Patents

Literature

125results about How to "Good flame retardant function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

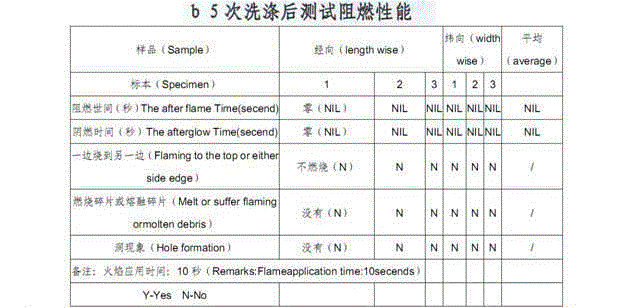

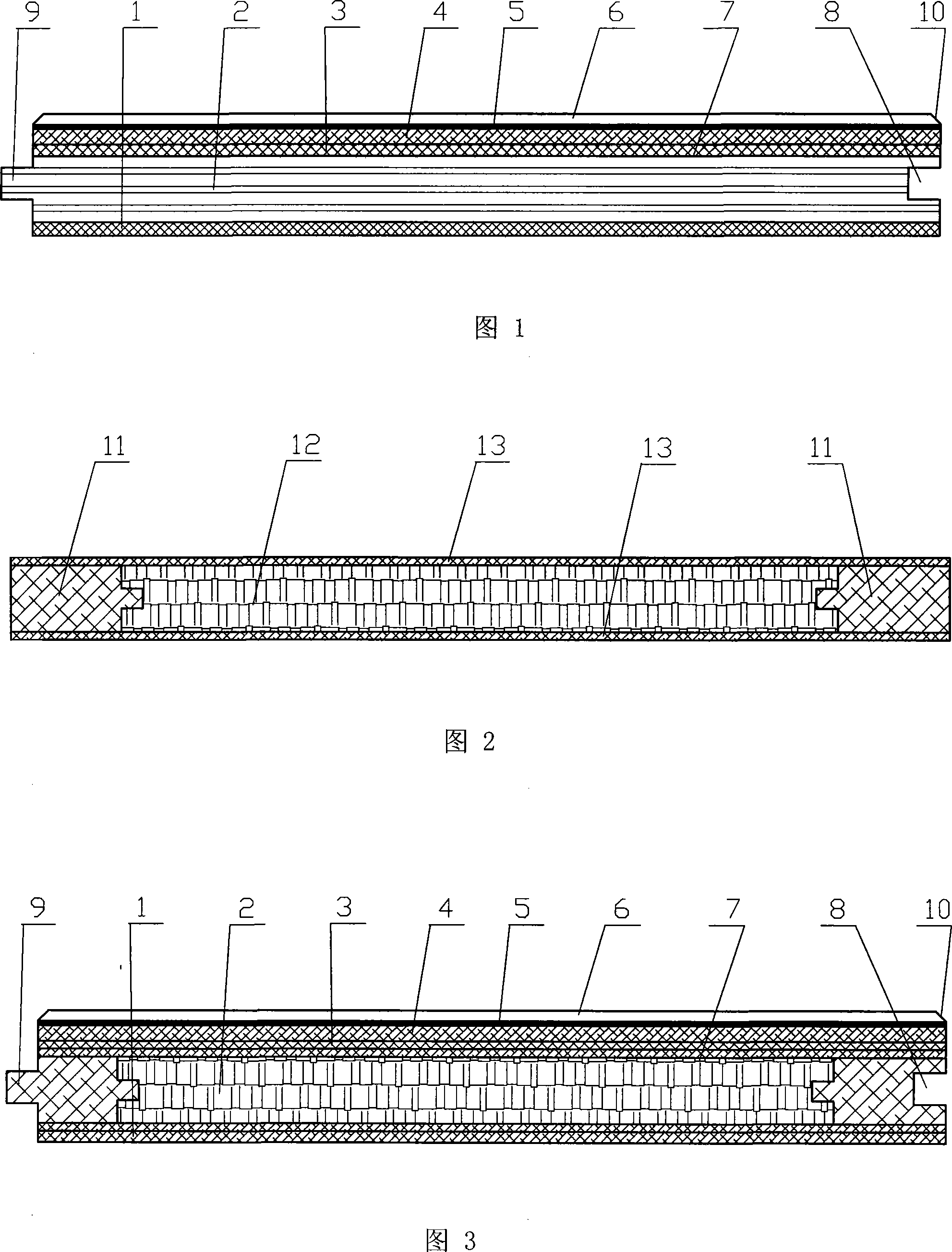

Flame-retardant nylon label cloth with wet-process glued layers and manufacturing method thereof

The invention relates to label cloth and a manufacturing method thereof, in particular to flame-retardant nylon label cloth which is provided with wet-process glued layers and can be used for thermal transfer printing and a manufacturing method thereof. The flame-retardant nylon label cloth comprises a base cloth layer as well as an upper flame-retardant layer and a lower flame-retardant layer applied to upper and lower surfaces of the base cloth layer, wherein the base cloth layer adopts nylon cloth having a flame-retardant function, the total thickness of the base cloth layer and the flame-retardant layers ranges from 0.120 mm to 0.140 mm, and the weight ranges from 75 g / m<2> to 85 g <2>; and each flame-retardant layer comprises a sizing material formed by a halogen-free flame retardant, nylon resin and an antistatic agent. The manufacturing method comprises the following steps in sequence: pretreatment of the base cloth: the pretreatment comprises desizing and heat setting; preparation of the sizing material: the sizing material comprises components in parts by weight as follows: 40-60 parts of methanol, 20-30 parts of calcium chloride, 8-20 parts of polycaprolactam, 5-10 parts of the flame retardant, 1-2 parts of the antistatic agent and 0.06-0.1 part of a brightening agent; wet process gluing: the base cloth after the pretreatment is dipped in the sizing material for gluing, wherein the temperature of the sizing material ranges from 35 DEG C to 50 DEG C, and the viscosity of the sizing material ranges from 1,500 cps to 3,000 cps. According to the label cloth, the flame-retardant layers are soft in texture, and the flame-retardant effect can meet FMVSS (federal motor vehicle safety standard) 302 standard.

Owner:HUZHOU SINY LABEL MATERIAL

Environment-friendly fire-retardant paint

InactiveCN102850881ANo harmGood adhesionFireproof paintsPolyurea/polyurethane coatingsMelamine phosphateAcrylic resin

The invention discloses an environment-friendly fire-retardant paint. The invention belongs to the technical field of decorative materials. The paint comprises the components of, by weight: 20 to 30 parts of water, 10-15 parts of hydroxyl acrylic resin, 10-15 parts of polyurethane resin, 5-8 parts of urea, 5-8 parts of pentaerythritol, 5-8 parts of amine polyphosphate, 5-8 parts of melamine phosphate, 10-12 parts of white carbon black, 5-8 parts of sodium silicate, 3-5 parts of titanium dioxide, 2-3 parts of dioctyl phthalate, and 2-3 parts of dithiocarbamate. The paint provided by the invention is composed of non-toxic or low-toxicity raw materials, and does not harm human bodies and especially bodies of construction workers during normal construction processes. The produced fire-retardant paint is transparent.

Owner:SHANDONG CHANGXING GROUP

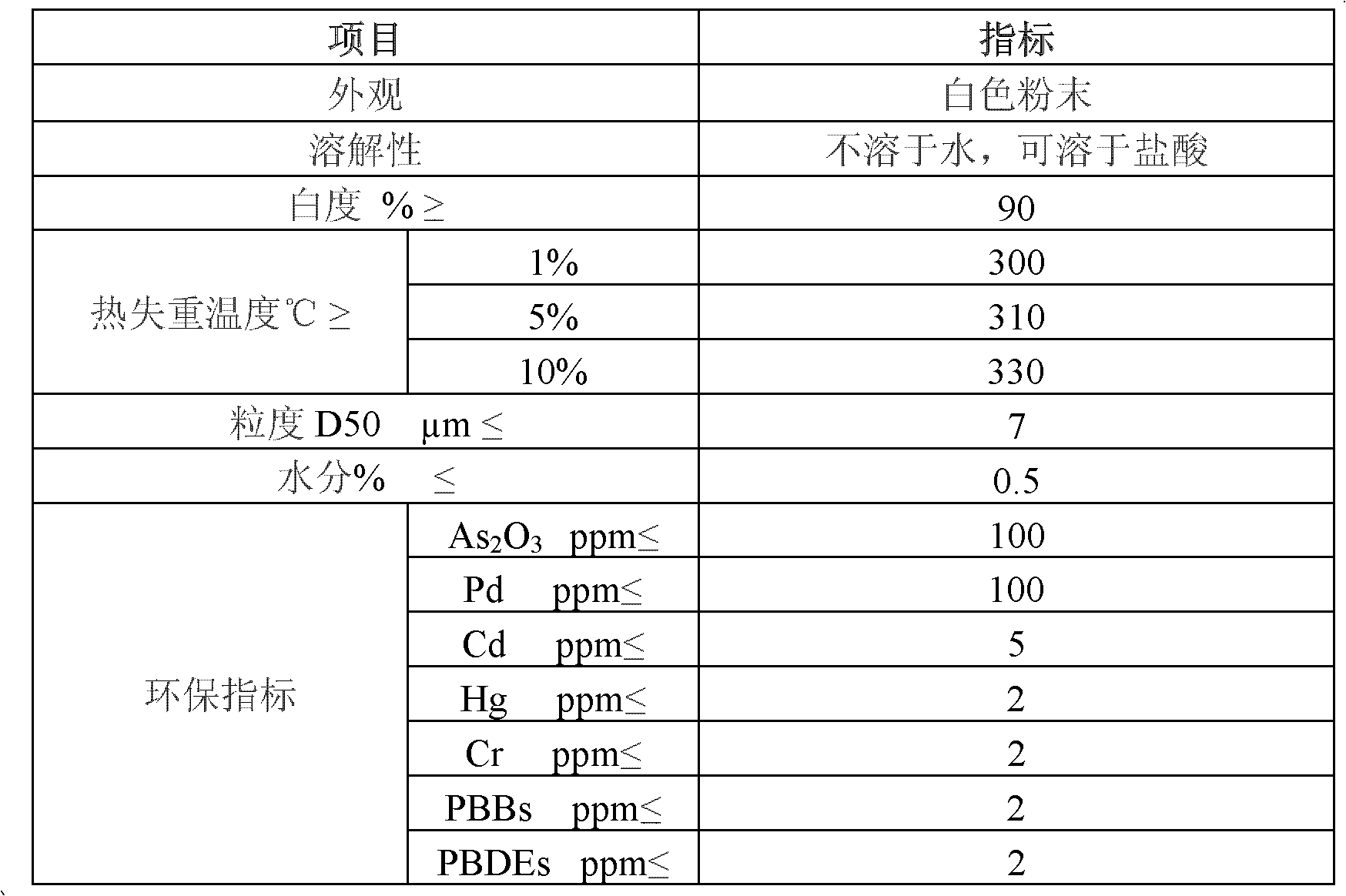

Environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 (polyamide) and preparation method thereof

The invention discloses an environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 (polyamide) and a preparation method thereof. The environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 consists of the following raw materials, by weight, 10-12 parts of aluminum phosphate, 4-5 parts of melamine cyanurate, 1-3 parts of ammonium polyphosphate, 0.5-3.0 parts of association-effect carbonatic, 0.5-3.0 parts of flame-retardant association effect agent and 0.2-1.0 part of anti-oxidizer, wherein the aluminum phosphate is prepared by phosphoric acid and aluminum hydroxide. The environment-friendly halogen-free flame retardant has the advantages of excellent flame-retardant function and low fuming quantity, can be used for retarding the glass fiber reinforced PA6 by substituting for antimony and bromide flame retardant, and is higher in cost performance when being compared with the antimony and bromide flame retardant in the aspect of cost andlower in usage when in application as compared with antimony and bromide flame retardant and is prior to the like products of antimony and bromide in indexes of environment protection. Besides, the environment-friendly halogen-free flame retardant can completely substitute for the antimony and bromide flame retardant and has higher flame retardant level.

Owner:JINAN TAIXING FINE CHEM

Polyurethane sponge and processing method thereof

InactiveCN106957408AWith flame retardant functionGood flame retardant functionDiethyl phosphateHalogen

The invention discloses polyurethane sponge and a processing method thereof. Polyether polyol with a flame retardant function is directly added to a material A, and a diethyl ethylphosphonate fire retardant is selectively added to a material B, so that the polyurethane sponge does not contain halogen, is low in viscosity and very stable in a two-component system of the material A and the material B, and a product is endowed with good fireproof and flame-retardant properties while the process is simple. The product is endowed with good mildew-proof and antibacterial effects through an antibacterial agent and a mildew preventive added to the material B; and through addition of nanoscale inorganic material tourmaline powder, the product has the function of lastingly emitting anions. The production technology and the formula are relatively simple on the premise that all performance indexes reach the expected requirements; the production process and the formula are relatively simple; the processes such as heating or refrigerating do not need to be specifically carried out in the production process and foaming and curing in a natural state can be carried out; the production success rate of sample post-detection is very high; the produced polyurethane sponge has obvious fireproof and flame-retardant functions, antibacterial and anti-mildew functions and continuous anion release function, and is beneficial to improvement of the competitiveness of the product.

Owner:东莞恒生高分子科技有限公司

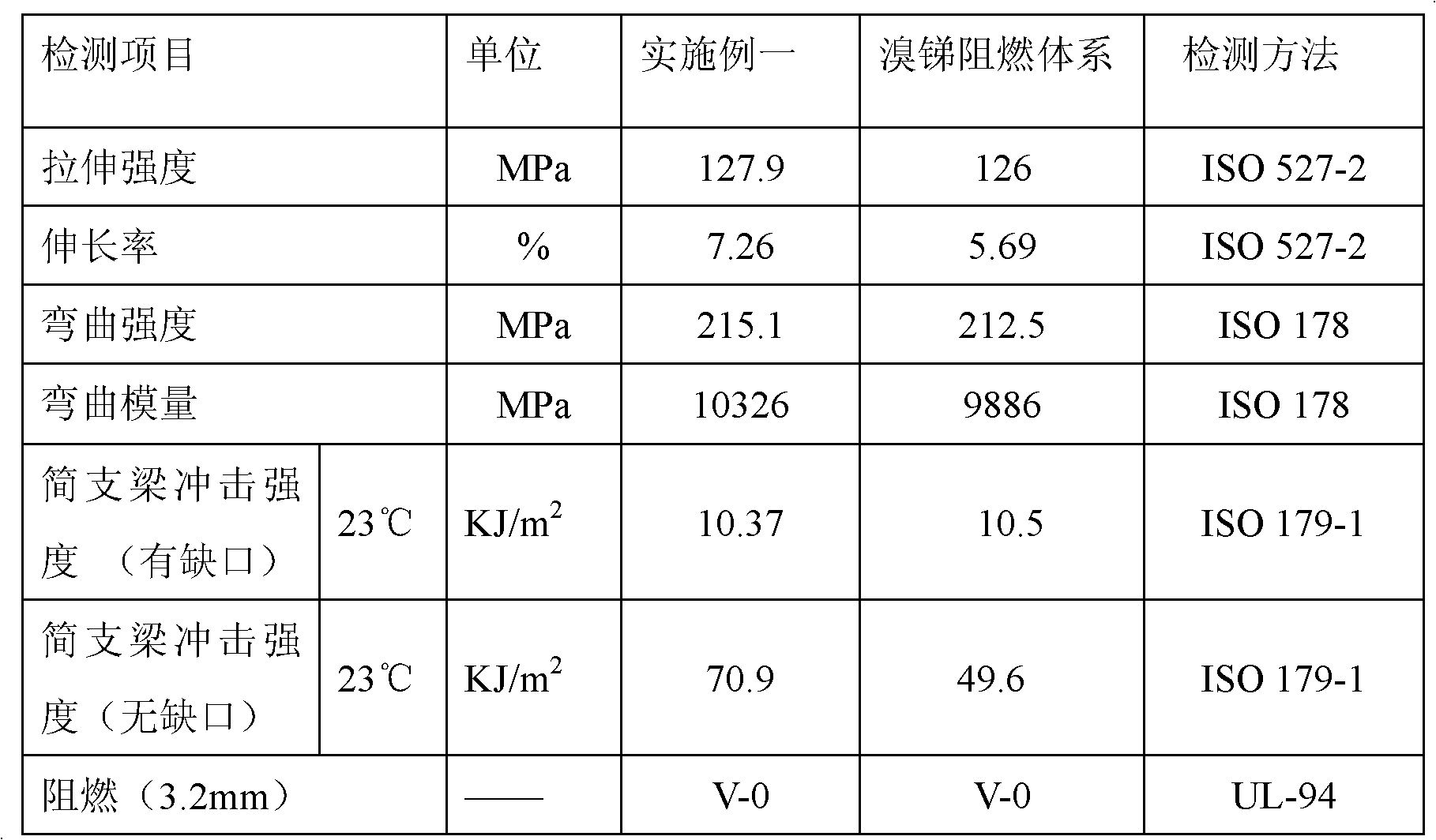

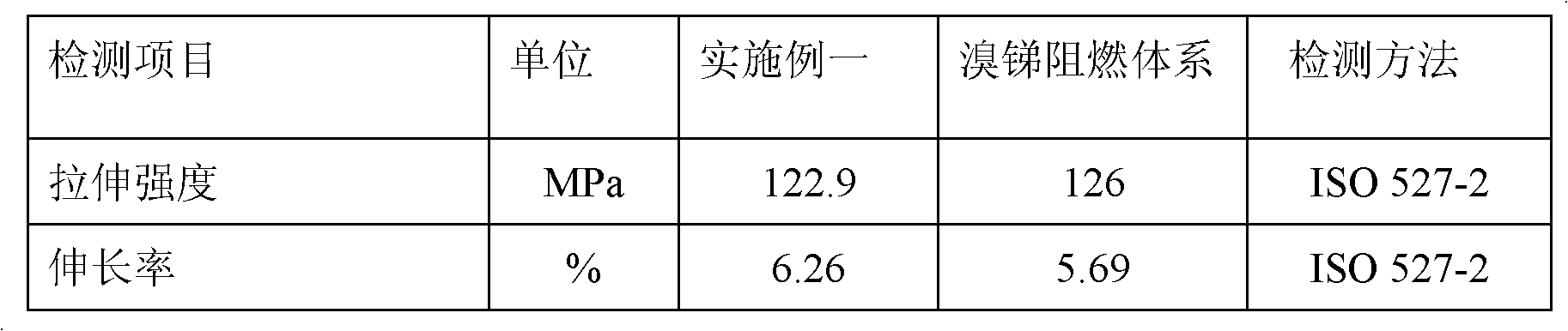

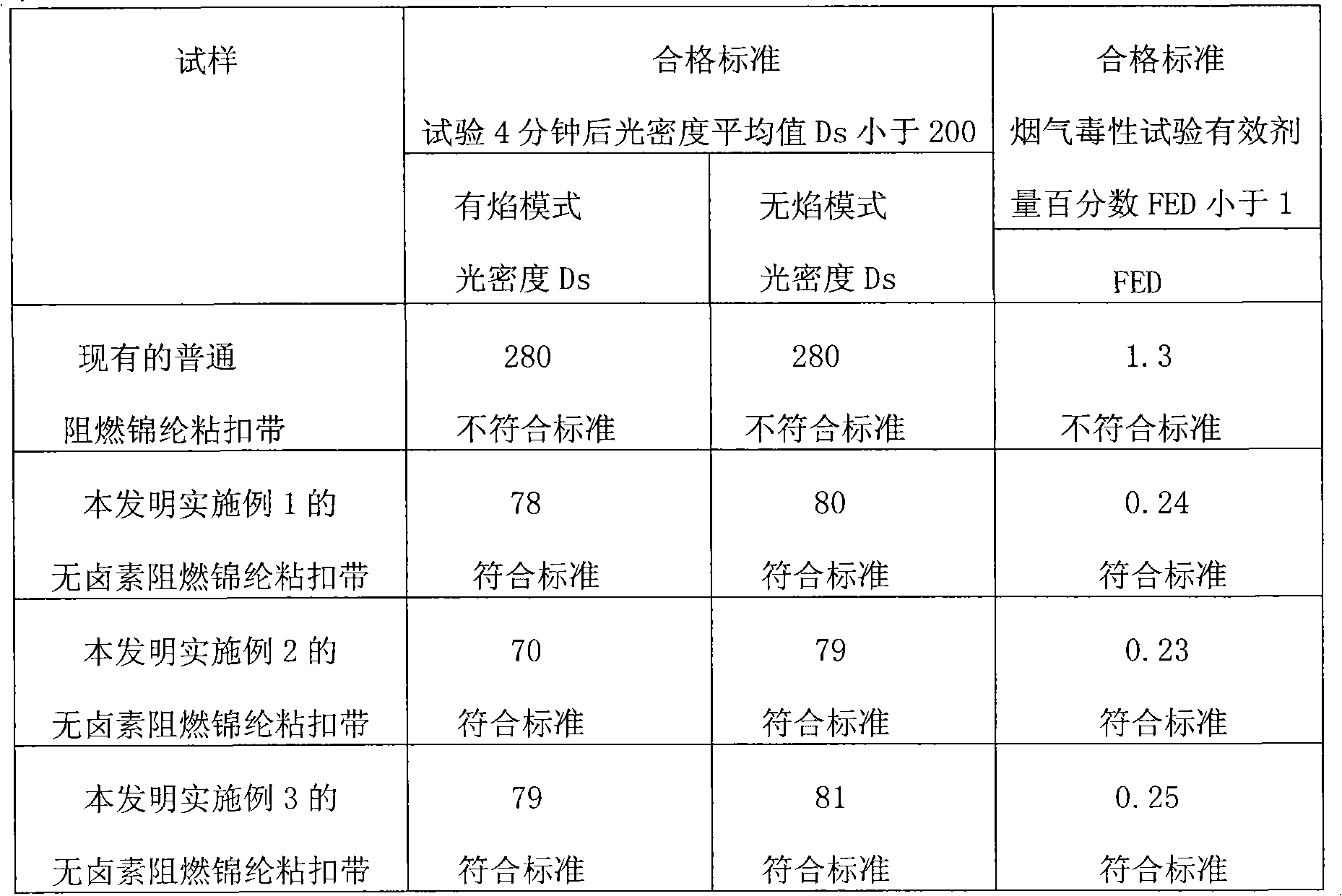

Method for manufacturing halogen-free flame retardant nylon sticky buckle strap

ActiveCN101942763AGood flame retardant functionAvoid harmInorganic/elemental detergent compounding agentsSurface-active detergent compositionsDyeingHeavy metals

The invention relates to a method for manufacturing a halogen-free flame retardant nylon sticky buckle strap, which comprises the following steps of: cleaning, dyeing, dehydration, sizing finishing, drying, retardant finishing, hot melt adhesive finishing and the like of the nylon sticky buckle strap. In the halogen-free flame retardant nylon sticky buckle strap manufactured by the method, dyes, a sizing finishing agent, a flame retardant finishing agent and a hot melt adhesive finishing agent which used in the production process do not contain halogen or heavy metal, adopt a water-based finishing agent and has zero release and no environmental pollution; compared with the prior art, the halogen-free flame retardant nylon sticky buckle strap improves the flame retardant effect, prevents the burning process from releasing toxic gas, has high visibility and meets the fireproofing safety standard of the American Boeing company and German rail vehicles; and when the halogen-free flame retardant nylon sticky buckle strap is used for sticky buckle straps of vehicles, the safety of persons and the vehicles is improved.

Owner:WUXI PAIHO TEXTILES CO LTD

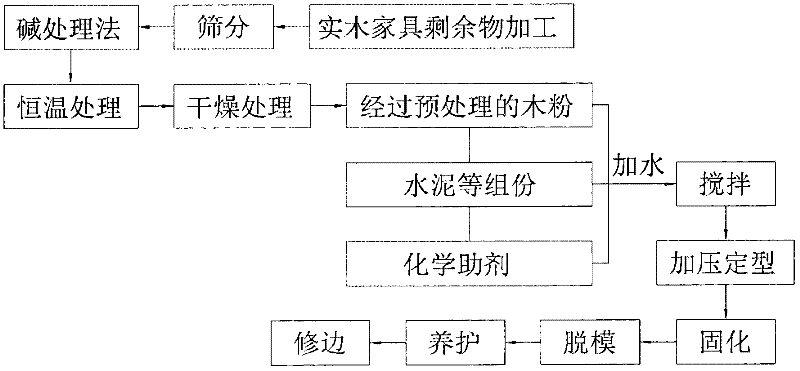

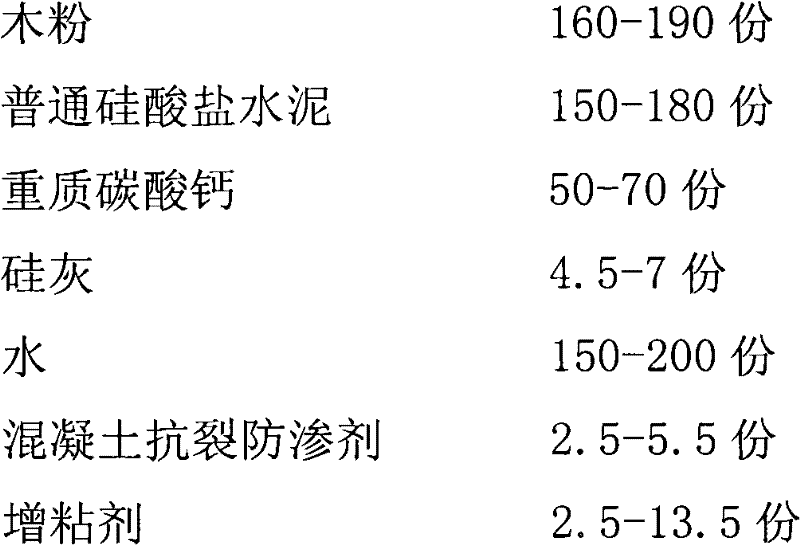

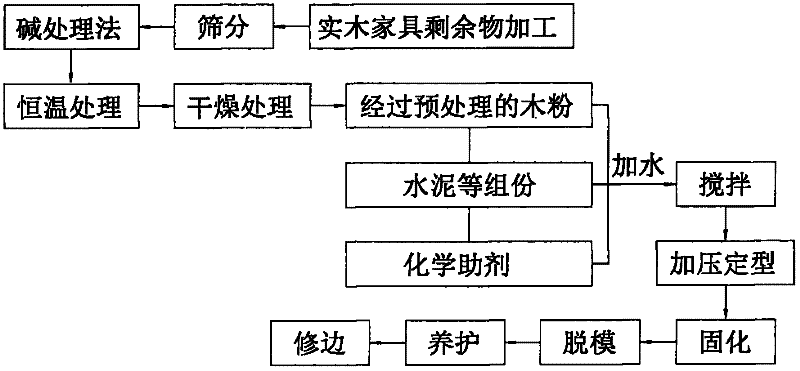

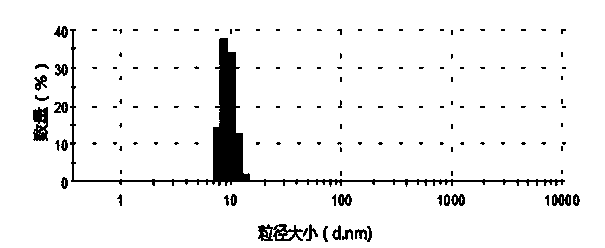

Cement-based wood fiber artificial board and manufacturing method thereof

InactiveCN102531492AReduce pollutionSave resourcesSolid waste managementCeramic shaping apparatusSolid woodFiber

The invention discloses a cement-based wood fiber artificial board and a manufacturing method thereof. According to the invention, the cement-based wood fiber artificial board is obtained by taking cement as a gel material and taking wood fibers as an organic reinforcing material, doping a certain amount of chemical addition agent, and carrying out steps of batching, agitating, pressurizing, curing, de-molding and maintaining. The artificial board provided by the invention is a novel material with water resistance, anti-oxidation, corrosion resistance and flame retardant property. The wood fiber raw material is selected from leftovers in the production of solid wood furniture and is mixed with cement slurry after being classified, machined and treated, so that the cost of the cement-based wood fiber artificial board is low; and bonding glue is not used so that the pollution to the environment is reduced while timber resources are protected and saved. The cement-based wood fiber artificial board and the manufacturing method thereof, provided by the invention, are applicable to lightweight wall materials for buildings, indoor and outdoor decorative sheet materials, and furniture decorative sheet materials.

Owner:LANGFANG HUARI FURNITURE CO LTD

Antistatic cotton-polyester blend clothing material

InactiveCN1811034AHigh cotton contentImprove breathabilityOther chemical processesWoven fabricsPolyesterFiber

The antistatic cotton-polyester blend clothing material contains cotton of 21*21 count in 50-70 wt%, chemical fiber of 127*66 or 45 / 2*21 count in 29-49 wt% and conducting fiber of 130*66 count in 1 wt%. It has high cotton content and embedded conducting fiber resulting in excellent antistatic effect, high permeability from proper cotton / polyester ratio, certain brightness, high stiffness, high color fastness and fire retarding function, and can meet the requirement of antistatic clothing for workers in petrochemical and other industry.

Owner:YI HE STOCK

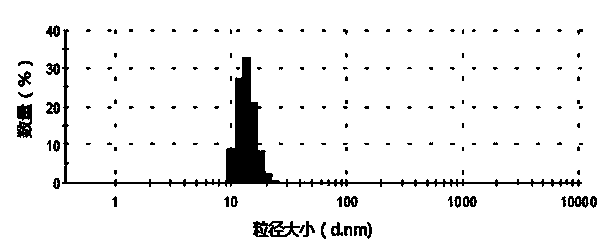

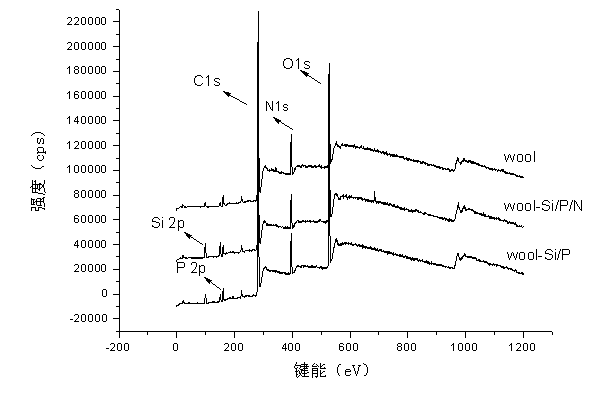

Preparation method of wool fabric with flame-retardant function

ActiveCN103938456AGood flame retardant functionRealize functional modification and finishingAnimal fibresInorganic phosphatePhosphate adsorption

The invention discloses a preparation method of a wool fabric with a flame-retardant function. The preparation method comprises the steps of preparing nano composite sol by taking ethyl silicate as a hydrolysis precursor and inorganic phosphate as a flame-retardant additive; adsorbing nano silicon dioxide composite phosphate on the wool fabric through sol-to-gel conversion; carrying out after finishing on the wool fabric by means of the synergistic effect of silicon and phosphorus to obtain a favorable flame-retardant effect. A nano sol-gel finishing technology is adopted in the preparation method, so that the consumption of phosphorous components can be greatly reduced, the flame-retardant efficiency can be increased, and the industrial production can be favorably realized.

Owner:吴江耀程纺织有限公司

Flame-retardant nanometer bamboo charcoal antibiosis filler fiber and manufacturing method thereof

InactiveCN102485981AWith flame retardant functionHas antibacterial functionHollow filament manufactureMelt spinning methodsSpinningBamboo charcoal

The invention provides a flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber comprises the following components, by mass, 1-20% of a nanometer bamboo charcoal antibiosis master batch and 80-99% of a sliced carrier. A manufacturing method of the fiber comprises the following steps: mixing the nanometer bamboo charcoal antibiosis master batch and the needed sliced carrier according to a certain ratio, uniformly stirring them, selecting a spinneret plate according to the fiber processing fineness and the section shape of the fiber, fusion-spinning, cooling, reeling, filament bunding, drafting, and spirally and curly cutting into short fibers to prepare the flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber of the invention has the advantages of substantial flame retardation and antibiosis, peculiar smell adsorption function possessing, soft handle, good elasticity, and wide application.

Owner:SHANGHAI JAROS NEW MATERIAL

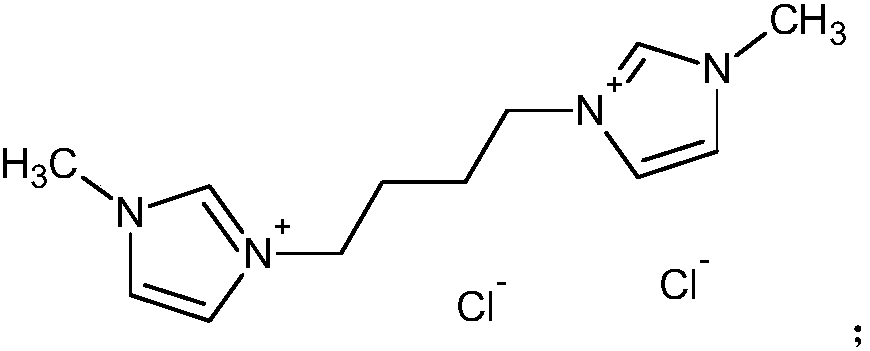

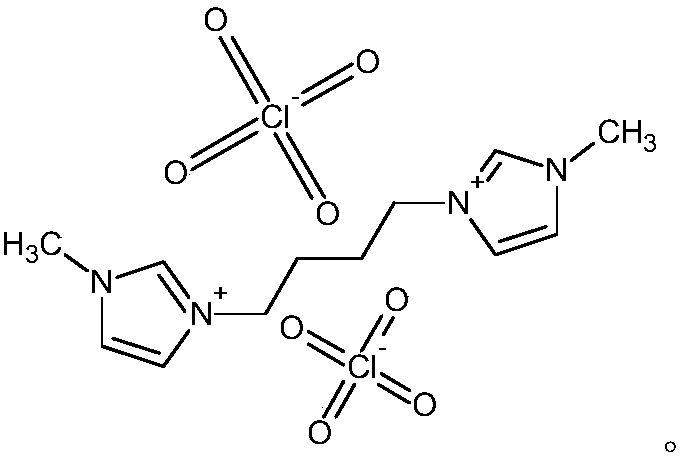

Preparation method of flame-retardant cellulose fiber

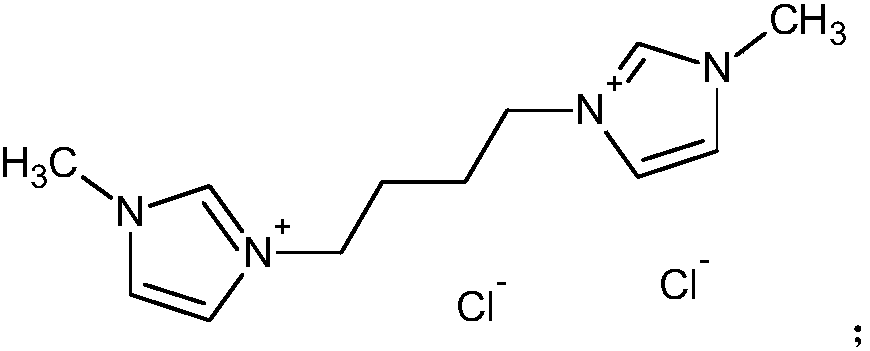

ActiveCN109208103ALow viscosityImprove mechanical propertiesArtificial filaments from cellulose solutionsFlame-proof filament manufactureOrganic solventPerchlorate

The invention discloses a preparation method of a flame-retardant cellulosic fiber. The preparation method comprises the following steps: a) mixing a flame retardant and cellulose to obtain a mixture,and then dissolving the mixture in an aqueous solution of an ionic liquid to prepare a mixed spinning stock solution; b) filtering the stock solution of the step a), performing spinning, solidification, stretching, water washing, bleaching, oiling and drying to obtain the flame-retardant cellulose fiber; wherein the ionic liquid is prepared by mixing 1-butyl-3-methylimidazolium chloride, bi-1,4-bis [1-(3-methylimidazolyl)] butyl dichloride and bi-1,4-bis[1-(3-methylimidazolyl) butyl diperchlorate. Experiments show that the flame-retardant cellulosic fiber prepared by the method has excellentmechanical properties, flame retardancy and stability, simple preparation process and low cost, does not need any organic solvent, is environment-friendly and pollution-free, does not need special equipment and harsh conditions, is easy to realize industrial production and has extremely high practical value.

Owner:龙丝(上海)新材料科技有限公司

Interior wall coating coil and preparation method thereof

InactiveCN102557518AIncreased durabilityGood air permeability and waterproof performanceLubricationWater resistance

The invention discloses an interior wall coating coil and a preparation method thereof. The interior wall coating coil comprises the following components in part by weight: 60 to 70 parts of inorganic powder, 10 to 20 parts of white pigment, 1 to 2 parts of dispersant, 1 to 2 parts of lubrication aid, 1 to 3 parts of stabilizer, 0.5 to 1 part of grafting agent and 8 to 12 parts of macromolecular polymer. The interior wall coating coil which has high air permeability, water resistance and flame retardance is prepared by utilizing mechano-chemical modification and stretch thermoforming of polymeric materials, and uniformly dispersing a large amount of inorganic powder and white pigment into a small amount of polymeric material. The interior wall coating coil has white and bright color, is odorless and convenient to use, and can be directly pasted on a mortar layer or a putty layer of an interior wall of a house. The interior wall coating coil avoids the pollution of various kinds of volatile matter generated in the production, construction and use of the traditional brushable interior wall coating, meets the national industrial policy of low cost, environment friendliness and energy conservation, has remarkable economic and social benefits, and is easy to popularize and use widely.

Owner:上海利民环保节能科技有限公司

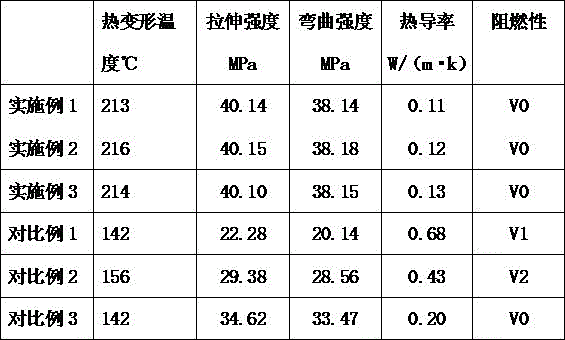

Composite environment-friendly flame retardant for ABS (Acrylonitrile Butadiene Styrene) and ABS flame-retardant plastic

InactiveCN102898684AImprove heat resistanceImprove flame retardant performanceHeat deflection temperatureWeather resistance

The invention discloses a composite environment-friendly flame retardant for ABS (Acrylonitrile Butadiene Styrene) and ABS flame-retardant plastic. The composite environment-friendly flame retardant for the ABS consists of the following components in parts by weight: 10-20 parts of trimethylsilyl methyl methylphosphonate, 30-50 parts of melamine cyanurate, 10-20 parts of zinc borate and 40-60 parts of magnesium hydroxide. The ABS flame-retardant plastic consists of the following components in parts by weight: 100 parts of ABS resin and 20-40 parts of composite environment-friendly flame retardant for the ABS. The composite environment-friendly flame retardant for the ABS contains no halogen, has high flame retardant function and excellent compatibility with the ABS, is not migrated, separated or extracted in the ABS, is easy to disperse uniformly, has high weather resistance and lasting property and is not decomposed in a high-temperature fusion and thermal forming processing project;the performance such as the thermal deformation temperature, the mechanical temperature and the electrical insulation of the prepared ABS flame-retardant plastic are not affected; and the plastic haslong-term flame retardancy.

Owner:FENGHUA XURI NEW MATERIAL

Preparing method for environment-friendly resin reinforced flame-retardant modified wood

InactiveCN107599086AGood dimensional stabilityHigh densityWood treatment detailsPressure impregnationPtru catalystComposite lumber

The invention relates to a wood preparing method based on environment-friendly resin reinforcement and flame-retardance modifying. The method comprises the following steps: furfuryl alcohol, maleic anhydride (catalysts), ethanol and ammonium dihydrogen phosphate (flame retardants) ) are used as raw materials, the raw materials are used to prepare an organic-inorganic composite wood modified solution according to a certain ratio; the modified solution is used for carrying out dipping treatment on artificial forest wood, and furfuryl alcohol resin and ammonium dihydrogen phosphate are fixed inside the wood through the solidifying and drying treatment, and the modified wood is finally obtained. According to the method, the dimensional stability, the density, the bending-resistant elasticity modulus and the anti-wrinkle compressive strength of the wood can be improved, the flame retardant is not prone to run off, the loss resistance is high, and the method is green and environment-friendly; and meanwhile, the wood is endowed with good flame-retardancy and dimensional stability, and the method has the advantages of remarkably improving the quality and the additional value of the artificial forest wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A high-performance capacitor plastic housing

ActiveCN106519600AImprove mechanical propertiesLow costPolytetramethylene terephthalateDibutyl sebacate

A high-performance capacitor plastic housing is disclosed. The plastic housing is prepared from polybutylene terephthalate, ABS plastic, a filler, a color concentrate, dibutyl sebacate, polyamide, a lubricant and an auxiliary agent. The auxiliary agent is prepared from, by weight, carboxyl cellulose, sorbitan trioleate, rosin, sodium hexametaphosphate, alkali lignin, acrylamide, diatomite, sodium tripolyphosphate, methyl salicylate, tea seed oil and mint oil. The plastic housing has characteristics of good mechanical properties, good processing performance, a low cost, a low melt viscosity, high impact strength, good thermal aging resistance and excellent thermal stability.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Flame-retardant PC plastic

The invention discloses a flame-retardant PC plastic. The flame-retardant PC plastic comprises the following components in parts by weight: 80-86 parts of PC, 7-9 parts of polyimide, 5-8 parts of titanium dioxide, 10-14 parts of alkyl benzene sulfonate, 5-9 parts of dimethyl siloxane, 2-3 parts of cupric oxalate, 10-15 parts of magnesium hydroxide, 7-9 parts of phthalate anhydride, 5-7 parts of coated red phosphorus, 10-20 parts of cobalt silicate and 8-10 parts of graphite. The flame-retardant PC plastic has a good flame-retardant function; an obvious flame-retardant function can be performed when a very small amount of flame-retardant PC plastic is used. The flame-retardant PC plastic does not affect the mechanical strength of a plastic product and particularly does not lower the thermal deformation temperature, the mechanical temperature and the electric insulation property of the plastic product.

Owner:WUJIANG TIANYUAN PLASTIC

A kind of resin type silicate wood modifier and preparation method of modified material thereof

ActiveCN104044193BImproves loss resistanceGood dimensional stabilityWood impregnation detailsTougheningPollution

The invention belongs to a resin type silicate wood modifier and a preparation method of a modified material of the modifier. According to the preparation method, the resin type silicate wood modifier is prepared by taking melamine, formaldehyde, urea and soluble sodium silicate as main raw materials as well as respectively taking polyvinyl alcohol and diethylene glycol as a toughening agent and a stabilizer; the resin type silicate wood modifier can be stably stored for a long time and can be repeatedly recycled. The modifier has the advantages that the dimensional stability, the density, the surface hardness, the anti-bending strength, the anti-bending elastic modulus, the impact toughness and the wear resistance of artificial forest wood processed by virtue of the modifier are substantially improved, the modifier has the advantages that the flame retardance and environment-friendly effect are achieved, no pollution is caused to a human body and the environment, the leachability resistance of the modifier in the processed wood is improved, and the application value of the artificial forest wood is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Composite environmental-friendly flame retardant for PVC (polyvinyl chloride) and PVC flame-retardant plastic

The invention discloses a composite environmental-friendly flame retardant for PVC (polyvinyl chloride) and PVC flame-retardant plastic. The composite environmental-friendly flame retardant for PVC comprises the following components in parts by weight: 10-20 parts of dimethyl trimethylsilylmethylphosphonate, 30-50 parts of melamine cyanurate, 10-20 parts of molybdenum trioxide and 40-60 parts of ammonium polyphosphate. The PVC flame-retardant plastic comprises the following components in parts by weight: 100 parts of PVC resin and 10-30 parts of composite environmental-friendly flame retardant for PVC. The composite environmental-friendly flame retardant for PVC provided by the invention does not contain halogen and has a good flame-retardant function. The PVC flame-retardant plastic provided by the invention has a long-term flame-retardant performance.

Owner:SICHUAN DUOLIAN IND LIMITED

Preparation method of flame retarding phosphorus-copolyester with better color phase

The invention discloses a preparation method of flame retarding phosphorus-copolyester with better color phase. 4000-12000ppm of phosphorus- copolymerization flame retardant, which is calculated by phosphorus element, and 10-150ppm of three-valued phosphorus stabilizer, which is calculated by phosphorus element, are added during the preparation reaction. The hue value of the flame retarding phosphorus-copolyester prepared by the method is as follows: b is equal to minus 2 to 6, and L is equal to 60 to 90. The whiteness and the brightness of fabrics are good, and the fire resistance is excellent so as to reach M1 grade.

Owner:TORAY IND INC

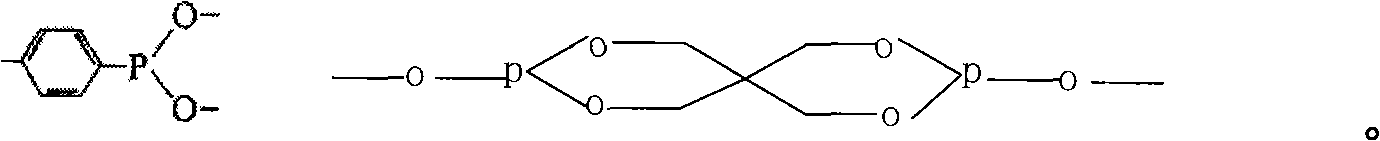

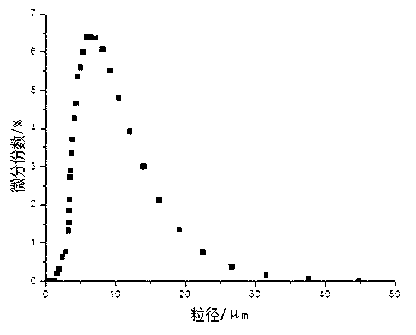

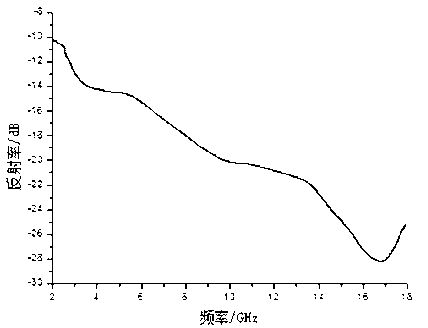

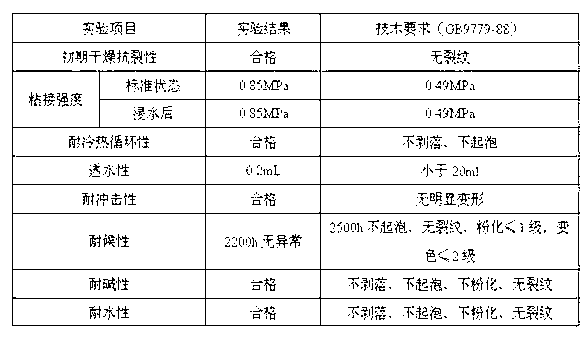

Indoor environment-friendly dry powder paint with microwave absorbing and flame-retardant functions, and preparation method and construction method thereof

InactiveCN103254696AHas harmControl damageFireproof paintsRadiation-absorbing paintsCelluloseMicrowave

The invention discloses an indoor environment-friendly dry powder paint with microwave absorbing and flame-retardant functions, and a preparation method and a construction method thereof. The indoor environment-friendly dry powder paint comprises the following components by weight percent: 20-50% of latex powder, 5-30% of titanium dioxide, 5-30% of calcium carbonate, 5-10% of silica, 5-10% of talcum powder, 10-40% of microwave-absorbing powder, 5-25% of halogen-free flame retardant, 5-15% of cellulose, 0.1-0.7% of solid defoaming agent, 2-8% of mildew preventive, 0.5-2% of assistant and 0.05-8% of paint. The obtained product has excellent microwave absorbing function and excellent flame-retardant effect; the flame-retardant effect can reach level V0; the dosage of the assistant is effectively reduced; and the VOC (volatile organic compound) emission of the dry powder paint is zero. Thus, the product is convenient to package, simple to transport, convenient to construct, free of special requirements, free of poison or pungent smell, and free of an injury to skin and a respiratory tract of a person, and can achieve ultra-thin construction; and the smallest coating thickness can be up to 20 microns.

Owner:熊丙志

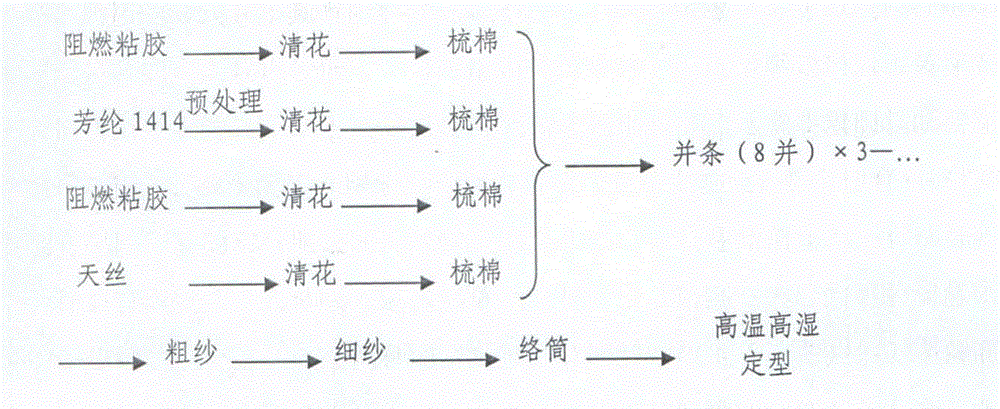

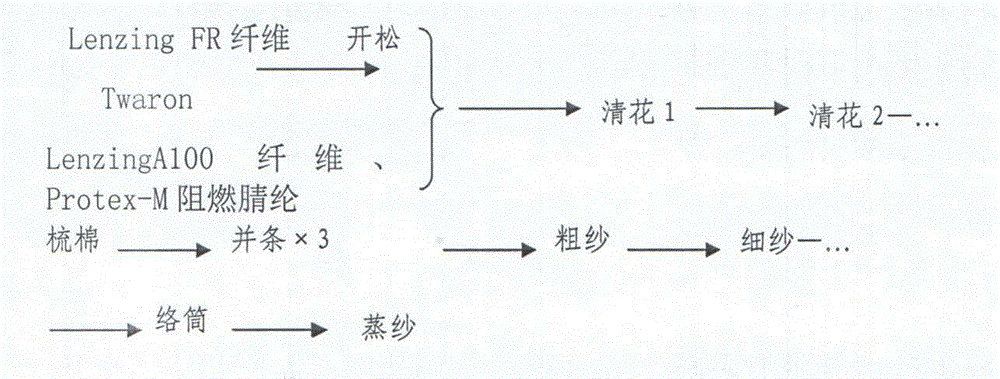

Fire resistant fiber blended yarn and production method thereof

InactiveCN104611796AWith flame retardant functionPermanent flame retardant functionYarnYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a fire resistant fiber blended yarn and a production method thereof. The fire resistant fiber blended yarn comprises, by weight, 30-45% of Lenzing FR fibers, 30-40% of Protex-M fire-resistant acrylic, 15-20% of Lenzing A100 fibers, and 5-10% of Twaron. The production method sequentially comprises the following steps of 1, conducting pretreatment on the Lenzing FR fibers and the Twaron, 2, conducting blowing for the first time, 3, conducting blowing for the second time, 4, conducting cotton carding, 5, conducting drawing, 6, conducting roving, 7, conducting spinning, 8, conducting spooling and 9, conducting yarn steaming. A garment manufactured by the yarn has the permanent fire resistant function, the adopted yarn is safe and environmentally friendly, and no poisonous gas is released; the garment manufactured by the yarn is soft in touch, a user wears the garment comfortably, and the moisture absorption and breathable performance is good; the yarn is formed by evenly mixing the fibers, and the thermal protection and comfort differences caused when the fibers are unevenly mixed at different places of a shell fabric are avoided.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Abrasion-proof composite floor

The present invention discloses an abrasion-resisting composite floor to provide an abrasion-resisting composite floor which has the advantages of good stability, small deformation, natural and beautiful surface grain, comfortable foot sense, high surface hardness and good abrasion-resisting property. The floor comprises a balance layer at the undermost layer, and a central plate, a balance layer, a decorating layer, a coating layer and an abrasion-resisting paper are laid from the bottom to top, each layer are adhered together with the adhesive and a wood structure board is manufactured, the side of the wood structure board is fabricated with keyway and / or joint tongue, the invention is characterized in that the abrasion-resisting paper is transparent, and the decorating layer is wood veneer obtained by planning or rotary-cutting the natural wood or the scientific wood skin. The transparent abrasion-resisting paper is used at the upmost layer, the using of coloring paint or fire retardant paint whereunder can lead to the more uniform color of the natural wood skin or scientific wood skin on the whole floor, and the floor can be endowed with the function of fire resisting if the fire retardant paint is used. The natural wood grain of the lower natural wood chip or scientific wood skin can be clearly seen through the abrasion-resisting paper.

Owner:金月华

Polypropylene flame-retardant plastic

ActiveCN103467852AImprove heat resistanceImprove flame retardant performanceParaffin waxDibutyl sebacate

The invention provides a polypropylene flame-retardant plastic. The plastic comprises the following components in parts by weight: 60-80 parts of polypropylene, 20-50 parts of polyethylene, 20-30 parts of terpene resin, 10-30 parts of polystyrene, 10-25 parts of acrylonitrile-butadiene rubber, 5-10 parts of dibutyl sebacate, 5-10 parts of polyimide, 10-20 parts of liquid paraffin, 10-15 parts of diantimony trioxide, 10-30 parts of nano-titanium oxide, 10-22 parts of zinc stearate, 20-40 parts of flame retardant, 0.1-0.3 part of antioxidant, 0.5-1 part of defoaming agent, and 1-3 parts of auxiliaries.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

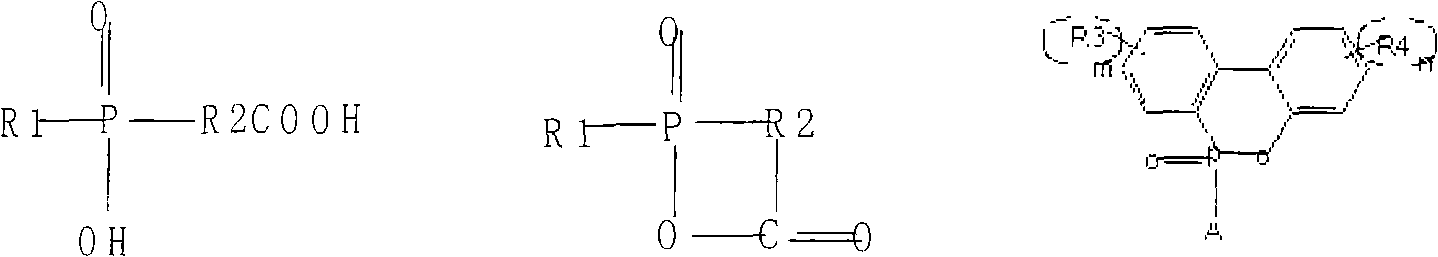

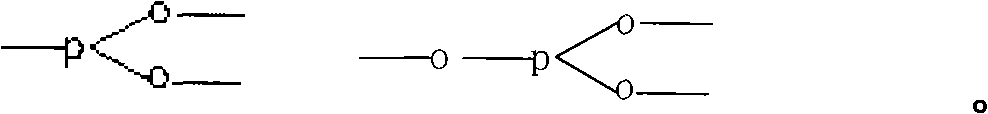

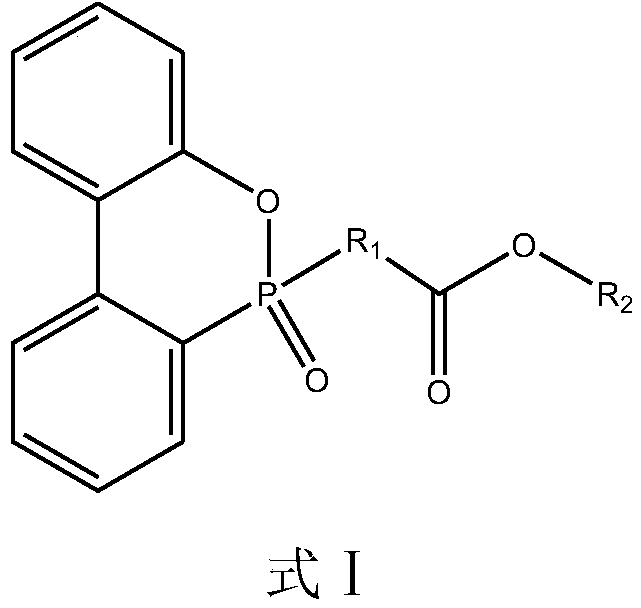

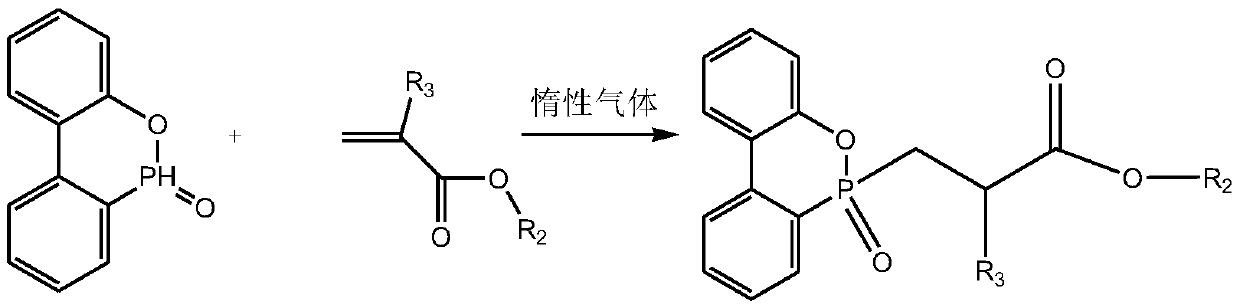

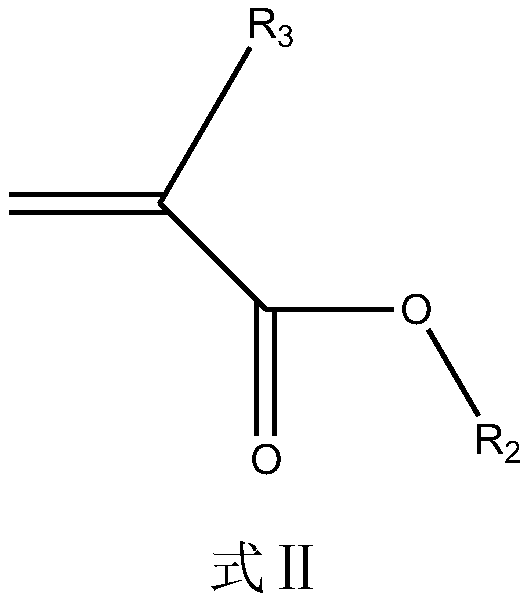

Flame retardant, preparation method and application thereof

InactiveCN109734746AImprove flame retardant performanceImprove electrochemical performanceGroup 5/15 element organic compoundsLi-accumulatorsFire retardantElectrolyte

The invention provides a flame retardant, which has a more obvious flame retardant effect compared with the conventional flame retardant. The invention further provides a preparation method of the flame retardant, the method has the characteristics of simple preparation process and low cost. The invention further provides a lithium battery electrolyte which is added with the flame retardant, can maintain good conductivity and has better compatibility with the negative electrode of the lithium battery, and can ensure that the lithium battery has better electrochemical performance and a better flame retardant effect at the same time. The invention further provides a lithium battery, which comprises the lithium battery electrolyte. The lithium battery not only has good electrochemical performance, but also has a good flame retardant effect and is safer in use.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

PC/PET alloy material prepared by utilization of waste PC and PET materials

The invention discloses a PC / PET alloy material prepared by the utilization of waste PC and PET materials. a preparation method of the PC / PET alloy material comprises the following steps: washing and crushing waste polycarbonate and poly(ethylene terephthalate) resin materials, adding auxiliaries such as a lubricant, a fire retardant, a fortifier and the like, fully mixing, and heating and conducting compression moulding forming to prepare the polycarbonate / poly(ethylene terephthalate) resin alloy material. The prepared material has high heat resistance, good toughness and impact strength and good flame retardancy, and is not easy to crack.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

High impact polystyrene (HIPS) flame-retardant plastic

InactiveCN103497477AGood flame retardant functionMechanical strength is not affectedPolymer sciencePolymer chemistry

The invention discloses high impact polystyrene (HIPS) flame-retardant plastic. The HIPS flame-retardant plastic comprises, by weight, 105-110 parts of HIPS, 10-15 parts of nano-silica, 10-15 parts of melamine cyanurate, 10-15 parts of glass fibers, 10-12 parts of sodium antimonate, 8-11 parts of styrene, 14-16 parts of alkylbenzene sulfonate, 2-3 parts of copper oxalate, 10-20 parts of triphenyl thiophosphate and 10 parts of zirconia. The HIPS flame-retardant plastic has good fire resistance and a small amount of the HIPS flame-retardant plastic can produce obvious flame retardation effects. Mechanical strength of the HIPS flame-retardant plastic is not influenced and especially, a heat deflection temperature, a kinetic temperature and electric insulation properties of a plastic product are not influenced. The HIPS flame-retardant plastic can be uniformly dispersed and has good weatherability, long action time and long-term flame resistance.

Owner:WUJIANG TIANYUAN PLASTIC

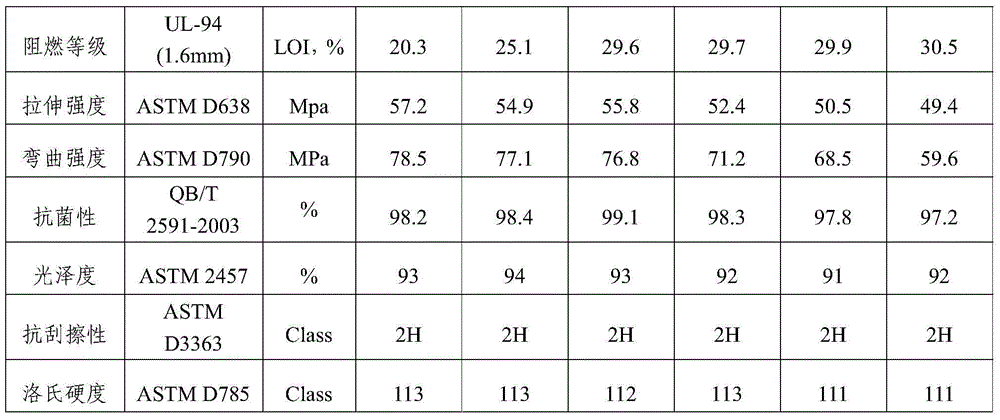

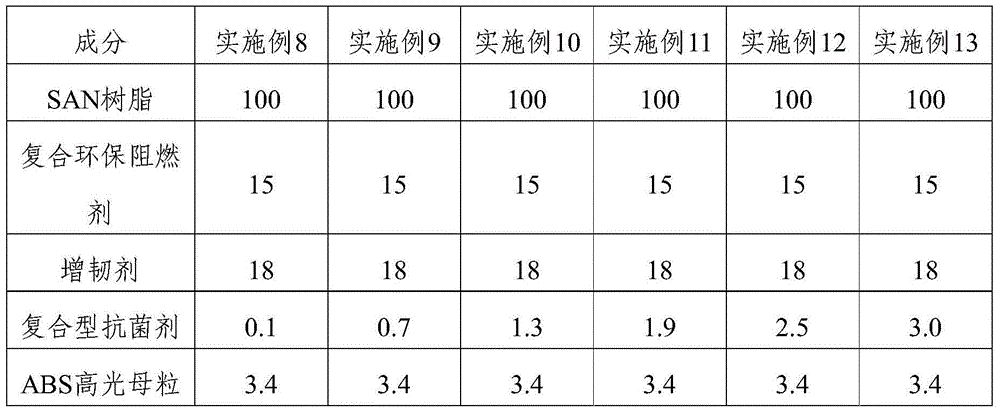

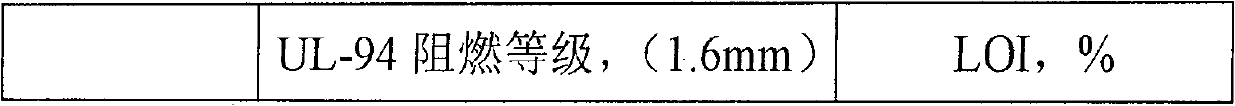

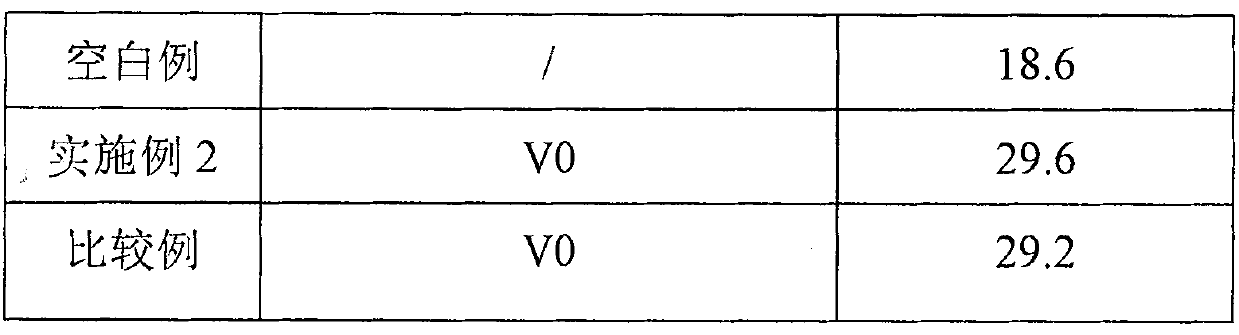

Antibacterial flame-retardant ABS plastic and preparation method thereof

InactiveCN105199302AImprove heat deflection temperatureImprove insulation performancePolymer scienceLow speed

The invention relates to the technical field of polymer modification and provides antibacterial flame-retardant ABS plastic and a preparation method thereof. The antibacterial flame-retardant ABS plastic is prepared from 100 parts by weight of SAN resin, 5-30 parts by weight of a composite eco-friendly fire retardant, 5-20 parts by weight of a flexibilizer, 0.1-3 parts by weight of a compound antiseptic, 0.2-7 parts by weight of a ABS specular master batch, 0.1-5 parts by weight of a scratch resistance agent, 0.1-1 part by weight an anti-oxidant and 2-4 parts by weight of a compatilizer. The preparation method comprises 1, drying the SAN resin, 2, orderly adding the above raw materials into a stirrer, carrying out high-speed stirring, then adding the ABS specular master batch into the mixture, and carrying out low-speed stirring to obtain a preliminary mixture, and 3, adding the preliminary mixture into an extruder and carrying out treatment. The antibacterial flame-retardant ABS plastic has effects of greatly inhibiting bacteria, killing bacteria and preventing mildew, has good flame retardation functions, and has physical properties such as high glossiness, strong scratch resistance, high toughness and high strength.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

Method for preparing multifunctional environment-friendly flame-retardant wall fabrics

InactiveCN107130438AImprove performanceMeet the needs of rich colorsFurniture partsTextiles and paperPolyesterEngineering

The invention provides a method for preparing multifunctional environment-friendly flame-retardant wall fabrics. The method includes steps of providing base cloth; carrying out heat setting on the base cloth, to be more specific, placing the base cloth in a baking oven and baking the base cloth; coating mould-proof flame-retardant coatings on the base cloth after the base cloth is subjected to heat setting, then placing the base cloth in the baking oven and drying the base cloth; carrying out calendering treatment on the base cloth with the coated mould-proof flame-retardant coatings in a calender; adding different types of pigment and pearl powder to the base cloth on the basis of the mould-proof flame-retardant coatings according to different color requirements and ultimately drying the base cloth in the baking oven. The base cloth comprises 80%-100% of polyester fabrics, and holes are reserved in the surfaces of the base cloth. The method has the advantage that environment-friendly flame-retardant colorful multifunctional fabrics can be prepared by the aid of the method.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Composite environment-friendly flame retardant for ABS (Acrylonitrile Butadiene Styrene) and ABS flame-retardant plastic

InactiveCN102898684BImprove heat resistanceImprove flame retardant performanceHeat deflection temperatureZinc borate

The invention discloses a composite environment-friendly flame retardant for ABS (Acrylonitrile Butadiene Styrene) and ABS flame-retardant plastic. The composite environment-friendly flame retardant for the ABS consists of the following components in parts by weight: 10-20 parts of trimethylsilyl methyl methylphosphonate, 30-50 parts of melamine cyanurate, 10-20 parts of zinc borate and 40-60 parts of magnesium hydroxide. The ABS flame-retardant plastic consists of the following components in parts by weight: 100 parts of ABS resin and 20-40 parts of composite environment-friendly flame retardant for the ABS. The composite environment-friendly flame retardant for the ABS contains no halogen, has high flame retardant function and excellent compatibility with the ABS, is not migrated, separated or extracted in the ABS, is easy to disperse uniformly, has high weather resistance and lasting property and is not decomposed in a high-temperature fusion and thermal forming processing project;the performance such as the thermal deformation temperature, the mechanical temperature and the electrical insulation of the prepared ABS flame-retardant plastic are not affected; and the plastic haslong-term flame retardancy.

Owner:FENGHUA XURI NEW MATERIAL

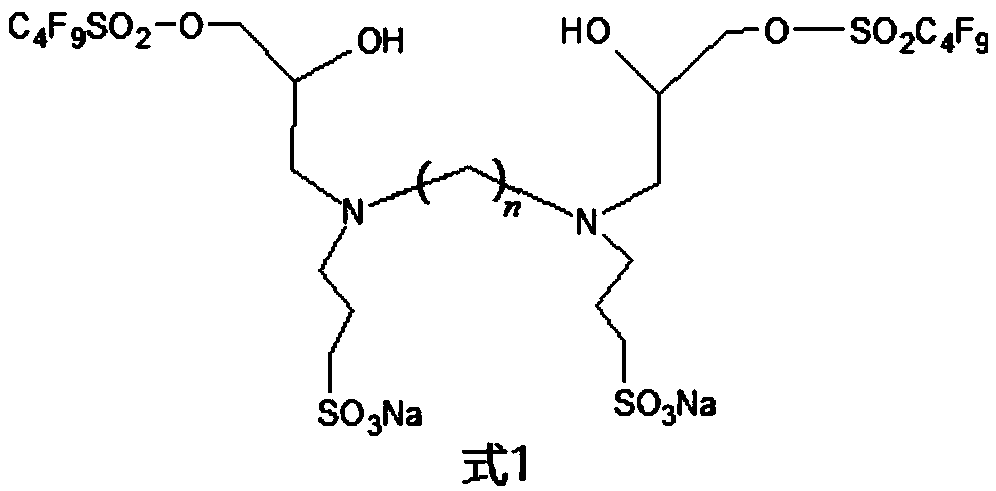

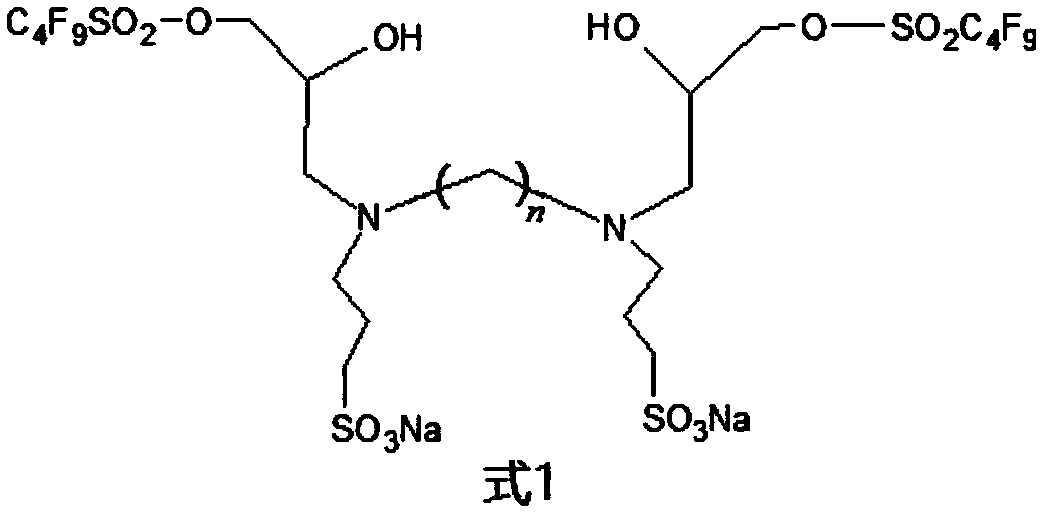

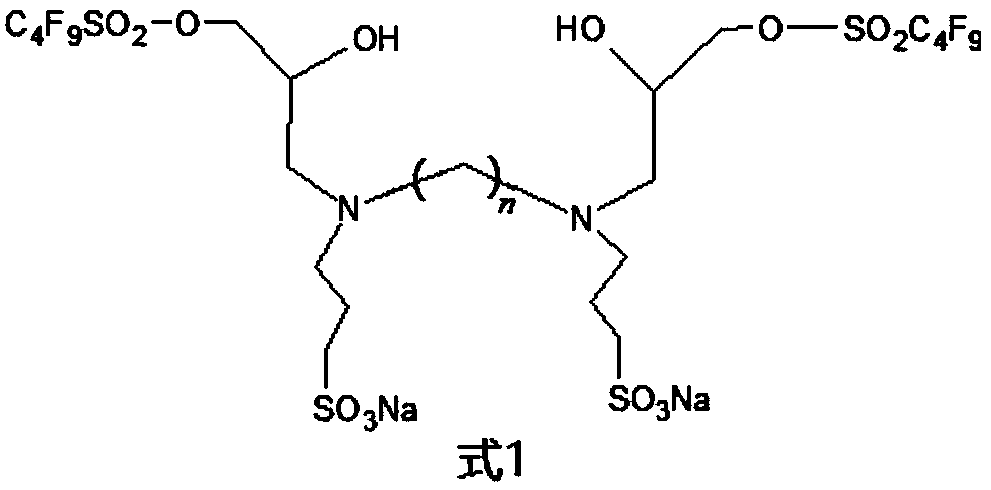

Water-based fire extinguishing agent

ActiveCN110124241AHigh fire extinguishing efficiencyEliminate pollutionFire extinguisherWater basedInorganic salts

The invention relates to a water-based fire extinguishing agent, which comprises, by mass, 1-6% of an inorganic salt, 0.5-5% of a surfactant, 1-5% of a foaming agent, 3-10% of a flame retardant, 4-10%of an anti-freezing agent, 0.1-1% of a penetrant, 2-3% of an emulsifier, and the balance of water, wherein the surfactant uses a combination of a fluorine surfactant and a hydrocarbon surfactant, andthe fluorine surfactant is an anionic gemini fluorine surfactant having a fluorocarbon chain length of 4 carbons. According to the present invention, the fire extinguishing agent adopts the self-madefluorocarbon surfactant, does not contain persistent organic pollutants, can be rapidly degraded, cannot pollute the environment, and has excellent fire extinguishing performance.

Owner:浙江睦田消防科技开发有限公司

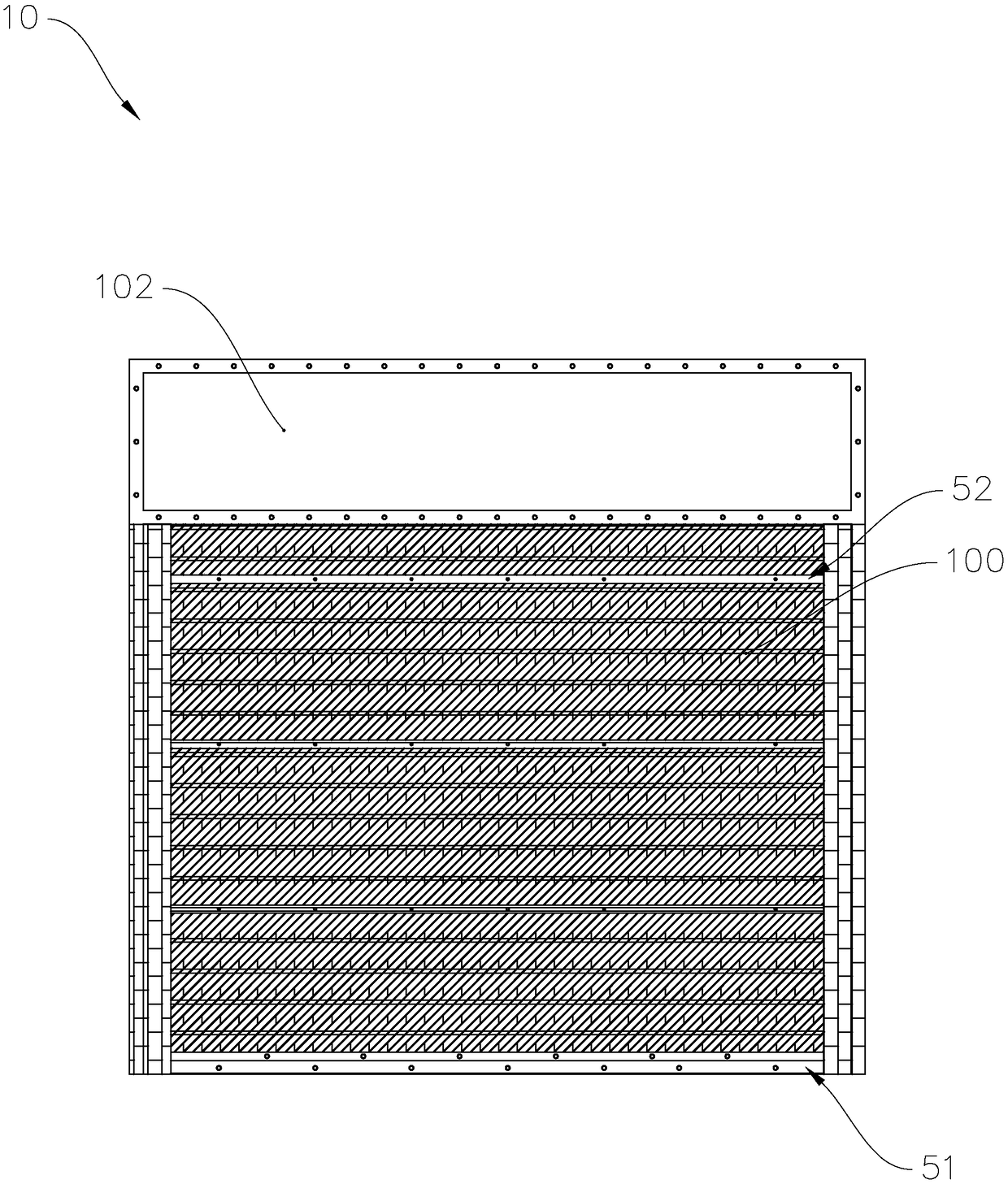

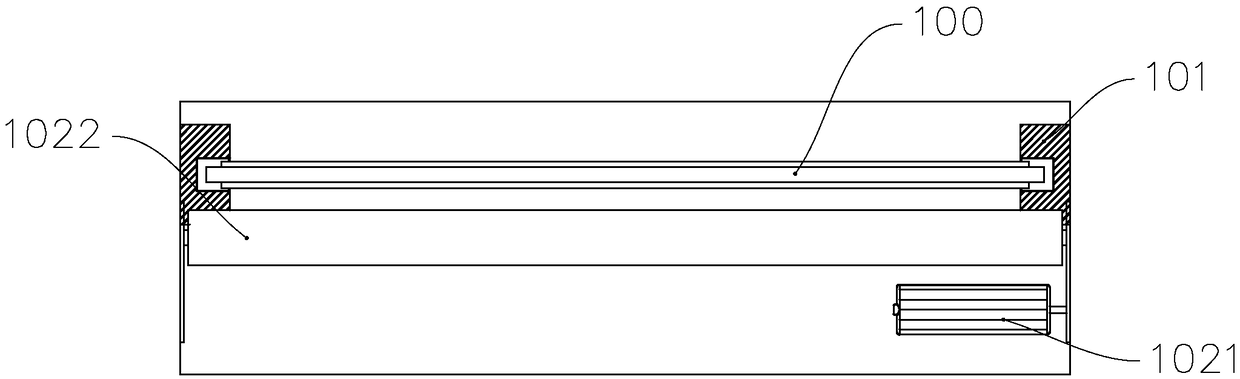

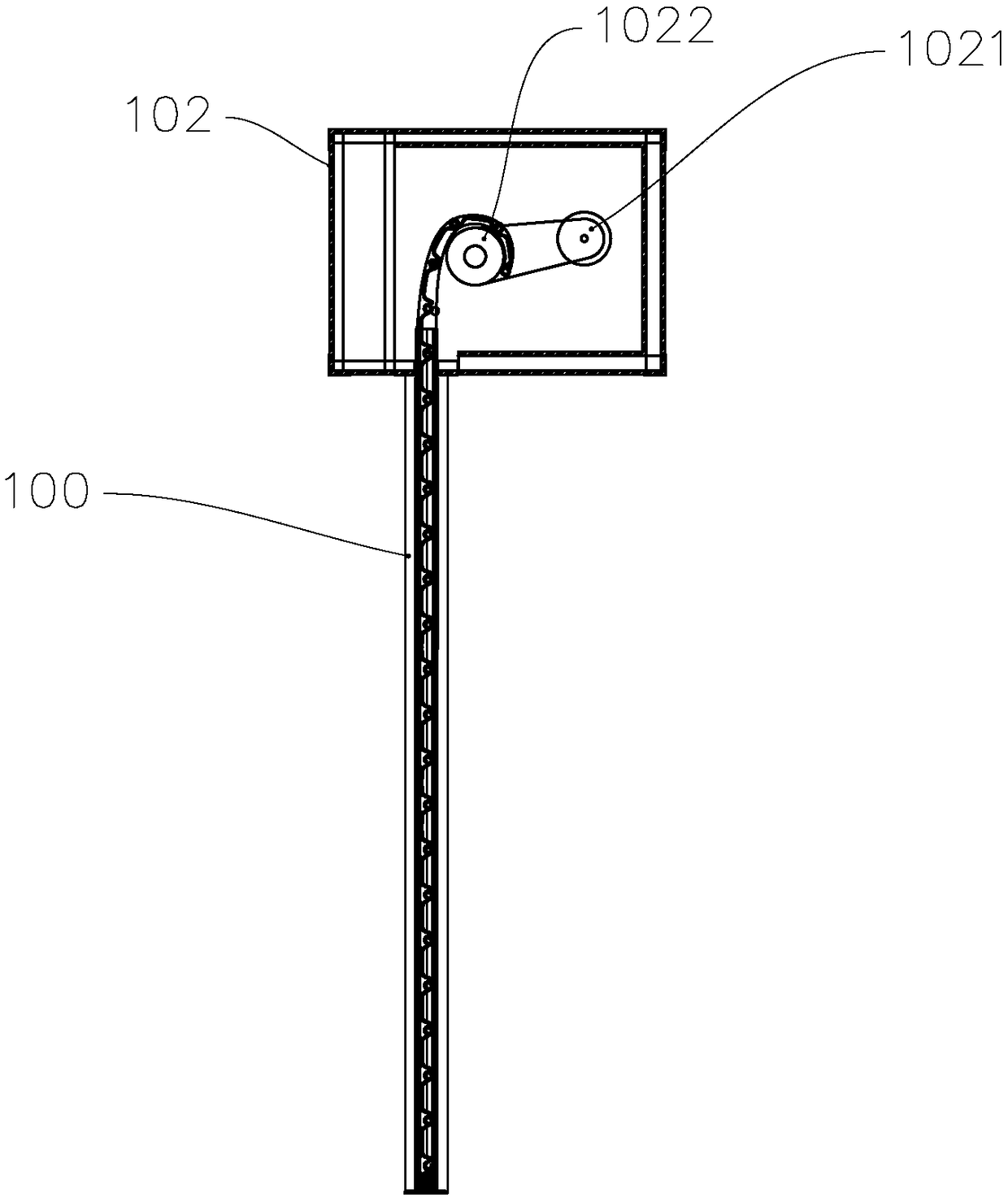

fire shutter door

ActiveCN107386941BImprove integrityGood heat insulationShutters/ movable grillesFireproof doorsFiberWinding machine

The invention provides a fireproof rolling shutter door. The fireproof rolling shutter door comprises a guide rail, a shutter body and a winding device; the shutter body is positioned in the guide rail; the winding device comprises a door winding machine and a winding shaft; a driving shaft of the door winding machine drives a rotating shaft of the winding shaft; the winding shaft is fixedly connected with the shutter body; the shutter body comprises a support piece, a first shutter surface, a second shutter surface, a fireproof bar and a bottom beam; the first shutter surface is outwards provided with a first inorganic fiber cotton, first inorganic fiber cloth and first silica gel cloth in sequence from the support piece; the second shutter surface is outwards provided with a second inorganic fiber cotton, second inorganic fiber cloth and second silica gel cloth in sequence from the support piece; the first shutter surface and the second shutter surface are respectively positioned on two sides of the support piece; the fireproof bar is arranged between the support piece and the first shutter surface; the fireproof bar is arranged between the support piece and the second shutter surface; and the bottom beam is connected between the bottom of the first shutter surface and the bottom of the second shutter surface. The fireproof rolling shutter door has the advantages of simple structure, excellent fire resistance, thermal insulation and flame isolation effect and excellent fire resistance.

Owner:新富利消防工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com