Patents

Literature

192results about How to "Mechanical strength is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

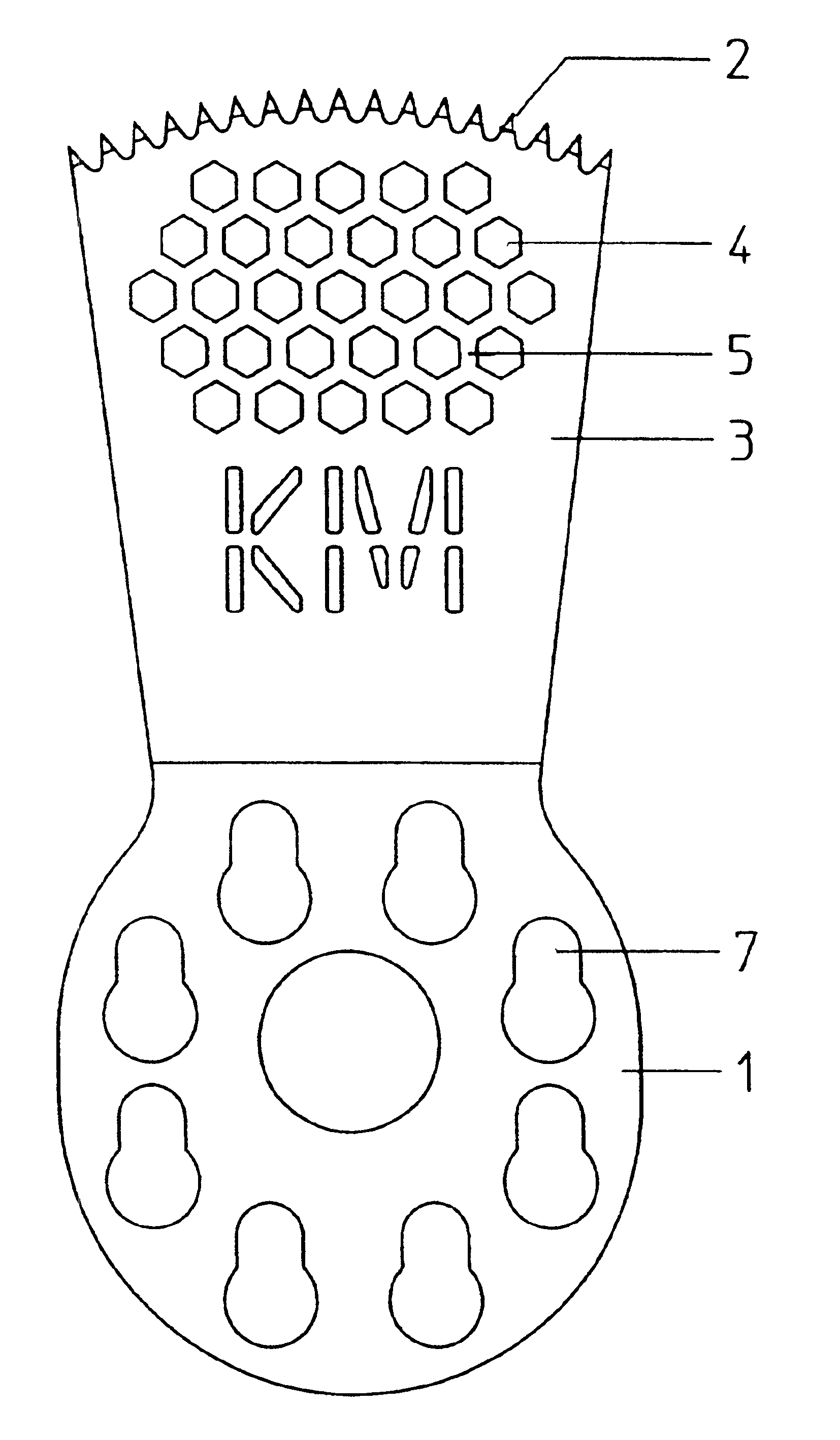

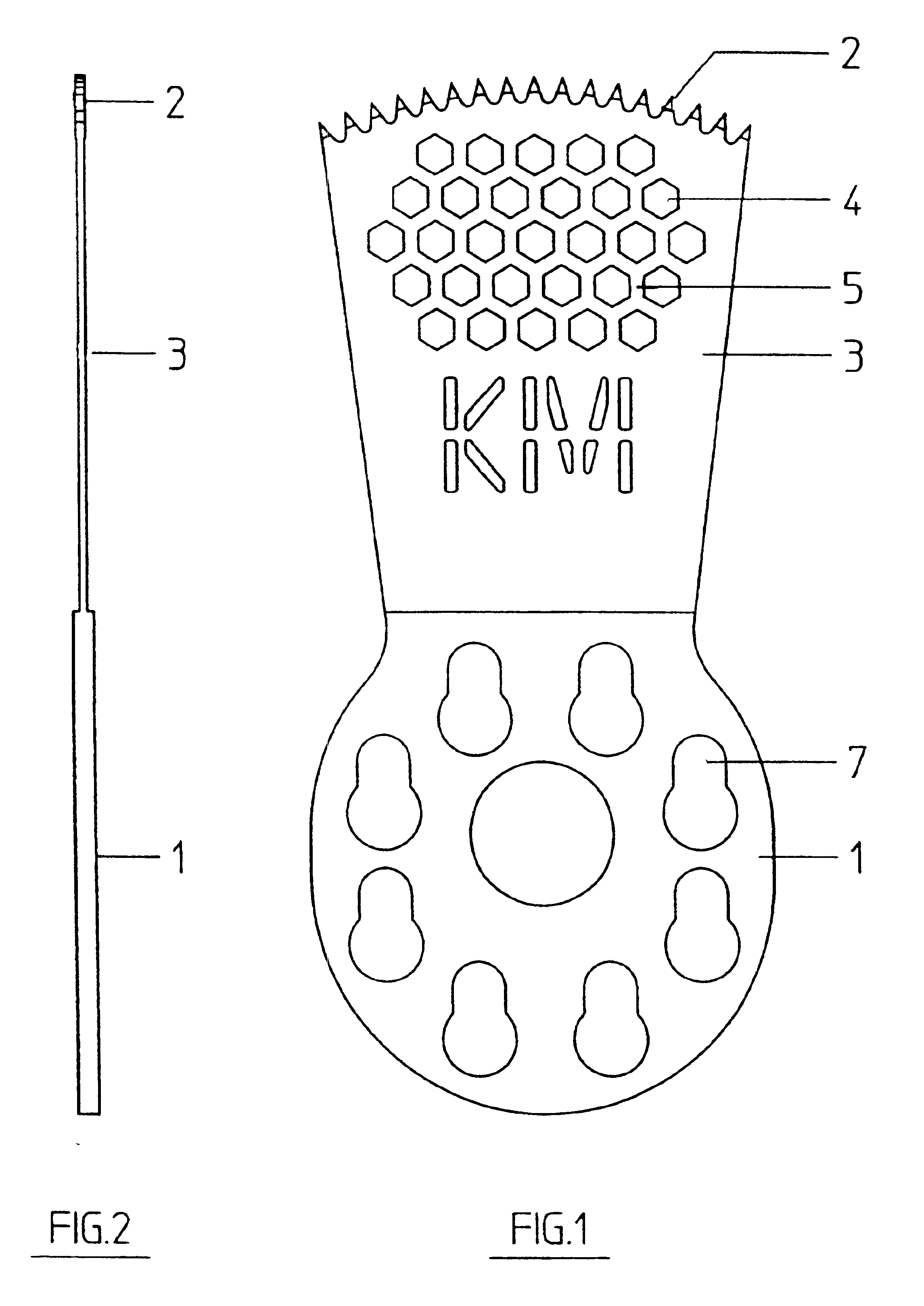

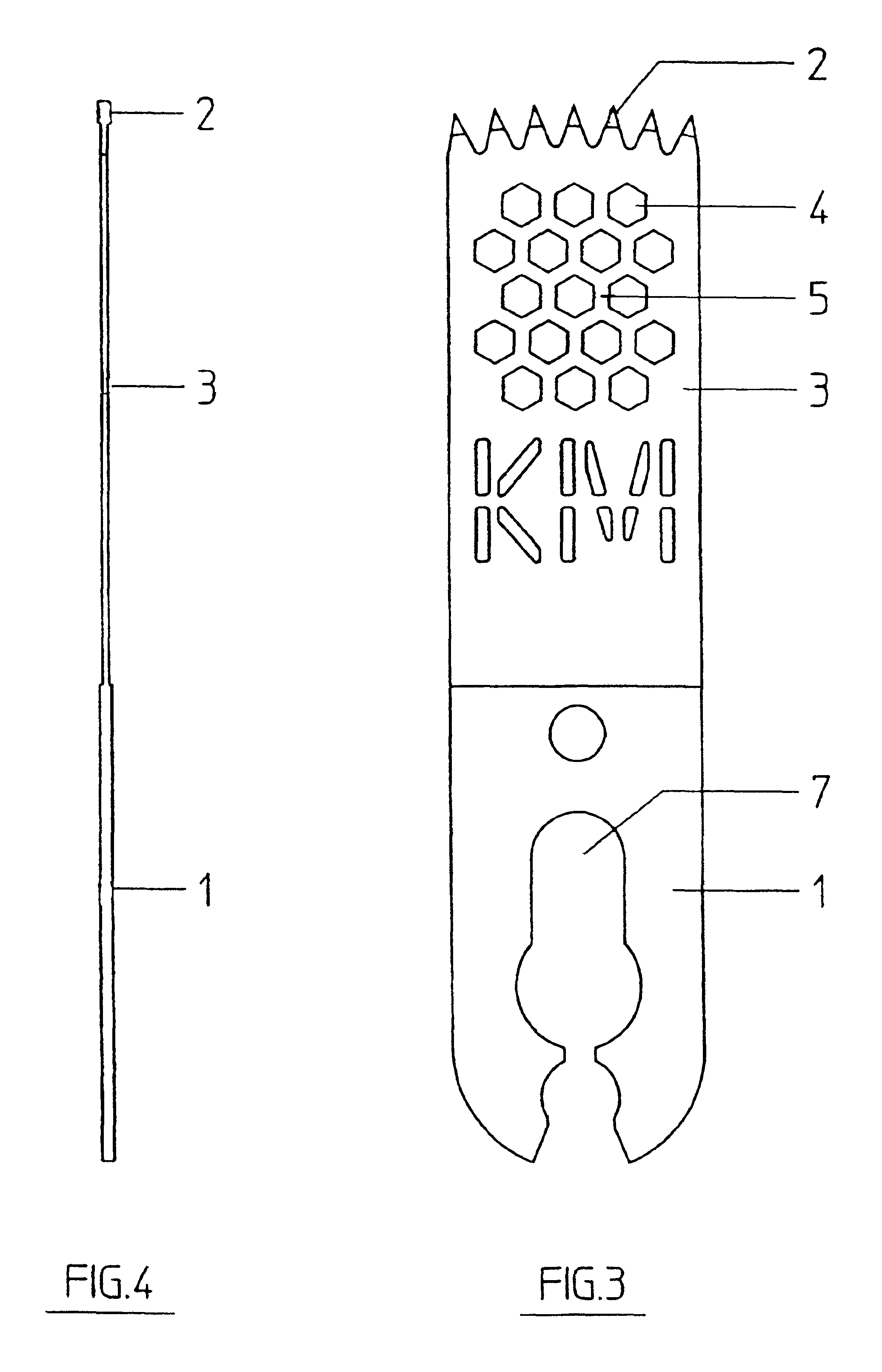

Surgical saw blade comprising recesses in the working area

The present invention relates to a surgical saw blade comprising a clamping portion and a working area provided with a toothing, wherein a plurality of recesses are formed in the working area.

Owner:GEBR BRASSELER

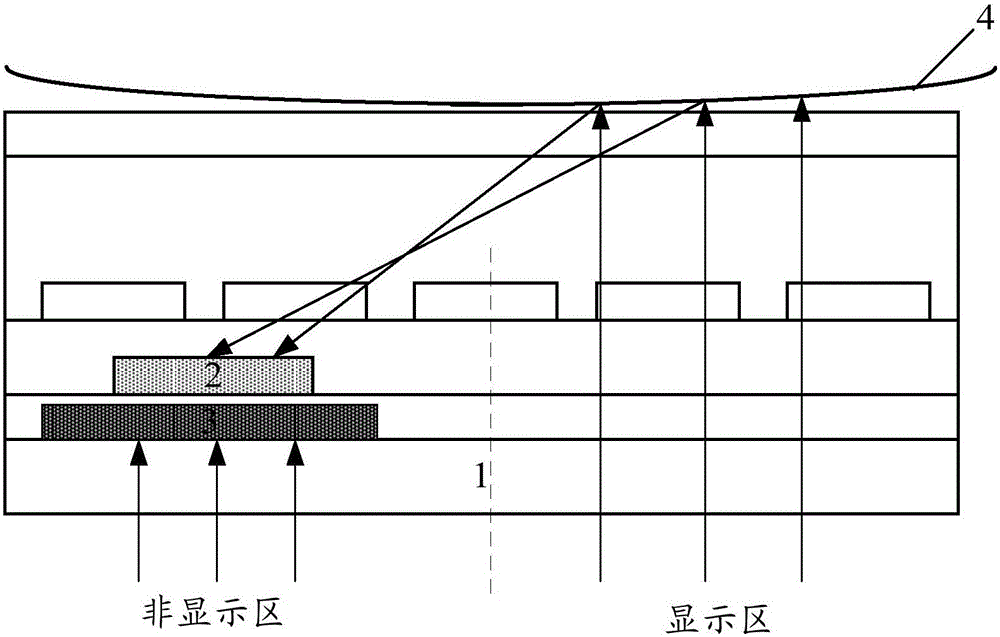

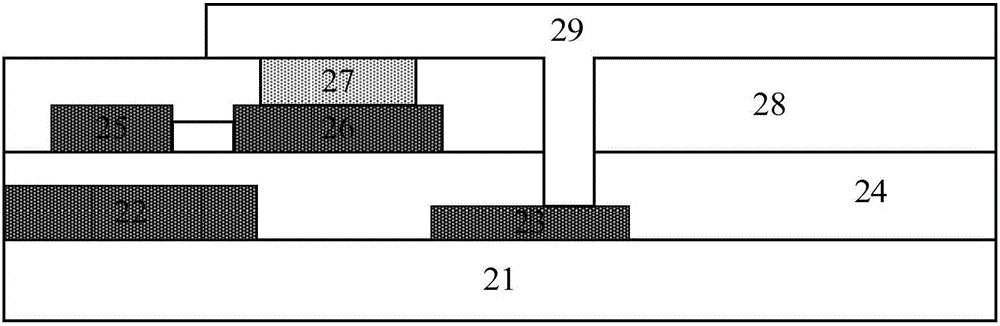

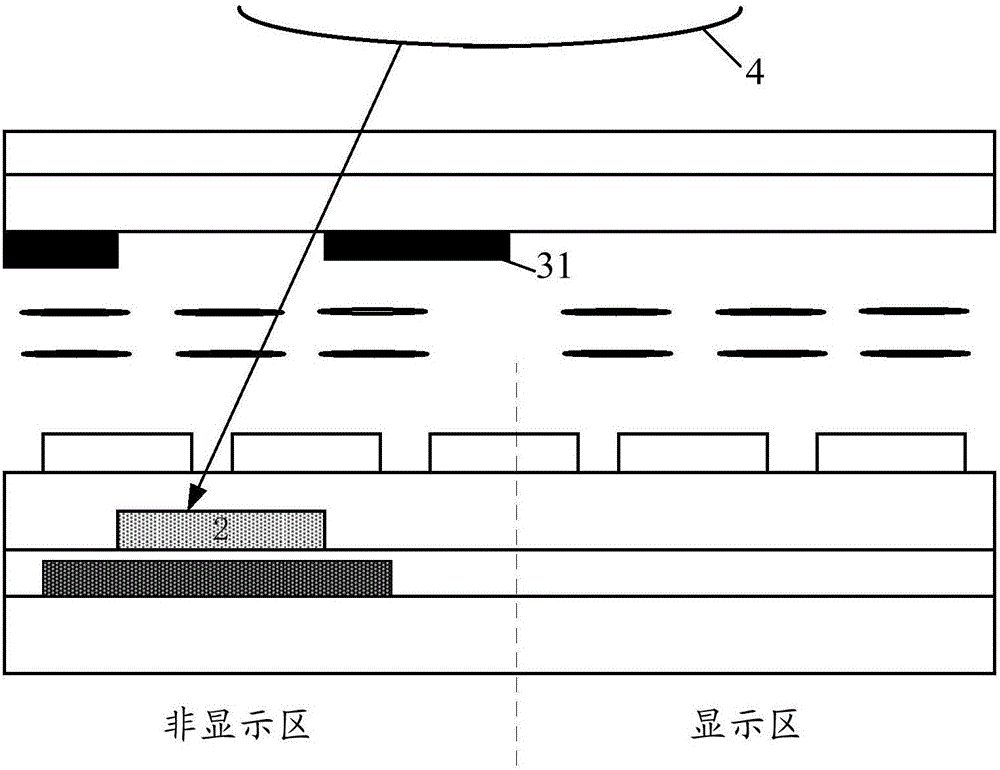

Array substrate, display panel, display device, and working method

InactiveCN106295527AMechanical strength is not affectedDoes not take up spacePrint image acquisitionNon-linear opticsDisplay deviceEngineering

The invention provides an array substrate, a display panel, a display device, and a working method. The array substrate comprises: a plurality of sub-pixel regions on a substrate. Each sub-pixel region includes a display area for displaying a frame and a non-display area. The non-display area is provided with an optical sensing element. The sensing element is capable of converting a received optical signal into an electrical signal. The non-display area is further provided with an opaque pattern between the optical sensing element and the substrate. The positive projection, on the substrate, of the opaque pattern completely covers the positive projection, on the substrate, of the optical sensing element. A fingerprint recognition function is realized inside a terminal screen, thereby improving the user experience.

Owner:BOE TECH GRP CO LTD

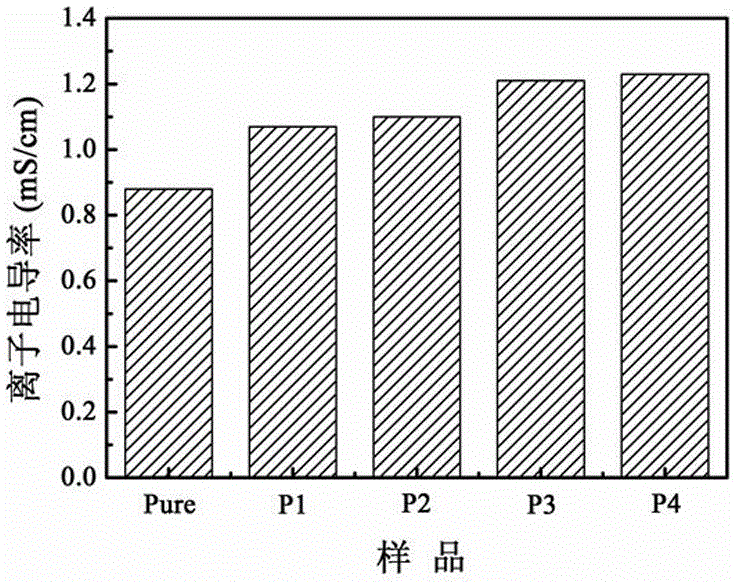

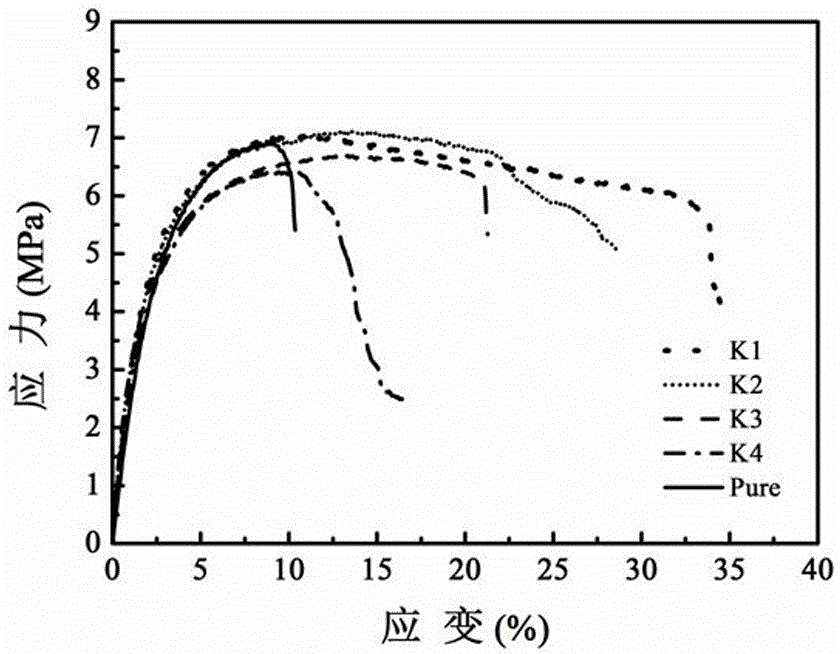

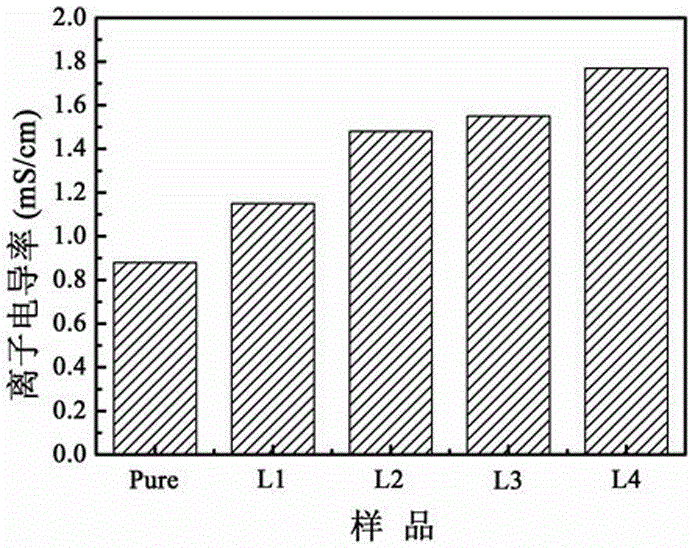

Porous lithium ion battery separator with interpenetrating polymer network structure, and preparation method and application for porous lithium ion battery separator

ActiveCN105932203AGood mechanical strengthGuaranteed ionic conductivityCell seperators/membranes/diaphragms/spacersSecondary cellsSolventPolyvinylidene fluoride

The invention discloses a porous lithium ion battery separator with an interpenetrating polymer network structure, and a preparation method and an application for the porous lithium ion battery separator. The preparation method specifically comprises the steps of uniformly mixing polyvinylidene fluoride-hexafluoropropylene, (methyl) acrylate monomers, octavinyl octa-silsesquioxane cross-linking agent and pore-forming auxiliary in a proper solvent to form porous gel polymer film with the interpenetrating polymer network structure through free radical polymerization, wherein the ion conductivity of the polymer film at a temperature of 25 DEG C can reach 1.0*10<-3>S / cm, the tensile strength can reach 7MPa, and excellent dimensional stability is realized; and on the basis, carrying out post processing on the gel polymer film to obtain the porous separator. By adoption of the lithium ion battery separator provided by the invention, the ionic conductivity can be greatly improved, and the high rate charging-discharging performance can be also obviously enhanced as well, so that the porous lithium ion battery separator is high in application potential.

Owner:SUZHOU UNIV

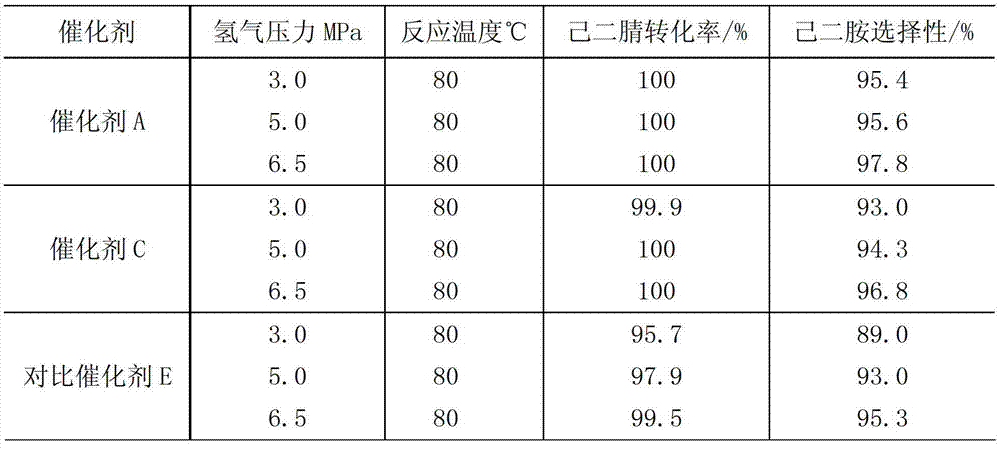

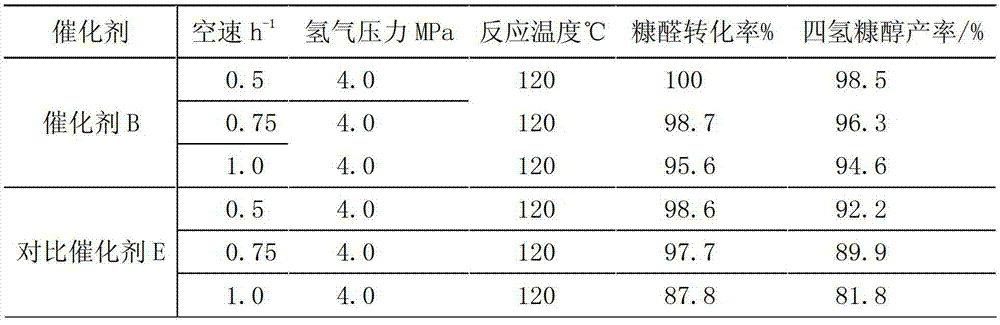

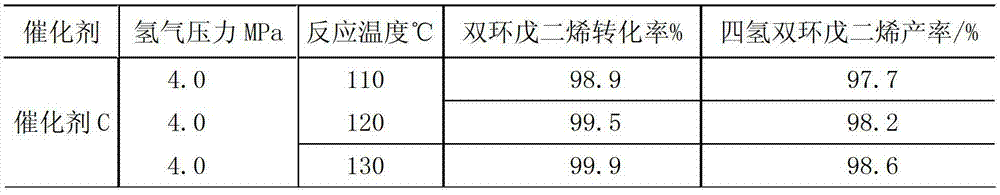

Preparation method and application of fixed bed framework metal catalyst

InactiveCN103203240ALow heat treatment temperatureImprove flame retardant performanceOrganic compound preparationHydrocarbon by hydrogenationKetoneOrganic compound

The invention discloses a preparation method and the application of a fixed bed framework metal catalyst. The method includes: adopting a halogen substituted organic polymer as a coupling agent of active metal aluminum alloy powder, preparing aluminum alloy powder containing transition metal in VIII class, IB class or VB class into particles in certain shapes, adopting forming methods like direct kneading method for band extrusion or tabletting or coating method for attaching the alloy powder on the surface of a carrier with certain strength, subjecting the formed particles to heat treatment under certain atmosphere for improving strength, and activating with an inorganic alkaline solution to obtain the fixed bed framework metal catalyst. The catalyst prepared by the method can be used for fixed bed hydrogenation reaction of unsaturated organic compounds like aldehyde, ketone, ester, nitrile, olefine, aromatic and nitro compounds. The aluminum alloy particles are low in heat treatment temperature, the strength of the carrier can be fully utilized by the coating method, and the aluminum alloy particles after being activated have excellent hydrogenation activity and stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

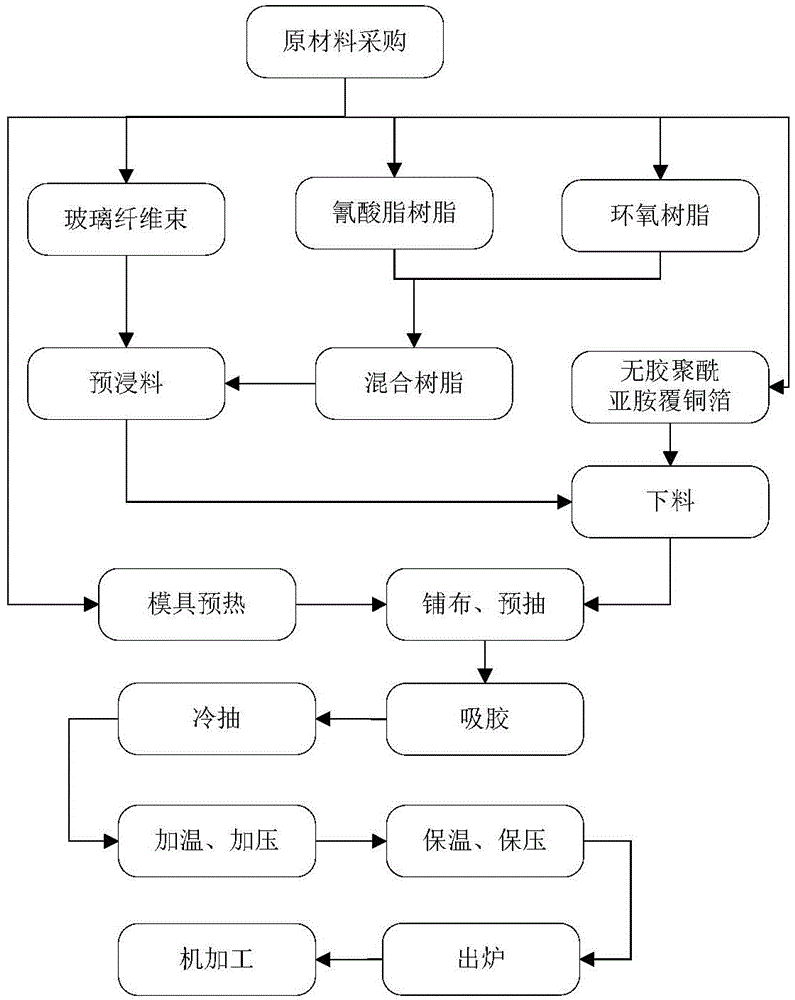

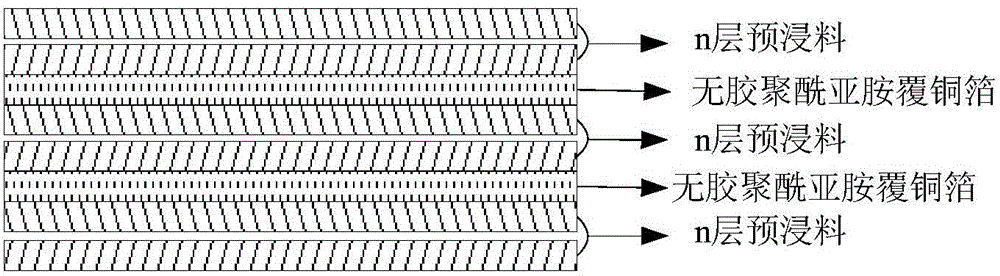

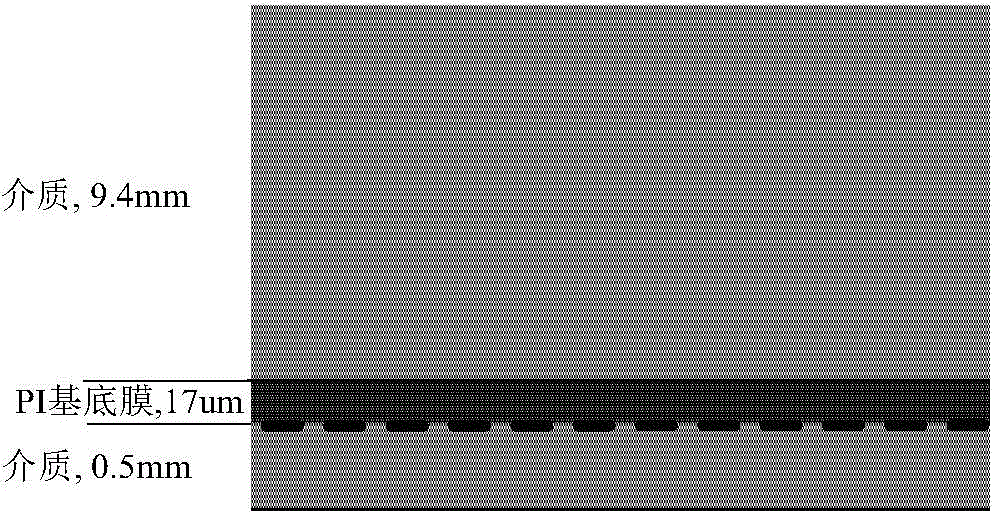

Preparation method of interlayer frequency selective surface composite material

ActiveCN104934721AMechanical strength is not affectedDoes not affect electrical characteristicsAntenna adaptation in movable bodiesRadiating element housingsEpoxyGlass fiber

The invention provides a preparation method of an interlayer frequency selective surface composite material, comprising 12 steps. The technical scheme comprises: manufacturing frequency selective surface films; and adding the thin films among prepreg layers of glass fibre cloth and epoxy resin to be laminated together. The method obtains conspicuous hiding effects under the condition of not changing the profile design of an original aircraft radome, and has no reverse impact on the electrical characteristics of an original radar system and the mechanical strength of a radome; a frequency selective surface bandpass radome is practical and feasible to solve the technical problem of invisibility of a radar antenna system.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

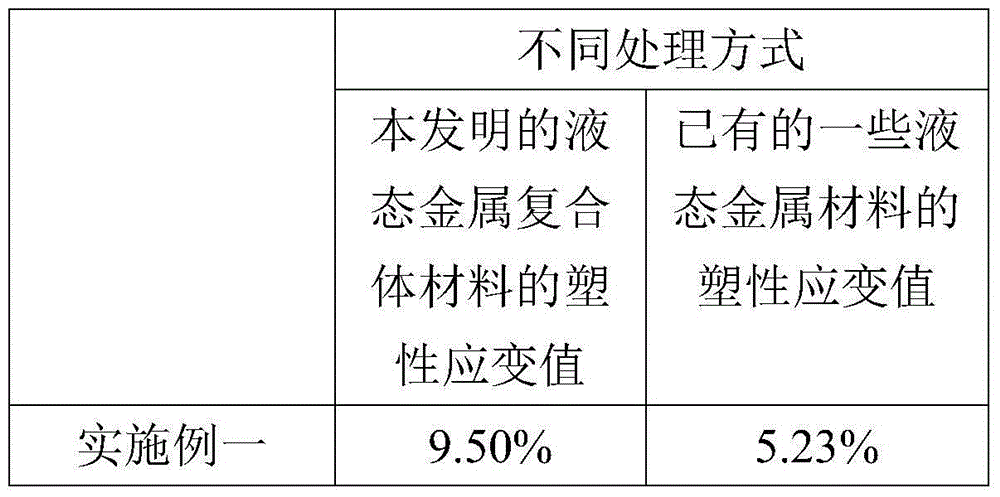

Graphene and liquid metal composite material and preparation method thereof

InactiveCN104831106AImprove plasticityMechanical strength is not affectedLiquid metalUltimate tensile strength

The invention discloses a graphene and liquid metal composite material and a preparation method thereof, the graphene and liquid metal composite material is prepared by the following method: 5-20 in parts by weight of graphene and 100 in parts by weight of liquid metal are put into a vacuum melting furnace with the vacuum degree reaching to 10<-3> to10<-2> for high temperature melting under the inert gas protection for full mutual mixing of the graphene and the liquid metal into a melting body; then by use of suction-casting means, the melting body is sucked into a shape-structural mold with a cooling system for fast cooling of the melting body to form the graphene plasticized liquid metal. The liquid metal plastic property can be significantly improved, and good mechanical strength can be kept.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

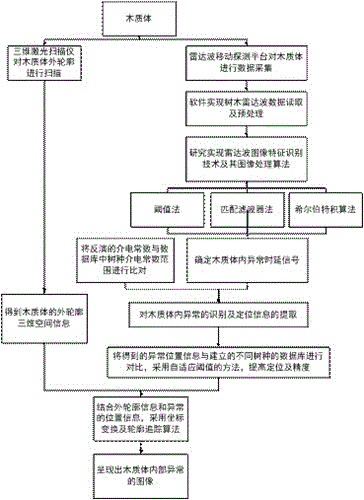

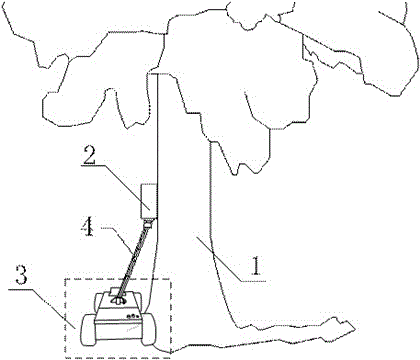

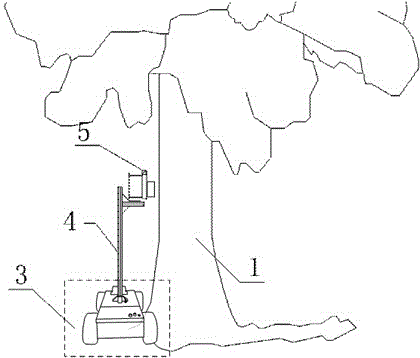

Nondestructive detection system for internal abnormality of woody body based on radar wave

InactiveCN106405061AImprove detection accuracyPrecise positioningWood testingRadio wave reradiation/reflectionData processing systemDistribution characteristic

The invention discloses a nondestructive detection system for positioning and imaging internal abnormality (such as decay, holes, scars, cracks and the like) of a woody body based on radar wave. The system comprises a radar detection movement platform, a three-dimensional laser scanner, a data processing system and imaging software. The system principle is characterized in that reflection characteristics of an abnormal layer are obtained by utilization of methods, such as threshold value, matched filter, Hilbert integral and the like according to transmission characteristics, such as spreading amplitude, wave speed change, reflection, and transmission, of the radar wave in the woody body and abnormal media and according to distribution characteristics of electrical properties and physical properties on the basis of images acquired through scanning by medium-coupled radar wave, and a contour of a tree is obtained by utilization of the three-dimensional laser scanner, therefore the decay in the tree is accurately positioned and imaged.

Owner:BEIJING FORESTRY UNIVERSITY

Antibacterial wear-resistant plastic tubular product, and preparation method thereof

InactiveCN107828118AImprove heat resistance and wear resistanceImprove performanceChemistryCarbon black

The invention belongs to the field of plastic tubular product, and more specifically relates to an antibacterial wear-resistant plastic tubular product, and a preparation method thereof. The antibacterial wear-resistant plastic tubular product is prepared from, by weight, 100 to 150 parts of high density polyethylene, 10 to 30 parts of acetylated monoglyceride, 10 to 30 parts of coumarone resin, 5to 10 parts of anti-oxidant 1010, 20 to 40 parts of hollow glass bead, 10 to 15 parts of nanometer silver, 1 to 6 parts of chlorinated polyethylene, 3 to 7 parts of high resistant carbon black, 5 to8 parts of silane coupling agent, 5 to 10 parts of nanometer titanium dioxide, 3 to 6 parts of zinc oxide, 10 to 15 parts of acrylic resin, and 15 to 20 parts of an auxiliary agent. The antibacterialwear-resistant plastic tubular product possesses excellent heat resistance, wear resistance, antibacterial performance, and mildew resistance. The mechanical strength of the antibacterial wear-resistant plastic tubular product is not influenced by the antibacterial performance and mildew resistance, wear resistance is excellent, service life is long, and market application prospect and economic benefit are excellent.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

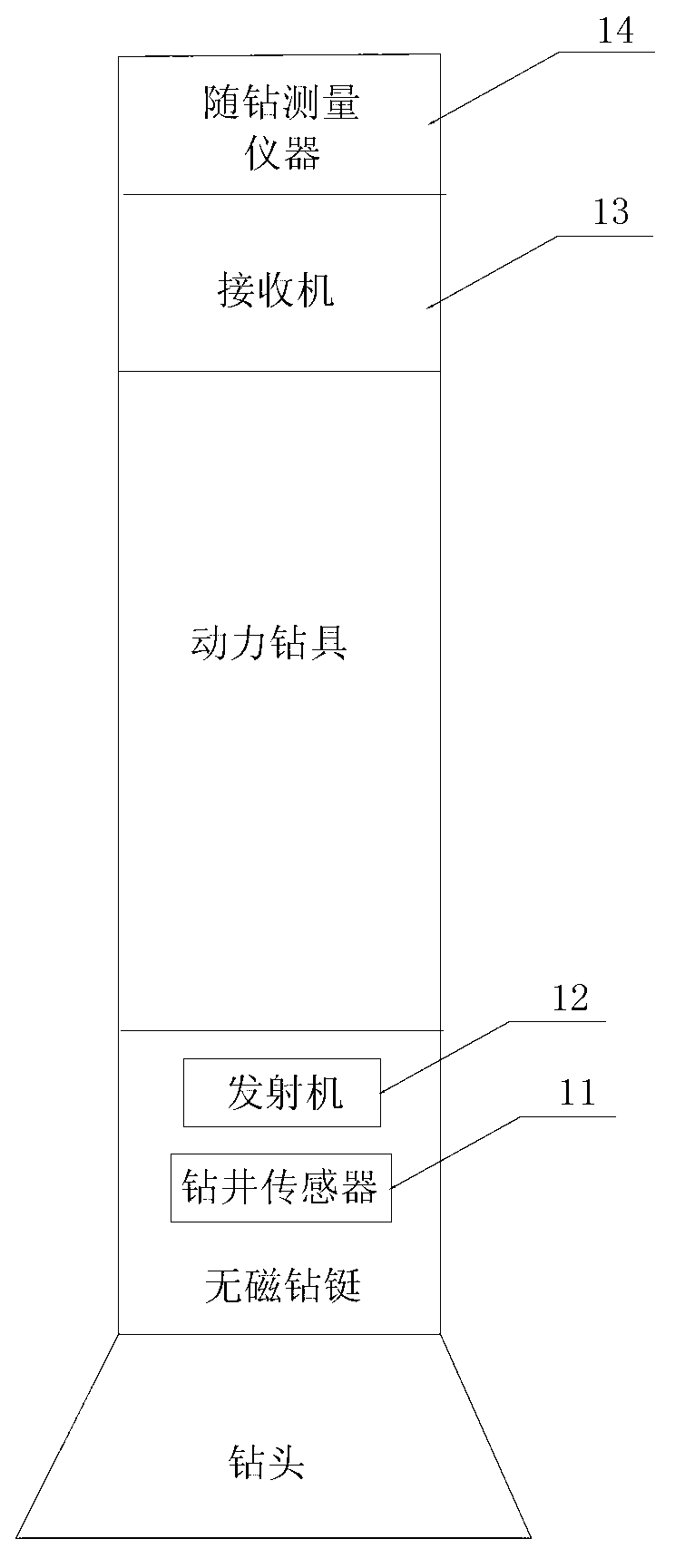

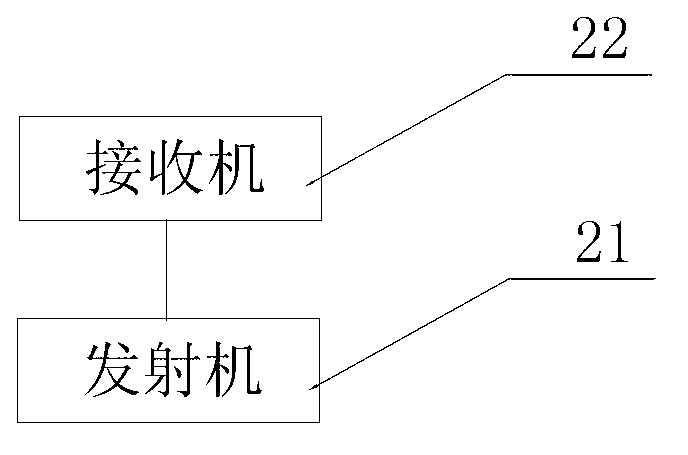

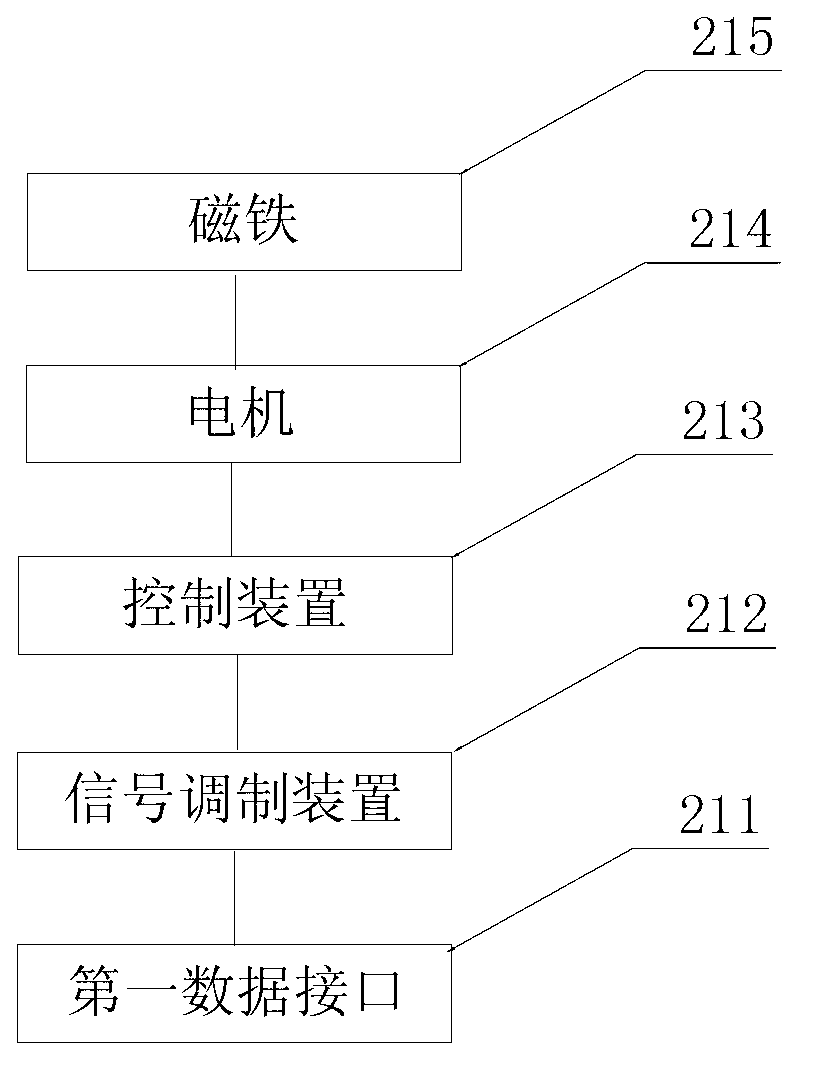

System, device and method for transmitting near-bit drilling signals

InactiveCN102937022AMechanical strength is not affectedStable transmission channelTransmission systemsConstructionsMeasuring instrumentTransmission channel

The invention provides a system, a device and a method for transmitting near-bit drilling signals. The system comprises a drilling sensor, a sender, a receiver and a measuring instrument while drilling, wherein the drilling sensor is packaged in a non-magnetic drill collar arranged between a power drilling tool and a drill and used for measuring drilling track parameter information and sending the information to the sender; the sender is packaged in the non-magnetic drill collar arranged between the power drilling tool and the drill, connected with the drilling sensor, and used for generating an alternating magnetic field according to the drilling track parameter information; the receiver is arranged at the end of the power drilling tool close to the measuring instrument while drilling, used for generating induced current signals by using the alternating magnetic field, and obtaining the drilling track parameter information according to the induced current signals and sending the information to the measuring instrument while drilling; and the measuring instrument while drilling is arranged between the power drilling tool and the ground and used for sending the drilling track parameter information to a ground receiver. According to the system, the device and the method, the drilling track parameter information collected by the drilling sensor is sent to the measuring instrument while drilling in the transmission mode in which the transmission channel is stable, the transmission rate is high and the bit error ratio is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

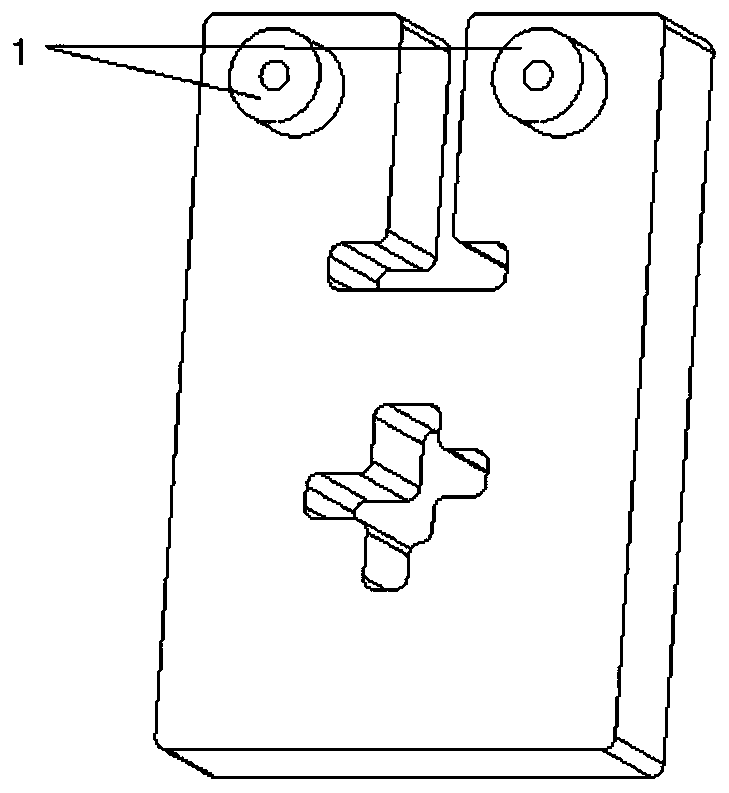

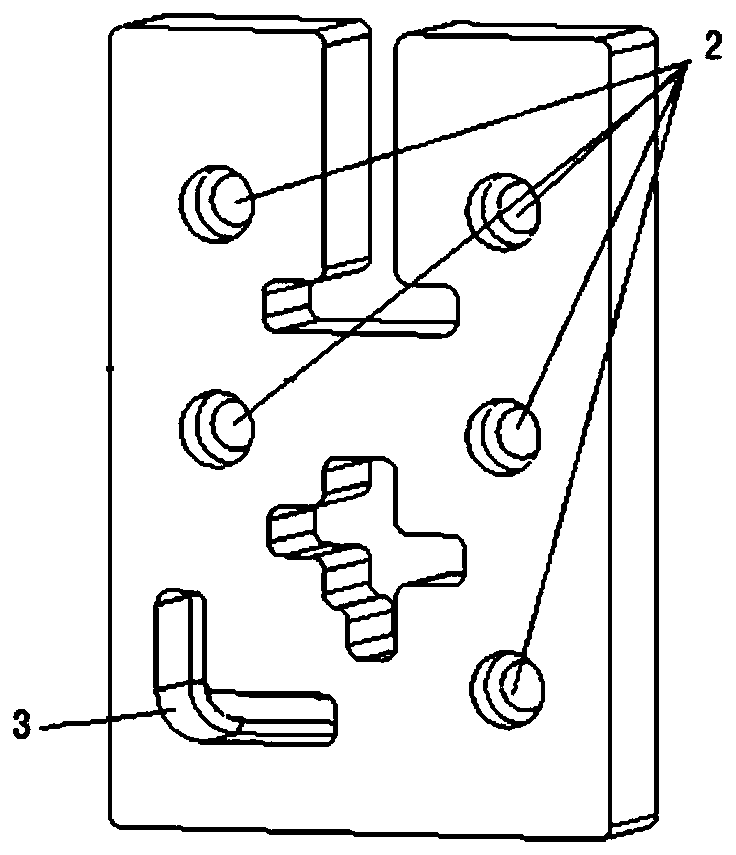

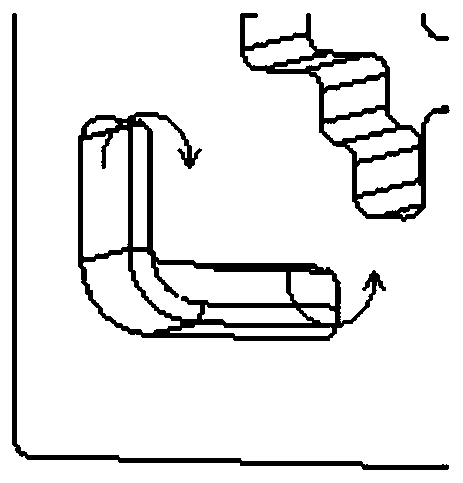

Preparation method for aluminum silicon carbide compound material IGBT (Insulated Gate Bipolar Translator) substrate and method for inlaying aluminum alloy

The invention relates to a preparation method for an aluminum silicon carbide compound material IGBT (Insulated Gate Bipolar Translator) substrate and a method for inlaying an aluminum alloy. The method comprises the following steps of: (1) designing a framework mould; (2) pressing a mould; (3) microwave sintering; and (4) vacuum pressure aluminizing, wherein the step of designing a framework mould comprises: designing punched or tapped parts on two opposite sides or four sides as male moulds, and designing non-punched or non-tapped parts as female moulds, thereby forming a convex-concave shape of a cavity of the framework mould; and convex-concave joints are transited by using R10-R20mm arcs; and the step of vacuum pressure aluminizing comprises: placing a part having a convex-concave side of a silicon carbide framework into an aluminizing mould vertical to an opening direction, and loading the aluminizing mould into a vacuum pressure steeping furnace while keeping an opening to be upward; and the aluminizing is performed under a 8MPa aluminizing pressure, thereby filling the silicon carbide framework and a concave part with aluminum alloys. By adopting the method, the inlaid aluminum alloys and the aluminum alloy in the silicon carbide framework are simultaneously condensed and crystallized, the connection is tight, and the aluminum alloys are inlaid in the punched or tappedparts, thereby promoting the punching or tapping efficiency.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

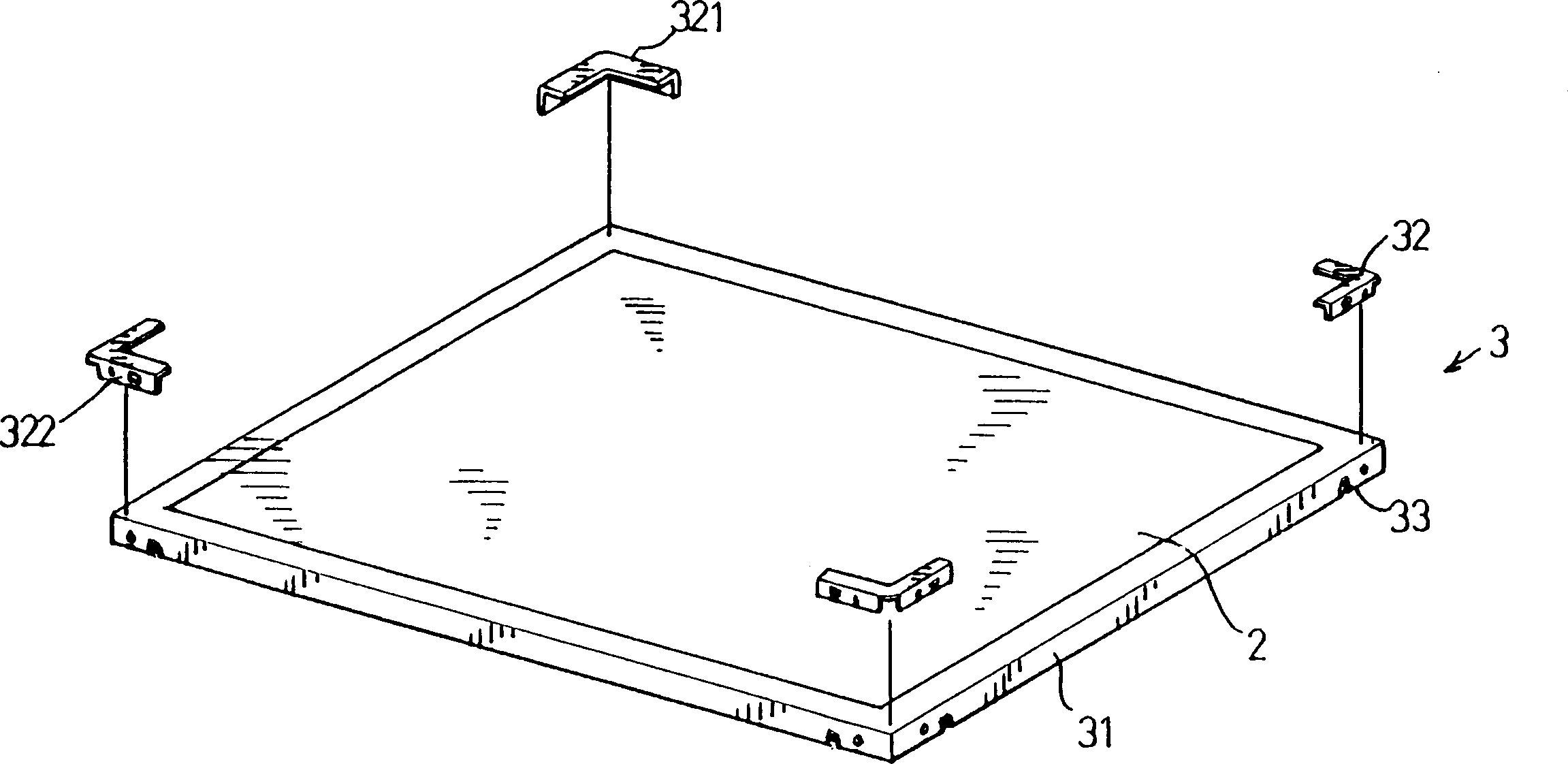

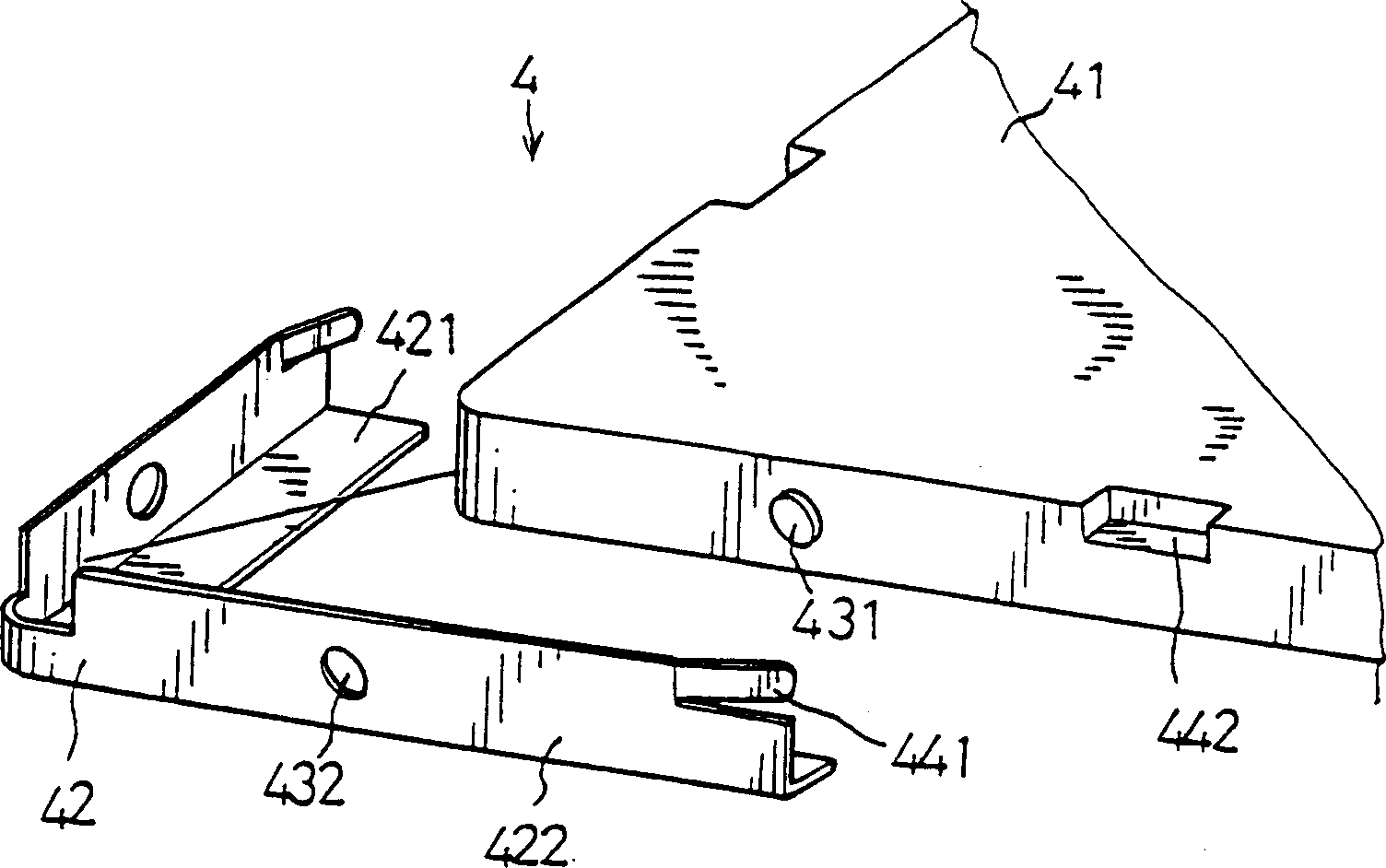

Liquid crystal display and its fixed frame

Owner:INNOLUX CORP

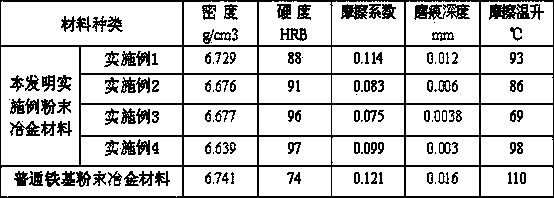

Phosphorous graphite ferrum-based powder metallurgy antifriction material

InactiveCN103981443AHigh hardnessImproved performance against adhesive galling during rubbingCopper platingWear resistant

The invention discloses a phosphorous graphite ferrum-based powder metallurgy antifriction material comprising the following raw material components:0.1-5% of copper-plated flake graphite, 0.1-3.5% of common graphite powder, 0.1-3% of zinc stearate, 0.1-4% of phosphorus and the balance of ferrum powder. The powder metallurgy material is prepared through the steps of powder mixing, pressing and sintering. Compared with the prior art, an adopted new powder mixing granulation method has the advantages that the problem that powders with different masses and densities are segregated and layered in a powder material mixing process is avoided, and the segregation of graphite in the material is avoided effectively; a copper-plated flake graphite and the common graphite powder mixed adding way is adopted, so that the pressing moldability and sintering characteristic of the material are improved; due to the addition of phosphorus, the hardness and adhesive abrasion resistance of the material are remarkably improved; in a word, the antifriction and wear resistant characteristics of the ferrum-based powder metallurgy antifriction material disclosed by the invention are improved, and the ferrum-based powder metallurgy antifriction material has the advantages of relatively low cost and wide application range.

Owner:HEFEI UNIV OF TECH

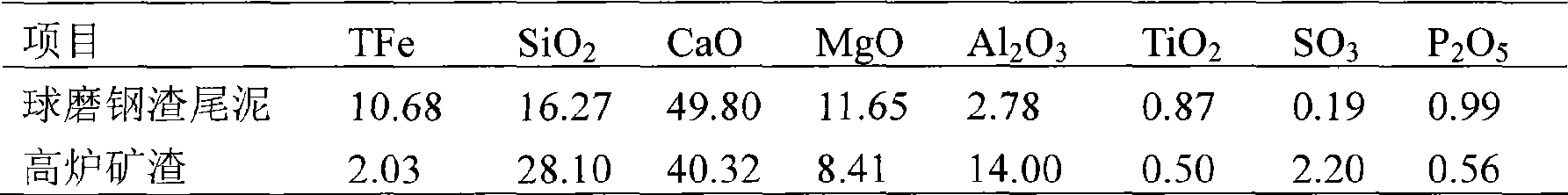

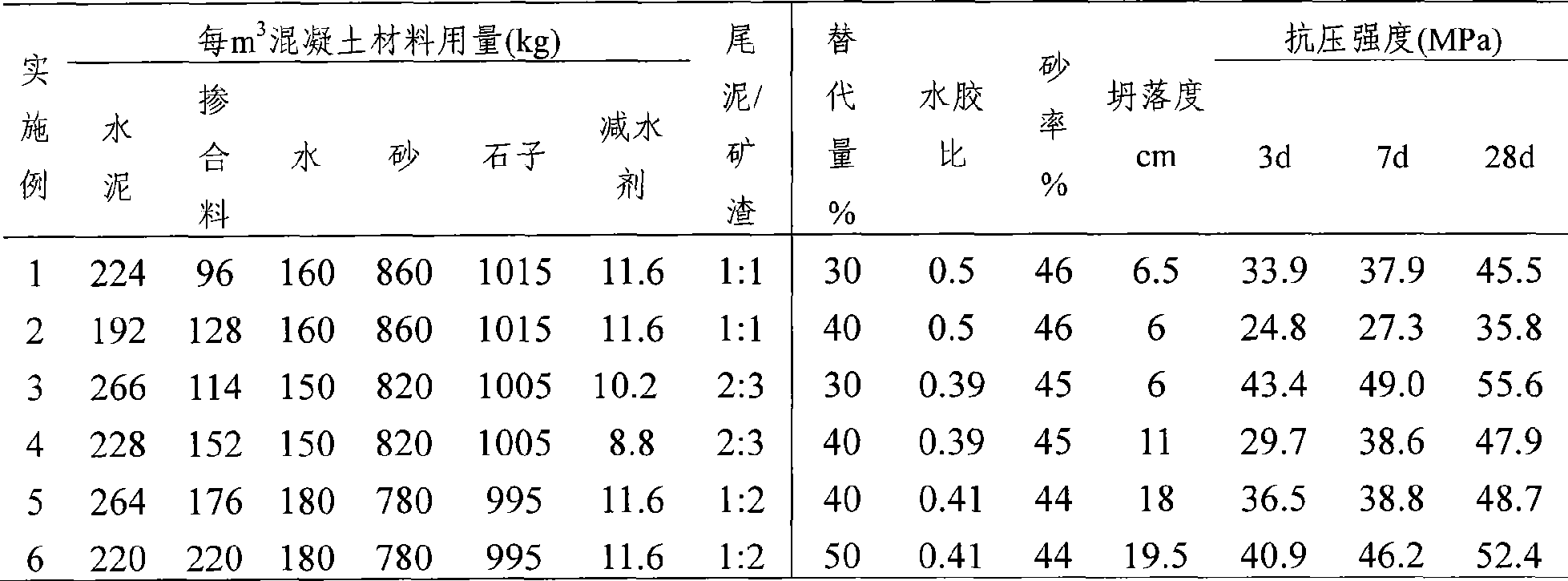

Compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and application of compound active powder in preparing concrete

InactiveCN101544479AReduced volume stabilityReduced Volume Stability EffectsCement productionSlagSlurry

The invention relates to compound active powder of ball milling steel slag tailing slurry and blast-furnace slag and the application of the compound active powder in preparing concrete. The admixture is prepared by mixing ball milling steel slag tailing slurry powder and blast-furnace slag powder with equal Brinell specific surface area of 500-600 m <2> / kg according to the weight ratio of 1:1-2. When the compound active powder is used as concrete admixture, proper concrete mixing portion is adopted; and the admixture can be used for partially replacing equivalent cement gel according to the proportion of 30-50 percent so as to prepare the concrete with C30-C50 strength degree. The invention utilizes solid wastes of steel enterprises, changes the solid wastes into valuable and has simple production process, ensures that the concrete has good performance and markedly lowered manufacturing cost.

Owner:LAIWU IRON & STEEL GRP

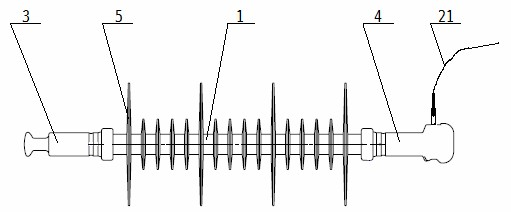

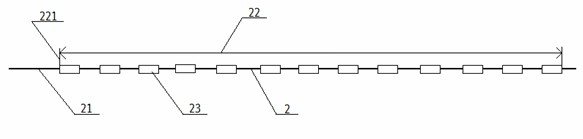

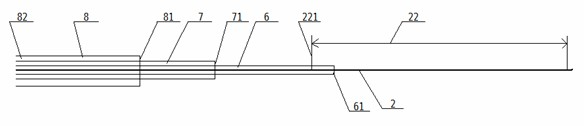

Fiber grating composite insulator and manufacturing method thereof

ActiveCN101937743AMaster the running performanceHigh precisionCladded optical fibreElectrical testingFiberComposite insulators

The invention relates to a fiber grating composite insulator comprising a core rod, a high-voltage end fitting and a low-voltage end fitting, wherein the high-voltage end fitting and the low-voltage end fitting are arranged on both ends of the core rod; the center of the core rod is provided with a fiber; the fiber comprises a grating coverage area and a tail fiber, wherein a grating coverage area is internally and uniformly provided with 3-20 gratings, and the length of the tail fiber is longer than or equal to 500mm; and the fiber is sequentially sleeved with a white sleeve, a metal hose and a hollow steel tube from inside to outside. A manufacturing method of the fiber grating composite insulator comprises the following steps of: firstly manufacturing the fiber; then packaging the fiber; then drawing the packaged fiber and soaked glass fibers out of a mould together to manufacture the core rod; then sawing the hollow steel tube to strip to expose the tail fiber; and then sequentially carrying out fitting pre-crimping, graded injection molding and secondary crimping to obtain the needed fiber grating composite insulator. The invention can not only realize the on-line monitoring of the mechanical property and the electric property of the fiber grating composite insulator and have difficult environmental corrosion and better mechanical property, but also accurately transmit the optimal sensing signals, save the production cost and enhance the manufacturing efficiency.

Owner:CENT CHINA GRID +2

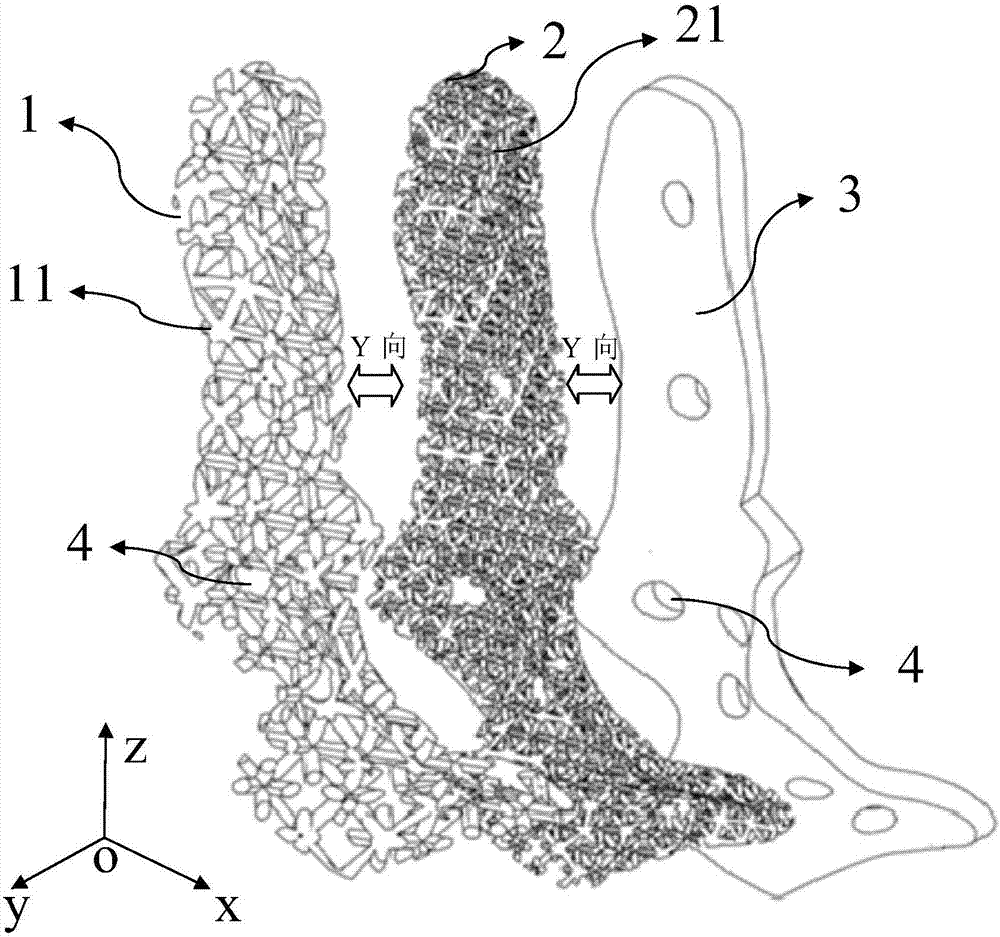

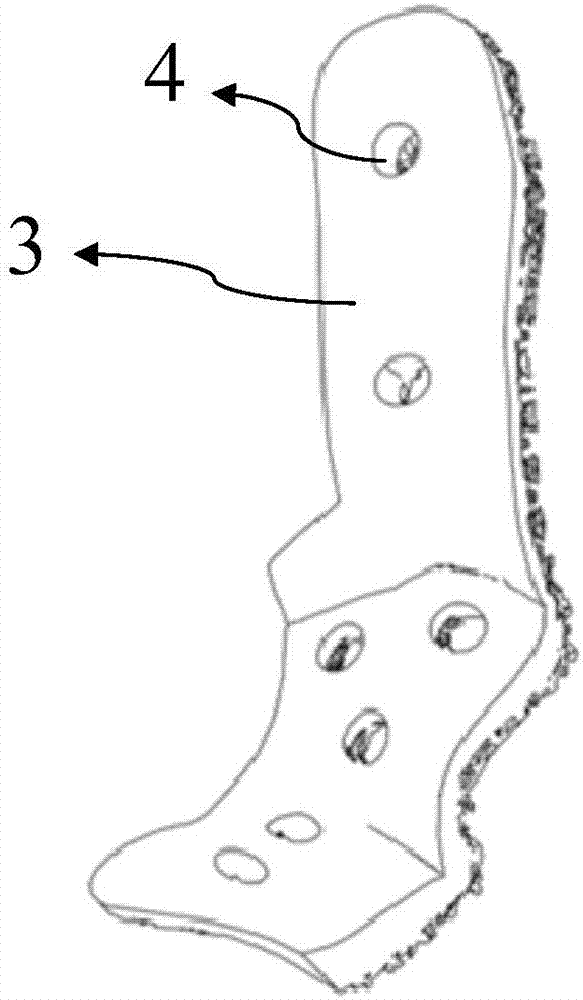

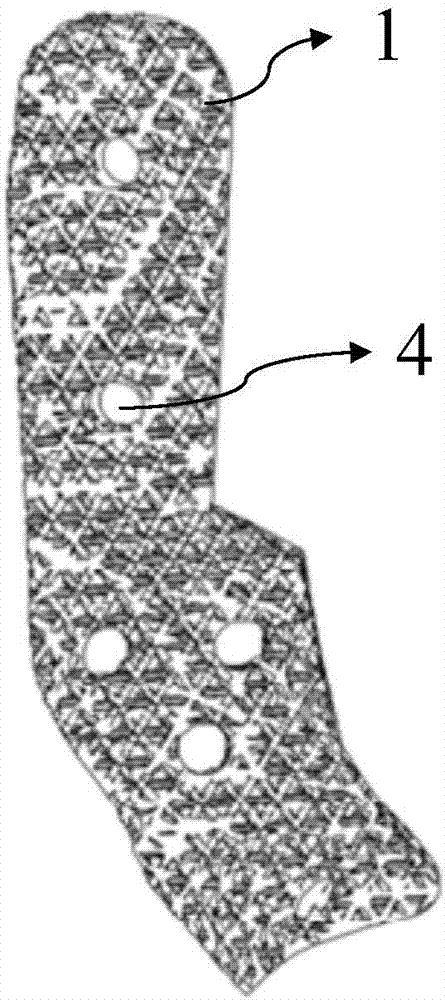

Porous composite bone plate with stiffness and gradient variation and preparation method thereof

ActiveCN106983551AReduce stiffnessImproved stress shielding effectBone platesBiocompatibility TestingStress shielding

The invention provides a porous composite bone plate with stiffness and gradient variation and a preparation method thereof. The bone plate is formed by sequentially connecting a bonding layer, a transition layer and a physical layer, wherein the bonding layer, transition layer and physical layer are successively increased in stiffness. The corresponding position of the layers is provided with a positioning hole in a penetrating mode. The bonding layer with smaller stiffness is in contact with the original bone, therefore the stiffness of the contact surface of the bone plate can be reduced and the stress shielding effect is improved; the physical layer with larger stiffness achieves the fixed connection; a porous structure is arranged on the bonding layer and the transition layer respectively, thereby promoting the adhesion growth of cells, forming the more solid biological fixation, and being conducive to the long-term effective service of the bone plate. The bone plate overall structure uses 3D printing to be molded integrally, thus the natural transition and convergence from the porous structure of the bonding layer and transition layer to the physical structure of the physical layer can be achieved; the bone plate possesses obvious heterogeneous mechanical properties. According to the porous composite bone plate with the stiffness and gradient variation and the preparation method thereof, an individualized composite bone plate with stiffness and gradient variation and multi-directional gradient structures can be designed for different parts according to the individual difference, thereby improving the adaptability and biocompatibility of the bone plate.

Owner:国家康复辅具研究中心

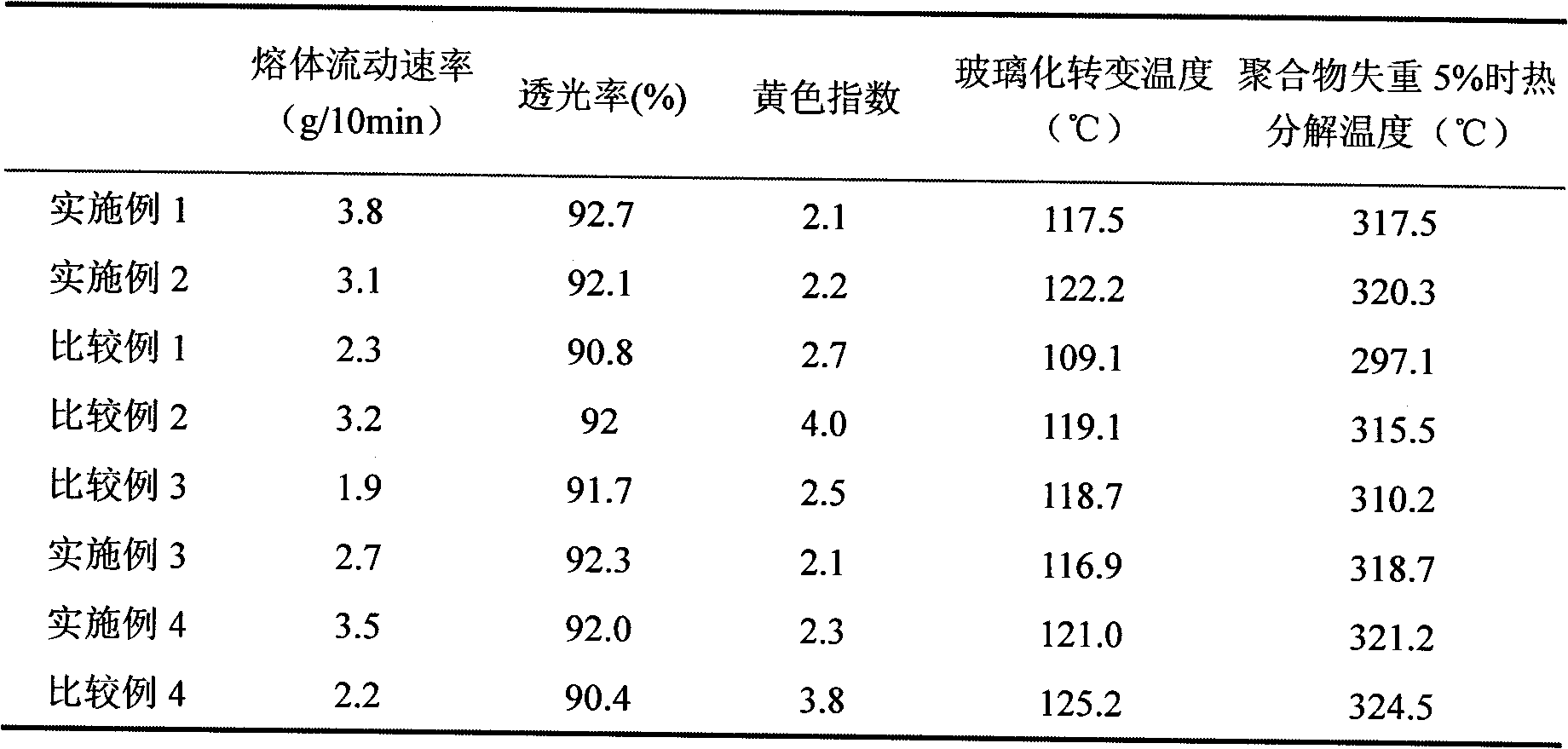

Method for preparing (methyl) acrylate polymer

ActiveCN102311518AHigh glass transition temperatureIncrease the initial thermal decomposition temperaturePolymer scienceReaction temperature

The invention relates to a method for preparing a (methyl) acrylate polymer. In the method, high-temperature continuous bulk polymerization is performed or less than or equal to 5 percent of atent solvent is added so as to perform solution polymerization in a circulating tube type reactor and a straight tube type reactor, and an N-alkyl maleimide monomer and a vinyl monomer are introduced into a (methyl) acrylate monomer and are copolymerized with the (methyl) acrylate monomer so as to prepare the (methyl) acrylate polymer with good heat resistant performance. The method comprises the following steps of: reducing the content of oxygen dissolved in a comonomer to 1 to 3 ppm by nitrogen; supplying the (methyl) acrylate monomer, the N-alkyl maleimide monomer and the vinyl monomer to the circulating tube type reactor continuously, and controlling the conversion rate to be 45 to 60 percent, wherein the polymerization temperature is between 130 and 150 DEG C; and conveying a reaction mixture to the straight tube type reactor continuously, wherein the reaction temperature is controlled to be 140 to 160 DEG C, and the polymerization conversion rate is controlled to be 55 to 90 percent. Bythe method, the glass transition temperature and initial thermal decomposition temperature of the polymer are improved obviously.

Owner:PETROCHINA CO LTD

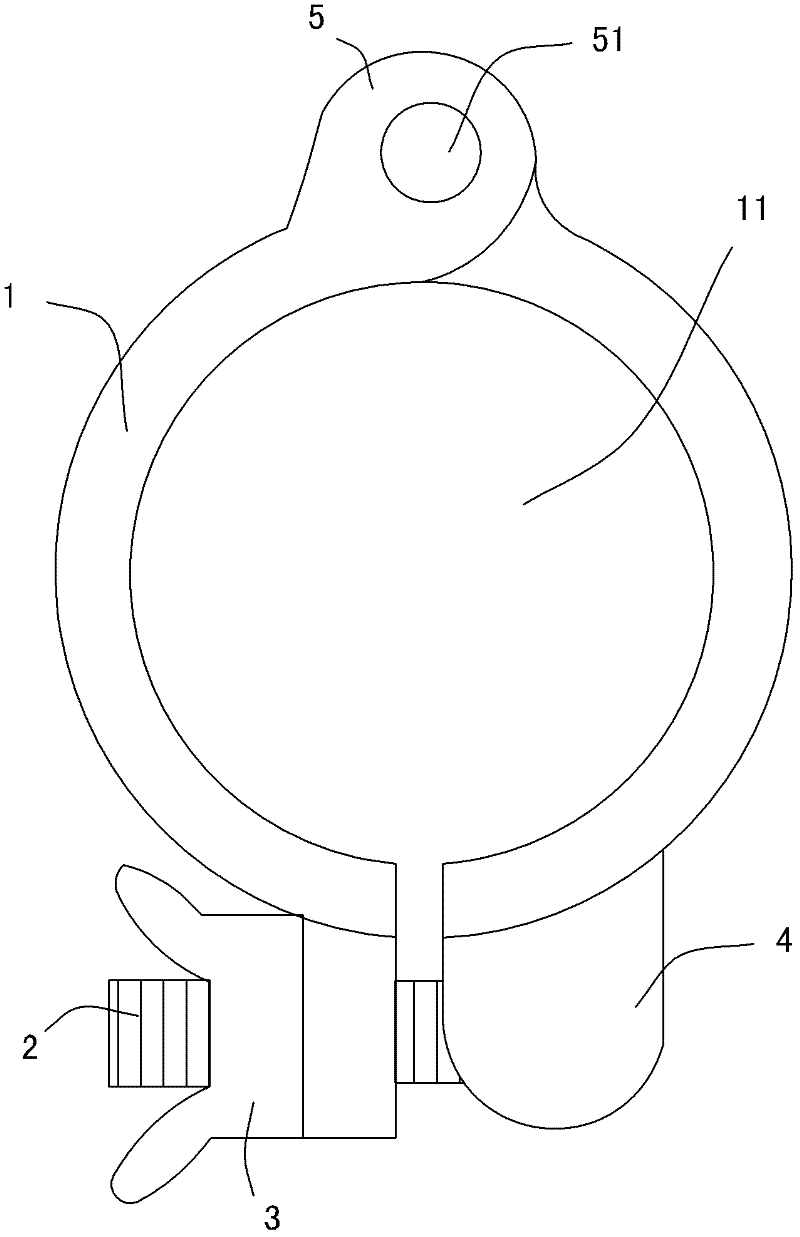

Compression joint clamp of steel-cored aluminum strand

ActiveCN102545132ADoes not affect mechanical strengthReduce scrap rateCable junctionsEngineeringUltimate tensile strength

Provided is a compression joint clamp of a steel-cored aluminum strand. Two split semi-ring clamp sheets are riveted through a hinge shaft, a connection seat is respectively arranged at the free-ends of the two semi-ring clamp sheets, and the two connection seats form a whole through a fastener. When the compression joint clamp is used, an aluminum strand arranged outside an opening of an aluminum pipe extends to the position where transformation quantity is easy to gather to achieve the aim of preventing aluminum strand transformation quantity generated by the compression joint aluminum pipe from extending to an aluminum-strand wire, so that the transformation quantity can be digested on the steel-cored aluminum strand in the aluminum pipe. Under the effect of compression joint force, transformation of the steel-cored aluminum strand in the aluminum pipe cannot affect mechanical strength of the steel-cored aluminum strand, the transformation enables the steel-cored aluminum strand and the inner wall of the aluminum pipe to generate stronger combining force, and connection reliability is higher. Practice proves that the clamp effectively reduces scrappage of the wire, strand broken rate and expansion rate of the wire are reduced to 3% from 40%, and the effect is obvious.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +2

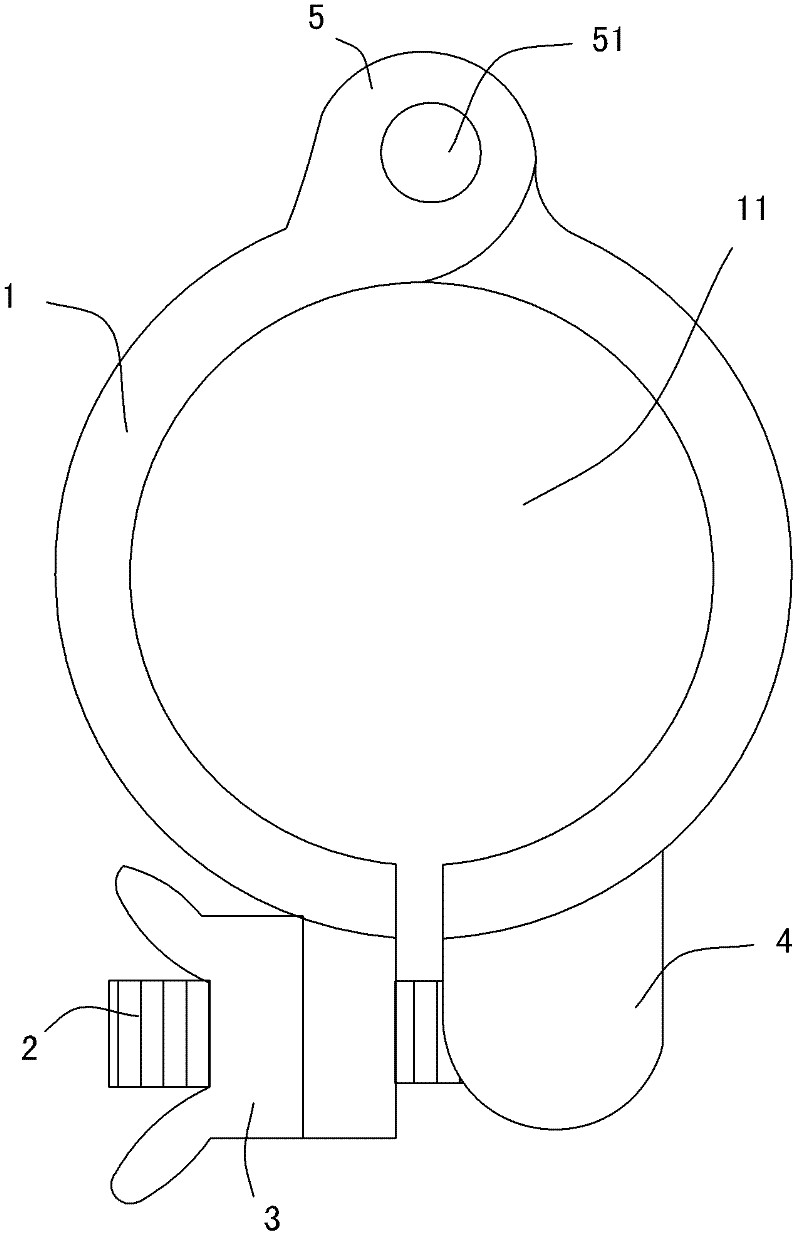

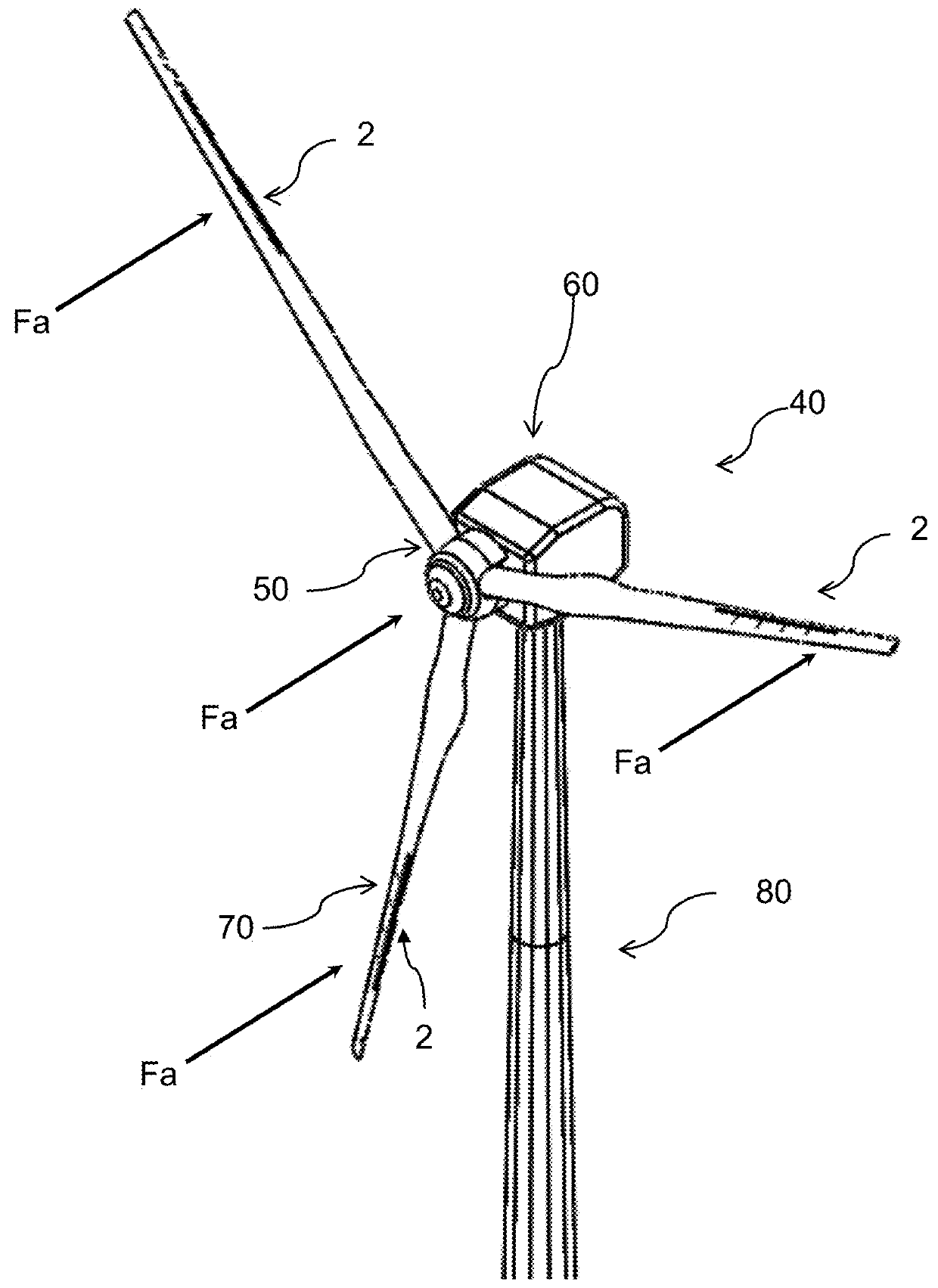

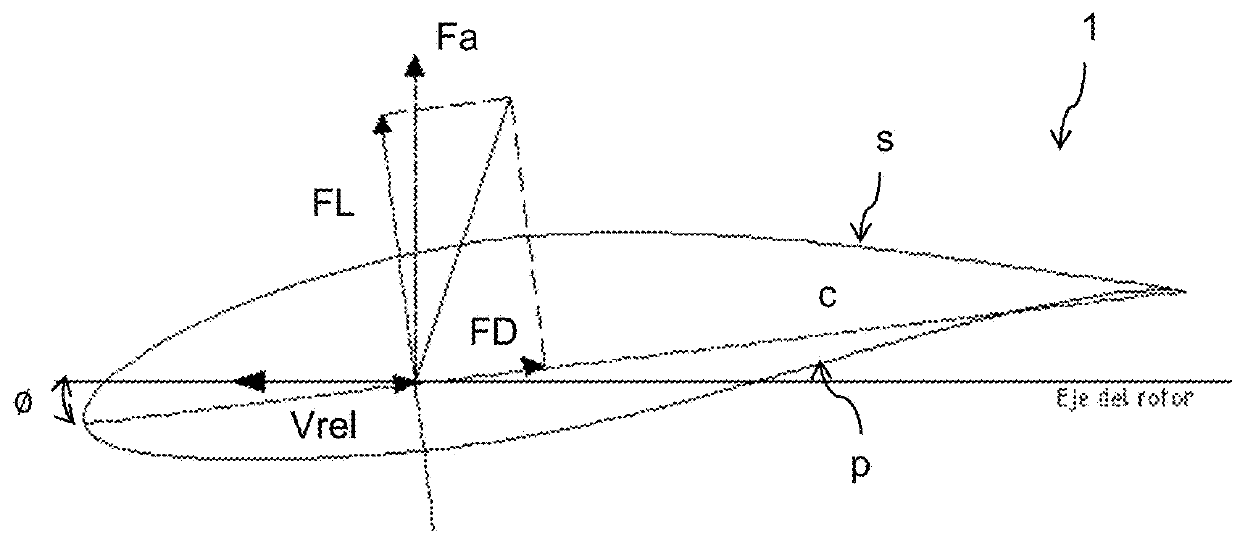

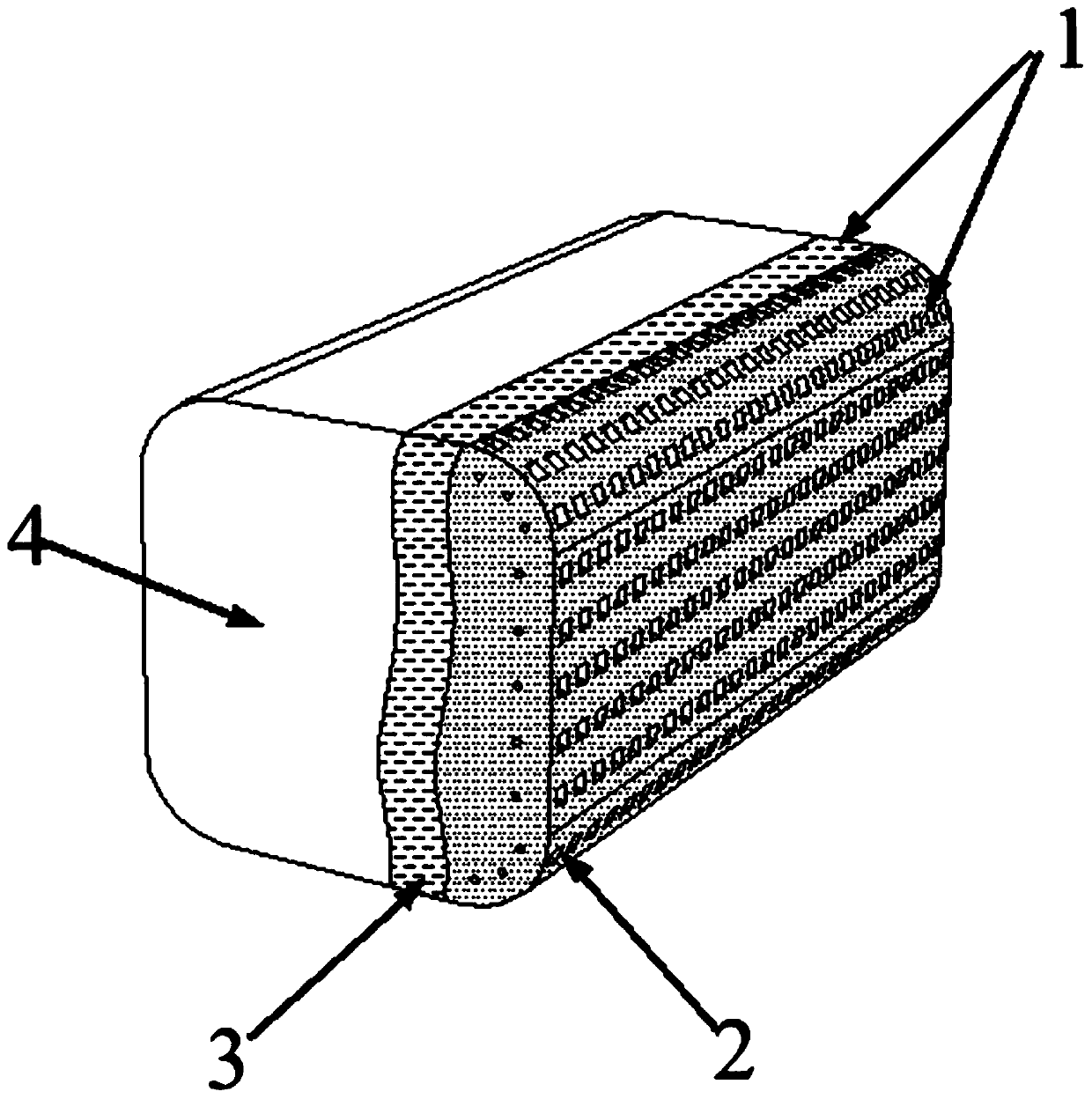

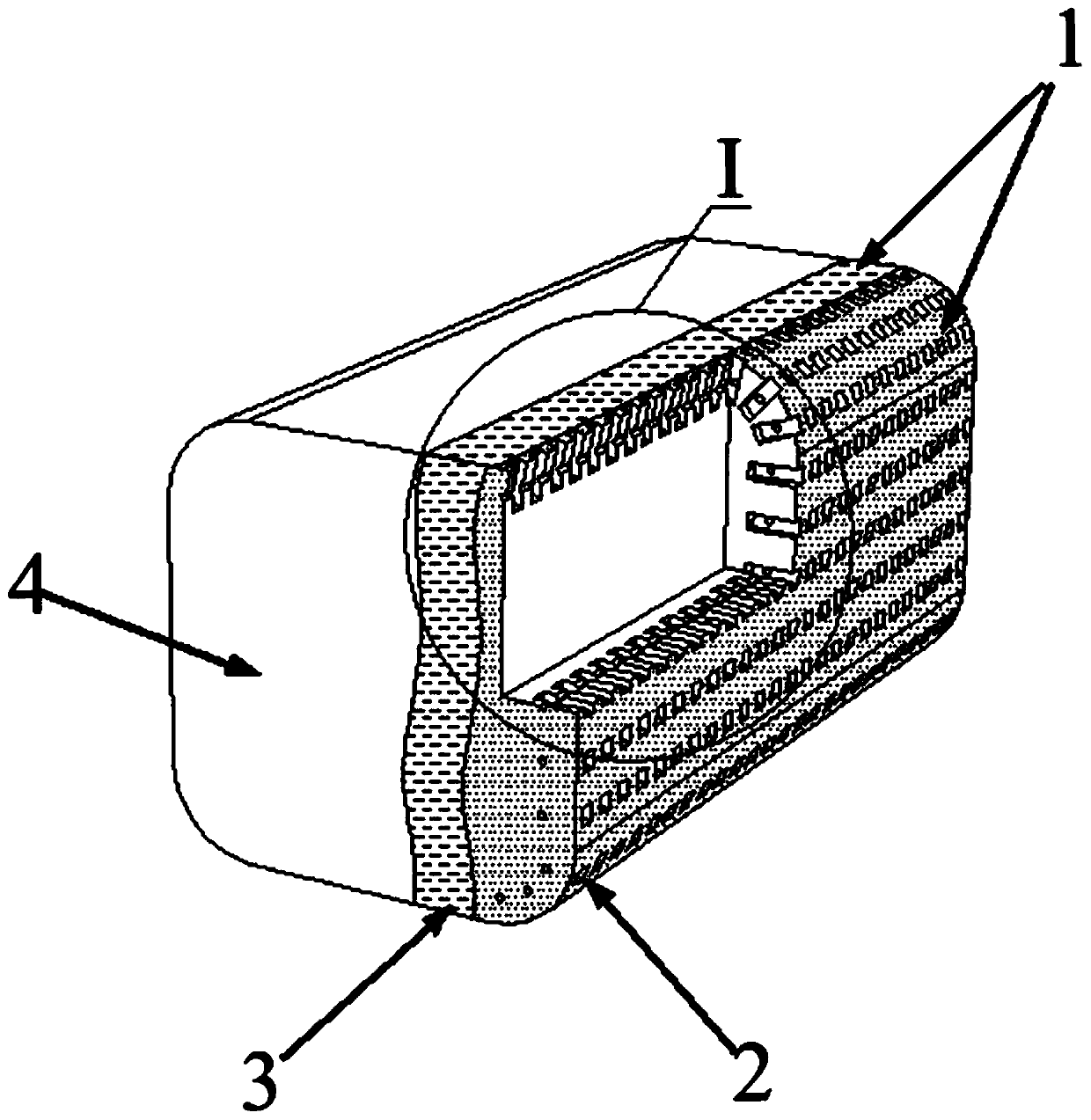

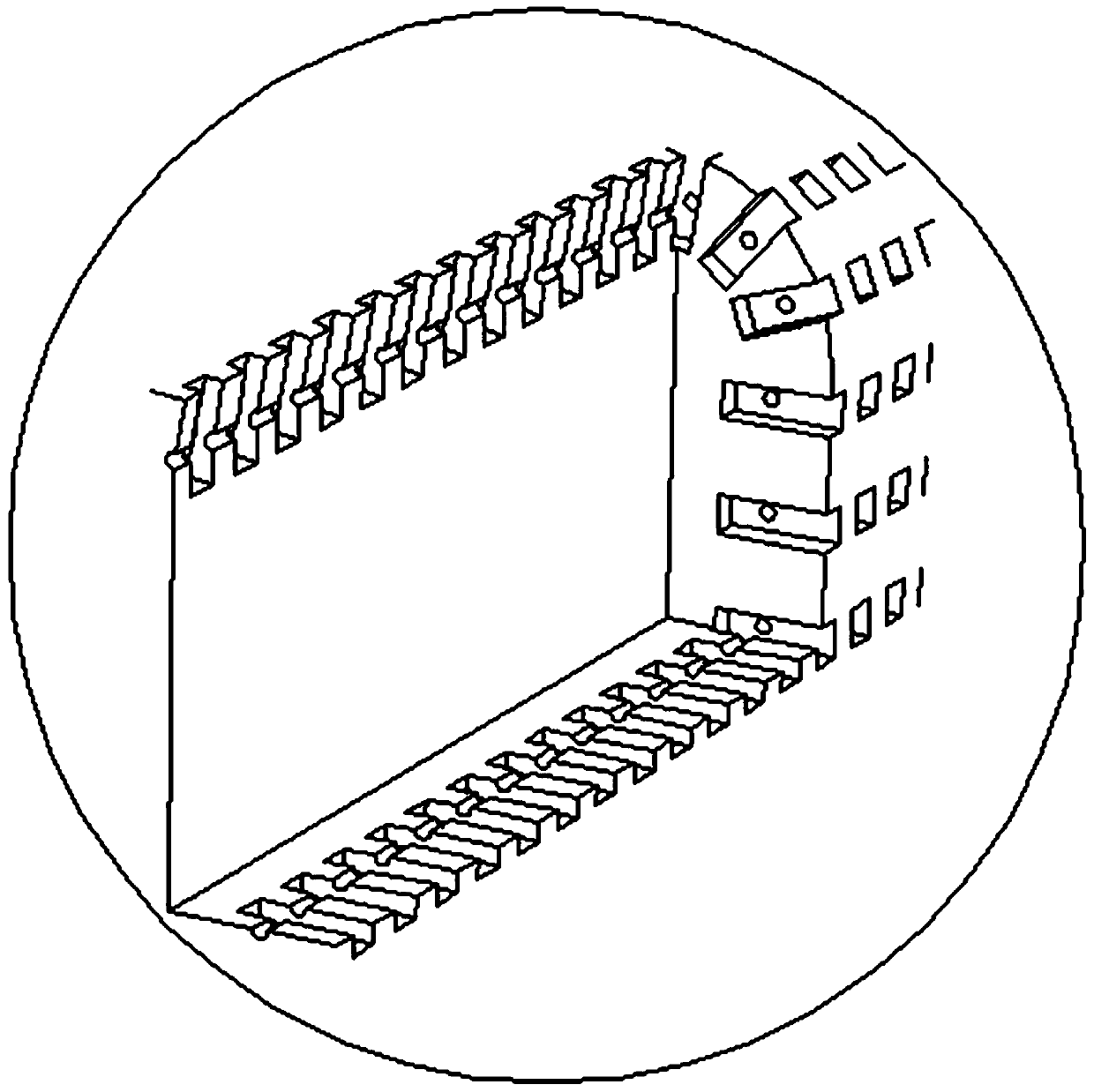

Pneumatic accessory to limit aerodynamic forces in horizontal axis wind turbine blades

InactiveUS20180163698A1Mechanical strength is not affectedPrevents fiber cutting and possible groovesWind motor controlMachines/enginesTurbine bladeHorizontal axis

This invention consists of a pneumatic accessory to limit aerodynamic forces in horizontal axis wind turbine blades, which is mainly integrated by an inflatable seal or microtab, a rigid cover with a specific shape that assembles onto a cavity external to the suction surface of the blade, and a pneumatic feed system.

Owner:CENT DE ING Y DESARROLLO IND

High-strength wear-resistant and fireproof pouring material

The invention discloses a high-strength wear-resistant and fireproof pouring material comprising the following raw materials in parts by weight: 20-25 parts of a coarse aggregate, 35-40 parts of a medium-fine aggregate, 15-20 parts of a fine aggregate, 5-10 parts of a binding agent, 5-10 parts of silicon micropowder, 10-15 parts of aluminum oxide micropowder and 1-5 parts of water, wherein the coarse aggregate is special-grade alumina, the medium-fine aggregate comprises silicon carbide and mullite, the fine aggregate is special-grade alumina, and the binding agent is prepared from the following components in parts by weight: 25-35 parts of sodium silicate, 15-25 parts of magnesium silicate and 30-60 parts of sodium hexametahposphate.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

3D-printed polyetheretherketone bone tissue symbiosis multihole skeleton substitute and method thereof

ActiveCN110680958ARealize the combinationEnhanced on-demand distributionTissue regenerationProsthesisBone tissueBone implant

The invention discloses a 3D-printed polyetheretherketone bone tissue symbiosis multihole skeleton substitute and a method thereof. The 3D-printed polyetheretherketone bone tissue symbiosis multiholeskeleton substitute comprises a bone tissue symbiosis region, wherein the bone tissue symbiosis region is a three-dimensional region where the bone substitute is in contact with bone tissue around thebone substitute and comprises a multihole region and an entity region, and the region except the bone tissue symbiosis region, in the substitute, is a bearing strengthening region. The problem that aPEEK material as a bone implant is difficult to be in symbiosis and combination with the bone tissue is solved, and the postoperative recovery of the PEEK bone implant is promoted.

Owner:XI AN JIAOTONG UNIV

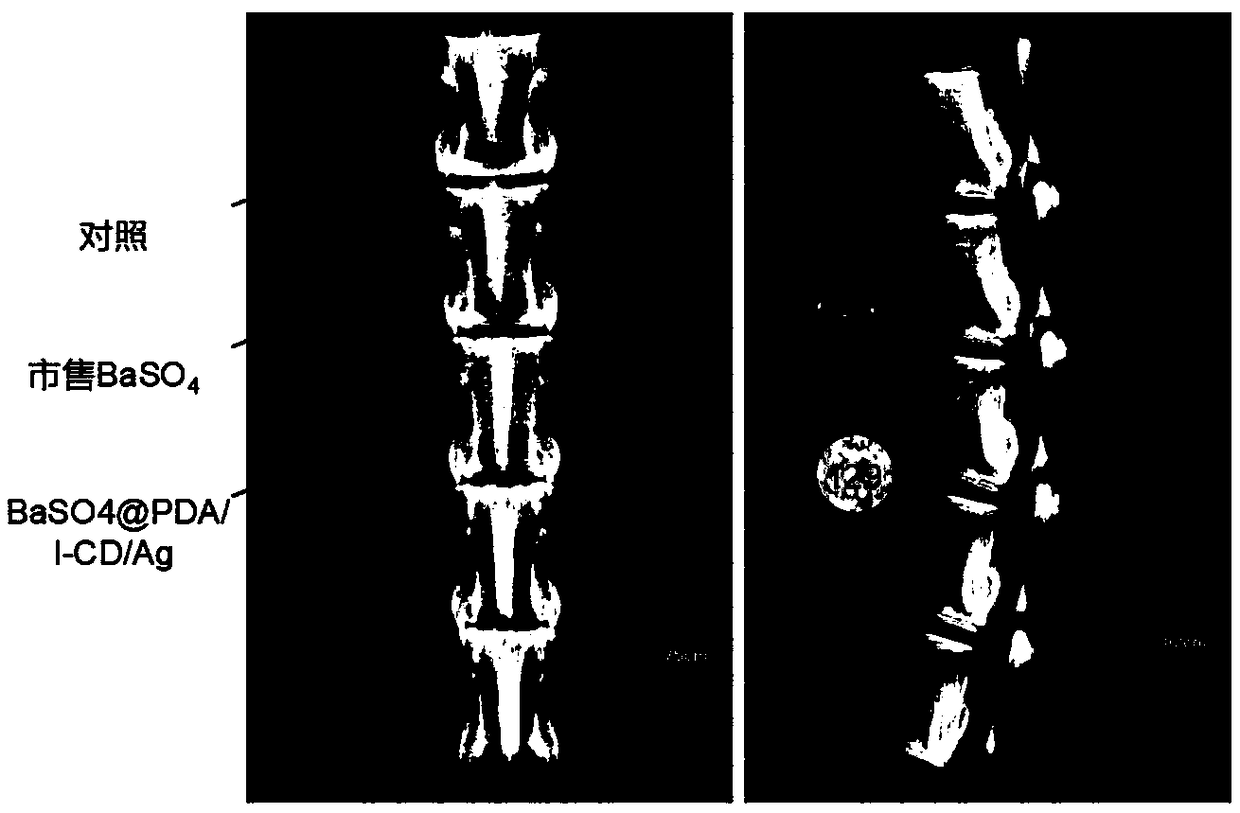

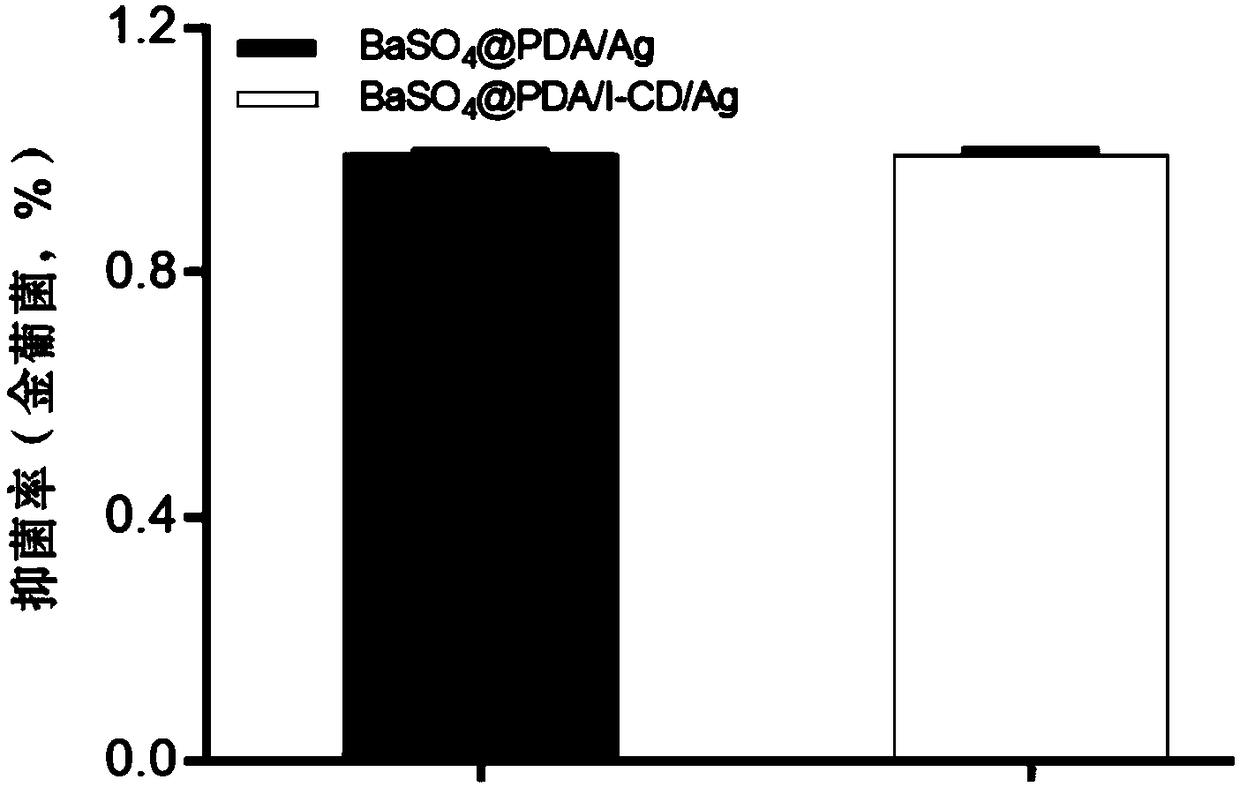

Coated barium sulfate nanoparticle, preparation method and use thereof

InactiveCN109224136ADoes not affect mechanical strengthLarge specific surface areaCoatingsProsthesisNanoparticlePolymethyl methacrylate

The invention relates to the technical field of materials, and discloses a coated barium sulfate nanoparticle used for bone cement developer. The coated barium sulfate nanoparticle mainly comprises porous barium sulfate nanoparticles coated on the surface of the porous barium sulfate nanoparticles and loaded with hexa (6-iodo-6-deoxy)-[alpha]-Polydopamine (PDA) coatings of cyclodextrin (I-CD) andsilver (Ag) were prepared to prepare barium sulfate nanoparticles. The invention discloses a coating barium sulfate nanoparticle, which is prepared by adding the coating barium sulfate nanoparticle into polymethyl methacrylate bone cement as a developer, and the preparation method and the use thereof show excellent X-ray diffraction characteristics. The preparation method is simple and can be usedas a new type of developer in bone cement because of its developmental properties, antibacterial properties, biocompatibility, mechanical properties and drug loading and release properties.

Owner:SUZHOU UNIV

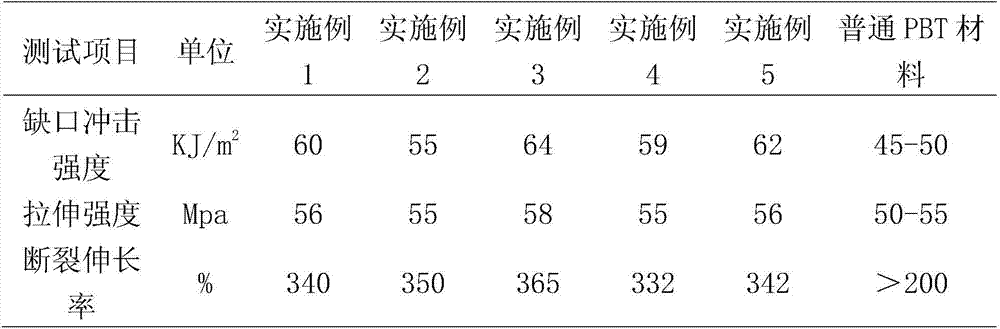

PBT material and preparation method thereof

The invention relates to a PBT material and a preparation method thereof, belonging to the technical field of high polymer materials. The PBT material comprises the following raw materials by weight: 55 to 75% of polybutylene telephthalate, 15 to 35% of TPEE, 0.2 to 1.0% of calcium carbonate, 2.0 to 5.0% of 1,4-butylene glycol, 0.5 to 2.0% of an anti-oxidant, 0.5 to 3.0% of dicumyl peroxide, 2.0 to 5.0% of a cross-linking agent, 0.2 to 1.5% of a light stabilizing agent and 0.2 to 1.0% of an anti-hydrolysis agent. The invention also discloses the preparation method for the PBT material. According to the invention, TPEE and the anti-oxidant 1010 are used for the PBT material, so the prepared PBT material has good elasticity and improved impact strength, toughness and ageing resistance, and thus, the PBT material has more excellent mechanical and machining properties, enables a product to have prolonged service life and better stability and is widened in the application scope; the PBT material and the preparation method overcome the technical problem that the mechanical strength of conventional PBT resin cannot meet usage requirements after toughening; and the preparation method is simple in process and easy to realize industrial production.

Owner:XINJIANG BLUE RIDGE TUNHE POLYESTER CO LTD

Photosensitive dry film and detection method thereof

ActiveCN103235485ASuppresses or eliminates specific odorsAct as a solubilizerWeighing by removing componentPhotosensitive materials for photomechanical apparatusPolyethylene terephthalateDeodorant

The invention discloses a photosensitive dry film which sequentially comprises a PET (Polyethylene Terephthalate) support film layer, a photosensitive resin layer and a PE (Polyethylene) protective film layer, wherein the photosensitive resin layer mainly comprises the following materials in parts by weight: 60-70 parts of alkali-soluble resin, 15-25 parts of a polymerizability compound with at least one ethylene unsaturated base, 1-2 parts of a photopolymerization initiator and 0.01-0.1 parts of deodorant. The deodorant can exert a solubilizing function on a low polymer in the photosensitive resin layer, and can inhibit volatilization of the low polymer, so that the photosensitive dry film can inhibit or eliminate the original distinctive odor in the photosensitive resin layer. After the deodorant is added, the performances, such as photosensitiveness, mechanical strength and resolving power of the photosensitive dry film are not affected.

Owner:湖南五江高科技材料有限公司

Method for spraying patterns on artificial board

InactiveCN102173261AMechanical strength is not affectedIncrease added valueDecorative surface effectsEmbossing decorationsAdditional valuesUltimate tensile strength

The invention relates to a method for spraying patterns on an artificial board, which comprises the following steps of: (1) preparing a template; (2) carving a mould; (3) selecting a baseplate; (4) mixing colors; (5) moulding and spraying; (6) demoulding and curing a coating; and (7) spraying a transparent paint on the surface of the coating. The artificial board with patterns sprayed by using the steps can be widely applied to decorations of indoor floors, wallboards and ceiling boards. The method has the advantages of simple process, high adaptability and no influence on the mechanical strength of the artificial board; various patterns can be painted on the surface of the artificial board, and the sprayed patterns have a high combination strength with the artificial board. By adopting the invention, the disadvantage of simplex patterns of floors manufactured from the traditional artificial board is overcome, the cultural atmosphere of indoor decorations is increased, the application scope of trees with simplex patterns is enlarged, and the additional value of a product is improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Dielectric filter and 5G communication equipment

PendingCN109860966ADoes not affect mechanical strengthRealize the process is simpleResonatorsResonant cavityDielectric resonator antenna

The invention discloses a dielectric filter. The dielectric filter comprises at least three dielectric resonators in successive connection; each dielectric resonator comprises a body composed of a solid-state dielectric material and a conductive layer covered on a body surface; a groove structure covered with the conductive layer is arranged on the body surface of at least one dielectric resonators except the dielectric resonators at the head and end locations, thereby realizing the capacitive cross-coupling; the groove structure and the located dielectric resonator commonly form a secondary-mode resonant cavity. The invention further discloses a 5G communication device. Compared with the prior art, the cross-coupling with negative polarity can be conveniently realized, the mechanical strength of the filter cannot be reduced, the preparation process is simple, and the mass production is convenient.

Owner:PIVOTONE COMM TECH

Flame-retardant PC plastic

The invention discloses a flame-retardant PC plastic. The flame-retardant PC plastic comprises the following components in parts by weight: 80-86 parts of PC, 7-9 parts of polyimide, 5-8 parts of titanium dioxide, 10-14 parts of alkyl benzene sulfonate, 5-9 parts of dimethyl siloxane, 2-3 parts of cupric oxalate, 10-15 parts of magnesium hydroxide, 7-9 parts of phthalate anhydride, 5-7 parts of coated red phosphorus, 10-20 parts of cobalt silicate and 8-10 parts of graphite. The flame-retardant PC plastic has a good flame-retardant function; an obvious flame-retardant function can be performed when a very small amount of flame-retardant PC plastic is used. The flame-retardant PC plastic does not affect the mechanical strength of a plastic product and particularly does not lower the thermal deformation temperature, the mechanical temperature and the electric insulation property of the plastic product.

Owner:WUJIANG TIANYUAN PLASTIC

Wearable refractory castable

The invention relates to wearable refractory castable which comprises the following raw materials in parts by weight: 20-25 parts of coarse aggregate, 35-40 parts of medium aggregate, 15-20 parts of fine aggregate, 5-10 parts of binder, 5-10 parts of silica micropowder, 10-15 parts of alumina micropowder, and 1-5 parts of water, wherein the coarse aggregate is special-grade alumina; the medium aggregate comprises silicon carbide and zirconite; the fine aggregate is special-grade alumina; the binder comprises the following components in parts by weight: 25-35 parts of magnesium silicate, and 75-65 parts of phosphate. According to the wearable refractory castable disclosed by the invention, corundum is replaced by the alumina, the silicon carbide and the zirconite, and therefore, the cost of raw materials is reduced; furthermore, the mechanical strength and the abrasive resistance of materials are not influenced.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

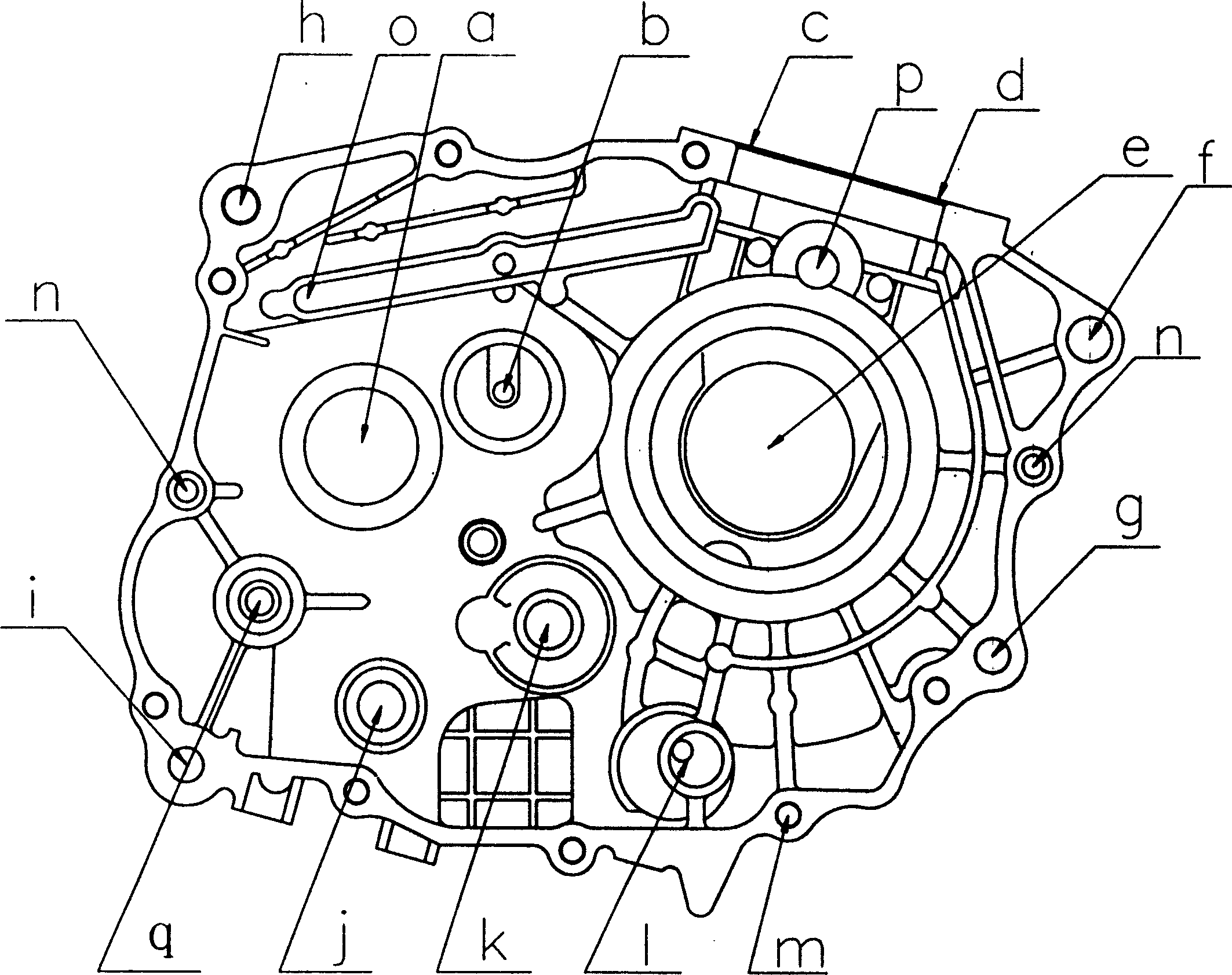

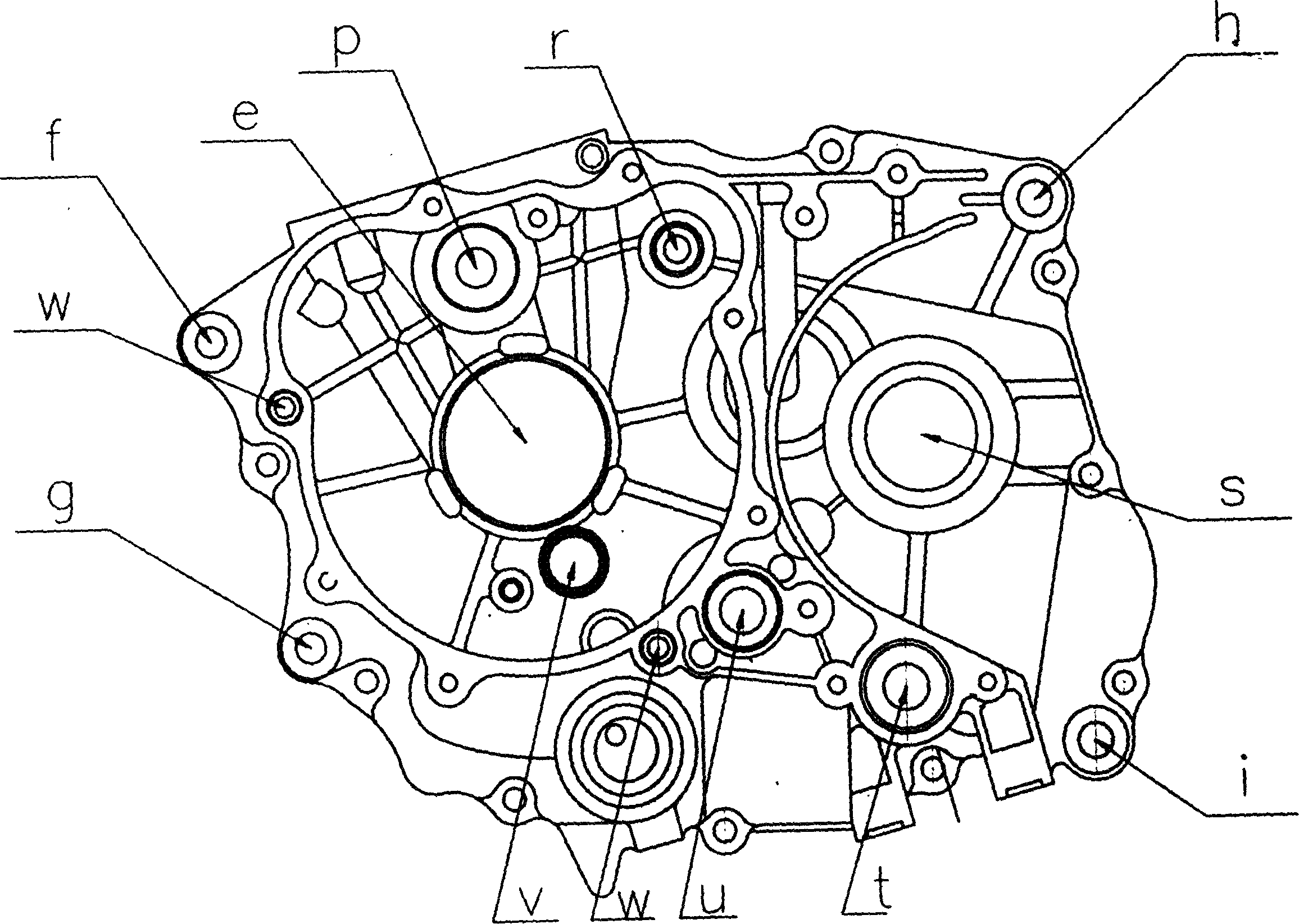

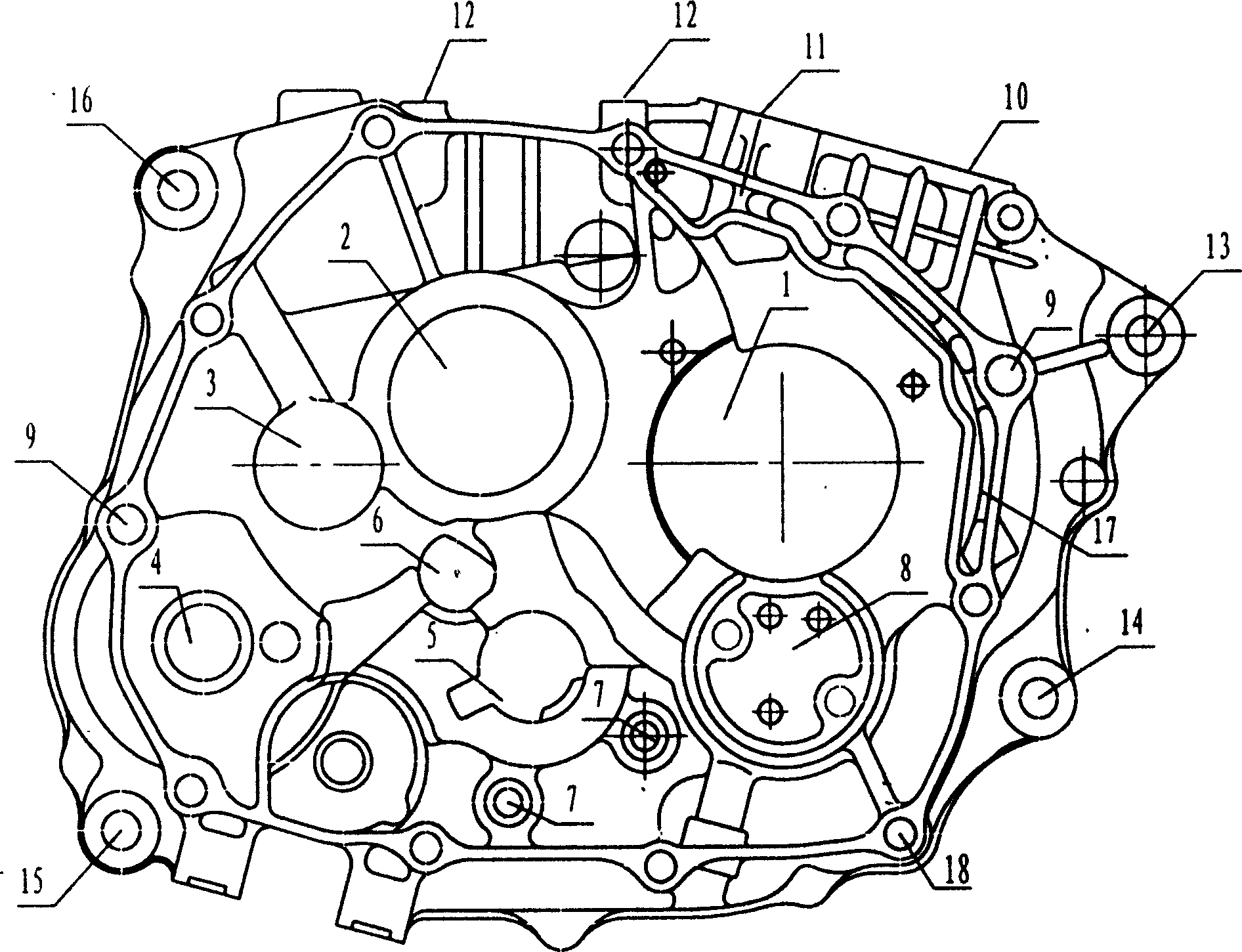

Reducing vibration type engine crankcase of motorcycle

InactiveCN1560460AImprove structural strengthIncrease cooling areaCasingsMachines/enginesCrankcaseEngineering

The invention belongs to combustion engine crank box, which is a crank box for the vibration damping motorcycle engine, made up of left crank box and the right crank box, the character lies in: the left and the right crank boxes use magnesium alloy to be cast and formed, the thickness of the box wall is 3.5-6mm, several reinforcing ribs with width of 3-5mm are arranged on the box surface and the cover. Compared to the gearing aluminum alloy crank box, when the structure intensity of the box is upgraded, the heat irradiating area is also increased, it can reduce the high temperature creep, the mechanical intensity of the magnesium alloy crank box in the high temperature environment is not affected; the experience to the same motorcycle LC125 testifies, the crank box of the invention caters all the demands of engine, and the weight is reduced, thus it can save 0.4l oil per hundred kilometers, the average heat vibration and noise only the 1 / 3 of the traditional crank box.

Owner:重庆镁业科技股份有限公司

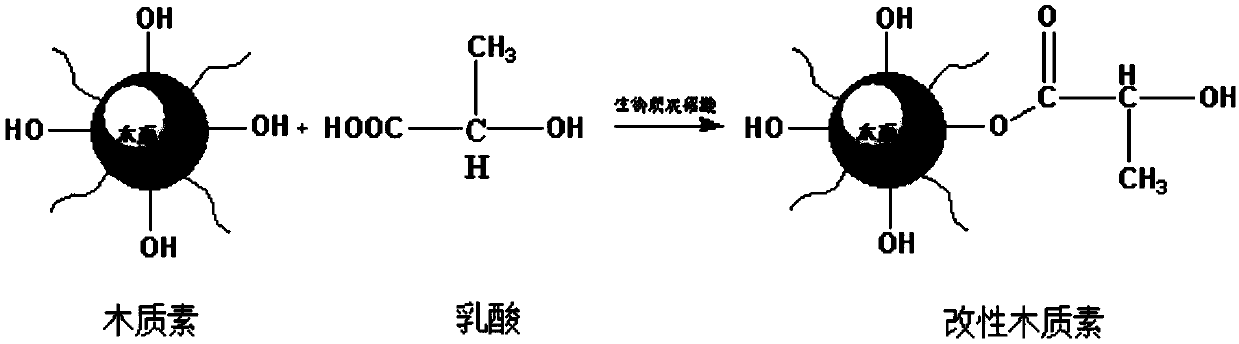

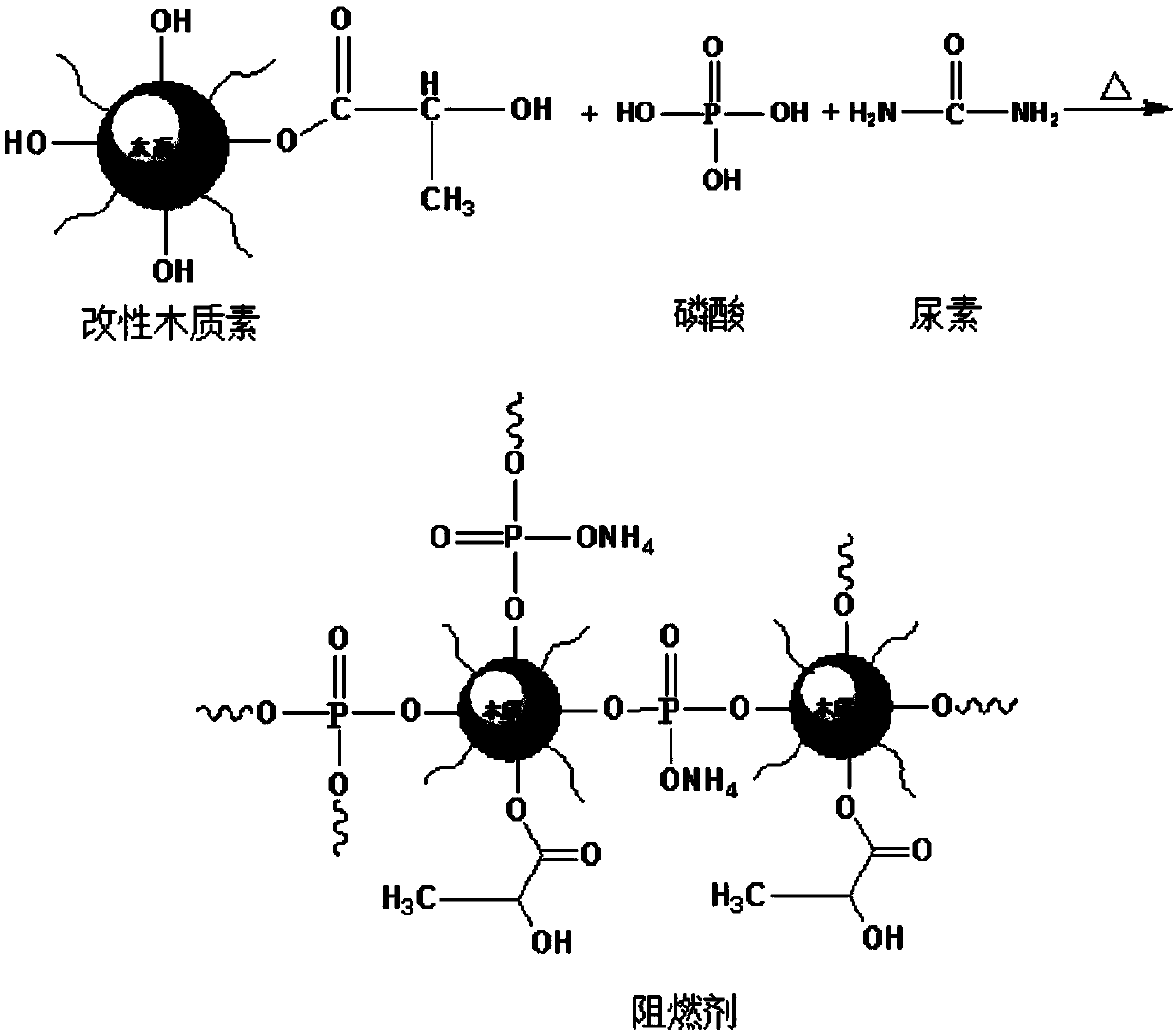

Fire retardant used for polylactic acid, antiflaming polylactic acid material and preparation method of fire retardant

ActiveCN109627453AMechanical strength is not affectedHigh mechanical strengthPhosphoric acidFire retardant

The invention relates to a fire retardant used for polylactic acid, an antiflaming polylactic acid material and a preparation method of the fire retardant. The preparation method mainly comprises thesteps that modified lignin is provided, a preparation method for the modified lignin comprises the following steps that lignin, lactic acid and biomass carbon sulfonic acid are mixed and extruded forforming, and the modified lignin is obtained; a first reaction product is mixed with phosphoric acid and the modified lignin, the temperature rises to 90-110 DEG C, the reaction is conducted until bubbles are generated, the reaction is conducted for 1-3 hours at the temperature of 220-240 DEG C, the fire retardant used for the polylactic acid is obtained, and the first reaction product is urea and / or melamine. The fire retardant used for the polylactic acid contains the structure similar to polylactic acid molecules, so that the fire retardant is compatible to the polylactic acid well, the fire retardant also contains lignin structures with excellent charcoal forming performance, the antiflaming effect of the fire retardant is better, meanwhile, the polylactic acid has the antiflaming performance, and the mechanical intensity of the polylactic acid cannot be influenced.

Owner:湖北玺悦新材料技术有限公司

Production method of antistatic nylon 56 fibers

PendingCN111321481ADoes not affect mechanical strengthGood compatibilityElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSpinning

The invention discloses a production method of antistatic nylon 56 fibers. The method comprises the following steps: (1) under the protection of nitrogen, bio-based pentane diamine reacts with adipicacid in water to obtain a nylon 56 saline solution; (2) the nylon 56 saline solution reacts with a molecular weight regulator, then an antistatic agent is added, vacuumizing is performed, and nylon 56polymer melt is obtained by stirring; and (3) the nylon 56 polymer melt is put into a spinning manifold and the antistatic nylon 56 fibers are obtained by spinning, cooling, oiling and moistening, drafting, tension heat setting, curling, oiling, relaxation heat setting and cutting. The antistatic nylon 56 fibers obtained by the invention have the advantages of excellent antistatic performance, good fabric air permeability, high moisture regain, wear resistance and comfort and can be widely applied to the aspects of textiles, general engineering materials, automobile manufacturing, sports equipment, aviation and space navigation.

Owner:优纤科技(丹东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com