaranteed; the invention reduces the three-waste emission and is suitable for the industrialized mass production.

Owner:SHANDONG GOUXIN BIOLOGY PROTEIN

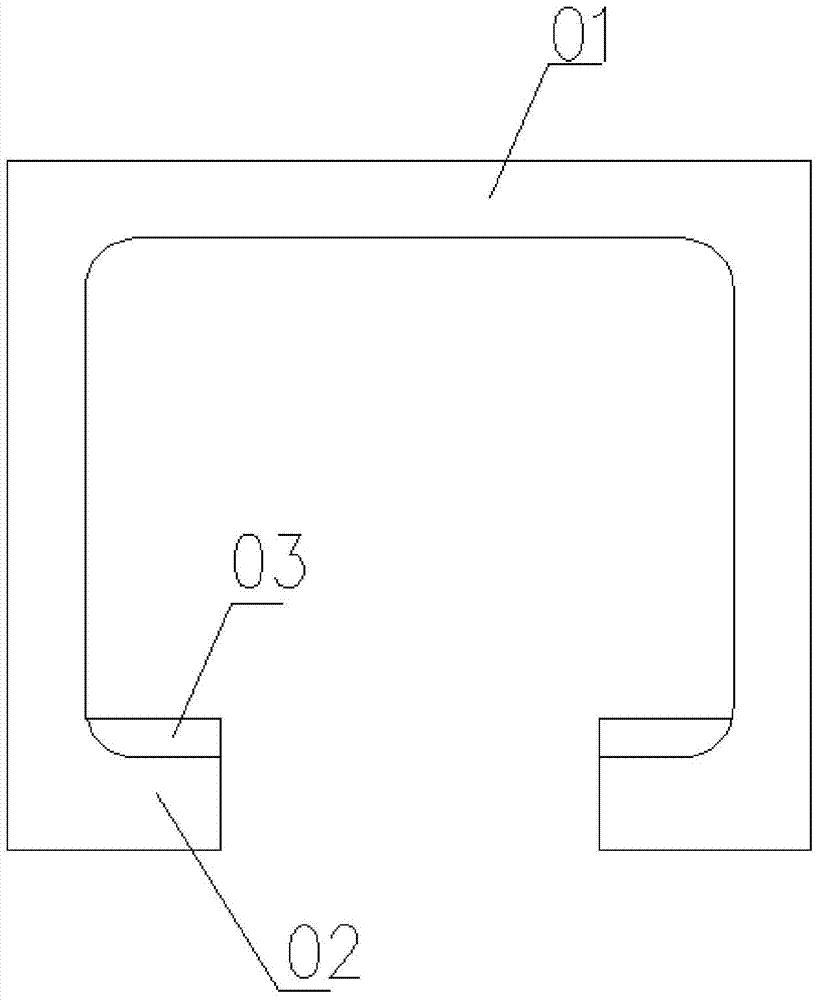

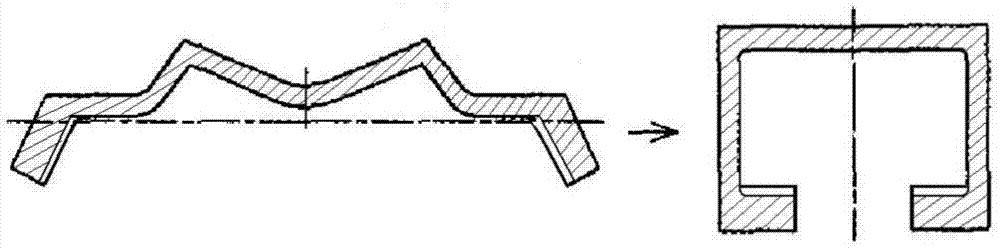

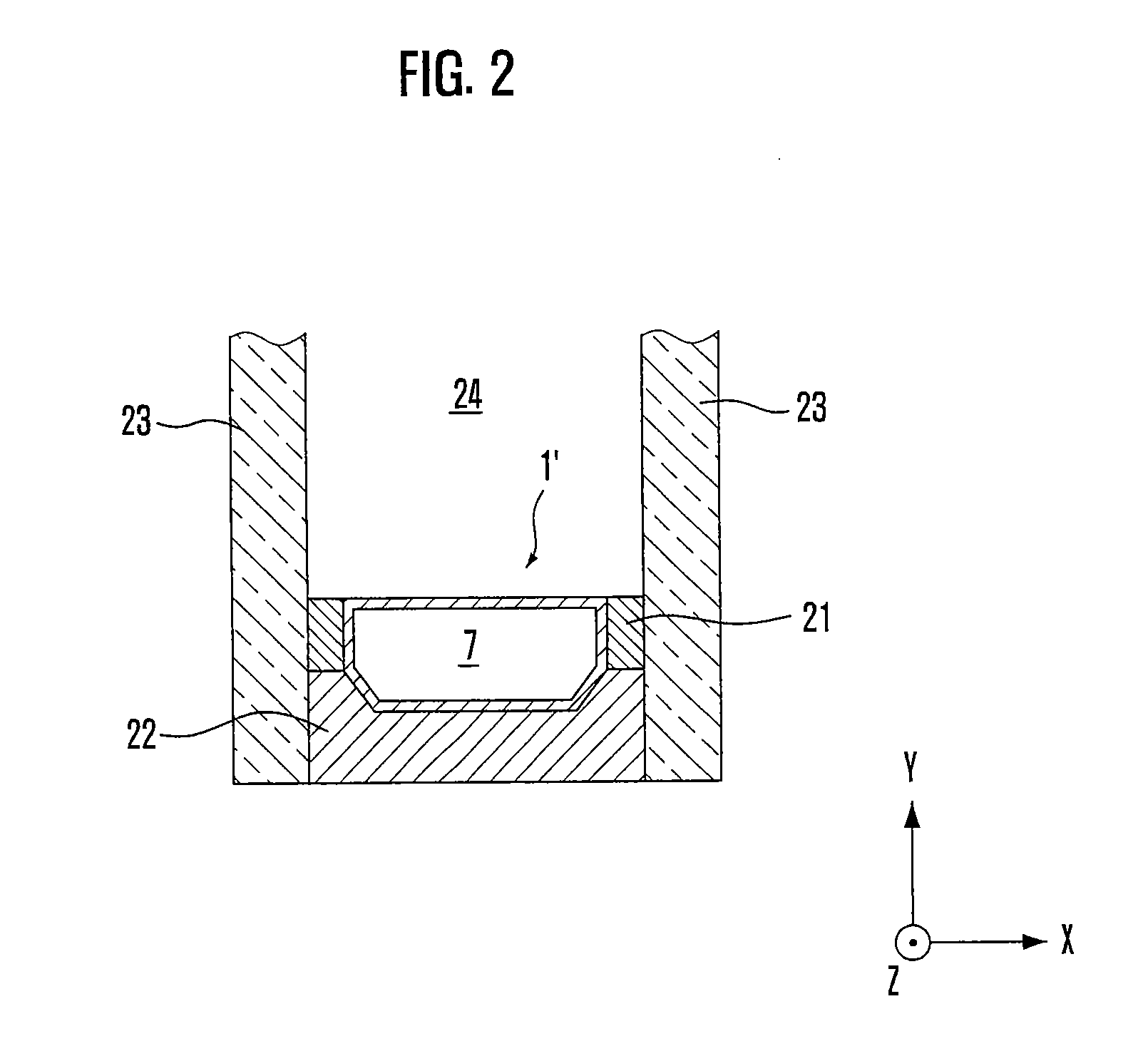

Spacer arrangement with fusable connector for insulating glass units

InactiveUS7757455B2Improve joint strengthShorten the production lineBuilding roofsAdhesivesInsulated glazingEngineering

A spacer frame arrangement for insulating glass units, comprising a spacer profile body extending in a first direction and having a predetermined cross section in a plane perpendicular to the first direction, the predetermined cross section defining a hollow inner space of the spacer profile body with predetermined dimensions in the plane perpendicular to the first direction, and a connector comprising a connector section adapted to be inserted in the first direction into the hollow inner space of the spacer profile body by having a cross sectional shape perpendicular to the first direction which corresponds, with predetermined tolerances, to the cross section of the spacer profile body limiting the hollow inner space, at least the outer surface of the connector section facing the inner surface of the hollow inner space of the spacer profile body after insertion of the same being made of a fusable material, preferably a material fusable by melting the same, wherein the connector section is inserted into the hollow inner space of the spacer profile body and the outer surfaces of the connector section and the inner surface of the spacer profile body facing each other are connected by fusing.

Owner:TECHNOFORM GLASS INSULATION HLDG

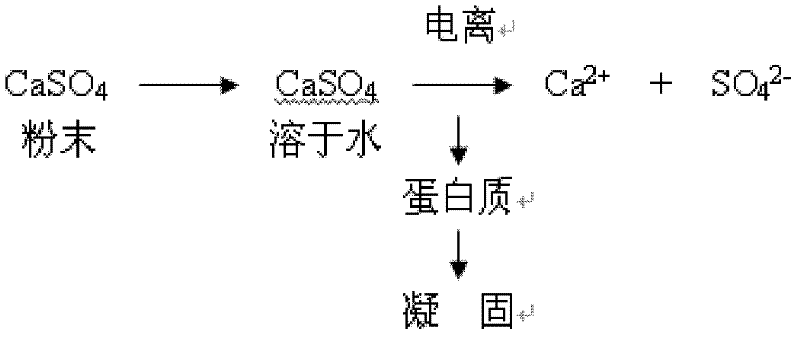

Production method for boxed bean curd and boxed bean curd

ActiveCN102550698AEnergy savingReduce energy consumptionCheese manufactureMilk substitutesChemistrySoybean oil

The invention discloses a production method for boxed bean curd and the boxed bean curd. The production method for the boxed bean curd comprises the following steps of: boiling soybean milk by taking soybeans as raw materials; controlling the temperature of the boiled soybean milk to be above 85 DEG C; mixing the boiled soybean milk with a coagulating agent; and filling the mixture into a packing container; keeping the temperature of mixed milk of the soybean milk and the coagulating agent in the packing container for 10 to 30 minutes; and solidifying to form the boxed bean curd. The production method has a scientific process and simple steps. According to the production method, defects in the prior art are overcome, a solidification process of the soybean milk can be more effectively controlled, industrialized production can be really realized, and the aims of reducing energy consumption to a great extent, simplifying equipment and diversifying varieties are fulfilled, and boxed lactone bean curd and boxed southern bean curd and northern bean curd which fit conventional taste can be prepared.

Owner:FOODSTUFF INST BEIJING

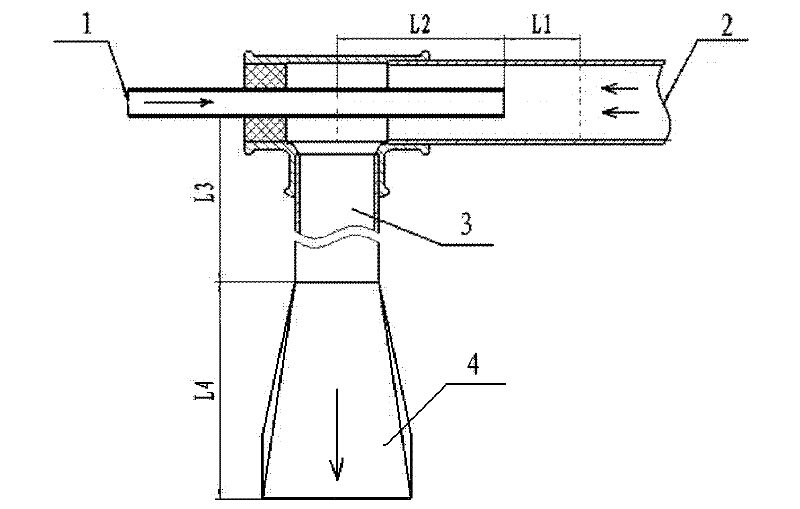

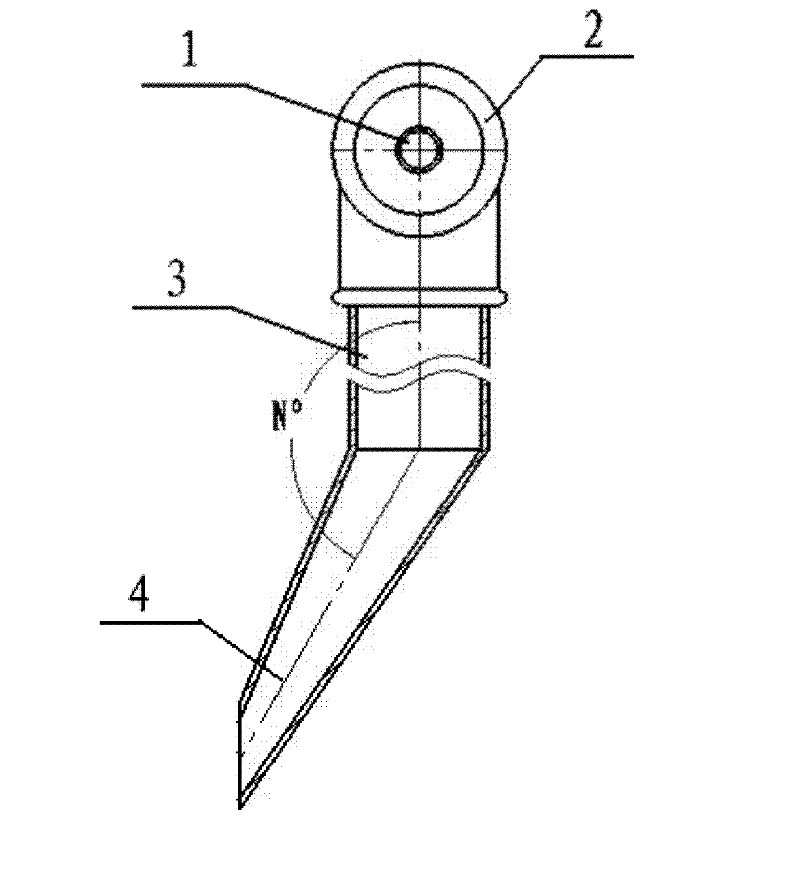

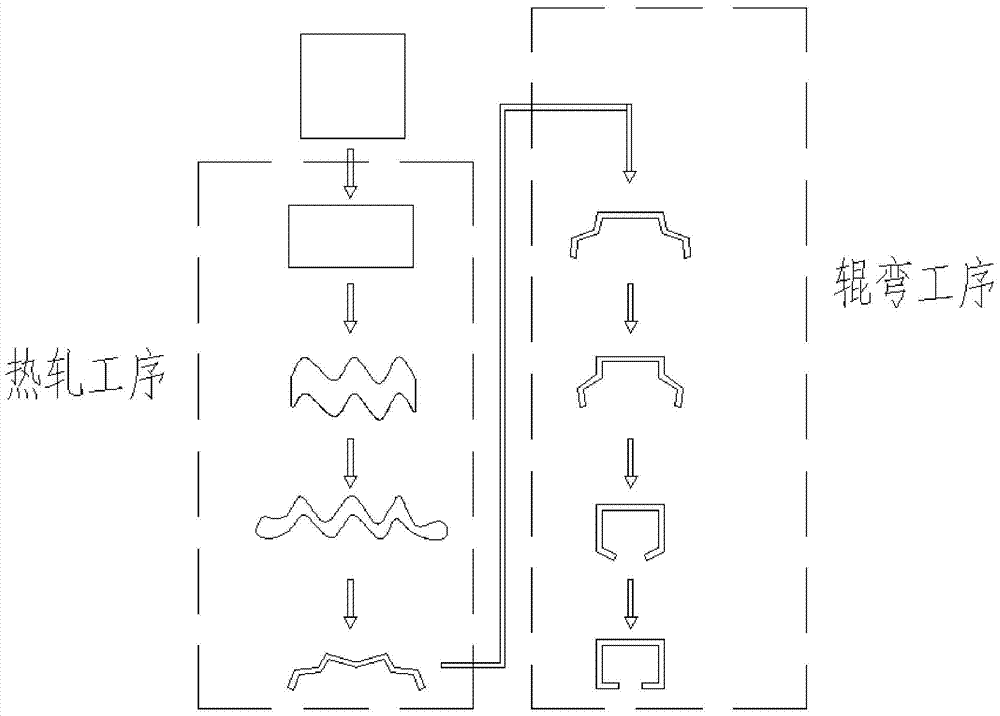

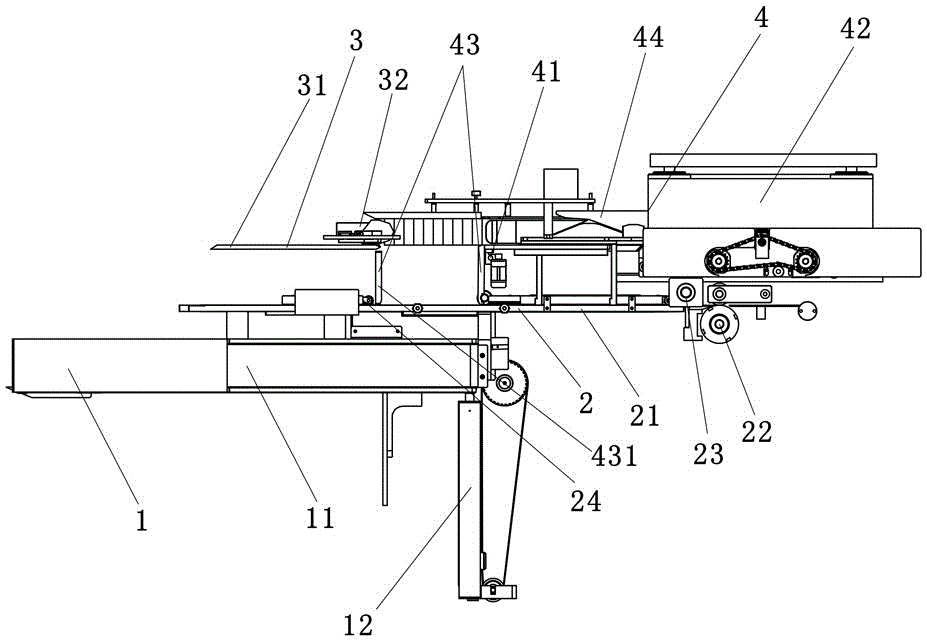

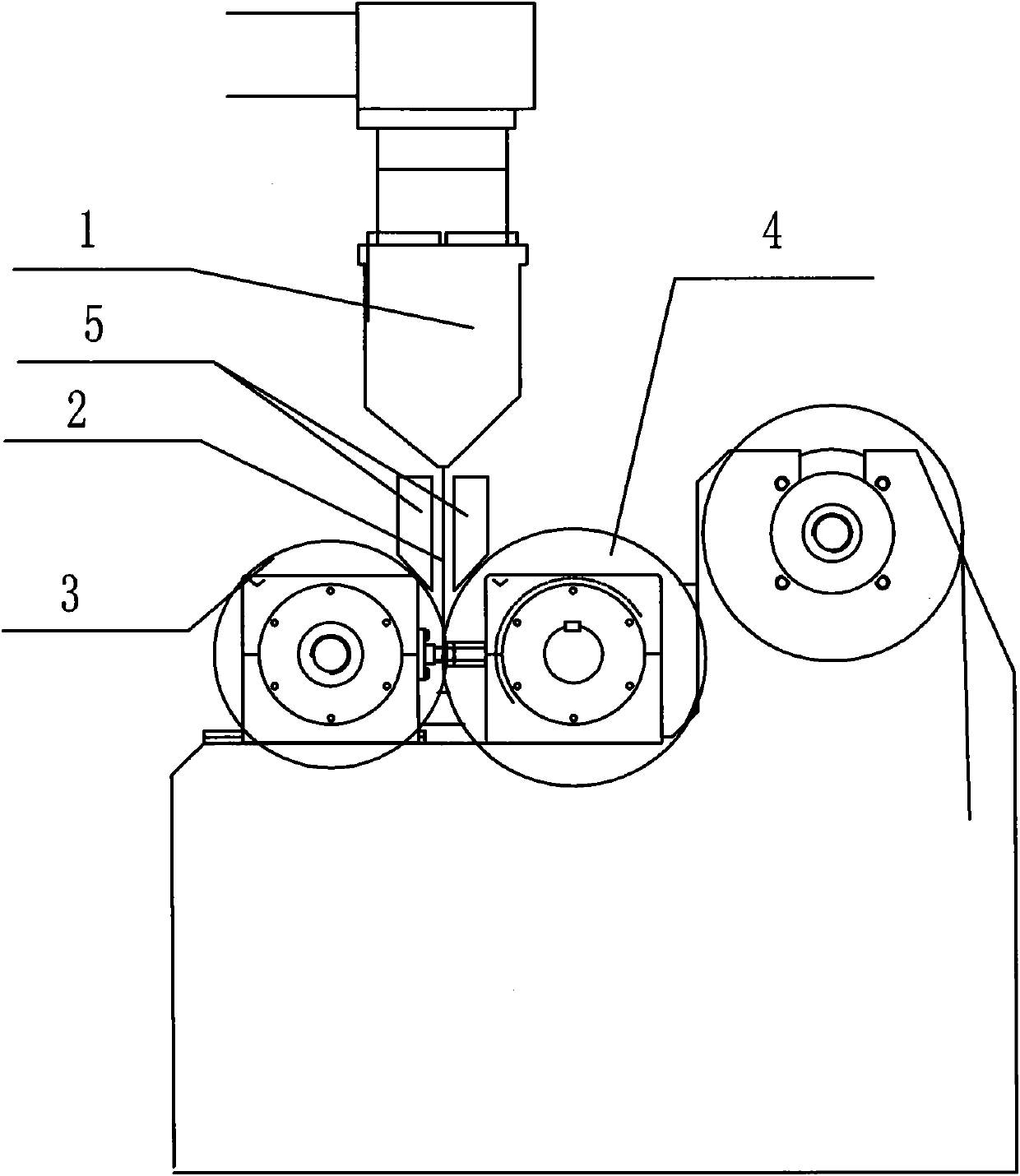

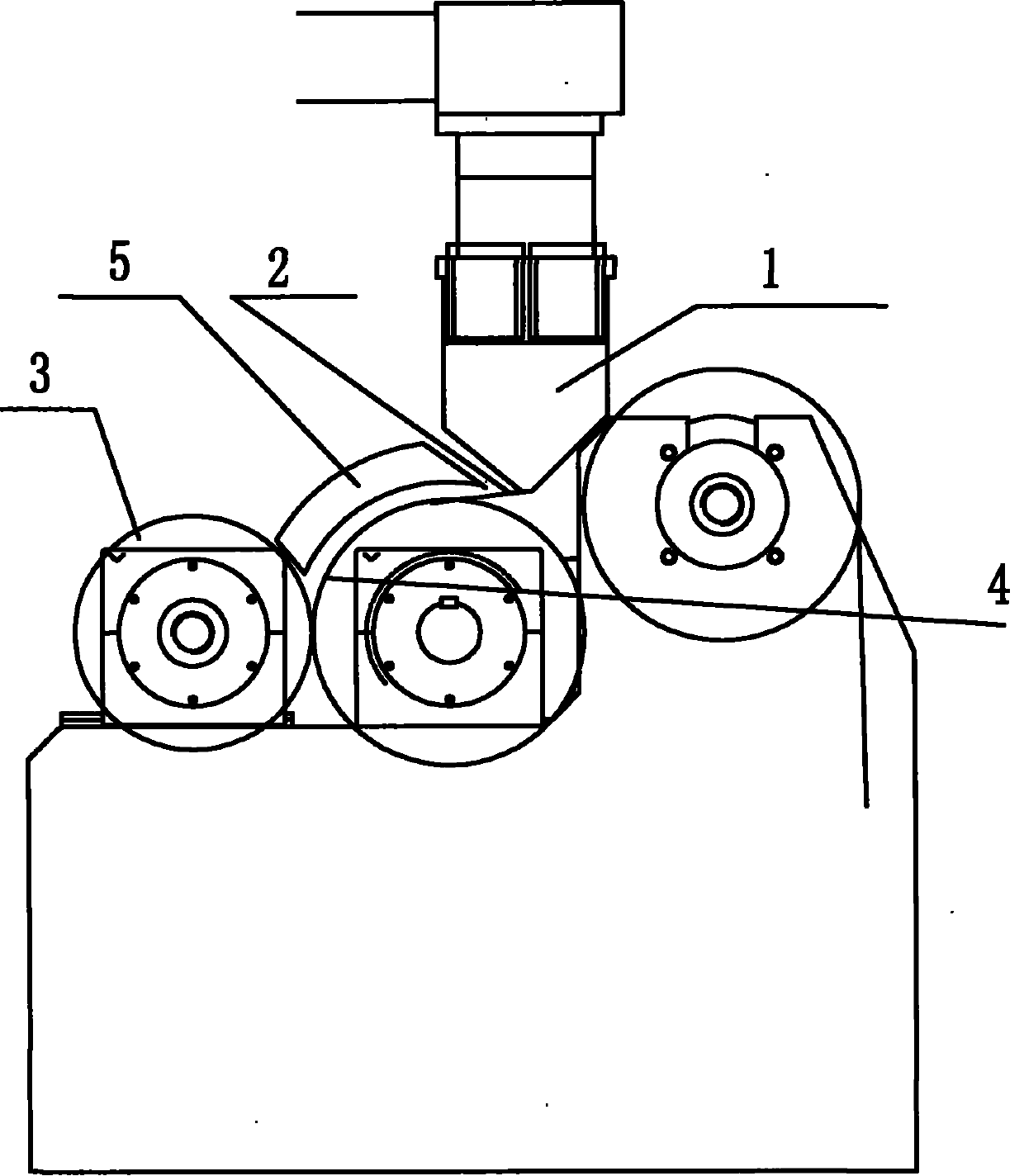

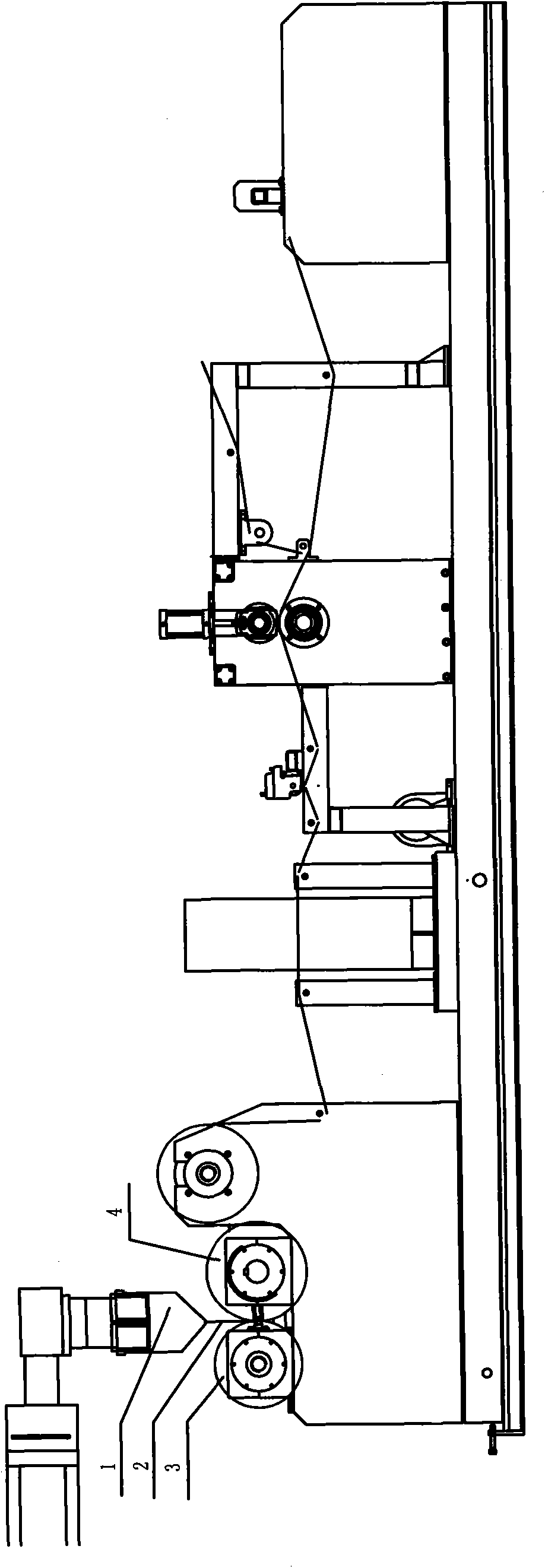

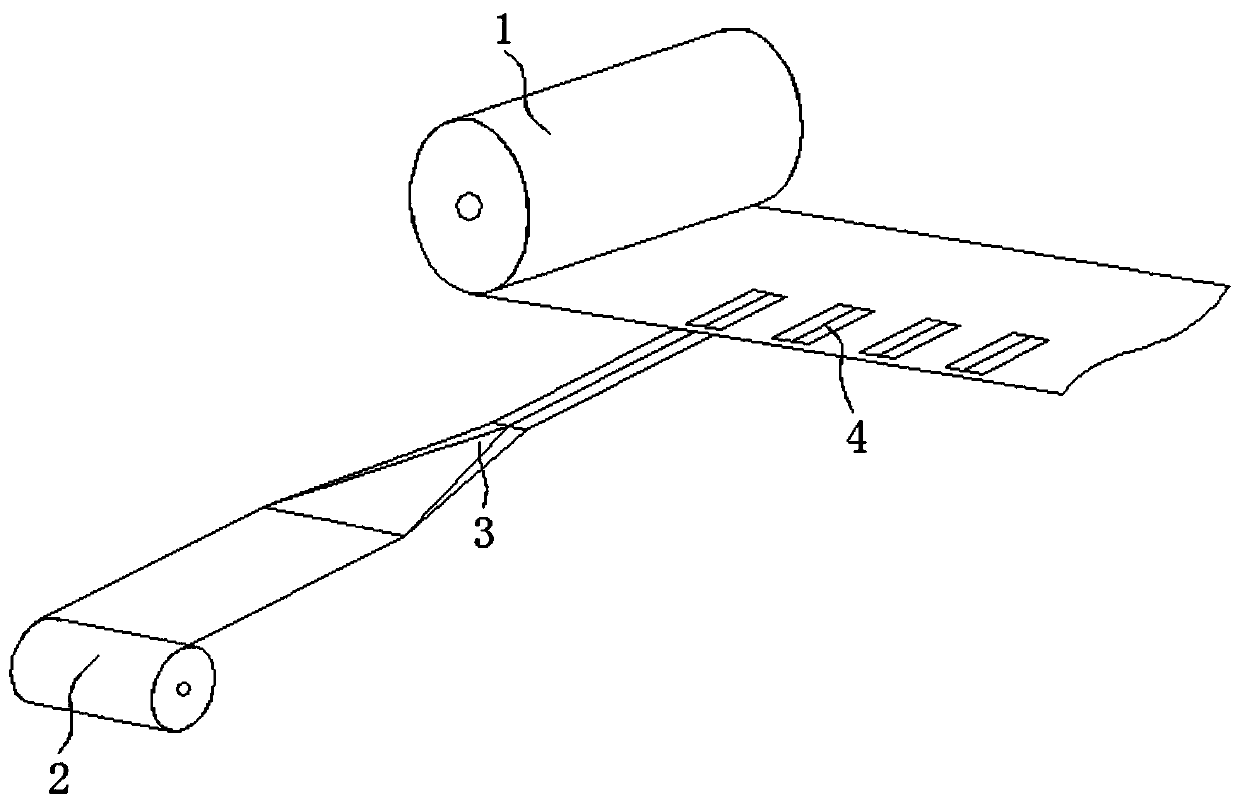

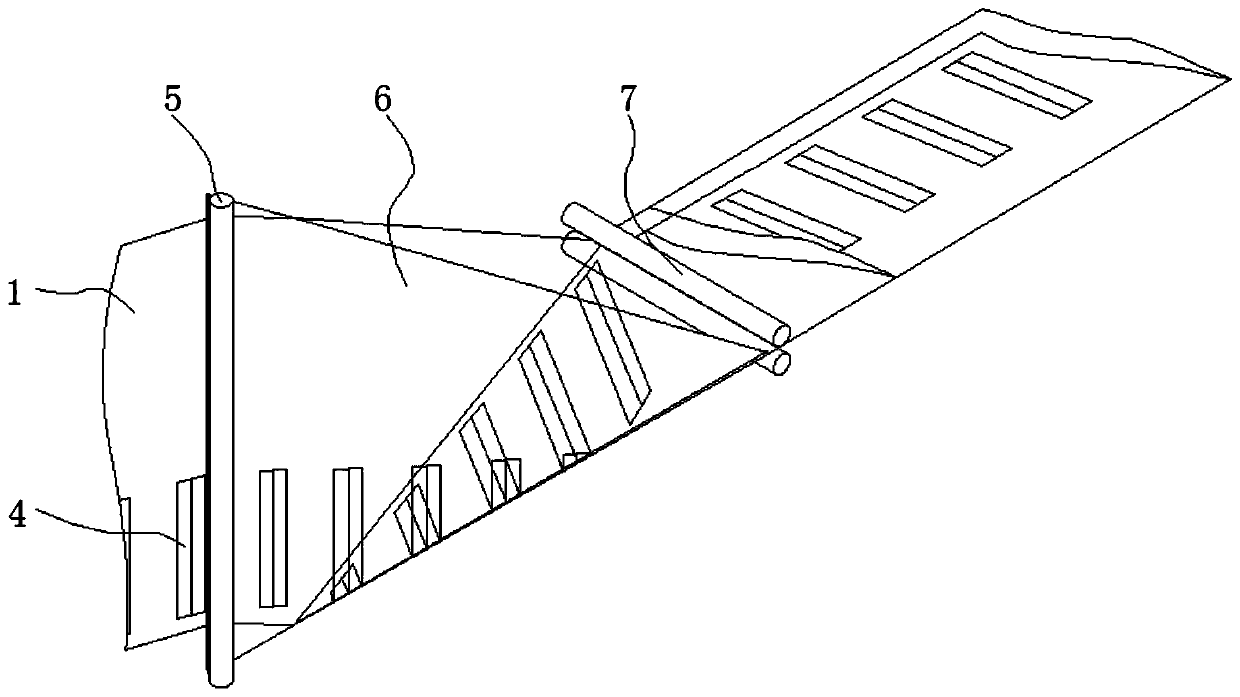

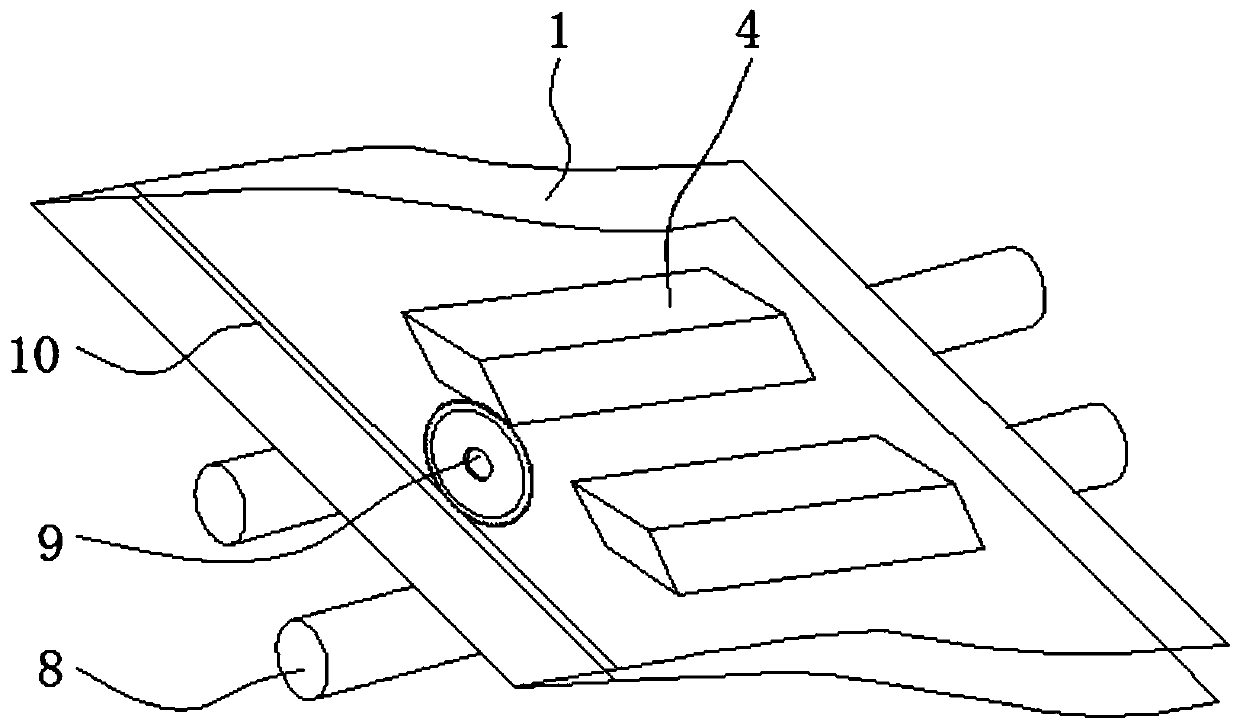

Channel section steel production system and production method thereof

ActiveCN104759892ASimple production processSimplified pass rolling passesOther manufacturing equipments/toolsProduction lineMethods of production

The invention provides a channel section steel production system and a production method thereof. The channel section steel production system comprises a feeding device, a heating device, a hot-rolling unit, a roll-bending unit and a fixed-length cutting device which are sequentially arranged. Flat steel blank raw materials are selected, heated through an electric induction heating device and then are fed into rolling mills of two machine frames to be subjected to rolling deformation, a first pass is used for thickness decrease, a second pass is used for plate shape forming of cross sections of rolled pieces before hot bending, and the two machine frames conducts deformation rolling on the raw materials simultaneously in a continuous-rolling state. By the adoption of simplified two-pass hot rolling, the thickness and plate shapes all cross section of flattened and spread channel section steel are rolled, waste heat is utilized to conduct hot bending forming on the continuous roll-bending unit, and fixed-length sawing, cooling and finishing are performed to obtain channel section steel products. The production method is simplified, hole type rolling pass is simplified, production difficulty is reduced, and the production success rate and finished material rate are improved. The number of the rolling mills is decreased, a production line is shortened, short-process production is achieved, and investment and follow-up maintenance cost are reduced.

Owner:CISDI ENG CO LTD +1

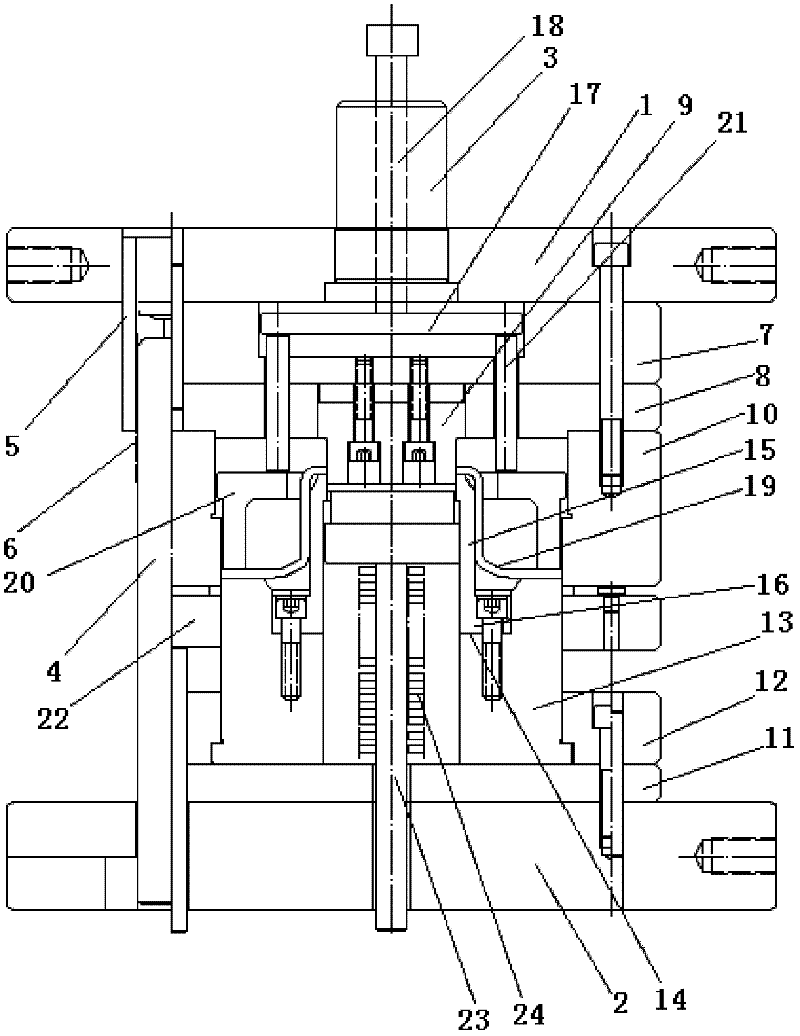

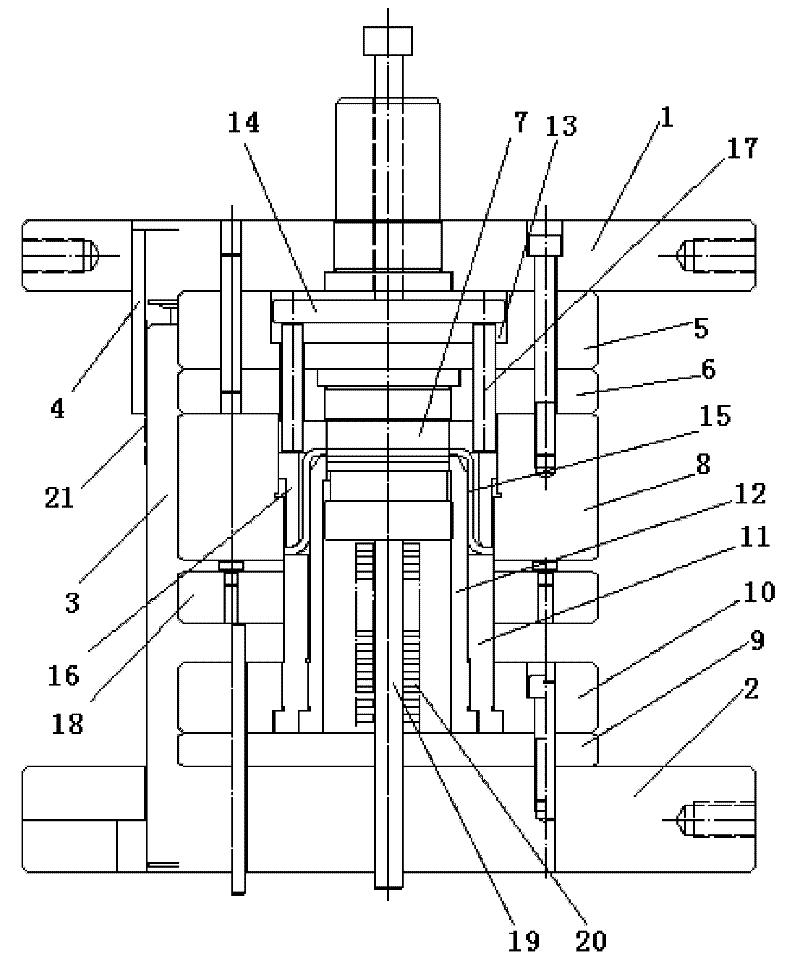

Composite die for edge cutting and punching

InactiveCN102397947AShorten the production lineReduce labor intensityShaping toolsPerforating toolsProduction linePunching

The invention discloses a composite die for edge trimming and punching, comprising an upper die plate, a lower die plate, an upper die shank being fixedly mounted on the upper die plate, and a guide pillar and a guide sleeve in sliding fit being respectively fixed between the upper die plate and the lower die plate. The lower end face of the upper die plate is fixedly mounted with a male die backup plate and a male die dead plate successively. The lower center and the edge of the male die dead plate are fixedly mounted with a punching male die and an edge cutting female die. The upper end face of the lower die plate is fixed with a female die backup plate and a female die dead plate. An edge cutting male die which is provide with steps inside is fixedly mounted in the female die dead plate. A punching female die which has a turnup at the lower end is fixedly mounted on the steps of the cutting edge female die. The invention integrates edge cutting and punching into one die, which shortens production line, reduces labor intensity, raises working efficiency and lowers production cost.

Owner:TONGLING BAIRUIHAO TECH

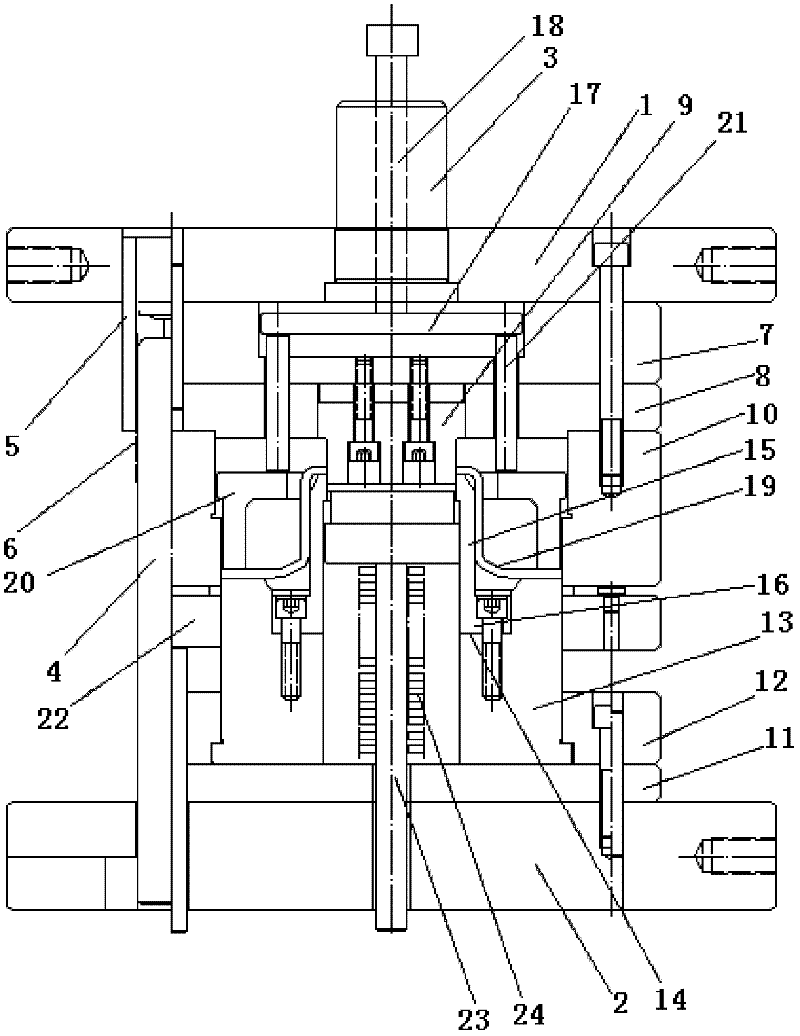

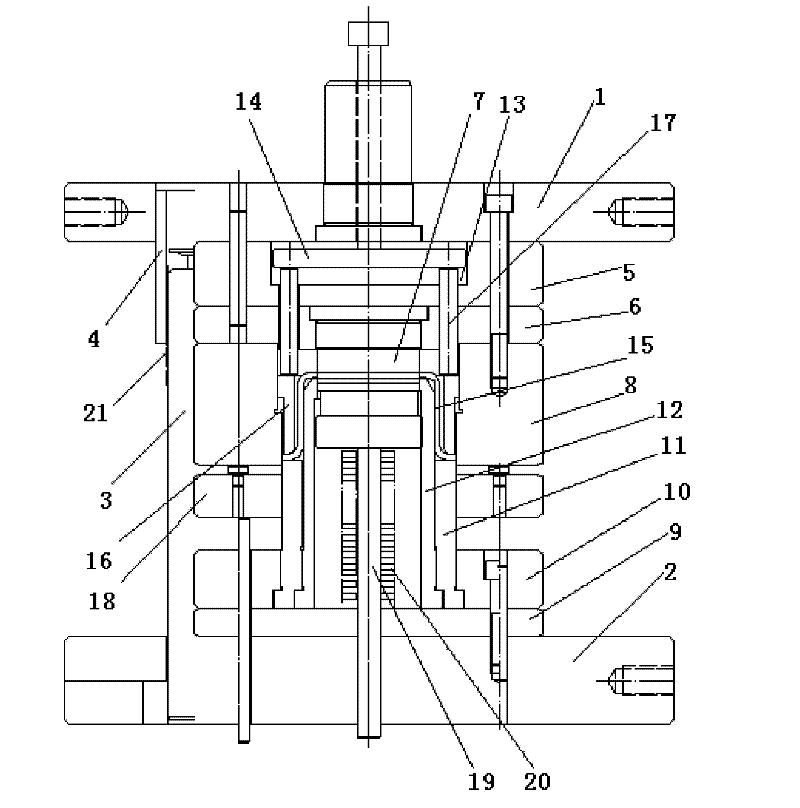

Trimming and punching die

InactiveCN102397945AShorten the production lineReduce labor intensityShaping toolsProduction linePunching

The invention discloses a trimming and punching die, which comprises an upper template and a lower template, wherein a guide pillar and a guide sleeve which are in mutual sliding fit are respectively fixedly arranged between the upper template and the lower template; a male die backing plate and a male die fixing plate are sequentially and fixedly arranged on the lower end surface of the upper template; a punching male die and a trimming female die are respectively and fixedly arranged at the center and the edge below the male die fixing plate; a female die backing plate and a female die fixing plate are fixedly arranged on the upper end surface of the lower template; a trimming male die and a punching female die are sequentially matched in the female die fixing plate; a die cavity of the punching male die is matched with that of the punching female die; and a die cavity of the trimming male die is matched with that of the trimming female die. According to the trimming and punching die disclosed by the invention, the punching and the trimming are finished in one set of dies, thus a production line is shortened, the labor intensity is reduced, the production efficiency is improved and the production cost is reduced.

Owner:TONGLING BAIRUIHAO TECH

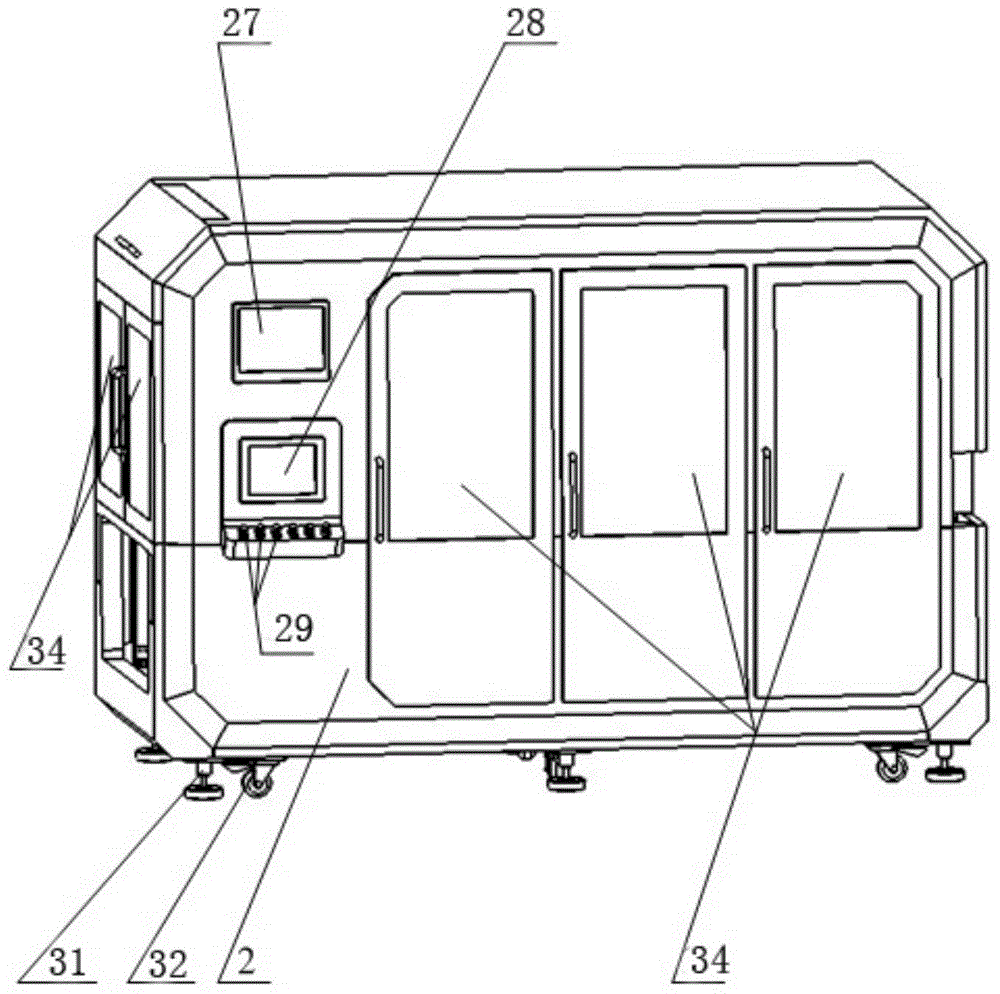

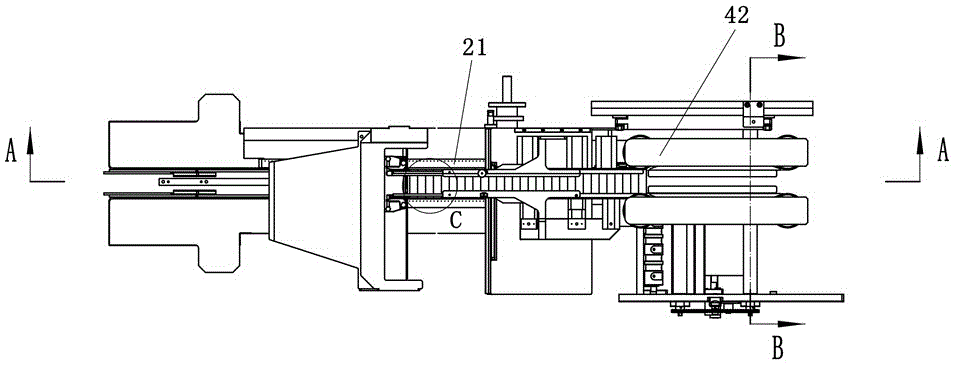

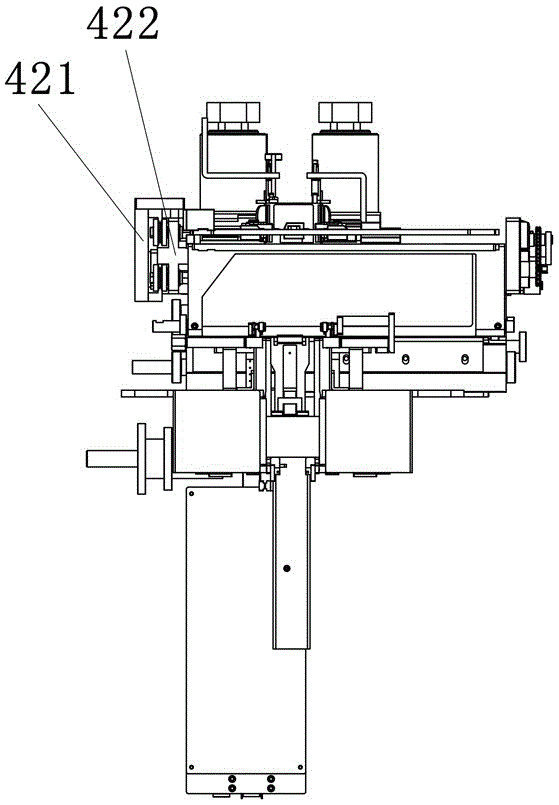

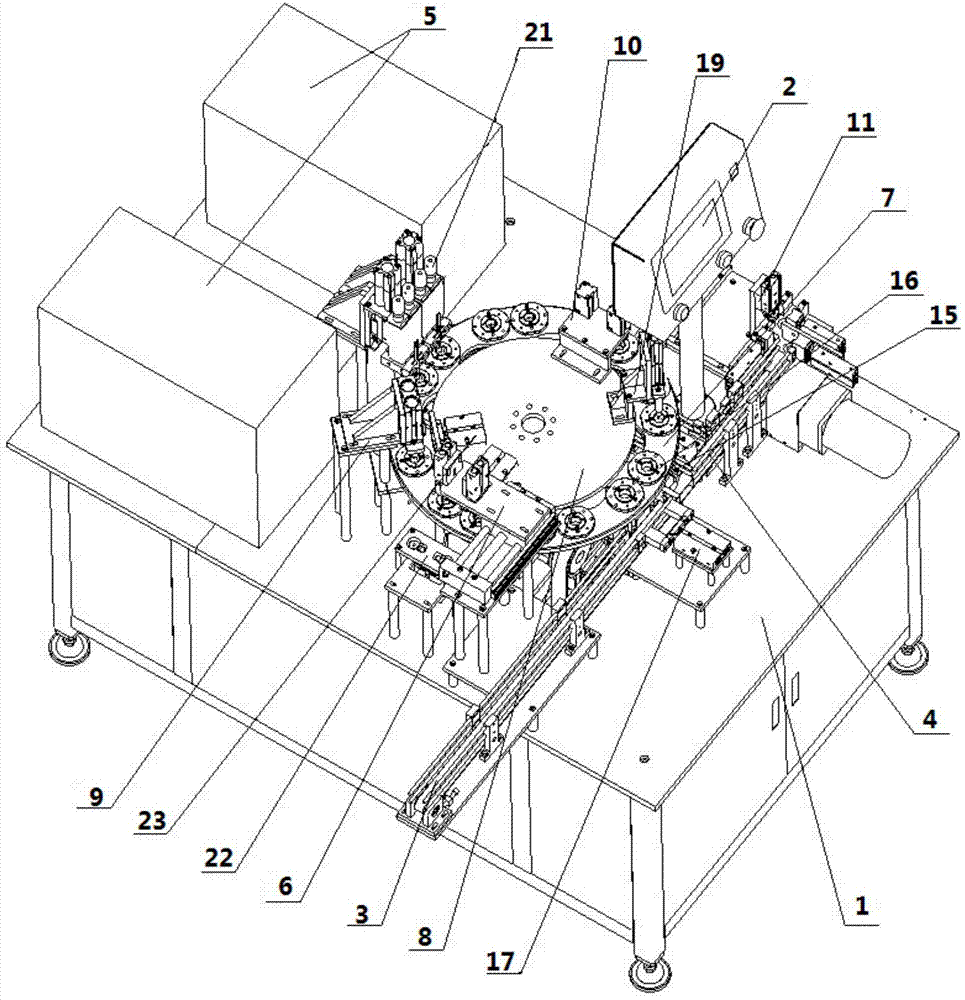

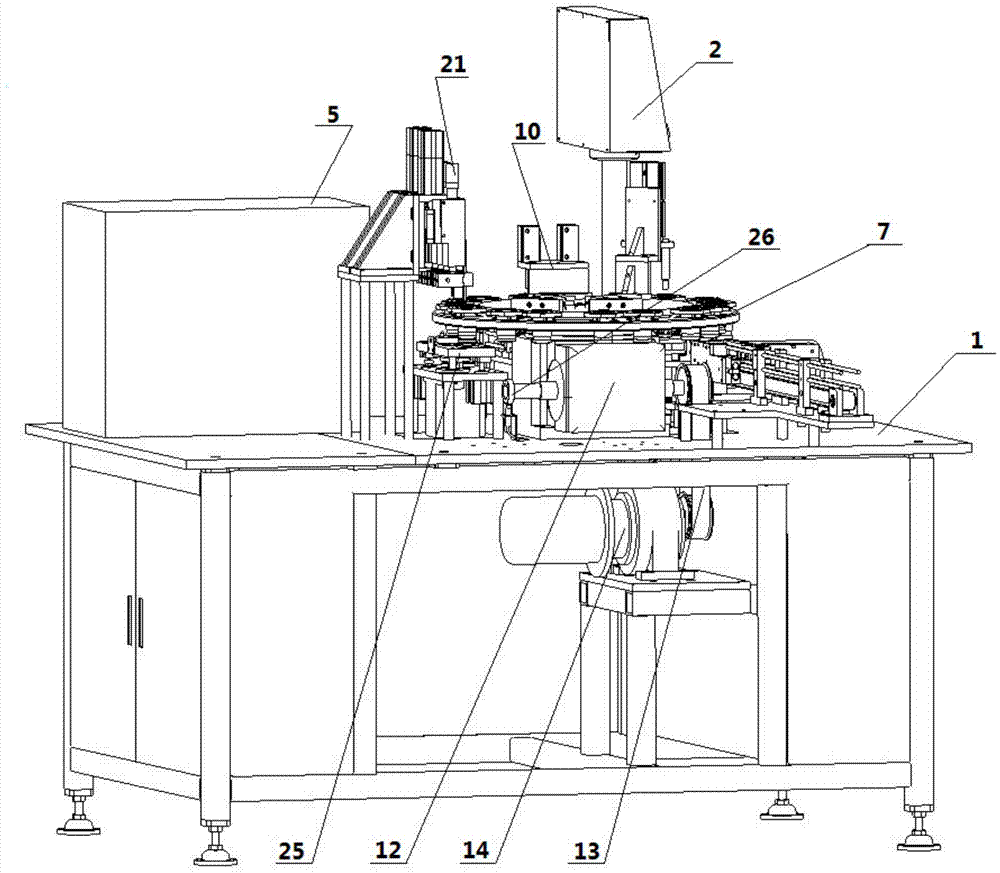

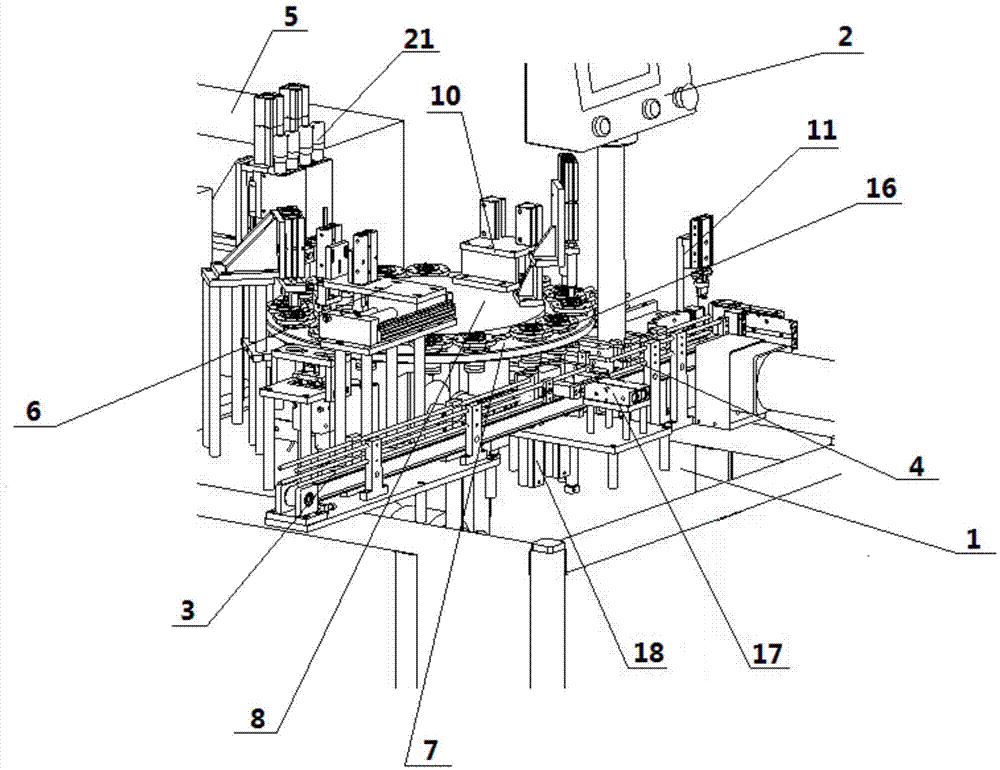

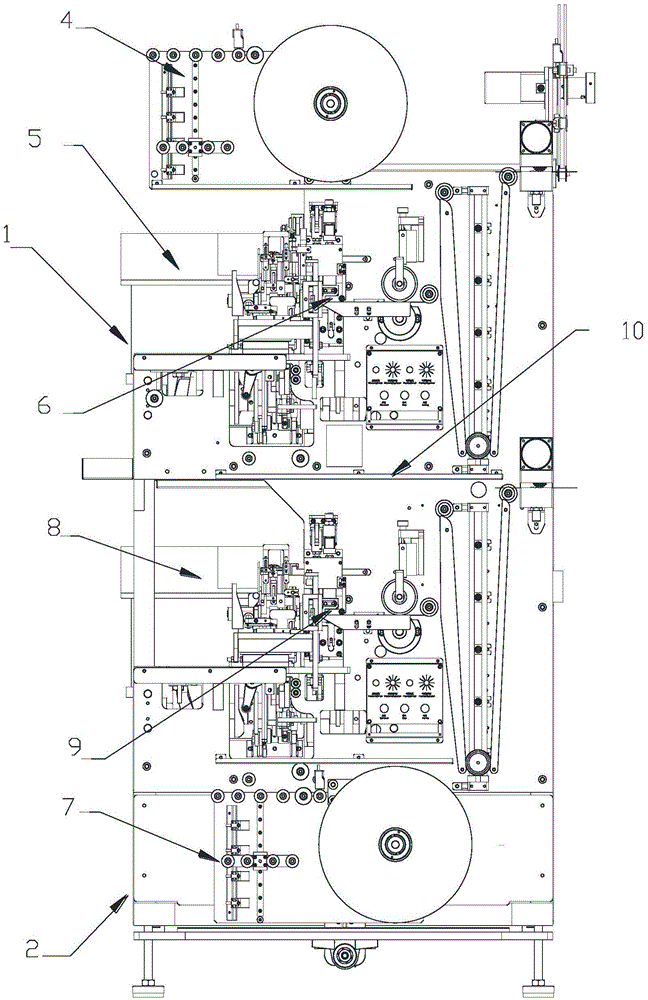

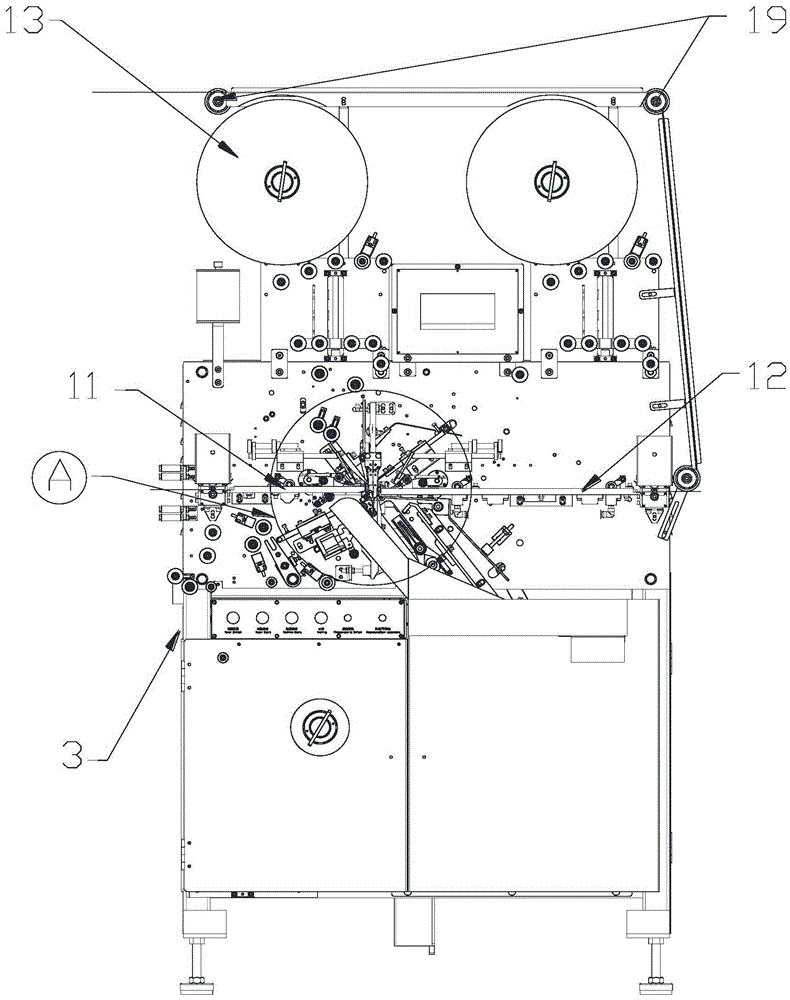

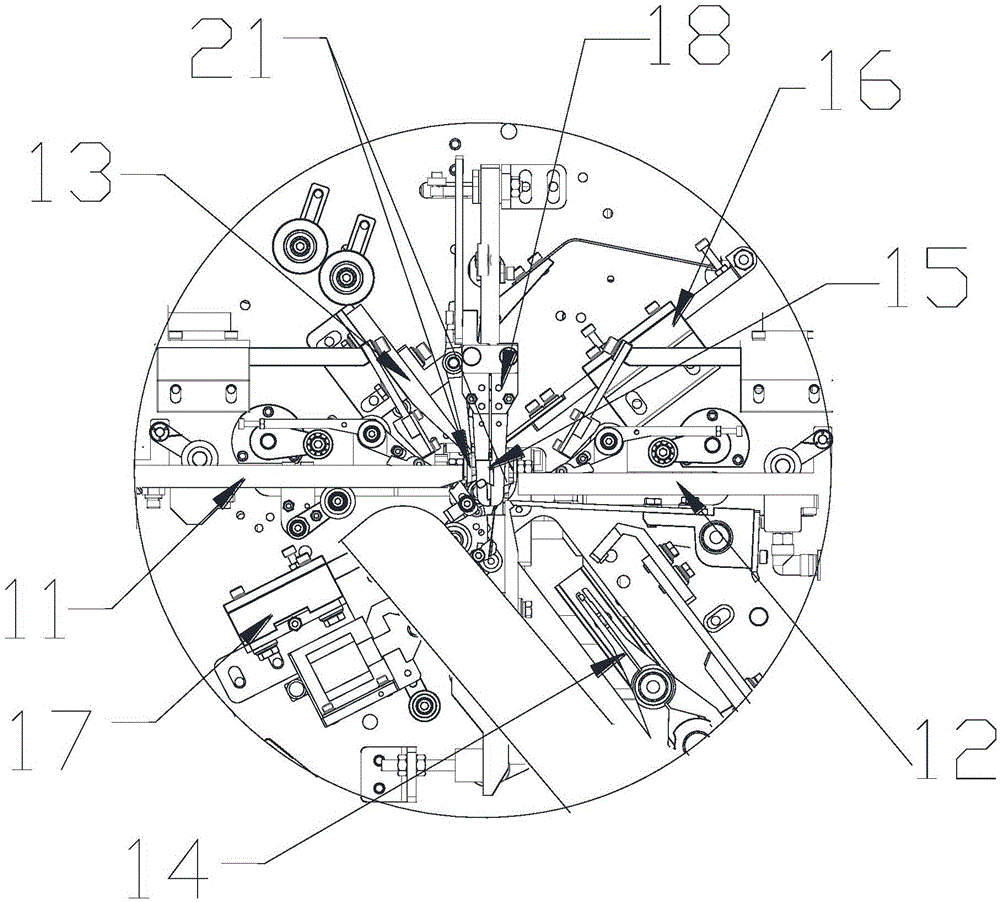

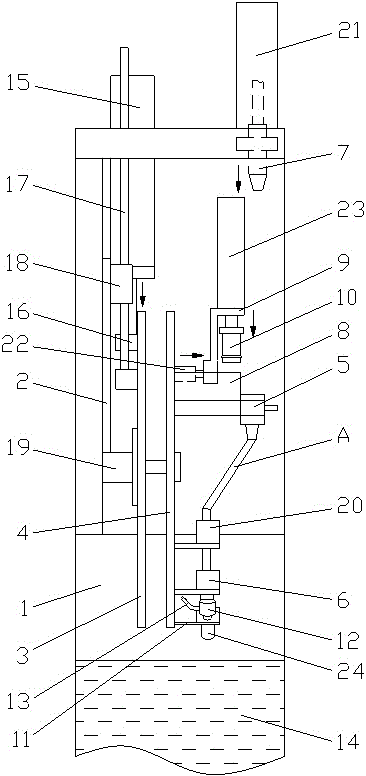

Full-automatic efficient precision assembling machine

ActiveCN105805114ACompact structureShorten the production lineFastening meansProduction lineHot melt

The invention discloses a full-automatic efficient precision assembling machine. The full-automatic efficient precision assembling machine comprises a rack, a workbench arranged on the rack, a feeding supporting disc station, a product locating station, a feeding station, an assembling hot melt adhesive station, a to-be-assembled piece assembling station, a to-be-assembled piece supporting disc placing station, a jig transferring station, a pressure maintaining station, a detection station, a material taking station, an unqualified product receiving station and a qualified product supporting disc station, wherein the feeding supporting disc station, the product locating station, the feeding station, the assembling hot melt adhesive station, the to-be-assembled piece assembling station, the to-be-assembled piece supporting disc placing station, the jig transferring station, the pressure maintaining station, the detection station, the material taking station, the unqualified product receiving station and the qualified product supporting disc station are sequentially distributed around the workbench. Product locating jigs are transferred among the stations through a supporting and conveying mechanism, and devices on all the stations are connected with a PLC. The assembling machine is compact in structure, can achieve efficient and precise assembly of products and pieces to be assembled and integrates the feeding, hot melt achieve gluing, to-be-assembled piece gluing, detection and discharging processes, and the product assembling production line can be shortened.

Owner:SUZHOU YIMEIDE TECH CO LTD

Novel integrative treating and producing technology of metal face

InactiveCN102009324AShorten the production lineIncrease productivityProduction lineChemical treatment

The invention relates to a novel integrative treating and producing technology of a metal face, comprising the following technical processes of decoiling a steel strip; trimming; treating corners; punching; shot blasting; chemically treating; cold bending and forming; cutting; and coating. The novel integrative treating and producing technology of the metal face integrates a forming technology and a surface treating technology of a metal panel into a whole, shortens a production line, increases production efficiency and ensures product quality.

Owner:刘永

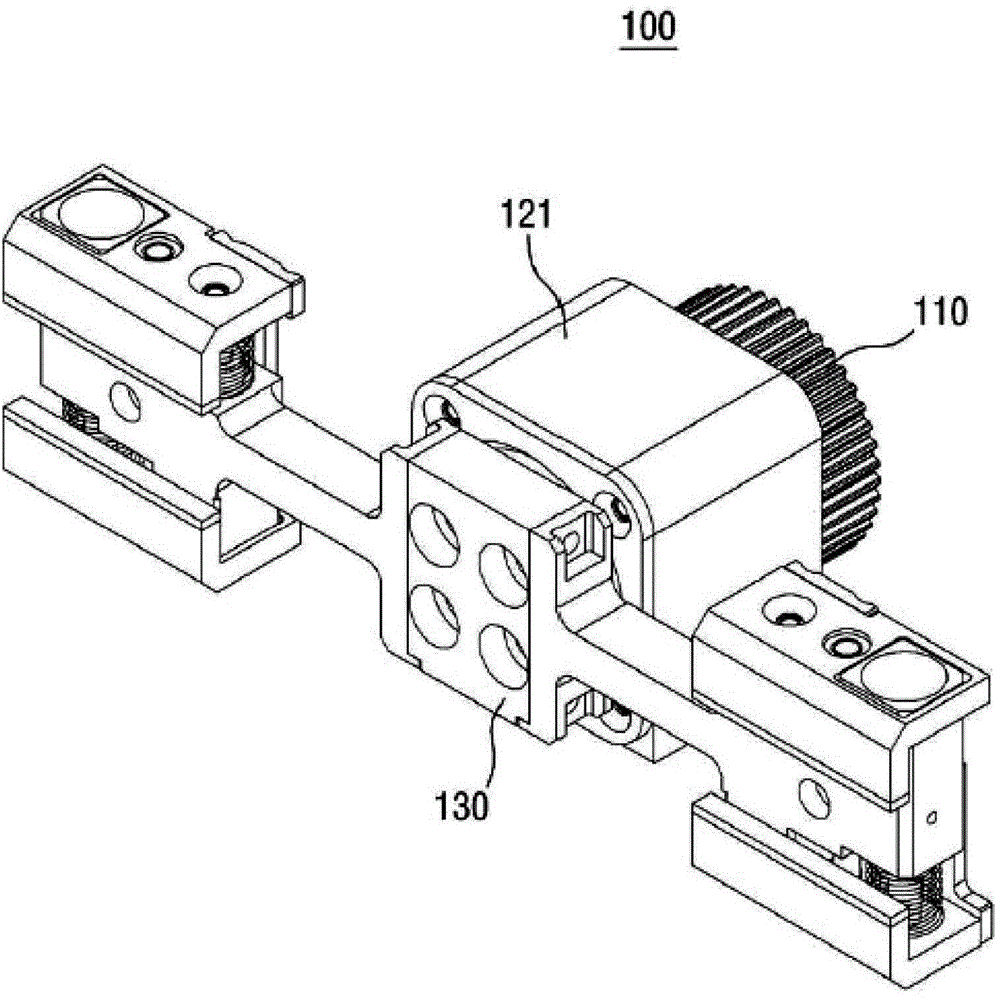

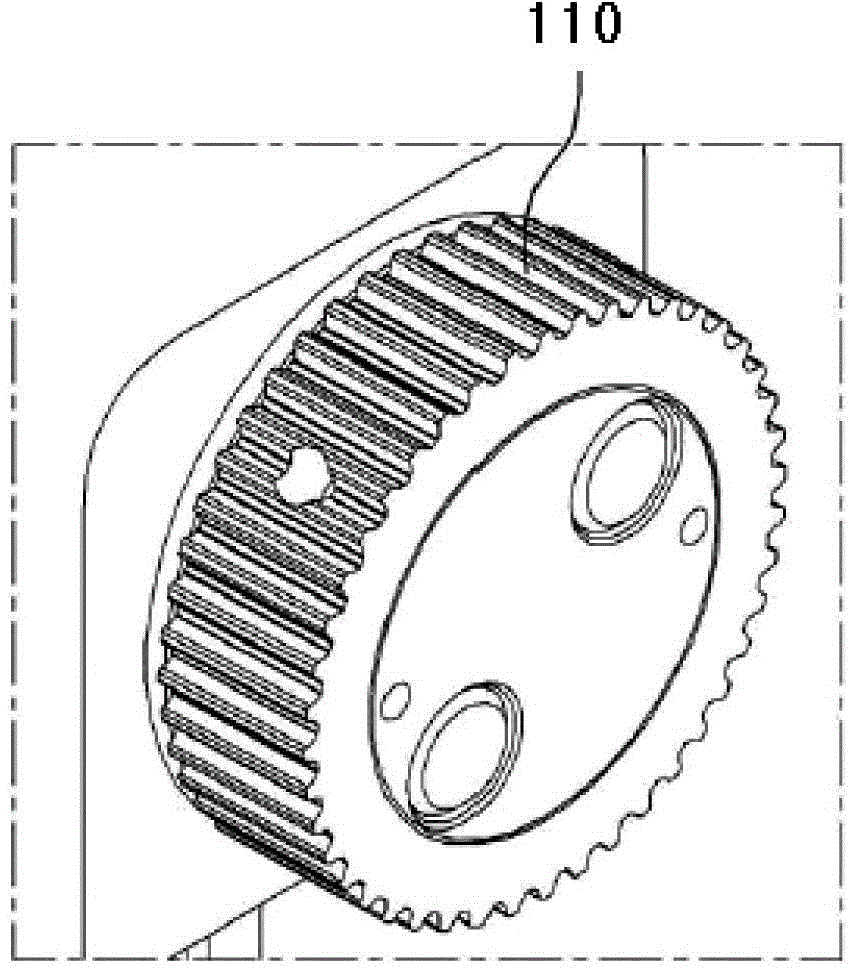

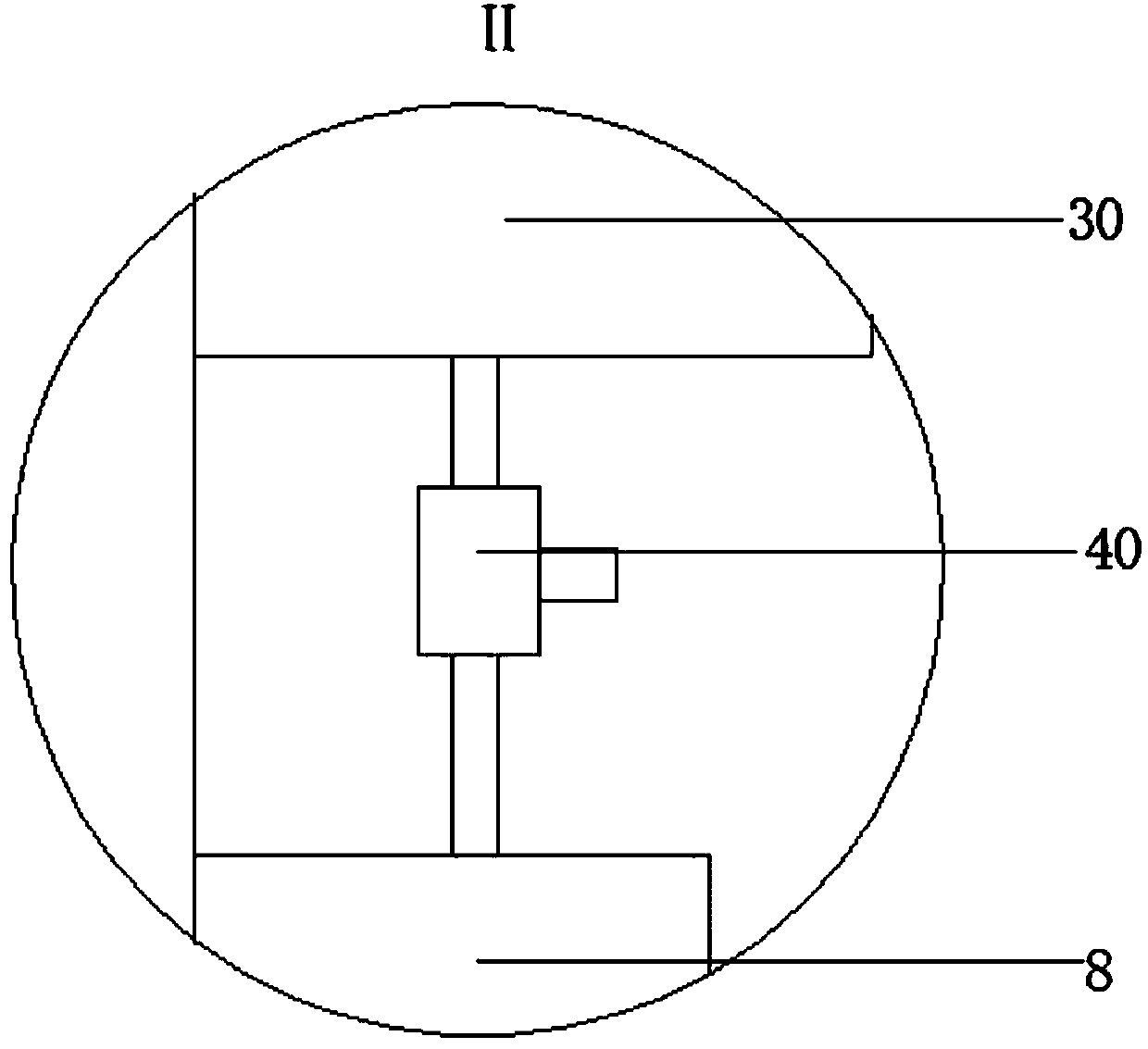

Device for rotating material in material production equipment

InactiveCN104097933AReduce equipment costsShorten the production lineElectrical componentsConveyor partsManufacturing engineeringProduction line

The present invention discloses a device for rotating a material in material production equipment. The device for rotating the material in the material production equipment according to the present invention performs corresponding production processes in the material production equipment serving as single independent equipment for producing predetermined material (such as substrates) and efficiently rotates the material at a predetermined time point. Therefore, the device of the present invention can perform working processes like component mounting for a plurality of faces of the material only through the single material production equipment (such as single substrate production equipment), thereby saving equipment cost required for material production process, reducing production line, and raising required process speed from beginning of the process to end of the process.

Owner:HANWHA TECHWIN CO LTD

Wrapping machine

InactiveCN105711877ACompact structureOptimize layoutWrappingWrapper twisting/gatheringButt jointSmall footprint

The invention discloses a wrapping machine which comprises a lower-layer box sending assembly, a middle-layer film sending assembly, an upper-layer box sending assembly and an upper-layer film sealing assembly. The lower-layer box sending assembly, the middle-layer film sending assembly and the upper-layer box sending assembly are in butt joint in sequence from bottom to top. The upper-layer box sending assembly and the upper-layer film sealing assembly are in horizontal butt joint. The wrapping machine has the beneficial effects of being simple and compact in structure, reasonable in layout, small in occupied area and high in wrapping efficiency.

Owner:TRUKING TECH LTD

Co-production method of polyphenols, pigments, tannin, procyanidins and wood powder through Chinese chestnut buds

InactiveCN105669633AThe dissolution rate is no less thanRetain structureEsterified saccharide compoundsSugar derivativesProanthocyanidinTannin

The invention relates to a co-production method of polyphenols, pigments, tannin, procyanidins and wood powder through Chinese chestnut buds. Chinese chestnut buds are smashed into 30-80 meshes, Chinese chestnut bud powder and alkaline deionized water are added into a tank, subjected to microwave radiation and stirred and extracted for three times, a water extract solution is separated through various films, polyphenols, pigments, tannin, procyanidins and wood powder are obtained after concentration and drying, and filter residues are dried into wood powder. By means of the scheme, comprehensive utilization of waste Chinese chestnut bud resources can be achieved, and the method belongs to the clean and efficient pollution-free ecological mode industry.

Owner:李斌

Novel conveying equipment for garment production

ActiveCN111115141ANot easy to slipWill not be damagedMechanical cleaningPressure cleaningManufacturing lineSizing

Novel conveying equipment for garment production comprises an electric sliding rail of a hanging type conveyer. A plurality of first sliders are installed in the electric sliding rail in a matched mode. First electric telescopic rods with downward movable rods are fixedly installed at the bottoms of the first sliders correspondingly. Vertical plates are hinged to the lower ends of the movable rodsof the first electric telescopic rods. Rectangular blocks are fixedly installed on the front side walls of the movable rods of the first electric telescopic rods. Fifth electric telescopic rods are arranged on the lower sides of the rectangular blocks. Elastic telescopic pipes with closed upper and lower end openings are fixedly installed at the bottoms of the vertical plates through connection rods. Through a reasonable structure, garment sizing, garment dedusting, garment ironing, garment folding, packaging and other series of automatic processing procedures are achieved, a garment production line is shortened, thus the needed plant area and garment production time are reduced, the garment processing process is more automatic, the phenomenon of too many unqualified garment products caused by errors of manual garment treatment is avoided, and garment production quality is improved.

Owner:潜江东颢制衣有限公司

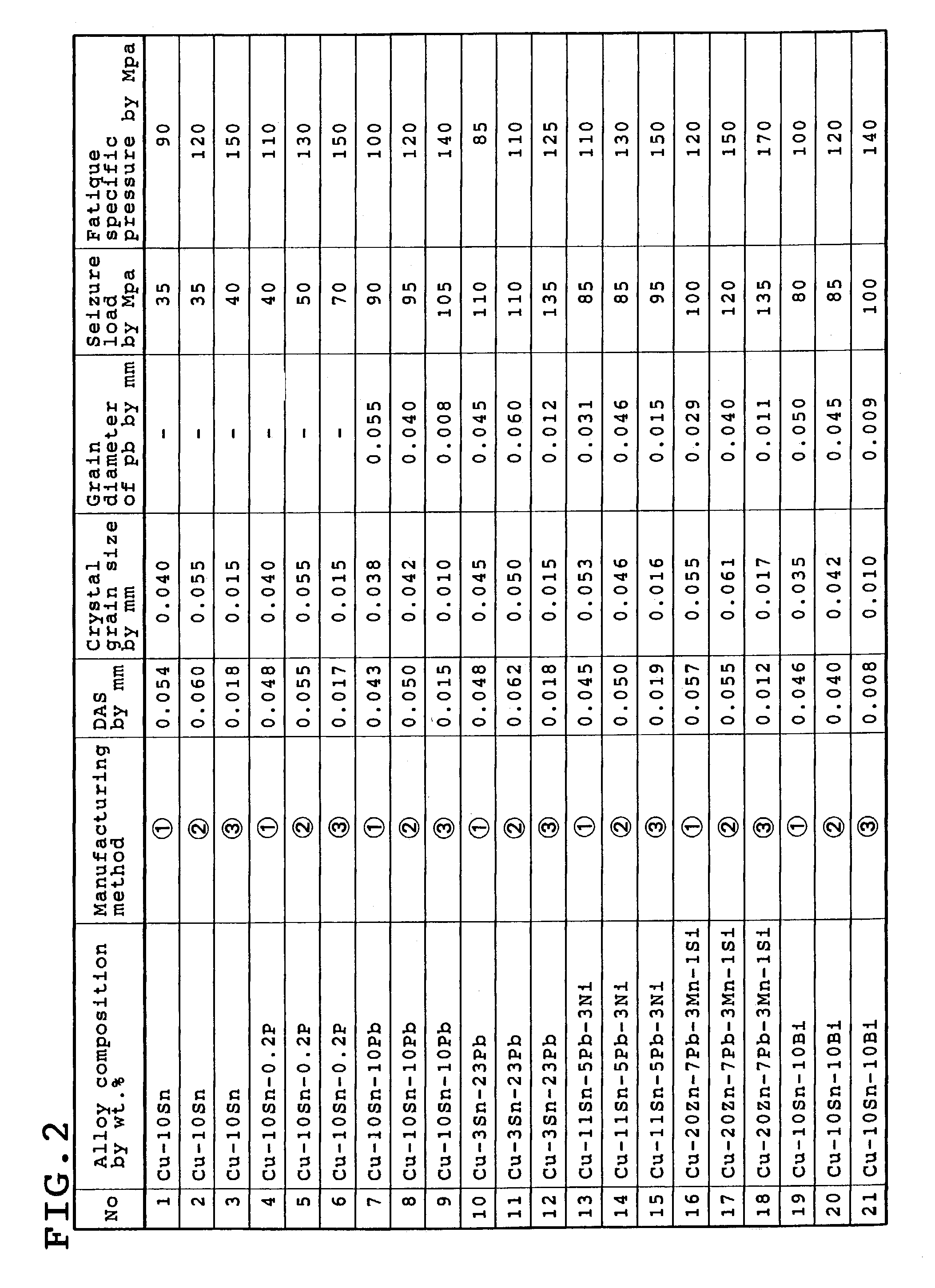

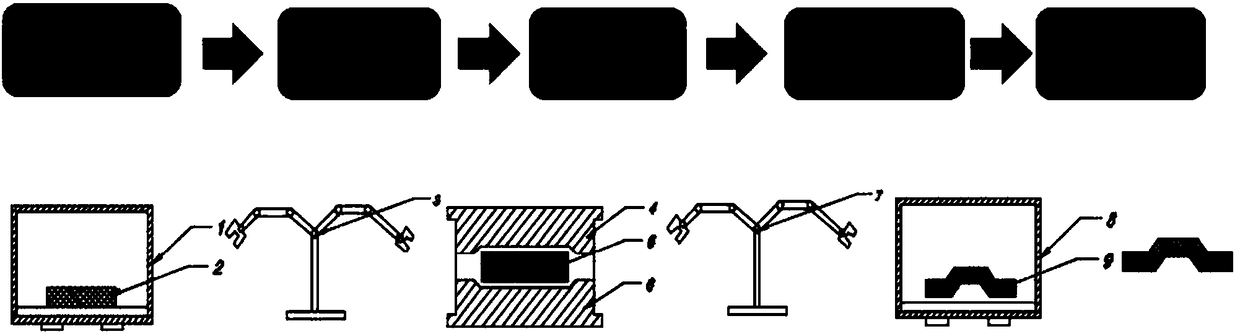

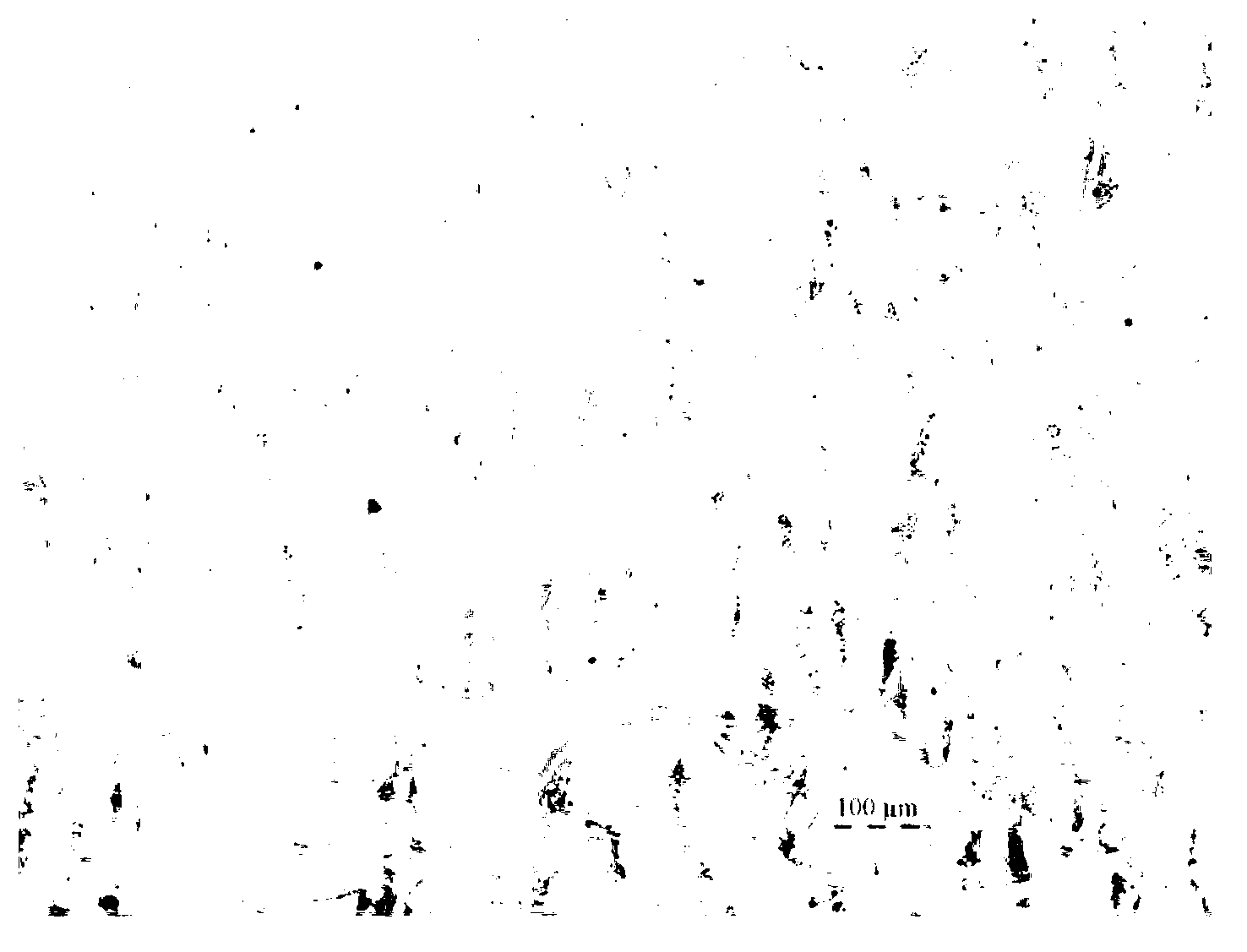

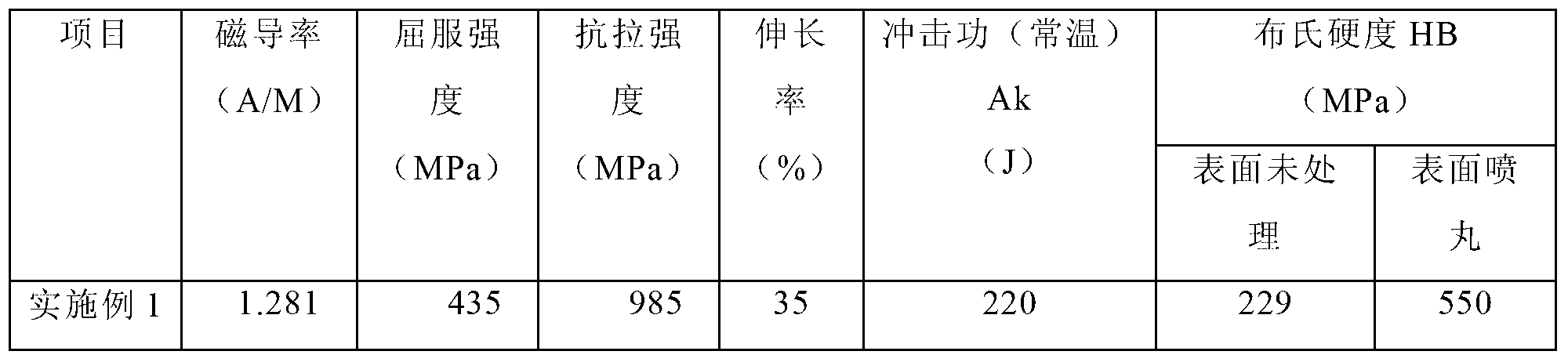

Method of manufacturing multilayer material for plain bearing

A method of manufacturing a multilayer material including a back metal and a metal plate made from a metal differing from the back metal is disclosed. The method includes heating powder of the metal formed into the metal plate in a reducing atmosphere so that an oxide on a surface of the metal powder is deoxidized, and spreading the deoxidized metal powder onto the back metal and irradiating laser beam having an energy density of 10 to 100 kW / cm2 onto the metal powder spread on the back metal so that the metal powder is partially heated to be melted, while the laser beam is moved relative to the spread metal powder, and quenching the melted part of the metal powder at an underside of the back metal so that the melted part is rapidly solidified, whereupon the multilayer material has a dendritic structure in which the metal plate extends substantially vertically from a surface of the back metal, and the dendritic structure has a crystal grain size equal to or smaller than 0.02 mm at a cut surface thereof parallel to a surface of the back metal and / or a dendritic arm spacing equal to or smaller than 0.02 mm at a cut surface thereof vertical to the surface of the back metal.

Owner:DAIDO METAL CO INC

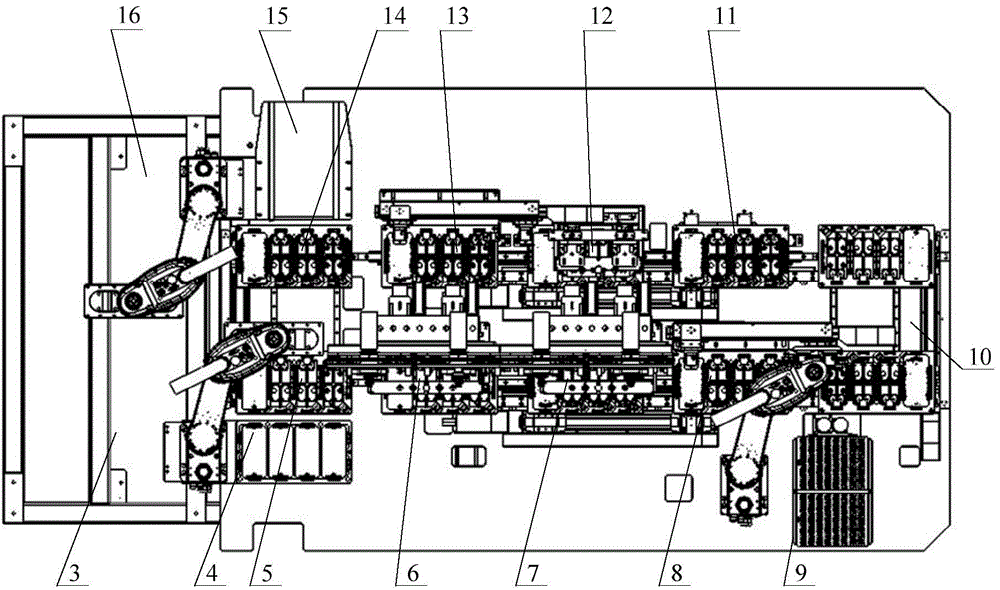

Automatic afflux disk all-in-one welding machine

ActiveCN104708219AImprove spot weld consistencyLower internal resistanceWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingComputer engineering

The invention provides an automatic afflux disk all-in-one welding machine comprising a machine frame platform, an operation and control panel, a feeding trough, a discharging trough and at least one spot welder and further comprises an afflux disk placing device, a round-ring-shaped rotating disk and a fixing disk arranged at the center of the rotating disk. The fixing disk and the rotating disk are both installed on a cam divider. The cam divider is provided with a sensor and installed on the machine frame platform. The cam divider is synchronous with a motor installed on the lower portion of the machine frame platform through a belt, multiple locating troughs are arranged on the periphery of the rotating disk, fixing dies are arranged in the locating troughs, the afflux disk placing device and the spot welders are sequentially installed on the periphery of the rotating disk, each spot welder is provided with at least one spot welding needle, a locating and rotating device is arranged below the rotating disk and is opposite to the spot welding needles, and an afflux disk bending device is arranged at the rear end of the afflux disk placing device. The automatic afflux disk all-in-one welding machine achieves automatic production and reduces labor cost.

Owner:YIYANG CORUN BATTERY

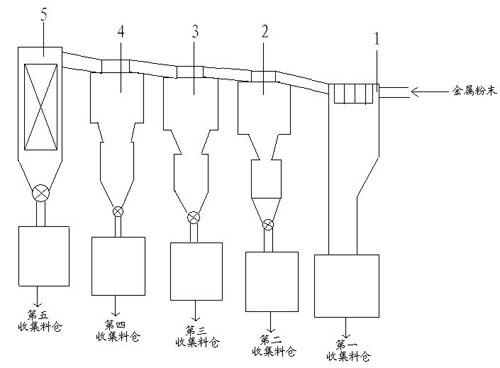

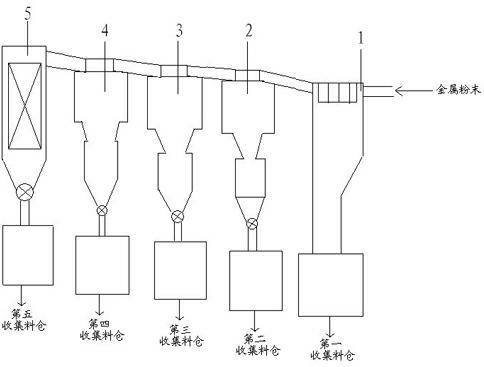

Method for separating metal powder off line

InactiveCN102380480AUniform particle sizeImprove product qualityGas current separationCycloneMaterial resources

The invention provides a method for separating metal powder off line, which is used for multi-pass classification of the metal powder to form products with different particle sizes. The method comprises the following steps that: the metal powder is classified by a classifier, and the metal powder with a first particle size enters a first collecting bin; the residual metal powder enters a first-stage cyclone classifier, and the metal powder with a second particle size enters a second collecting bin; the residual metal powder enters a second-stage cyclone classifier, and the metal powder with a third particle size enters a third collecting bin; the residual metal powder which passes through the second-stage cyclone classifier enters a third-stage cyclone classifier, and the metal powder with a fourth particle size enters a fourth collecting bin; and the residual metal powder enters a dust removing box, and the metal powder with a fifth particle size enters a fifth collecting bin. By the method for separating the metal powder off line, the production speed is improved, the particle size distribution of the products is narrower, the particle size of the powder is more uniform, the aims of improving product quality and enriching product specifications are fulfilled, and manpower and material resources are saved.

Owner:SUZHOU DIAMOND METAL POWDER

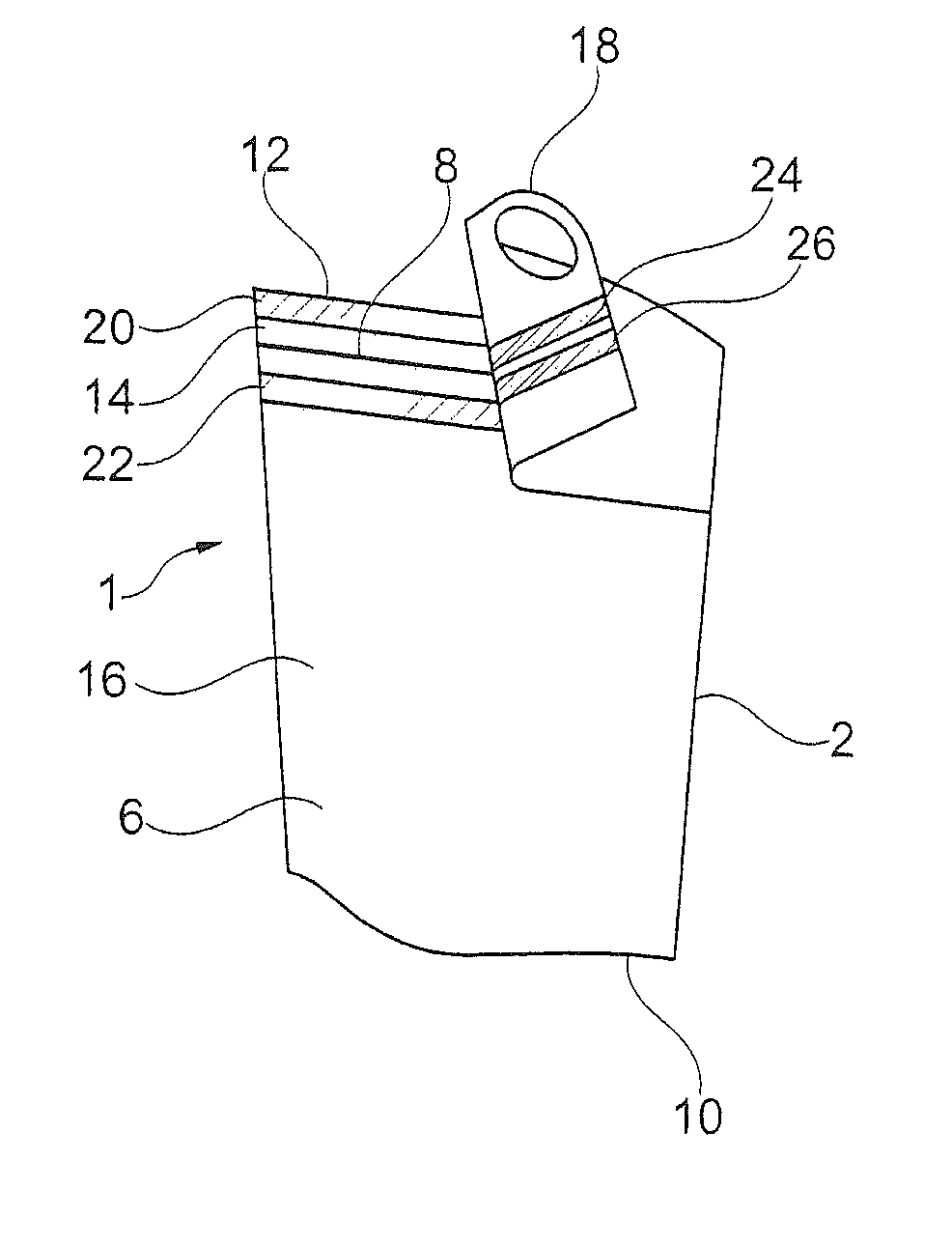

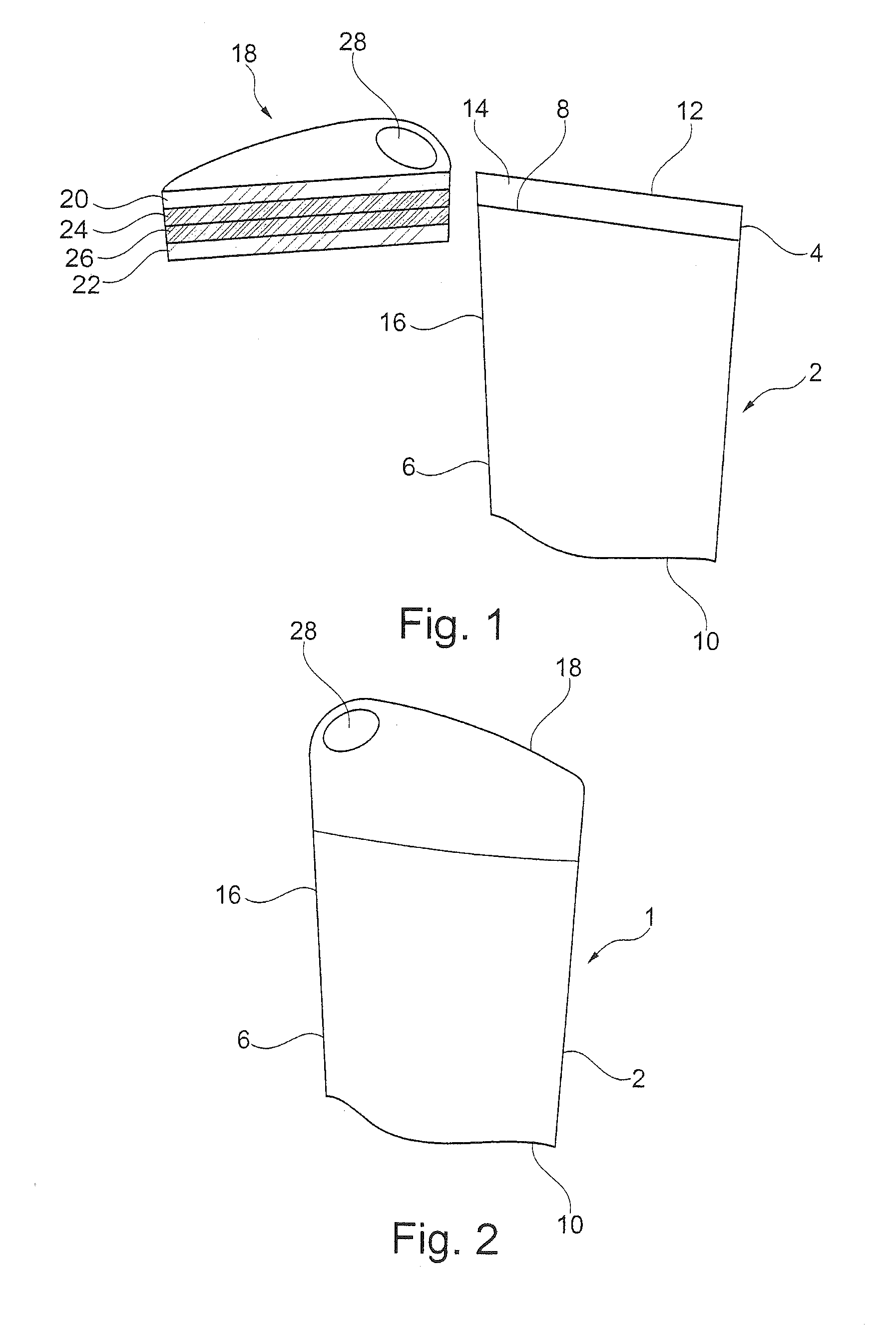

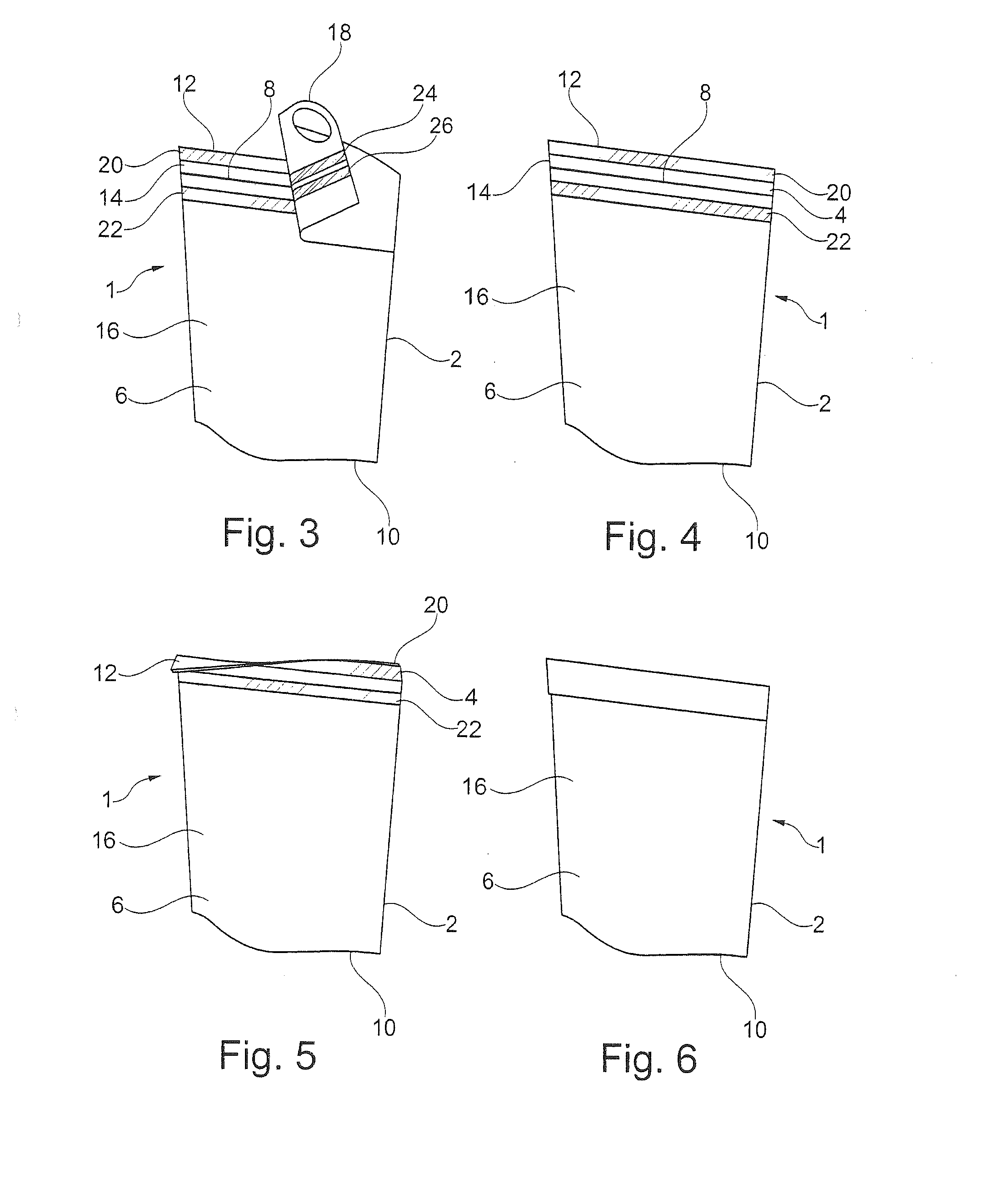

Resealable package, method for producing the resealable package and apparatus for producing the resealable package

ActiveUS20150055892A1Simple processIncrease coefficient of frictionBag making operationsBox making operationsEngineeringMechanical engineering

The invention relates to a resealable package (1, 1′, 1″), comprising a package body (2) having a first side wall (4), a second side wall (6) opposite the first side wall (4), an openable top end (8) and a closed bottom end (10), wherein a portion (12) of the first side wall (4) protrudes beyond the second side wall (6) at the top end (8) in a direction from the bottom end (10) to the top end (8), and a closure element (18) which is releasably adhered to an inner surface (14) of the portion (12) of the first side wall (4) which protrudes beyond the second side wall (6) and the second side wall (6) so as to close the top end (8), Upon removal of the closure element (18) from the package body (2), a resealable adhesive arrangement (20, 22; 23; 25) is exposed so as to allow the inner surface (14) of the portion (12) of the first side wall (4) which protrudes beyond the second side wall (6) and an outer surface (16) of the second side wall (6) to be resealably adhered to one another in a position to close the top end (8). Further, the invention relates to a method and an apparatus (100) for producing the resealable package (1, 1′, 1″).

Owner:INTERCONTINENTAL GREAT BRANDS LLC

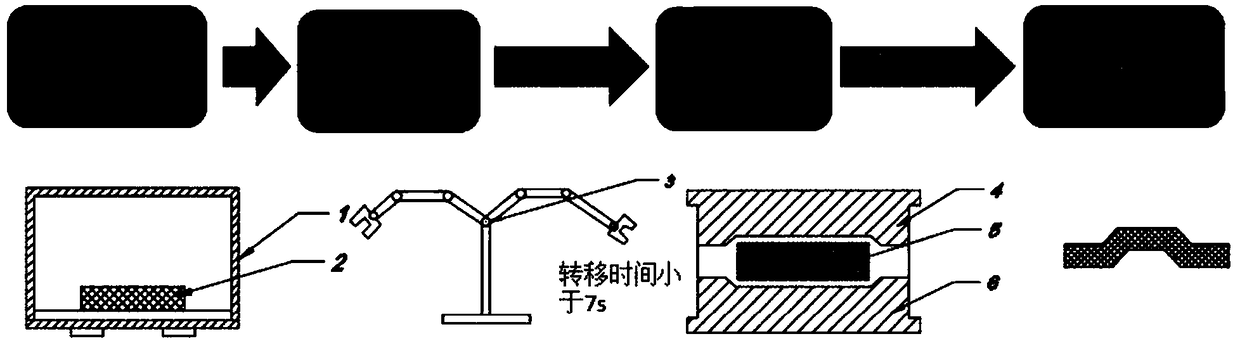

Machining method of lightweight aluminum alloy chassis part

PendingCN108405773AImprove plasticityShorten production timeMetal-working apparatusHeating timeRoom temperature

The invention relates to a machining method of a lightweight aluminum alloy chassis part. A T6 state aluminum alloy is used as a blank for blanking, the blank is heated in a heating device till temperature is lower than the solid solution temperature by 50-150 DEG C; the heating time and the heat preserving time are 3-30 min, a mold is heated to 300-550 DEG C, and the blank is transferred into themold and made to form a forged piece; then the forged piece is taken out and subjected to water quenching till room temperature is achieved; and then the forged piece is subjected to edge cutting after cooling, machining treatment is performed, and a final product is obtained. Because the blank is the aging hardened state aluminum alloy, it is not needed to perform subsequent solid solution agingheat treatment reinforcing essential for a traditional hot die forging process, and therefore the forming production period is shortened, and the production efficiency is greatly improved; and meanwhile, the using performance of products can be guaranteed, and cost is also reduced.

Owner:WUHAN UNIV OF TECH

Production method and production device for vinyl acetate resin copolymer packaging film

The invention discloses a production method and a production device for an EVA diaphragm of a photovoltaic cell packaging film, wherein a heating radiator is additionally arranged between a flat die orifice and a cooling and forming roller to heat the diaphragm from the flat die first and then processes such as subsequent forming, drawing, rolling and the like are carried out so that unilateral stretching occurs in a special temperature range to enlarge the openness of the flat die. Thickness of the diaphragm is determined by a certain extension ratio and stress memory is eliminated by temperature in the stretching process so that the diaphragm is crosslinked appropriately to achieve high-speed production of a low shrink hot-melt film. The invention has the advantages of low cost of device, simple production process and capability of improving the capacity to a great extent and the like.

Owner:徐维军

Processing equipment of upper and lower membrane integrated packing bag and processing method of upper and lower membrane integrated packing bag

PendingCN109955532AReduce generationImprove firmnessBag making operationsPaper-makingBiomedical engineeringWaste material

The invention discloses processing equipment of an upper and lower membrane integrated packing bag and a processing method of the upper and lower membrane integrated packing bag, and relates to the technical field of packing bag processing equipment. The processing equipment of the upper and lower membrane integrated packing bag mainly comprises a main membrane conveying device, a lateral organ membrane conveying device, a lateral organ membrane folding device, a main membrane folding device, a tangent line device, a spot scalding device, a template forming device, a lateral organ angle-breaking device and a cutting device. According to the processing equipment of the upper and lower membrane integrated packing bag and the processing method of the upper and lower membrane integrated packing bag, a simple layer membrane is adopted as a packing bag raw material, a production mode of two-layer membranes adopted in traditional packing bag processing is replaced, the two-layer membranes arenot required to be pressed and scalded, the problem of deflection or unstable pressing occurring to press fit positions of the packing bag cannot be caused, and the firmness of the finished packing bag is greatly improved; and the simple layer membrane is adopted as the raw material, the material loss of the packing bag is reduced to the minimum, and generation of a large number of waste materials caused by edge cutting is reduced in the production process of the packing bag.

Owner:SHANGHAI ZHOUTAI LIGHT IND MACHINE MFG

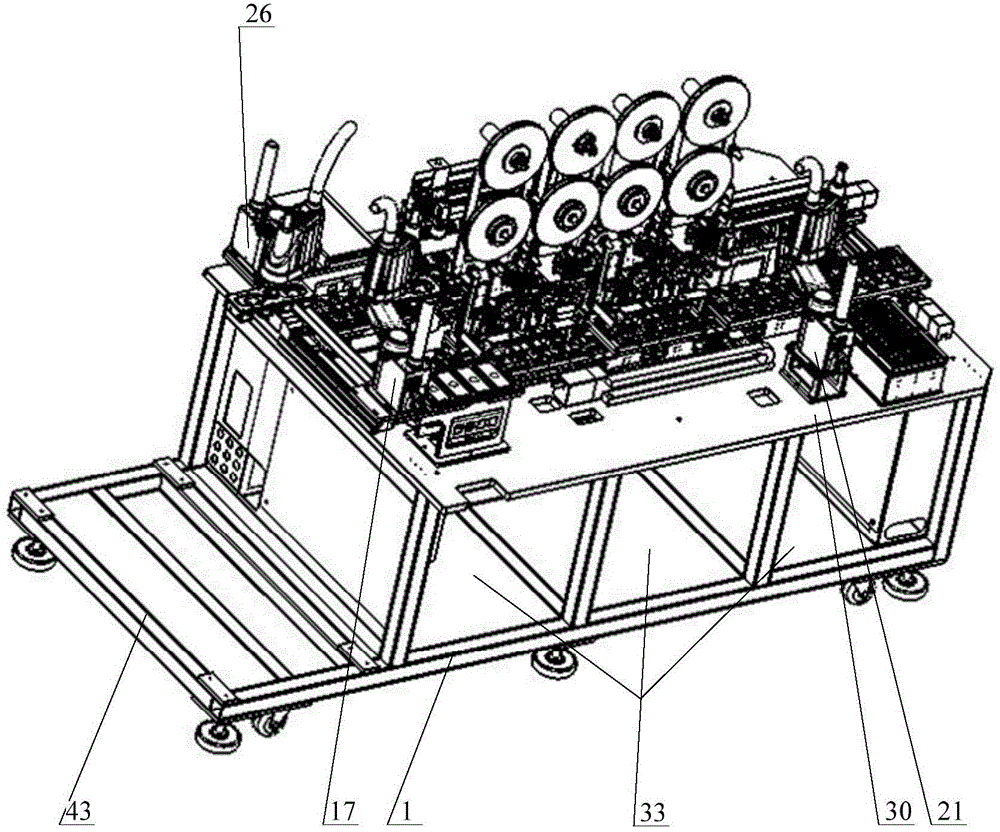

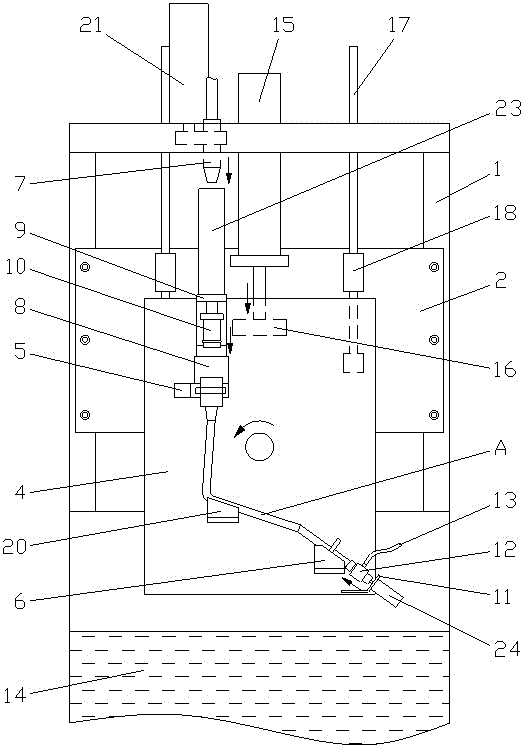

Full-automatic nail-connecting and winding all-in-one machine

InactiveCN105590761AReduce maintenance difficultyReduce occupancyWinding capacitor machinesTerminal applying apparatusWinding machineMetallurgy

The invention relates to a full-automatic nail-connecting and winding all-in-one machine which is used for connecting guiding pins with an anode aluminum foil and a cathode aluminum foil in a nail-connecting manner and winding the anode aluminum foil and the cathode aluminum foil after nail-connecting and electrolytic paper. The full-automatic nail-connecting and winding all-in-one machine is characterized in that the full-automatic nail-connecting and winding all-in-one machine comprises an anode nail-connecting machine, a cathode nail-connecting machine and a winding machine; the anode nail-connecting machine is fixedly connected with the upper end or the lower end of the cathode nail-connecting machine; the anode nail-connecting machine and the cathode nail-connecting machine are arranged at one side of the winding machine; a first conveying mechanism for conveying the anode aluminum foil after nail-connecting to the winding machine for realizing winding is arranged between the anode nail-connecting machine and the winding machine; and a second conveying mechanism for conveying the cathode aluminum foil after nail-connecting to the winding machine for realizing winding is arranged between the cathode nail-connecting machine and the winding machine. The full-automatic nail-connecting and winding all-in-one machine has advantages of small occupation space, convenient operation and convenient maintenance.

Owner:SHENZHEN JINLIANXIN TECH CO LTD

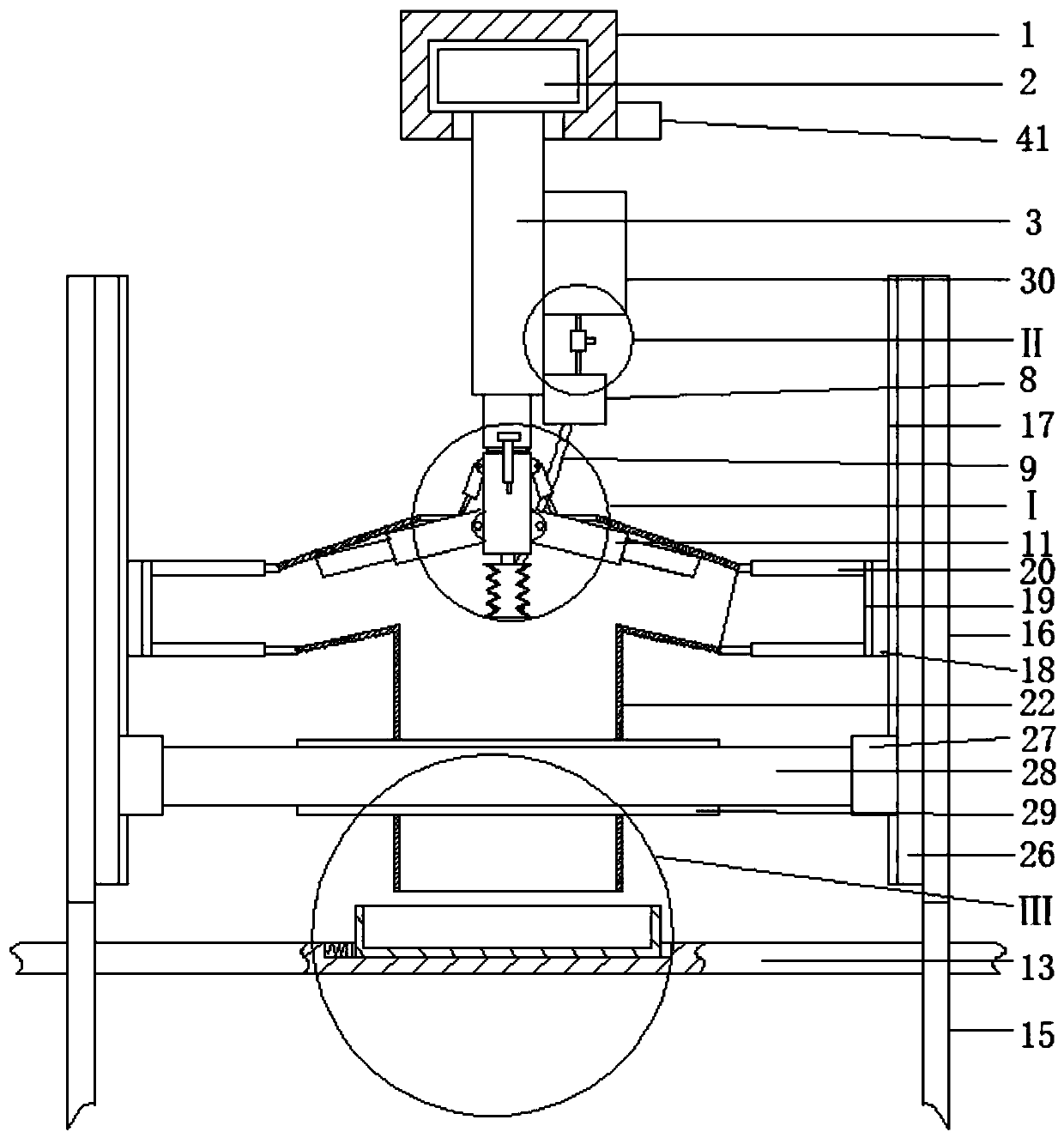

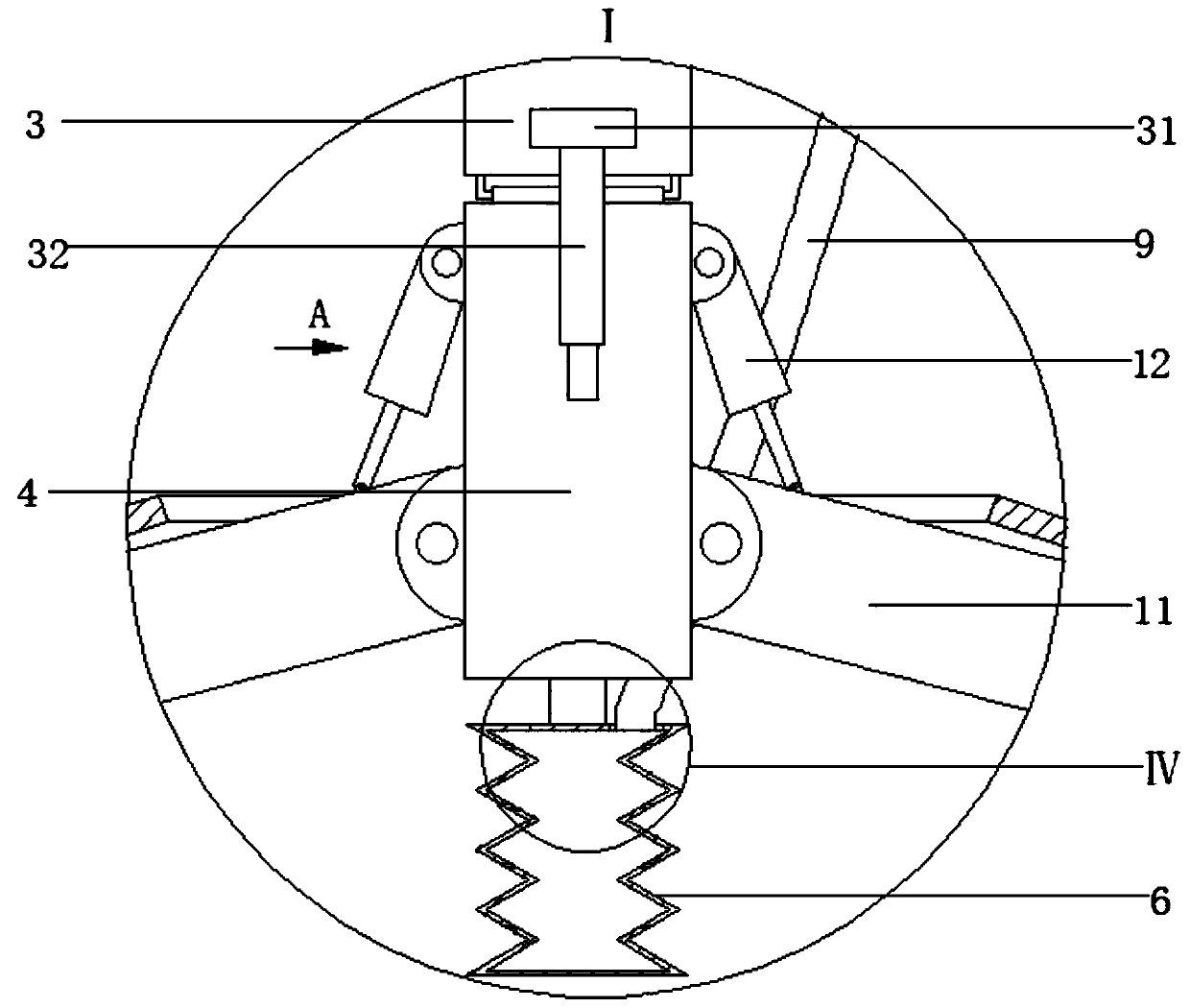

Inner cleaning and airtightness detecting device for oil filling pipe, and method thereof

InactiveCN104977135AShorten the production lineLow costDetection of fluid at leakage pointEngineeringHigh pressure

The invention relates to an inner cleaning and airtightness detecting device for an oil filling pipe, and a method thereof. The method comprises the following steps: (1) fixing, namely respectively fixing the upper end and the lower end of the oil filling pipe with an upper clamping seat and a lower clamping seat; (2) cleaning, namely making a high-pressure jet head to an appropriate position for extending into the upper port of the oil filling pipe, then starting a high-pressure water pump for cleaning the inner part of the oil filling pipe, and after cleaning is finished, making the high-pressure jet head rise to an original position; (3) plugging, namely making a slide carriage frontwards move to an appropriate position so that an upper plugging head is aligned with the upper port of the oil filling pipe, then making the upper plugging head fall to an appropriate position for plugging the upper port of the oil filling pipe, and simultaneously making a lower plugging head perform oblique upward movement for plugging the lower port of the oil filling pipe; (4) inflating, namely starting an air pump and performing inflation on the inner part of the oil filling pipe through the lower plugging head; and (5) immersing, namely rotating a rotating board for 180 DEG so that the upper end of the oil filling pipe is arranged at the lower part, then making a sliding board fall for immersing the upper end of the oil filling pipe into a water tank. The inner cleaning and airtightness detecting device for the oil filling pipe and the method have advantages of novel design, compact structure, low production cost and high detecting efficiency.

Owner:FUZHOU NOBLE FUJI MECHANICAL & ELECTRICAL LIMITED

Machining technology and machining equipment for riveting base boards and caster axles of oil heaters

InactiveCN103394601AReduce the number of handlingReduce labor intensityMetal-working feeding devicesPositioning devicesAssembly lineEngineering

The invention discloses machining equipment for riveting base boards and caster axles of oil heaters. The machining equipment comprises an automatic riveting machine, a vibration disc and an automatic loading machine. The vibration disc is used for assembling caster axles and a base board body to form a base board combination, and the automatic loading machine is used for conveying the base board combination to the automatic riveting machine and penetrates the automatic riveting machine and the vibration disc. The machining equipment for riveting the base boards and the caster axles of the oil heaters has the advantages that the base board combination can be assembled, automatically loaded, riveted and unloaded under the matched actions of the vibration disc, the automatic loading machine and the automatic riveting machine, only the caster axles need to be placed into the vibration disc, and the base board body is placed into the automatic loading machine, so that the base board combination can be assembled, automatically loaded, riveted and unloaded without being repeatedly carried, the base board combination carrying frequency and the labor input are reduced, an assembly line is shortened, the production efficiency is improved for products, the yield of the products is increased, the labor intensity of workers is reduced, and the production cost is lowered.

Owner:NINGBO SINGFUN ELECTRIC APPLIANCE

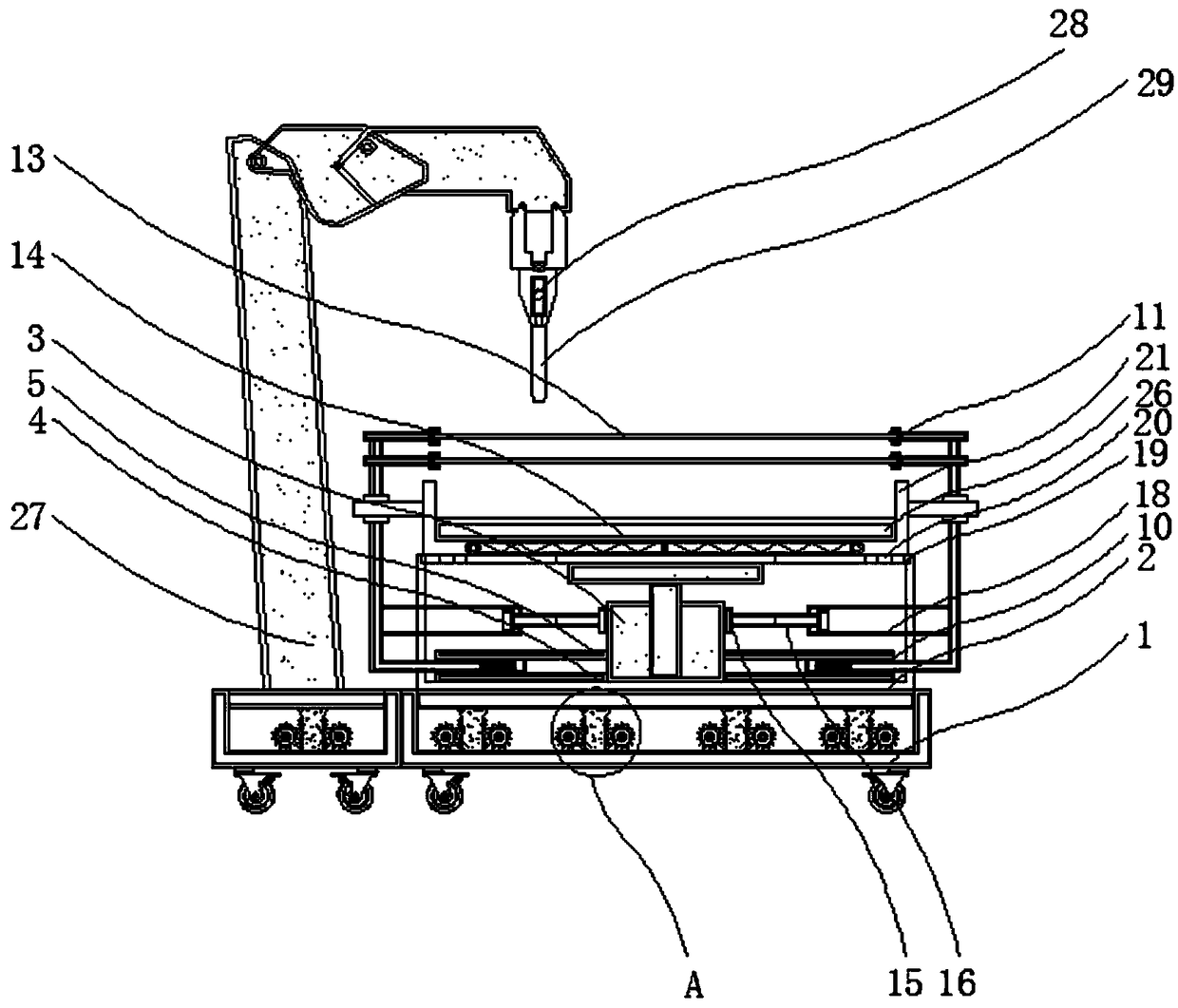

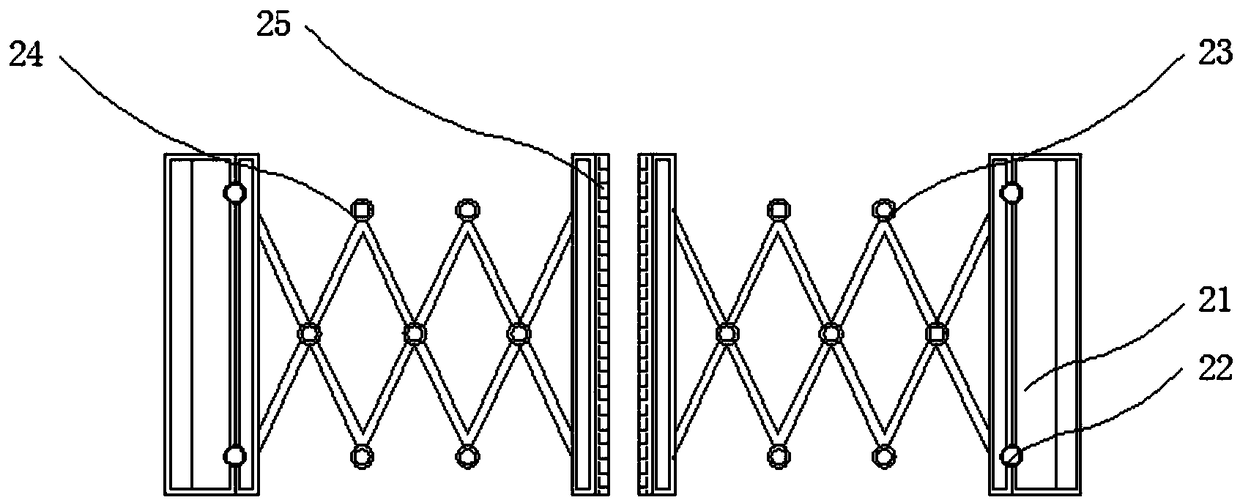

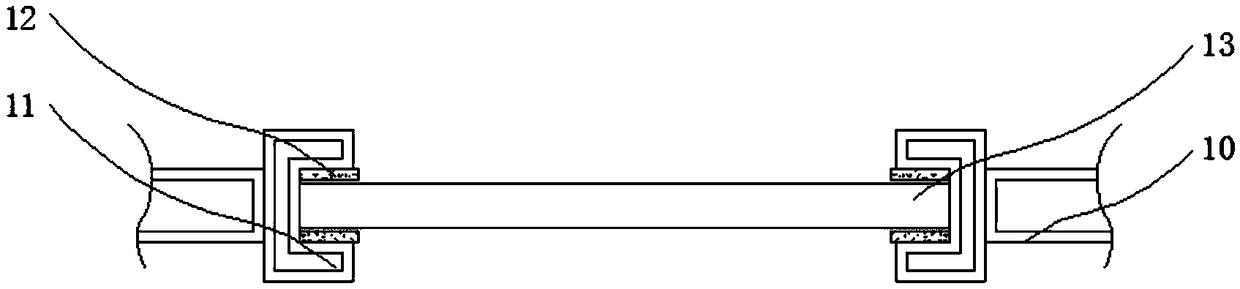

Stable intelligent engraving and etching equipment with anti-dithering function

ActiveCN109466218AWith anti-shake functionHas developedDecorative surface effectsModel makingLaser etchingABSORPTION BASE

The invention discloses stable intelligent engraving and etching equipment with an anti-dithering function, and relates to the technical field of the metal etching, in particular to a shock absorptionbase and an intelligent rotary mechanical arm. A worktable is fixedly welded to the upper end of the shock absorption base. A telescopic sleeve is fixedly welded on the upper end of the side wall ofa compression resistance column. A guide connecting strip is arranged on the top end of a connecting rod. The edge of the top end of the worktable is provided with a sliding groove. A positioning strip is fixedly welded on the top end of a sliding block. The intelligent rotary mechanical arm is arranged on the left of the worktable. The output end of a laser is electrically connected with a laseretching head. A shock absorption rod is arranged inside the shock absorption base. By means of the stable intelligent engraving and etching equipment with the anti-dithering function, a moving block can be moved under the action of external thrust, and the moving block can be firmly fixed in a certain position through the interaction between a lock groove and a lock block, so that the distance between moving rods is advantageously adjusted.

Owner:临沂鹏泰新型建材合伙企业(有限合伙)

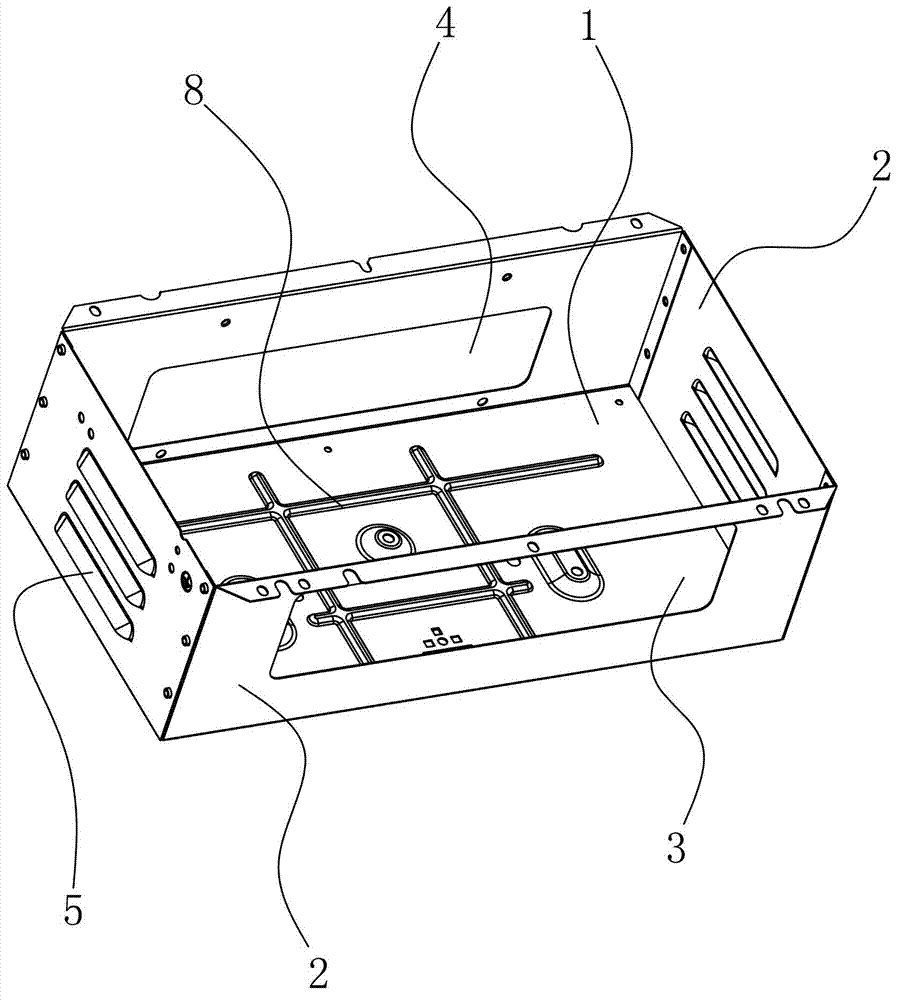

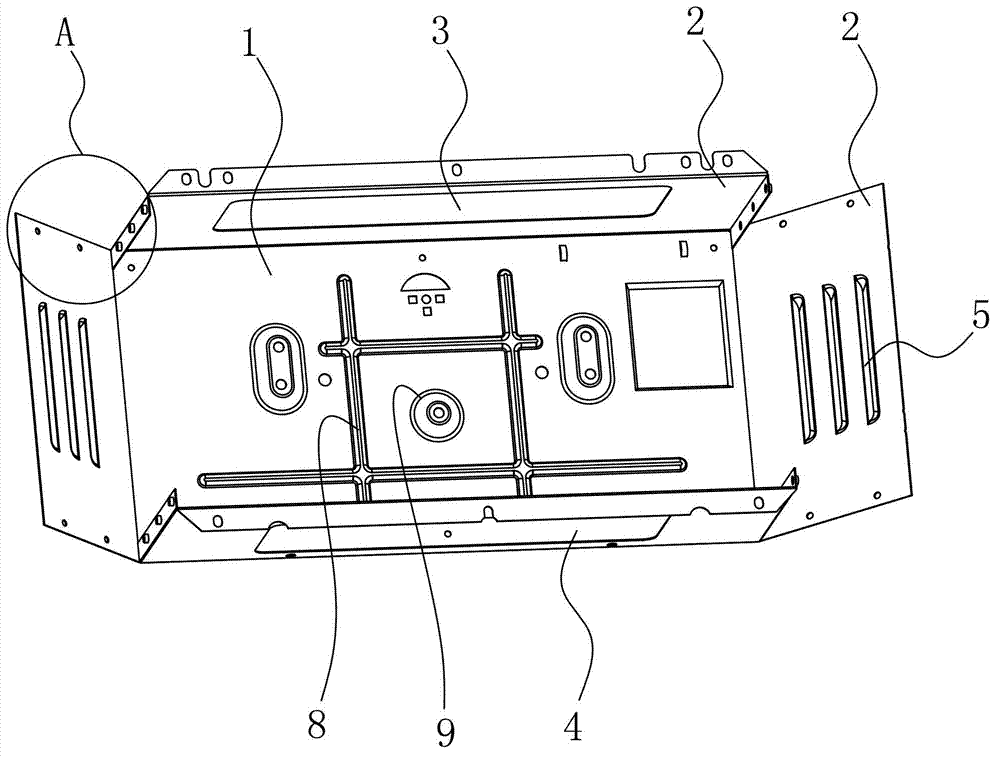

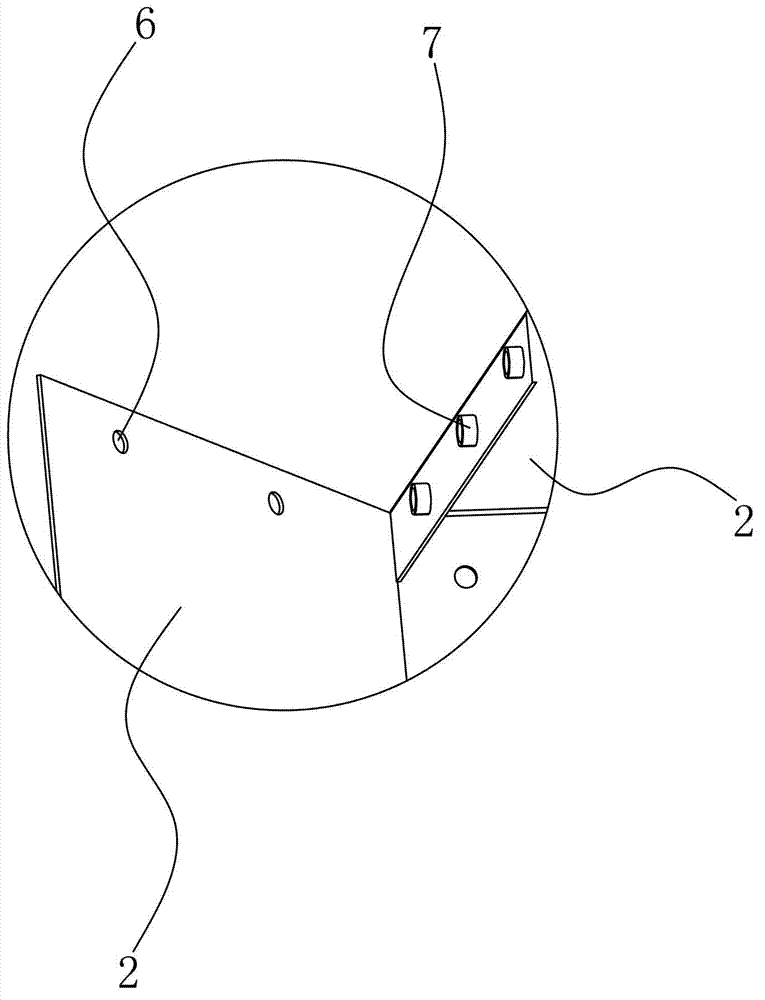

Fan box, die and machining technology for machining fan box

The invention discloses a fan box which comprises a body. An air inlet, an air outlet and a heat dissipation hole are respectively arranged on the body; a reinforcing rib and a fan mounting position are also arranged on the body; and the body adopts integral punch forming. The fan box has the benefits that the structure is simple, the fan box is convenient and rapid to manufacture and adopts integral punch riveting forming, all side plates and a bottom plate form an integral structure, all the side plates are fixed through riveting, compared with the traditional welding, the connection is firmer, the sealing effect is better, and simultaneously, the production efficiency and the yield of products are greatly improved.

Owner:NINGBO SINGFUN ELECTRIC APPLIANCE

Spacer arrangement with fusable connector for insulating glass units

ActiveUS20100275538A1Improve joint strengthShorten the production lineLamination ancillary operationsLaminationInterior spaceInsulated glazing

A spacer frame arrangement for insulating glass units, comprising a spacer profile body extending in a first direction and having a predetermined cross section in a plane perpendicular to the first direction, the predetermined cross section defining a hollow inner space of the spacer profile body with predetermined dimensions in the plane perpendicular to the first direction, and a connector comprising a connector section adapted to be inserted in the first direction into the hollow inner space of the spacer profile body by having a cross sectional shape perpendicular to the first direction which corresponds, with predetermined tolerances, to the cross section of the spacer profile body limiting the hollow inner space, at least the outer surface of the connector section facing the inner surface of the hollow inner space of the spacer profile body after insertion of the same being made of a fusable material, preferably a material fusable by melting the same, wherein the connector section is inserted into the hollow inner space of the spacer profile body and the outer surfaces of the connector section and the inner surface of the spacer profile body facing each other are connected by fusing.

Owner:TECHNOFORM GLASS INSULATION HLDG

Online high manganese steel toughening heat treatment method

ActiveCN103266214AReduce consumptionShorten the production lineHeat treatment process controlWater resourcesRoom temperature

The invention discloses an online high manganese steel toughening heat treatment method and belongs to the field of online steel heat treatment. According to the method, hot-rolled steel is directly cooled to room temperature on line, wherein the finishing rolling temperature of the steel is over 950 DEG C, the difference between the initial online cooling temperature and the finishing rolling temperature of the steel is 0-10 DEG C, and the cooling speed is 50-70 DEG C per second. According to the process, a product can achieve the required excellent performance, and a large amount of energy and a large quantity of water resources can be saved; and meanwhile, the production process is greatly simplified, the production efficiency is improved, and the production cost is reduced.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com