Machining technology and machining equipment for riveting base boards and caster axles of oil heaters

A processing equipment and foot plate technology, which is applied in the field of processing equipment for riveting the oil base plate and caster shaft, can solve the problems of high stamping risk, high product scrap rate, long production line and other problems of the stamping machine, so as to shorten the production line and reduce handling The effect of reducing the number of times and reducing manual input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

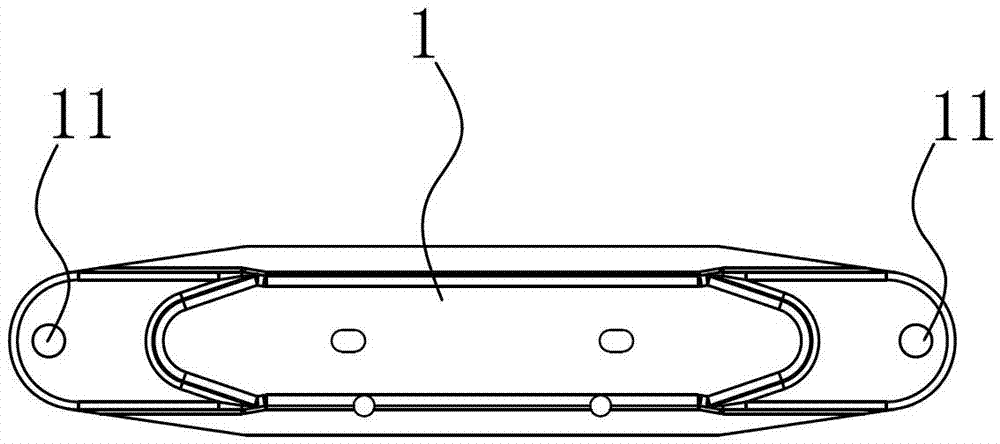

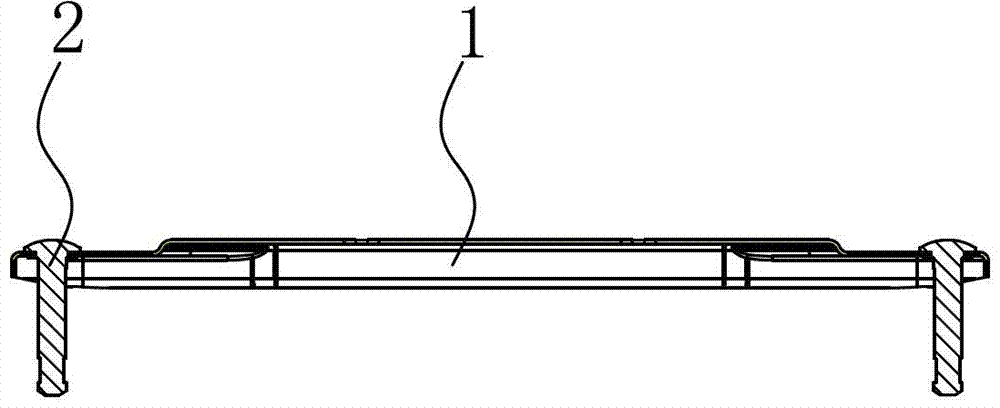

[0027] see Figure 1 to Figure 4 According to the processing technology of riveting the oil base plate and the caster shaft provided by the present invention, it mainly includes the following steps:

[0028] (1) Send the foot plate body 1 made by the continuous stamping die to the automatic feeder 3, and the automatic feeder 3 pushes the foot plate body 1 to the assembly station, and stops intermittently.

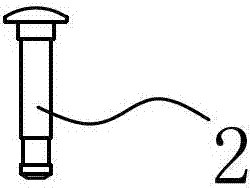

[0029] (2) The caster shaft 2 is sent to the assembly station through the vibrating plate 4, and when step (1) pauses intermittently, the caster shaft 2 is inserted into the riveting hole 11 of the foot plate body 1 under the action of the vibrating plate 4, and the riveted end It is located at the riveting hole 11 to form a foot plate assembly.

[0030] (3) The automatic feeder 3 sends the foot plate assembly to the lifting trampoline of the automatic riveting machine 5, the upper template 51 of the automatic riveting machine 5 descends and docks with the lower template 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com