Inner cleaning and airtightness detecting device for oil filling pipe, and method thereof

A technology of air tightness detection and filling pipe, which is applied in liquid/vacuum degree measurement for liquid tightness, and by detecting the appearance of fluid at the leak point, etc., can solve the problems of high labor cost, low production efficiency and high equipment investment. , to achieve the effect of reducing labor costs, reducing equipment costs, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

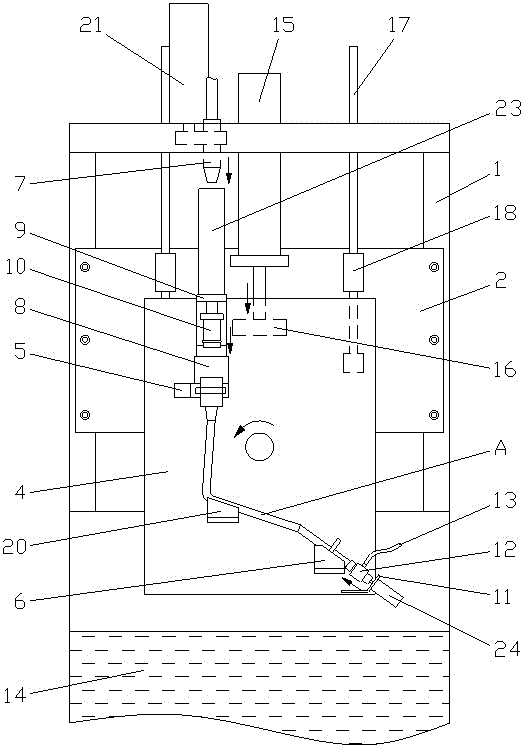

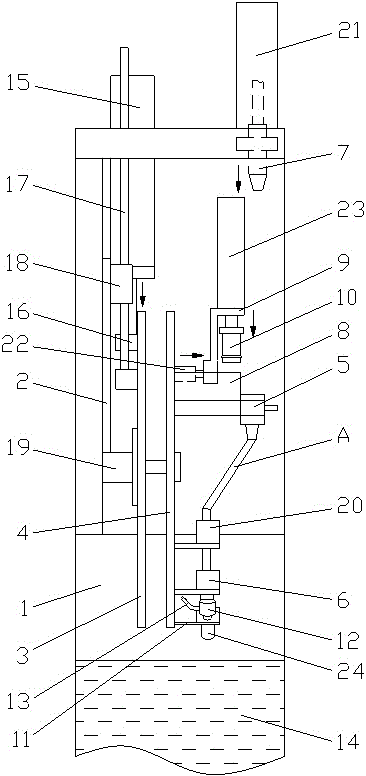

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0024] Such as Figure 1~2 As shown, a gas-tightness detection device for cleaning the inside of the oil filling pipe includes a cabinet 1. A worktable 2 is erected inside the cabinet 1. A sliding plate that can move up and down relative to the worktable 2 is installed on the front side of the worktable 2. 3. The front side of the sliding plate 3 is equipped with a rotating plate 4 that can rotate relative to it, and the rotating plate 4 is provided with an upper clamping seat 5 and a lower clamping seat 6 for fixing the two ends of the filling pipe A respectively, The upper part of the cabinet 1 is provided with a high-pressure nozzle 7 that can be moved up and down and aligned with the upper port of the filling pipe A to clean the inside of the filling pipe A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com