Preparation method of flame retarding phosphorus-copolyester with better color phase

A technology of copolymerizing flame retardants and copolymerizing flame retardants, applied in the field of preparation of phase phosphorus copolymerized flame retardant polyesters, which can solve the problems of poor color tone of flame retardants, no final improvement of slice color, low polyester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

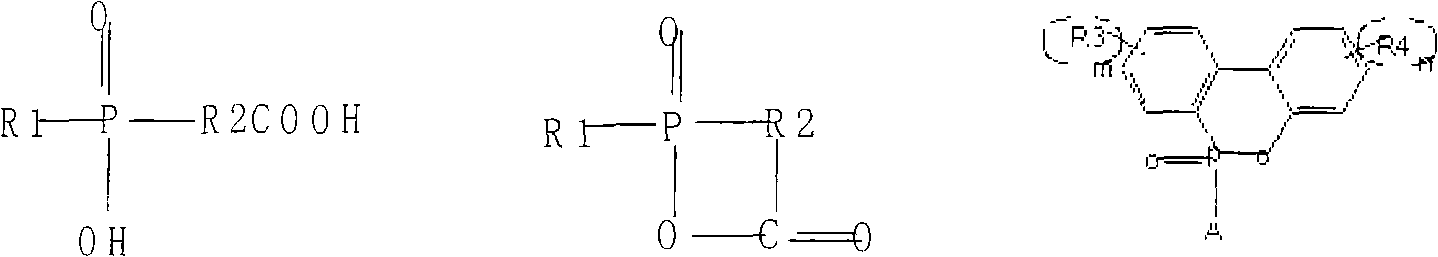

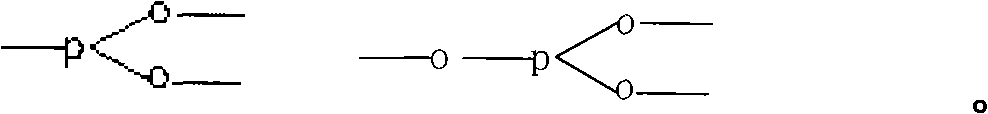

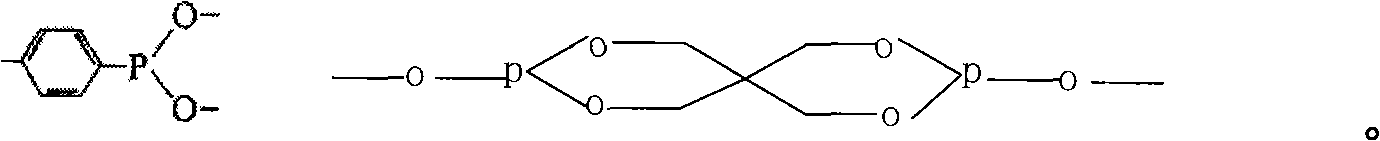

Method used

Image

Examples

Embodiment 1

[0093] The process is the same as in Comparative Example 1. After migration, add 390ppm IR1010, PEP36, antimony trioxide, titanium dioxide, and flame retardant PE-100.

Embodiment 2

[0095] The process is the same as in Comparative Example 1. After migration, add PW9225, antimony trioxide, titanium dioxide, and flame retardant PE-100.

Embodiment 3

[0097] The process is the same as in Comparative Example 1. After migration PW9225, antimony trioxide, titanium dioxide, flame retardant PE-100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com