A high-performance capacitor plastic housing

A plastic shell and capacitor technology, which is applied in the field of capacitors, can solve the problems of physical and mechanical properties degradation, poor impact resistance, low flame retardancy, etc., and achieve the effects of improving organizational structure, good weather resistance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Polybutylene terephthalate 78, ABS plastic 39, filler 12, color masterbatch 1, dibutyl sebacate 3, polyamide 10, lubricant 3, additive 0.5, flame retardant 0.2; The auxiliary agent is made of the following ingredients in parts by weight: carboxy cellulose 3, sorbitol trioleate 2, rosin 8, sodium hexametaphosphate 1, alkali lignin 2, acrylamide 2, diatomite 1, trimer Sodium phosphate 1, methyl salicylate 1, tea seed oil 4, peppermint oil 0.1; the flame retardant is made of the following ingredients in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, dodecane Sodium sulfate 2, modified starch 4.

Embodiment 2

[0023] Polybutylene terephthalate 86, ABS plastic 42, filler 14, color masterbatch 3, dibutyl sebacate 6, polyamide 14, lubricant 5, additive 0.8, flame retardant 0.4; The auxiliary agent is made of the following ingredients in parts by weight: carboxycellulose 5, sorbitol trioleate 6, rosin 10, sodium hexametaphosphate 3, alkali lignin 4, acrylamide 4, diatomite 4, trimer Sodium phosphate 3, methyl salicylate 4, tea seed oil 6, peppermint oil 0.3; the flame retardant is made of the following components in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, dodecane Sodium sulfate 2, modified starch 4.

Embodiment 3

[0025] Polybutylene terephthalate 82, ABS plastic 41, filler 13, color masterbatch 2, dibutyl sebacate 4, polyamide 12, lubricant 4, additive 0.6, flame retardant 0.3; The auxiliary agent is made of the following ingredients in parts by weight: carboxycellulose 4, sorbitol trioleate 4, rosin 9, sodium hexametaphosphate 2, alkali lignin 3, acrylamide 3, diatomite 2, trimer Sodium phosphate 2, methyl salicylate 3, tea seed oil 5, peppermint oil 0.2; the flame retardant is made of the following components in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, dodecane Sodium sulfate 2, modified starch 4.

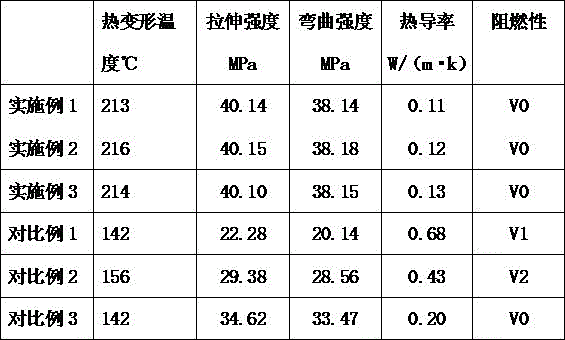

[0026] Through experiments to compare the performance of capacitor plastic casings:

[0027] Table 1

[0028]

[0029] Wherein, comparative example 1 is: without adding additives in embodiment 2 of the present invention, other ingredients remain unchanged;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com