Patents

Literature

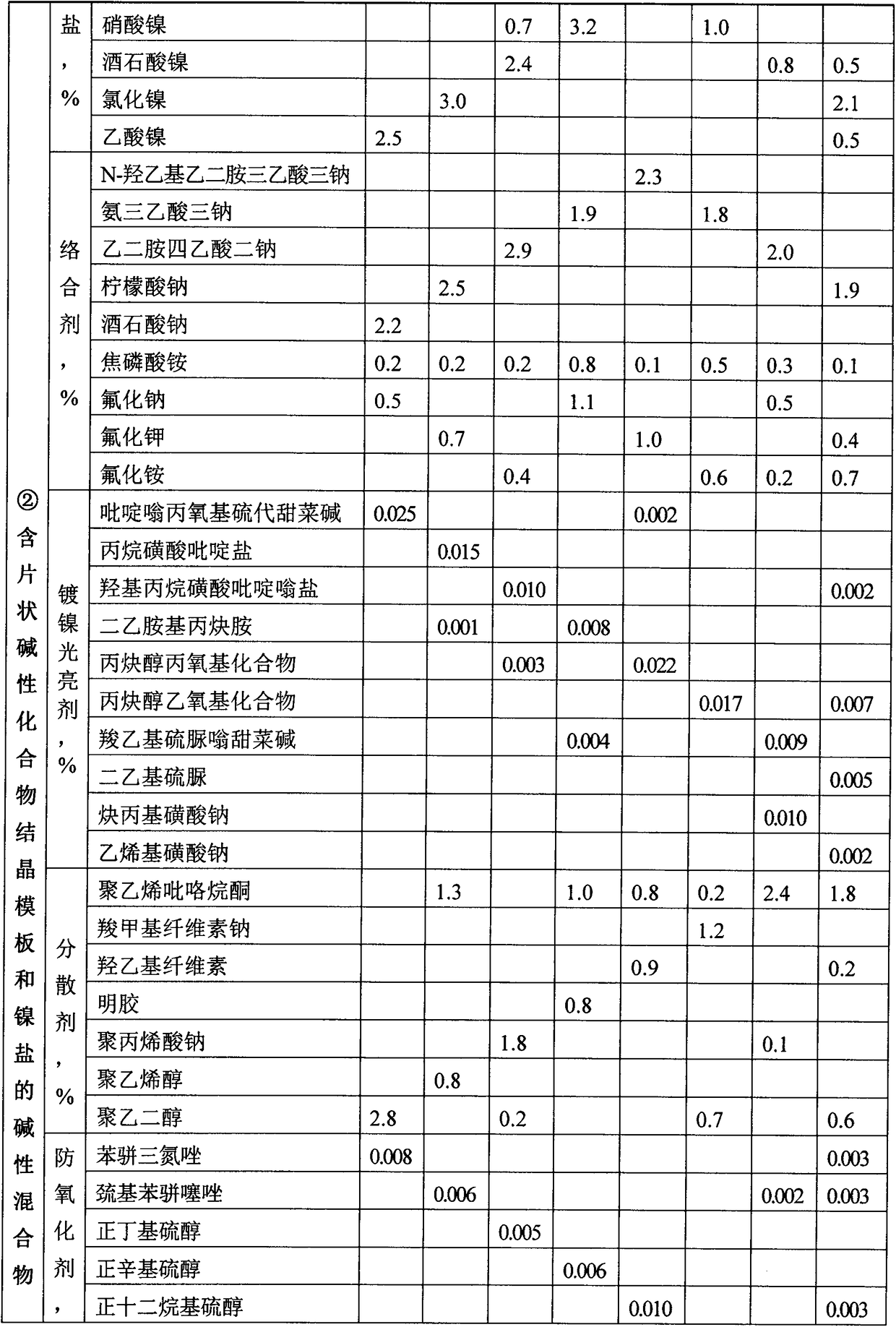

38results about How to "Improve production success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane sponge and processing method thereof

InactiveCN106957408AWith flame retardant functionGood flame retardant functionDiethyl phosphateHalogen

The invention discloses polyurethane sponge and a processing method thereof. Polyether polyol with a flame retardant function is directly added to a material A, and a diethyl ethylphosphonate fire retardant is selectively added to a material B, so that the polyurethane sponge does not contain halogen, is low in viscosity and very stable in a two-component system of the material A and the material B, and a product is endowed with good fireproof and flame-retardant properties while the process is simple. The product is endowed with good mildew-proof and antibacterial effects through an antibacterial agent and a mildew preventive added to the material B; and through addition of nanoscale inorganic material tourmaline powder, the product has the function of lastingly emitting anions. The production technology and the formula are relatively simple on the premise that all performance indexes reach the expected requirements; the production process and the formula are relatively simple; the processes such as heating or refrigerating do not need to be specifically carried out in the production process and foaming and curing in a natural state can be carried out; the production success rate of sample post-detection is very high; the produced polyurethane sponge has obvious fireproof and flame-retardant functions, antibacterial and anti-mildew functions and continuous anion release function, and is beneficial to improvement of the competitiveness of the product.

Owner:东莞恒生高分子科技有限公司

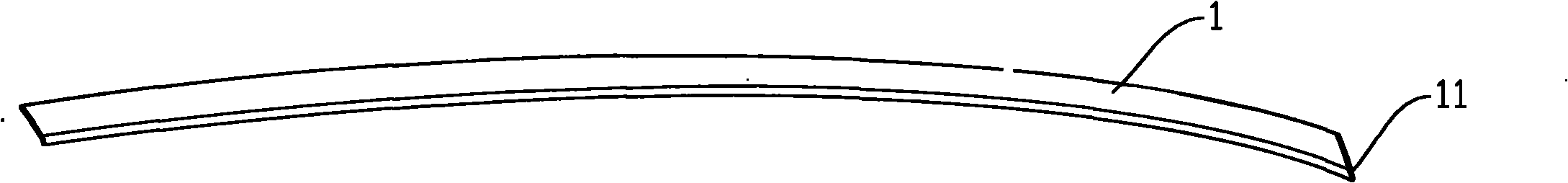

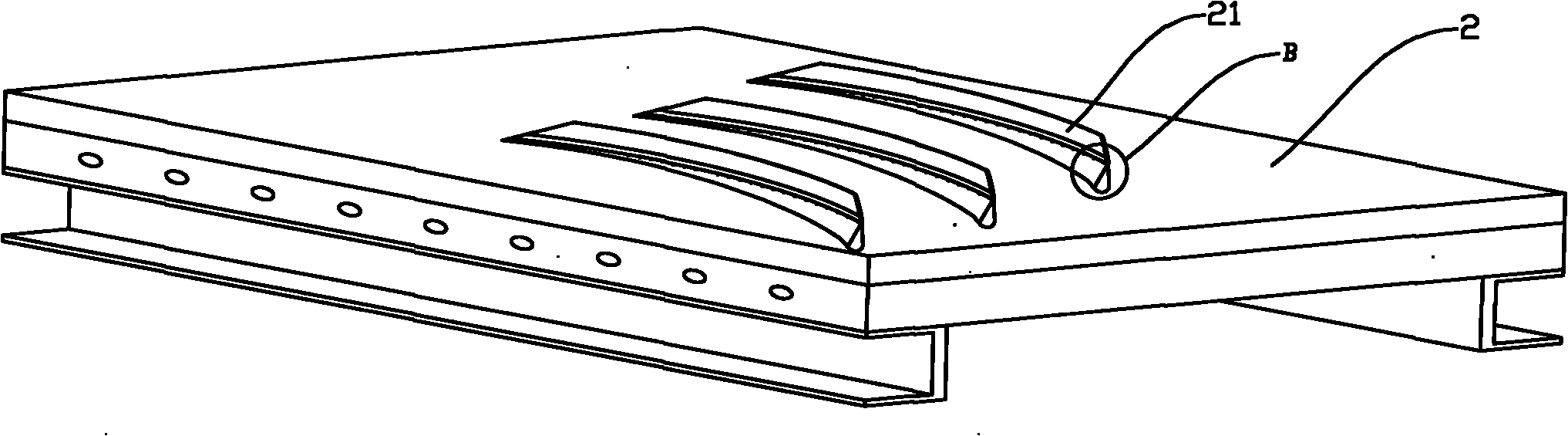

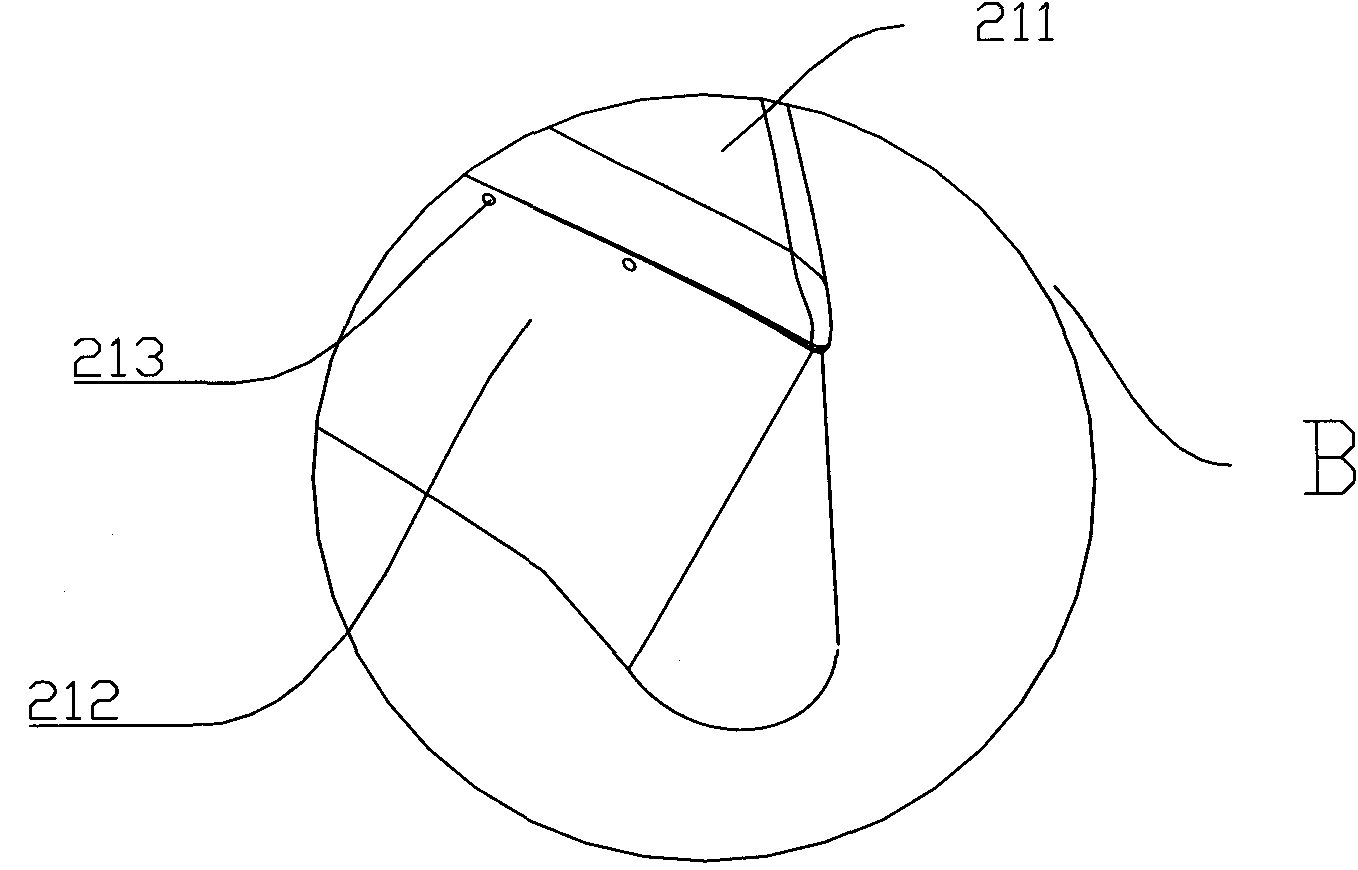

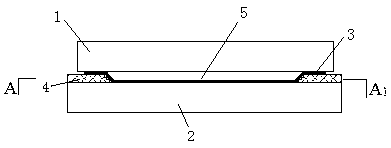

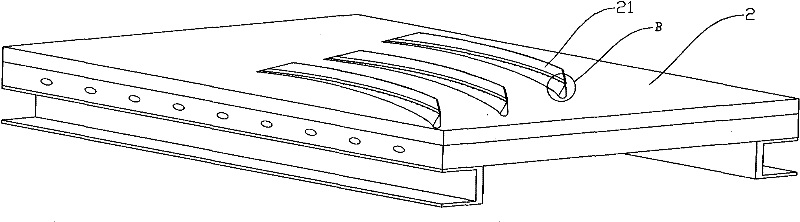

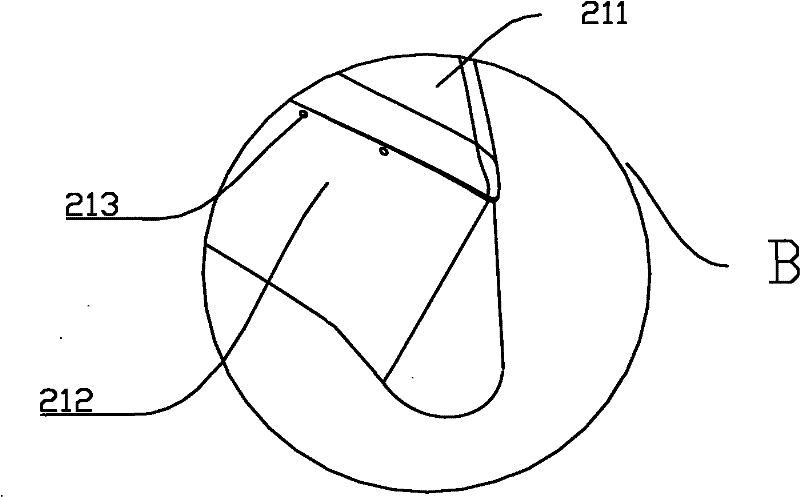

Plastics suction mould

The invention discloses a plastics suction mould, comprising press frames, wherein the press frames comprise press frame substrates and plastics suction part fixture; and the plastics suction part fixture is arranged at the upper end of the press frame substrates and is provided with first acute angles. The invention is characterized in that convex plates which extend outwards along the press frame substrates are arranged on the press frame substrates, positioned below the first acute angles and distant from the plastics suction part fixture. The plastics suction mould can reduce the under-cut depth and drawing of the thin films, thereby improving the mould yield.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213AImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the bale is more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

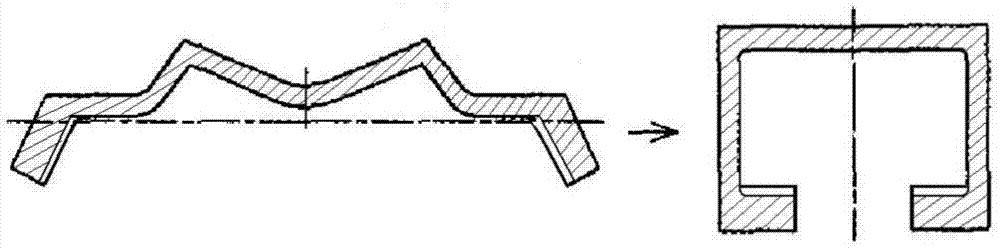

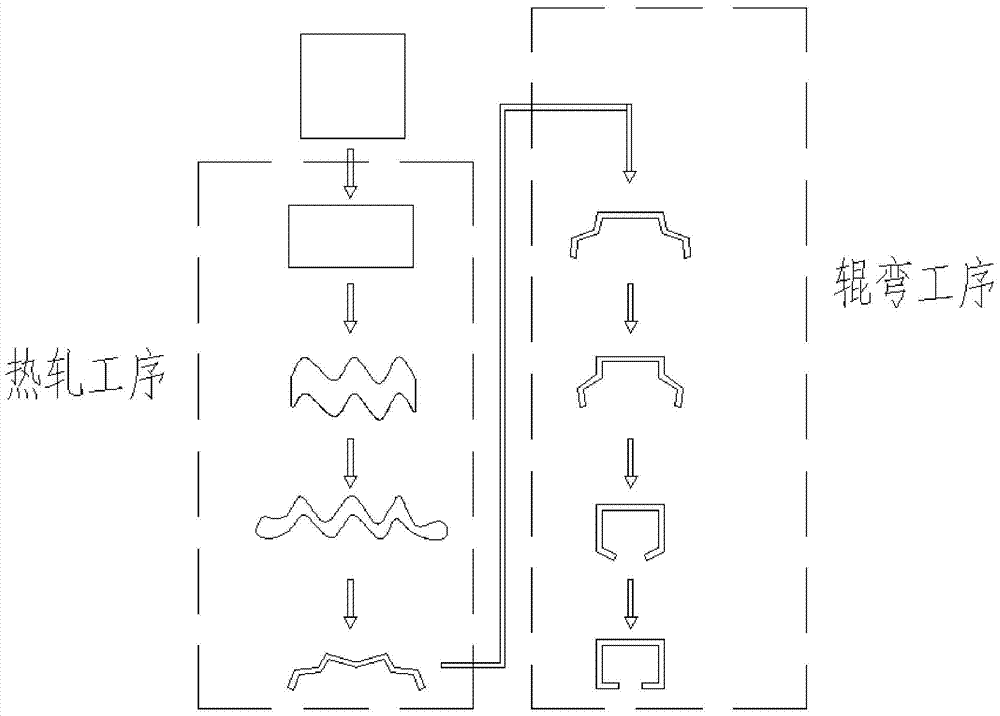

Channel section steel production system and production method thereof

ActiveCN104759892ASimple production processSimplified pass rolling passesOther manufacturing equipments/toolsProduction lineMethods of production

The invention provides a channel section steel production system and a production method thereof. The channel section steel production system comprises a feeding device, a heating device, a hot-rolling unit, a roll-bending unit and a fixed-length cutting device which are sequentially arranged. Flat steel blank raw materials are selected, heated through an electric induction heating device and then are fed into rolling mills of two machine frames to be subjected to rolling deformation, a first pass is used for thickness decrease, a second pass is used for plate shape forming of cross sections of rolled pieces before hot bending, and the two machine frames conducts deformation rolling on the raw materials simultaneously in a continuous-rolling state. By the adoption of simplified two-pass hot rolling, the thickness and plate shapes all cross section of flattened and spread channel section steel are rolled, waste heat is utilized to conduct hot bending forming on the continuous roll-bending unit, and fixed-length sawing, cooling and finishing are performed to obtain channel section steel products. The production method is simplified, hole type rolling pass is simplified, production difficulty is reduced, and the production success rate and finished material rate are improved. The number of the rolling mills is decreased, a production line is shortened, short-process production is achieved, and investment and follow-up maintenance cost are reduced.

Owner:CISDI ENG CO LTD +1

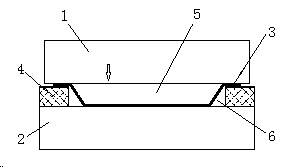

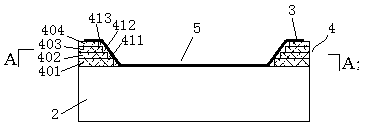

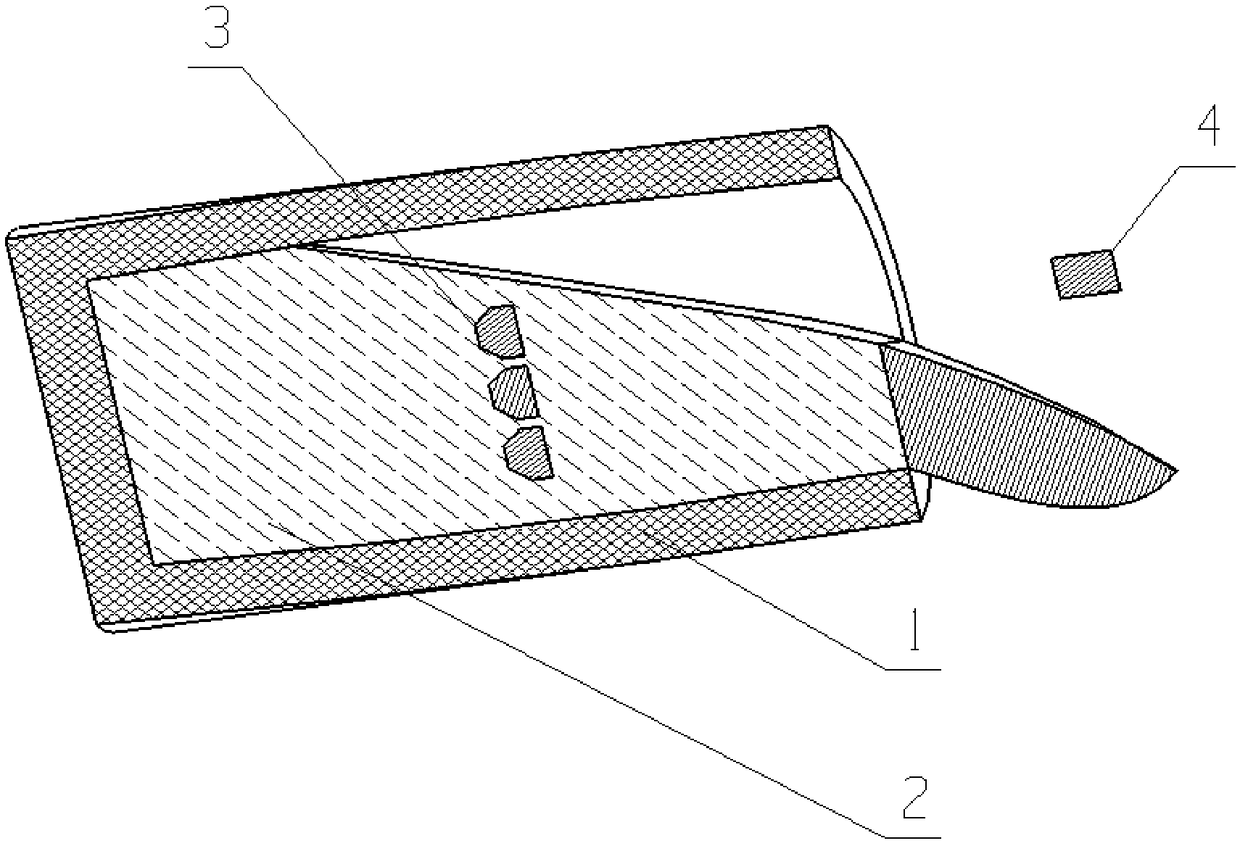

Touch panel structure

InactiveCN102707838AReduce space sizeReduce air contentInput/output processes for data processingTouch SensesAir content

The invention discloses a touch panel structure which comprises a protective layer, a touch sensing layer, and a rubber layer placed between the protective layer and the touch sensing layer, wherein inks are coated on the periphery of the edges on one face of the protective layer attached to the touch sensing layer; the inks are divided into at least two ink layers with each ink layer comprising a first ink layer and a second ink layer, wherein the first ink layer is placed on the protective layer, while the second ink layer is placed on the first ink layer; the internal edge of the second ink layer is contracted toward the edge of the protective layer so as to form a step with the first ink layer. With the adoption of the touch panel structure provided by the invention, the space size of an angle step clearance formed between the ink and the protective layer is reduced, the air content in the angle step clearance is greatly reduced, the generation of bubbles at the internal edge of the oil inks is prevented, the success rate of the production of the touch panel is improved, and the requirements of a user on the appearance quality of the touch panel attached to a module are met.

Owner:HANNSTAR DISPLAY NANJING

Method for casting thick-wall nodular iron casting of blower in power plant

InactiveCN101716671AImprove production success rateSolve the problem of sticky sandFoundry mouldsFoundry coresFine structureThick wall

The invention relates to a method for casting a fine structure of a thick-wall nodular iron casting, in particular to a method for casting the thick-wall nodular iron casting of a blower in a power plant, which comprises the steps of core bar manufacturing, core manufacturing, molding, mould assembling, pouring and sand falling and cleaning; the invention provides the method for casting the thick-wall nodular iron casting of the blower in the power plant; and the process method is unique, can improve the success ratio of sand core production, reduce the difficulty of core manufacturing and solve the problem that sand is adhered in pores.

Owner:NINGXIA KOCEL GRP CO LTD +1

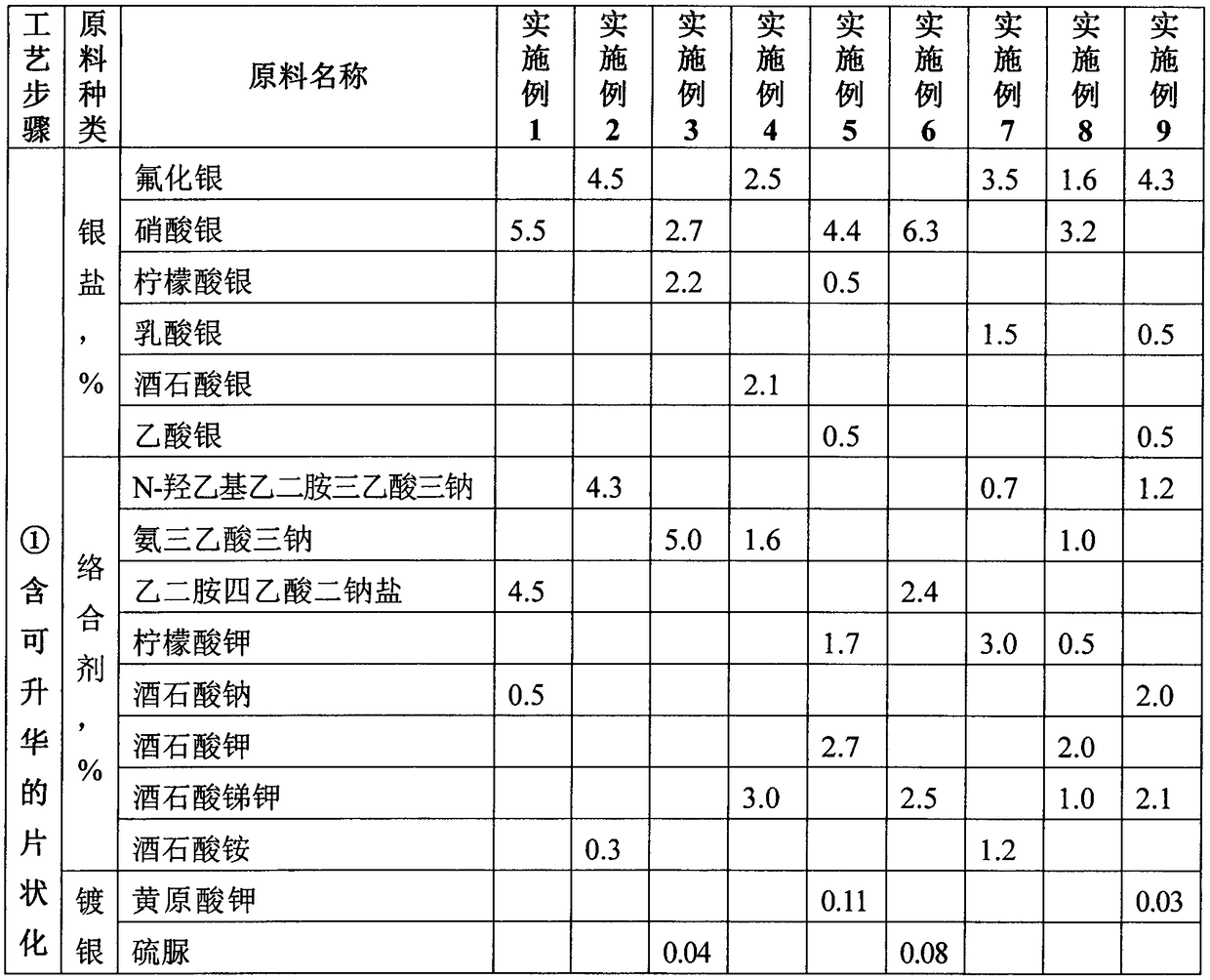

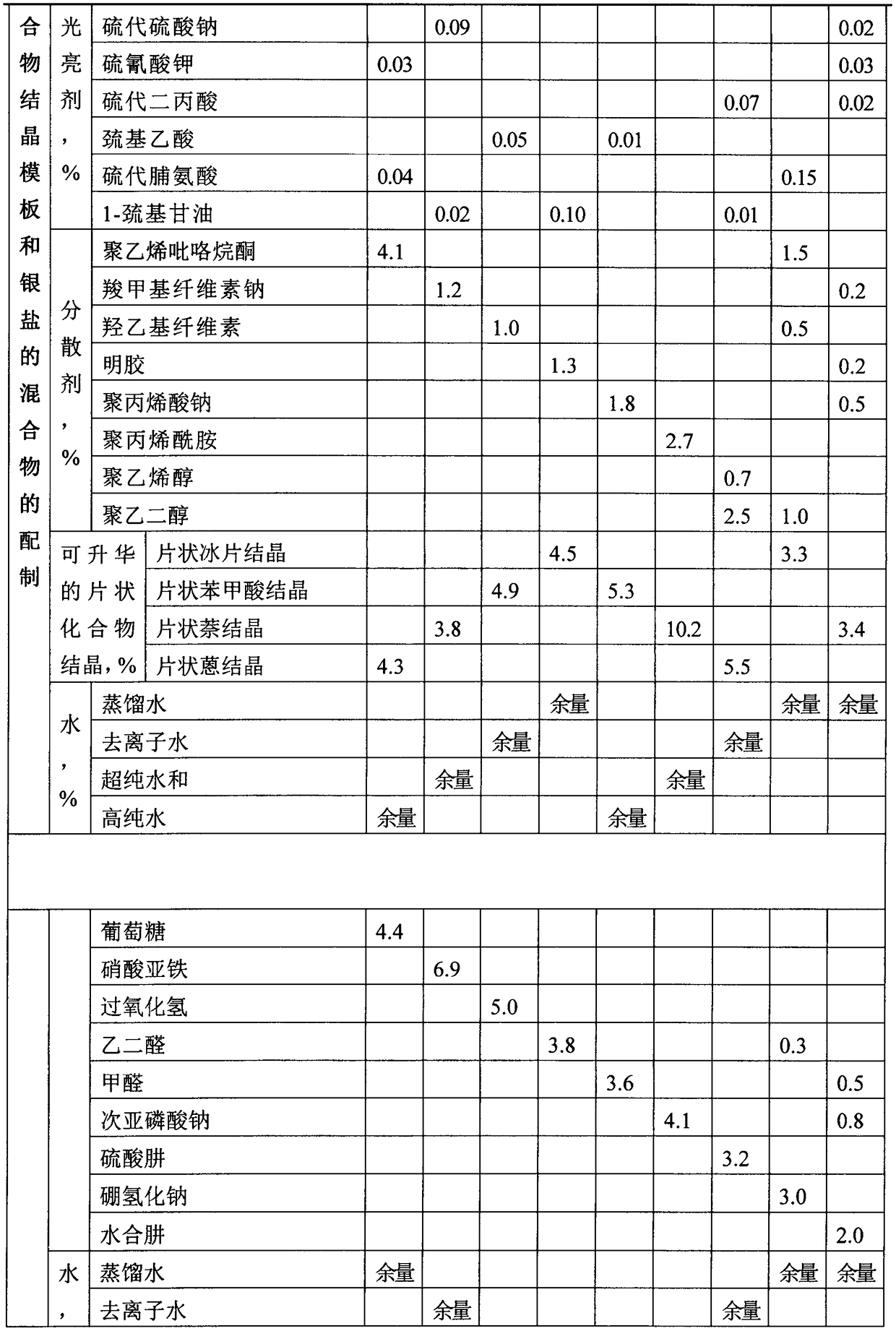

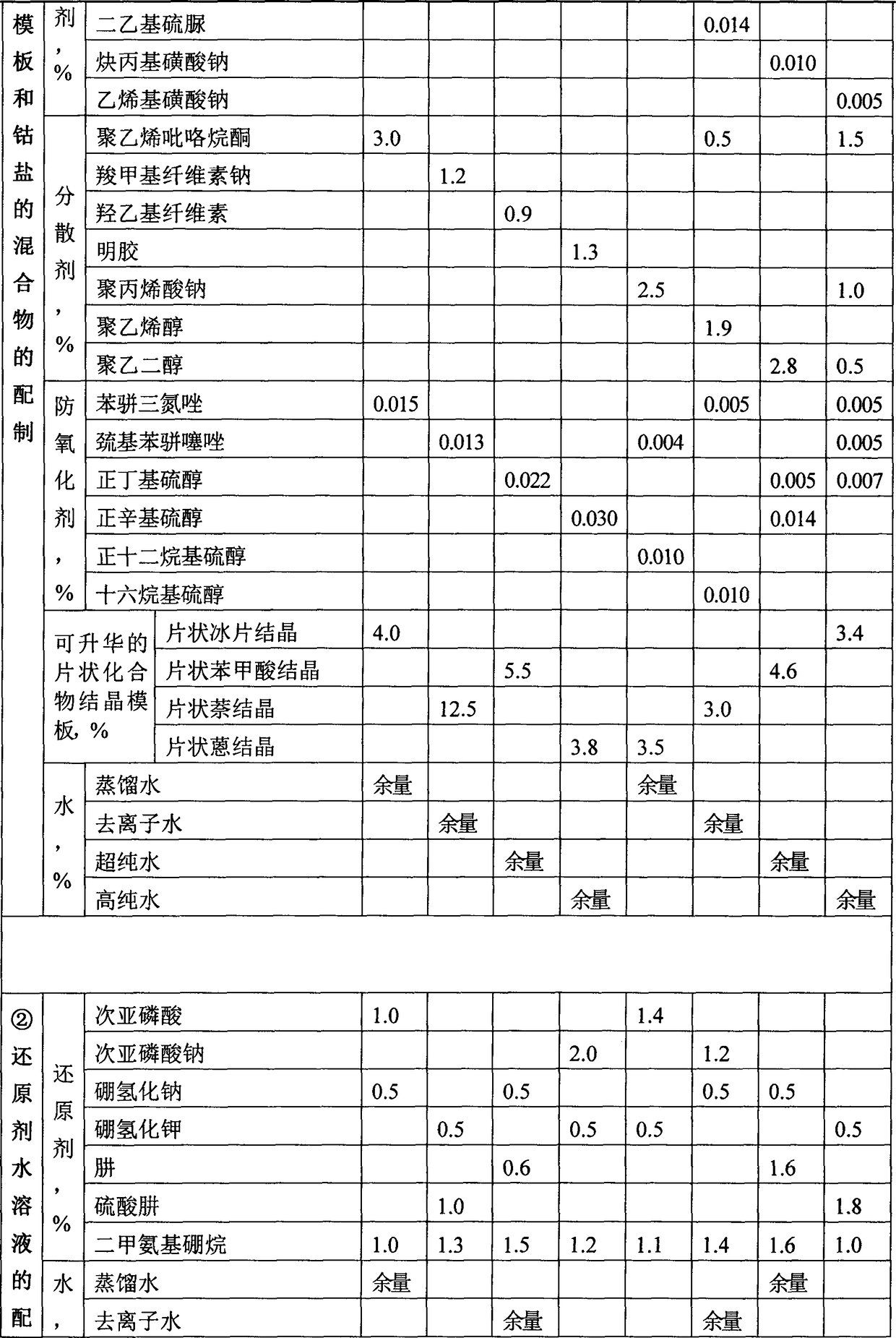

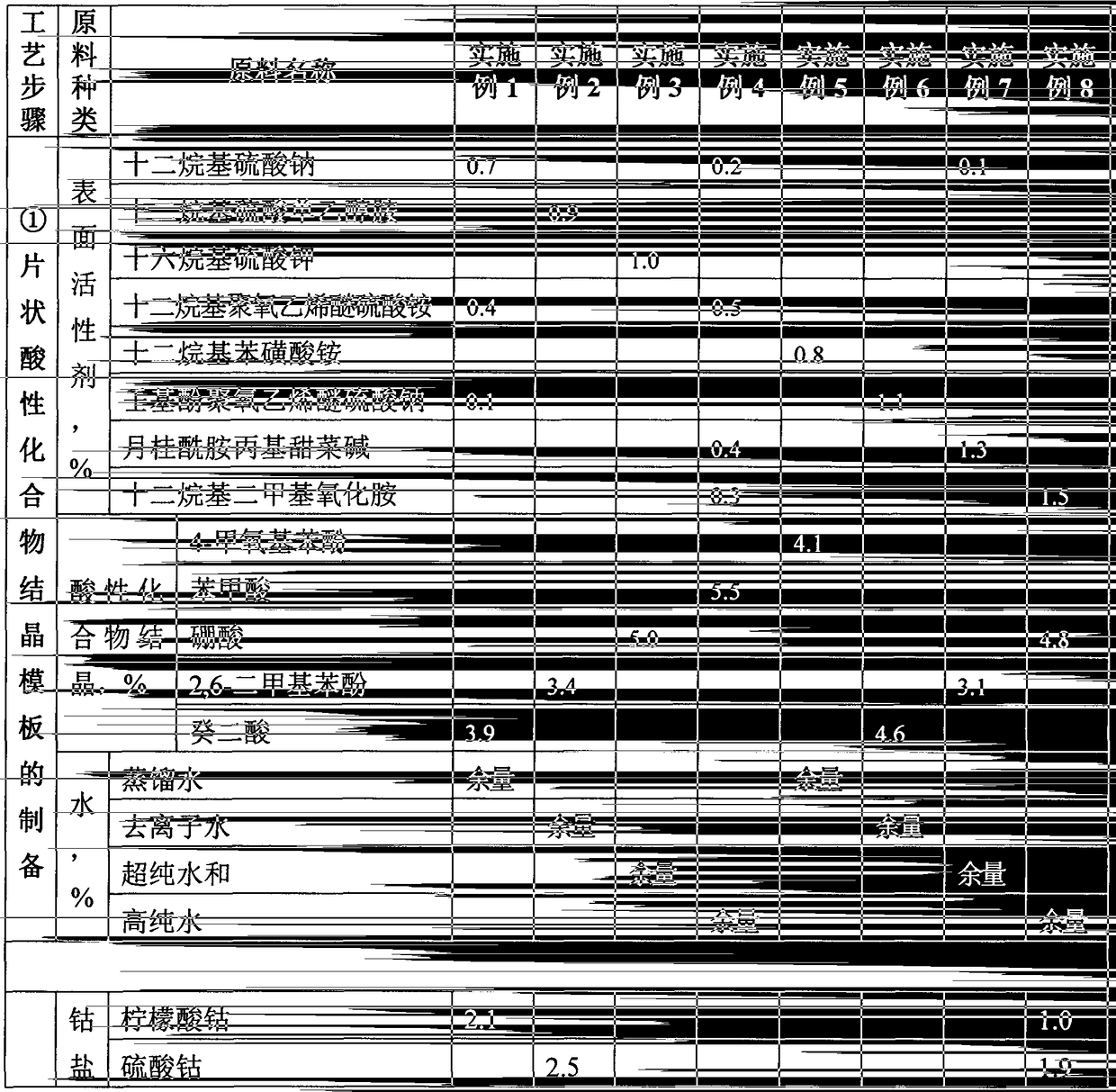

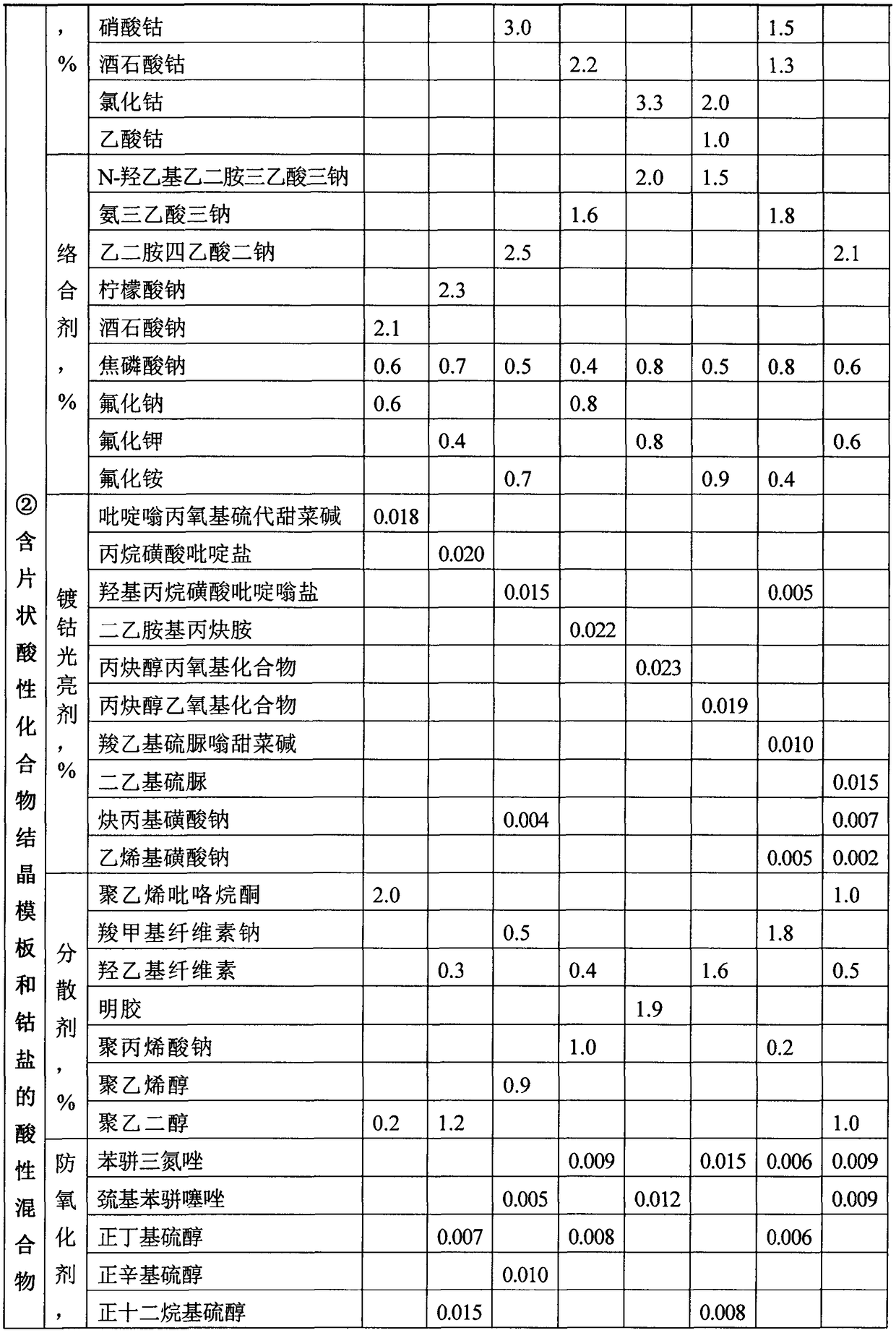

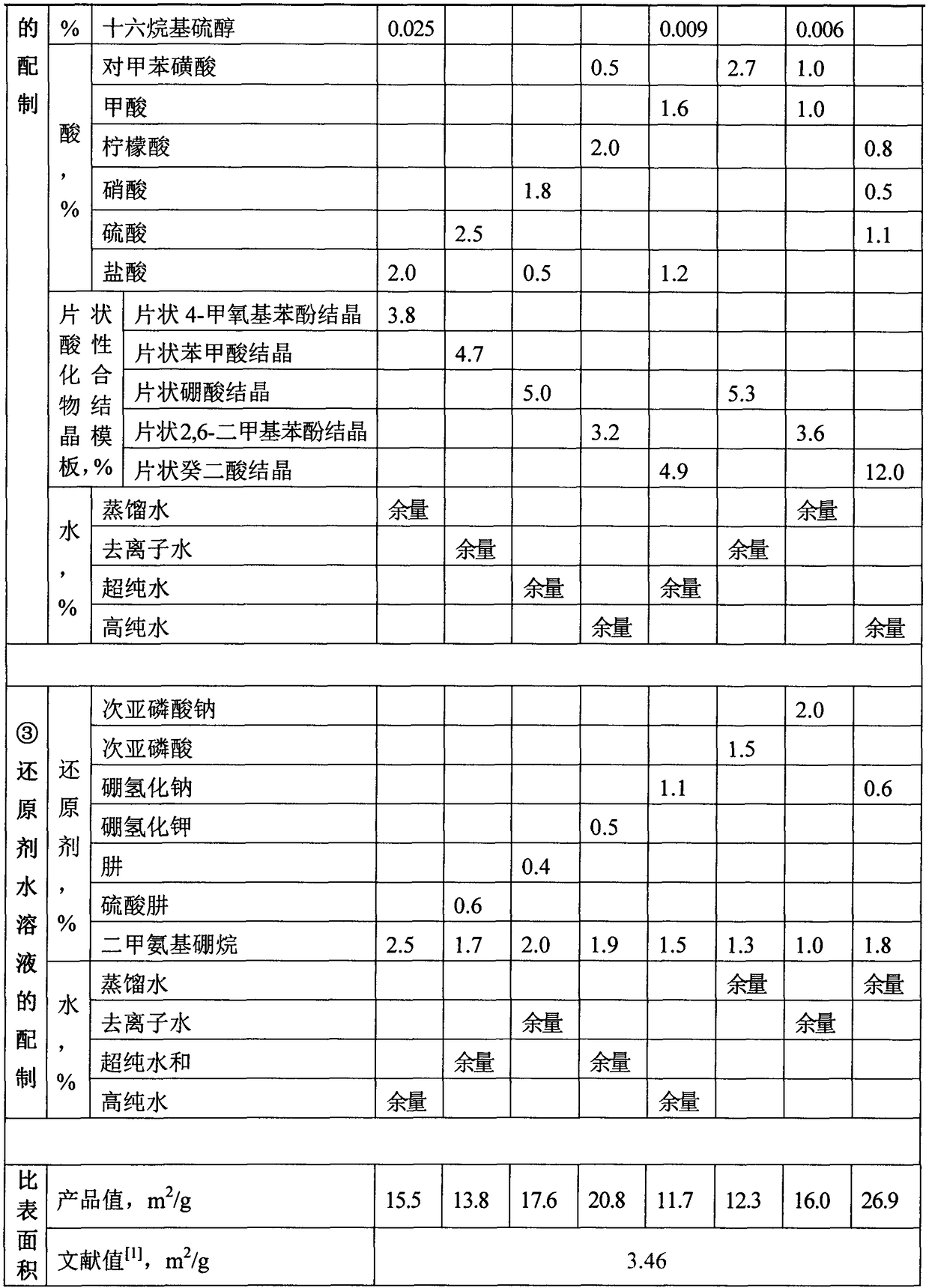

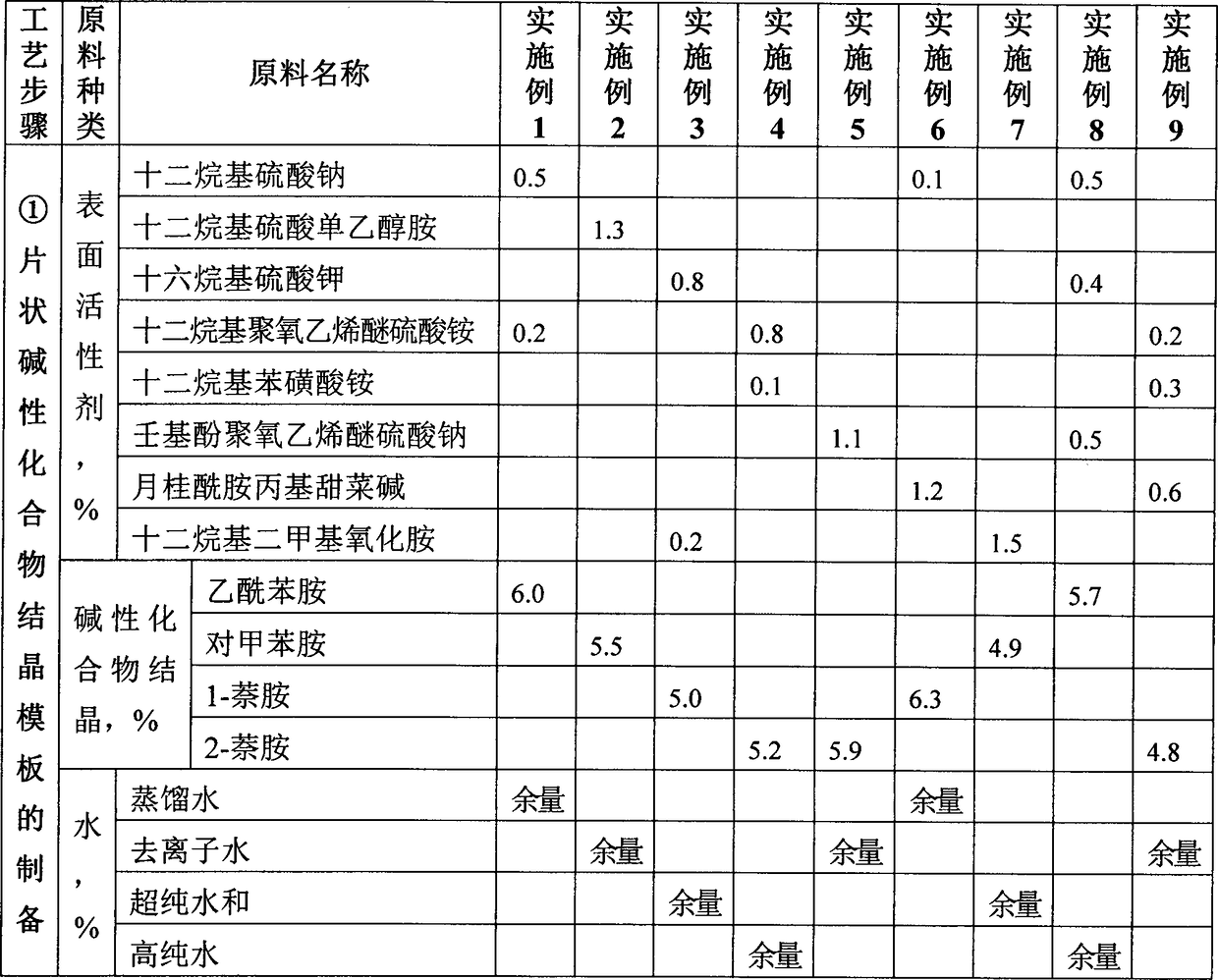

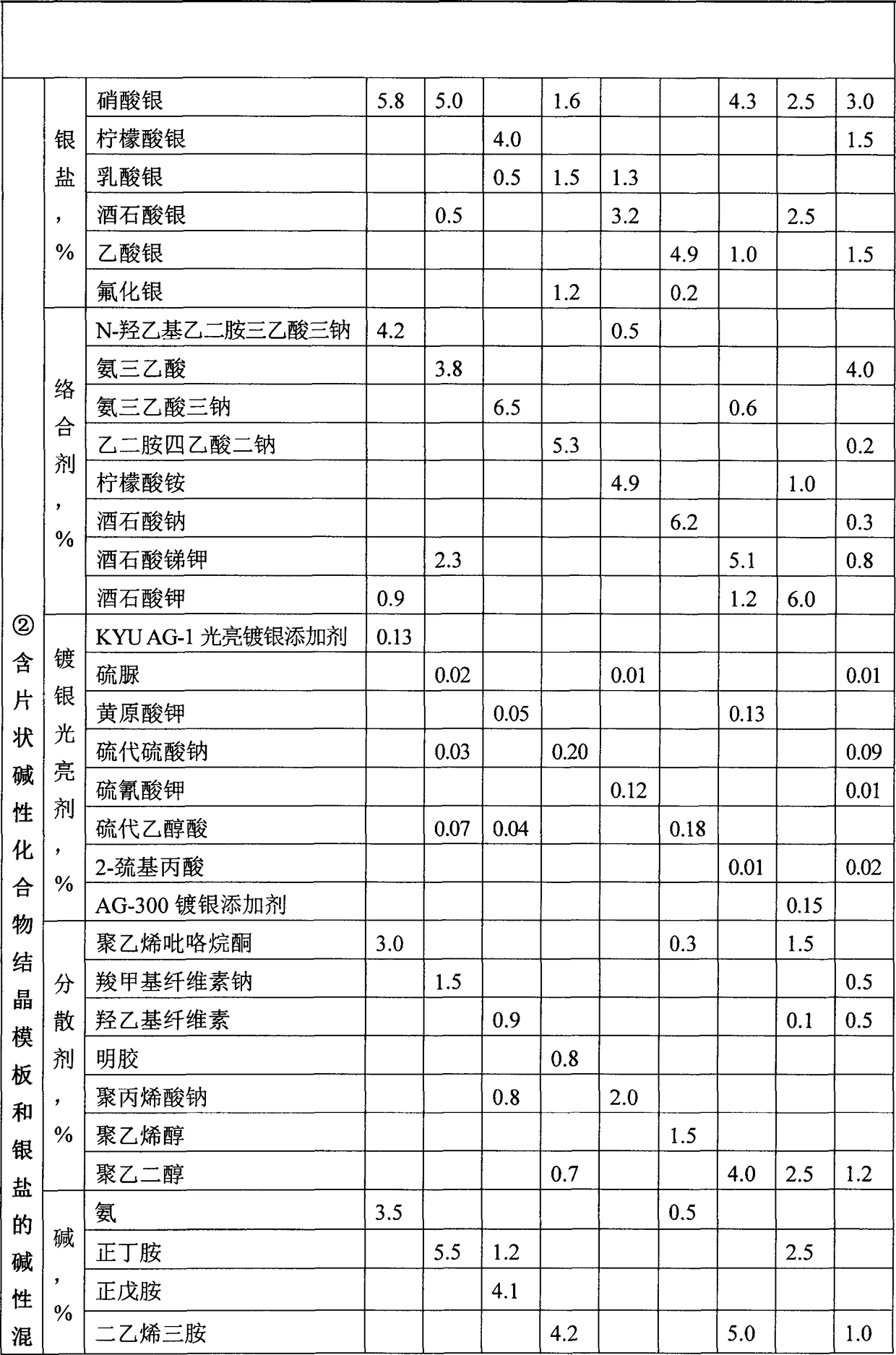

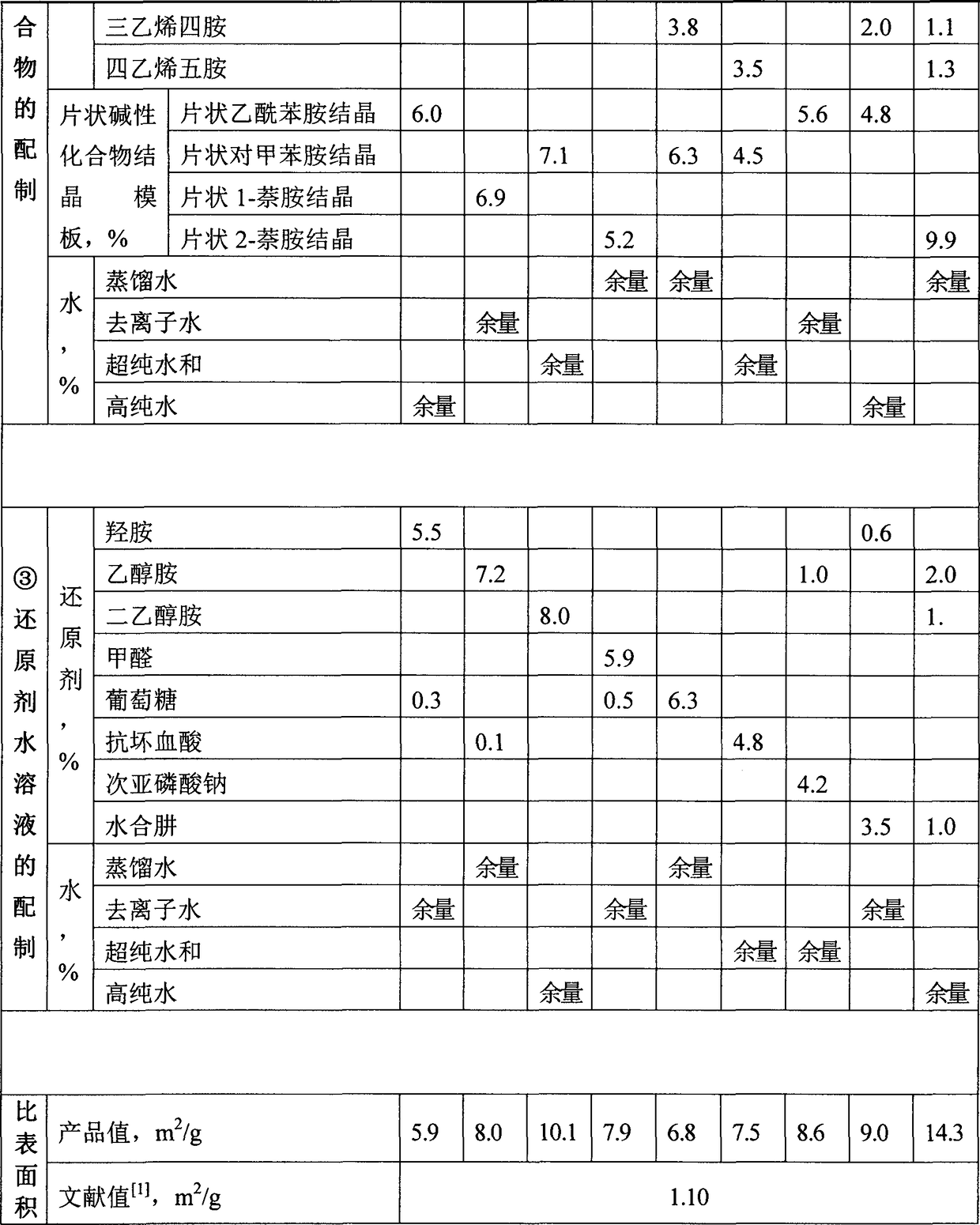

Preparation method of flake silver powder

InactiveCN108580920ASimple purification processHigh product purityMaterial nanotechnologyTransportation and packagingChemical platingEnergy consumption

The invention provides a preparation method of flake silver powder. The method comprises the steps that water, silver salt, a complexing agent, a silver-plated brightener, a dispersing agent, sublimated flake compound crystals and a reducing agent are adopted as raw materials, a chemical plating method is adopted, silver is plated on the surface of the sublimated flake compound crystal until silver ions react completely, and after the reaction is finished, the flake silver powder is directly obtained through separation and purification and processing treatment processes without ball milling. The preparation method has a series of advantages of being low in energy consumption, small in environmental pollution, simple in production process, short in process route, low in the large-scale production equipment investment, high in production efficiency, lower in production cost, good in product dispersion performance, good in product conductivity and the like, the method is suitable for large-scale production, the problems existing in the process of preparing the sheet-like silver powder by a ball milling method are solved, and the method has the good industrialization prospects.

Owner:NANJING FORESTRY UNIV

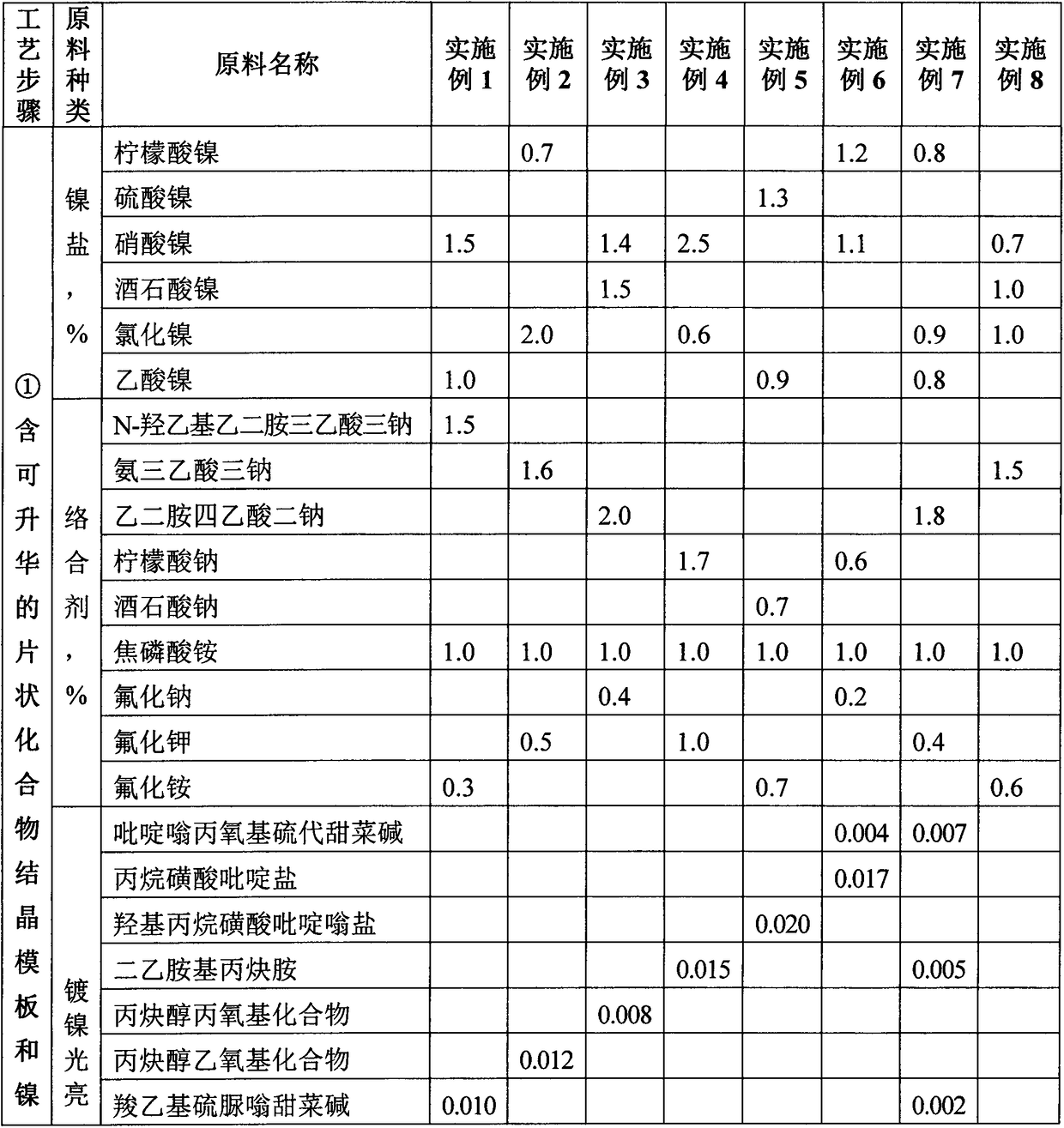

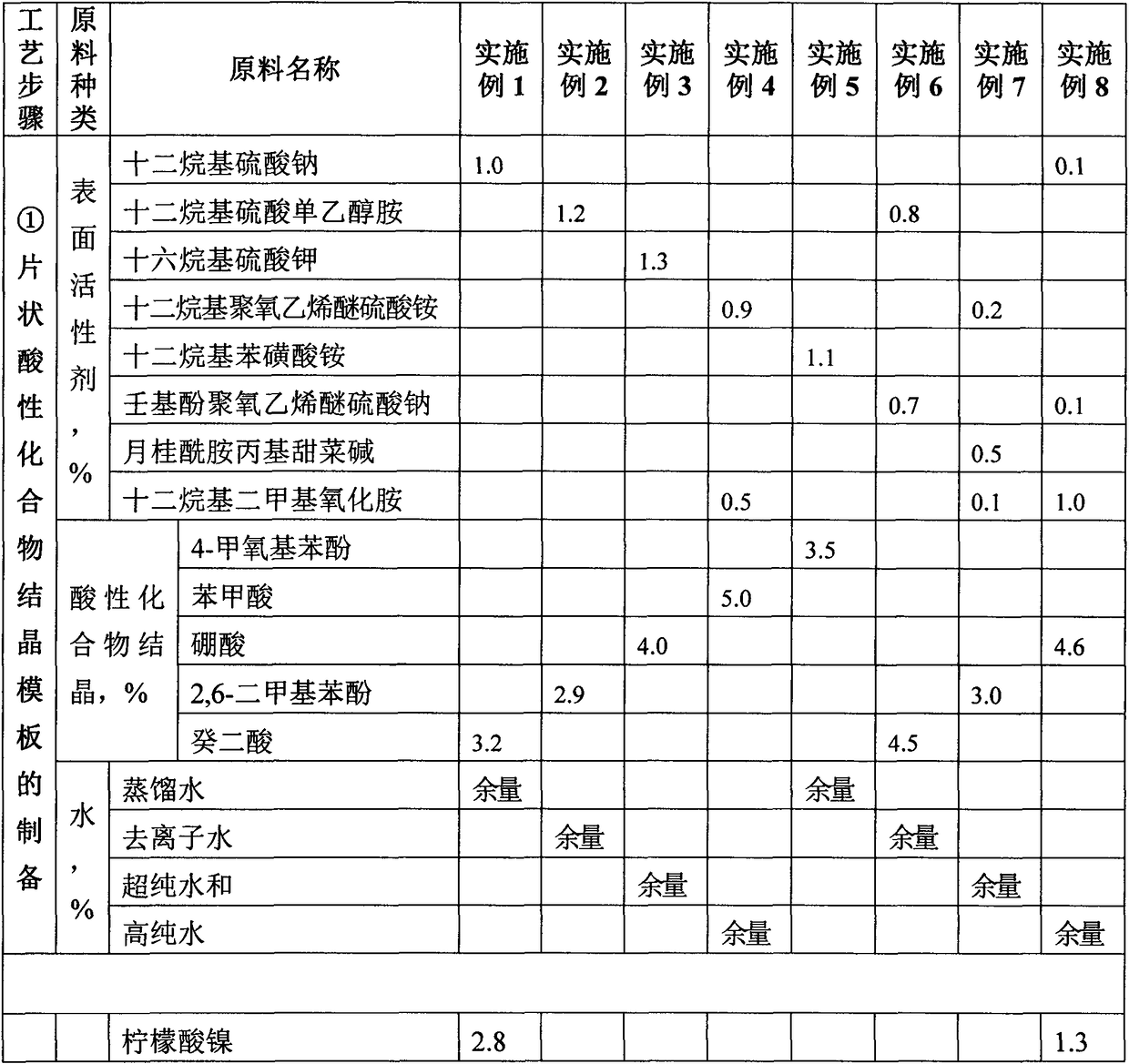

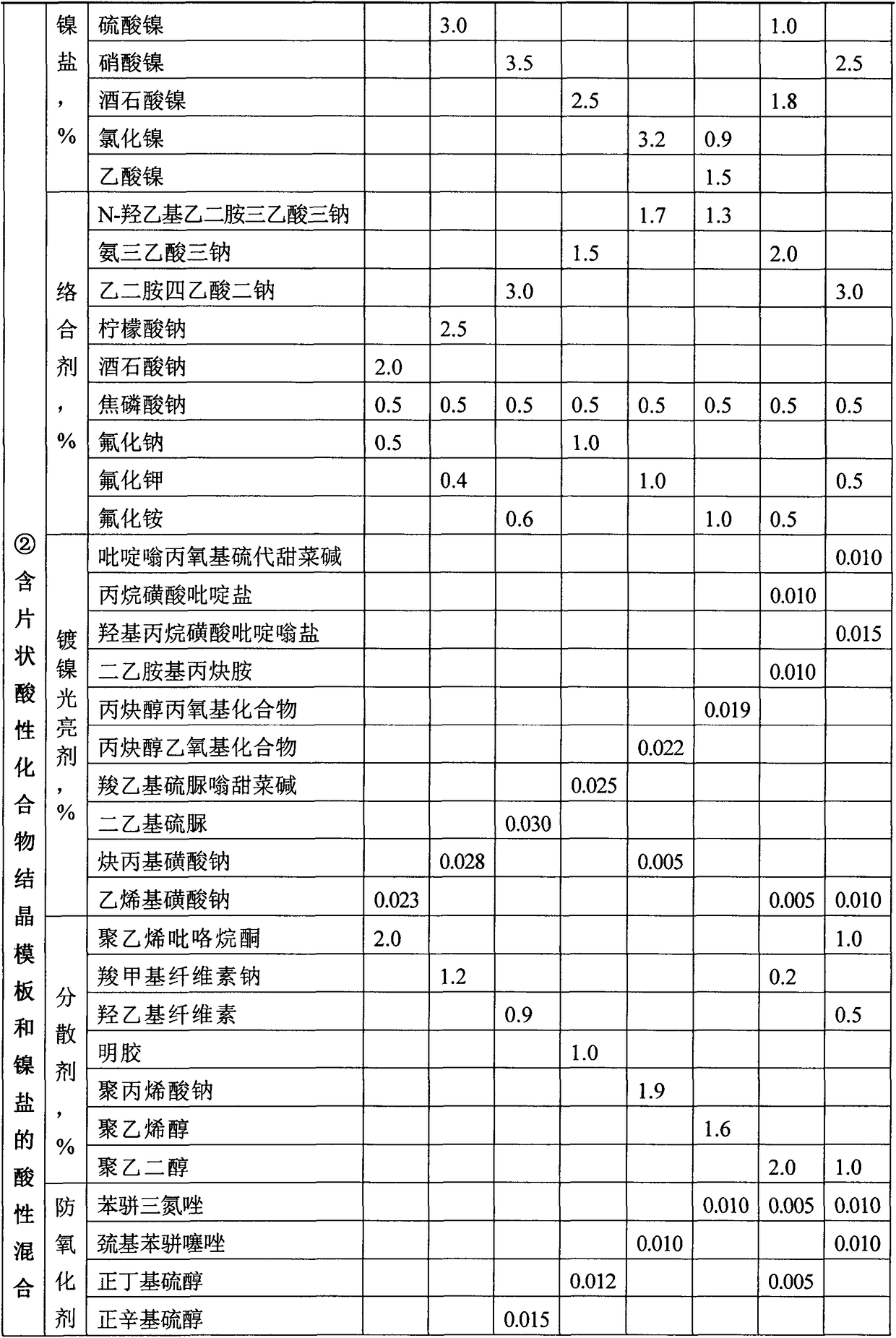

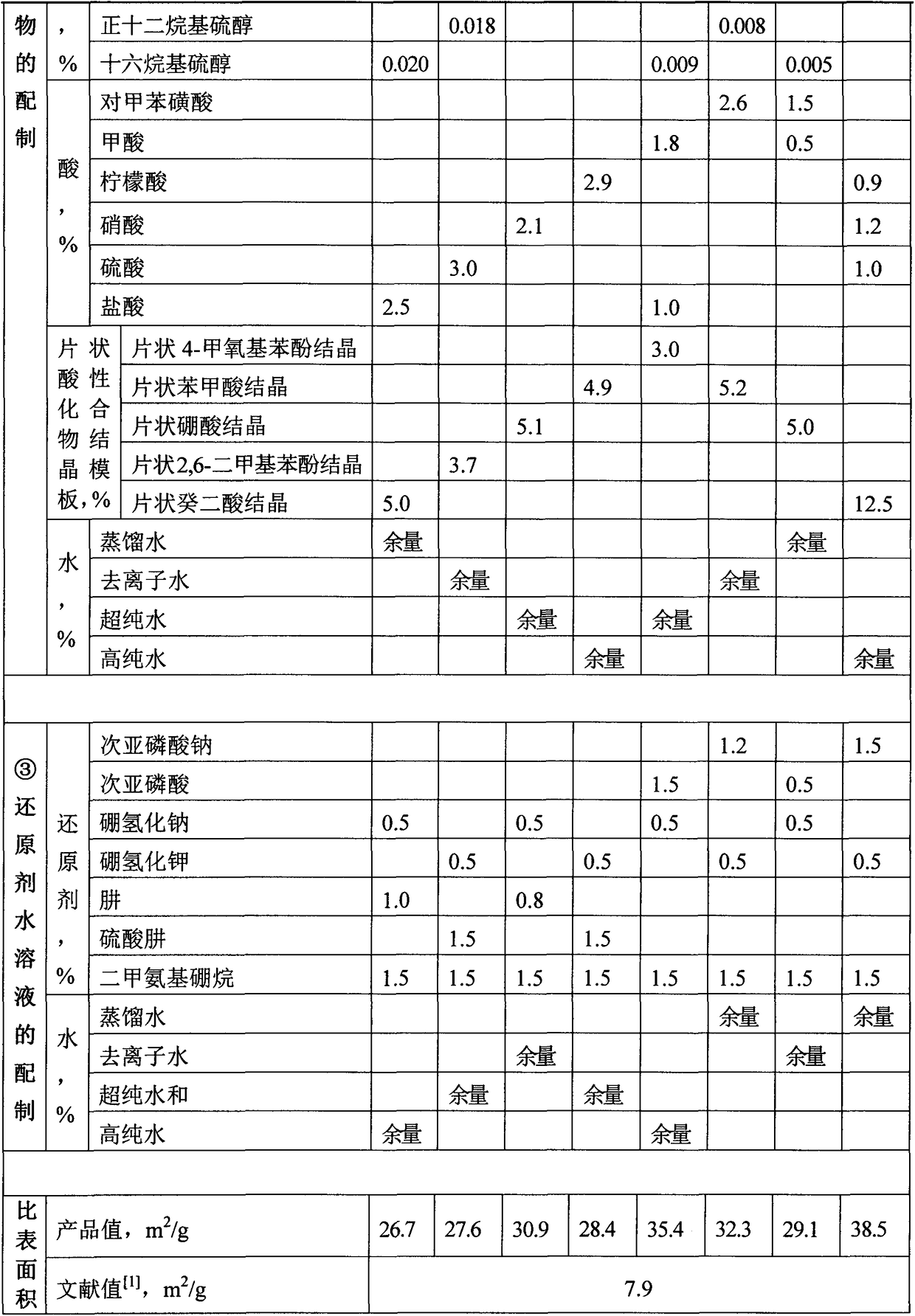

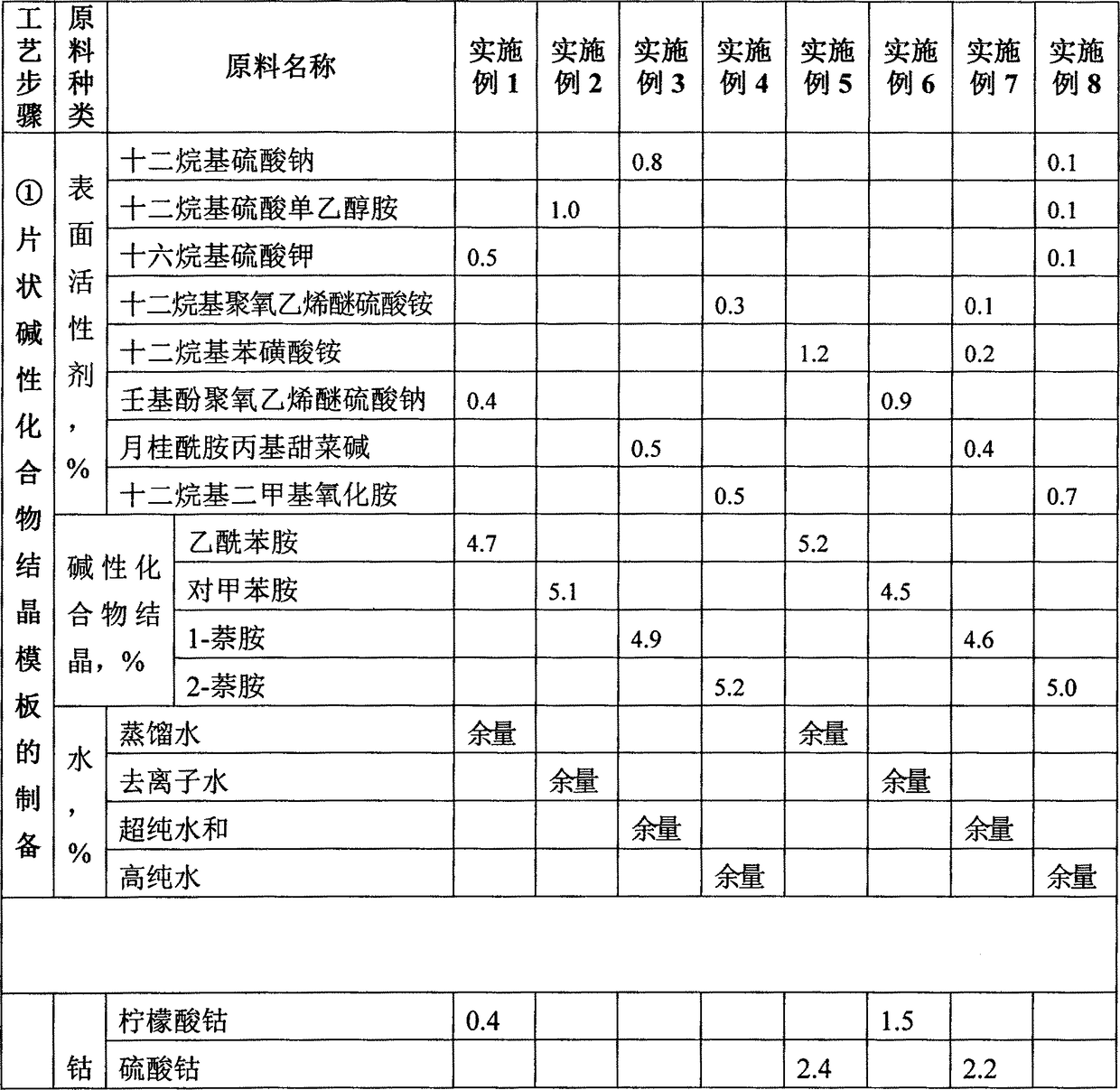

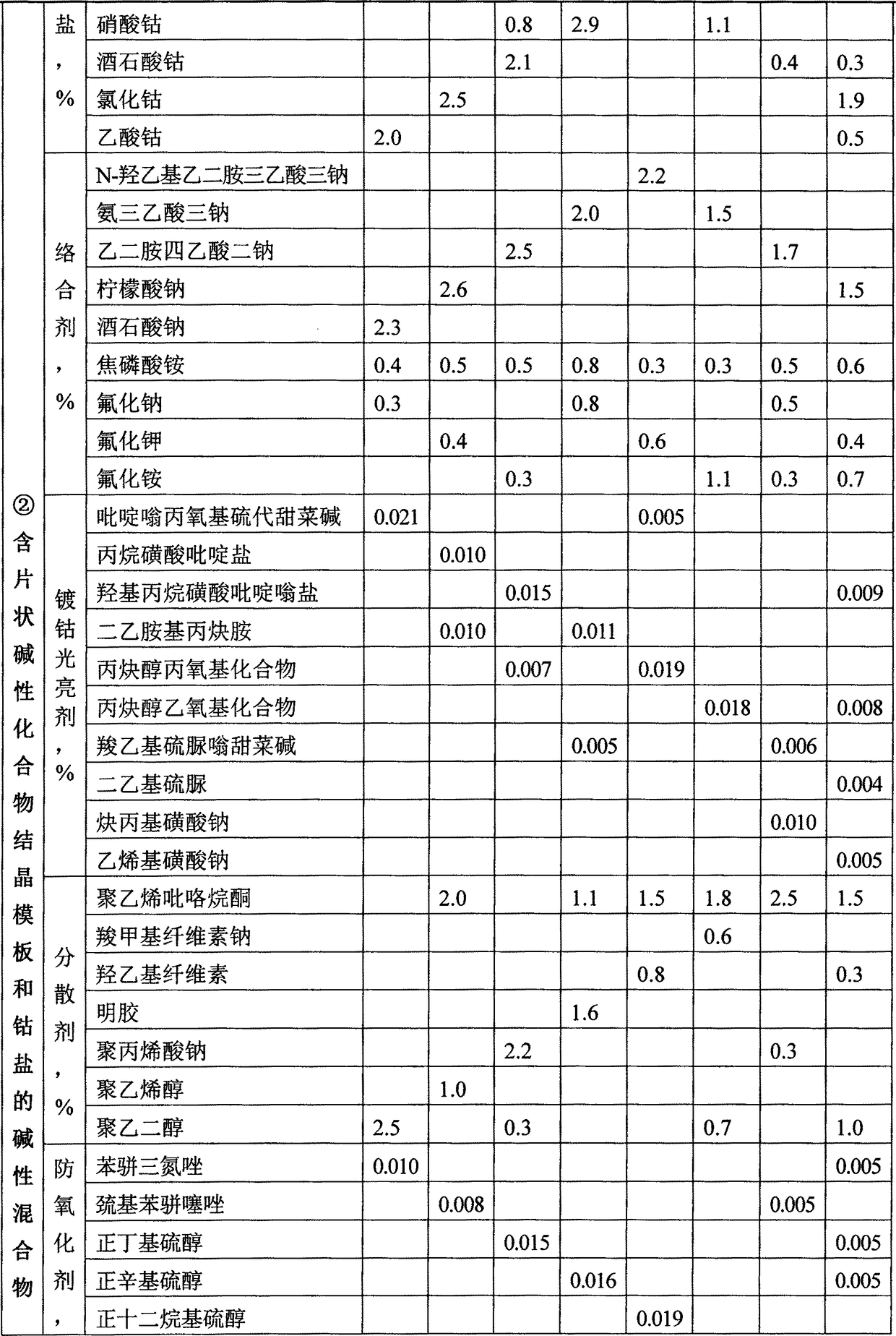

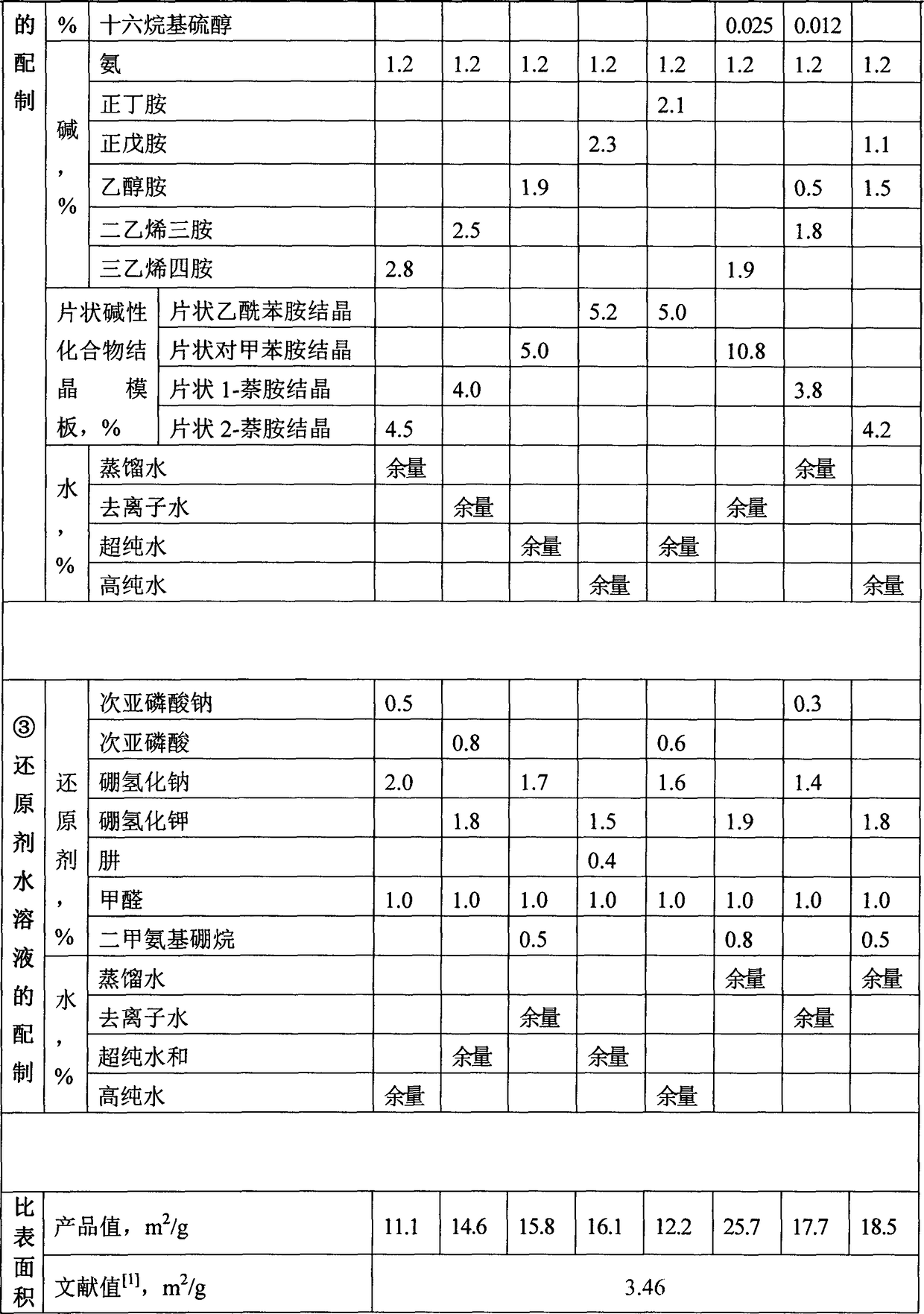

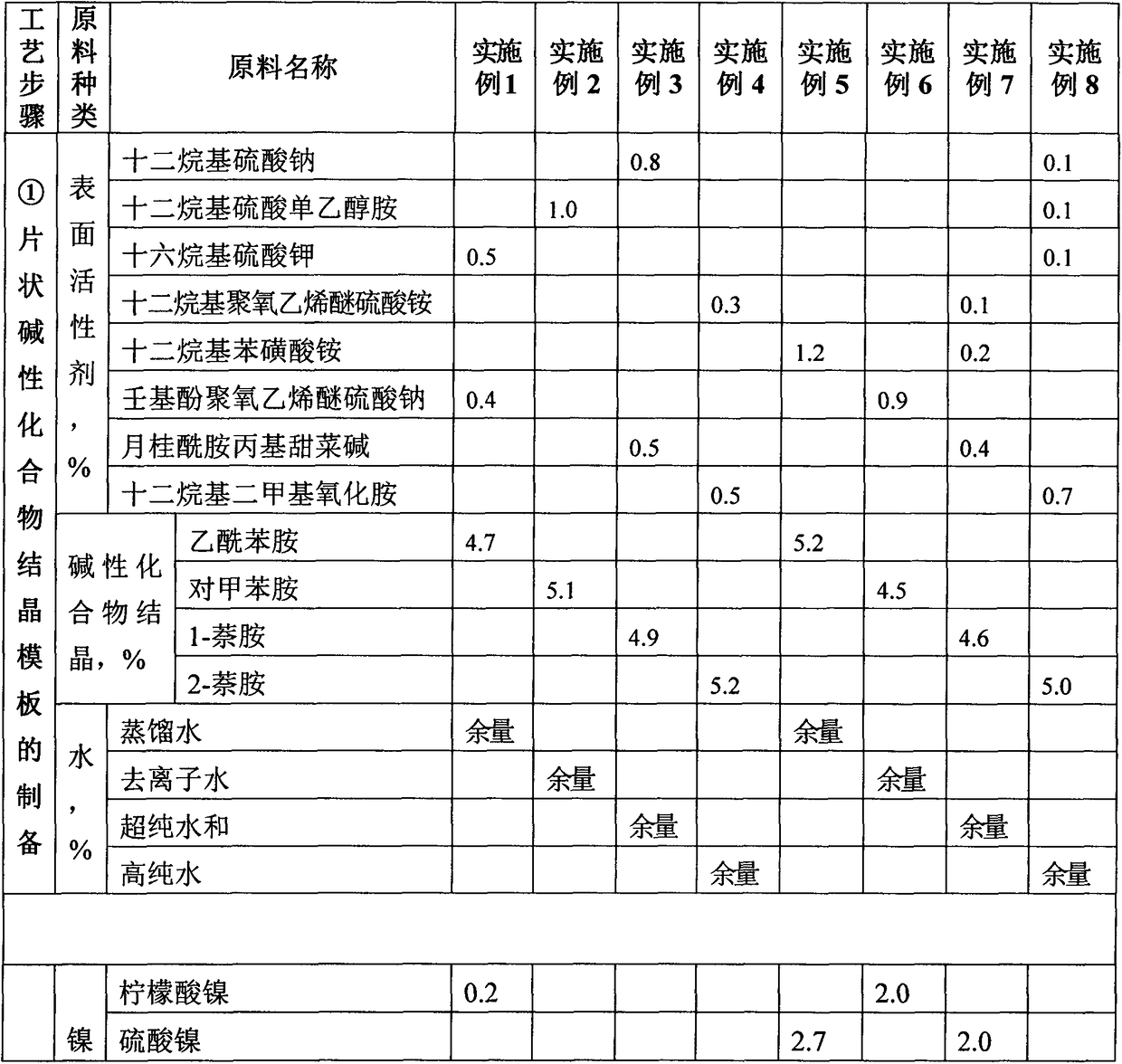

Preparation method for flaky nickel powder

InactiveCN108356281AEasy to removeSimple purification processTransportation and packagingMetal-working apparatusChemical platingNickel salt

The invention provides a preparation method for flaky nickel powder. According to the method, water, nickel salt, a complexing agent, a nickel plating brightening agent, a dispersing agent, an antioxidant, a sublimable flaky compound crystal template and a reducing agent serve as raw materials, a chemical plating method is adopted, the surface of the flaky compound crystal template is plated withnickel until nickel ions are reacted completely, and after a reaction is completed, by means of the technological processes of separation and purification and processing treatment, the flaky nickel powder is directly obtained without ball milling. By means of the technical scheme, the preparation method has a series of beneficial effects that the energy consumption is low, the environmental pollution is small, the production process is simple, the process route is short, the investment of large-scale production equipment is small, the production efficiency is high, the production cost is low,and the dispersing performance and the conductive performance of the product are good; and the preparation method is suitable for large-scale production, the problem existing in the process of preparing the flaky nickel powder through a ball milling method is solved, and the industrialization prospects are good.

Owner:NANJING FORESTRY UNIV

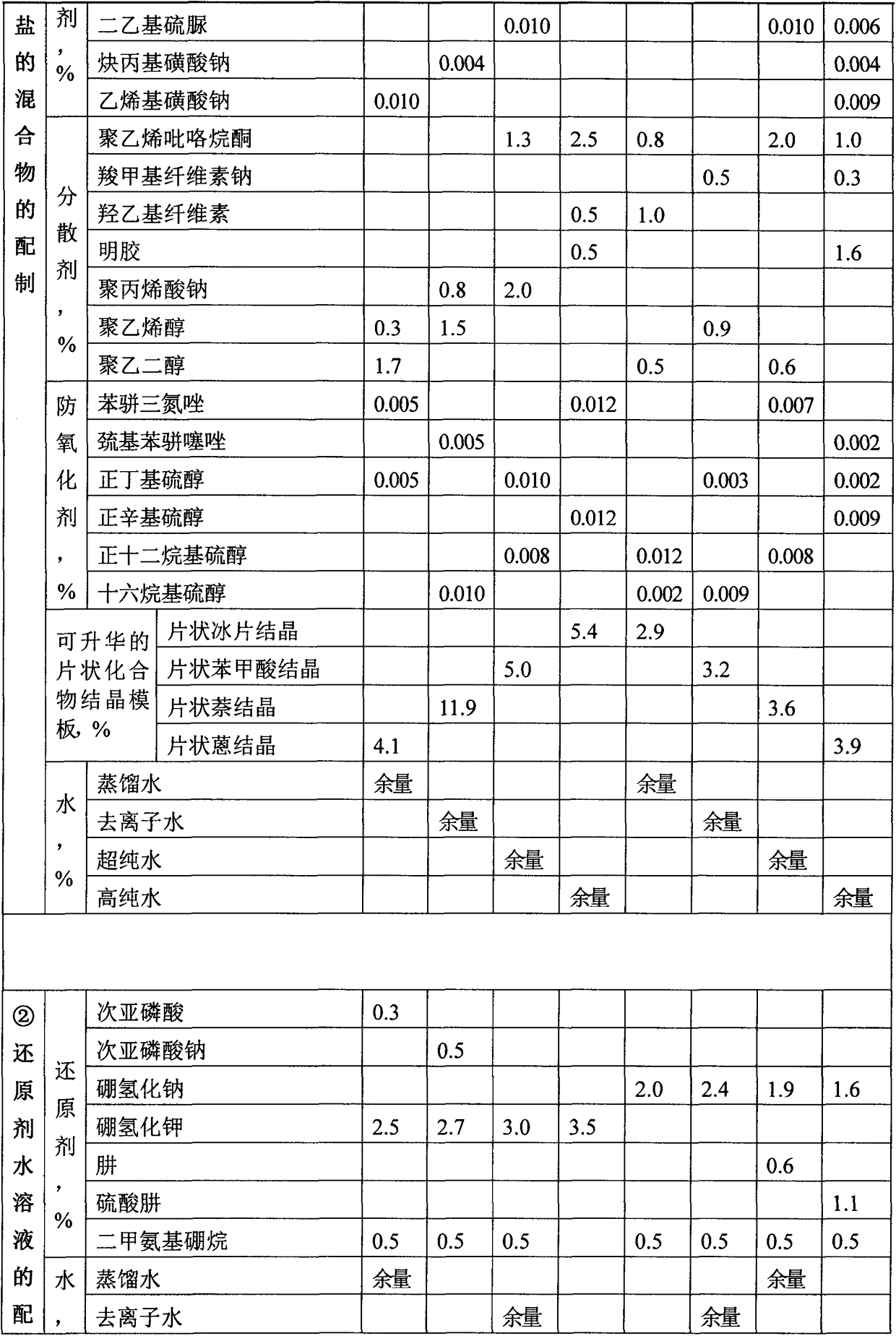

Preparation method of piece shaped cobalt powder

InactiveCN108500290ASimple purification processThe particle size control method is simple and effectiveTransportation and packagingMetal-working apparatusChemical platingAntioxidant

The invention provides a preparation method of a piece shaped cobalt powder. The method is characterized in that water, cobalt salt, a complexing agent, a cobalt plating brightener, a dispersing agent, an antioxidant, a sublimable piece shaped compound crystal die plate and a reducing agent are used as the raw materials; cobalt is plated on the surface of the sublimable piece shaped compound crystal die plate by a chemical plating method until cobalt ions completely react; after the reaction, the product is separated, purified and processed, and thus the piece shaped cobalt powder can be directly obtained without ball milling. According to the technical scheme, the preparation method has a series of advantages such as low energy consumption, low environmental pollution, simple production process, simple and short technical routes, small investment on scale production equipment, high production efficiency, low production cost, high product dispersing performance and high product conductivity; the method is suitable for scale production; the problems in a technology for preparing the piece shaped cobalt powder by a ball milling mode can be solved; and the method has a good industrialization prospect.

Owner:NANJING FORESTRY UNIV

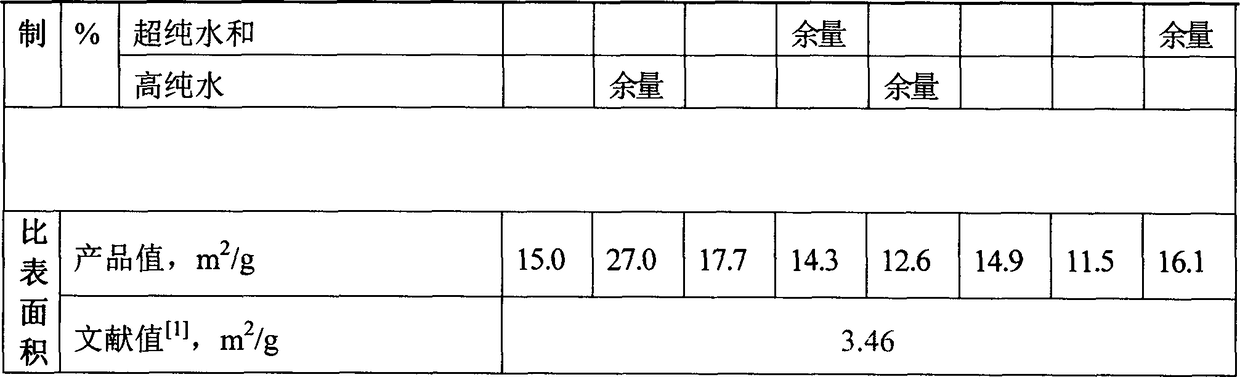

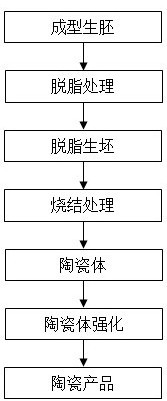

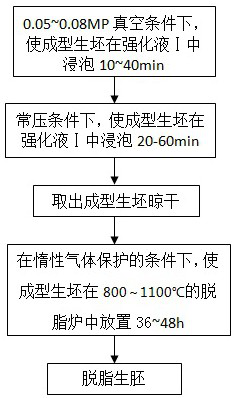

Ceramic strengthening treatment method based on 3D printing

The invention belongs to a ceramic strengthening method, and particularly relates to a ceramic strengthening treatment method based on 3D printing. The method comprises the following steps: degreasinga molded green body subjected to ceramic 3D printing to obtain a degreased green body; sintering the degreased green body to obtain a ceramic body, and finally strengthening the ceramic body. The degreasing treatment comprises green body primary strengthening and green body degreasing, and the sintering treatment comprises green body secondary strengthening and green body sintering. According tothe technical scheme, the problems of low strength and large shrinkage of a molded green body of existing ceramic 3D printing after degreasing can be solved, so that the reliability of ceramic post-treatment is improved, and the success rate of a ceramic 3D printing technology is increased, namely, the yield of ceramic 3D printing products is increased; and meanwhile, the strength of the ceramic products is also improved.

Owner:康硕(德阳)智能制造有限公司

Preparation method for flaky cobalt powder in acid medium

InactiveCN108356283ASave resourcesEmission reductionMaterial nanotechnologyTransportation and packagingChemical platingCobalt salt

The invention provides a preparation method for flaky cobalt powder. According to the method, water, cobalt salt, a complexing agent, a cobalt plating brightener, a dispersing agent, an antioxidant, acid, a flaky acidic compound crystal template and a reducing agent serve as raw materials, the surface of the flaky acidic compound crystal template is plated with cobalt by adopting a chemical plating method until cobalt ions react completely, and after the reaction, the flaky cobalt powder is directly obtained through the technological processes of separation, purification and processing treatment without ball milling. The technical scheme of the preparation method has the advantages that the energy consumption is low, the environmental pollution is small, the production process is simple, the process route is short, the large-scale production equipment investment is low, the production efficiency is high, the production cost is low, the dispersing performance and the conductivity of a product are good, the method is suitable for large-scale production, the problems existing in a technology for preparing the flaky cobalt powder through a ball milling method can be solved, and the method has a good industrialization prospect.

Owner:NANJING FORESTRY UNIV

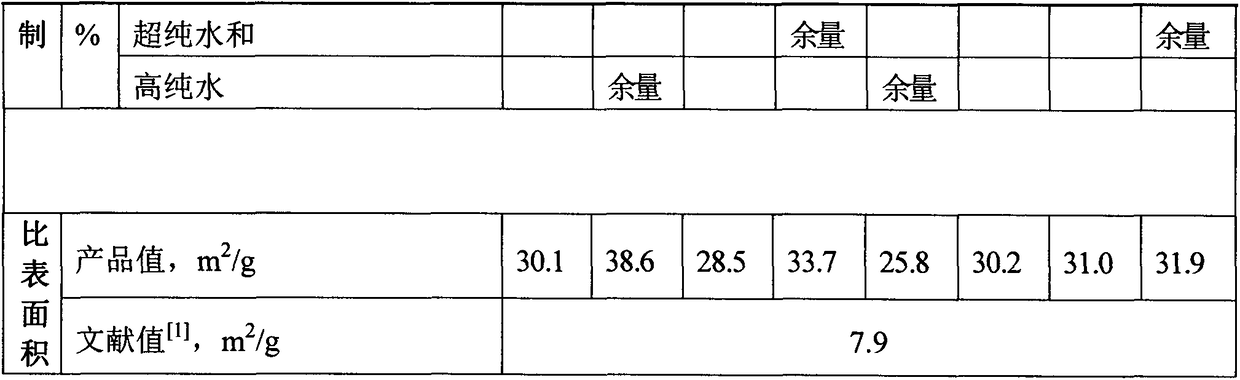

Method for preparing flaky nickel powder through acid medium

InactiveCN108500287AHigh process requirementsImprove production success rateTransportation and packagingMetal-working apparatusChemical platingNickel salt

The invention provides a method for preparing flaky nickel powder. The method is characterized in that water, nickel salt, a complexing agent, a nickel plating brightening agent, a dispersing agent, an antioxidant, acid, a flaky acidic compound crystal template and a reducing agent are taken as raw materials, nickel plating is carried out on the surface of the flaky acidic compound crystal template by adopting a chemical plating method until nickel ions react completely, and after the reaction is finished, the flaky nickel powder is directly obtained through a separation and purification treatment and a processing treatment without ball milling. The technical scheme of the method has the advantages that the energy consumption is low, environmental pollution is low, the production process is simple, the process route is short, the investment to the large-scale production equipment is low, the production efficiency is high, the production cost is low, and the dispersion performance and the conductivity of the products are good; and the method is suitable for large-scale production and capable of solving the problems exist in the ball milling process when the ball milling process is used for preparing the flaky nickel powder, and has good industrialization prospect.

Owner:NANJING FORESTRY UNIV

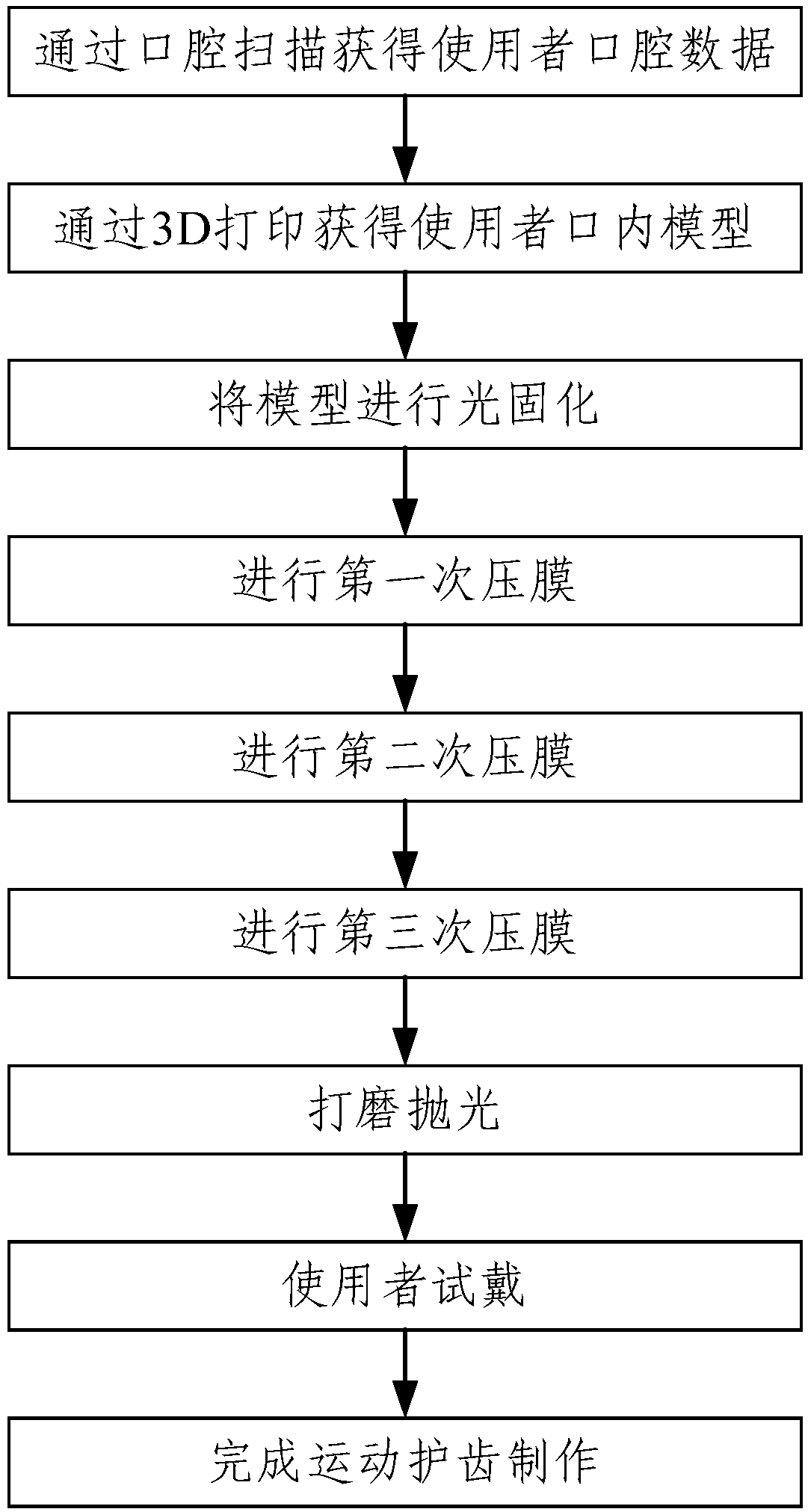

Oral custom-made sports tooth protection manufacturing method and obtained sports tooth protection

InactiveCN109260695AAvoid defectsImprove stabilityOrgan movement/changes detectionUltrasonic/sonic/infrasonic dianostic techniquesEngineeringSports mouth guard

The embodiment of the invention discloses a manufacturing method of an oral custom-made sports tooth protection, which is used for solving the problems of uncomfortable wearing, poor protective effectand high manufacturing difficulty of various types of sports tooth protection in the prior art. The embodiment of the invention also provides a sports tooth protection obtained by the manufacturing method. The tooth protection originally creates a three-laminated film structure, improves the technical defects of the original processing links, and improves the protection level of the existing professional oral customized sports tooth protection to level 8-9.

Owner:沈阳市佳艺义齿加工厂

Method for preparing flaky silver powder through alkaline medium

InactiveCN108500289AHigh purityEasy to removeTransportation and packagingMetal-working apparatusChemical platingEnergy consumption

The invention provides a method for preparing flaky silver powder. The method is characterized in that water, silver salt, a complexing agent, a silver plating brightening agent, a dispersing agent, alkali, a flaky alkaline compound crystal and a reducing agent are taken as raw materials, silver plating is carried out on the surface of the flaky alkaline compound crystal by adopting a chemical plating method until silver ions react completely, and after the reaction is finished, the flaky silver powder is directly obtained through a separation and purification treatment and a processing treatment without ball milling. The technical scheme of the method has the advantages that the energy consumption is low, environmental pollution is low, the production process is simple, the process routeis short, the investment to the large-scale production equipment is low, the production efficiency is high, the production cost is low, and the dispersion performance and the conductivity of the products are good; and the method is suitable for large-scale production and capable of solving the problems exist in the ball milling process when the ball milling process is used for preparing the flakysilver powder, and has good industrialization prospect.

Owner:NANJING FORESTRY UNIV

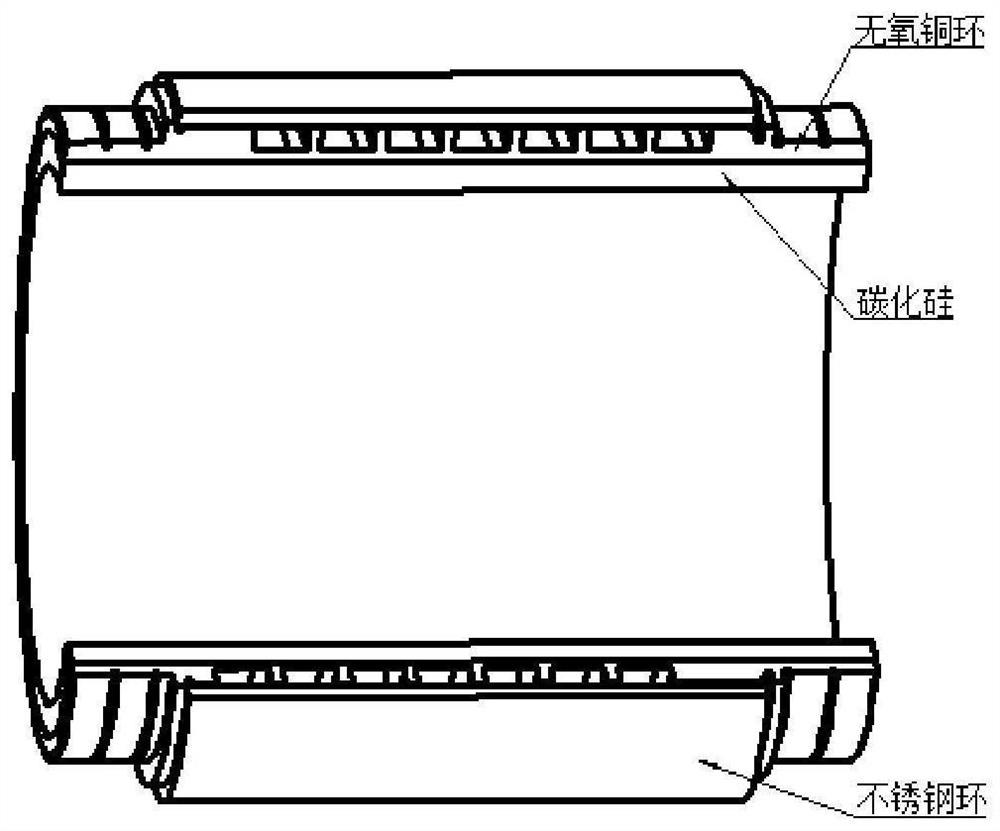

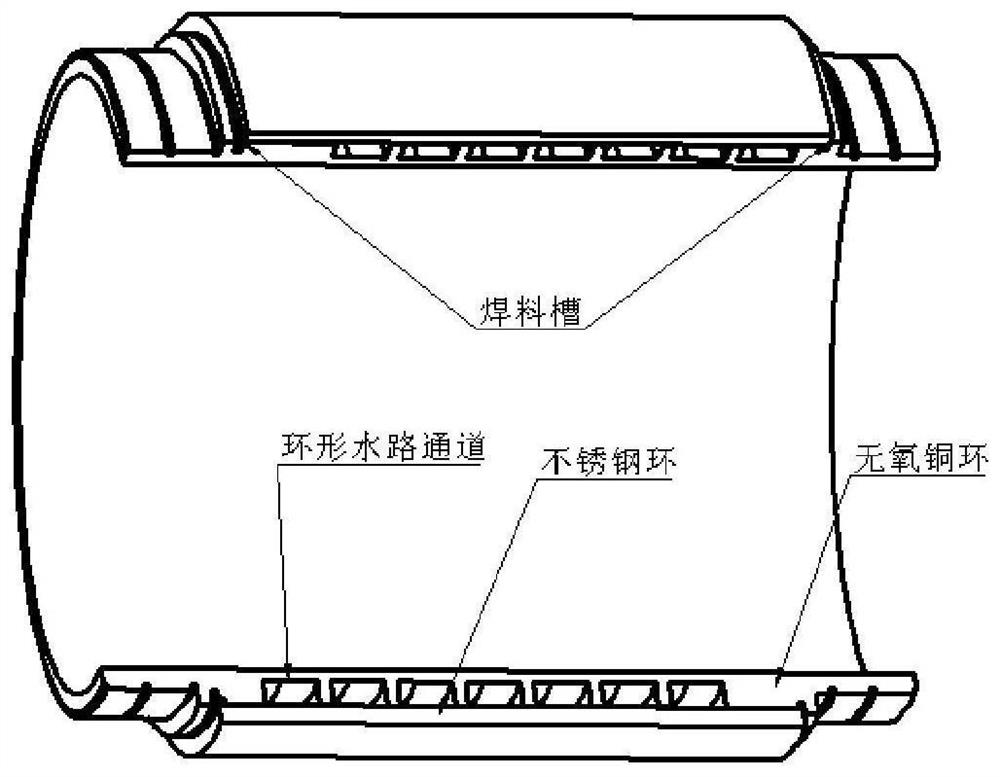

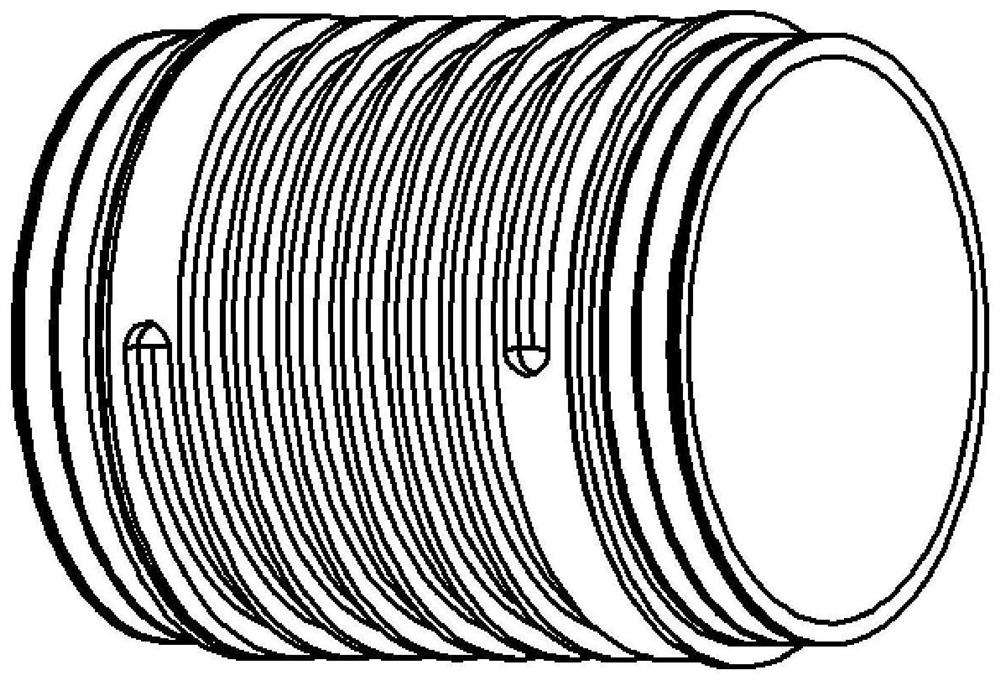

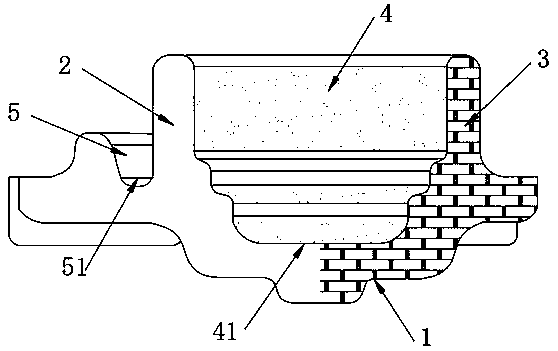

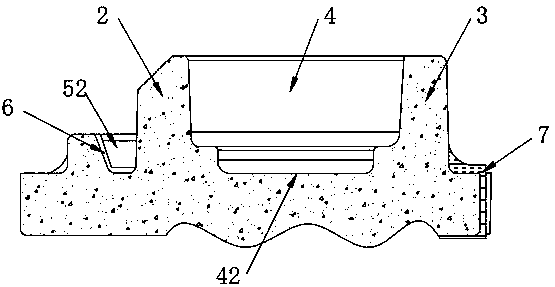

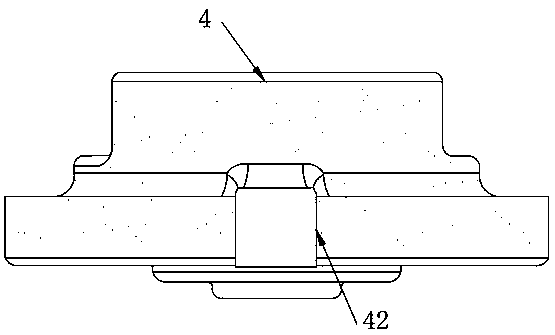

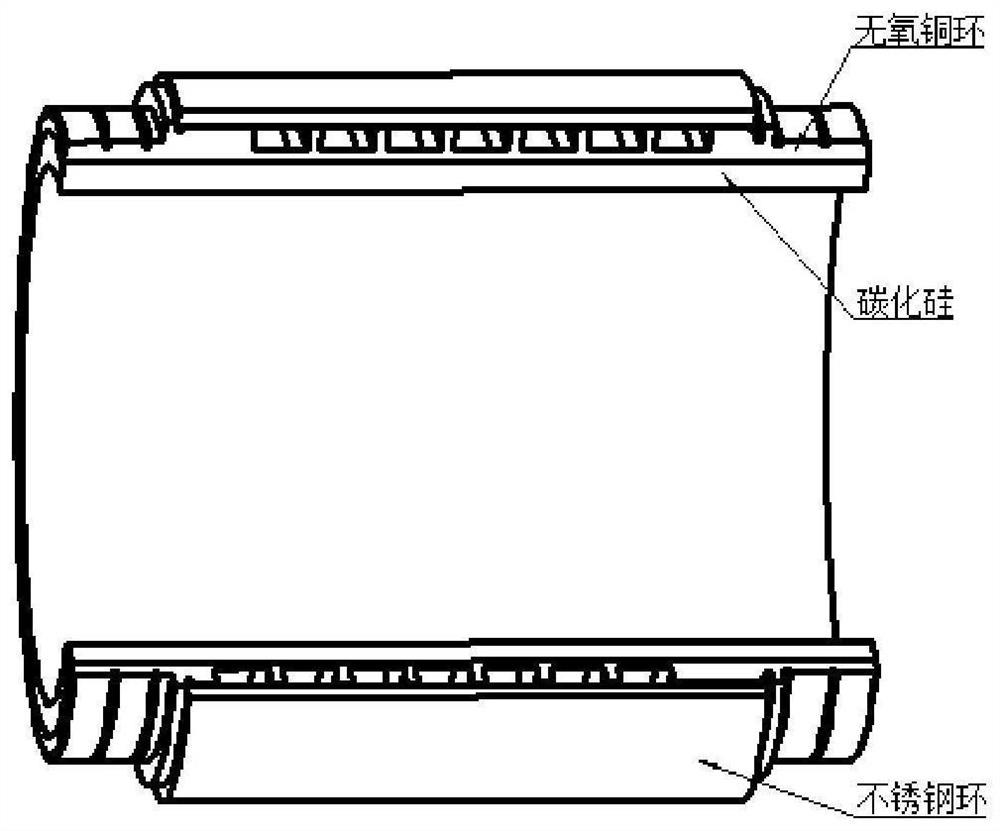

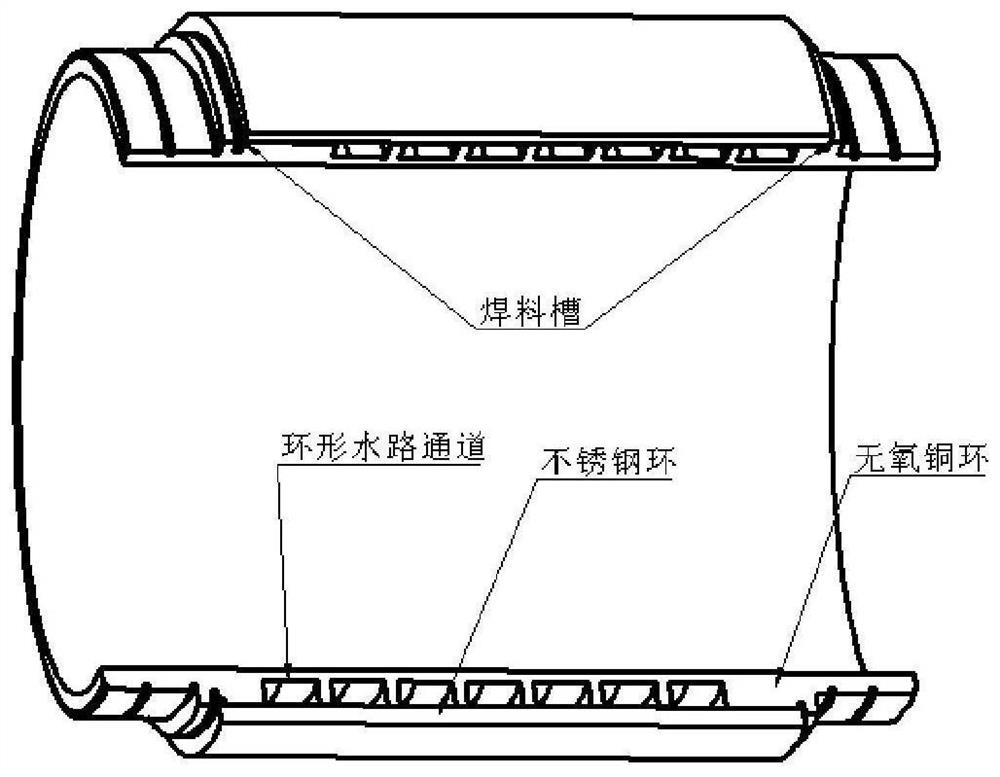

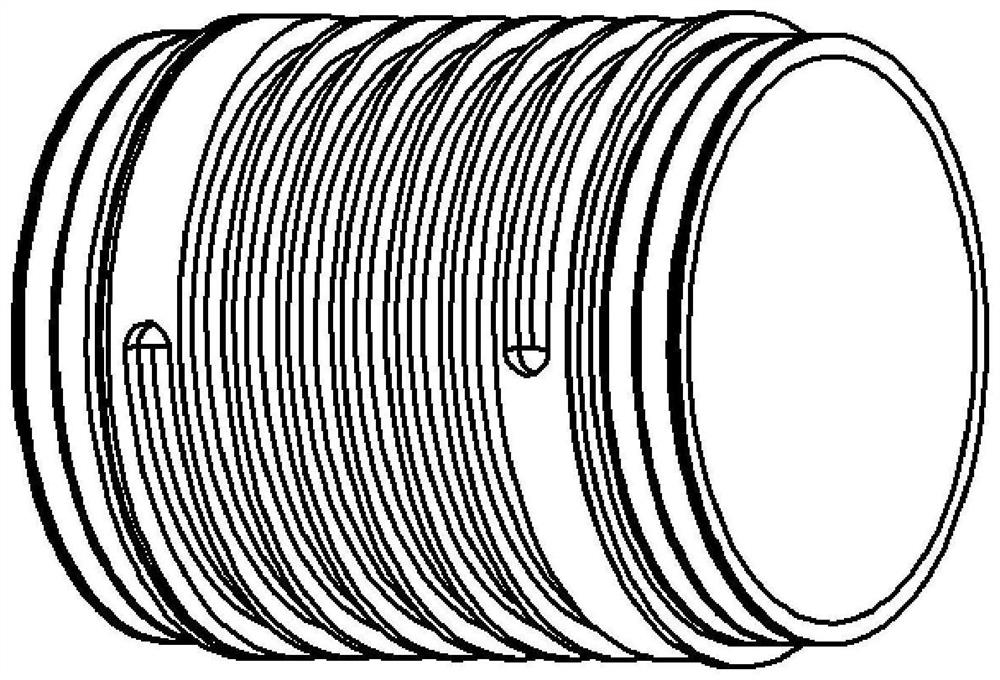

Manufacturing method of high-order mode absorber

ActiveCN111889834BImprove protectionCompact structureSoldering apparatusAssembly machinesEngineeringSS - Stainless steel

The invention discloses a novel structure of a high-order mode absorber, which includes barrel-shaped silicon carbide, an oxygen-free copper ring and a stainless steel ring, which are sequentially sleeved and assembled from the inside to the outside; the outer wall of the oxygen-free copper ring and the inner wall of the stainless steel ring are jointly A ring-shaped water channel for cooling is formed, and matching solder grooves and positioning bosses are formed at the joint surfaces of the two ends of the oxygen-free copper ring and the stainless steel ring. The utility model has the advantages of simple structure, small volume, easy manufacture, high strength and good reliability, and is suitable for mass production. A manufacturing method is also disclosed, including: a, feasibility demonstration of oxygen-free copper ring and silicon carbide thermal assembly; b, welding of oxygen-free copper ring and stainless steel ring; c, installation of absorber; d, oxygen-free copper ring and Absorber assembly tightness inspection; e, water pressure inspection. The method is simple, compact in structure, high in production success rate, and short in cycle; at the same time, less chemicals and metal raw materials are used in production, which reduces production risks and is beneficial to environmental protection.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Automatic forming technology for airbag gas generator

The invention relates to an automatic forming technology for an airbag gas generator. The technology comprises steps as follows: 1, cutting: raw materials are cut and pre-pressed, and a to-be-processed blank material is formed; 2, deep drawing: the blank material is subjected to two sections of deep drawing, and a two-layer stepping pipe body is formed; 3, pre-shaping: force is uniformly applied to the surface of the stepping pipe body through vertical buckling of a shaping die to correct the appearance; 4, rough cutting: excess materials on the outer edge of the bottom of the stepping pipe body is cut off; 5, punching: the top side wall of the stepping pipe body is punched; 6, accurate cutting: the outer edge of the bottom layer of the stepping pipe body is subjected to further accurate cutting according to defined size; 7, chamfering: the stepping pipe body is buckled by a die provided with chamfers, and the chamfers are punched; 8, shell nosing: the bottom of the stepping pipe bodyis bent inwards gradually, and final closed shell noising is performed; 9, setting: a finished product is subjected to final shaping processing by a shaping die. A highly integrated automatic processing device is obtained on the basis of the whole processing technology, so that the occupied area is reduced, the processing efficiency is improved, the processing time is shortened, and the success rate of product production is increased.

Owner:伟业精密科技(惠州)有限公司

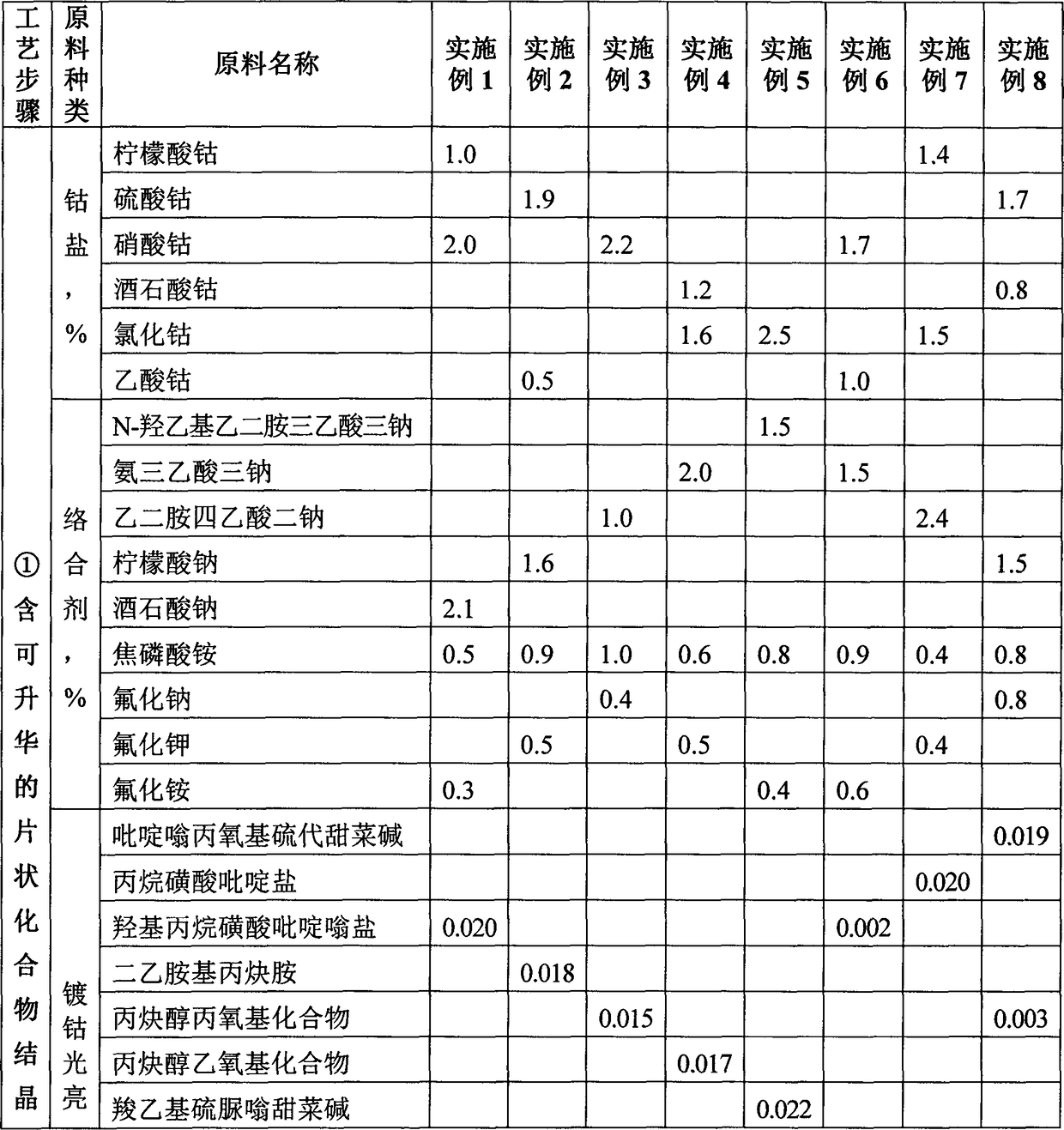

Preparation method of flaky cobalt powder in alkaline medium

ActiveCN108500291ASave template resourcesReduce manufacturing costTransportation and packagingMetal-working apparatusChemistryChemical plating

The invention provides a preparation method of flaky cobalt powder in an alkaline medium. The preparation method of the flaky cobalt powder in the alkaline medium comprises the steps that water, cobalt salt, a complexing agent, a cobalt plating brightener, a dispersing agent, an antioxidant, alkali, flaky alkaline compound crystal templates and a reducing agent are used as raw materials, a chemical plating method is adopted, the surfaces of the flaky alkaline compound crystal templates are plated with cobalt until cobalt ions completely react, after reaction is ended, the technological processes of separation, purification and processing treatment are conducted, and the flaky cobalt powder is directly obtained without ball milling. The preparation method of the flaky cobalt powder in the alkaline medium has a series of advantages of being low in energy consumption, low in environmental pollution, simple in production technology, short in operational path, small in large-scale production equipment investment, high in production efficiency and low in production cost, achieving that the dispersing performance and the catalytic performance of the product are good and the like. The preparation method of the flaky cobalt powder in the alkaline medium is suitable for large-scale production, solves the problems existing in the technology of preparing the flaky cobalt powder with a ball-milling method and has good industrial prospects.

Owner:NANJING UNIV OF TECH

Preparation method for flake nickel powder in alkaline media

InactiveCN108405877ASave resourcesEmission reductionMaterial nanotechnologyTransportation and packagingNickel saltAntioxidant

The invention provides a preparation method for flake nickel powder in alkaline media. According to the method, water, nickel salt, complexing agents, nickel plating brighteners, dispersing agents, antioxidants, alkalis, a flake alkali compound crystallization template and reducing agents are used as raw materials, a chemical plating method is adopted, the surface of the flake alkali compound crystallization template is nickelplated until a nickel ion reaction is complete, and after the reaction is over, the flake nickel powder is directly obtained through separation, purification and processing treatment technological processes without ball milling. The technical scheme has a series of beneficial effects that energy consumption is low, environmental pollution is low, the production process is simple, the process route is short, large-scale production equipment investment is low, the production efficiency is high, the production cost is low, the dispersing performance and conductivityof a product are good, and the like, the method is suitable for large-scale production, the problems existing in the process of preparing the flake nickel powder by ball milling are solved, and the industrialization prospects are good.

Owner:NANJING FORESTRY UNIV

Continuous punch forming technology for airbag gas generator

InactiveCN107983841ASmall footprintImprove processing efficiencyVehicle componentsEngineeringProduct gas

The invention relates to a continuous punch forming technology for an airbag gas generator. The technology comprises steps as follows: raw materials are cut and pre-pressed, and a to-be-processed blank material is formed; the blank material is subjected to first-section deep drawing, and a columnar workpiece with height H is produced; the workpiece is subjected to second-section deep drawing, a punch of a second-section deep drawing position is arranged along a center axis of the columnar workpiece, the deep drawing height after the punch is ejected out is larger than H, and the diameter of the punch of the second-section deep drawing position is smaller than that of a punch of a first-section deep drawing position; N sections of deep drawing positions are set, the workpiece is subjected to stepping deep drawing, and the specific number of sections of the deep drawing and height are set according to processing parameters; cavities based on vertical buckled ejection press are adopted, and the workpiece after deep drawing is subjected to shaping press; the workpiece in a shaping position is conveyed to a cutting position by a conveying device; unnecessary waste is removed by cuttingedges and corners of the workpiece. The whole processing technology is highly integrated, so that the processing efficiency is improved, the processing time is shortened, and the success rate of product production is increased.

Owner:伟业精密科技(惠州)有限公司

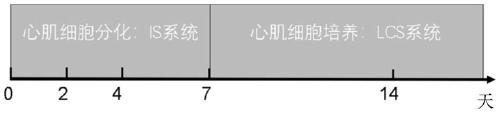

Myocardial cell induction and growth medium

PendingCN111500532AImprove production success rateProduction success rate advantageCulture processSkeletal/connective tissue cellsHuman albuminCell culture media

Owner:上海中医大生物科技有限公司

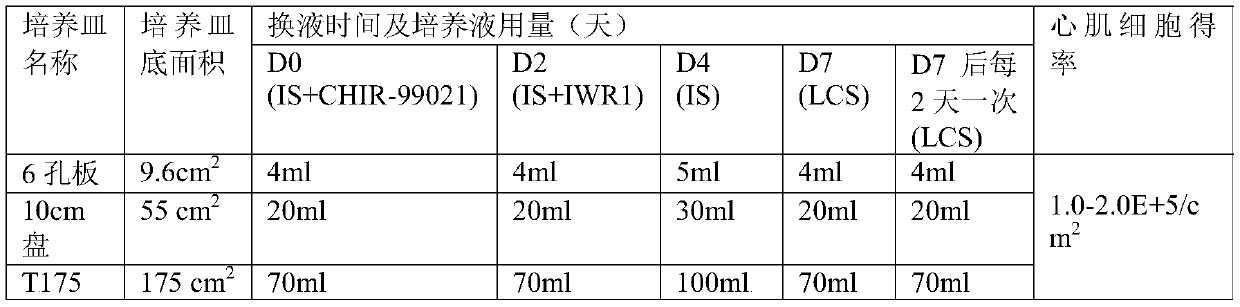

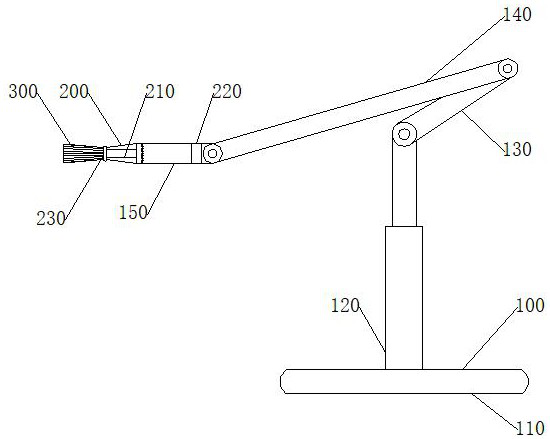

Multifunctional diagnosis and treatment manipulator for midwifery

ActiveCN113633361AReduce vacuum suctionReduce deformationObstetrical instrumentsEngineeringFetus fetus

The invention discloses a multifunctional diagnosis and treatment manipulator for midwifery. The multifunctional diagnosis and treatment manipulator comprises a mechanical arm assembly, and further comprises an operation assembly and an adsorption assembly; the mechanical arm assembly is used for traction operation of a fetus; the mechanical arm assembly comprises a plurality of rotating arms, so that the mechanical arm assembly can adjust the fetus traction angle; the mechanical arm assembly comprises a positioning arm, and the positioning arm is a section of rotating arm at the moving end of a rotating arm of the mechanical arm assembly; the operation assembly is fixed on the positioning arm; the adsorption assembly comprises a disc-shaped piece, a unit suction cup, a guide pipe, a traction pipe, a central negative pressure pipe and a camera; the disc-shaped piece is made of a flexible airtight material and is used for covering the head of the fetus; and a through hole is formed in the center of the disc-shaped piece, the through hole is fixedly communicated with the center negative pressure pipe, and the through hole of the disc-shaped piece is fixedly connected with a telescopic rod at the same time, so that the telescopic rod can drive the disc-shaped piece to penetrate through a positioning ring to move. The manipulator can assist the delivery process of a puerpera.

Owner:济南高投园区运营管理有限公司

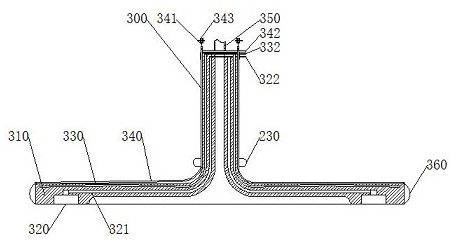

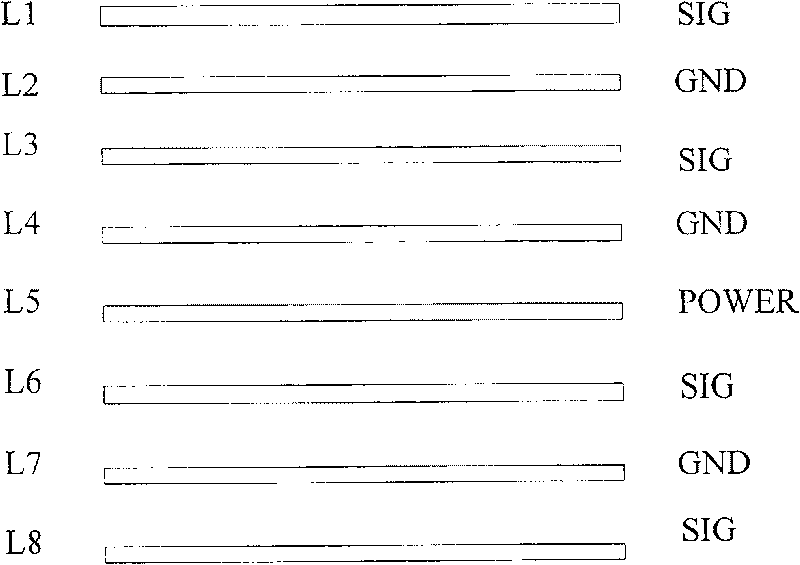

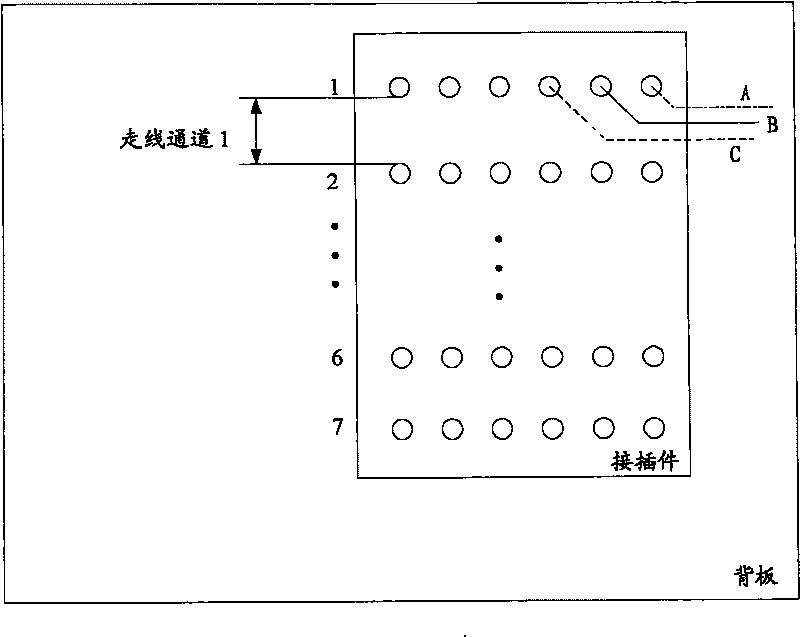

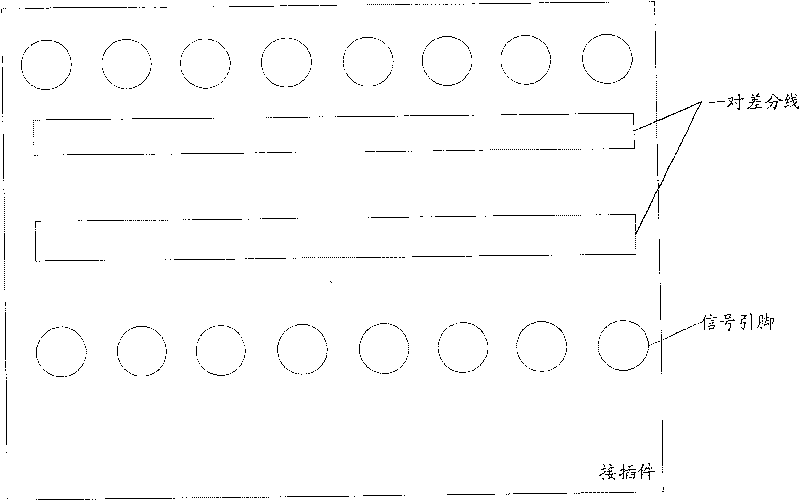

Circuit board

InactiveCN101146399BReduce the difficulty of productionReduce manufacturing costPrinted circuit detailsMinimum distanceElectrical and Electronics engineering

The invention discloses a multilayered circuit board which is connected with an element to improve the utilization rate of circuit boards stacking and to reduce the number of layers of stacked circuitboards, thereby reducing production difficulty and production cost of the circuit board and improving production success rate of the circuit board. The element has rows of signal pins; the circuit board has rows of through-holes; the signal pins of the element are inserted to rows of through-holes of the circuit board; and on the same layer of the circuit board, at least two signal wires connected to the signal pins, which are inserted to two adjacent rows of the through-holes, are arranged between two adjacent rows of the through-holes to which the signal pins are inserted. The signal wirestransport non-paired signals.

Owner:RUIJIE NETWORKS CO LTD

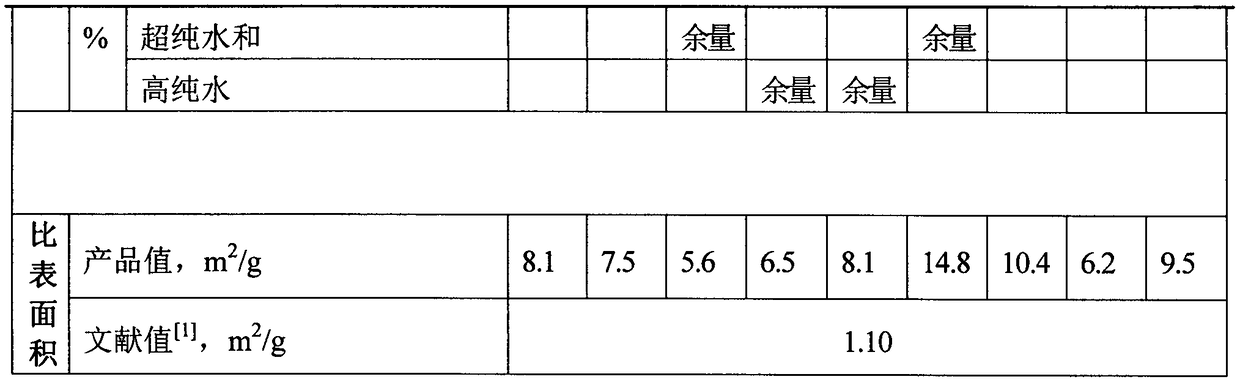

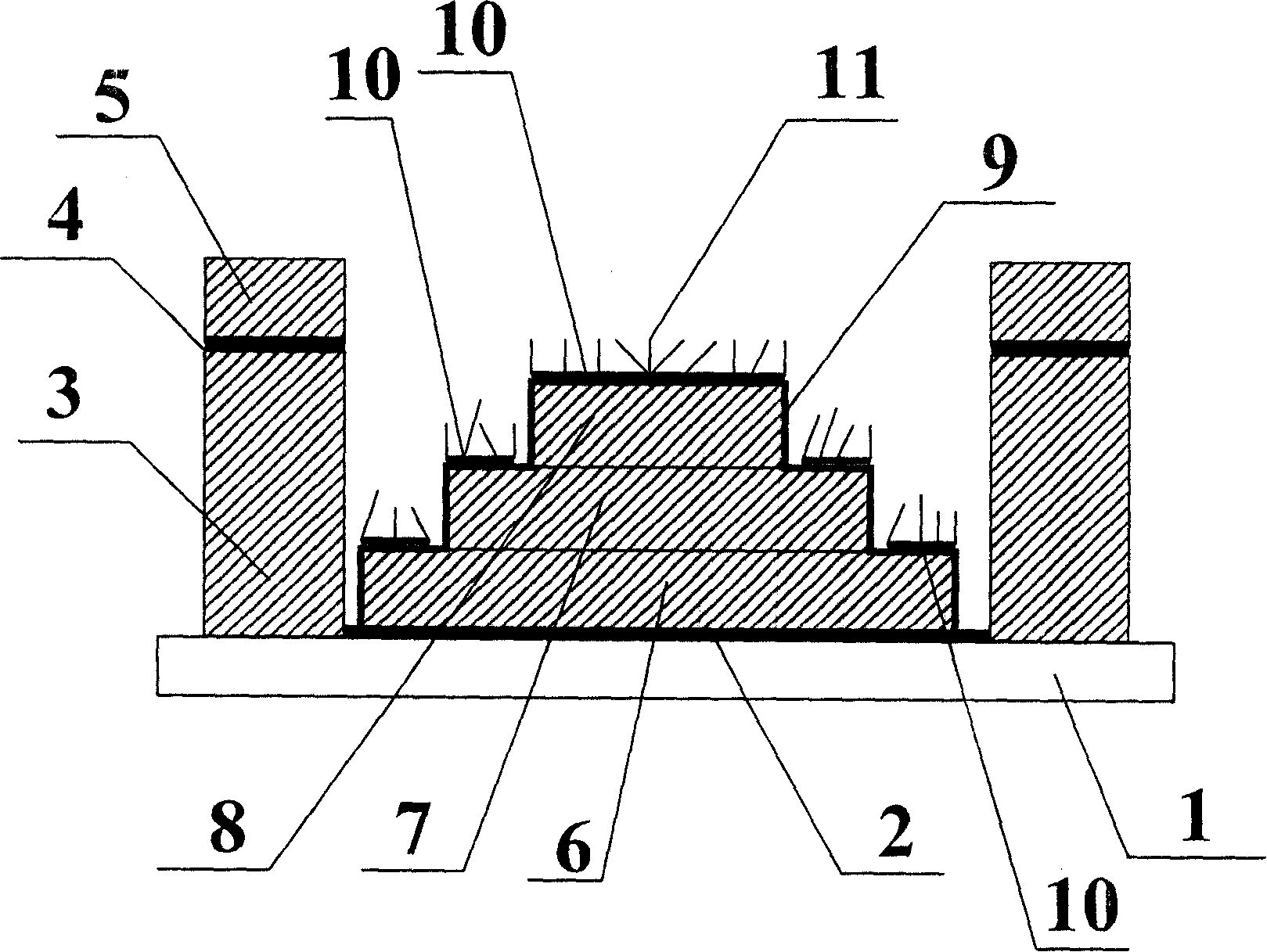

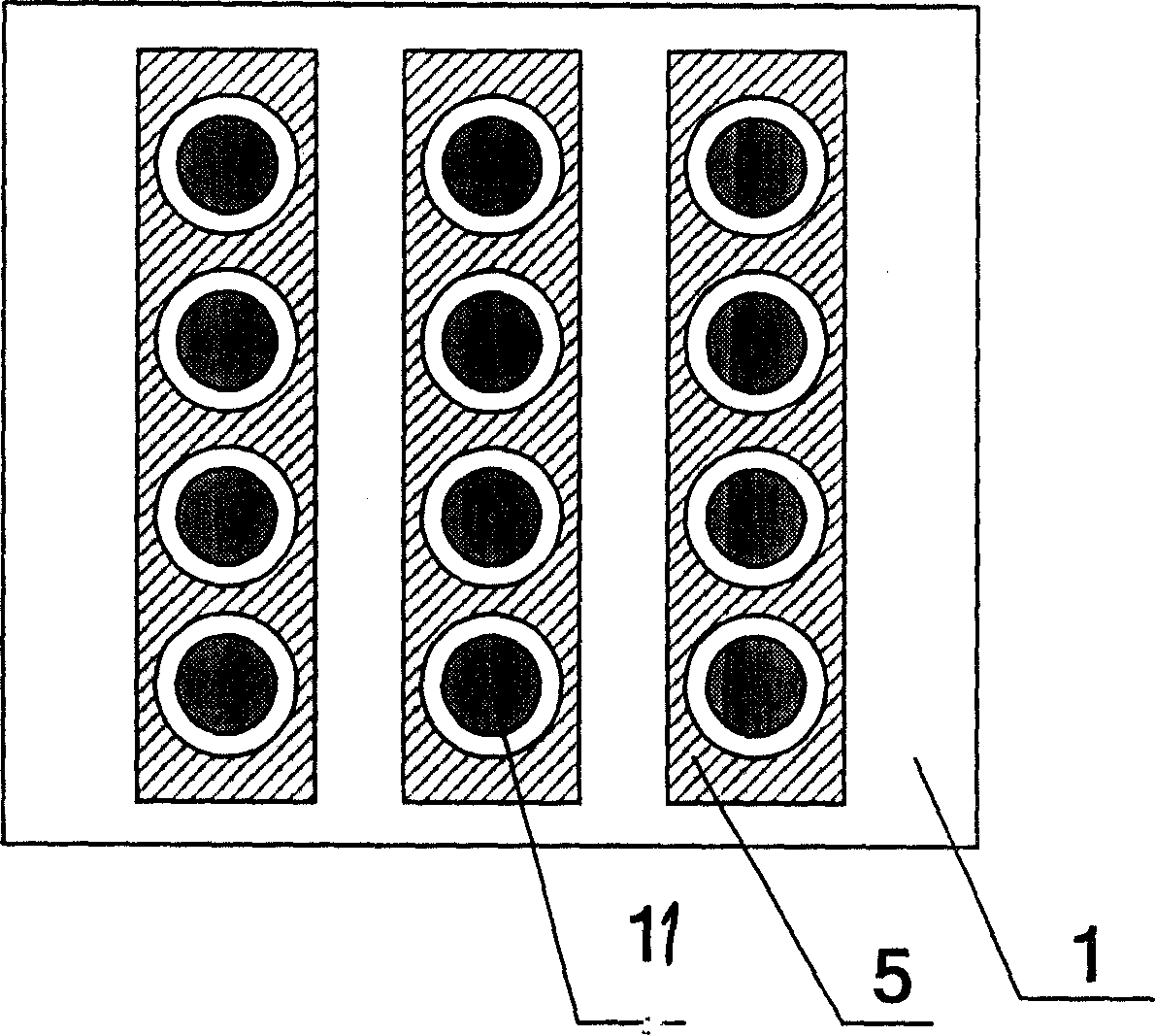

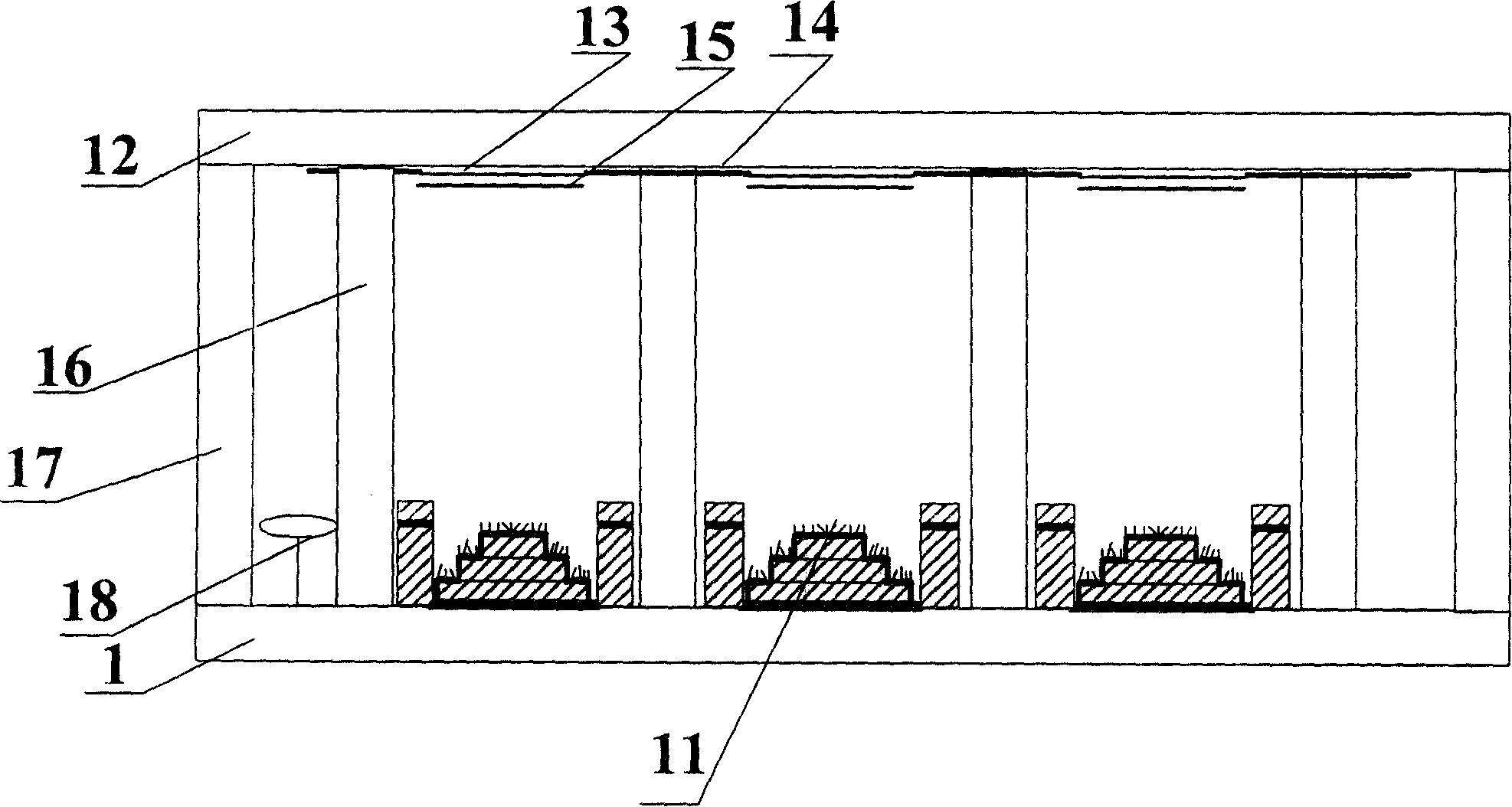

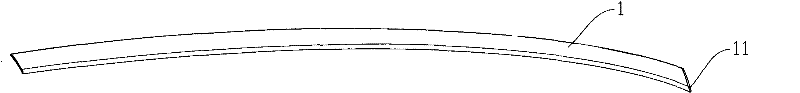

Coaxial multi-loop column type cathode array structural panel display device and its production technique

InactiveCN1909166AAvoid short circuitImprove production success rateControl electrodesImage/pattern display tubesCarbon nanotubeControl grid

The invention relates to a plate display in coaxial multi-annular cylinder cathode array emission structure and relative production, wherein it comprises an anode glass panel, a cathode glass panel, and a sealing vacuum chamber surrounded by four glass frames; the anode glass panel is arranged with anode conductive layer and a fluorescent powder layer is above the conductive layer; a support wall structure and a gattering additional element are between the anode glass panel and the cathode glass panel; a control grid, a carbon nanometer tube cathode and coaxial multi-annular cylinder cathode array emission structure are arranged on the cathode glass panel. The invention can effectively shorten the distance between grid and cathode, reduce the working voltage, improve the emission area of carbon nanometer tube and improve the display brightness, with lower cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of pouch-shaped potatoes

PendingCN110754634AImprove appearanceImprove production success rateFood scienceBoiled potatoProcess engineering

The invention relates to the technical field of potato processing, and discloses a preparation method of pouch-shaped potatoes. The preparation method comprises the following steps: selecting fresh potatoes, cleaning the selected potatoes, cutting the cleaned potatoes into pieces with consistent thickness and smooth double-cut surfaces by a special roller slicing knife, heating an oil pot, measuring the oil temperature by a thermodetector, heating the oil to 80 DEG C, weighing the slicing-completed potatoes, pouring 500 grams of the potato slices into the heating-completed oil pot, repeatedlyrolling and frying the potato slices to uniformly heat the potato slices and better achieve a frying effect, and after 1 minute of frying time, cooling the oil in the oil pot to 40-50 DEG C and continuously frying the potato slices for 2 minutes. According to the invention, through the continuous change of the oil temperature, the accuracy of the temperature and the mastering of the thickness during slicing when processing the pouch-shaped potatoes, the preparation method makes the mouthfeel of the pouch-shaped potatoes crisp outside and sandy inside, which not only maintains the soft textureof the boiled potatoes, but also increases the crisp appearance of the pouch-shaped potatoes, and the success rate of making the pouch-shaped potatoes is greatly improved.

Owner:曹靖

Plastics suction mould

The invention discloses a plastics suction mould, comprising press frames, wherein the press frames comprise press frame substrates and plastics suction part fixture; and the plastics suction part fixture is arranged at the upper end of the press frame substrates and is provided with first acute angles. The invention is characterized in that convex plates which extend outwards along the press frame substrates are arranged on the press frame substrates, positioned below the first acute angles and distant from the plastics suction part fixture. The plastics suction mould can reduce the under-cut depth and drawing of the thin films, thereby improving the mould yield.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213BImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the baleis more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

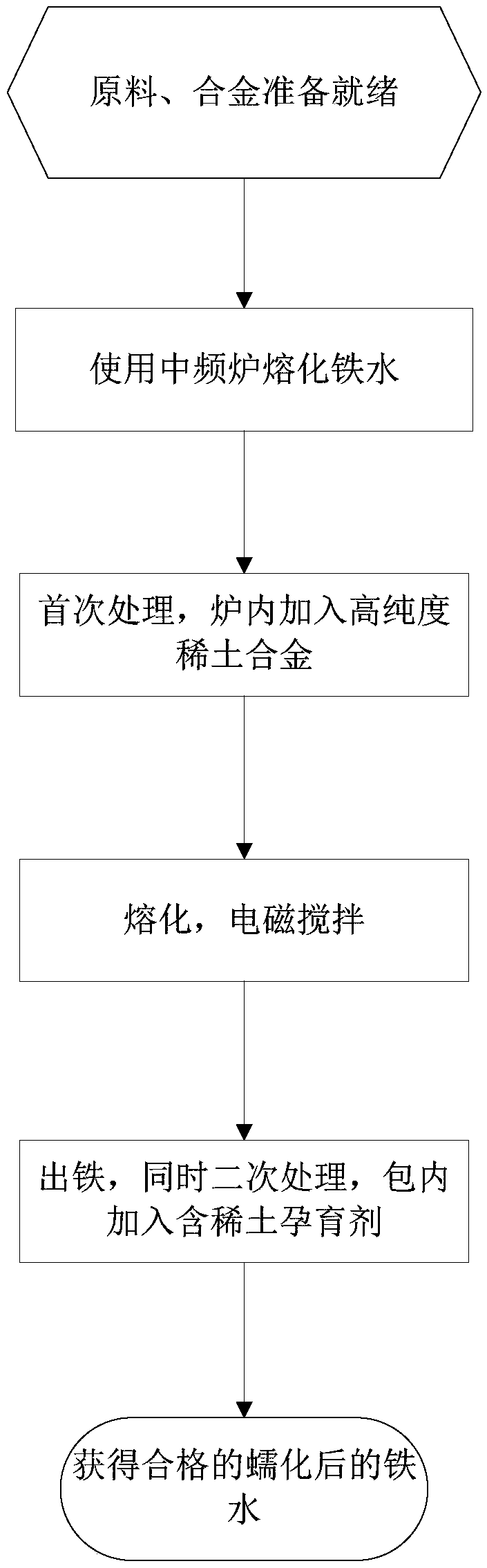

Vermicularizing inoculation method of vermicular graphite cast iron

The invention discloses a vermicularizing inoculation method of vermicular graphite cast iron. In the smelting process of molten iron in a medium-frequency furnace, a high-purity rare earth alloy is fed in the molten iron before tapping, and is fully dissolved through an electromagnetic stirring effect of the medium-frequency furnace for primary vermicularizing treatment; a vermicularizing sensitive area of the molten iron is enlarged to improve the vermicularizing success rate and the vermicularizing effect; then, a rare earth-contained inoculation alloy is fed in a ladle after tapping for secondary vermicularizing treatment; the quantity of residual rare earth is supplemented to improve the inoculation effect and prolong the fading time; and obtained qualified vermicular graphite cast iron liquid is used for pouring castings. The method effectively improves the vermicularizing success rate, widens the vermicularizing sensitive range, prolongs the inoculation fading time, increases the product pass percent, and in particular, is suitable for a casting process of vermicular graphite cast iron cylinder jackets of marine diesel engines.

Owner:SHANGHAI HULIN HEAVY IND +1

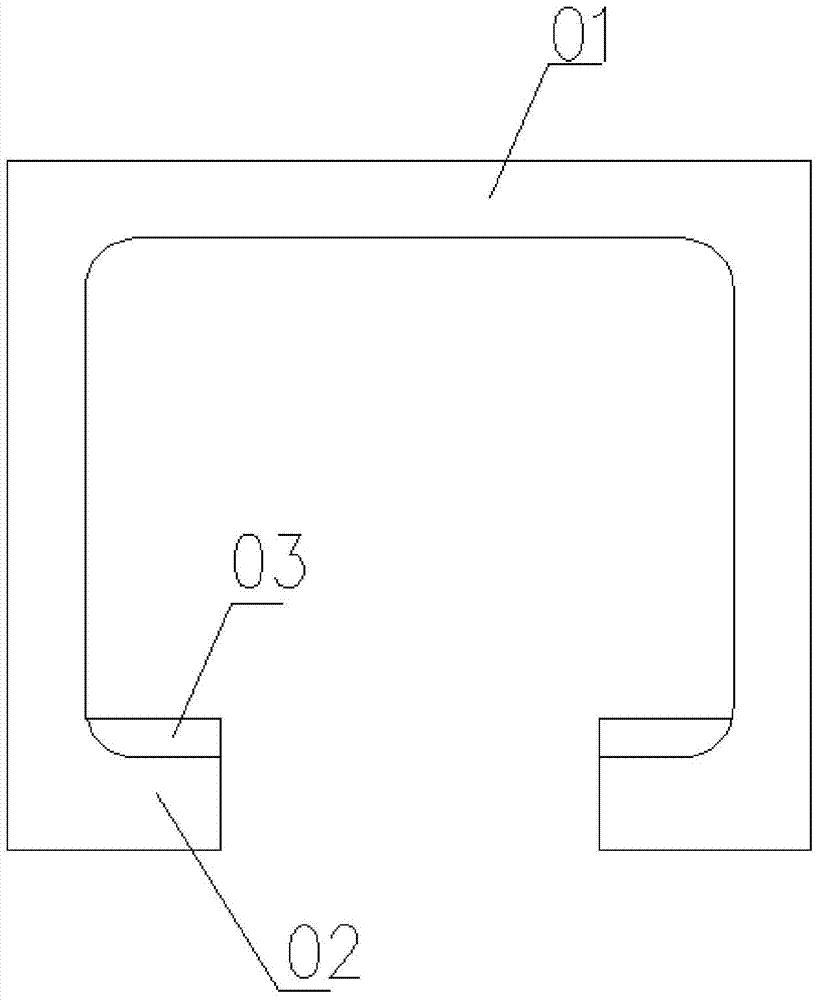

Process method and optimized structure for eliminating shrinkage porosity of side cover of valve body of steering gear

PendingCN110116190AIncrease the tilt angleEfficient feedingFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses an optimized structure for eliminating the shrinkage porosity of a side cover of a valve body of a steering gear. The optimized structure for eliminating the shrinkage porosityof the side cover of the valve body of the steering gear comprises a side cover casting body and a valve body casting body, wherein a weight reduction groove is formed in the top end of the left sideof the side cover casting body; a casting dead head is fixedly installed at the middle position of the side cover casting body; a station B is arranged at the left side of the casting dead head; a station A is arranged at the right side of the casting dead head; and a die drawing layer is bonded and fixed to the outer side of the weight reduction groove. According to the optimized structure for eliminating the shrinkage porosity of the side cover of the valve body of the steering gear, by increasing the size of the dead head, the dead head is made to effectively feed a casting; by adding a process patch layer, an effective feeding channel is established between the dead head and the casting, so that the effect of eliminating the shrinkage porosity at the position of the station A is achieved; by increasing the inclination angle of die drawing, the wall thickness at the position of the station B can be effectively reduced, so that the position is capable of being rapidly solidified; and moreover, due to the dimension increasing of the weight reduction groove, the casting can be better removed from a die, so that the appearance of the casting is ensured.

Owner:HENAN GUANGRUI AUTO PARTS

A method for increasing the molecular weight and yield of polyphosphazene elastomer

Owner:山东航橡新材料有限公司

Novel structure and manufacturing method of higher-order mode absorber

ActiveCN111889834AImprove protectionSimple productivitySoldering apparatusAssembly machinesCarbide siliconManufactured material

The invention discloses a novel structure of a higher-order mode absorber. The novel structure comprises silicon carbide adopting a barrel-shaped structure, an oxygen-free copper ring and a stainlesssteel ring which are sequentially assembled from inside to outside in a sleeve manner; an annular water path channel for cooling is jointly formed in the outer wall of the oxygen-free copper ring andthe inner wall of the stainless steel ring, and besides, a solder groove and a positioning boss which are mutually matched are formed on the joint surfaces of two ends of the oxygen-free copper ring and the stainless steel ring. The novel structure is simple, small in size, easy to manufacture, high in strength, good in reliability and suitable for mass production. The invention also discloses a manufacturing structure comprising the following steps: a, feasibility demonstration of thermal assembly of the oxygen-free copper ring and the silicon carbide; b. welding of the oxygen-free copper ring and the stainless steel ring; c. installation of the absorber; d. test of the assembly tightness of the oxygen-free copper ring and the absorber; and e. water path pressure detection. The method issimple, compact in structure, high in production success rate, and short in cycle; and meanwhile, less chemicals and metal raw materials are used in production and manufacturing, so that the production risk is reduced, and the environmental protection is facilitated.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com