fire shutter door

A technology for rolling shutter doors and rolling door machines, which is applied in the field of rolling shutter doors, can solve the problems of easy occurrence of gaps, off-threads, and the curtain surface sewing is not temperature-resistant, and achieves the effects of improving stability, convenient and smooth retractable and smooth, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

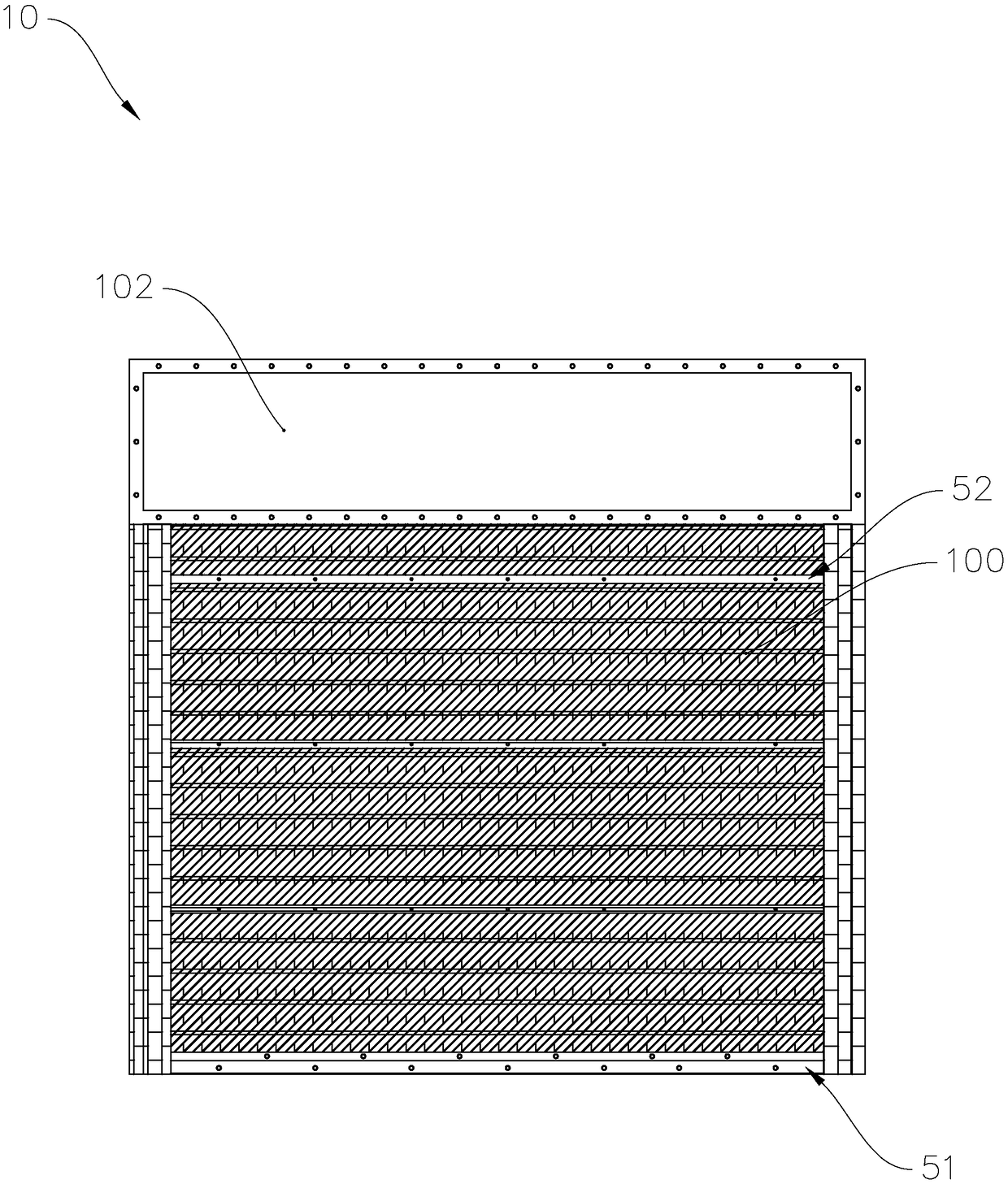

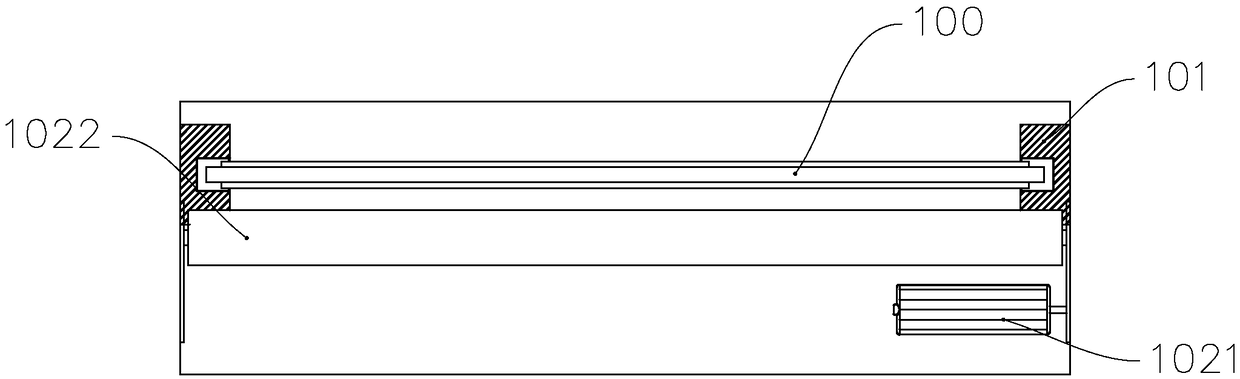

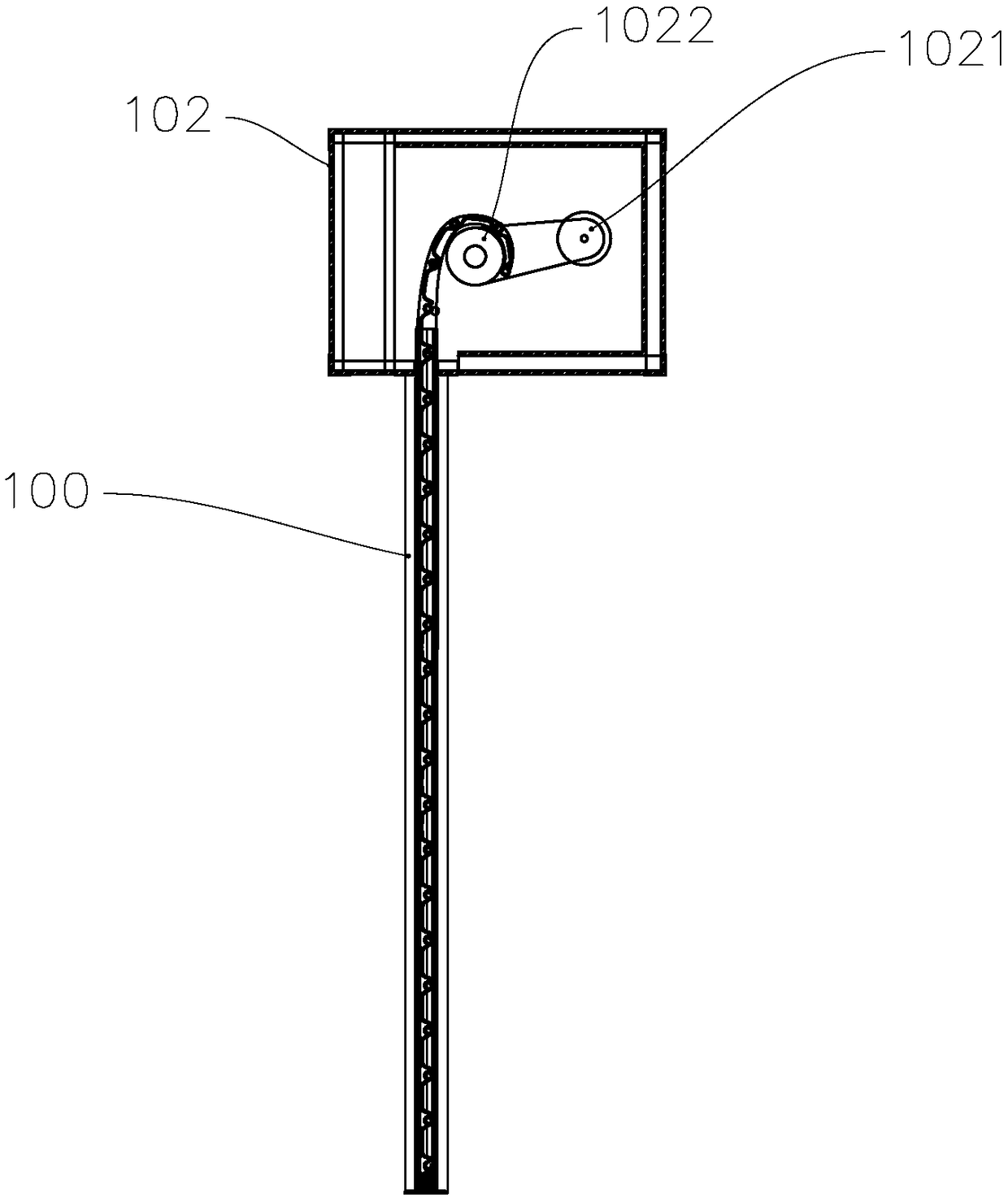

[0036] refer to Figure 1 to Figure 4, The fire shutter door 10 includes a curtain body 100, a guide rail 101, a winding device 102 and a control device. Wherein, the guide rail 101 is fixedly connected with the wall of the building, and the curtain body 100 is located in the guide rail 101 . Winding device 102 comprises door rolling machine 1021 and reel 1022, and reel 1022 is positioned at the top of guide rail 101, and reel 1022 is fixedly connected with curtain body 100; Since the driving reel 1022 rotates around the axis of the reel 1022 itself to realize winding or releasing of the curtain body 100 , the guide rail 101 plays a role of guiding and limiting the retraction of the curtain body 100 .

[0037] The curtain body 100 includes a support member, a first curtain surface, a second curtain surface, a fire protection strip 4 , a bottom beam 51 , a bead set 52 and a fixing piece 53 . Specifically, the supporting member is a brake plate set 1, and the brake plate set 1...

no. 2 example

[0077] like Figure 7 to Figure 8 As shown, applying the inventive concept of the first embodiment of the fire shutter door, the second embodiment of the fire shutter door differs from the first embodiment in that the number of curtain bodies 6 in the second embodiment is two, and the number of guide rails 61 is two. group, the number of reels 62 of the winding device is two. A curtain body 6 is located in a corresponding group of guide rails 61, and a reel 62 is fixedly connected to a curtain body 6, and the driving shaft of the rolling door machine of the winding device drives two reel shafts 62 at the same time, so that the fireproof shutter door 105 forms a The double-track double-curtain fire shutter door can further improve the fire prevention, heat insulation and flame isolation effect of the fire shutter door. Preferably, the number of door rollers in the winding device can be set to two, and one door roller drives one reel 62 to rotate.

no. 3 example

[0079] like Figure 9 As shown, applying the inventive concept of the first embodiment or the second embodiment of the fire shutter door, the difference between the third embodiment of the fire shutter door and the first embodiment or the second embodiment lies in the support of the curtain body 7 of the third embodiment Part is a support net 71, and the thickness of the support net 71 is 0.7 mm to 1.2 mm. Preferably, the thickness of the support net 71 is 0.8 mm; or the thickness of the support net 71 is 1 mm. When the support net 71 is a supporting member, the support net 71 can also support the curtain body 7, thereby improving the overall stability of the curtain body 7, and preventing the curtain body 7 from being easily burned through when subjected to flames. . In addition, the supporting net 71 has good flexibility, which makes it more convenient and smooth when the winding device retracts and unwinds the curtain body 7 .

[0080] To sum up, the fireproof rolling do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com