Extraction method for dephenolize cotton seed protein

A dephenolized cottonseed protein extraction technology, which is applied in the field of preparation of dephenolized cottonseed protein, can solve the problems of elongated production line, increased equipment investment, and increased equipment footprint, and achieve shortened production line, reduced equipment investment, and equipment Effect of footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

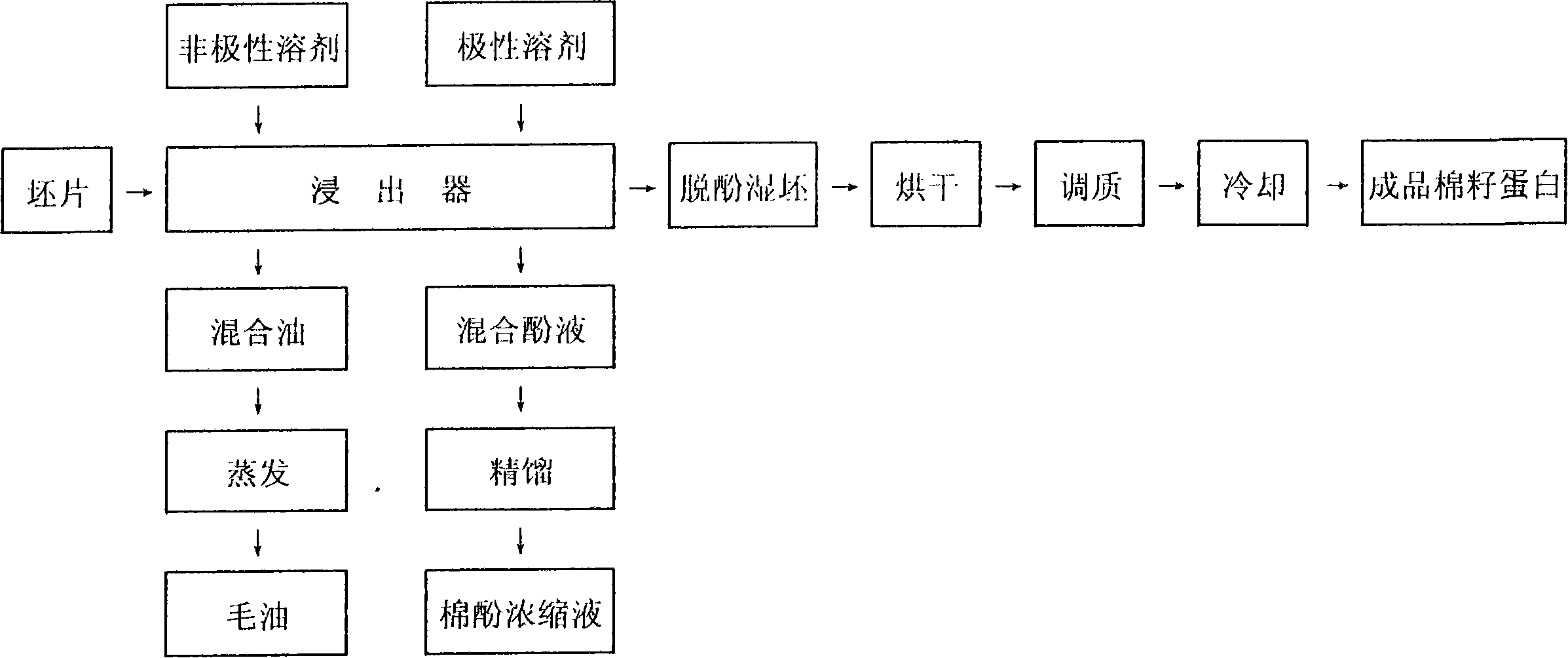

[0009] Accompanying drawing shows the process flow of the extraction method of dephenolized cottonseed protein of the present invention, after the pretreated flakes are sent into the extractor, the cottonseed oil is first sprayed and extracted with a non-polar solvent to obtain a mixed oil, and the mixed oil is obtained after evaporation Crude oil; then spray and extract gossypol with a polar solvent in the extractor to obtain a mixed phenol solution, and the mixed phenol solution is rectified to obtain a gossypol concentrated solution; the dephenolized wet billet separated from the extractor is first sent to the drying The dryer is then sent to the conditioner, and then cooled to obtain the finished cottonseed protein. The specific process is as follows: After the wool cottonseed after the ginning process is delinted by a delint machine, the short fluff on the surface of the wool cottonseed is removed to obtain light seeds, and the light seeds are peeled by a sheller and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com