Machining method of lightweight aluminum alloy chassis part

A processing method and technology of aluminum alloy, applied in the field of hot forming of aluminum alloy forgings, can solve the problems of high energy consumption in multiple heating and transfer, short time under high temperature, short production time, etc., and reduce labor costs, equipment costs, and high temperature time. The effect of shortening and reducing the production time of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

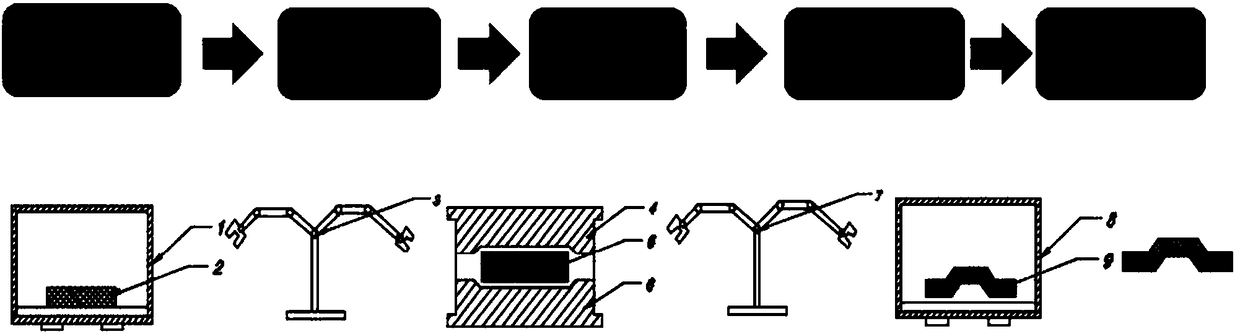

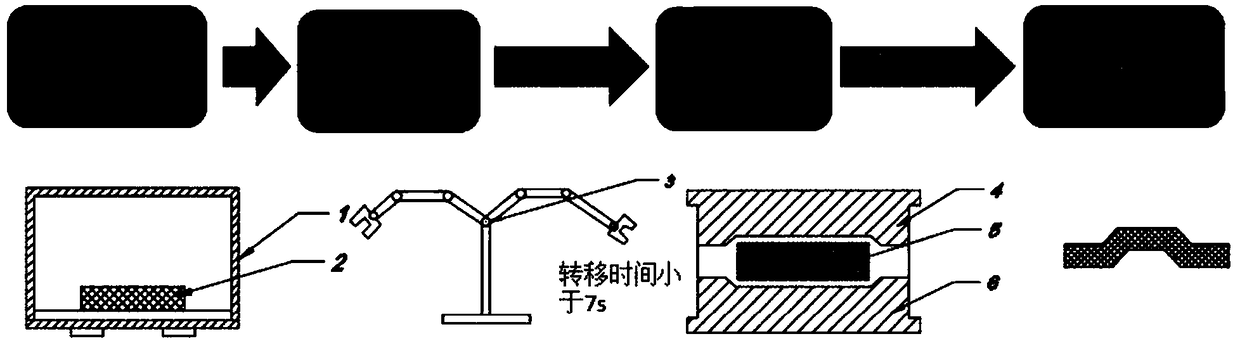

[0023] A method for processing lightweight aluminum alloy chassis parts, such as figure 2 As shown, for a forging that only needs to be forged once, the steps include:

[0024] S1. Use the T6 aluminum alloy as the billet blanking, put the billet into the heating equipment and heat it at 50-150°C below the solid solution temperature, and the heating time and holding time are 3-30 minutes;

[0025] S2, heating the blocker to 300-550°C;

[0026] S3, taking out the blank and transferring it to the pre-forging die to form it into a forging;

[0027] S4, the forging is taken out, then water quenched to room temperature;

[0028] S5. Cut the edge after cooling the forging, and then perform machining treatment to obtain the final product.

[0029] The billet heated in step 1 is an age-hardened aluminum alloy billet, and after the forging and pressing are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com