Composite environment-friendly flame retardant for ABS (Acrylonitrile Butadiene Styrene) and ABS flame-retardant plastic

A technology of flame retardant plastics and flame retardants, applied in the field of flame retardants and ABS plastics, can solve the problems of not being able to reduce the thermal deformation temperature, mechanical temperature and electrical insulation performance of plastic products, not affecting the mechanical strength of plastics, and being unable to provide, etc. Achieve good flame retardant function, low product cost, excellent heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation of embodiment 1ABS composite environment-friendly flame retardant

[0025] Weighing: 15 kg of dimethyl trimethylsilylmethylphosphonate, 40 kg of melamine cyanurate, 15 kg of zinc borate, and 50 kg of magnesium hydroxide.

[0026] Stir and mix dimethyl trimethylsilylmethylphosphonate, melamine cyanurate, zinc borate and magnesium hydroxide evenly to prepare the composite environmentally friendly flame retardant for ABS.

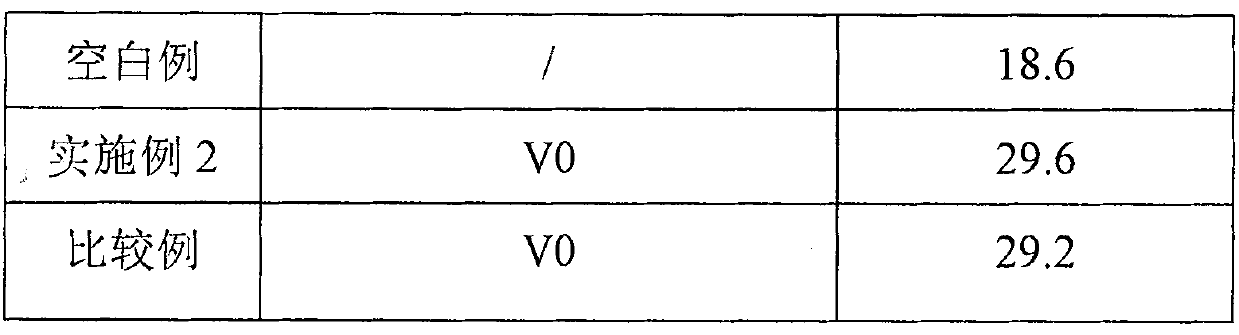

Embodiment 2

[0027] The preparation of embodiment 2ABS flame-retardant plastics

[0028] Weigh 100 kg of ABS resin and 30 kg of the composite environmentally friendly flame retardant for ABS prepared in Example 1. After mixing evenly, adopt the common method in this industry to melt and knead, extrude and granulate to obtain the ABS flame retardant plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com