Channel section steel production system and production method thereof

A production system and production method technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high pass design accuracy, complex pass rolling process, difficult production adjustment, etc., to achieve maximum production benefits , reduce investment and follow-up maintenance costs, shorten the effect of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

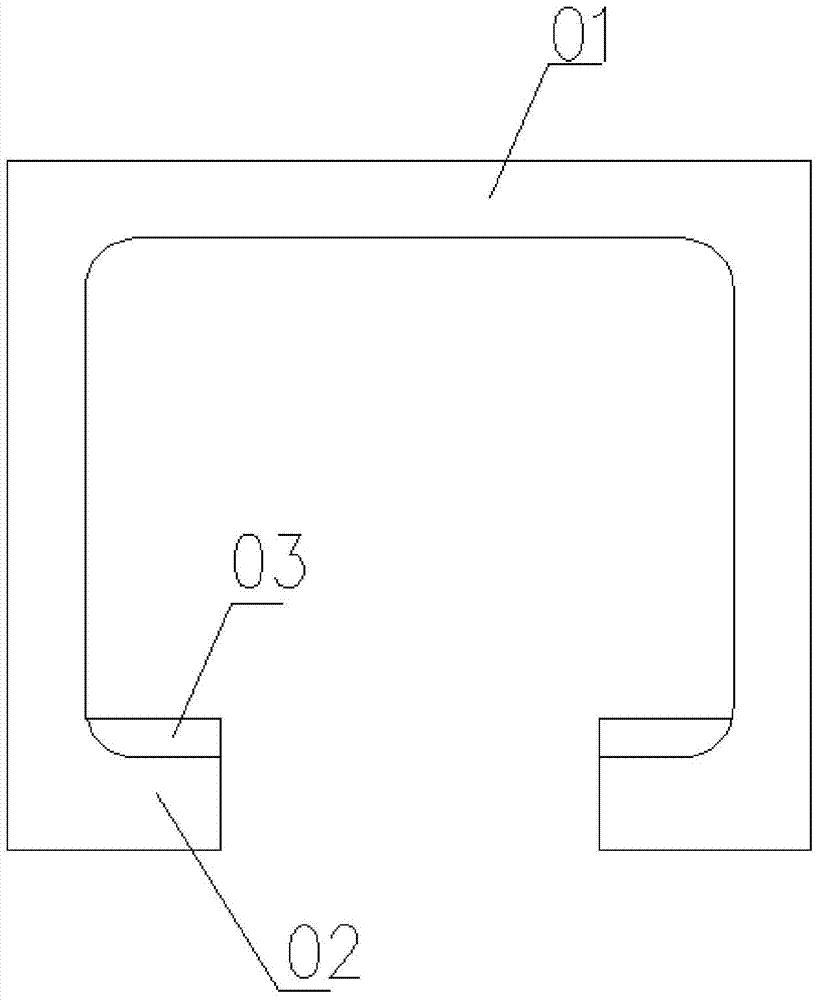

[0060] figure 1 As shown, it is a schematic structural view of the channel section steel in the present invention, including the channel section steel body 01, the turning part 02, and the internal teeth 03 arranged on the inner side of the turning part 02, and the middle of the channel section steel is It is plate-shaped, and still has a folded part 02 on both sides.

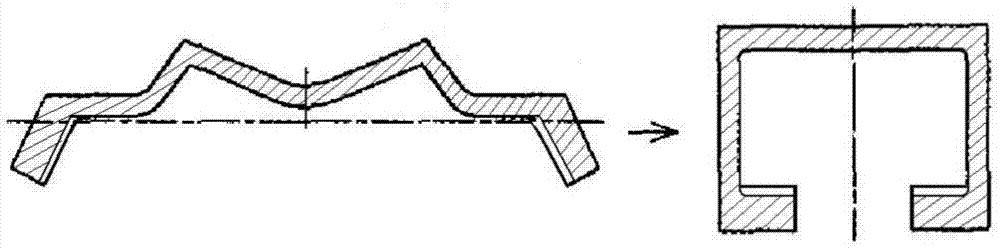

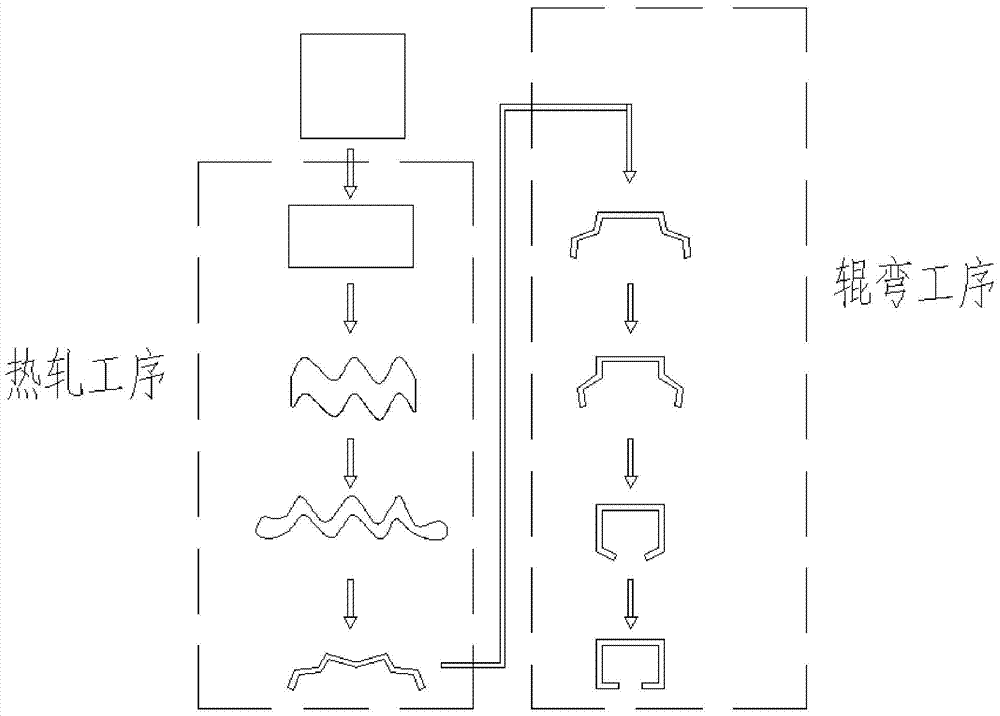

[0061] figure 2 and image 3 The schematic diagram of the traditional production process is shown, that is, the rectangular / square raw material with large cross-section is rolled into the "M" type intermediate rolling piece required for roll bending through the traditional pass rolling method, and then passed through the "M" type intermediate rolling piece with a certain shape. Roll-shaped rolls bend the "M"-shaped rolling stock into the final section. The mechanical equipment is old, complex, and heavy; the pass rolling process is complex and cumbersome; the pass design accuracy is high, the guide design i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com