Plastics suction mould

A technology of plastic-absorbing mould, plastic-absorbing part frame, applied in the field of plastic-absorbing mould, to achieve the effect of saving raw materials, reducing stretching, and improving production success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

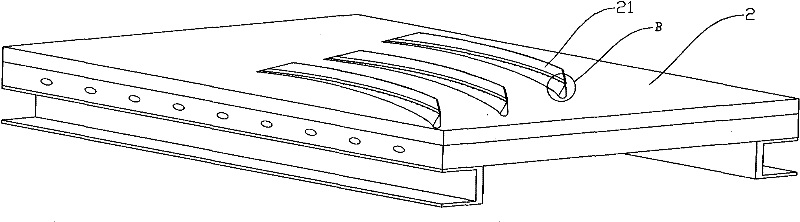

[0035] The press frame 3 includes a press frame base 4 and a plastic-absorbing part frame 5, and the shape of the plastic-absorbing part frame 5 is the same as that of the plastic-absorbing part to be manufactured. The plastic-absorbing part frame 5 is arranged on the upper end of the pressure frame base 4 . The molded frame 5 of the plastic-absorbing part extends outward along the base body 4 of the press frame, that is, the mold frame 5 of the plastic-absorbing part is larger than the base body 4 of the press frame.

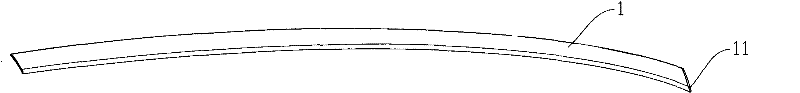

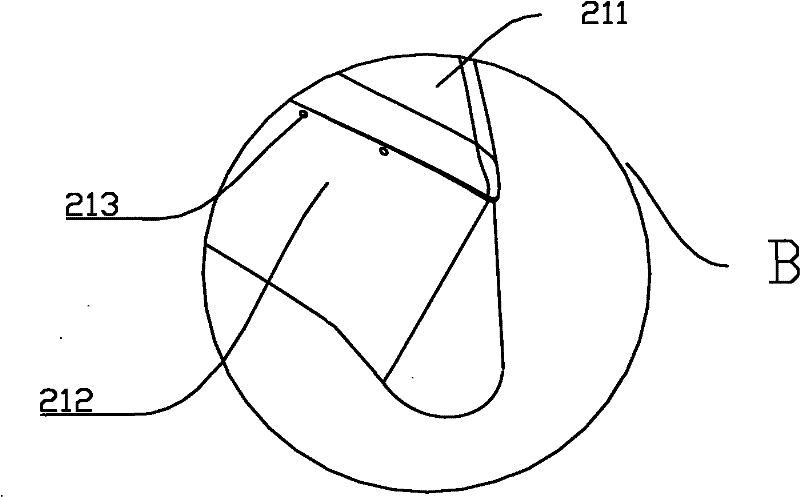

[0036] There is a first sharp corner 51 on the plastic part frame 5, and the first sharp corner 51 is an arc angle between the two sides (52, 53) of the bottom surface of the plastic part frame 5, and its two sides (52, 53) pass through The arc segments 54 are connected, and the central angle corresponding to the arc segments 54 is the first sharp angle. The bottom surface refers to the surface that cuts the plastic forming frame 5 along a direction parallel t...

Embodiment 2

[0046] The embodiments in the present invention are only used to illustrate the present invention, and do not constitute a limitation to the scope of the claims. Other substantially equivalent substitutions that can be thought of by those skilled in the art are within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com