Production method and production device for vinyl acetate resin copolymer packaging film

A production method and vinyl resin technology are applied in the field of production equipment for acetic acid-vinyl resin copolymer packaging films, which can solve the problems of difficulty in controlling the flatness of the film after tempering, increase in equipment costs, doubts about feasibility, and the like, and achieve shrinkage. rate reduction, lower equipment cost, and eliminate the effect of stretch memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

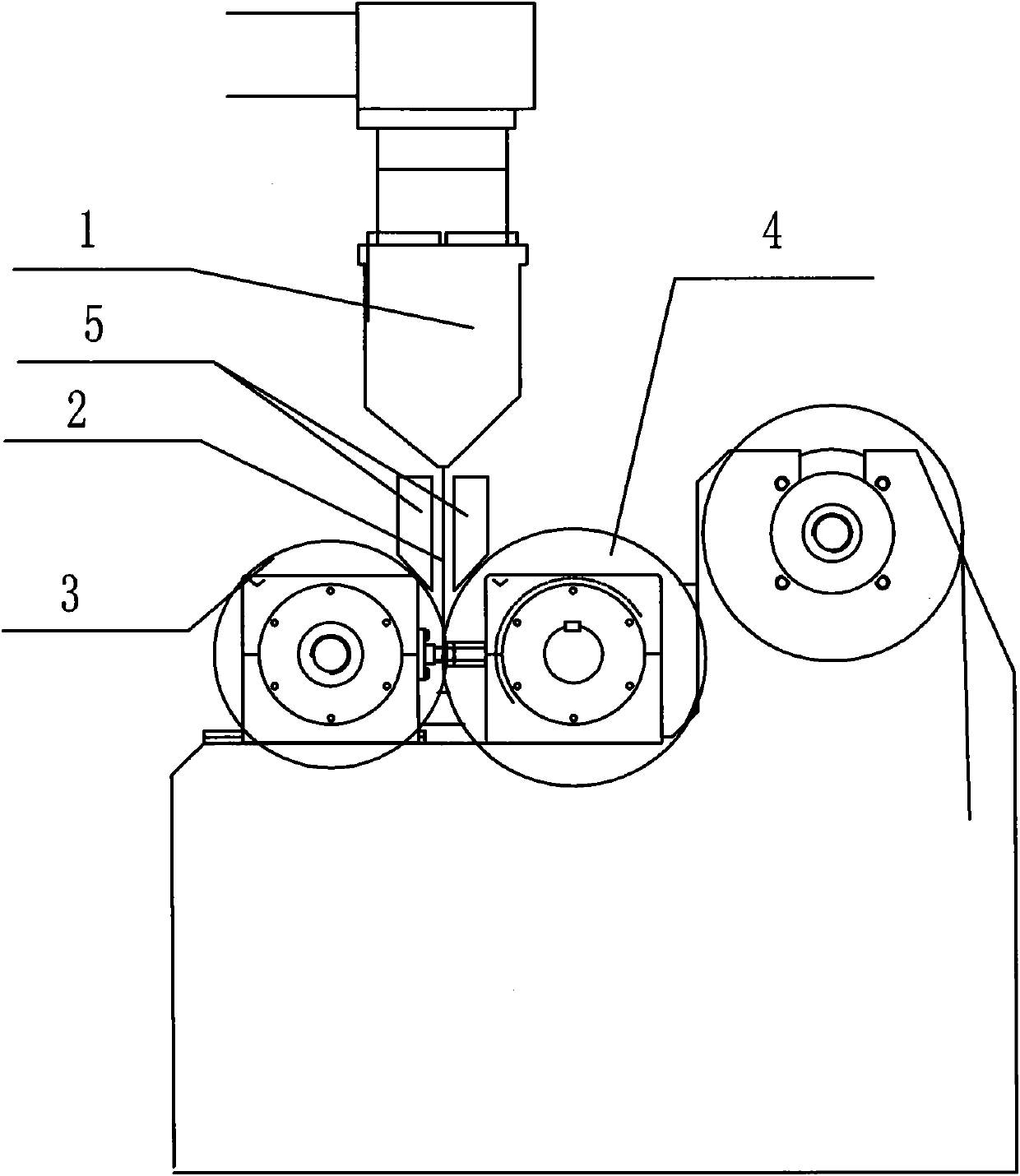

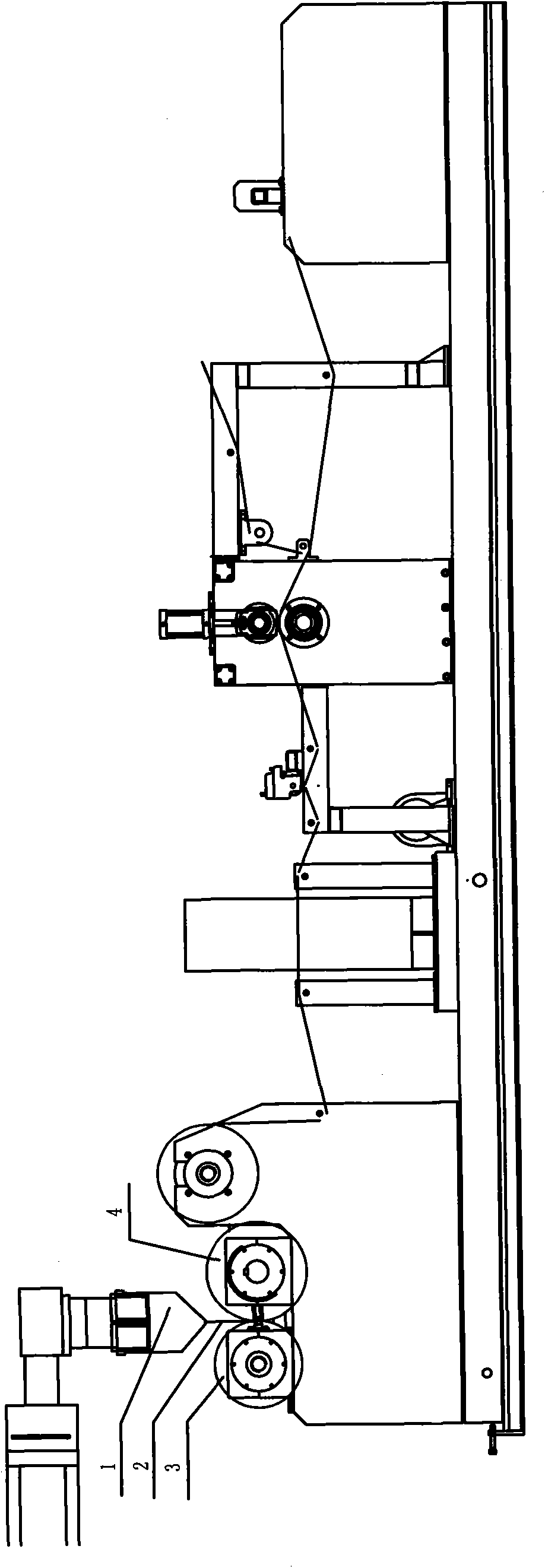

[0030] as attached figure 2 As shown, the production equipment of the acetic acid-vinyl ester copolymer packaging film of the present invention comprises a flat mold 1, a silica gel pressure roll 3, an embossed cold roll 4, the silica gel pressure roll 3 and the embossed cold roll 4 are circumscribed, and the silica gel The connecting line between the center of the pressure roller 3 and the embossing cold roller 4 is horizontal, the flat mold 1 is located directly above the tangent point between the silicone pressure roller 3 and the embossing cold roller 4, and the embossing cold roller 4 and the silicone pressure roller 3 are at the same point of tangency The tangent line of the flat mold 1 is on the diaphragm 2, and the distance from the tangent line from the die lip of the flat mold 1 to the silicone pressure roller 3 and the embossing cold roller 4 is about 350mm. Infrared heating devices 5 are installed on both sides of the diaphragm between the tangent lines of 4; the ...

Embodiment 2

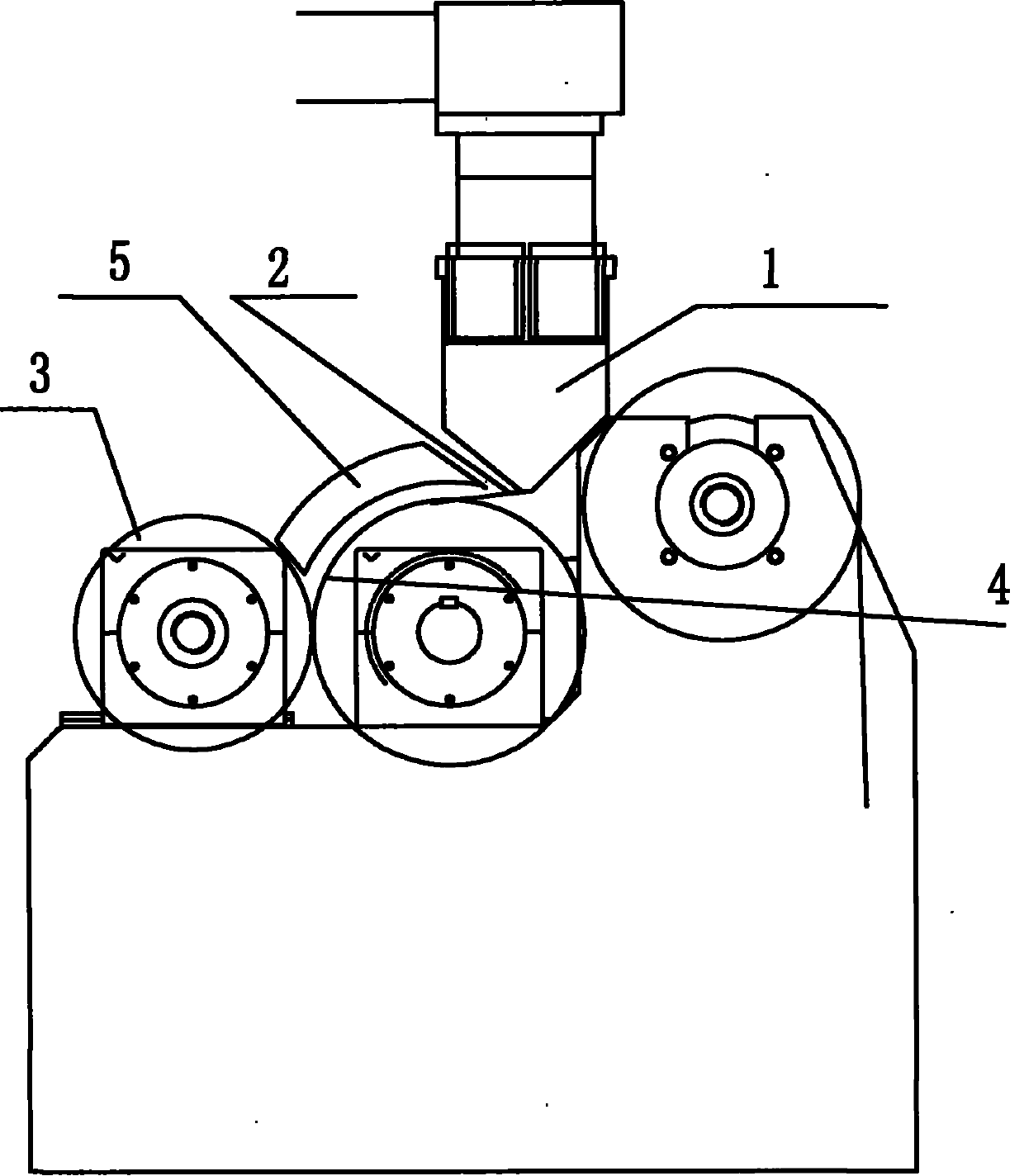

[0033] as attached image 3 As shown, the production equipment of the acetic acid-vinyl ester copolymer packaging film of the present invention comprises a flat mold 1, a silica gel pressure roll 3, an embossed cold roll 4, the silica gel pressure roll 3 and the embossed cold roll 4 are circumscribed, and the silica gel The connecting line between the center of the embossing cold roll 3 and the embossing cold roll 4 is horizontal, and the flat mold 1 is located above the embossing cold roll 4, from the contact point between the diaphragm 2 and the embossing cold roll 4 until the embossing cold roll 4 is in contact with the silicone pressure roll 3 An infrared heating device 5 is installed on the outside of the embossing cold roll 4 between the cuts; the diaphragm 2 is heated by the heating device 5 to keep the fluidity of the diaphragm 2 good, which effectively improves the production efficiency. The opening of the die opening of the mold 1 is increased correspondingly at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com