Fan box, die and machining technology for machining fan box

A technology for fans and stamping dies, used in forming tools, manufacturing tools, machines/engines, etc., can solve the problems of high spot welding process requirements, low qualification rate of fan boxes, low productivity, etc., to reduce labor intensity and production costs. , the effect of shortening the production line and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

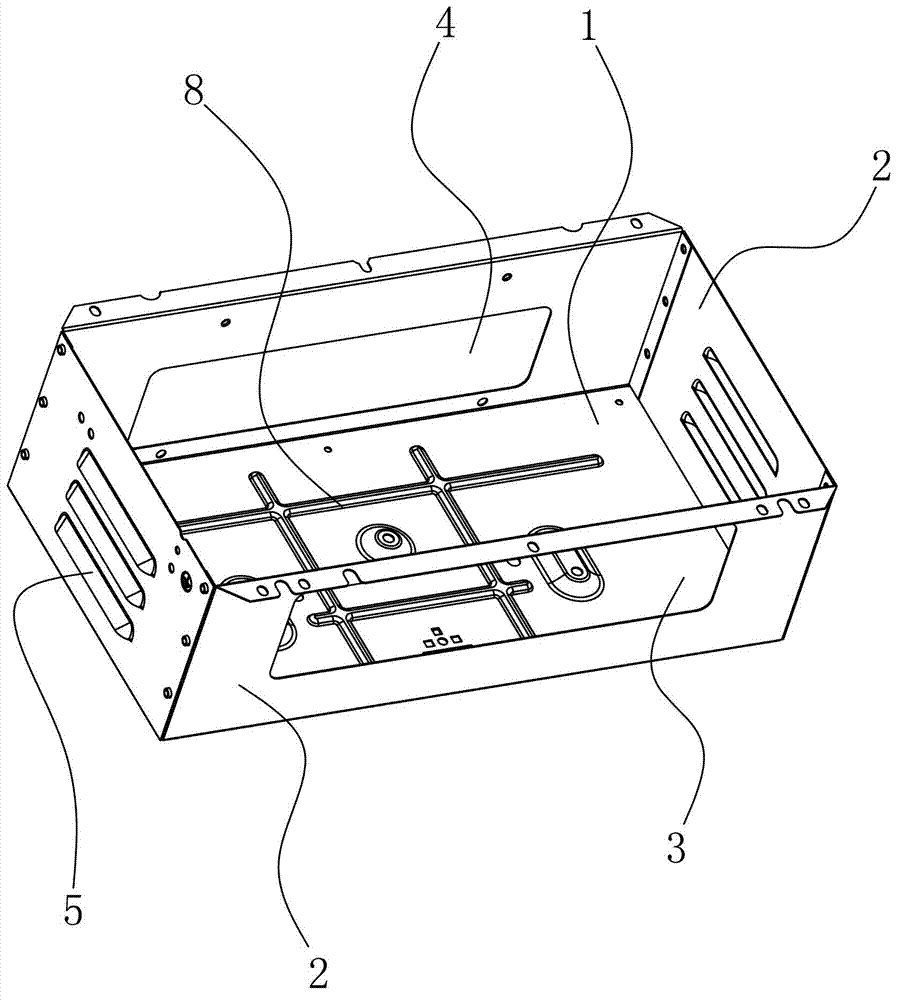

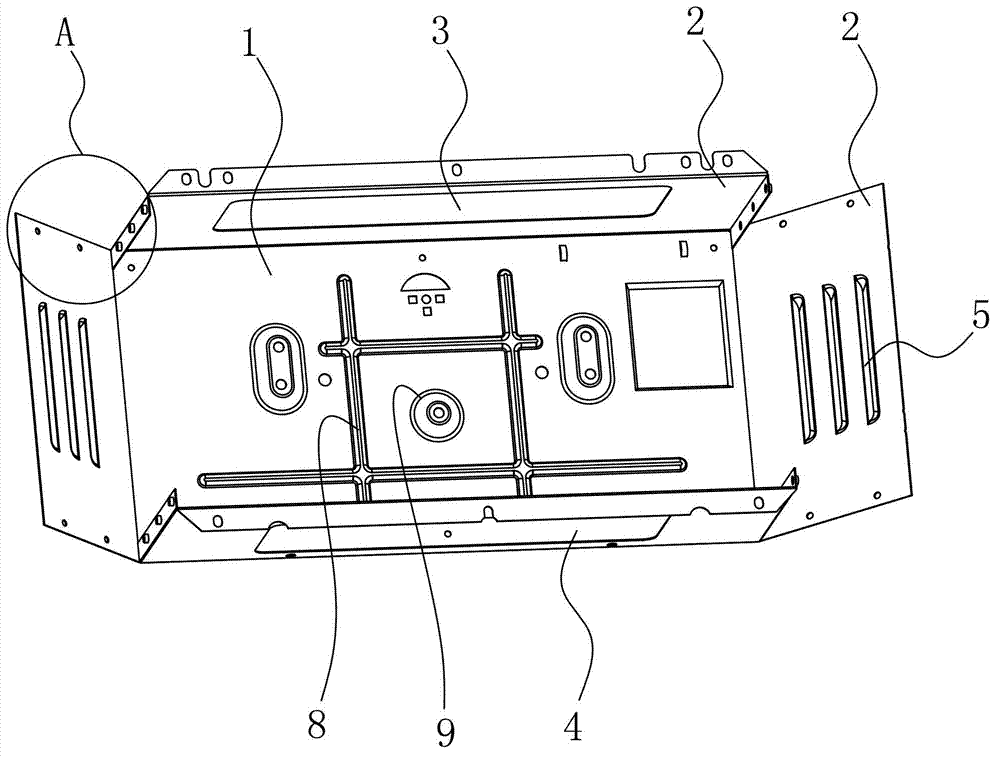

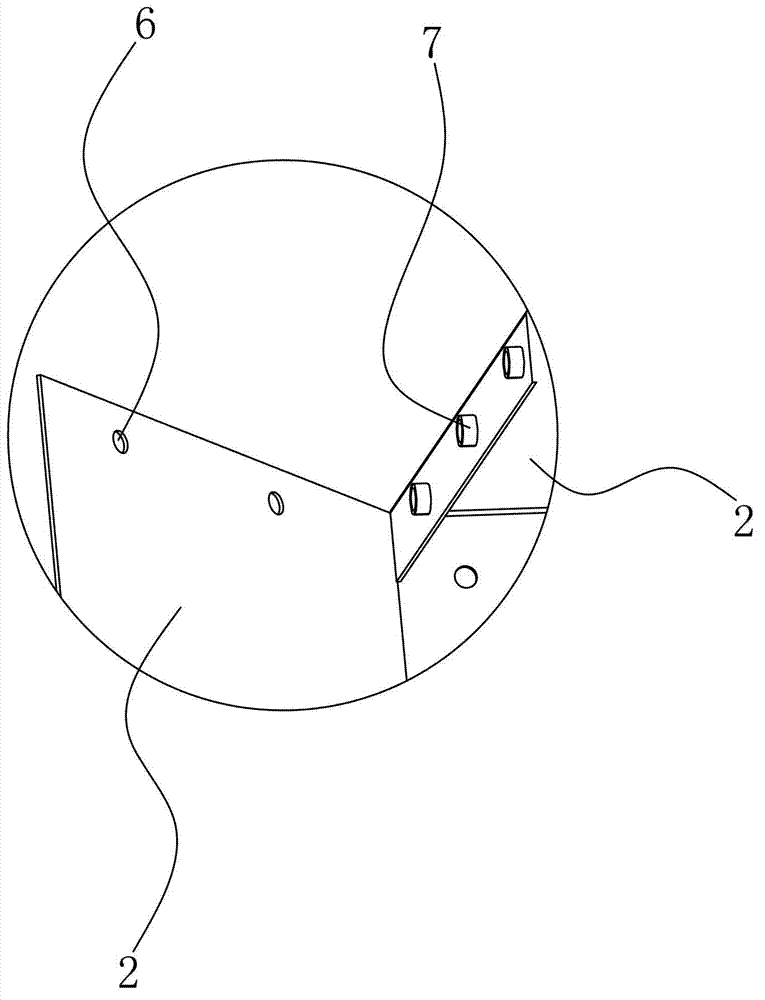

[0028] see Figure 1 to Figure 4 According to the embodiment of the fan box provided by the present invention, it includes a body, the body is respectively provided with an air inlet 3, an air outlet 4, and a cooling hole 5, and the body is also provided with reinforcing ribs and a fan installation position, and the body Integral stamping and forming. The body includes a bottom plate 1 and a plurality of side plates 2 arranged around the bottom plate. The bottom plate 1 and the side plates 2 are integrally structured, and the side plates 2 are folded upwards to be perpendicular to the bottom plate 1 . The adjacent side plates 2 are riveted and fixed. The present invention is simple in structure, convenient and quick to manufacture, adopts integral stamping and riveting forming, each side plate 2 and the bottom plate 1 are integrally structured, and the side plates are fixed by riveting, compared with traditional welding, the connection is more reliable and the sealing effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com