Patents

Literature

1727results about "Embossing decorations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

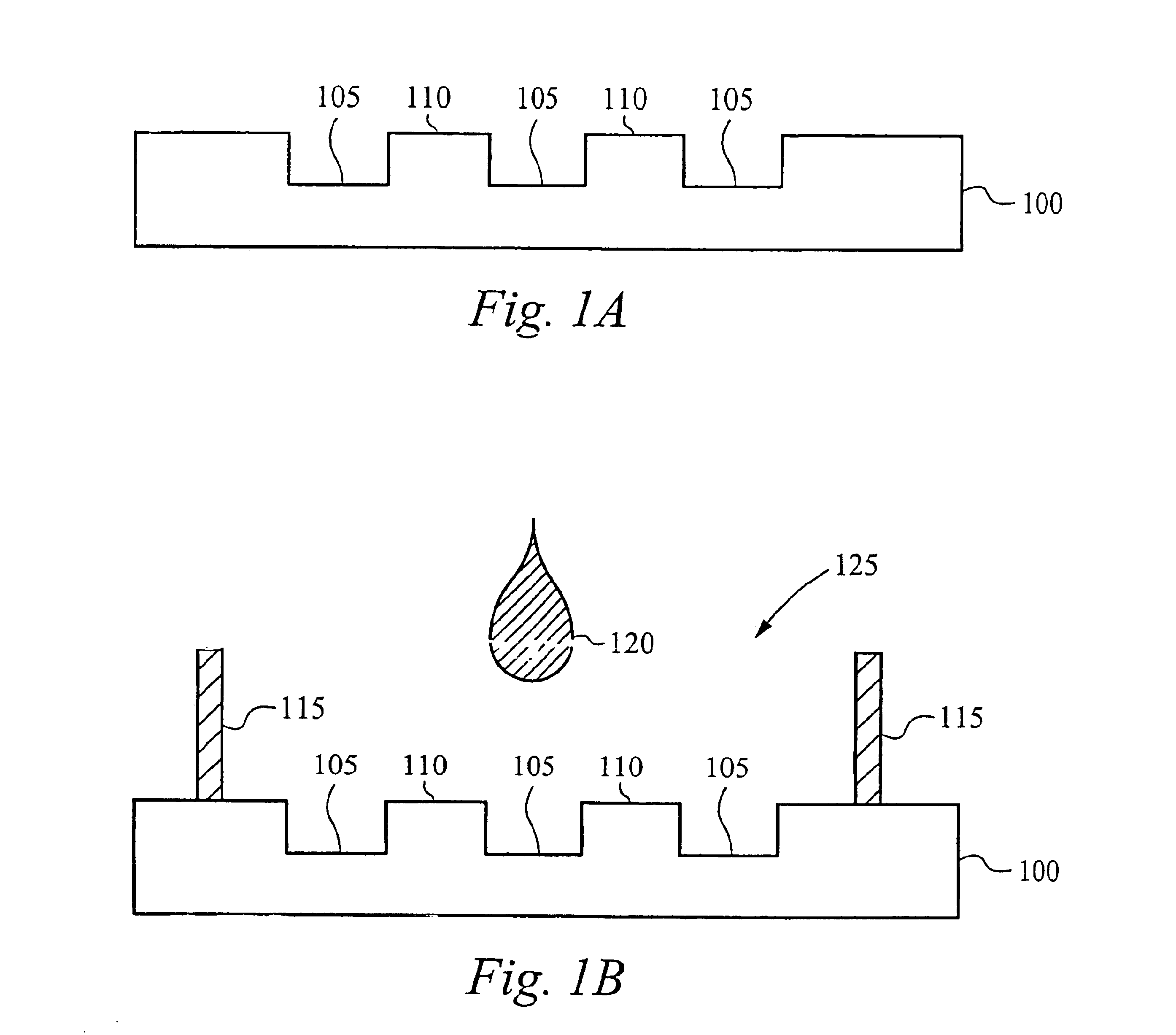

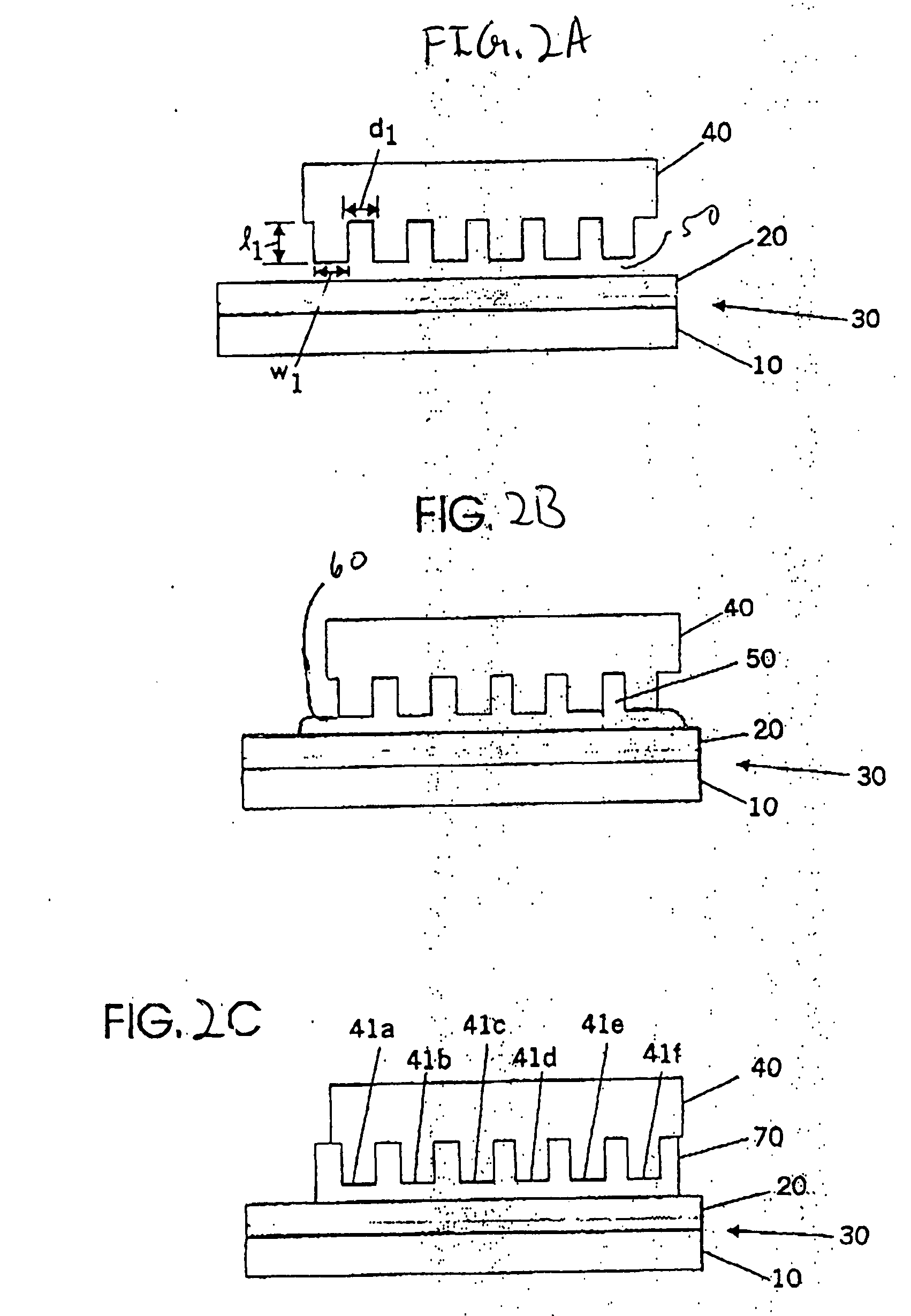

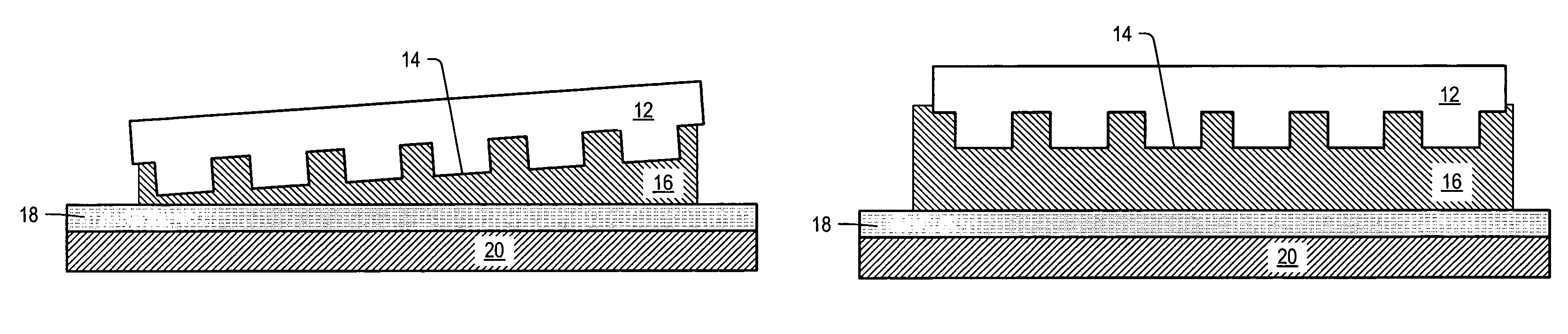

Contact print methods

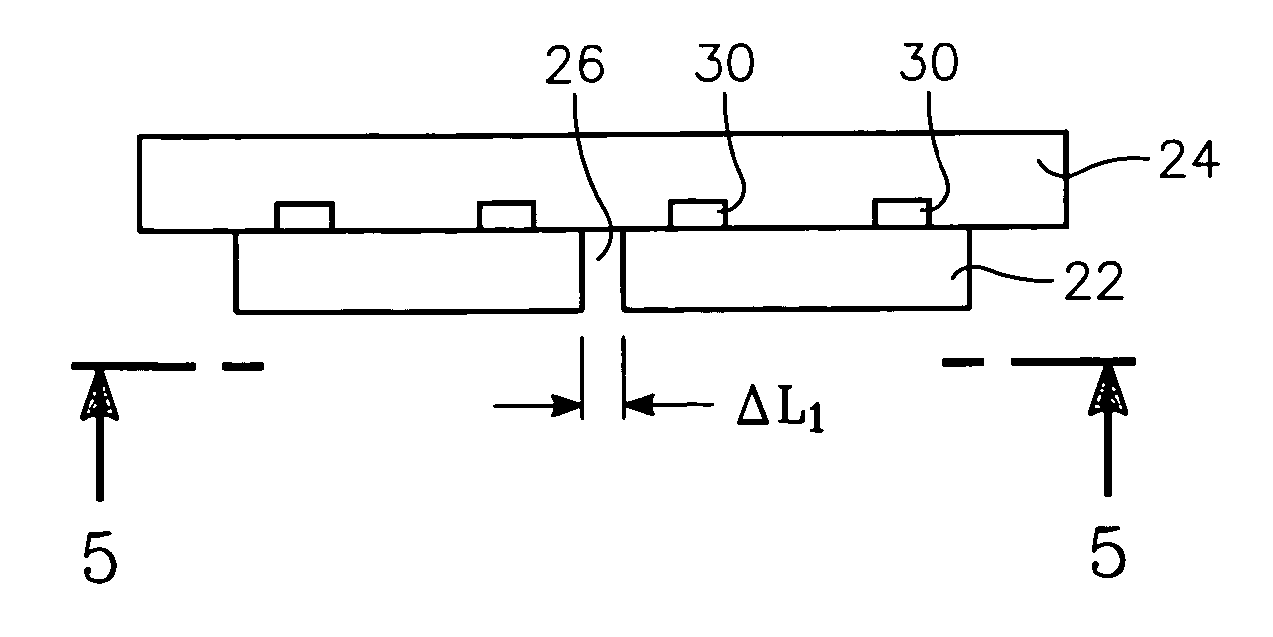

InactiveUS6957608B1High definitionImprove printing effectMechanical working/deformationSolid-state devicesContact printSolvent

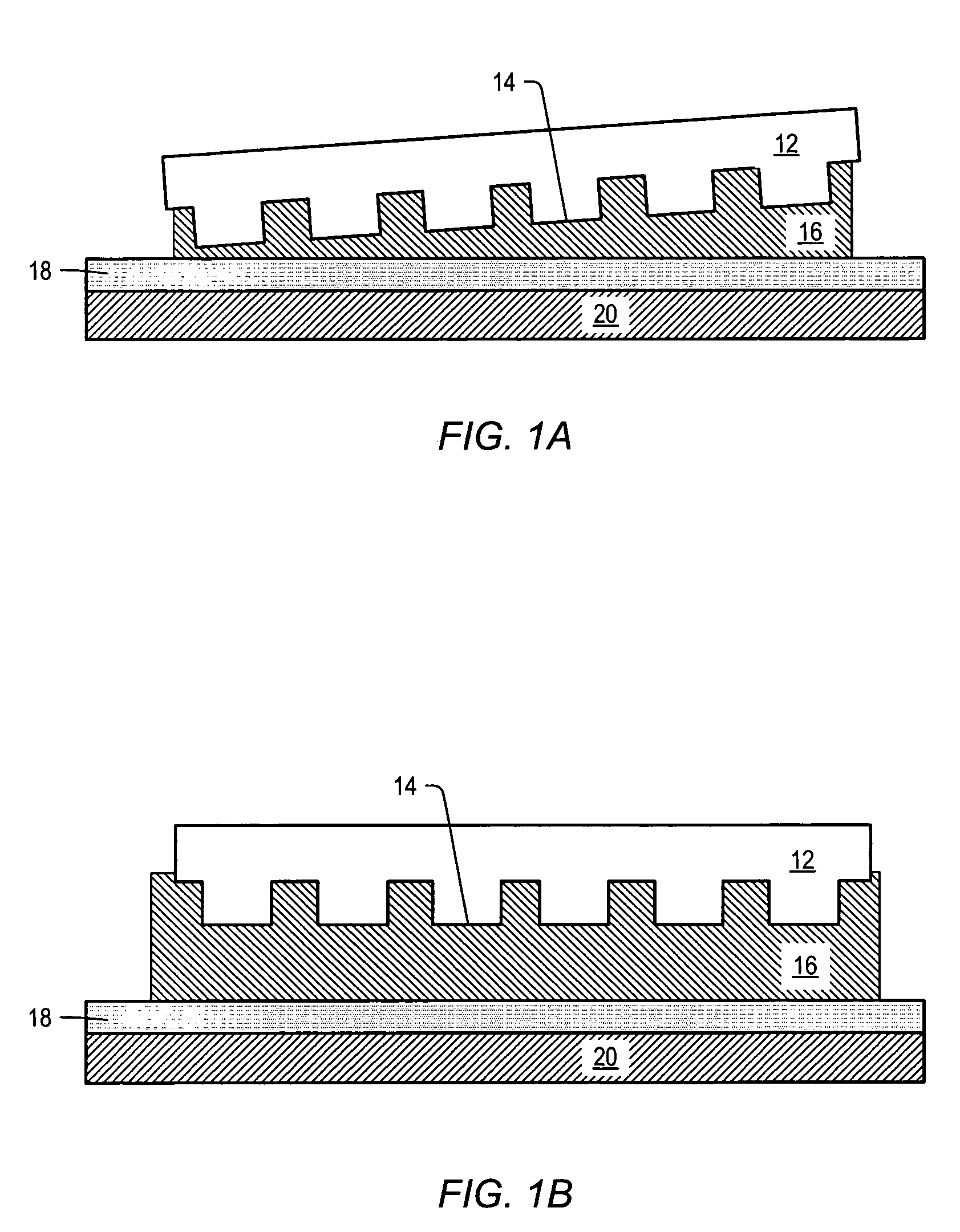

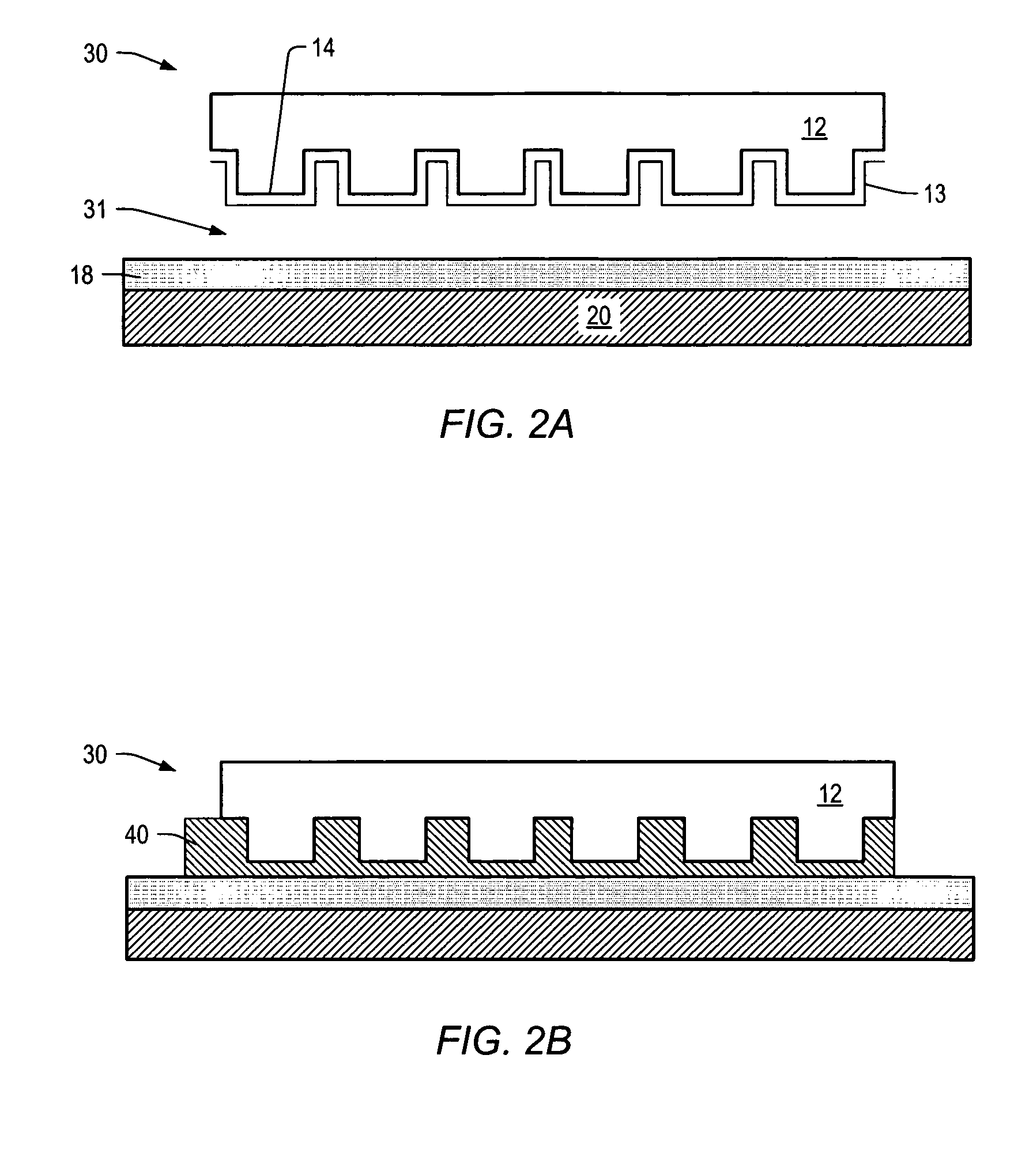

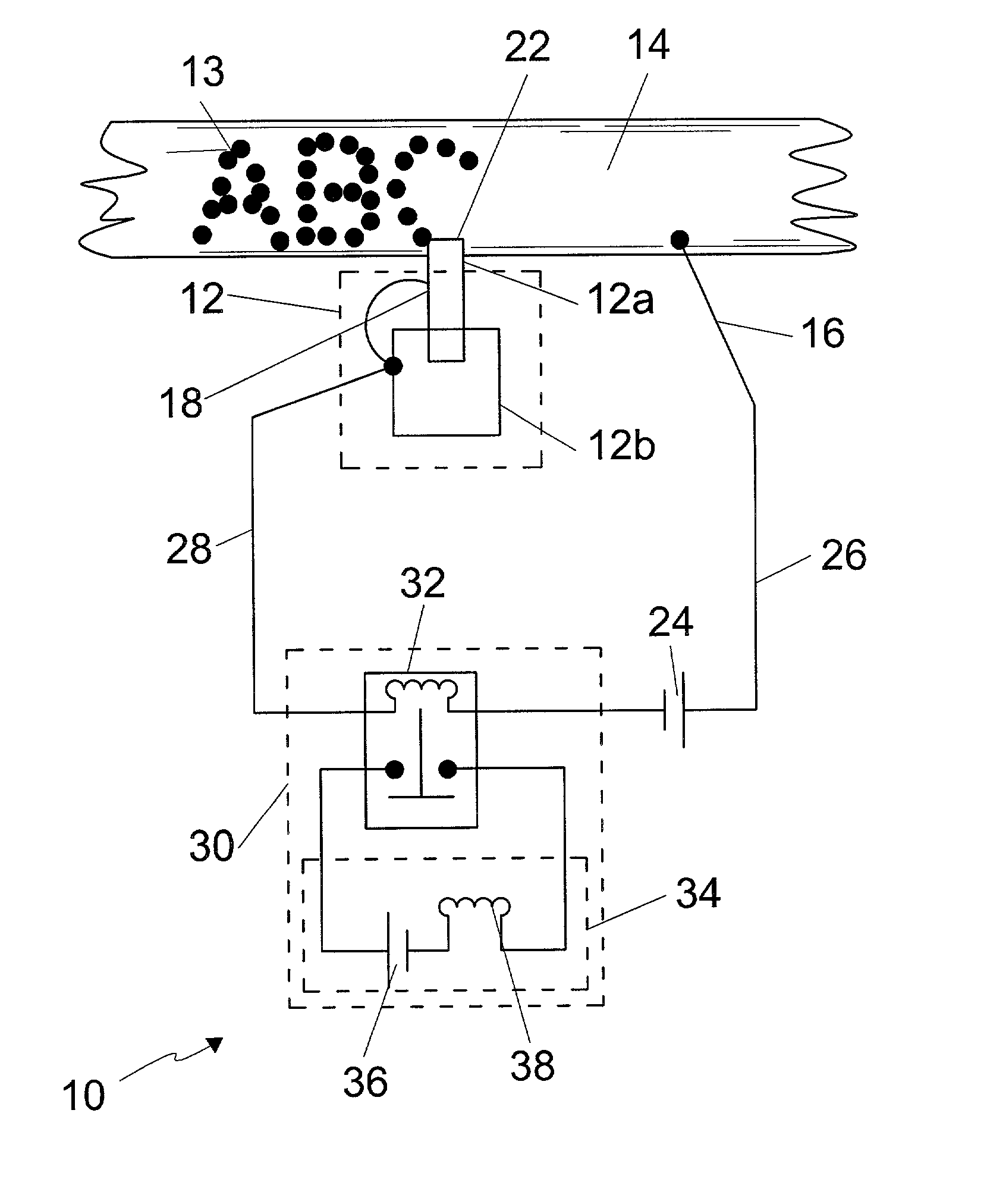

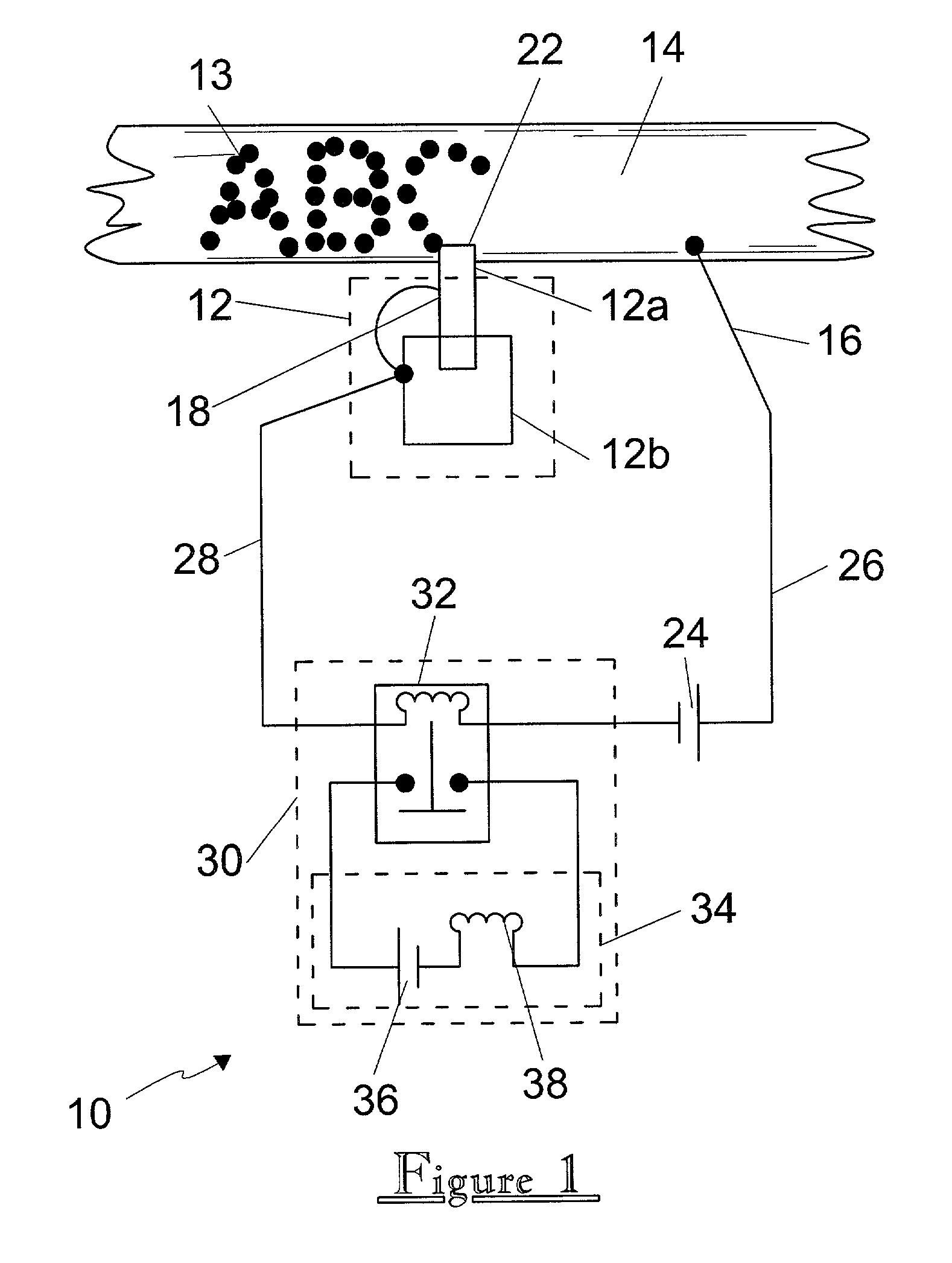

A method of and device for controlled printing using liquid embossing techniques is disclosed. In accordance with the embodiments of the invention a stamp comprises a differentiated embossing surface with protruding and recessed surfaces to enhance the ability of the stamp to selectively displace liquid ink from a print surface and / or remove solvent from the liquid in a soft curing process. A stamp with differentiated surfaces is fabricated by selectively coating, or otherwise treating the protruding features, the recessed features, or a combination thereof, such that the surface energies and / or wettability of the protruding surfaces and the recessed surfaces are differentiated.

Owner:KOVIO

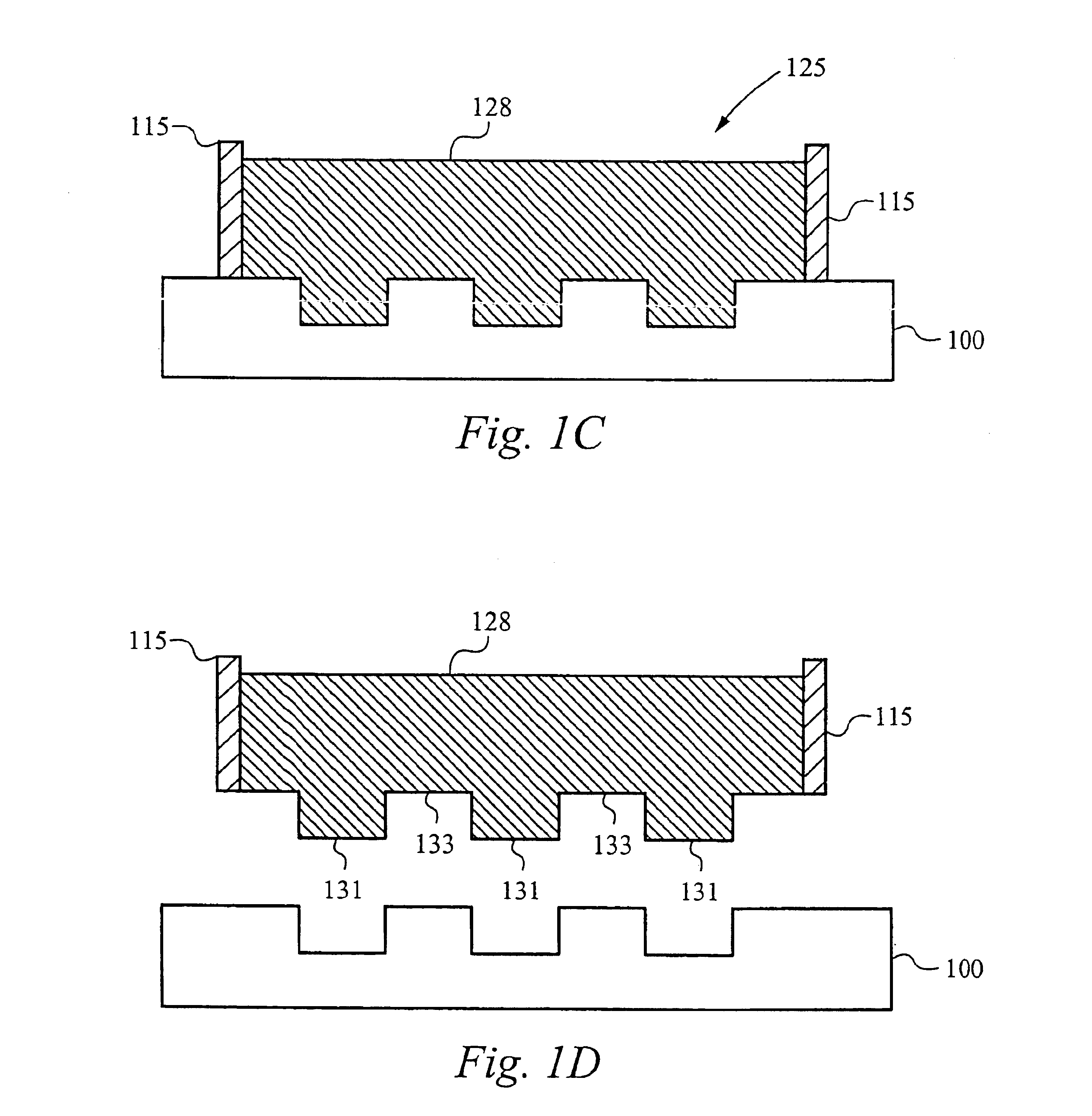

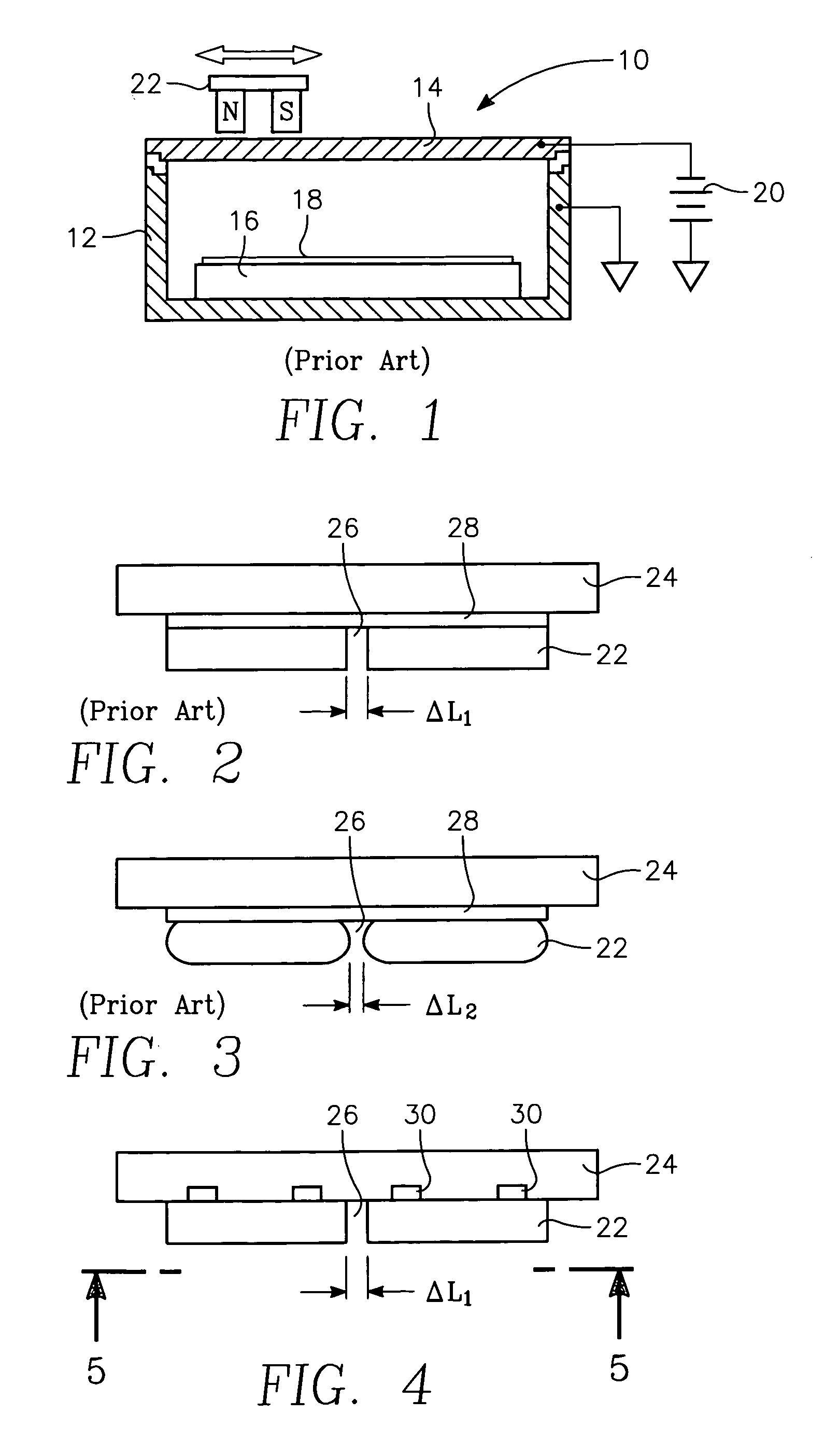

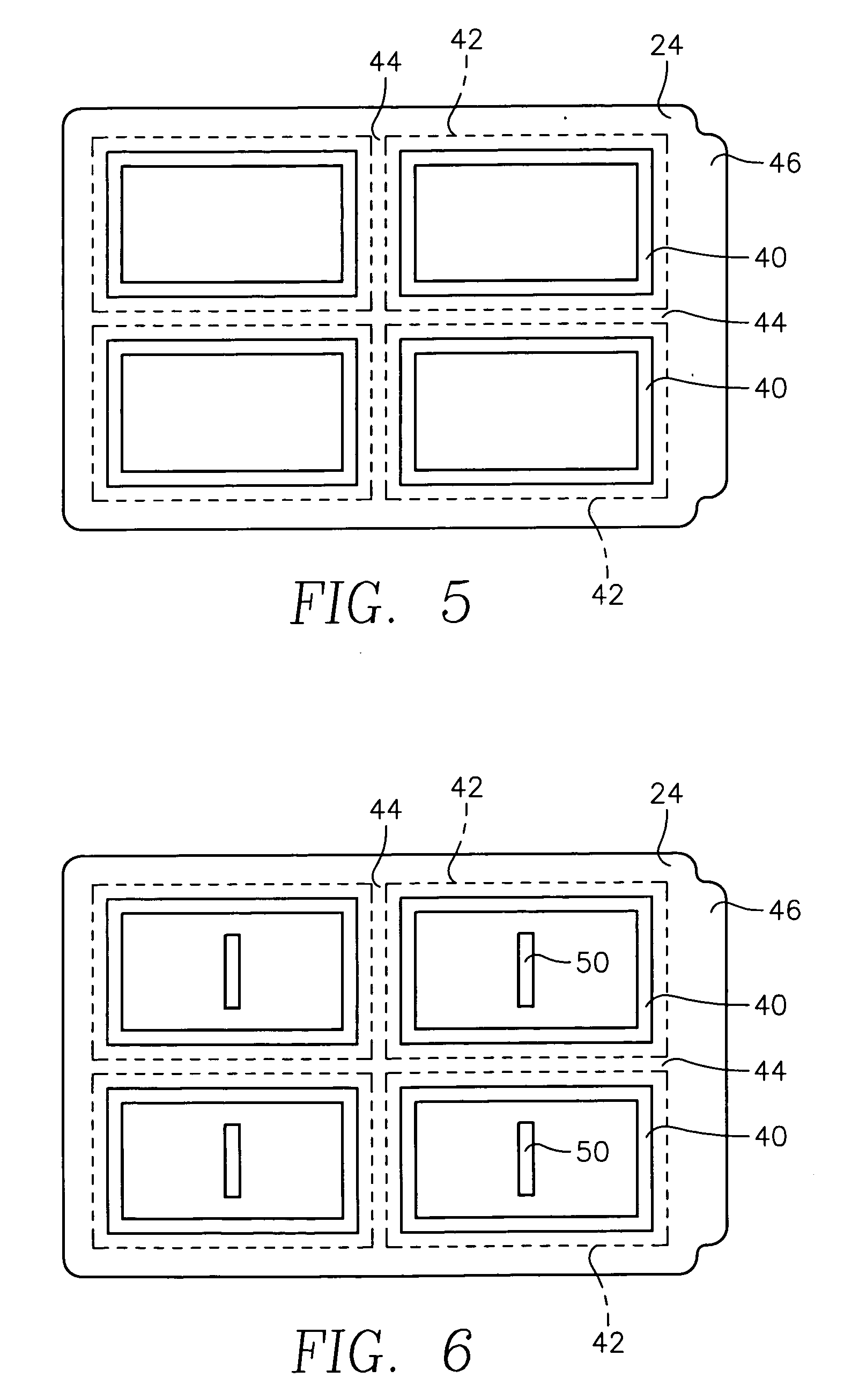

Imprint lithography templates having alignment marks

One embodiment of the present invention is an imprint template for imprint lithography that comprises alignment marks embedded in bulk material of the imprint template.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

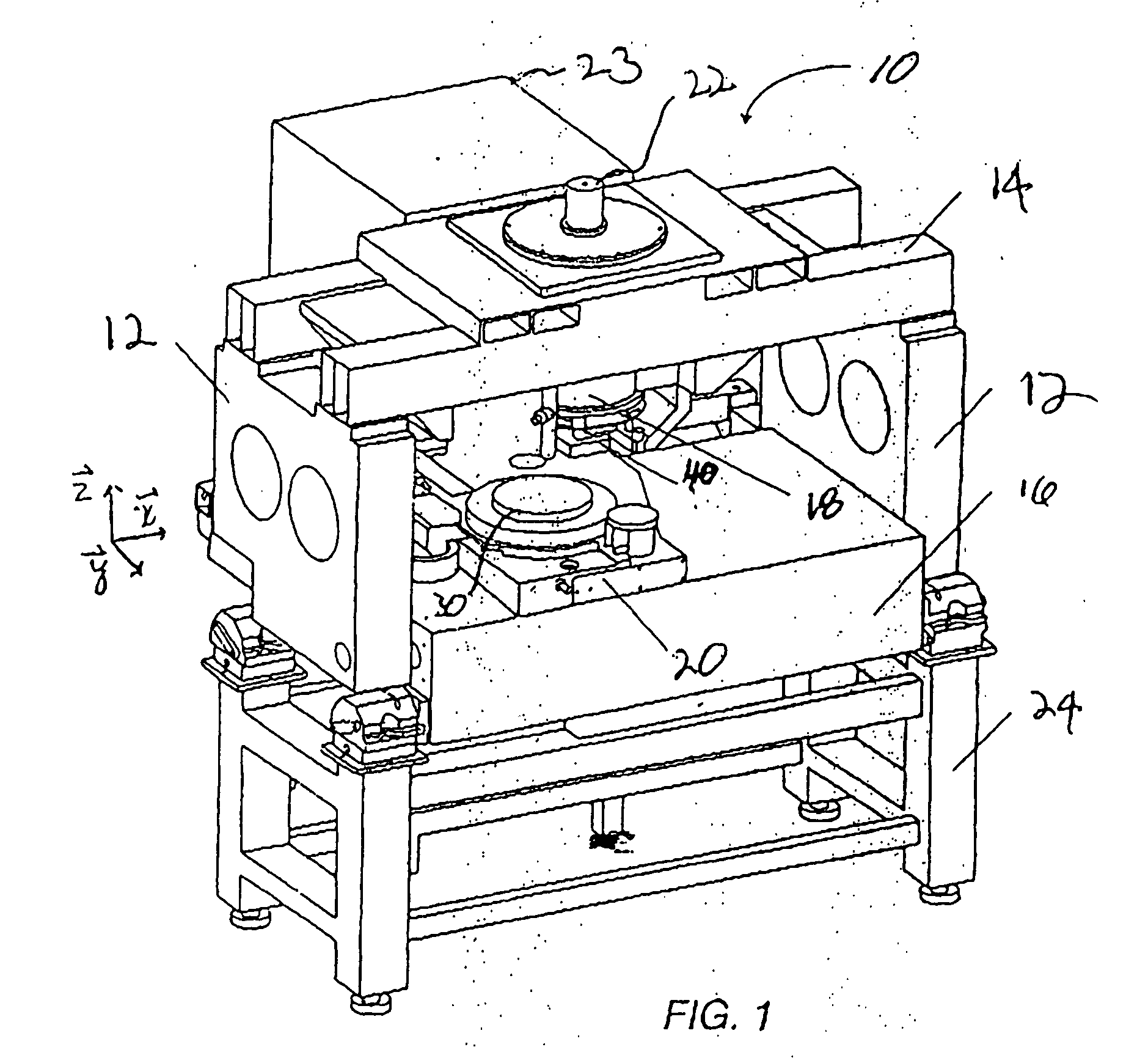

Embossing apparatus

InactiveUS6846172B2Improve viewing effectNon-fibrous pulp additionNatural cellulose pulp/paperEngineering

Disclosed is an embossing method and material made by the method, including at least a pair of embossing rolls having unmatched embossing patterns engraved independently from each other, and having enlarged sidewall clearances between adjacent, inter-engaged protrusions and recessions of the embossing patterns. The sidewall clearances can range from about 0.002″ (about 0.050 mm) to about 0.050″ (about 1.27 mm). The width of the protrusions can be greater than about 0.002″ or about 0.050 mm. The peripheral surface of at least one of the embossing rolls can comprise a metal, a plastic, a ceramic, or a rubber. Also disclosed is an embossed web material capable of being used as a wrap material for food products, made by the above process.

Owner:THE PROCTER & GAMBLE COMPANY

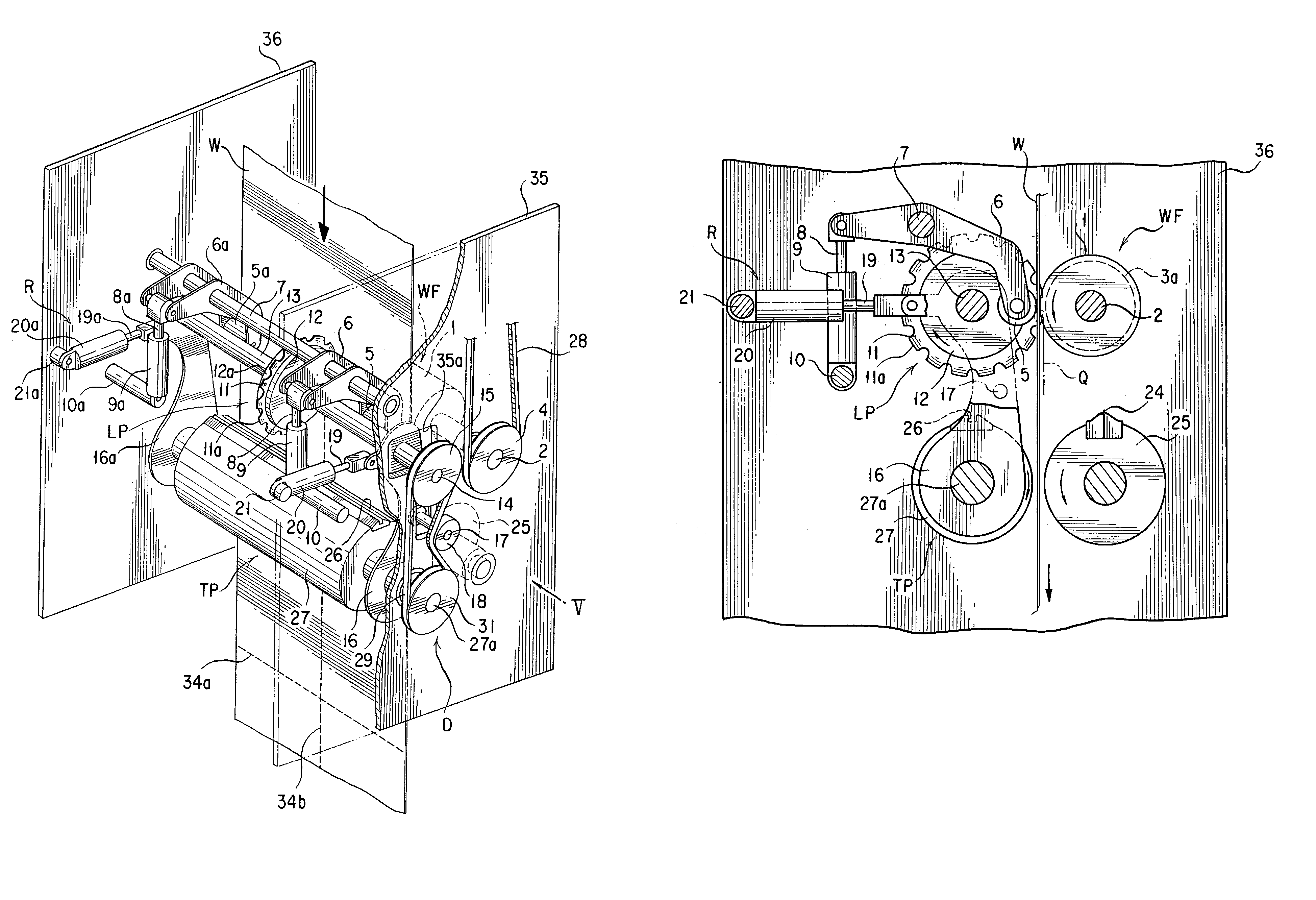

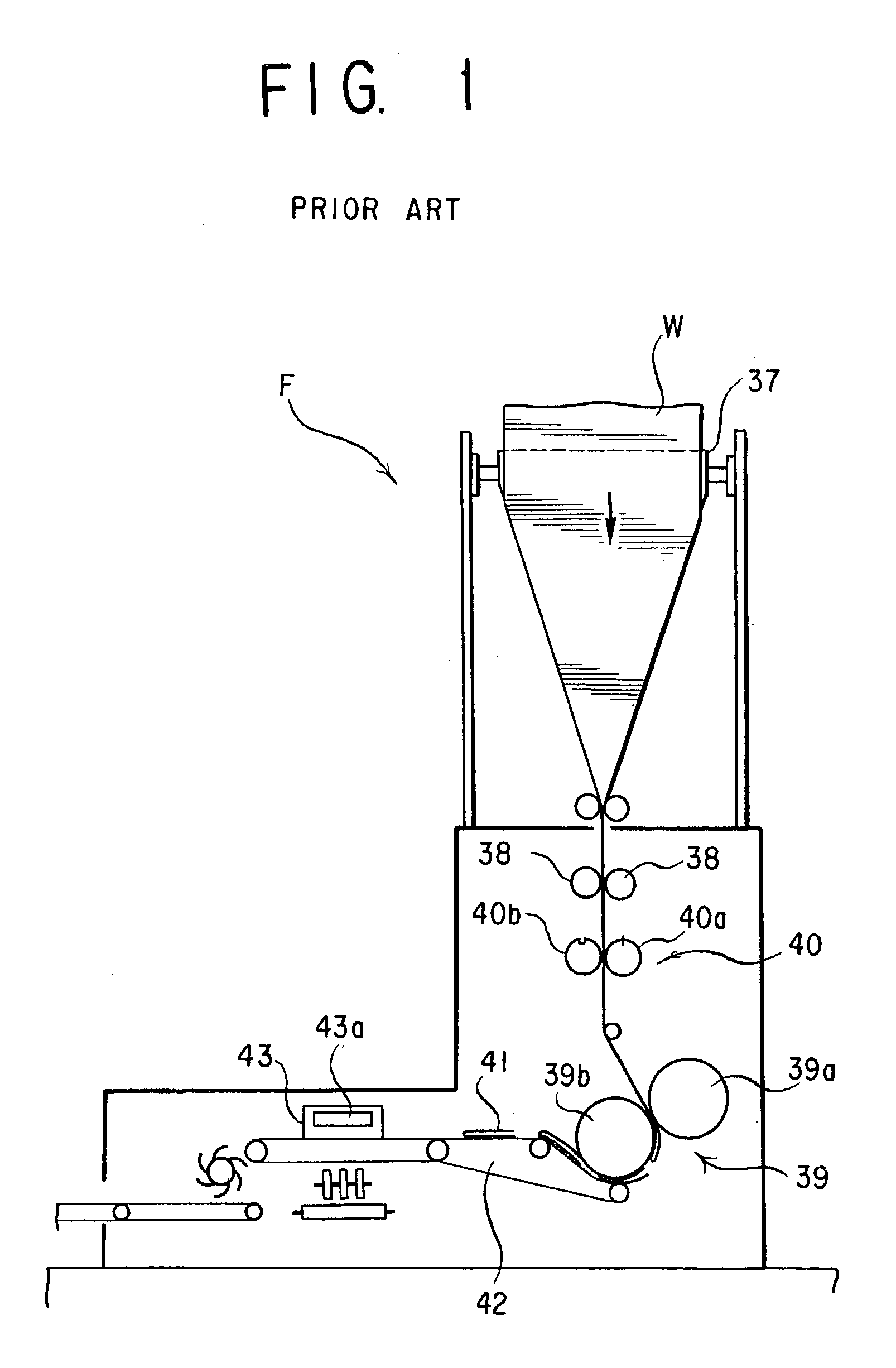

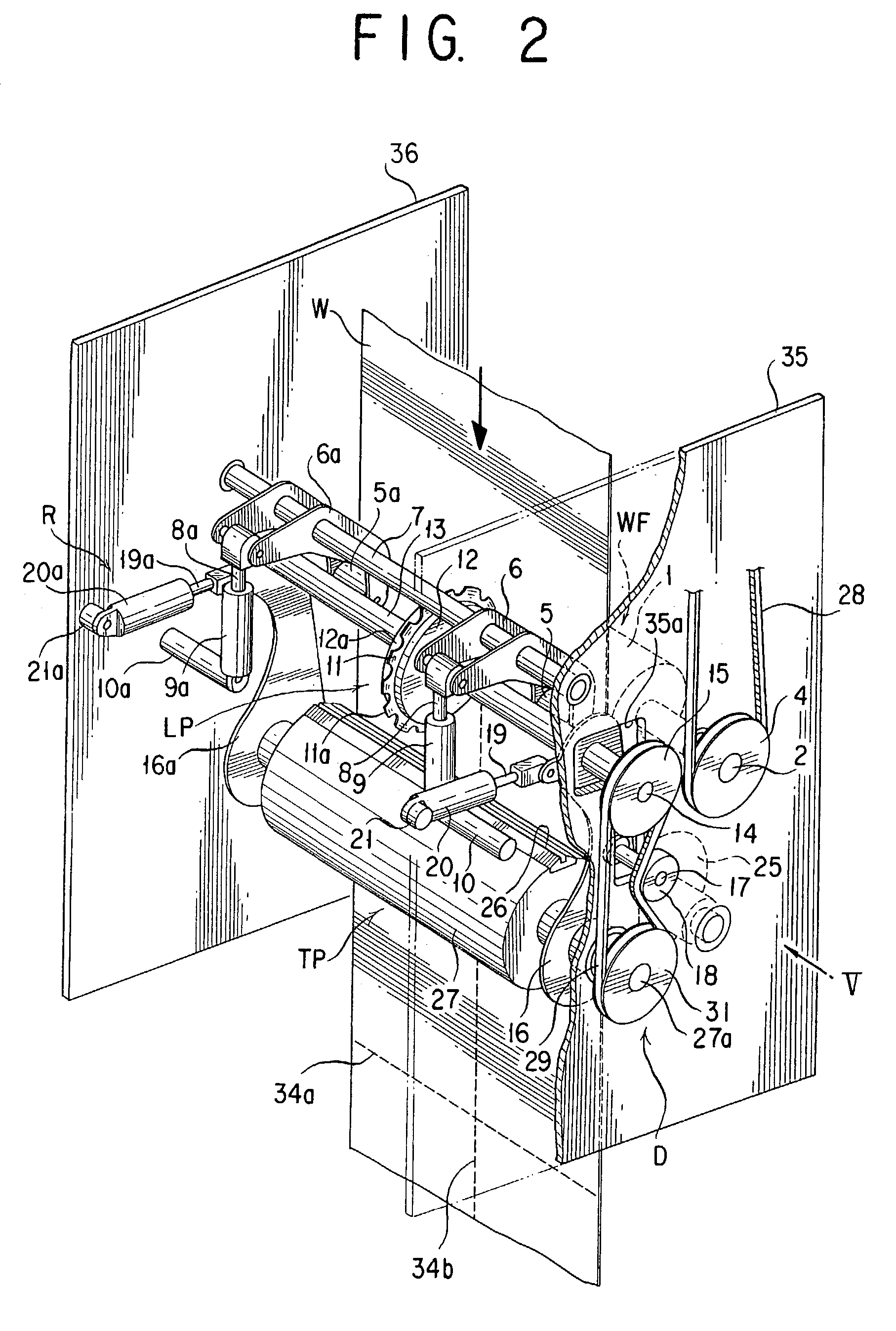

Apparatus for longitudinally perforating a web of paper in a rotary printing press

A rotary printing press has a folding station where the printed web is perforated both transversely and longitudinally in order to expedite subsequent folding thereof into signatures. In order to incorporate a longitudinal perforator into the folding station without adding to its size, a longitudinally perforating blade similar to a circular saw is mounted to a blade carrier shaft which is rotatably supported opposite a feed roller by which the web is frictionally fed into and through the folding station. An annular, longitudinally grooved anvil is formed circumferentially on the feed roller for engaging the longitudinally perforating blade via the web being thereby perforated. The longitudinally perforating blade is movable with the blade carrier shaft into and out of perforating engagement with the anvil on the feed roller.

Owner:TOKYO KIKAI SEISAKUCHI LTD

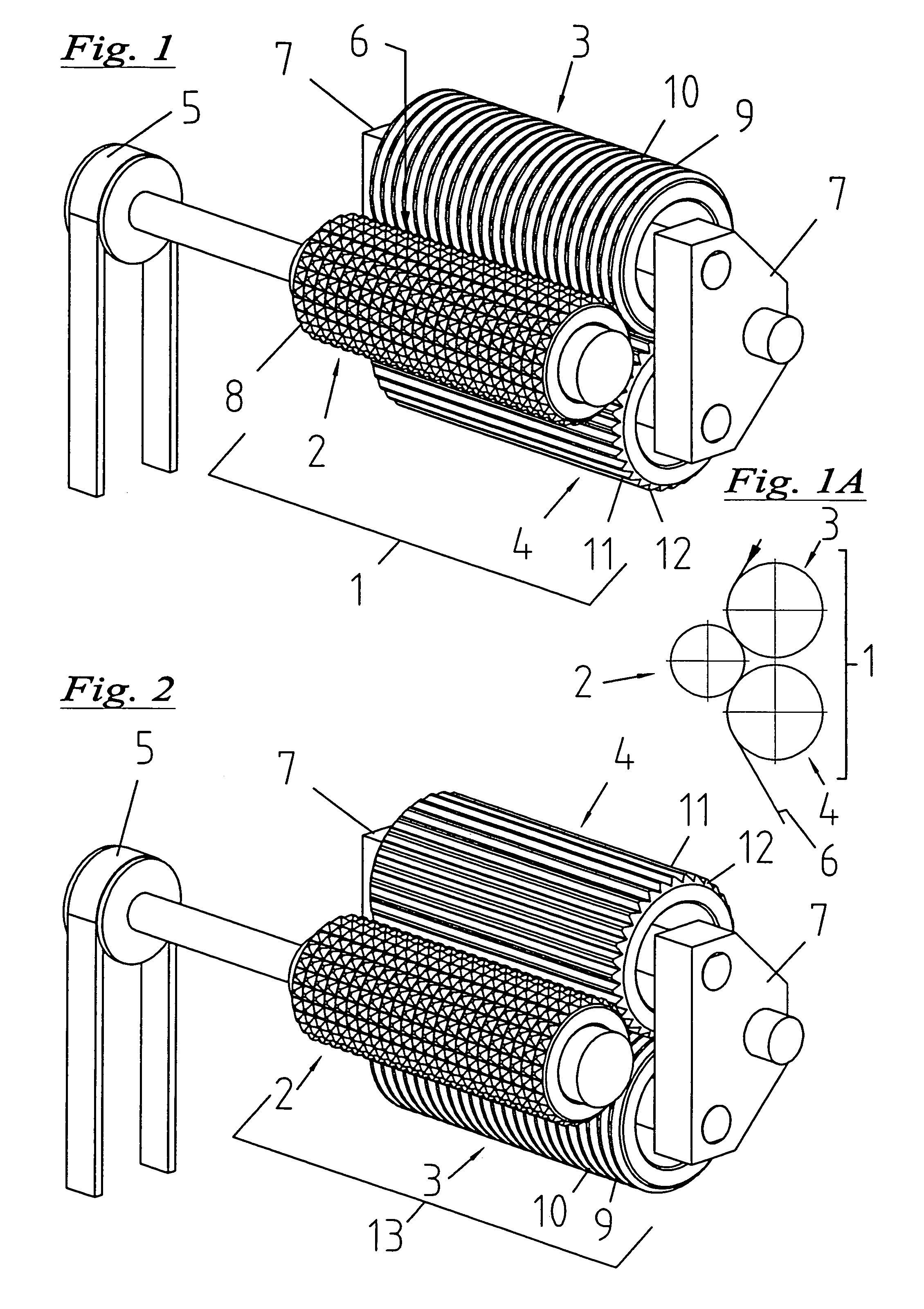

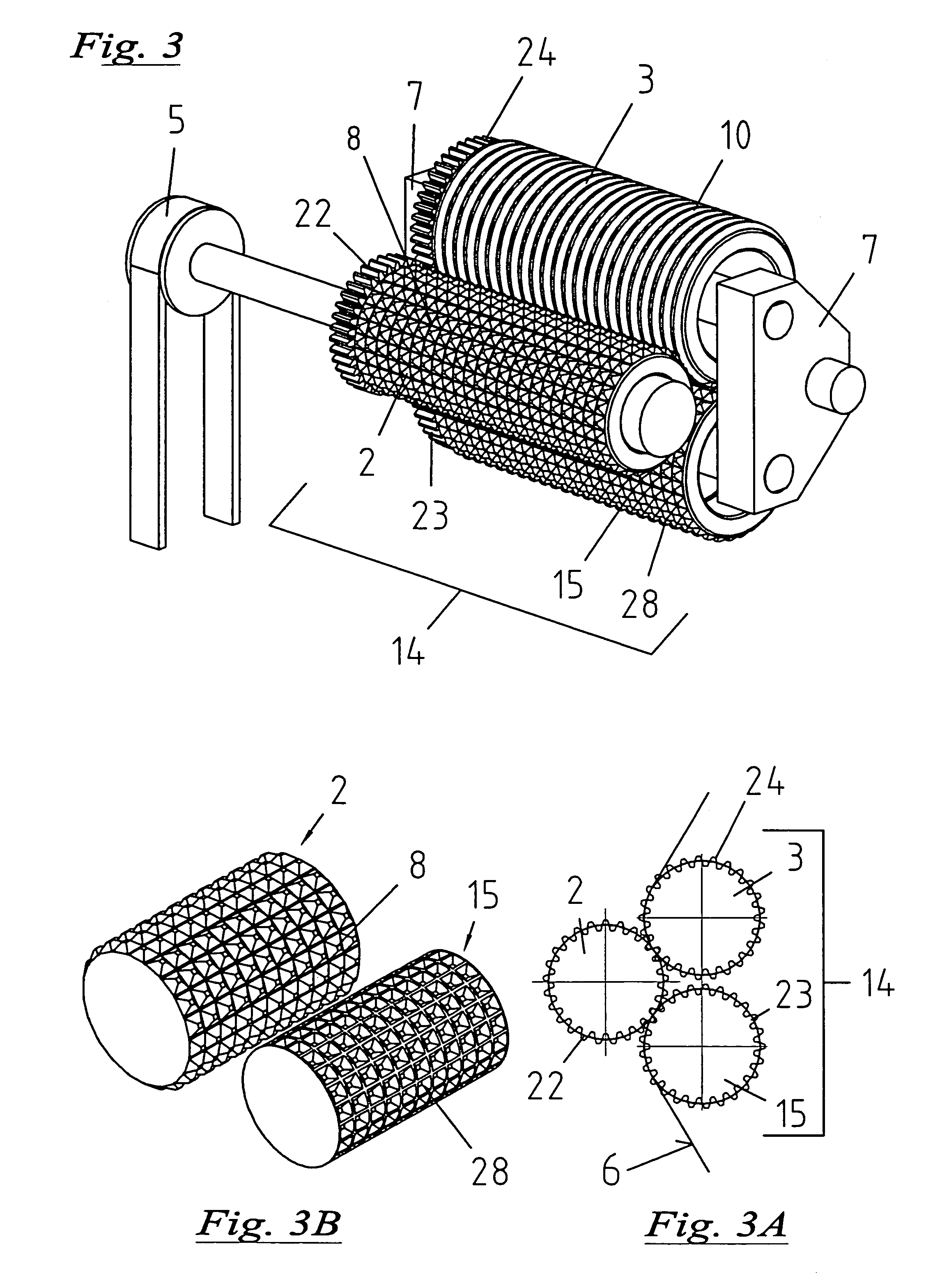

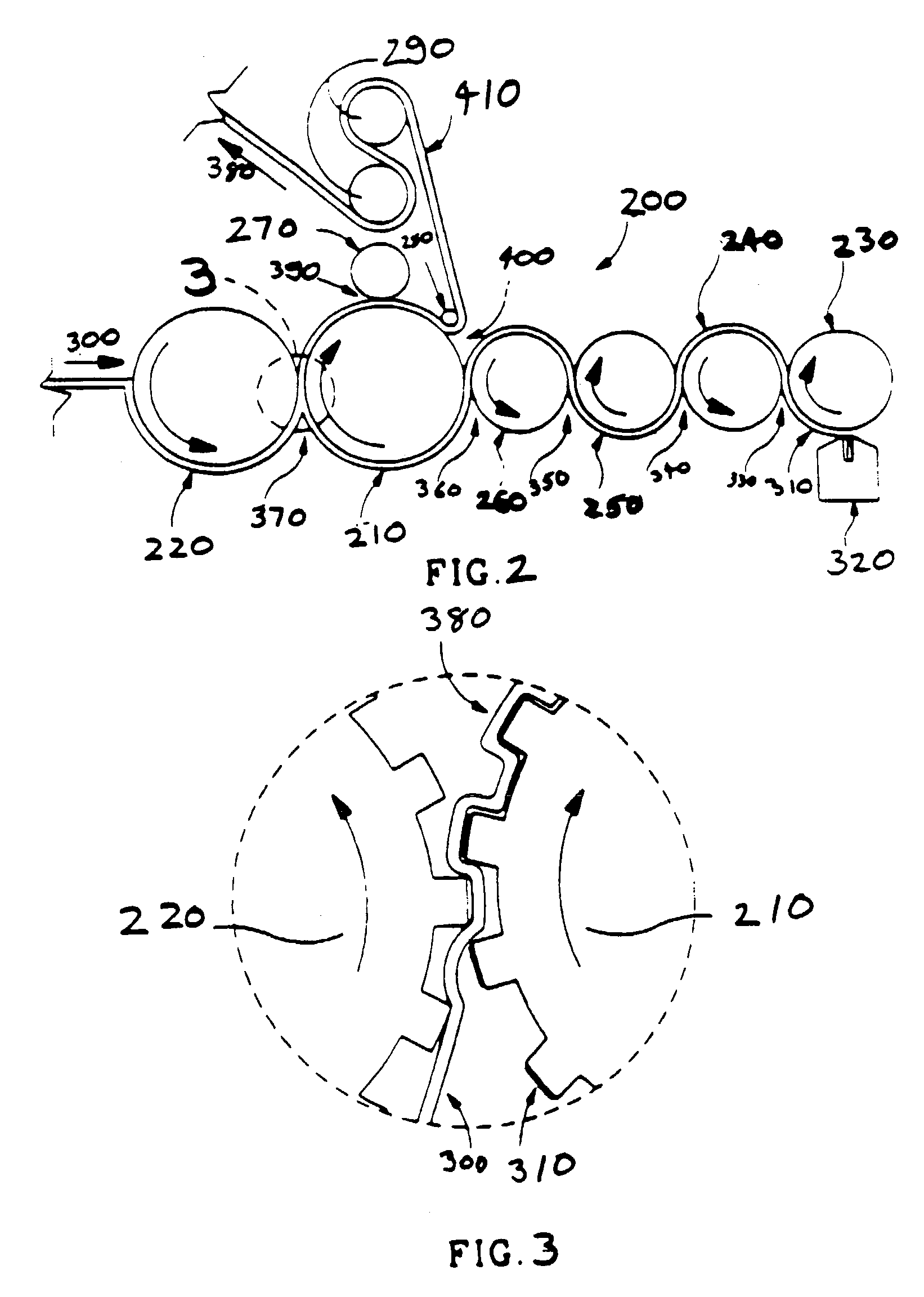

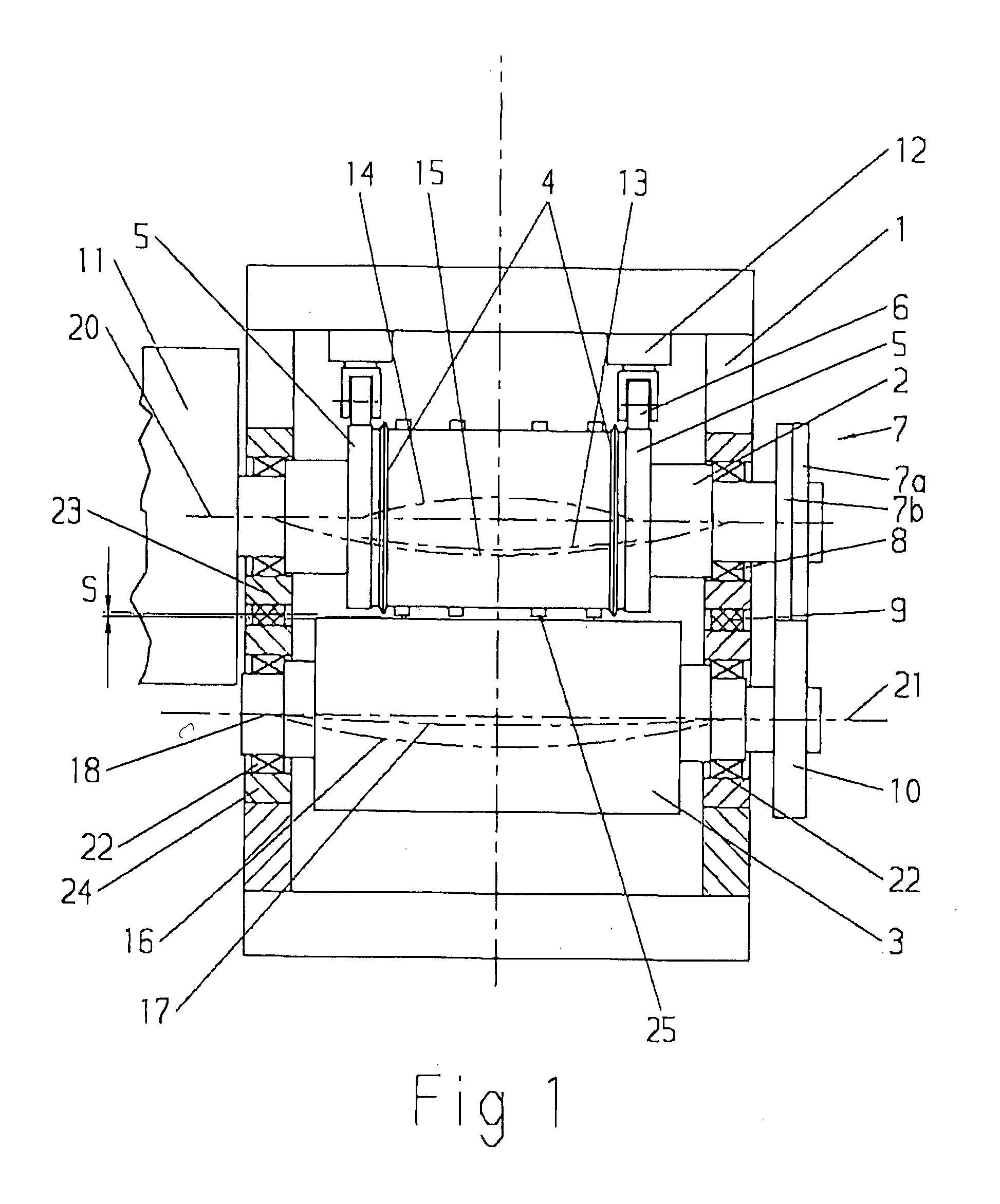

Device for treating flat material

InactiveUS7147453B2Not easy to copyImprove accuracyMechanical working/deformationDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

The invention relates to a device for embossing and / or glazing films. The device for embossing includes a first and second embossing roll, through which flat material can be fed under pressure, in order to create a pattern. An additional embossing roll is connected downstream of the second embossing roll, this additional embossing roll interacting with the first or preceding embossing roll. The patterned flat material may be fed between these embossing rolls, in order to be embossed again with essentially the same pattern. In a simplified embodiment, only a total of two rolls are used. In order to achieve as precise an embossing as possible, with special effects, the first driven embossing roll is provided with teeth, while at least one other embossing roll comprises rings or longitudinal ribs, or is smooth.

Owner:BOEGLL GRAVURES SA

Imprint lithography template having a feature size under 250 nm

InactiveUS7229273B2Nanostructure manufactureMechanical working/deformationEngineeringPhotolithography

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

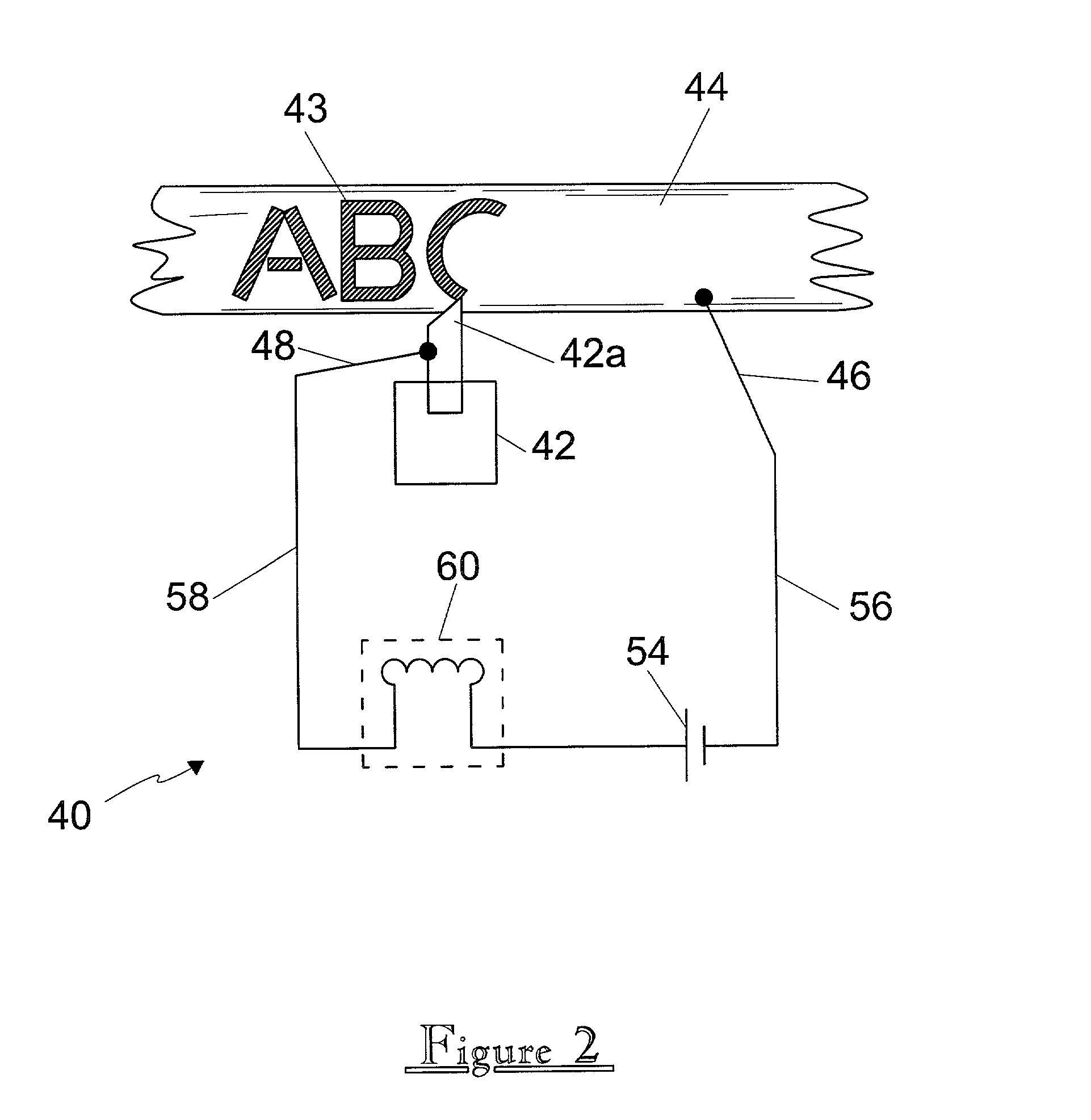

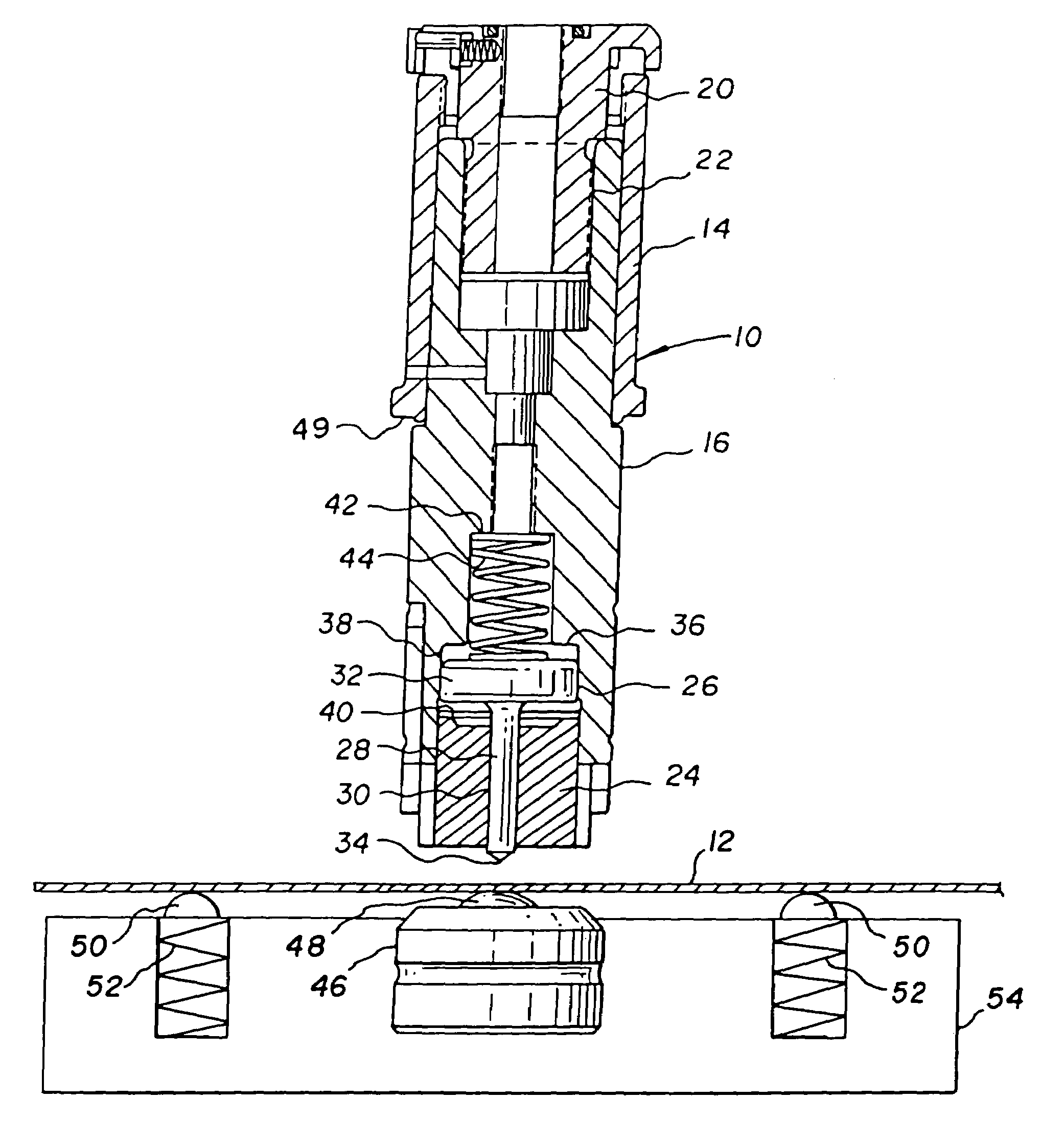

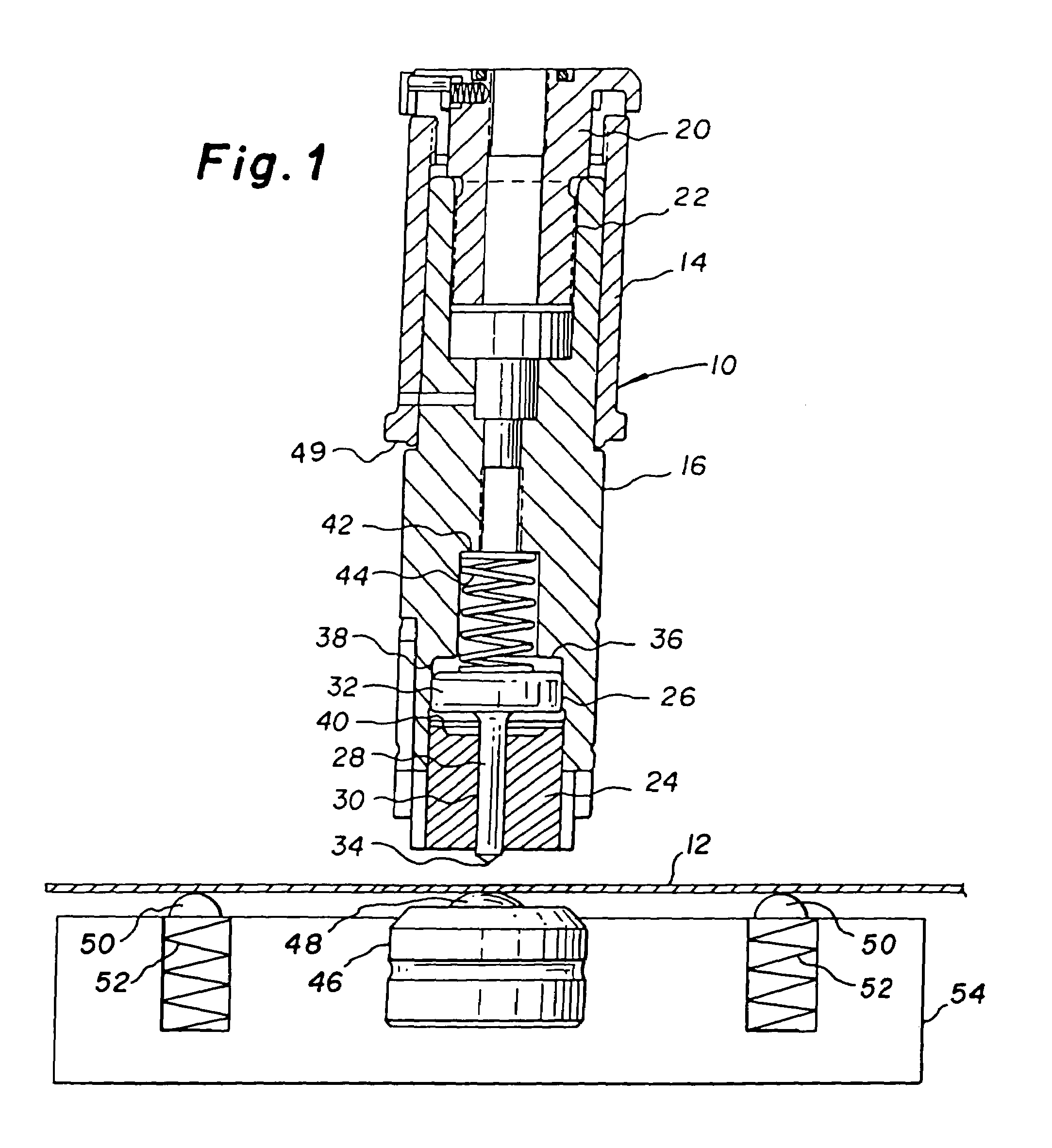

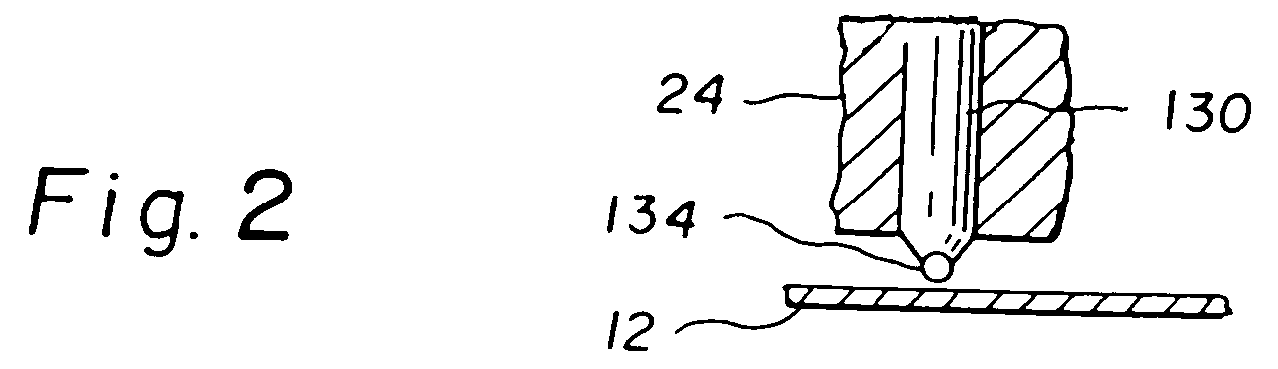

Positive piece engagement indicator for marking tool

InactiveUS20020114653A1Automatic control devicesMechanical working/deformationMechanical engineeringVoltage

A positive piece engagement indicator for marking tool is provided in which a metal workpiece is contacted with a workpiece contact probe for providing physical contact with, as well as electrical communication with the metal surface of a workpiece. A test voltage and indicator means are placed in series between the workpiece and marking tool. Upon physical contact of the marking tool engagement surface with the surface of the metal workpiece, a circuit is completed by the electrical communication there between, thereby engaging the indicator means. This allows positive verification of actual engagement of worktool to workpiece.

Owner:GATTA RAYMOND P

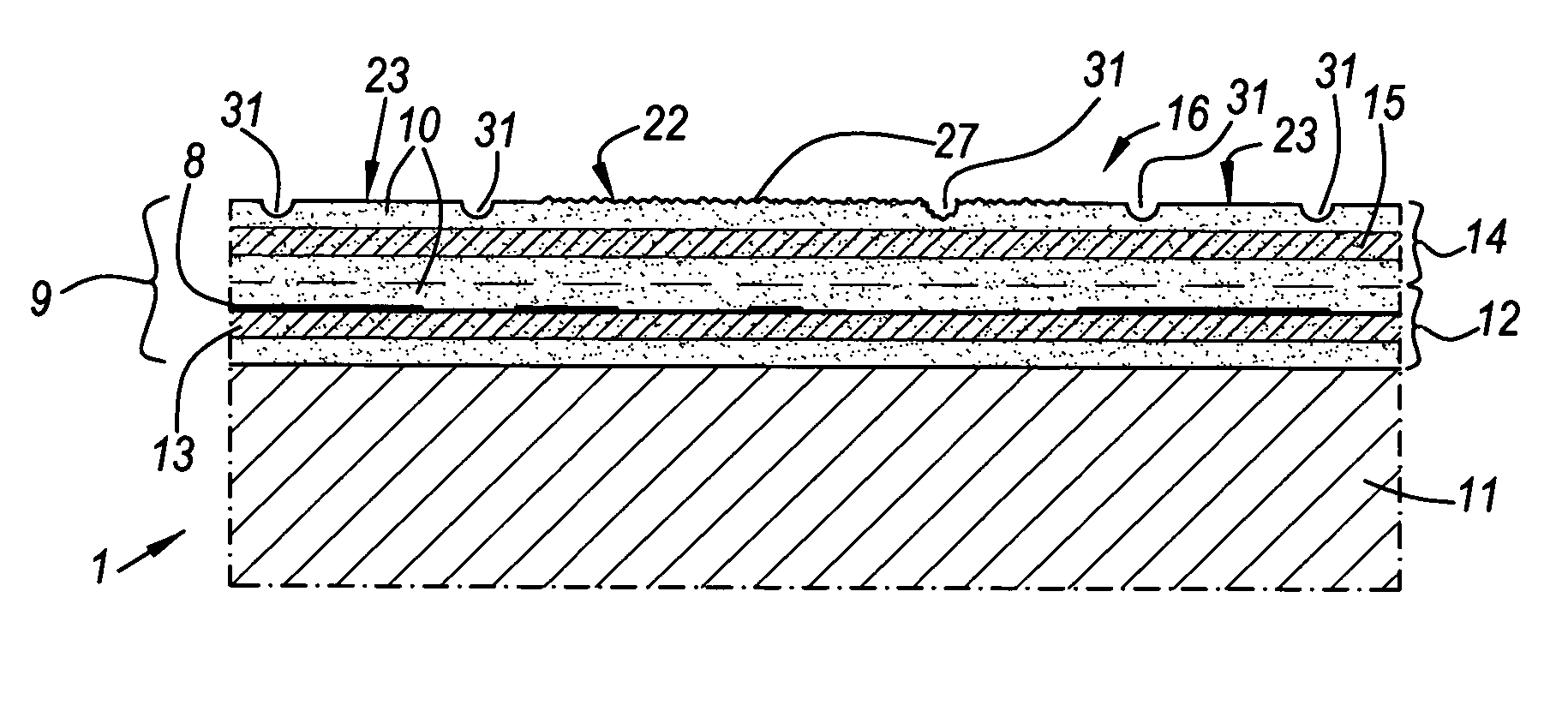

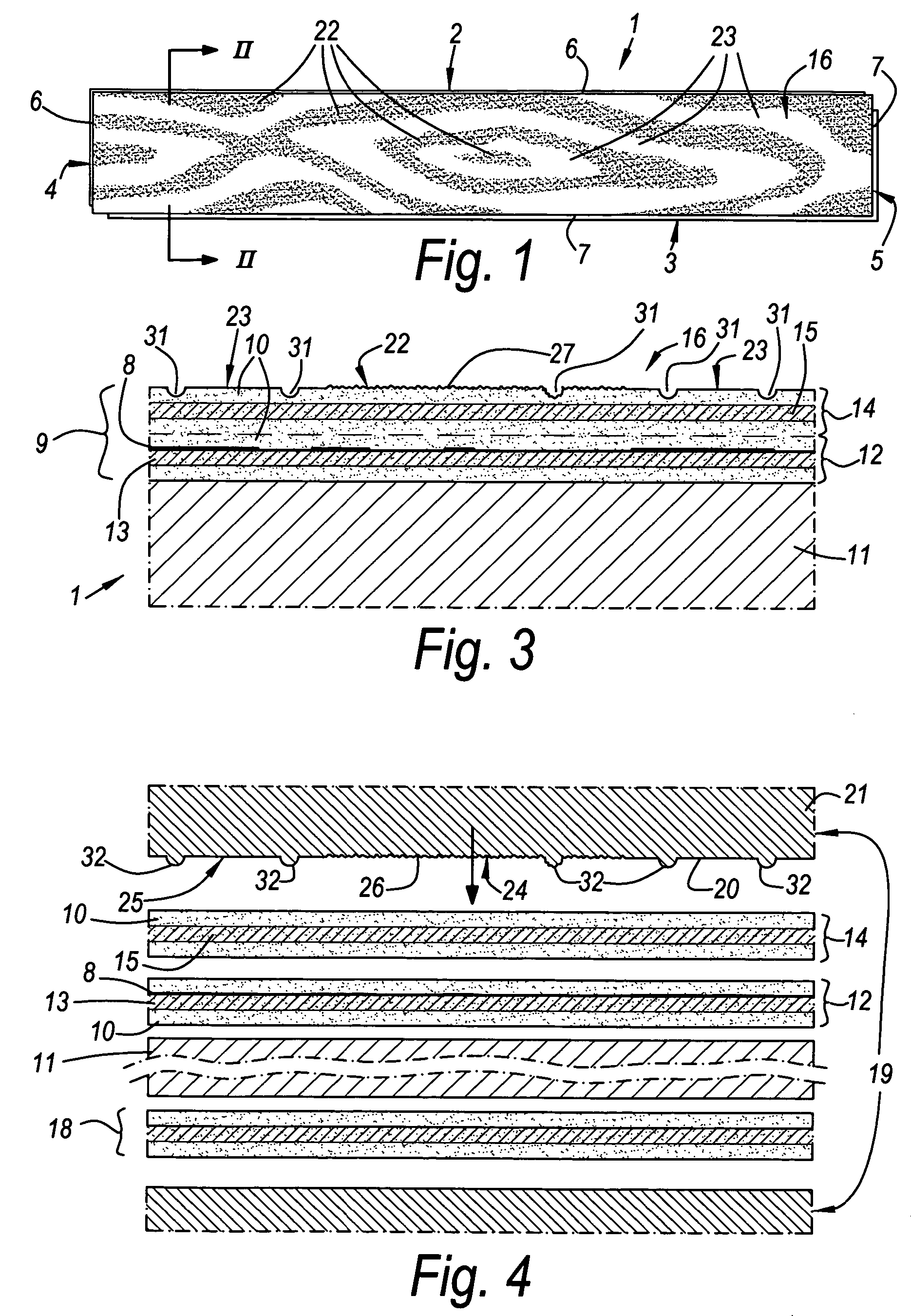

Floor panel and method for manufacturing a floor panel

ActiveUS8153234B2Easy to distinguishFlexible and inexpensiveDecorative surface effectsLayered productsFace sheetCivil engineering

Owner:FLOORING IND LTD

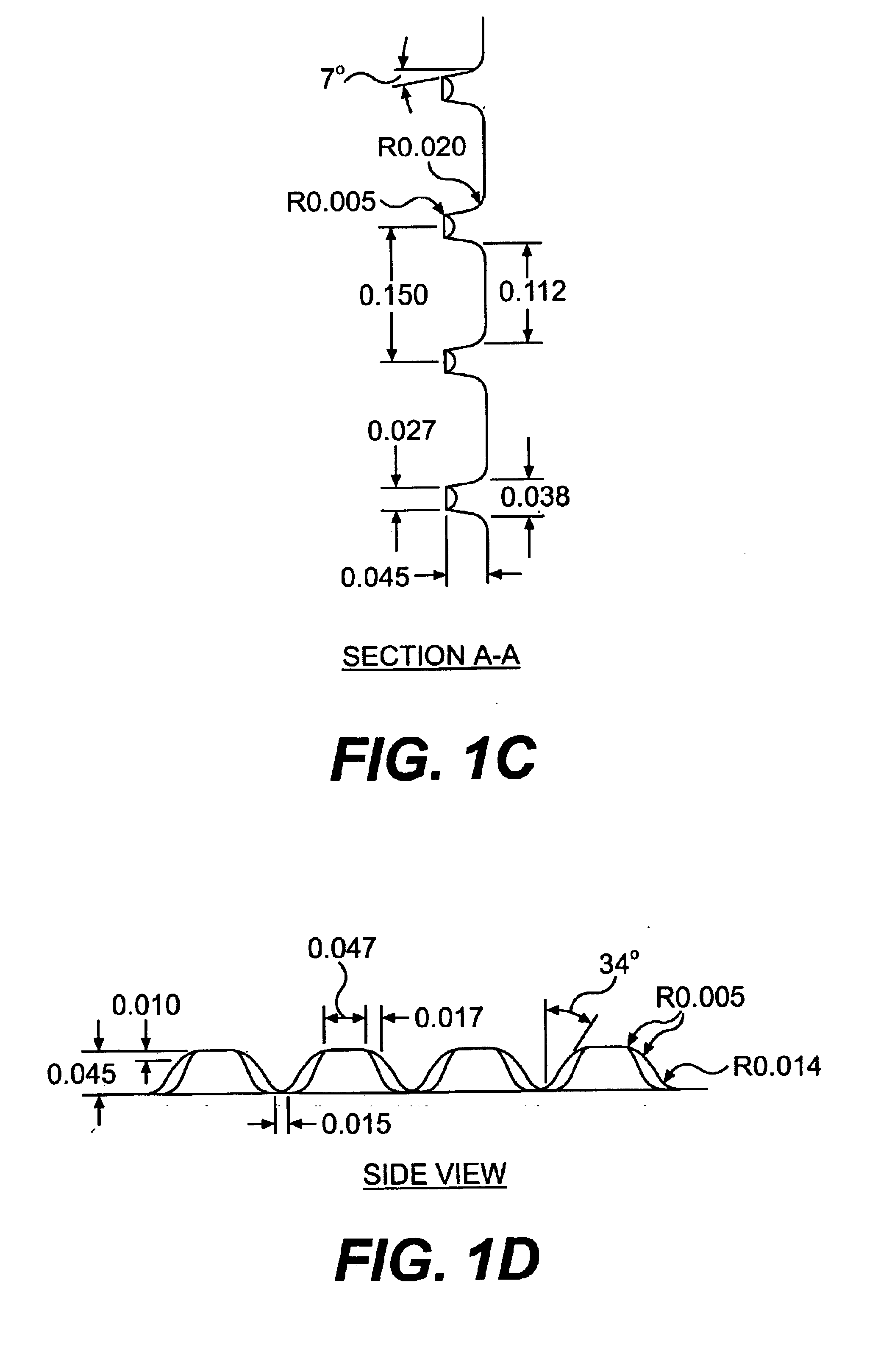

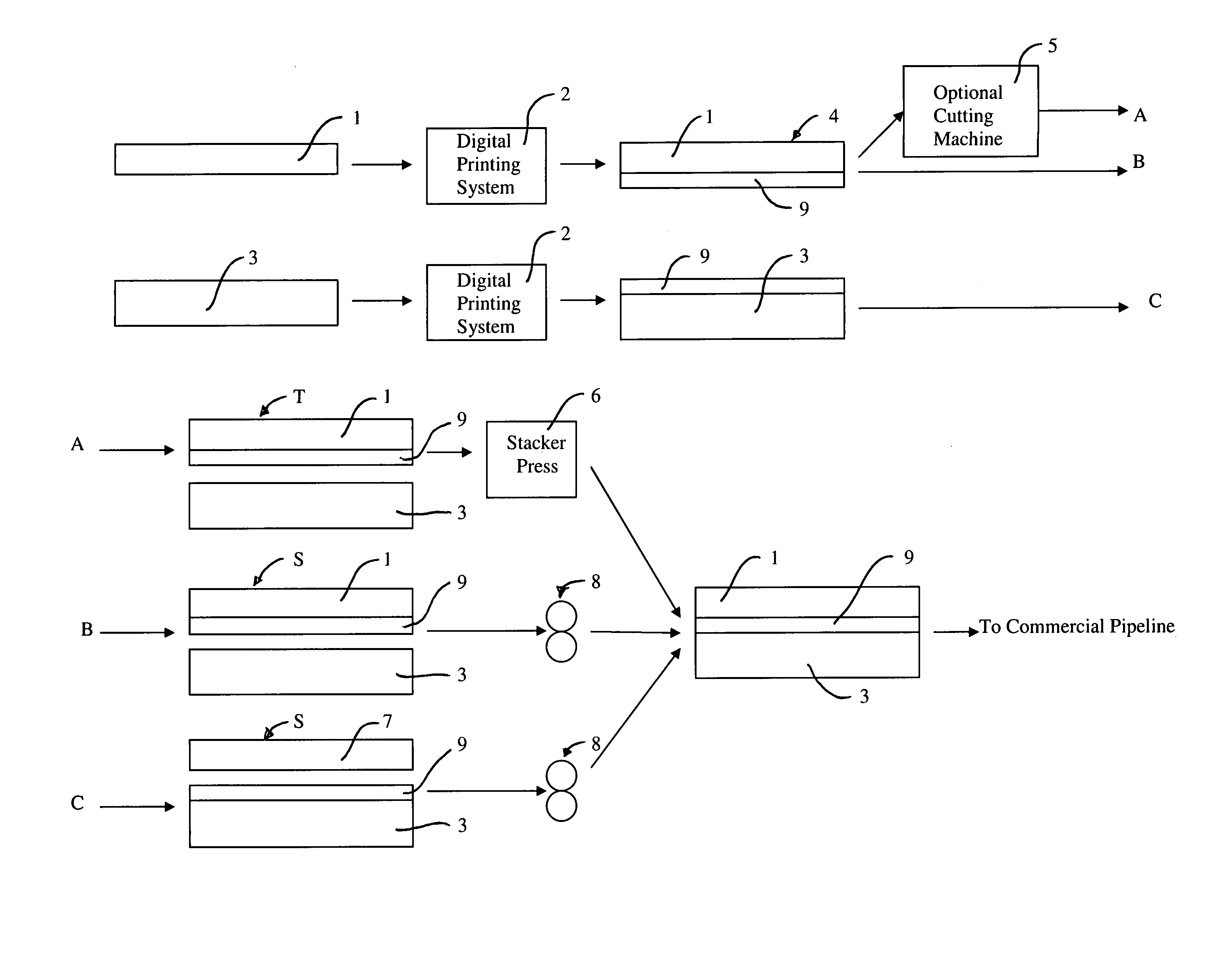

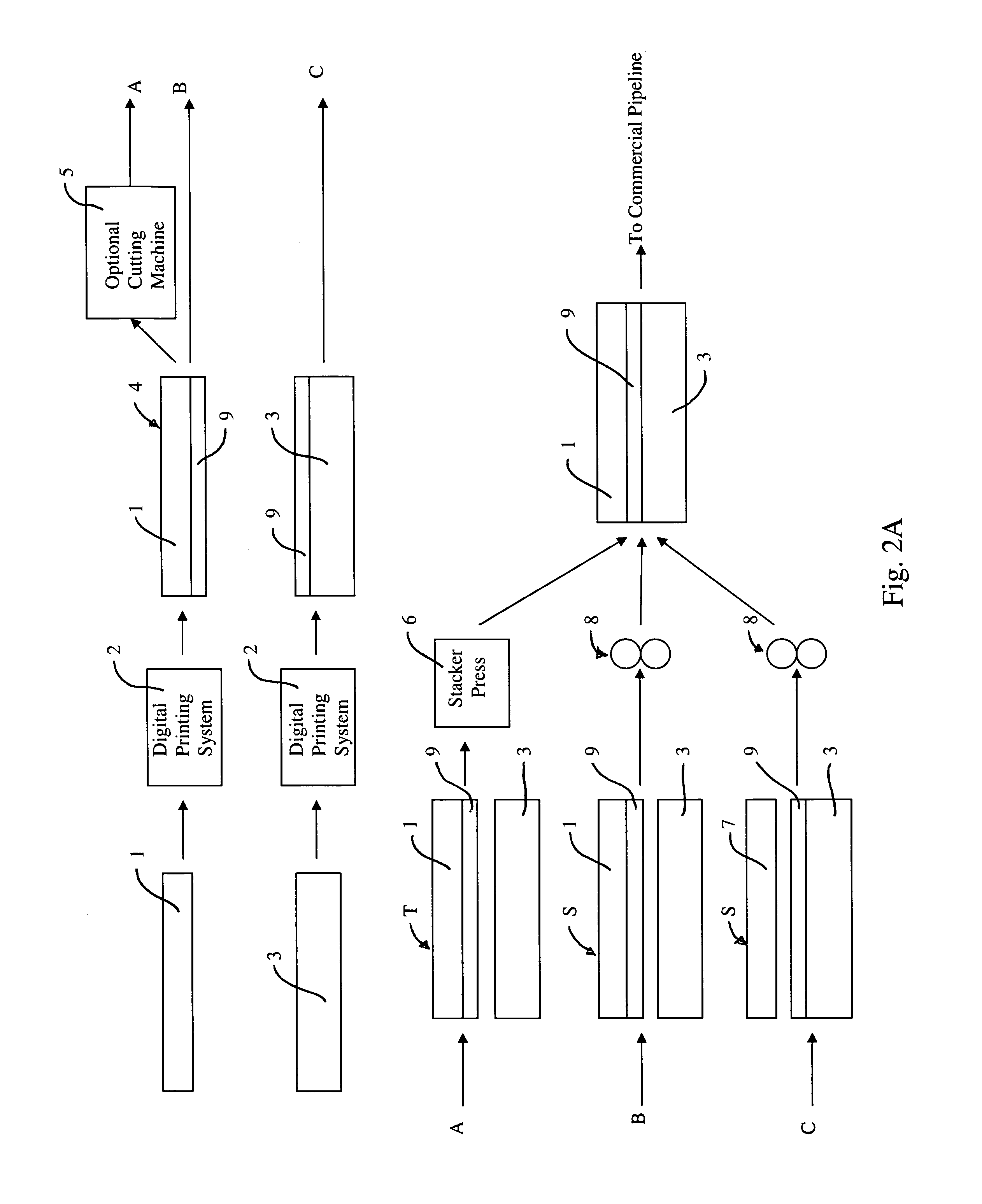

Rapid prototyping and filling commercial pipeline

InactiveUS20050247216A1Cheap and quickFast formingAdditive manufacturing apparatusMechanical working/deformationEngineeringDigital printing

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

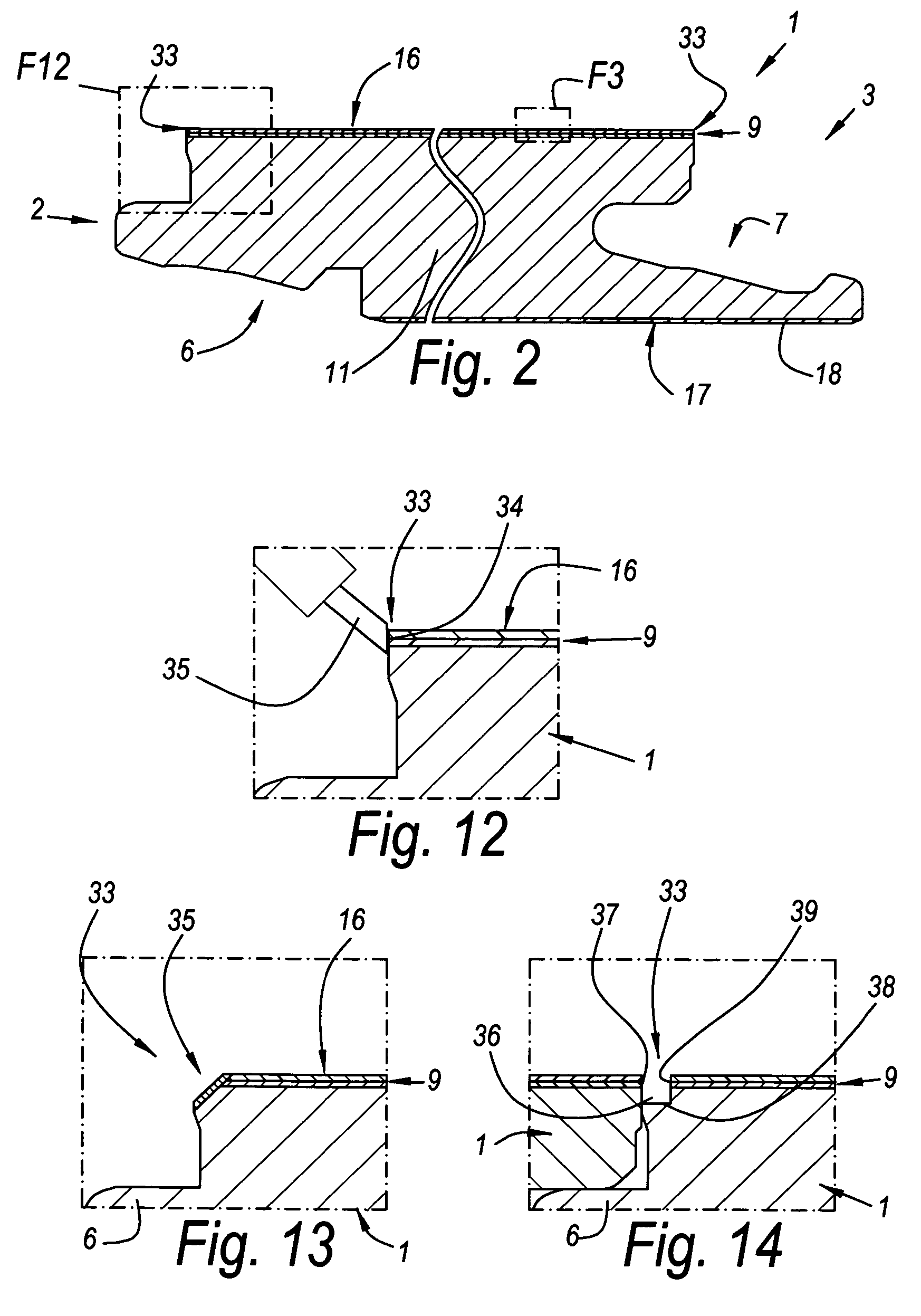

Method for finishing a building board and building board

ActiveUS20070193174A1Simple and cost-effective production methodCovering/liningsNatural patternsCivil engineering

A method for finishing a building board, in particular a wood material or plastic board or a mixture of wood material and plastic. The building board includes a top side and an underside and opposite side edges. The method includes embossing a structure and / or a relief in at least the top side of the building board. A pattern is applied to the embossed side of the building board. The pattern is sealed by the application of an abrasion-resistant layer to the pattern.

Owner:FLOORING TECH

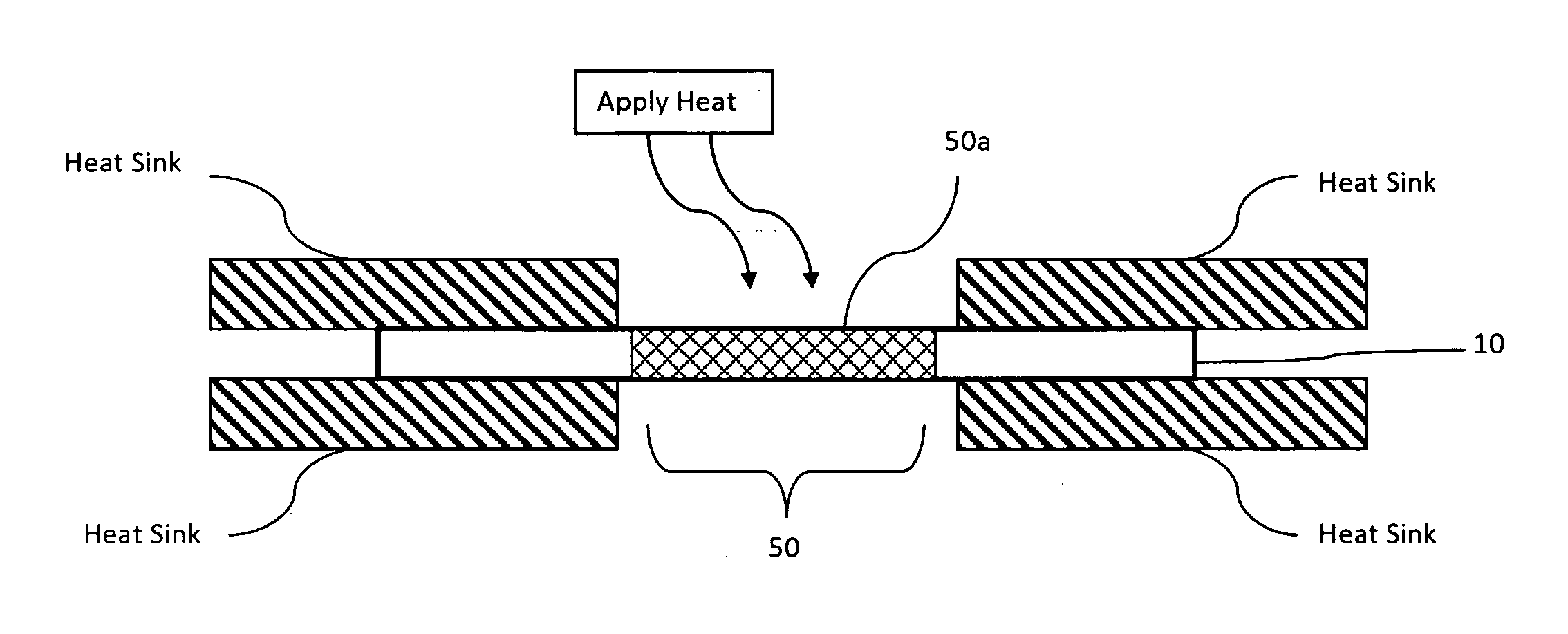

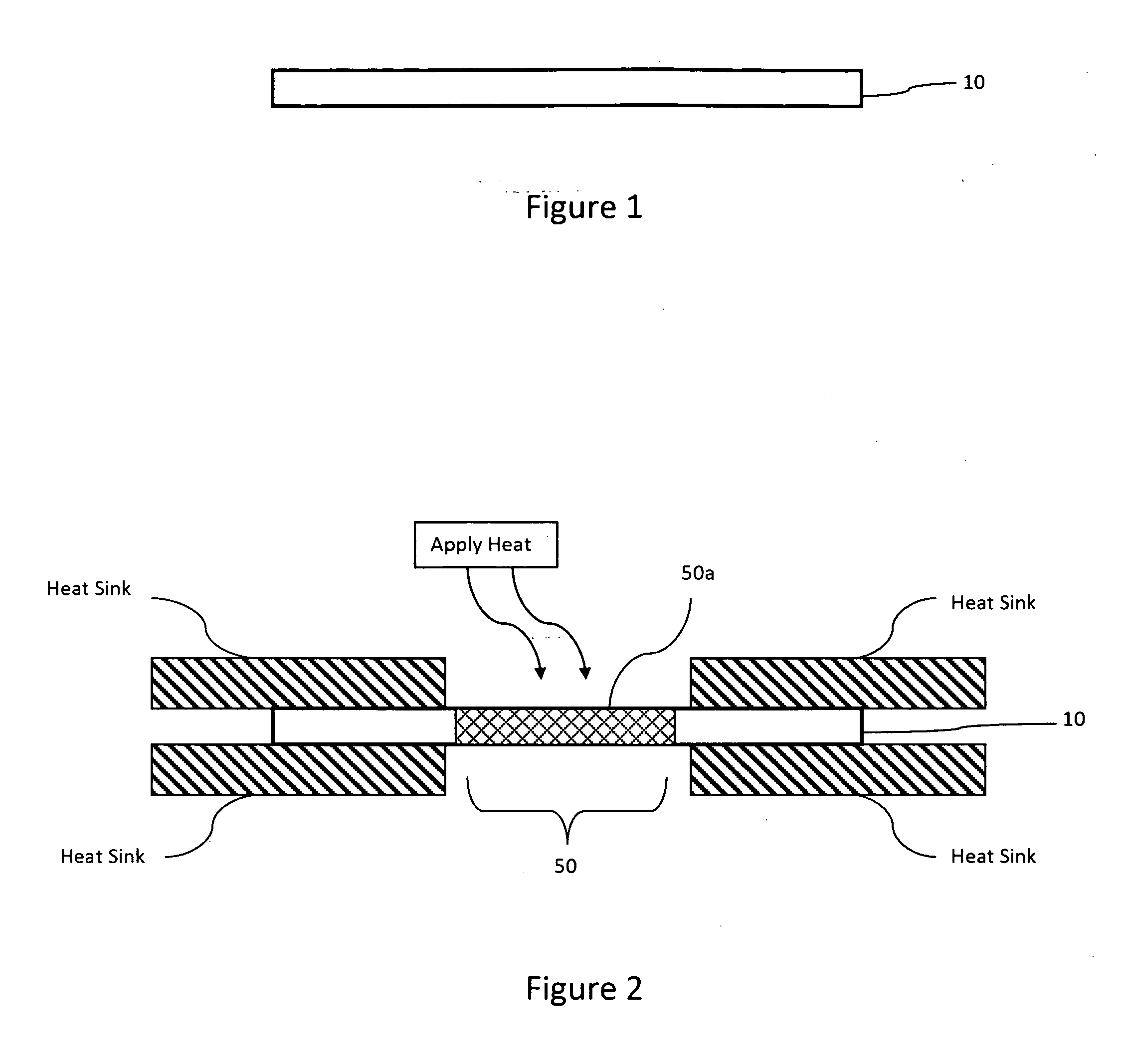

Metal card

ActiveUS20110189620A1Easy embossingSimple equipmentOther heat production devicesCharge manipulationMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

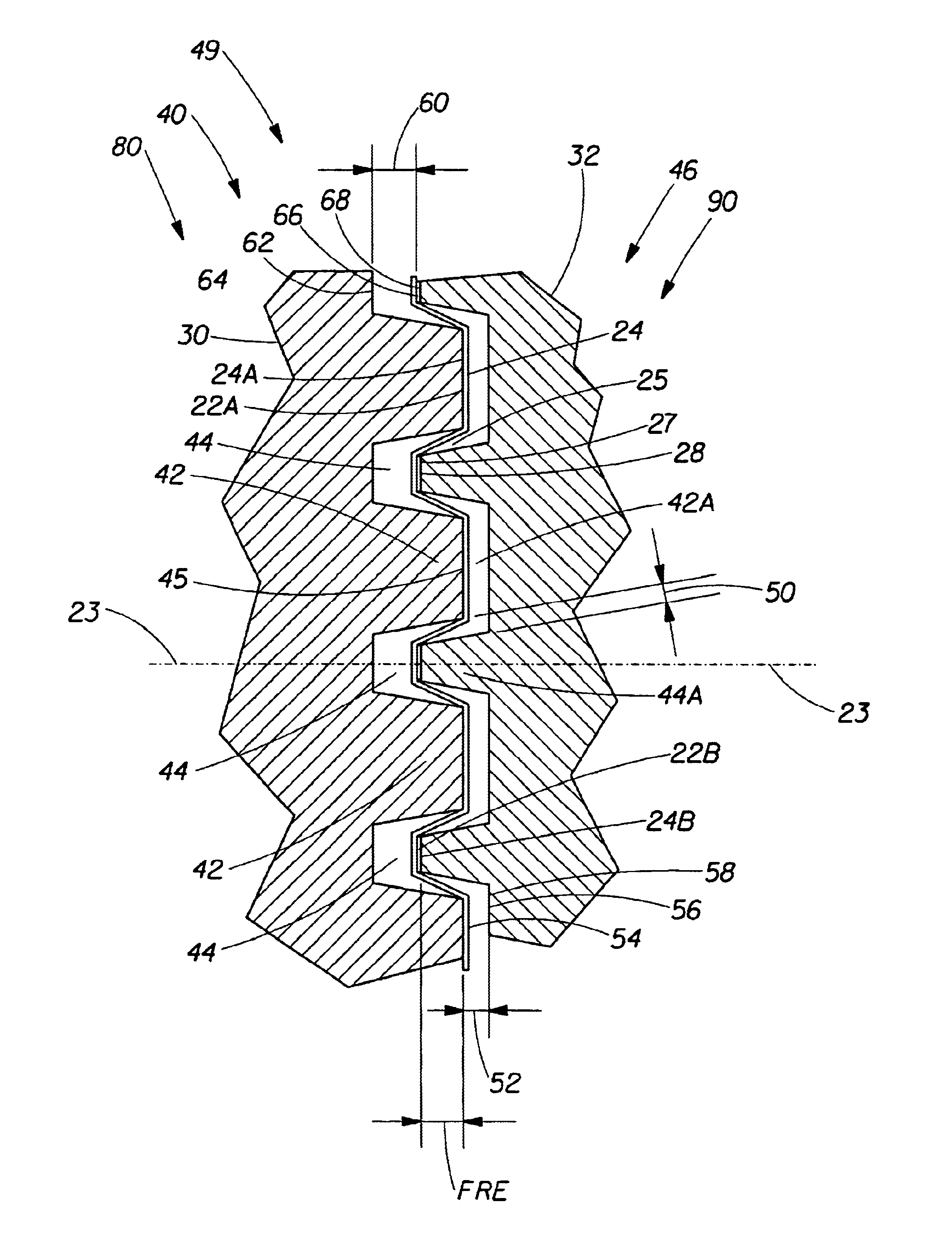

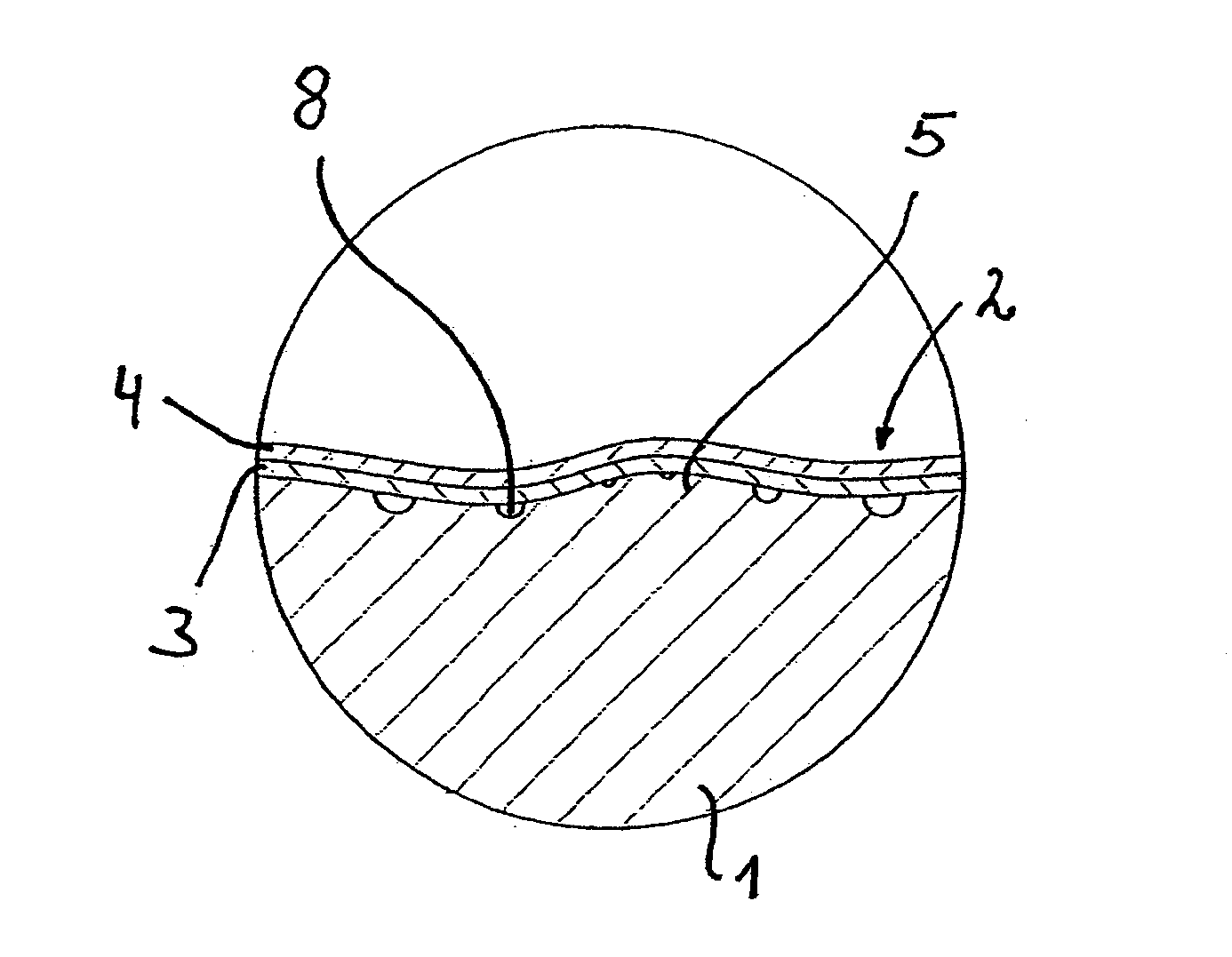

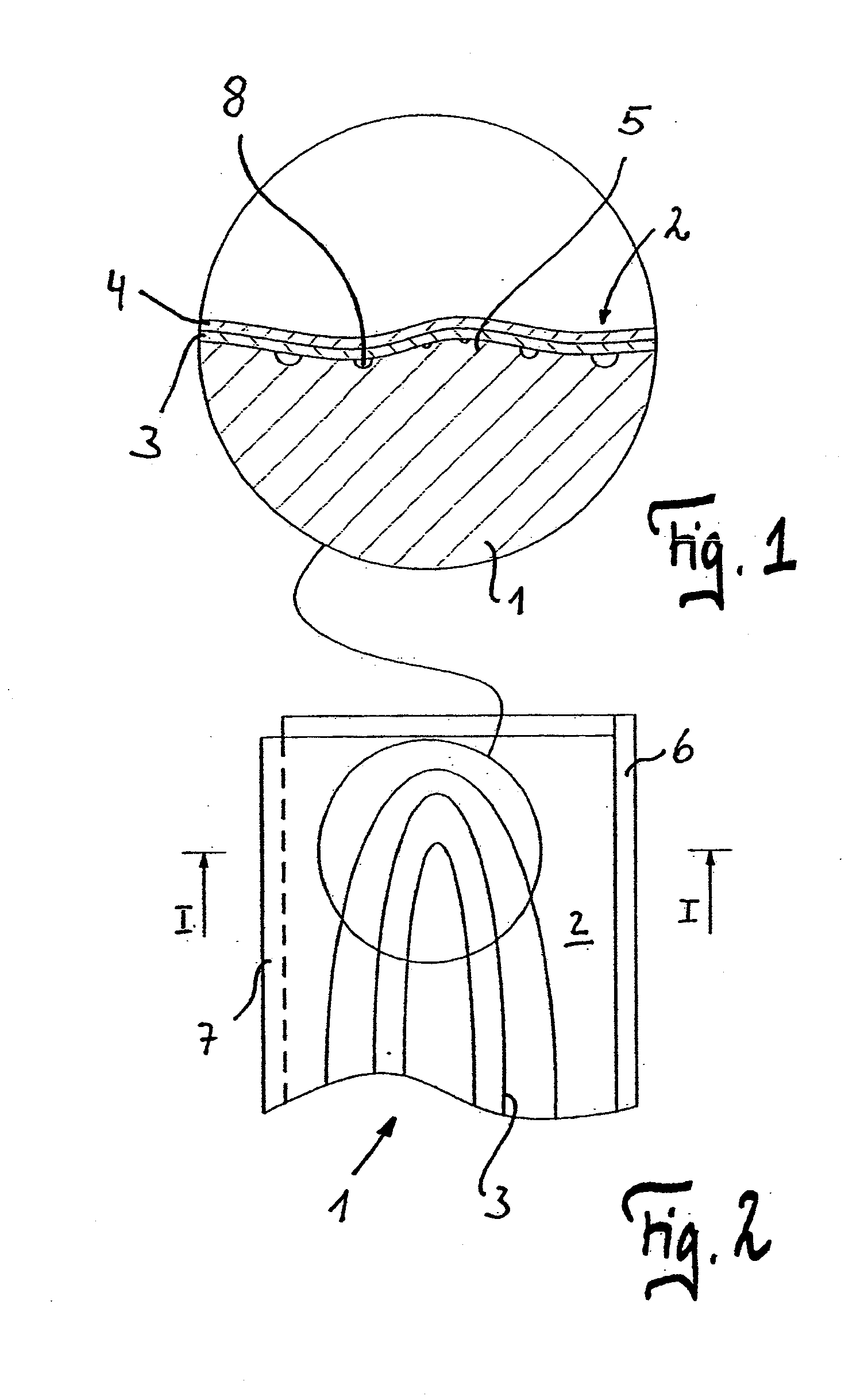

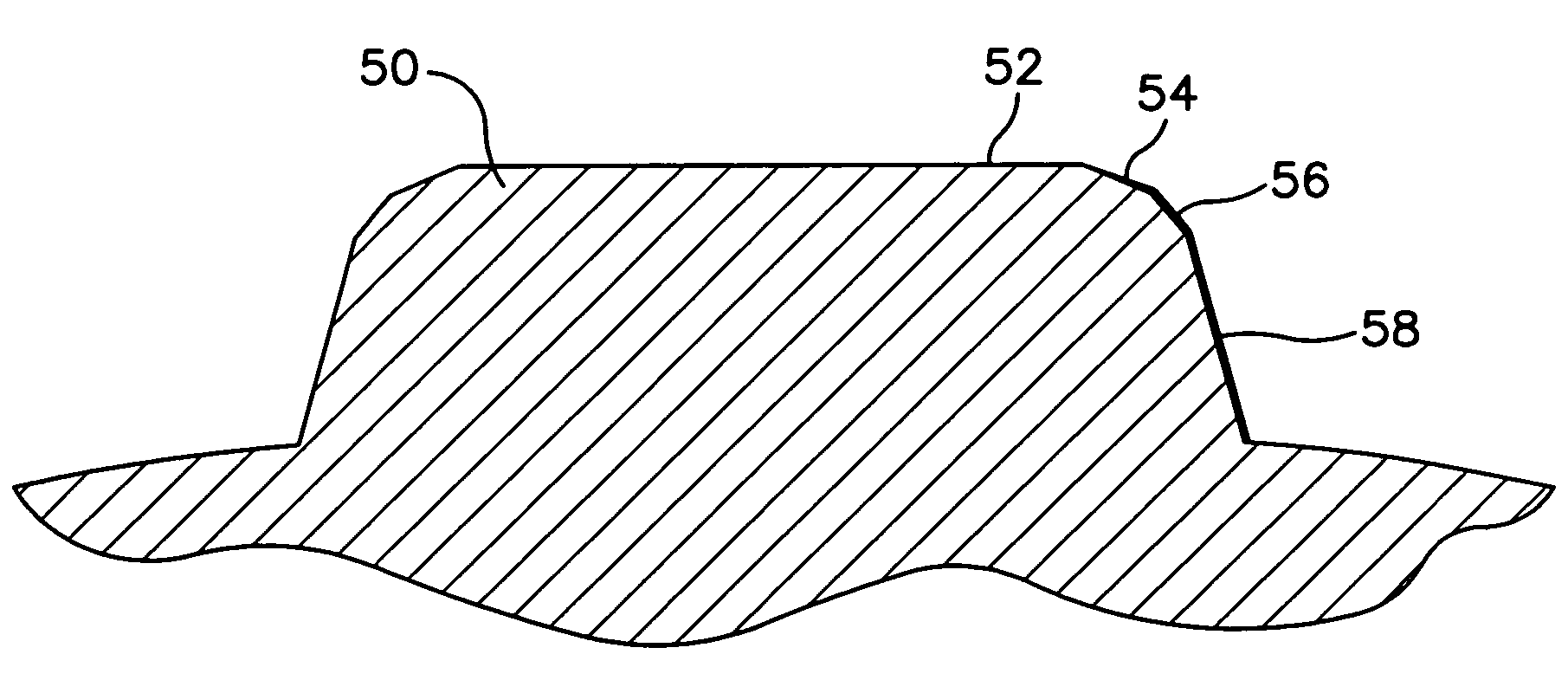

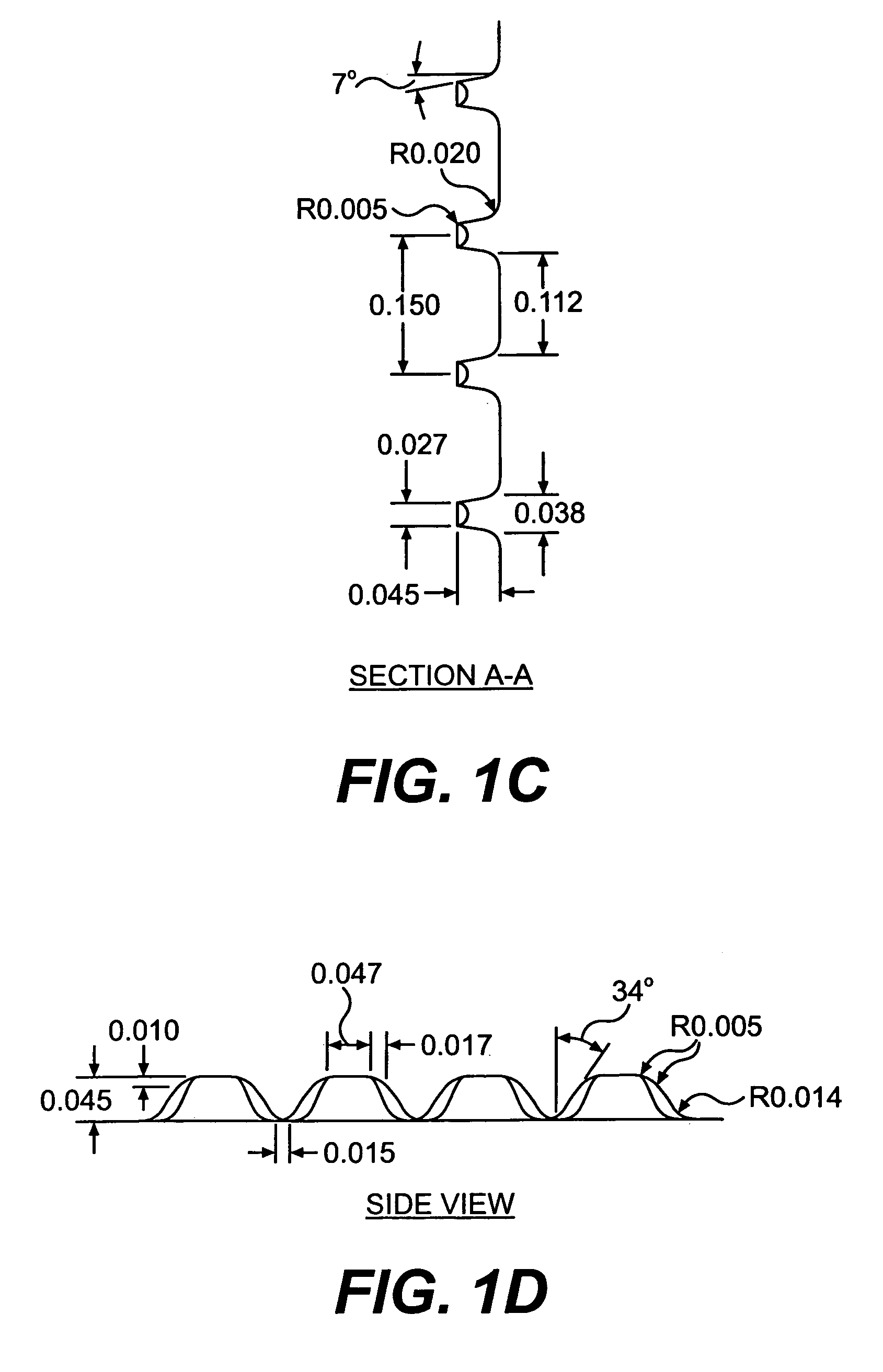

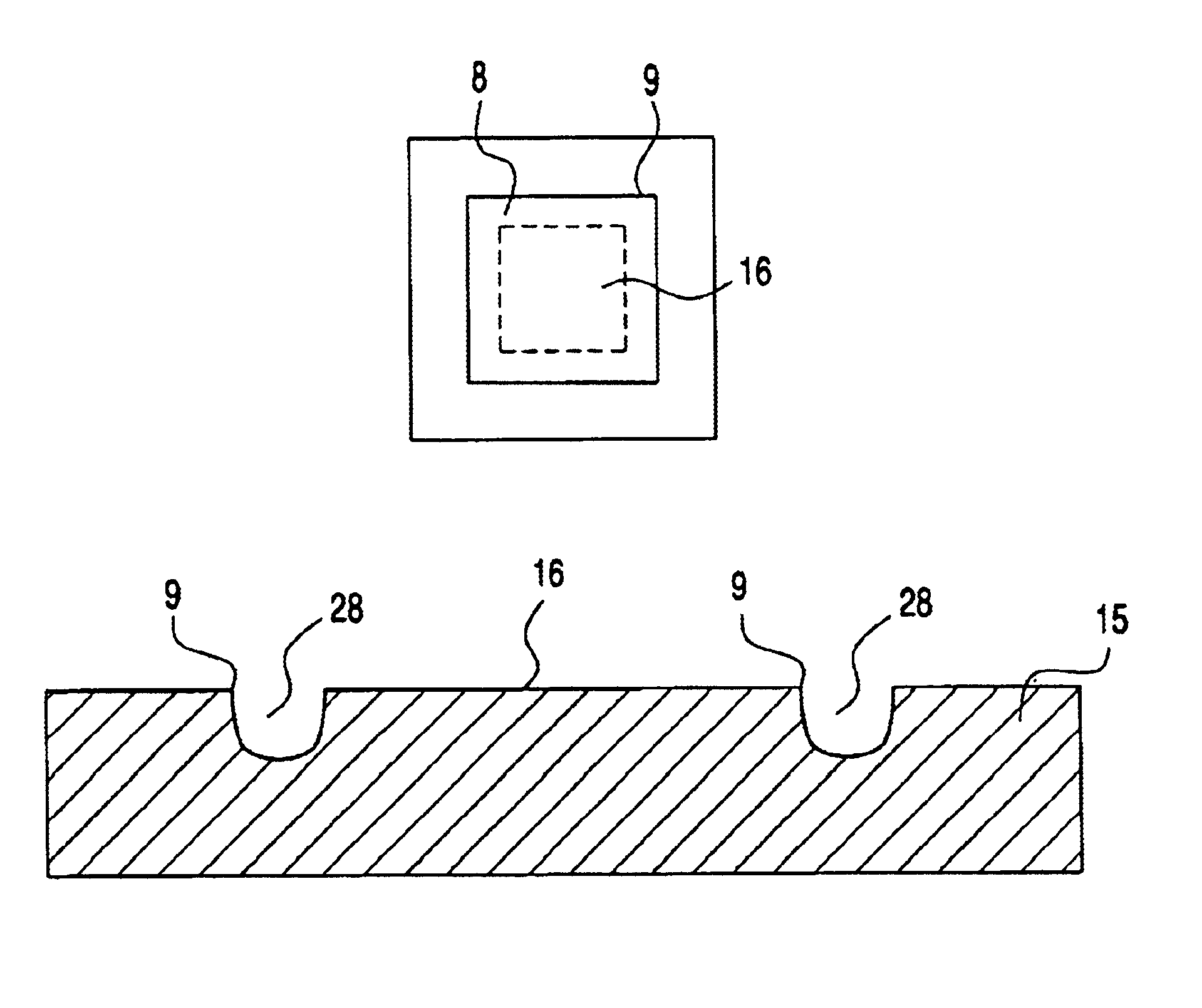

Embossing or bonding device containing facetted impression elements

InactiveUS7971526B2Material minimizationReduce fracturesMechanical working/deformationBoltsBonding processMechanical engineering

Facetted impression elements are disclosed. The impression elements can be located, for instance, on an anvil roll and may be used during an embossing or bonding process. The impression elements include at least two chamfered surfaces that at least partially surround the top surface. The chamfered surfaces are at an angle to the top surface that lower and reduce drag that may occur between the impression element and a sheet of material as the impression element enters and exits the sheet. In one embodiment, the impression element includes a first chamfered surface having an angle of from about 5° to about 40° and a second chamfered surface having an angle of from about 40° to about 70°.

Owner:KIMBERLY-CLARK WORLDWIDE INC

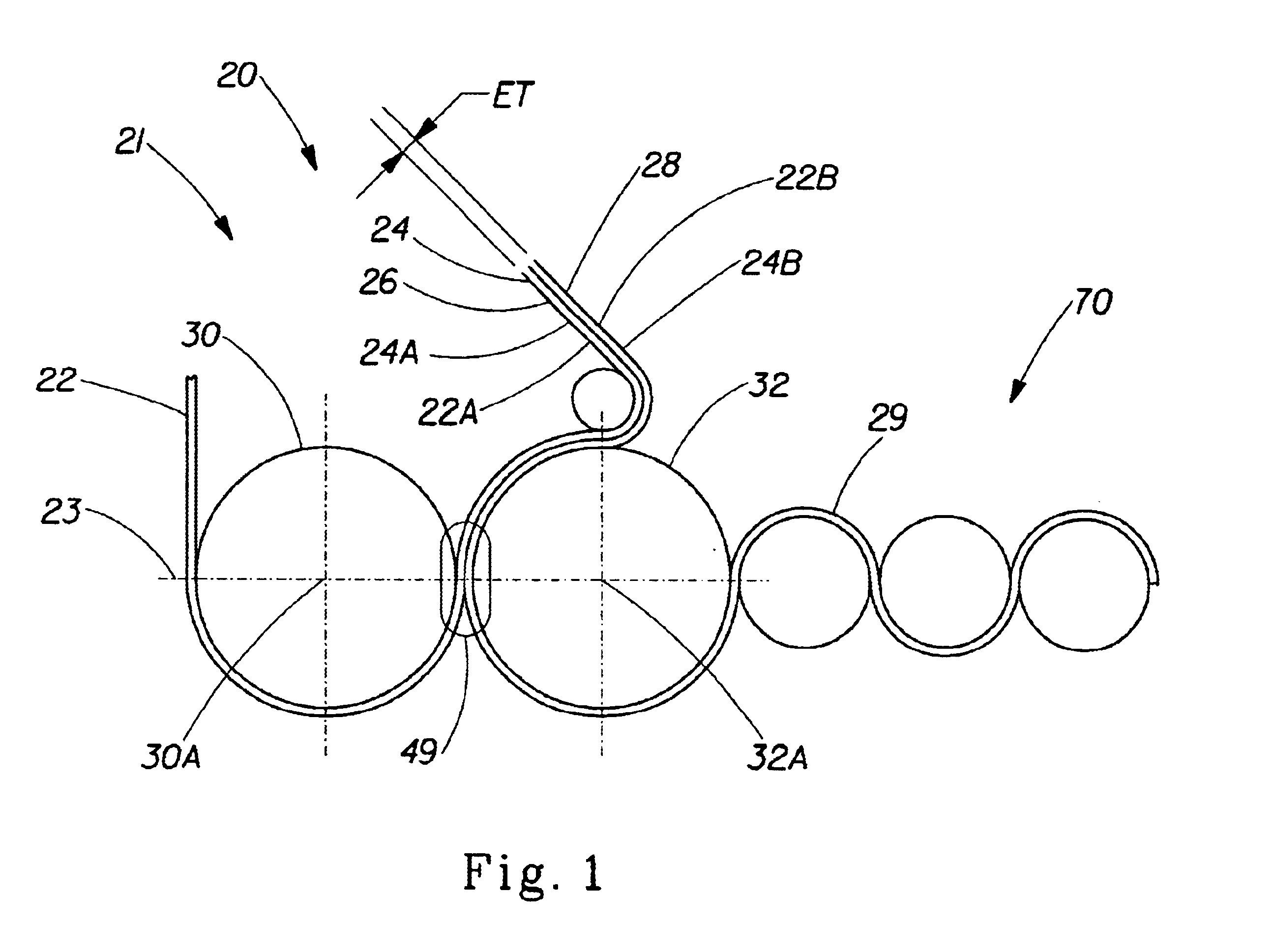

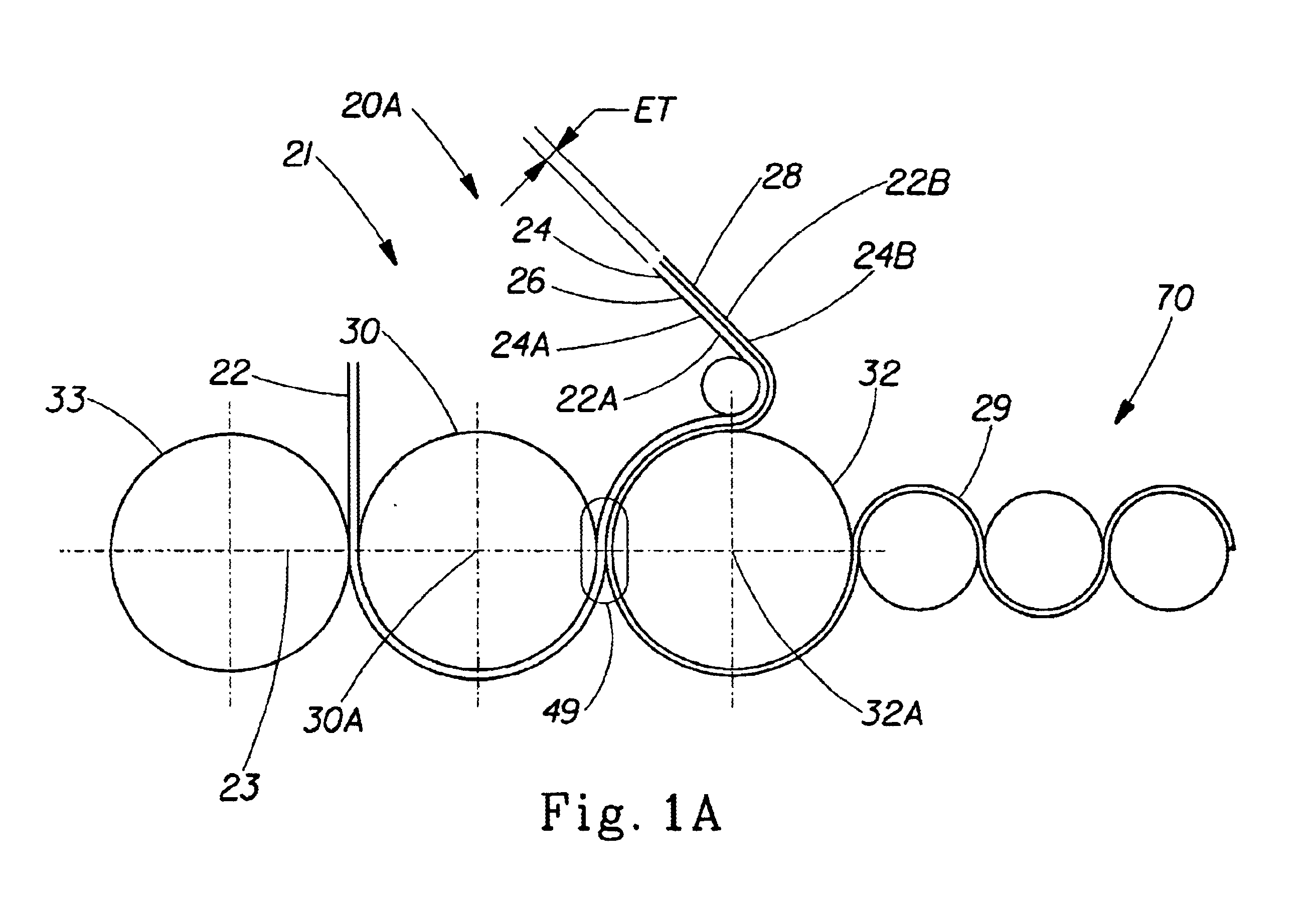

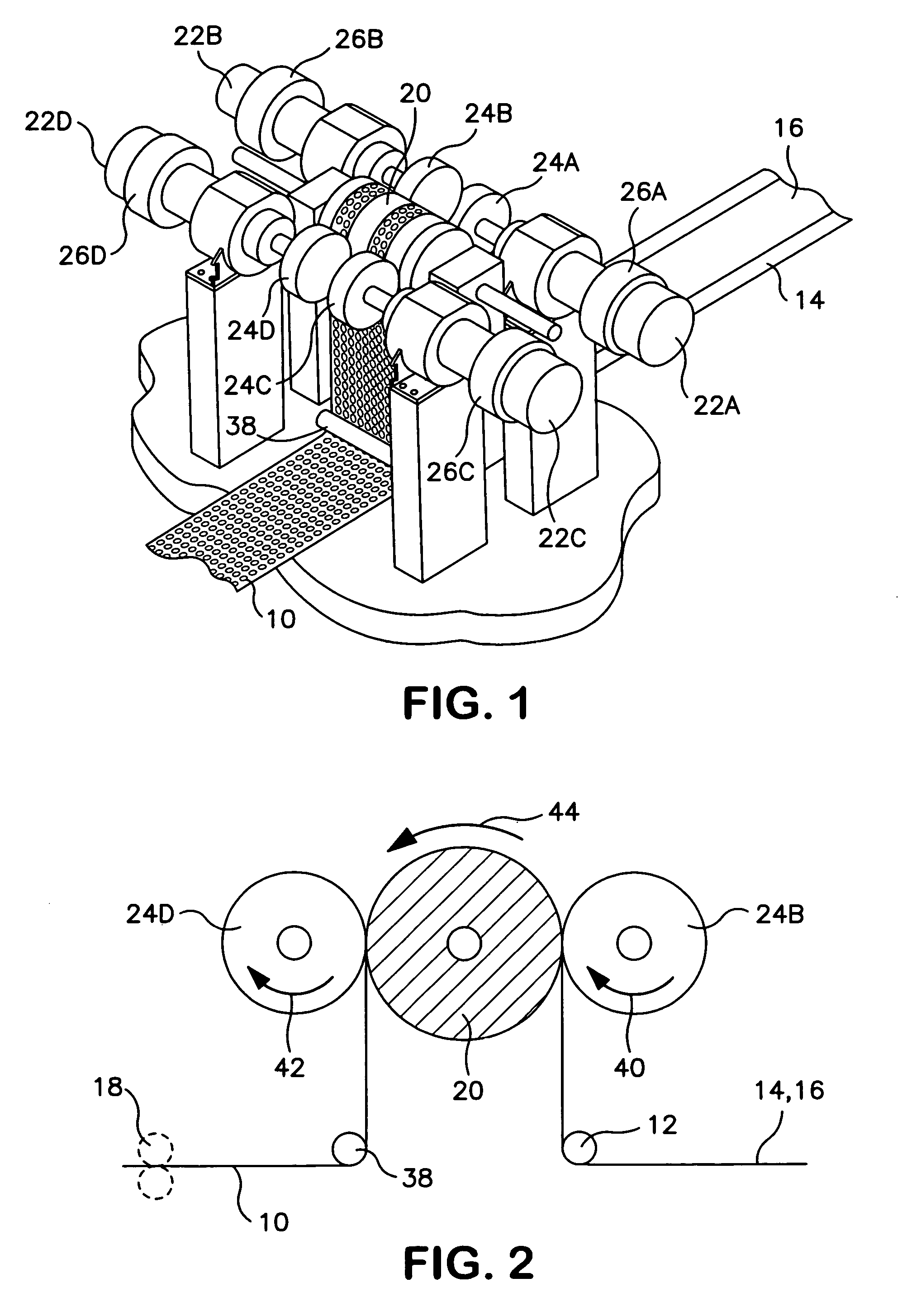

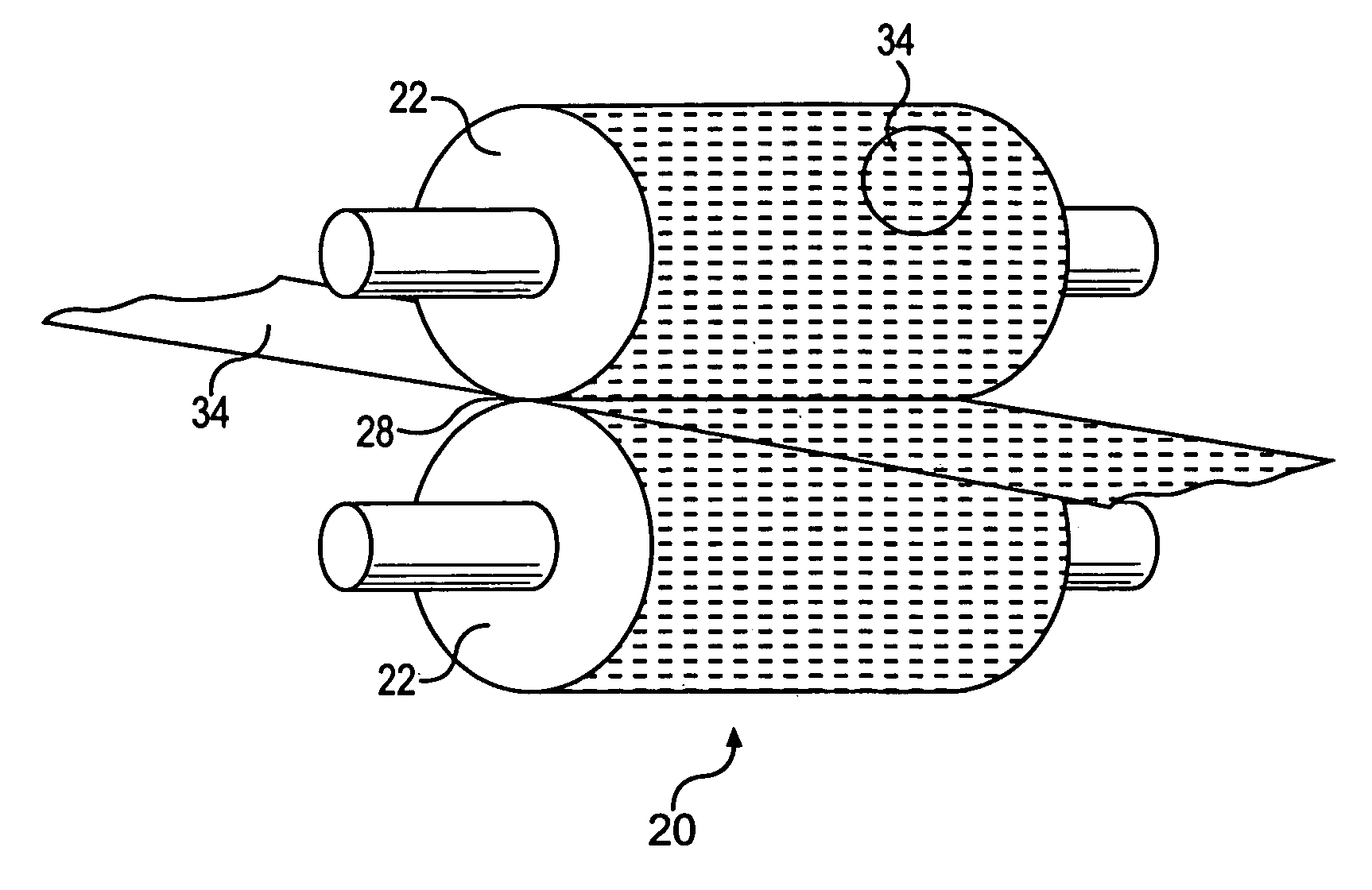

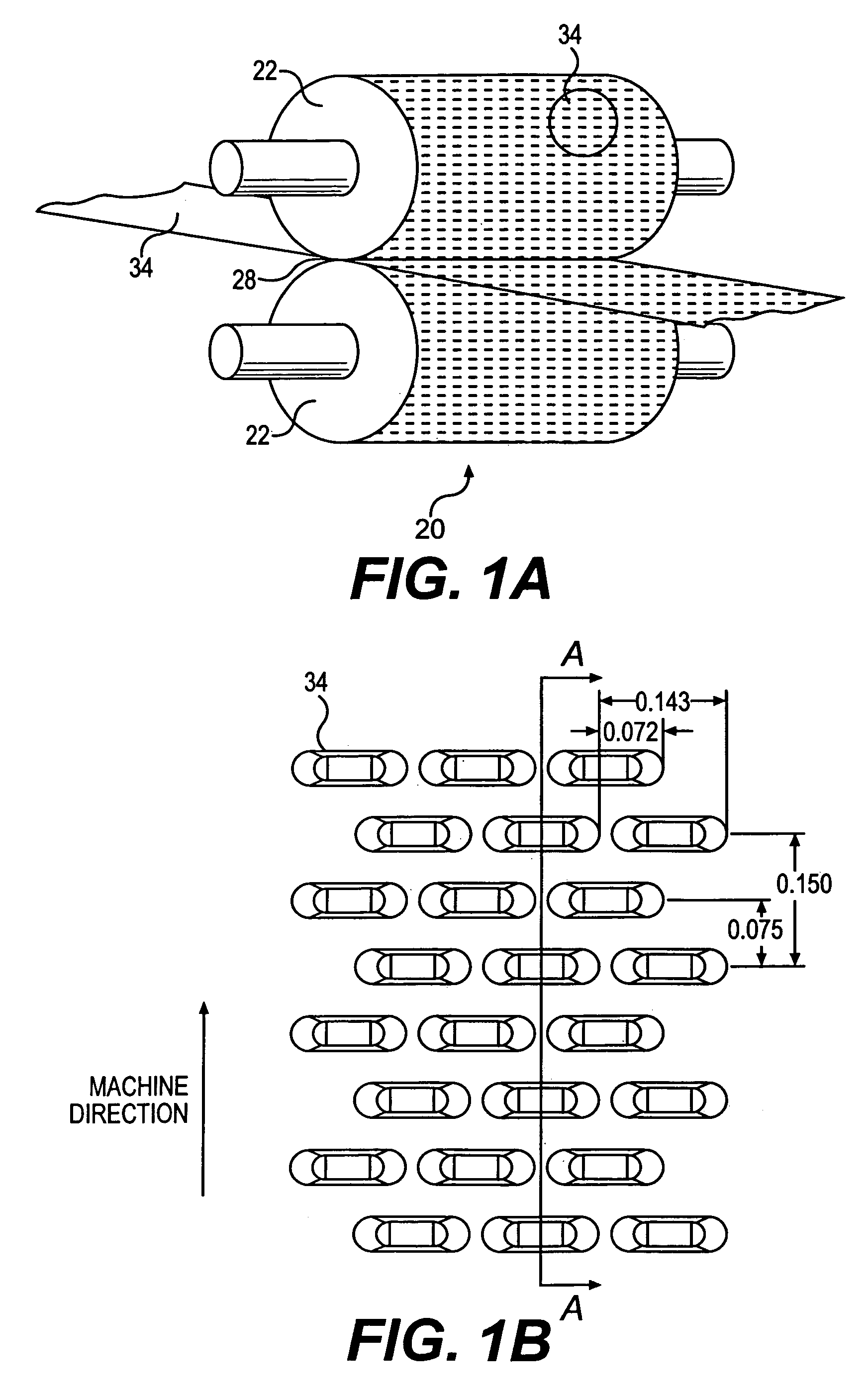

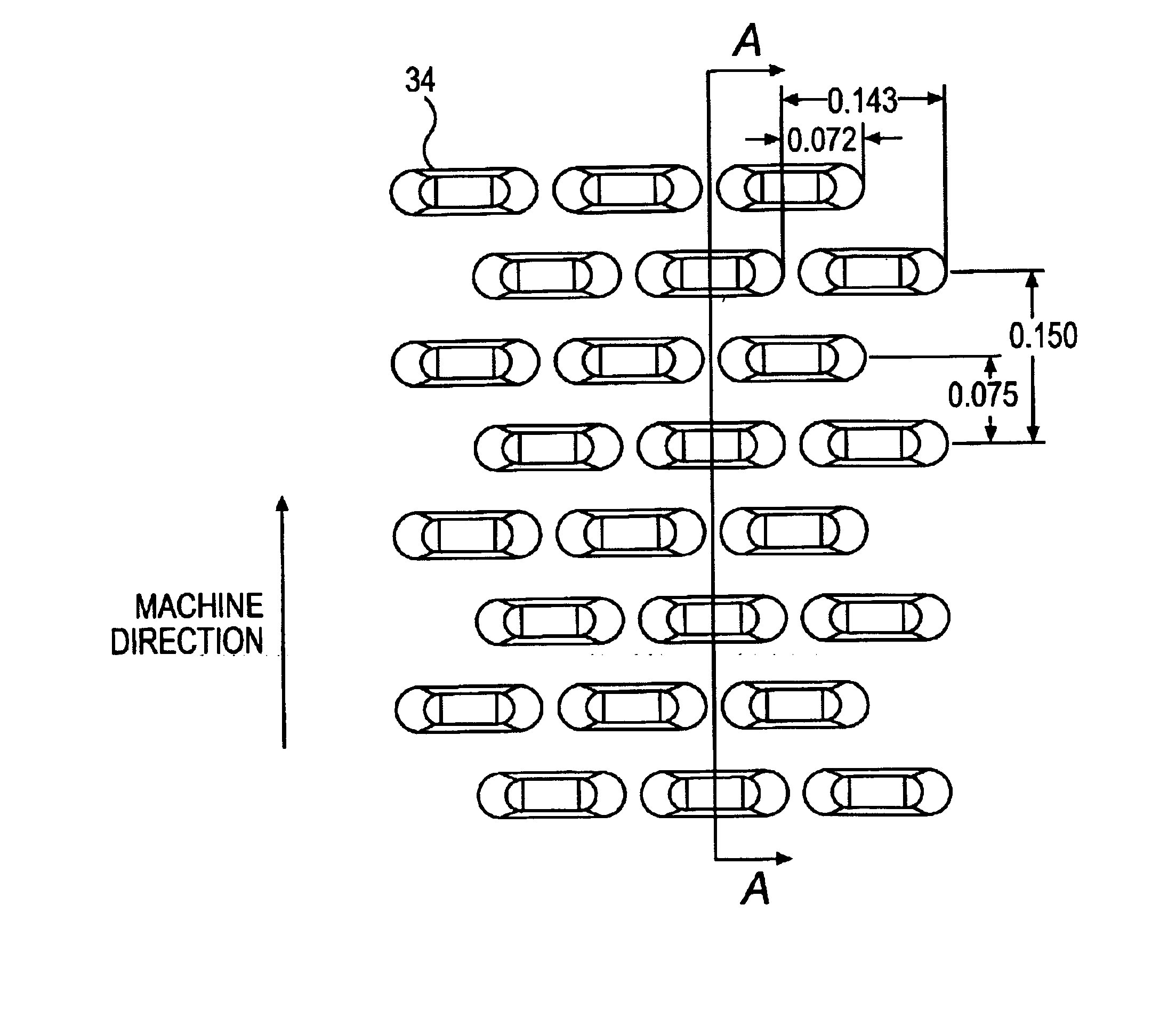

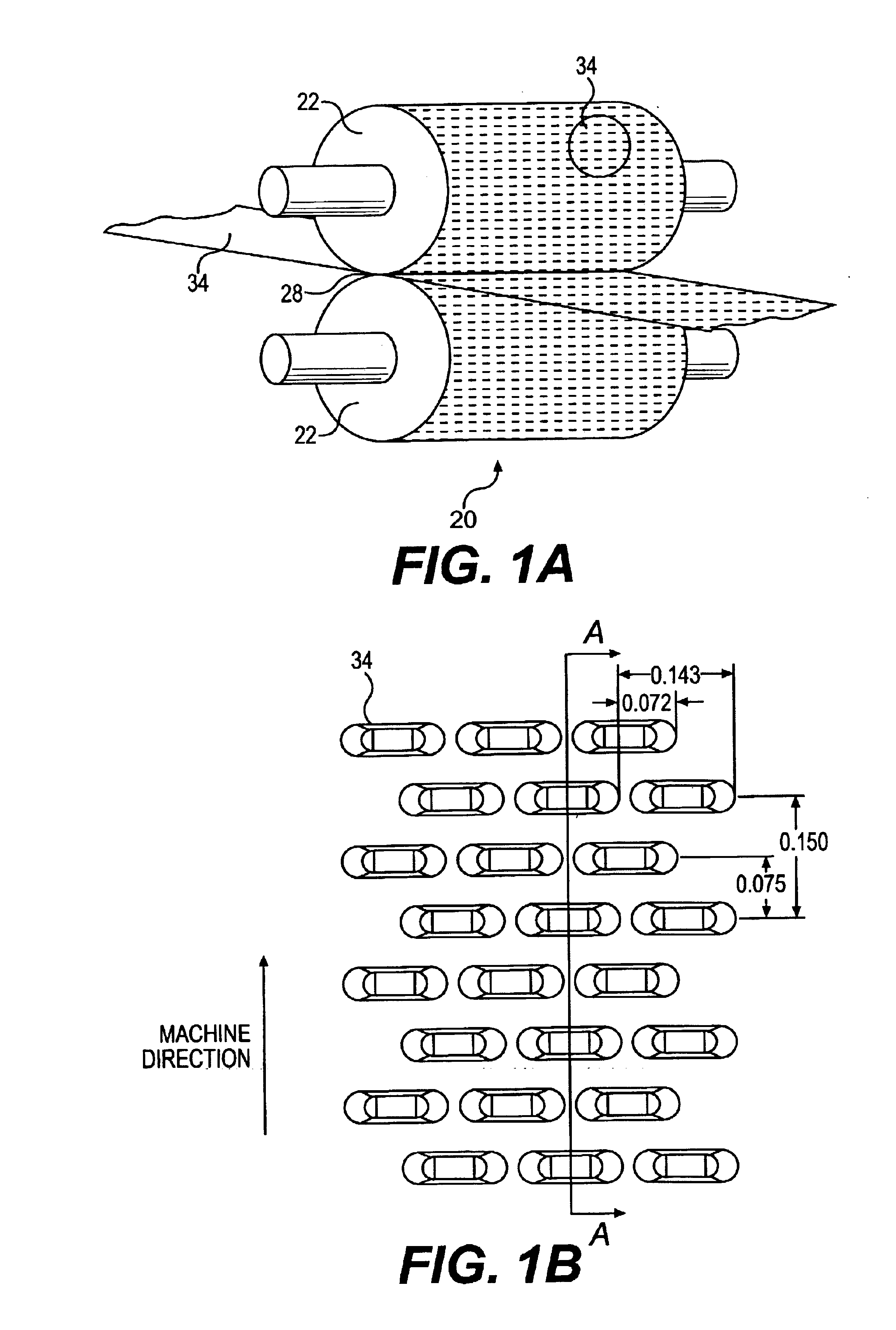

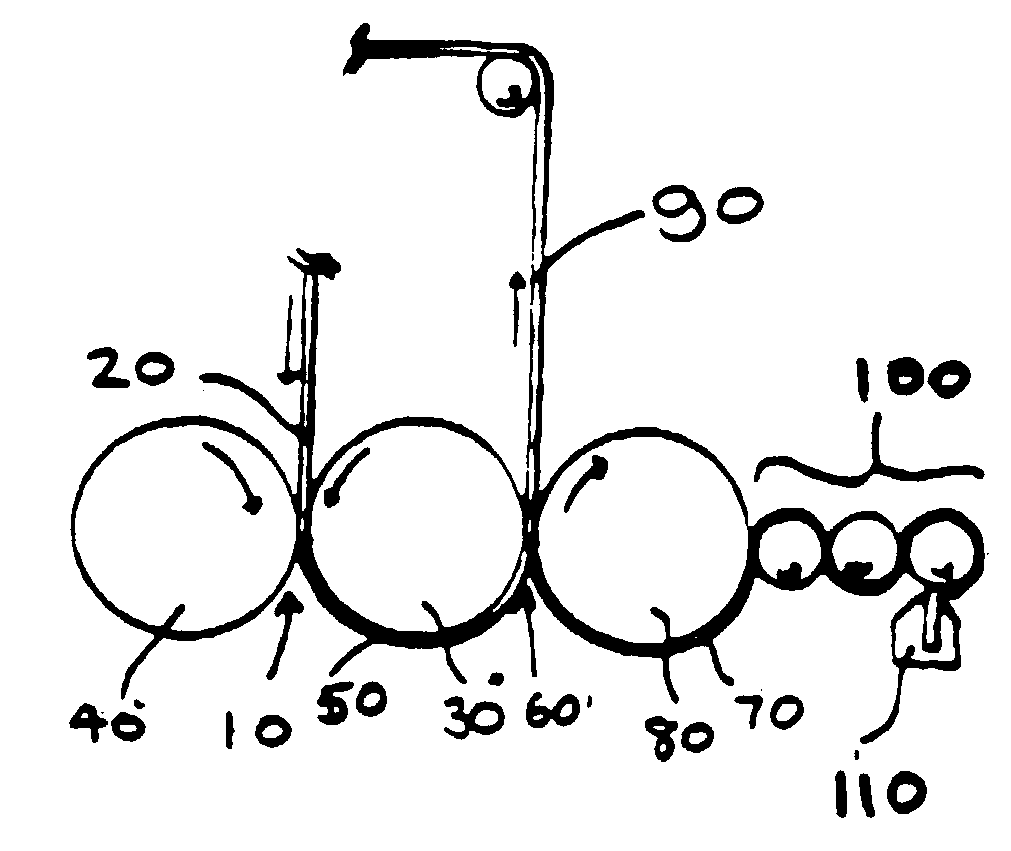

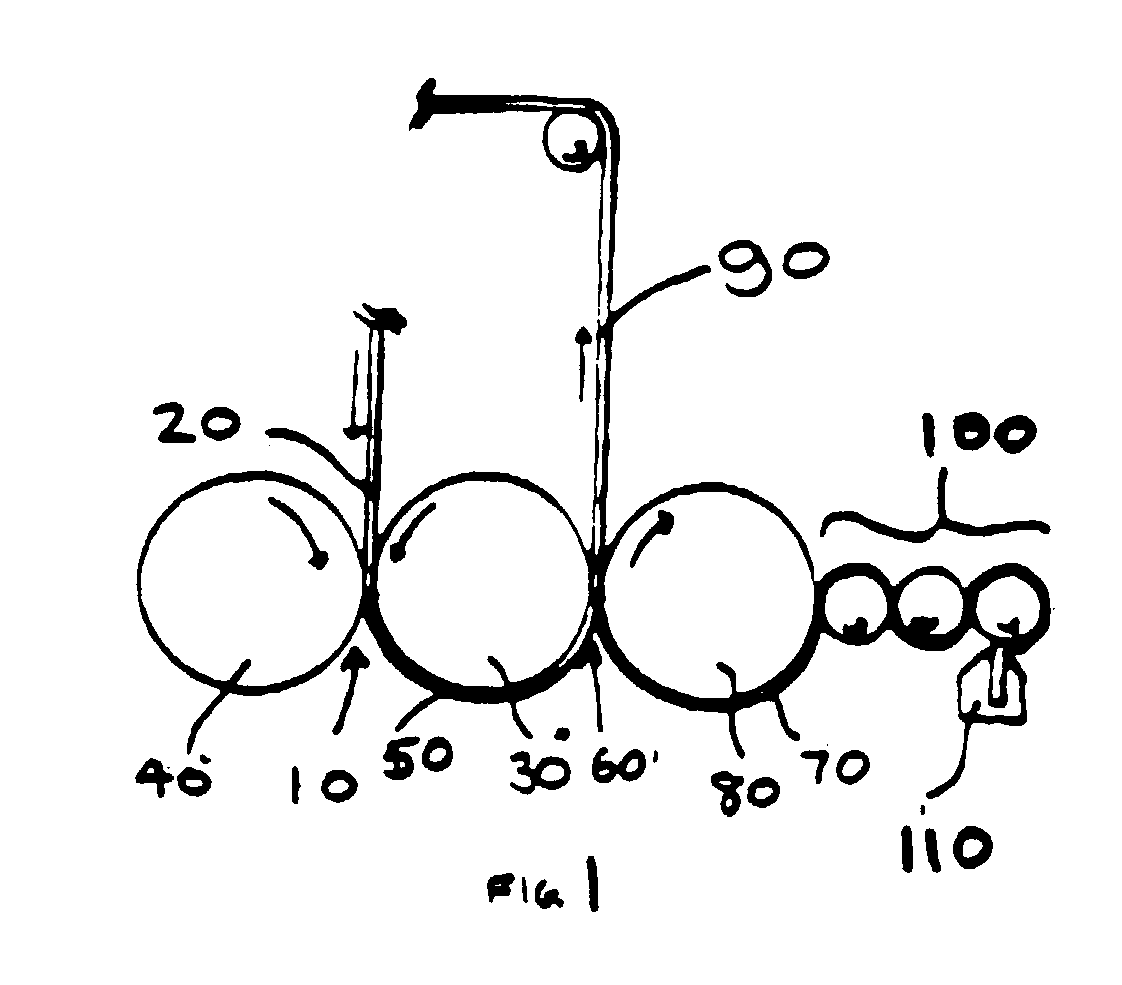

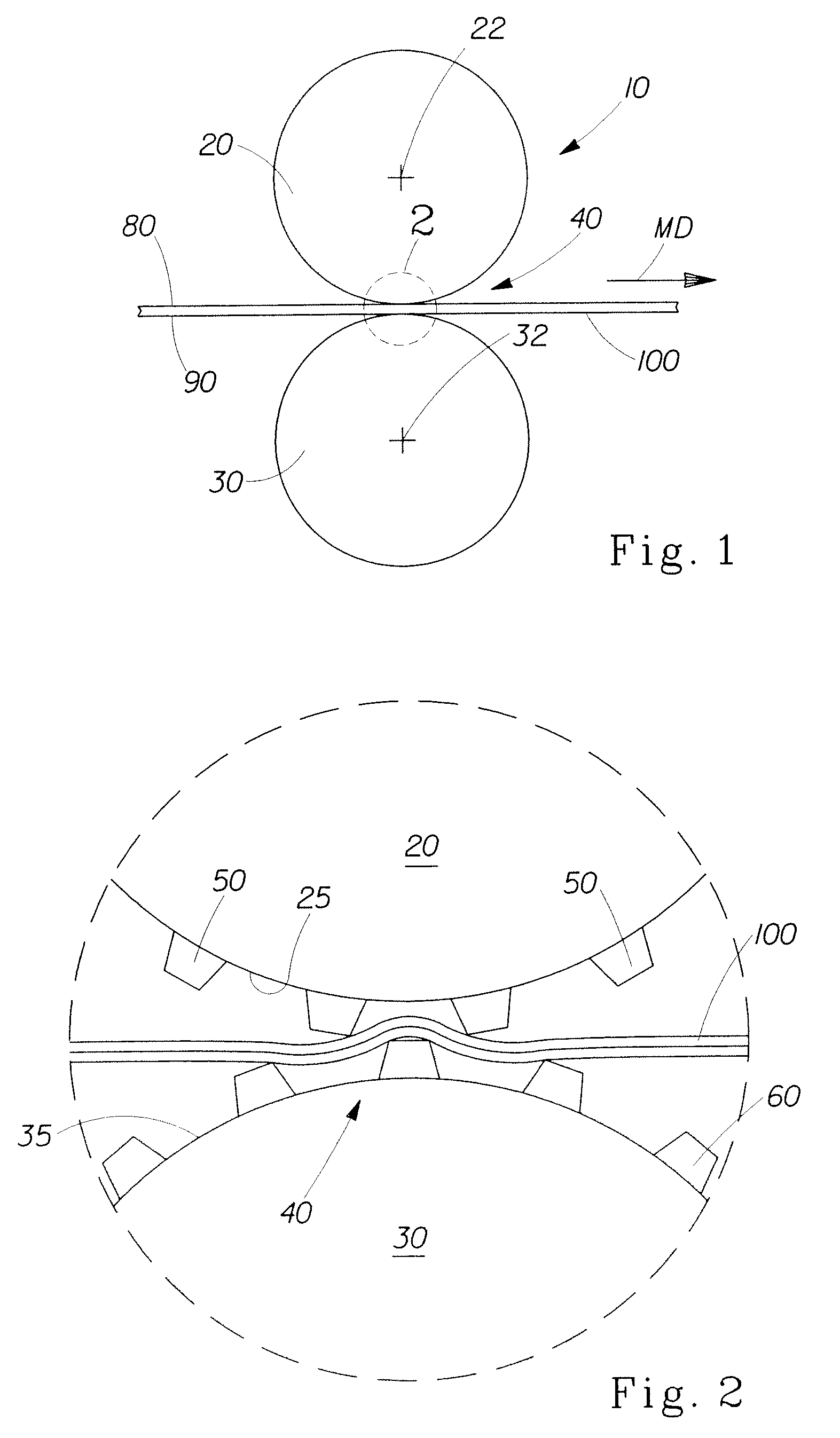

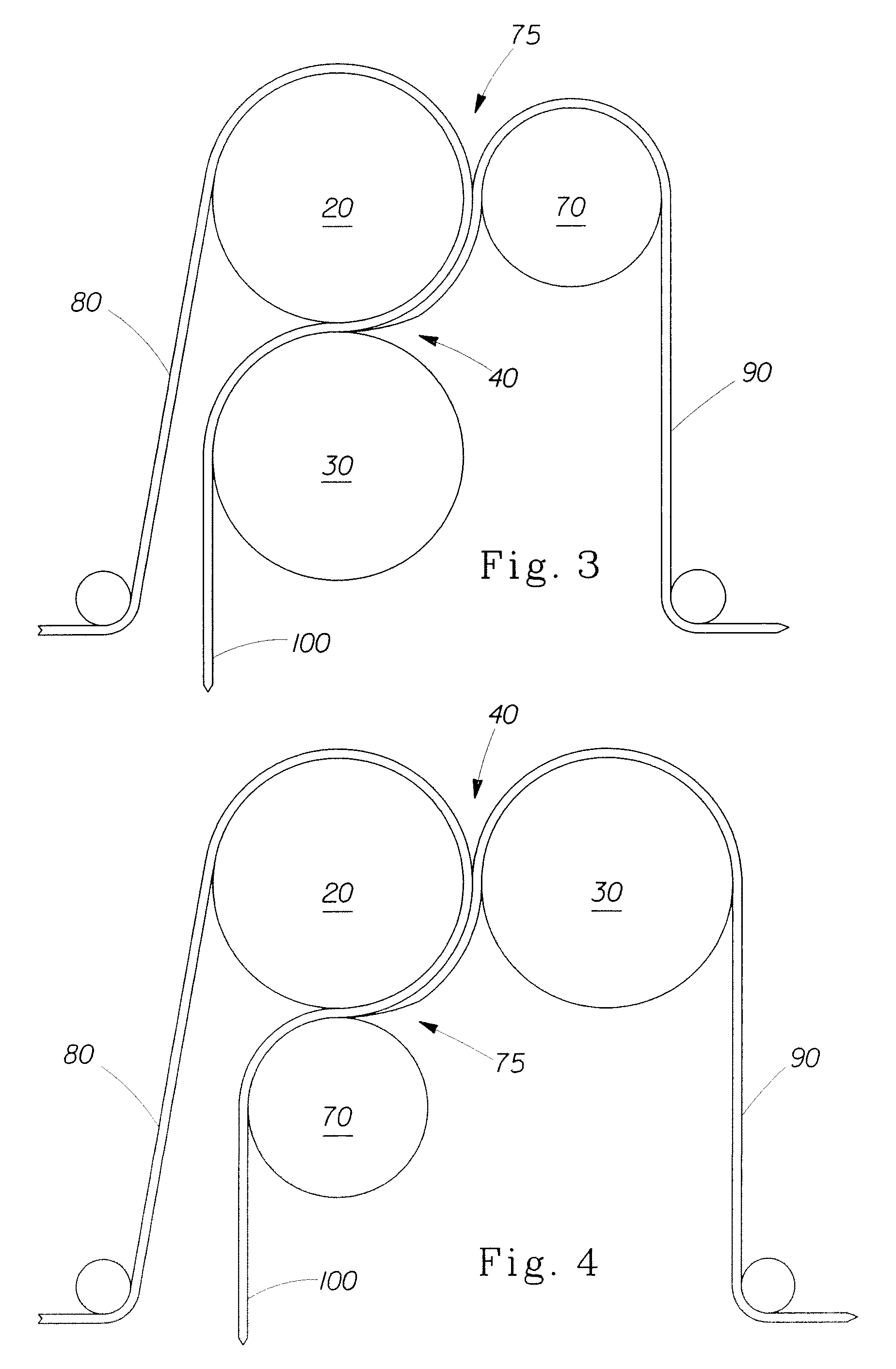

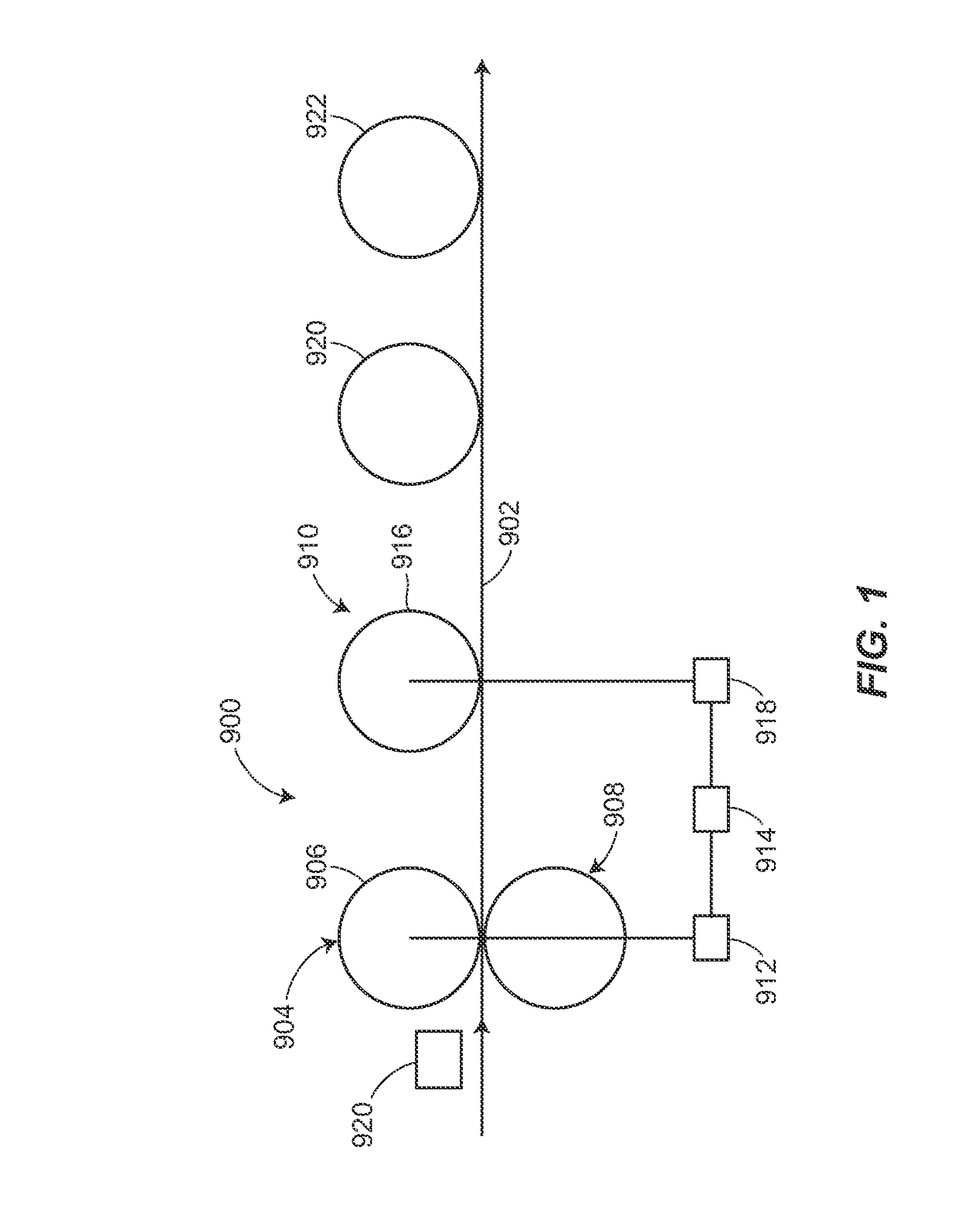

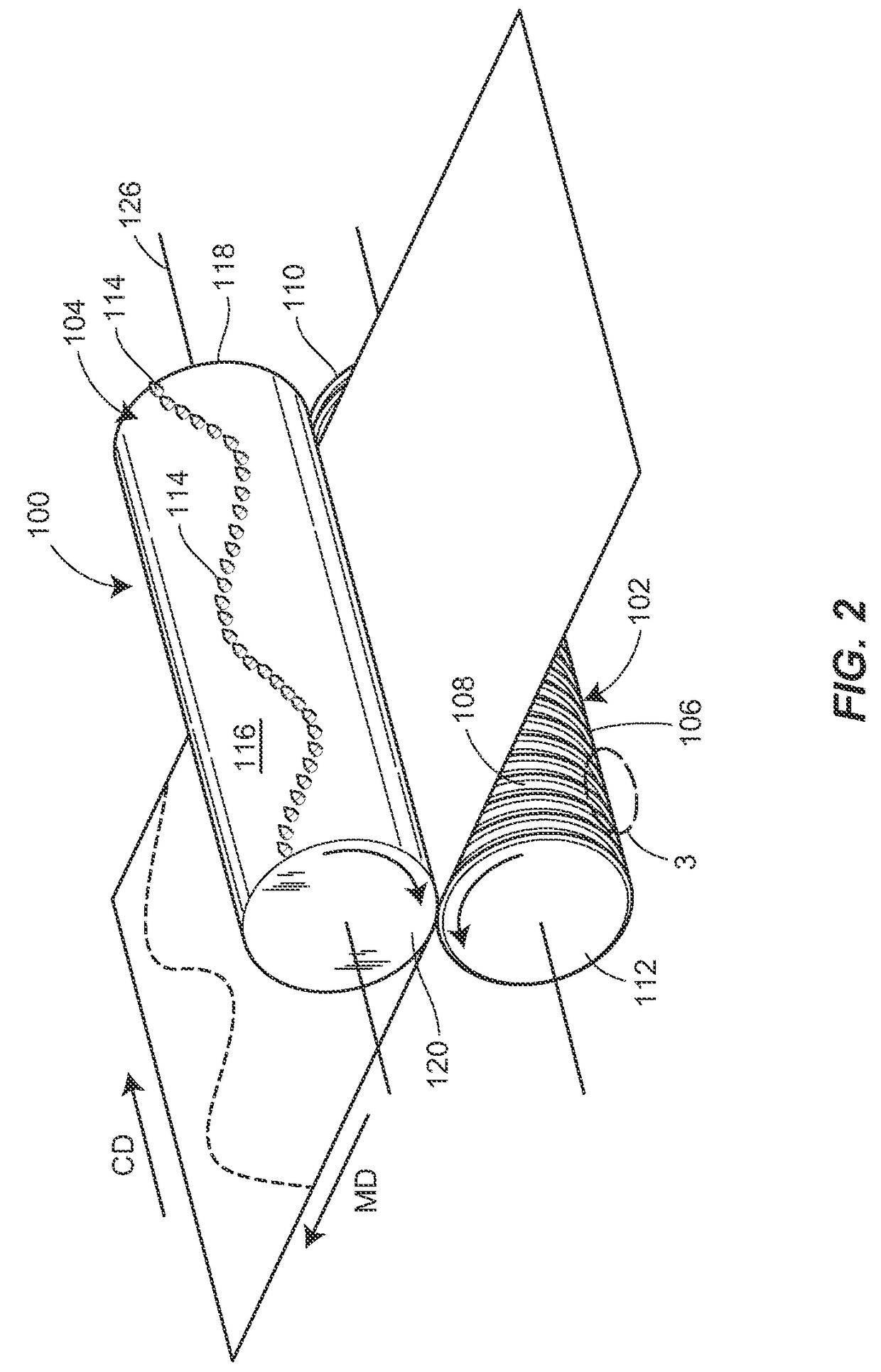

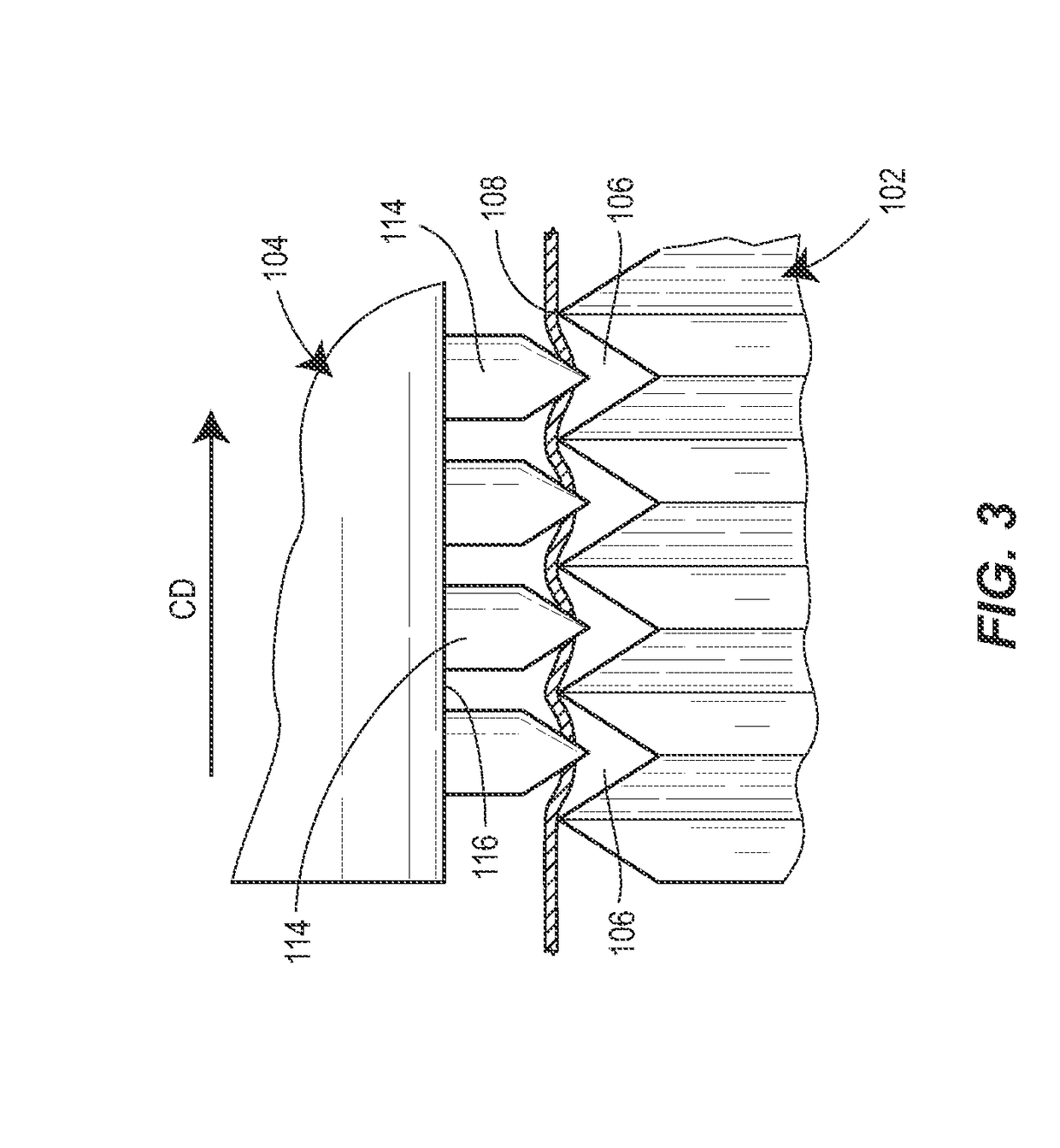

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS7326322B2Prevent degradationIncrease flexibilityNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringUltimate tensile strength

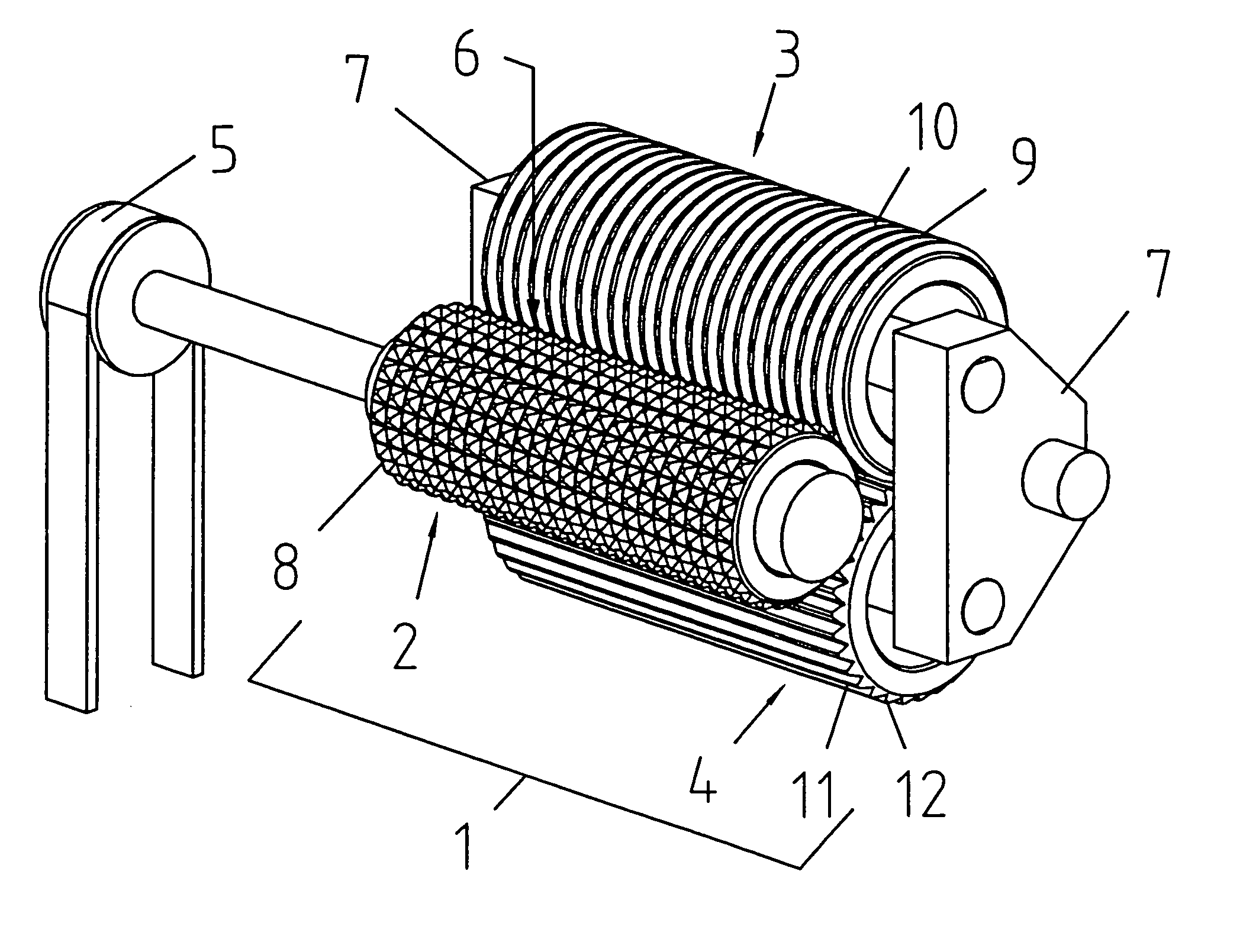

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS6887349B2Reducing tensile ratioPrevent degradationNon-fibrous pulp additionNatural cellulose pulp/paperUltimate tensile strengthMechanical engineering

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

Rapid prototyping and filling commercial pipeline

InactiveUS7383768B2Quick changeCheap and quickAdditive manufacturing apparatusMechanical working/deformationEngineeringPrinting press

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

Elements for embossing and adhesive application

A patterned element for use in an embossing and adhesive application process. The patterened element comprises a material having an pattern disposed thereon, wherein the material comprises a polymer and has a Shore A hardness of greater than about 70, and has a critical surface energy of less than about 30 dynes / cm.

Owner:THE PROCTER & GAMBLE COMPANY

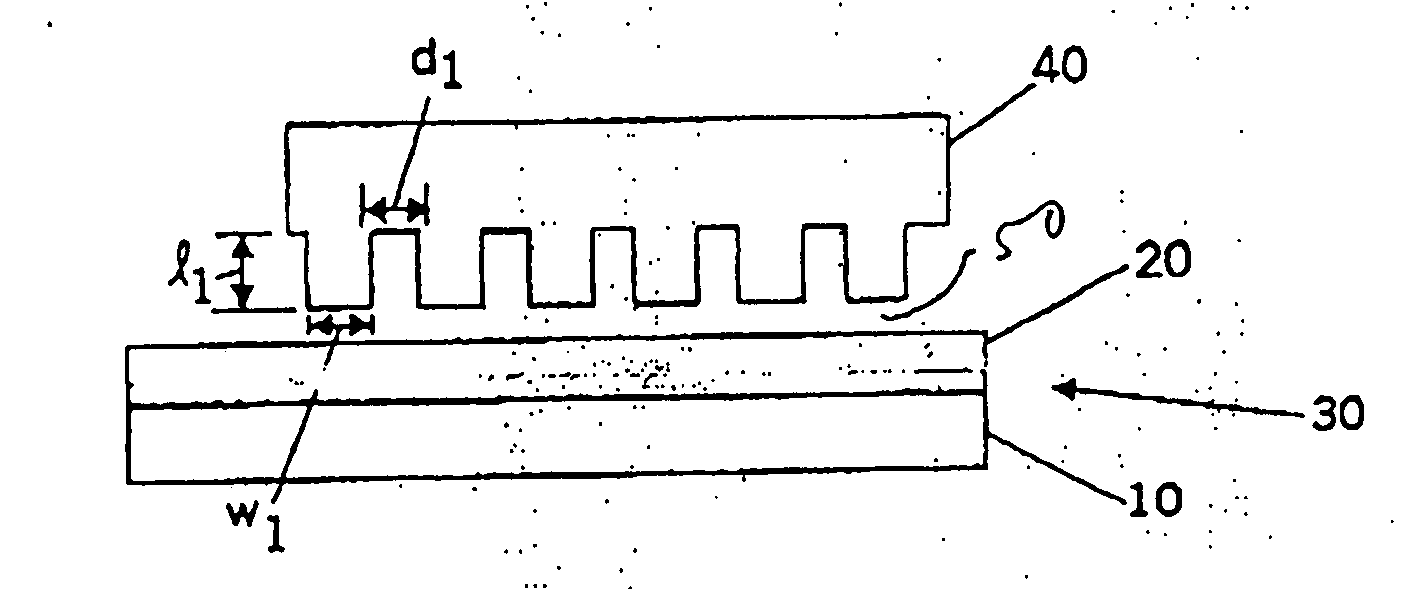

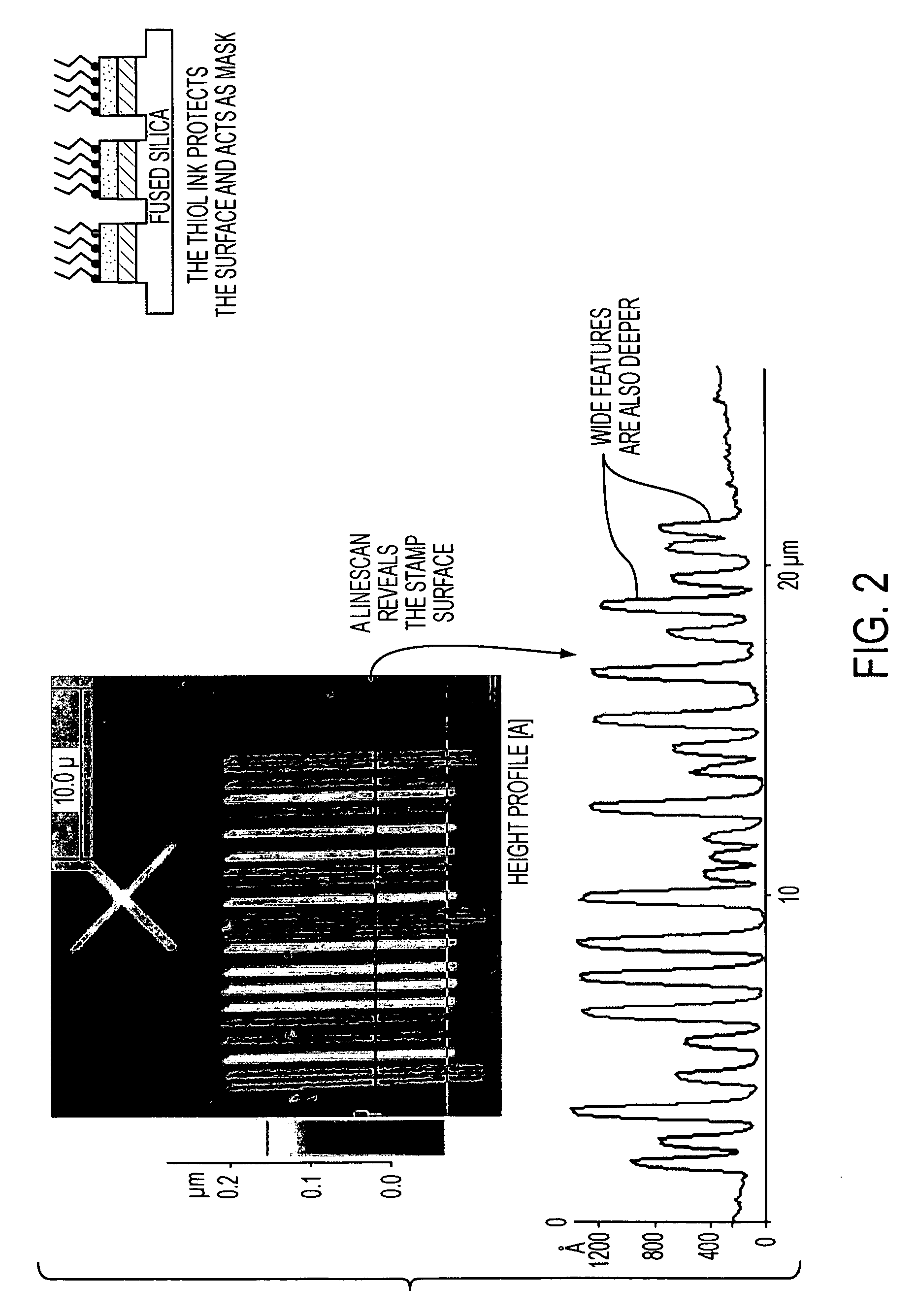

Mold for nano imprinting

InactiveUS6923930B2Avoid reactionSimplified representationMechanical working/deformationDecorative surface effectsOrganic sulfide compoundMetal mold

A metal mold for use in a nano-imprinting process comprises a firmly adhering monomolecular non-sticking layer. The layer was obtained by subjecting the mold to a reaction with a fluoroalkyl compound having a mercapto group. As a result of said reaction, the layer comprises an organic sulfide of said metal.

Owner:OBDUCAT AB SE

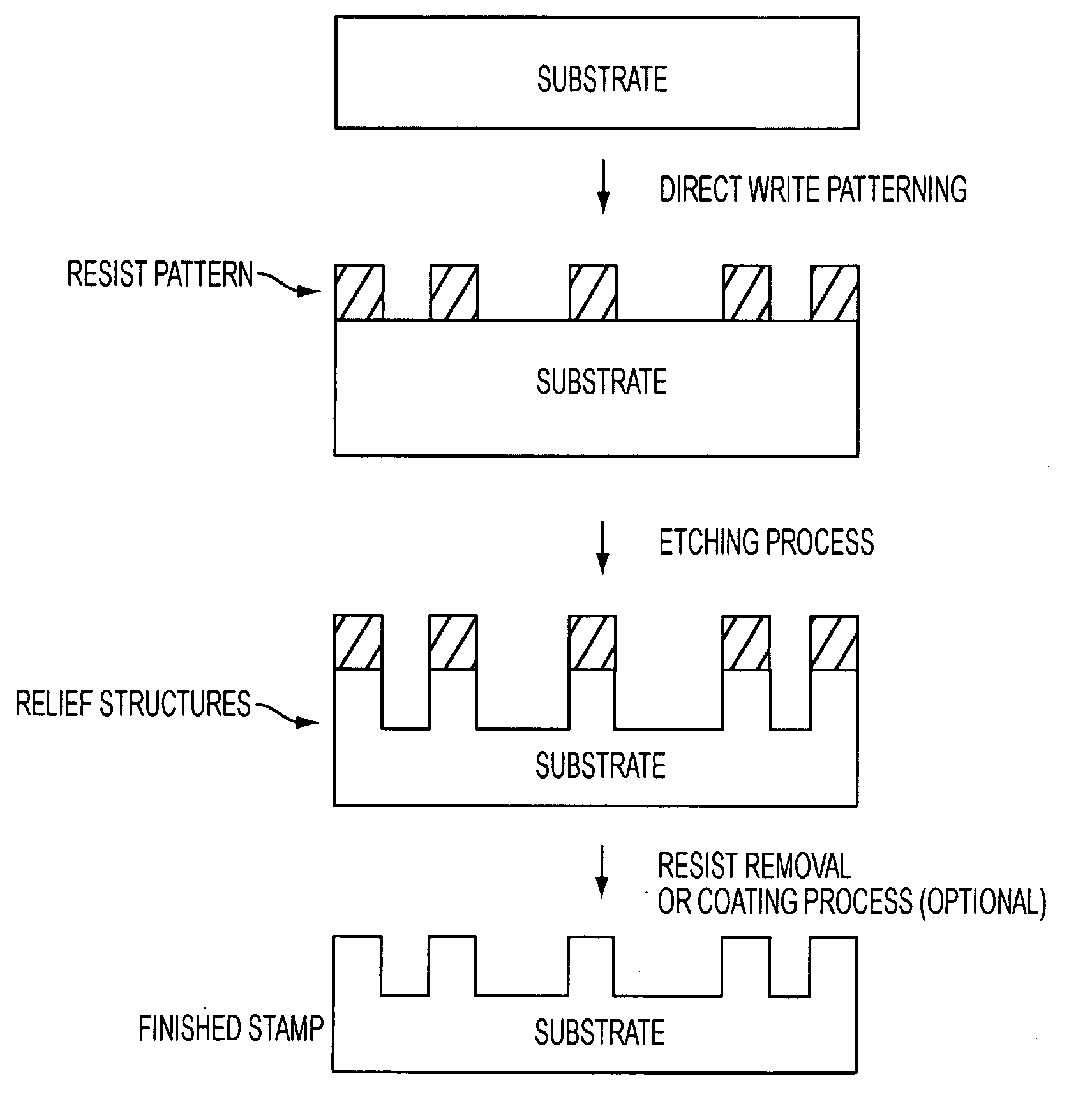

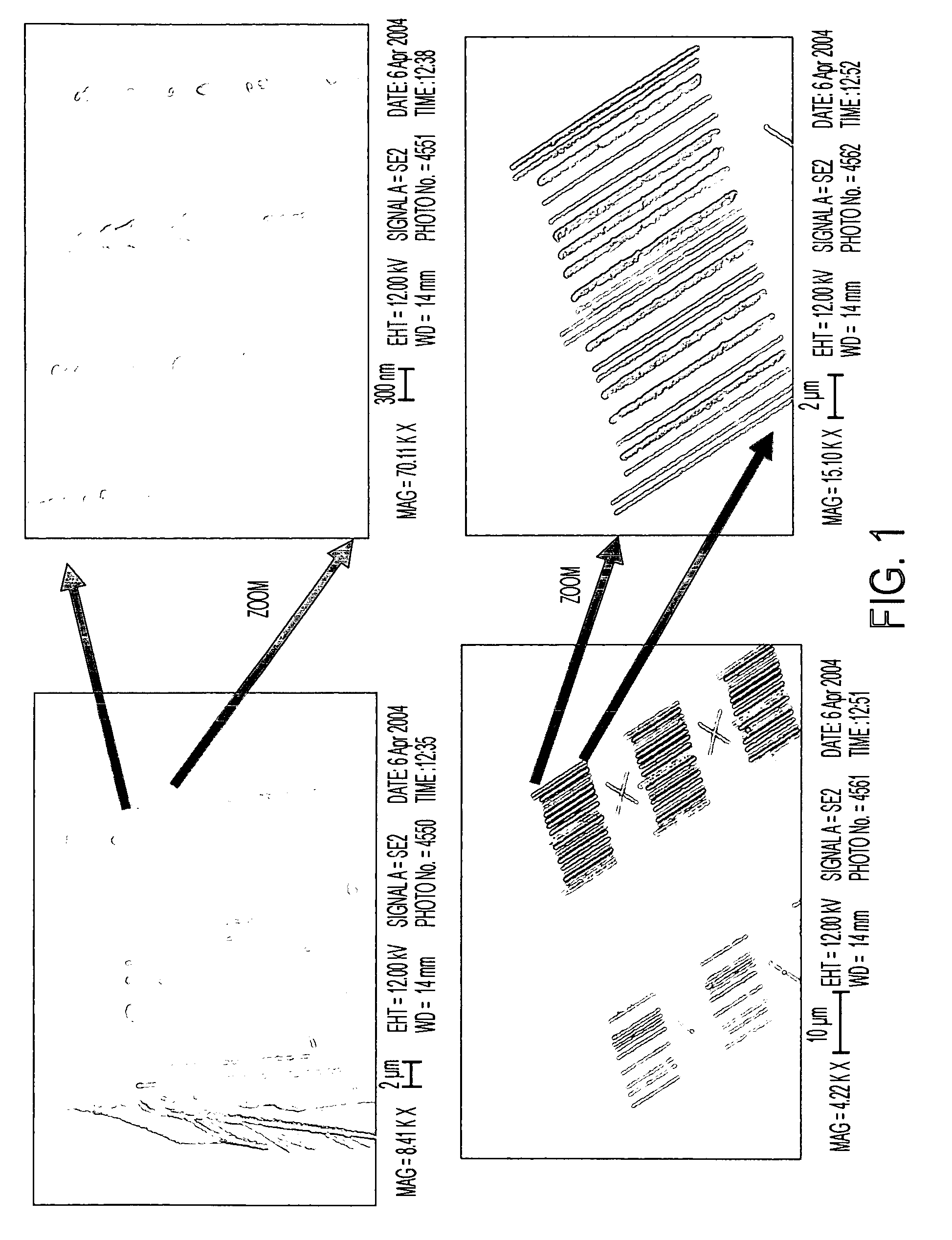

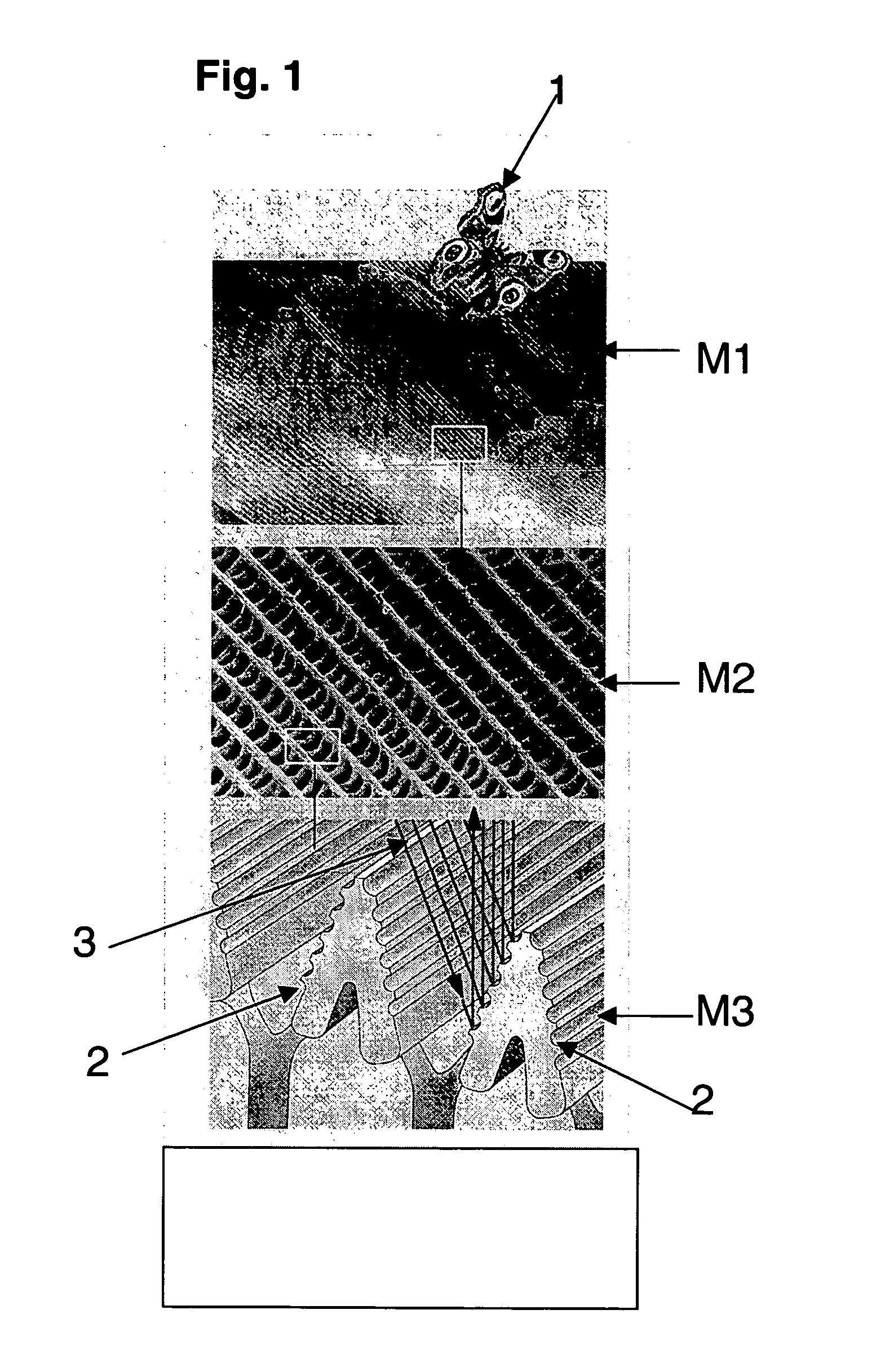

Stamps with micrometer-and nanometer-scale features and methods of fabrication thereof

InactiveUS20100294146A1Digitally marking record carriersMechanical working/deformationMicrometerElectron-beam lithography

Stamps and methods of making stamps for applications in anti-counterfeiting and authentication. The stamps are relatively small in size and feature nanoscale and microscale identification regions and features. High throughput manufacturing and high resolution methods are used to make the stamps including electron beam lithography and optical lithography. Anti-fouling coatings can be applied.

Owner:NANOINK INC +1

Solvent soluble poly(urethane/urea) resins

InactiveUS6723820B1Non-fibrous pulp additionLamination ancillary operationsPolyvinyl butyralNitrocellulose

Solvent based poly(urethane / urea) resins suitable for formulating flexographic and gravure laminating printing ink and coating compositions formed from a poly(urethane) prepolymer solution made from a blend of polymeric diols and diols reacted with diisocyanates and then with diamine in an organic solvent. The resin is prepared by adding the poly(urethane) prepolymer solution at a controlled rate to the diamine in a organic solvent which allows a resin solution to be formed, which may be used in the formulation of laminating printing ink and coating compositions without the need for adjuvants, grinding in polyvinyl butyral or blending with nitrocellulose base.

Owner:SUN CHEM CORP

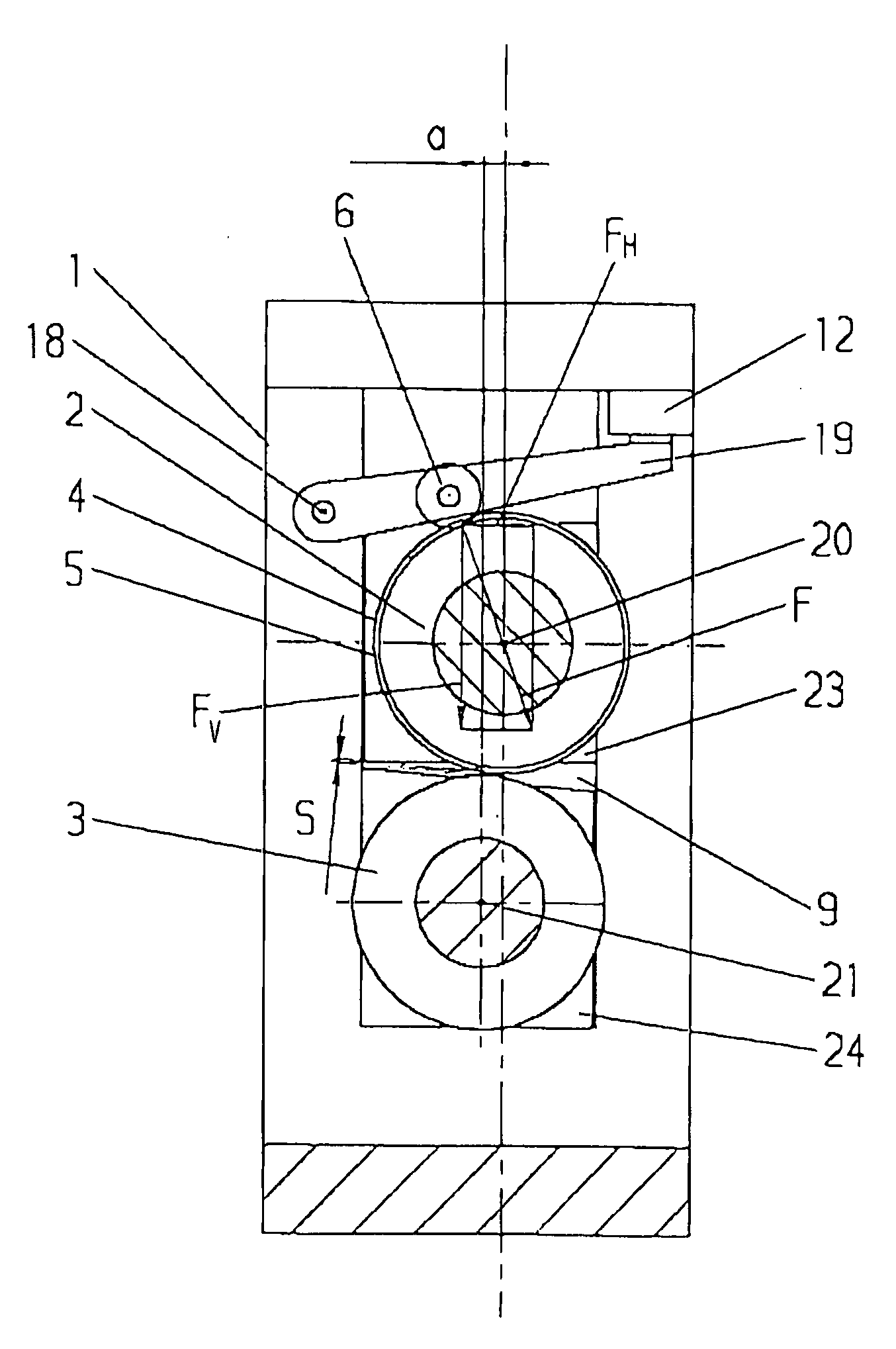

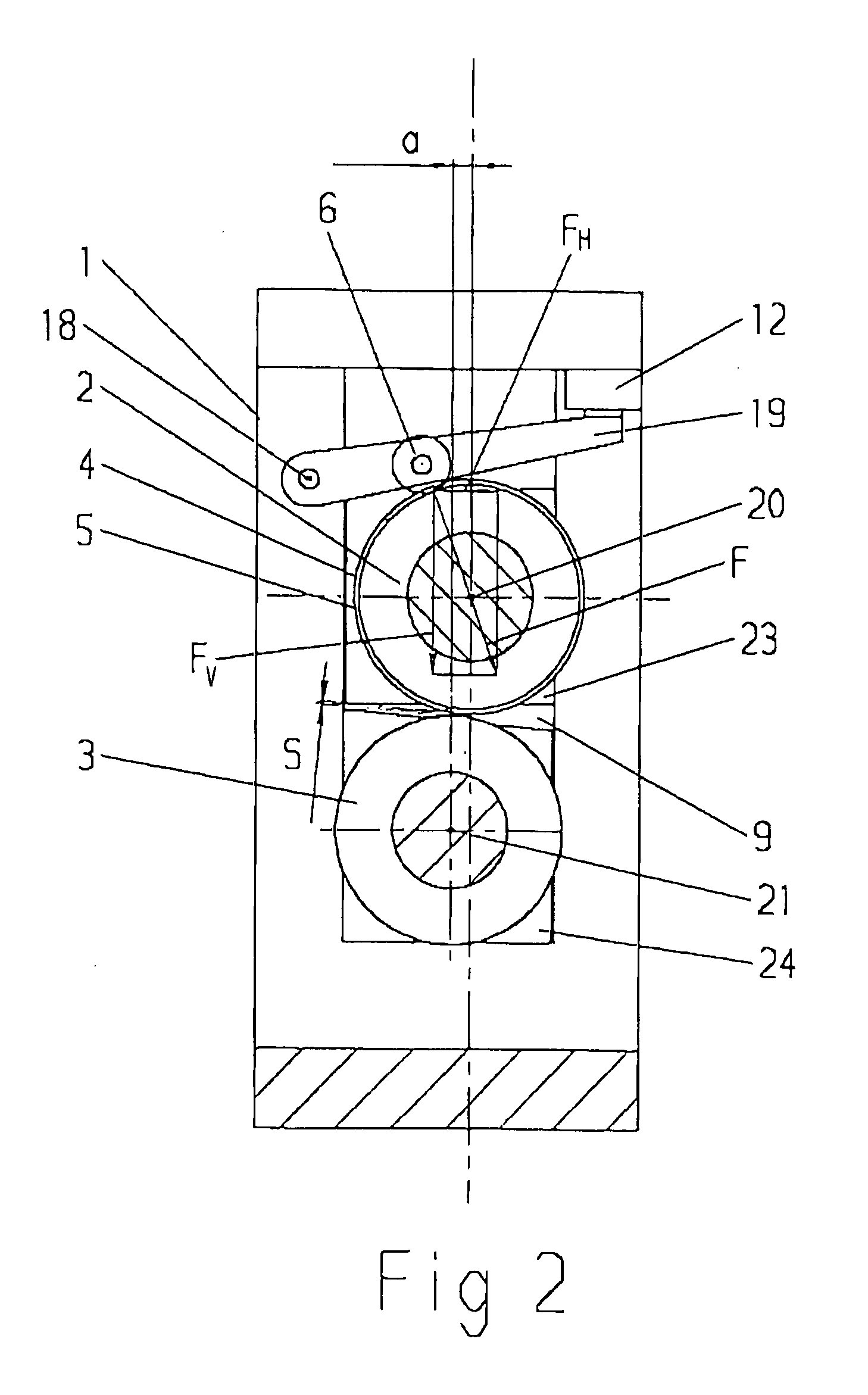

Device for cutting and/or embossing a pre-cut blank or a material web

InactiveUS20080066632A1Uniform widthBending of the counter-roller is advantageously reducedMechanical working/deformationRotary pressesEngineeringGap width

A device for cutting and / or embossing a sheet, a pre-cut blank, or a material web has a cutting and / or embossing roller having a longitudinal axis, which is mounted, at its two ends, in at least one bearing so as to rotate, a counter-roller that works together with the embossing roller and is mounted so as to rotate, and a force application device for applying a pressure force to a circumference surface of the cutting and / or embossing roller. This device makes it possible to set a uniform gap width of the gap between the cutting and / or embossing roller and the counter-roller, over its axial width. The pressure force applied to the circumference surface is diverted by the force application device into the at least one bearing by way of at least one part of the cutting and / or embossing roller, so that the pressure force is not applied to the counter-roller.

Owner:WINKLER DUNNEBIER GMBH

Bonding of target tiles to backing plate with patterned bonding agent

A target assembly including a plurality of target tiles bonded to a backing plate by adhesive, for example of indium or conductive polymer, filled into recesses in the backing plate formed beneath each of the target tiles. A sole peripheral recess formed as a rectangular close band may be formed inside the tile periphery. Additional recesses may be formed inside the peripheral recess, preferably symmetrically arranged about perpendicular bisectors of rectangular tiles. The depth and width of the recesses may be varied to control the amount of stress and the stress direction.

Owner:APPLIED MATERIALS INC

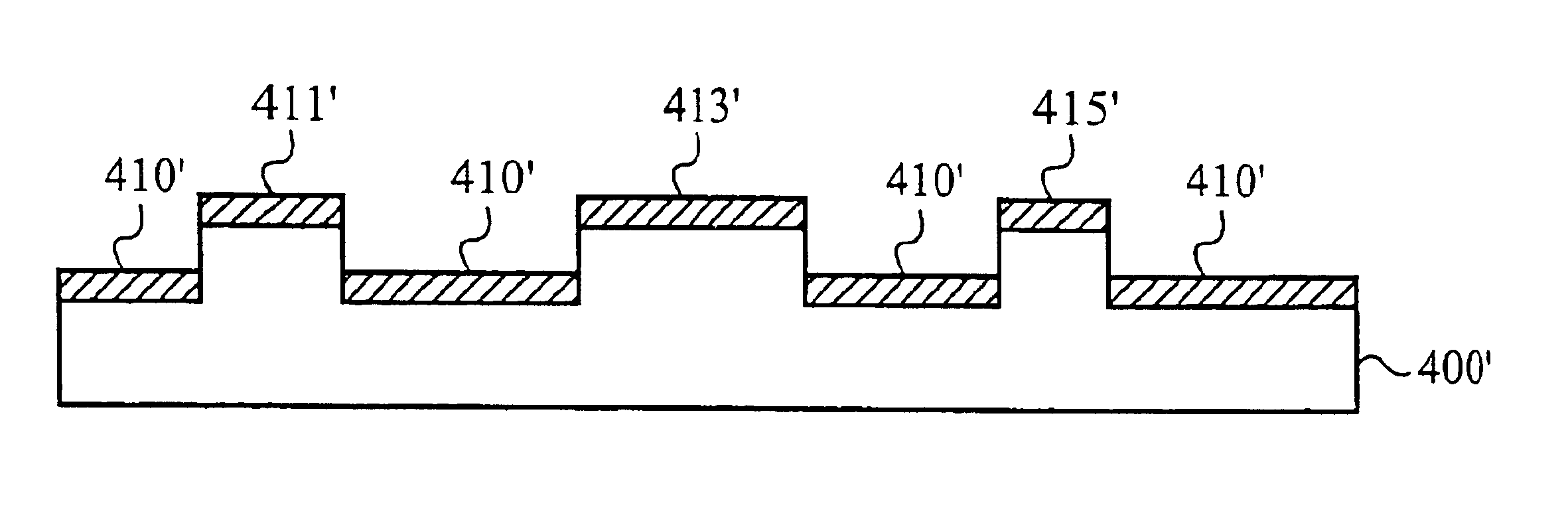

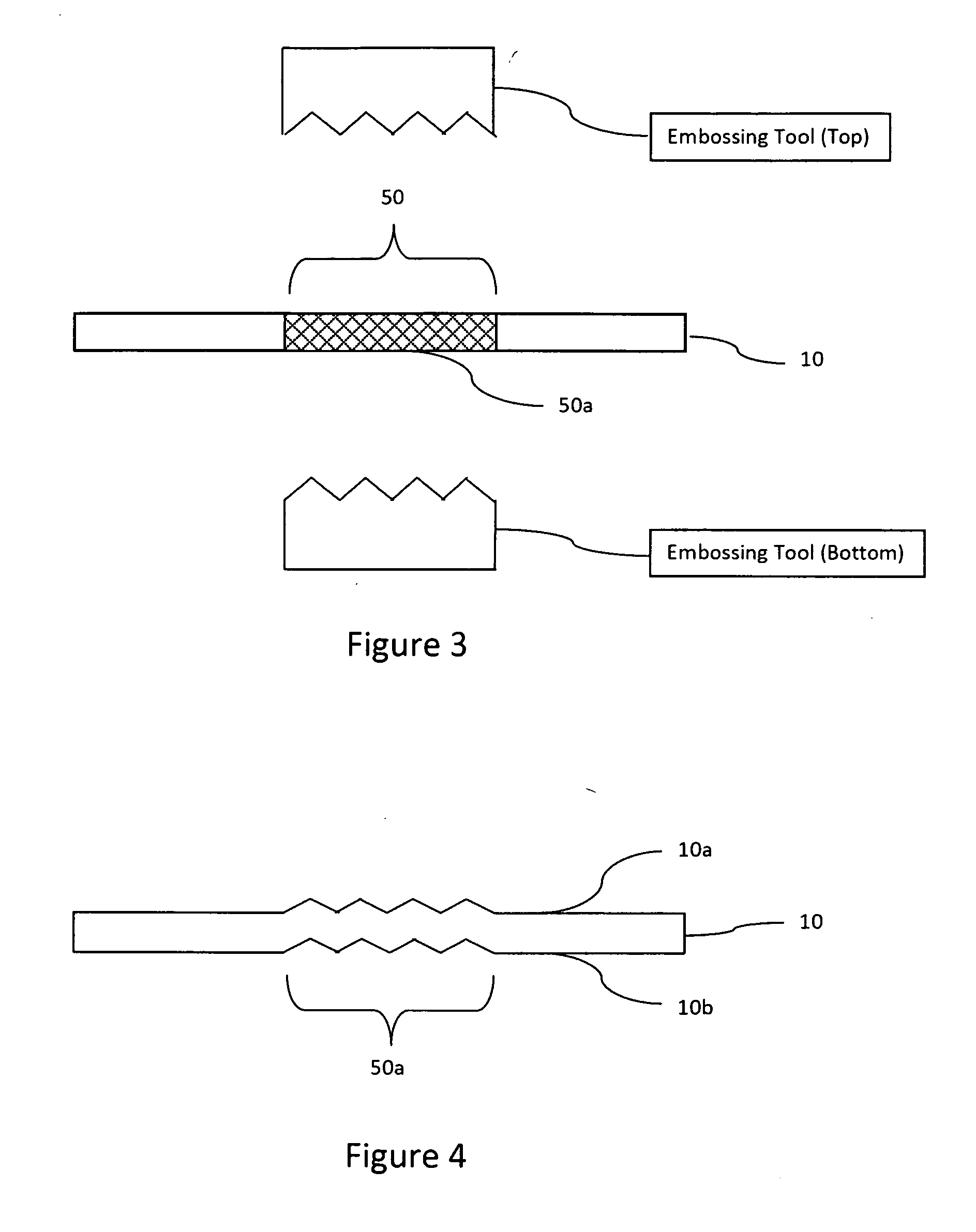

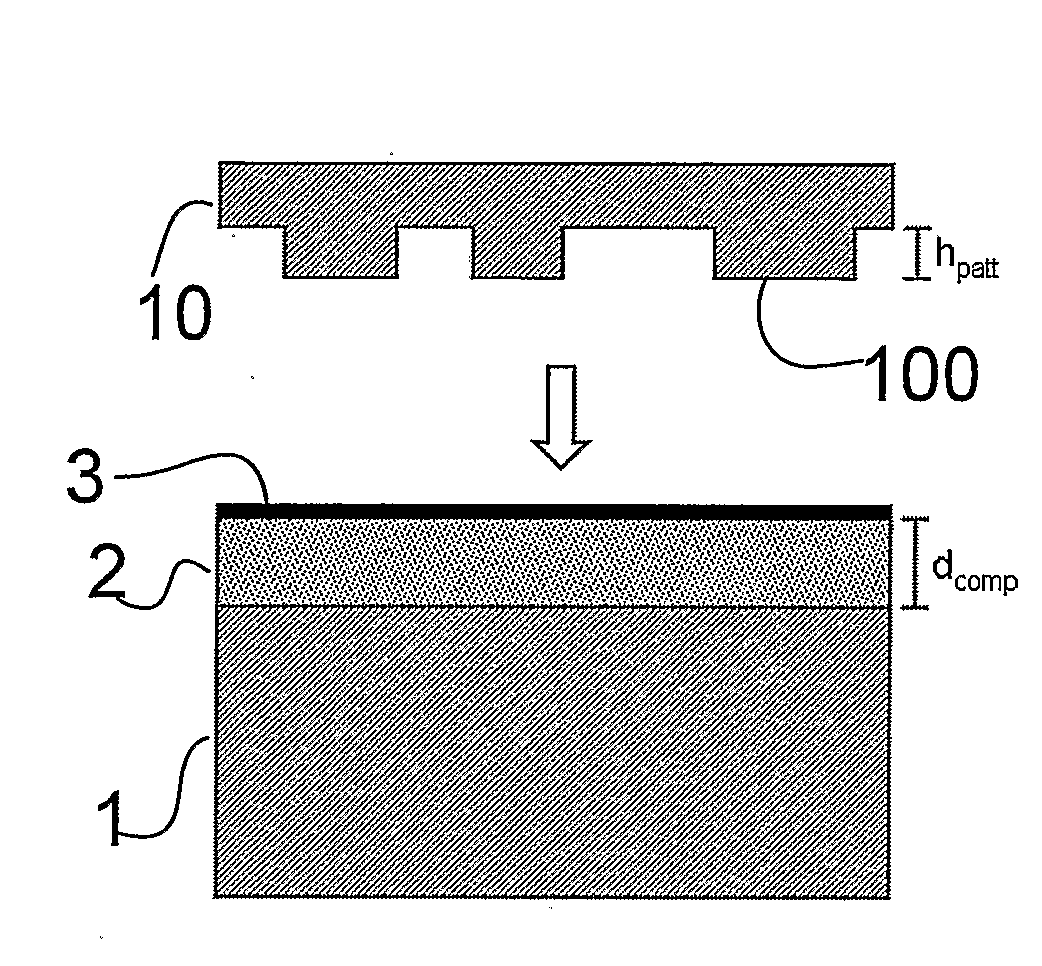

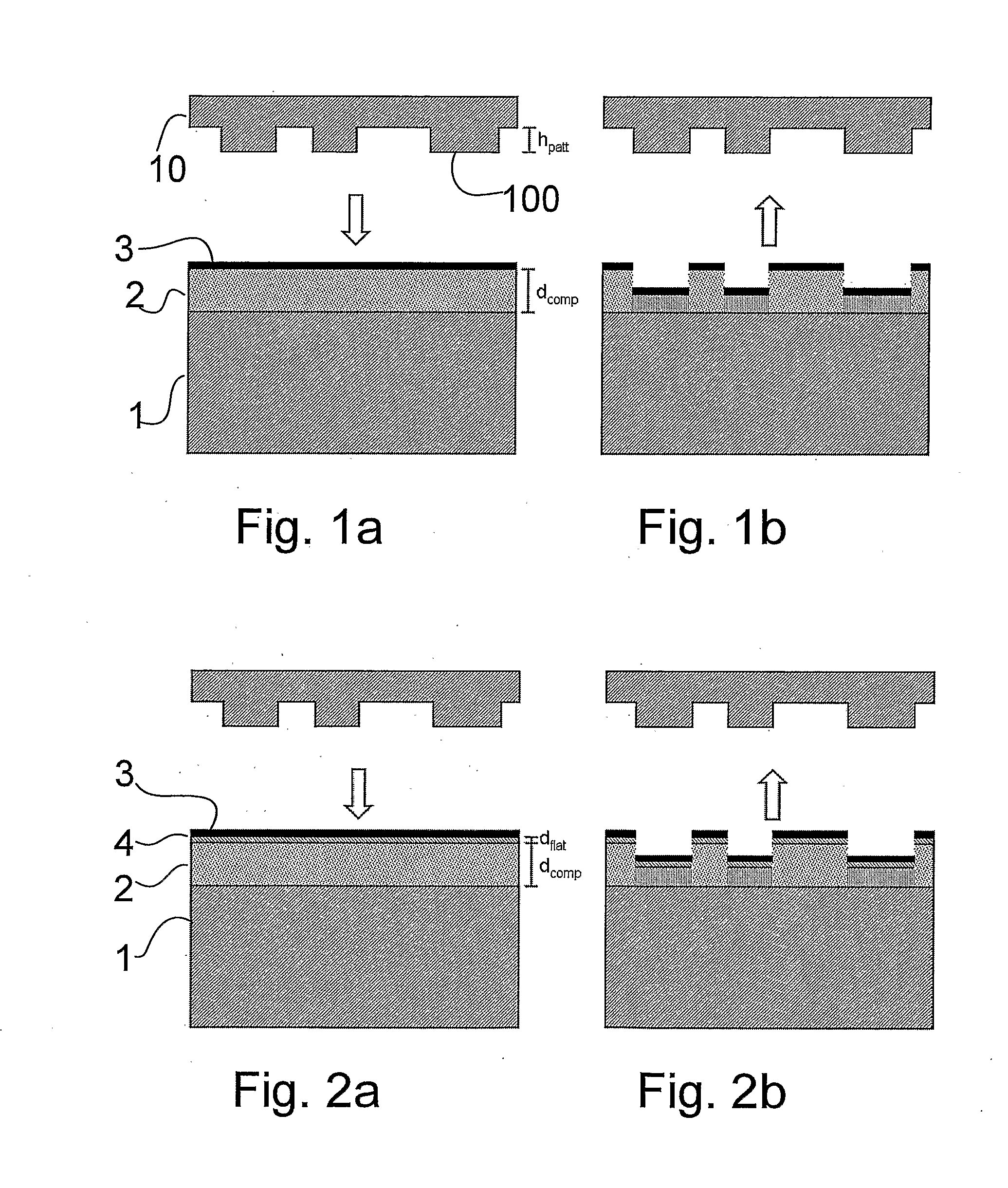

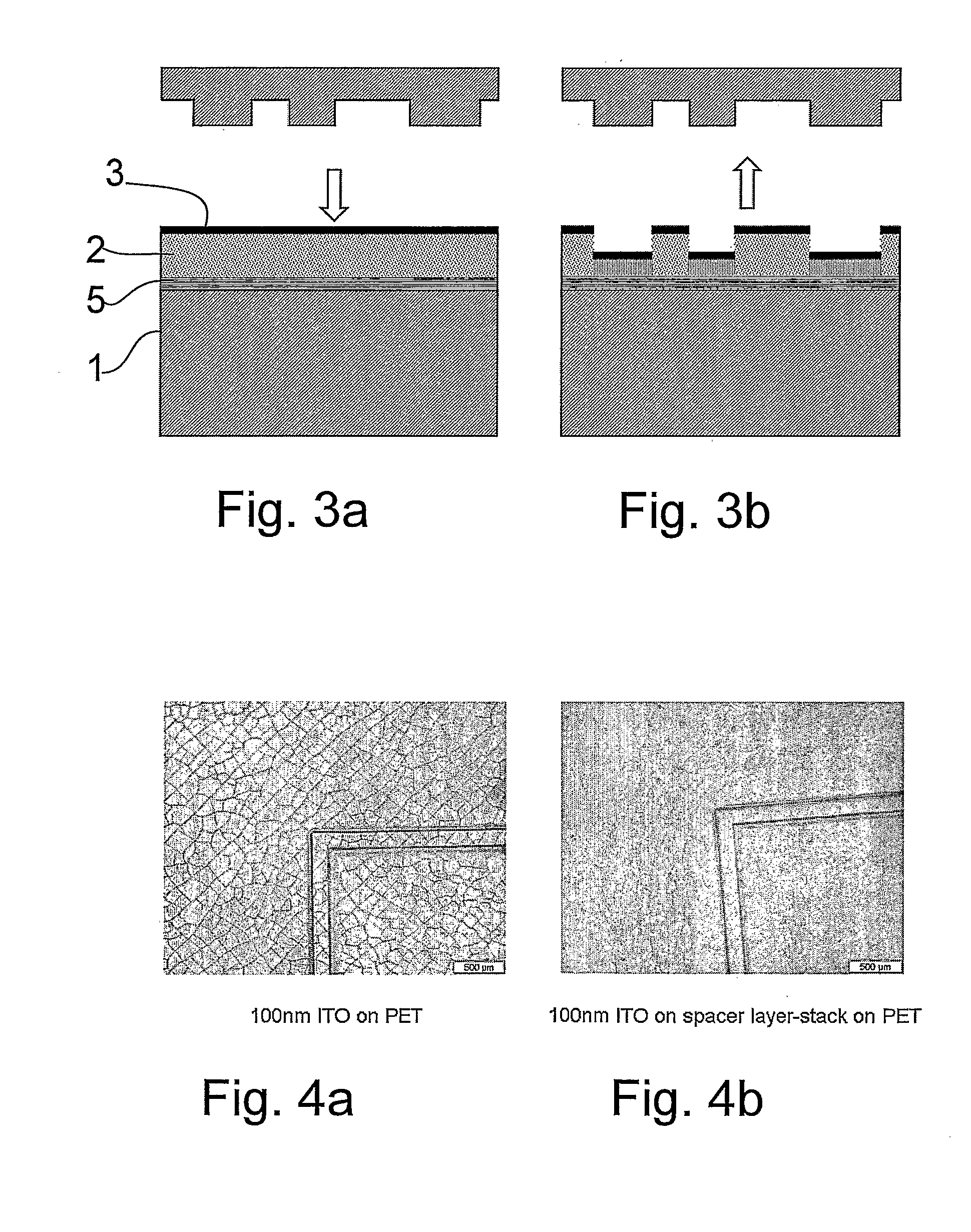

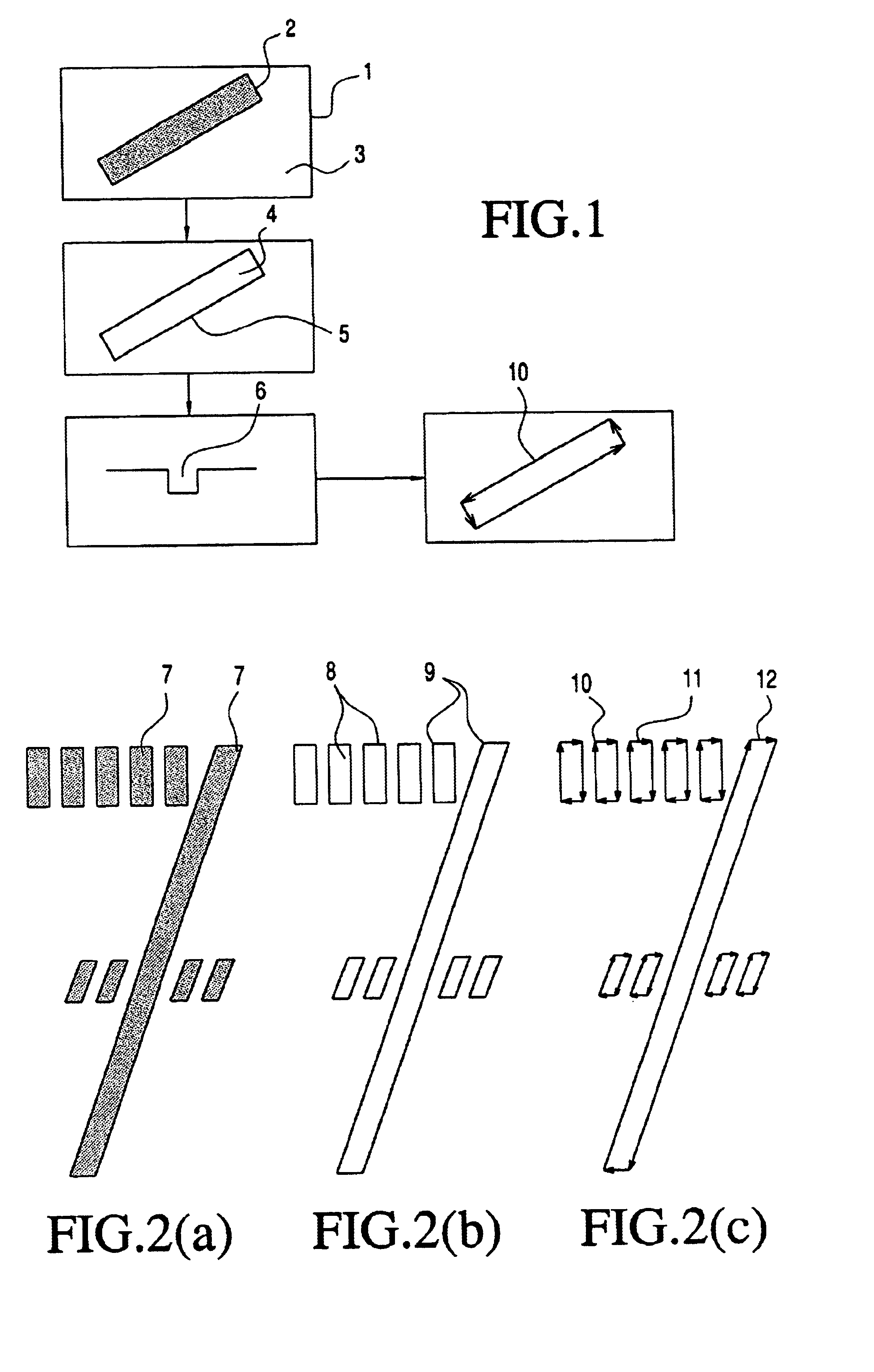

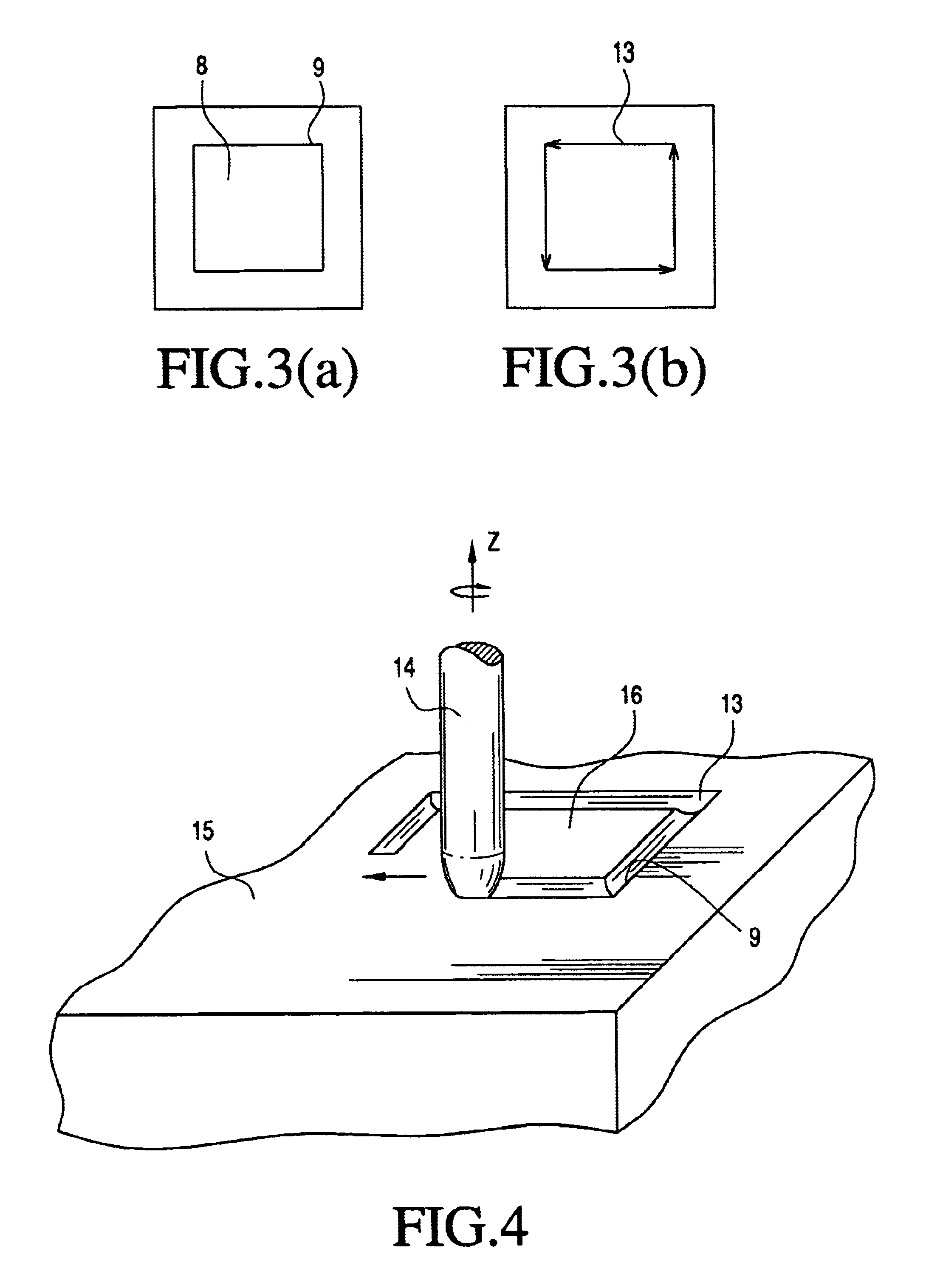

Method and Apparatus for Patterning a Conductive Layer, and a Device Produced Thereby

InactiveUS20090038683A1Drawback can be obviatedLarge-area productionMechanical working/deformationSolid-state devicesEngineeringElectrical and Electronics engineering

A device is fabricated by a method in which a conductive layer or layer stack is formed over a compressible layer or layer stack, and contacted with an embossing tool. Raised portions of the embossing tool compress the compressible layer or stack and countersink the conductive layer or stack into the compressible layer or stack.

Owner:CIBA SPECIALTY CHEM CORP

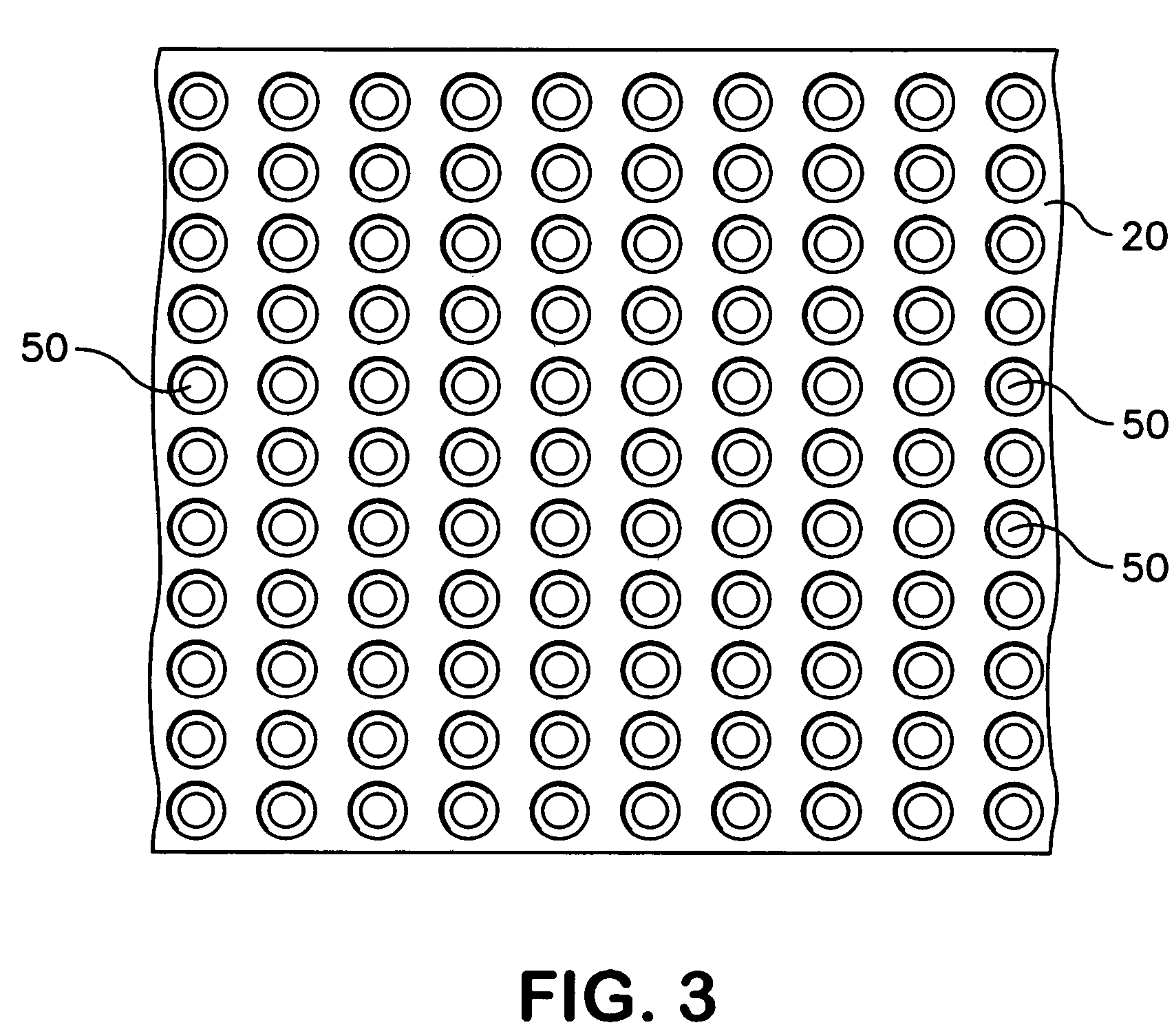

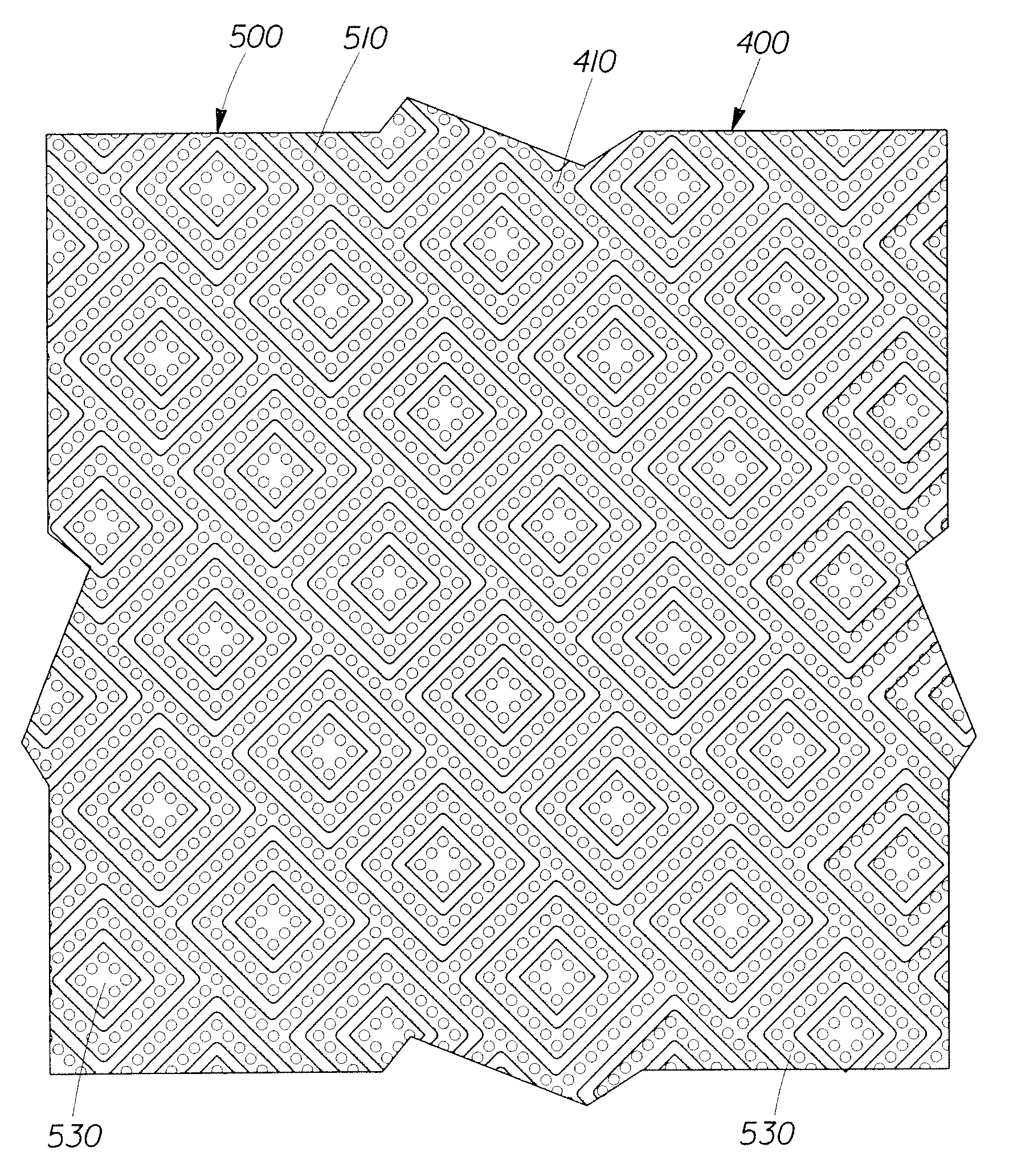

Embossing process including discrete and linear embossing elements

ActiveUS7435316B2Non-fibrous pulp additionMechanical working/deformationEngineeringMechanical engineering

An apparatus for producing a deep-nested embossed product including a first embossing member and a second embossing member. The first embossing member has a plurality of discrete embossing elements disposed in a first non-random pattern. The second embossing member has a plurality of second embossing elements including at least one linear embossing element. The second embossing elements are disposed in a second non-random pattern such the first non-random pattern and the second non-random pattern nest together to a depth of greater than about 0.01 mm.

Owner:THE PROCTER & GAMBLE COMPANY

Process for producing dies

InactiveUS6840721B2Increase speedSimple possibilityPlaten pressesMilling machinesEngineeringMechanical engineering

In a method for producing embossing plates, in particular steel intaglio printing plates, a plane element is determined from a line drawing, the edge of the plane element defining a desired contour. A tool track is then calculated from the desired contour and a desired depth associated with the plane element, to be used for guiding an engraving tool such that the partial area is removed.

Owner:GIESECKE & DEVRIENT GMBH

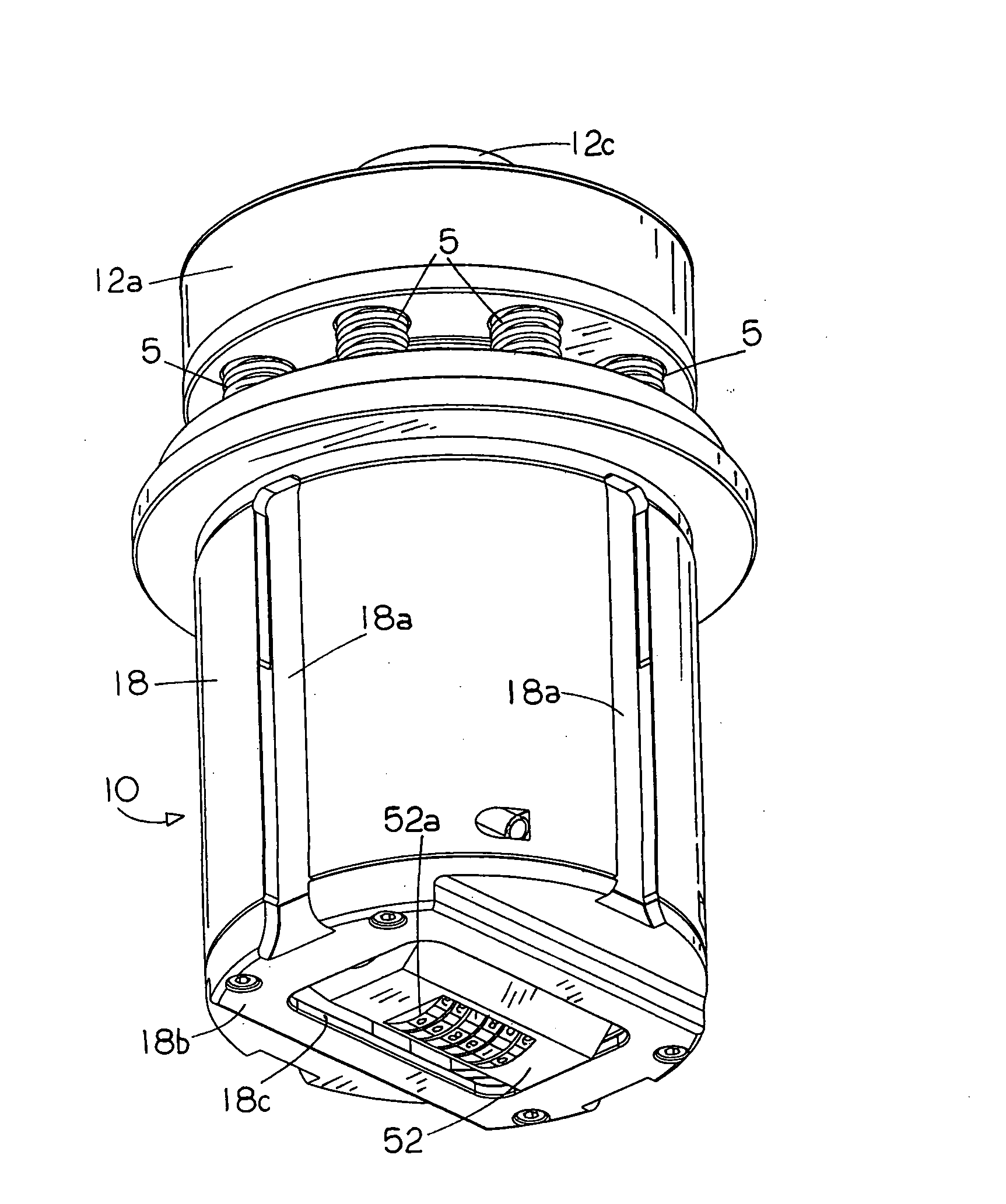

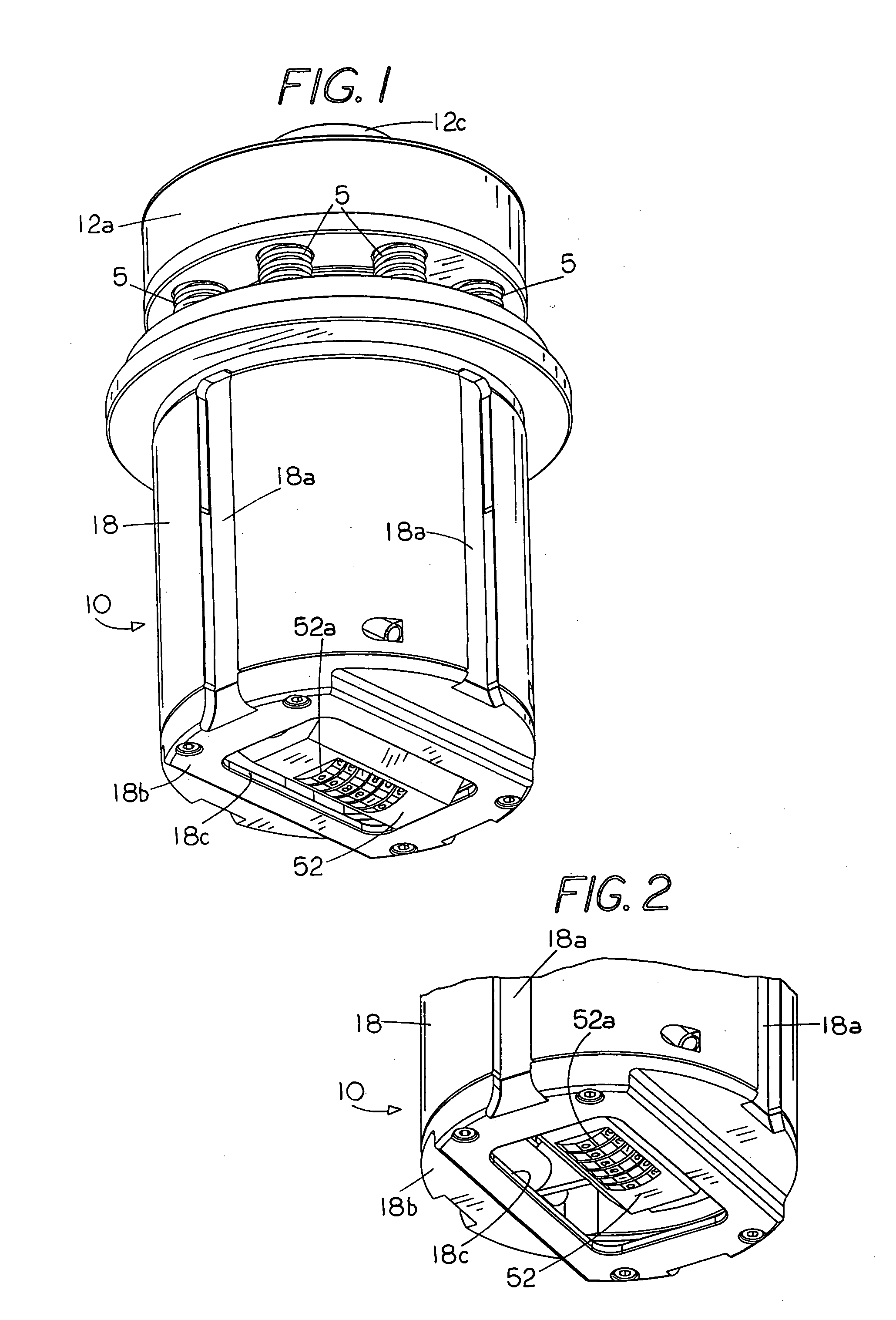

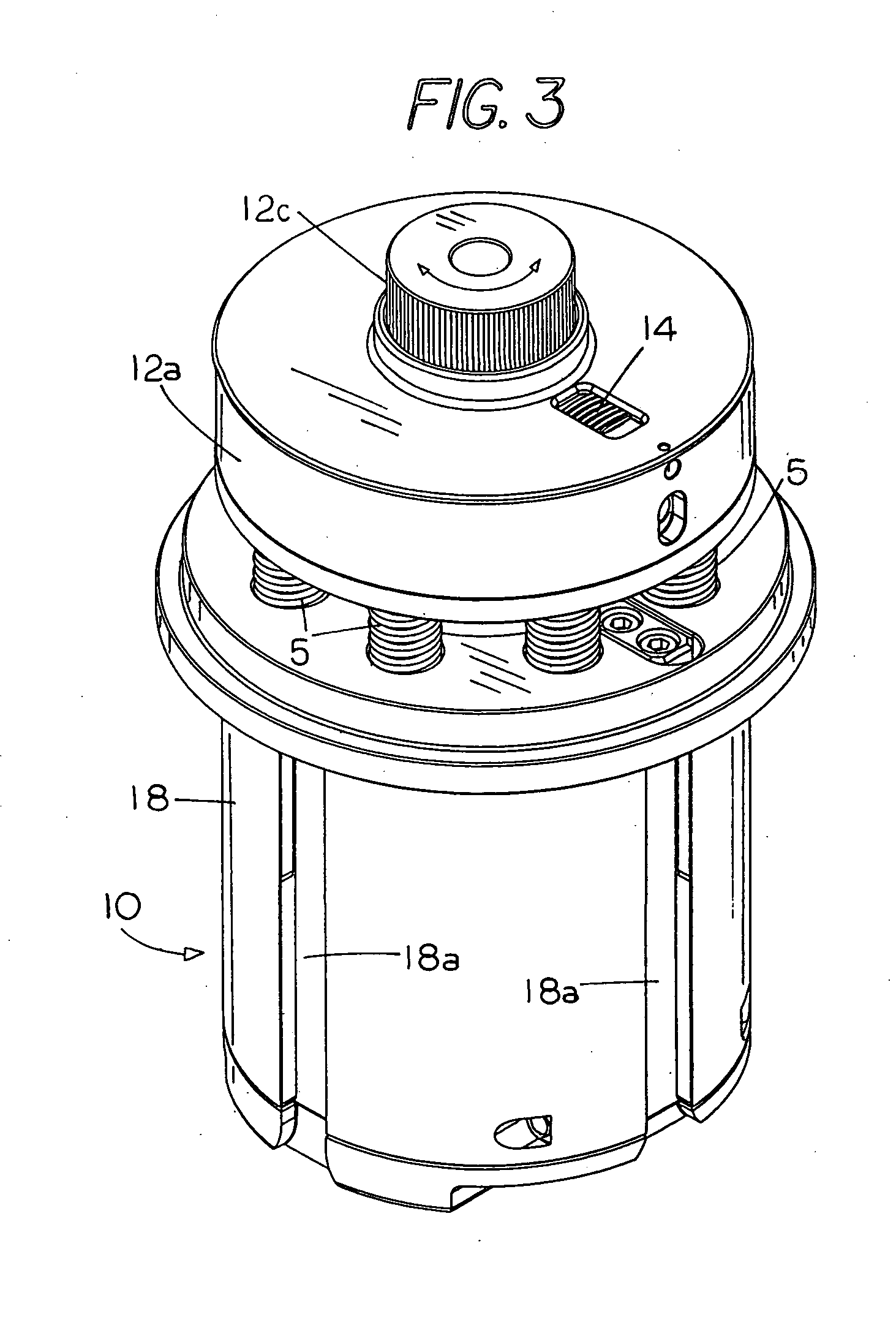

Punch press tool for stamping successive multicharacter impressions into a workpiece

ActiveUS20080314220A1Addressing machinesMechanical working/deformationPunch pressReciprocating motion

A punch press tool for stamping successive multicharacter impressions into a workpiece such as a piece of steel, sheet metal, or other workpiece, includes a guide body in which a stamp driver is slidably mounted for being driven downwardly toward the workpiece by a punch press ram which is a standard part of a high speed commercial punch press. A multicharacter marking stamp is supported at the lower end of the stamp driver for reciprocal movement therewith. The marking stamp includes multicharacter wheels that are rotated automatically during operation for advancing characters in sequence responsive to the movement of a character advancing arm. At least one character stamp operating lever is operatively associated with the punch press tool for articulation responsive to motion imparted to the tool by the ram. The lever has an operating element that is operatively associated with the character advancing arm of the multicharacter stamp for indexing the arm to enable successive characters thereof to be placed in an operating position responsive to a stroke of the punch press ram.

Owner:MATE PRECISION TOOLING

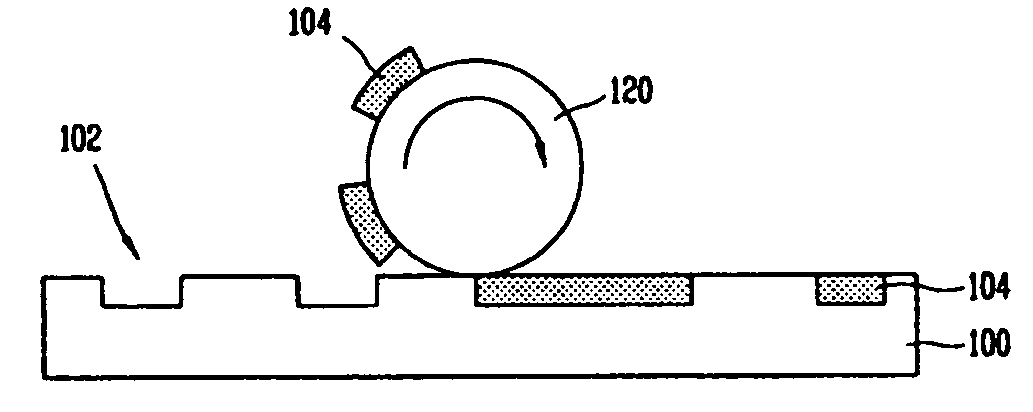

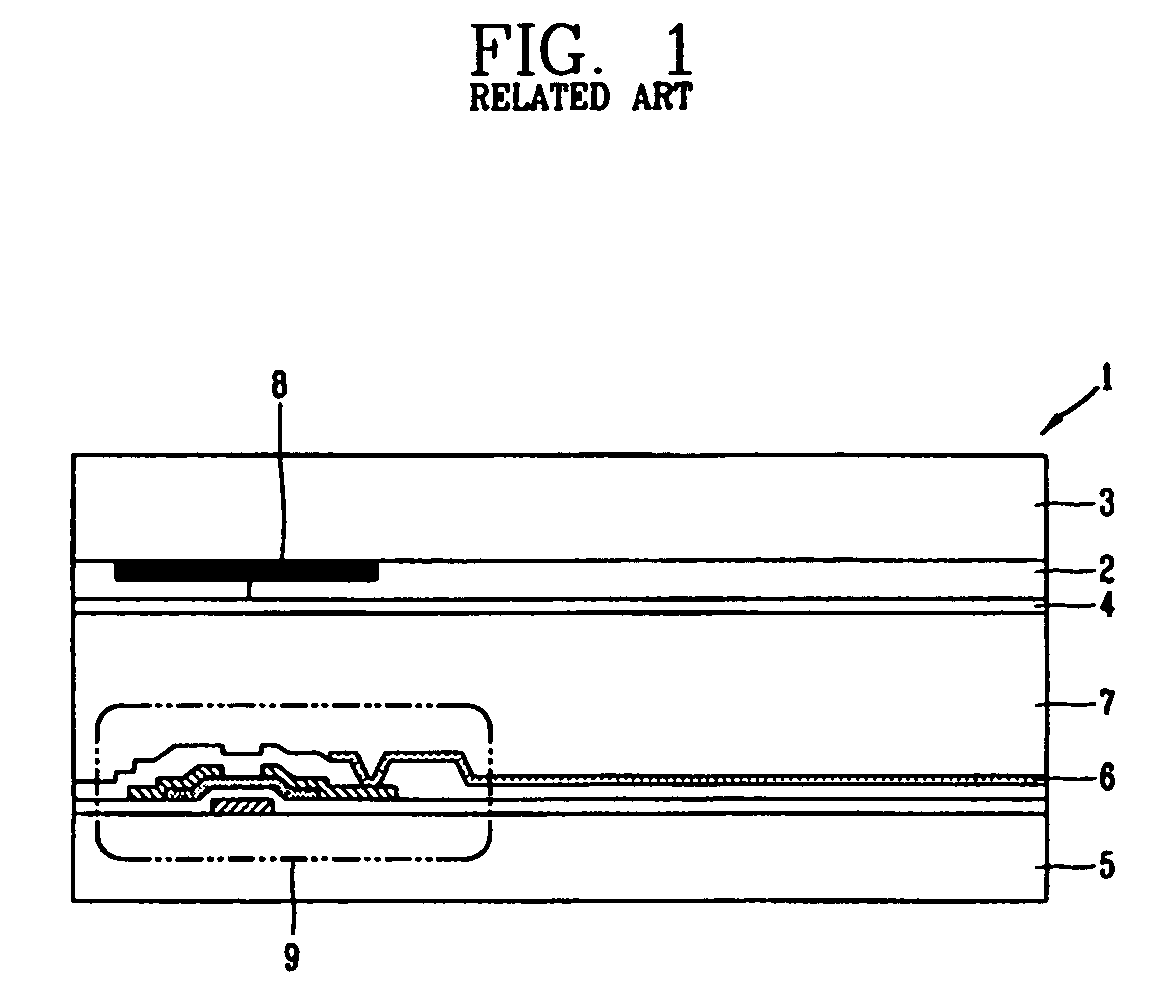

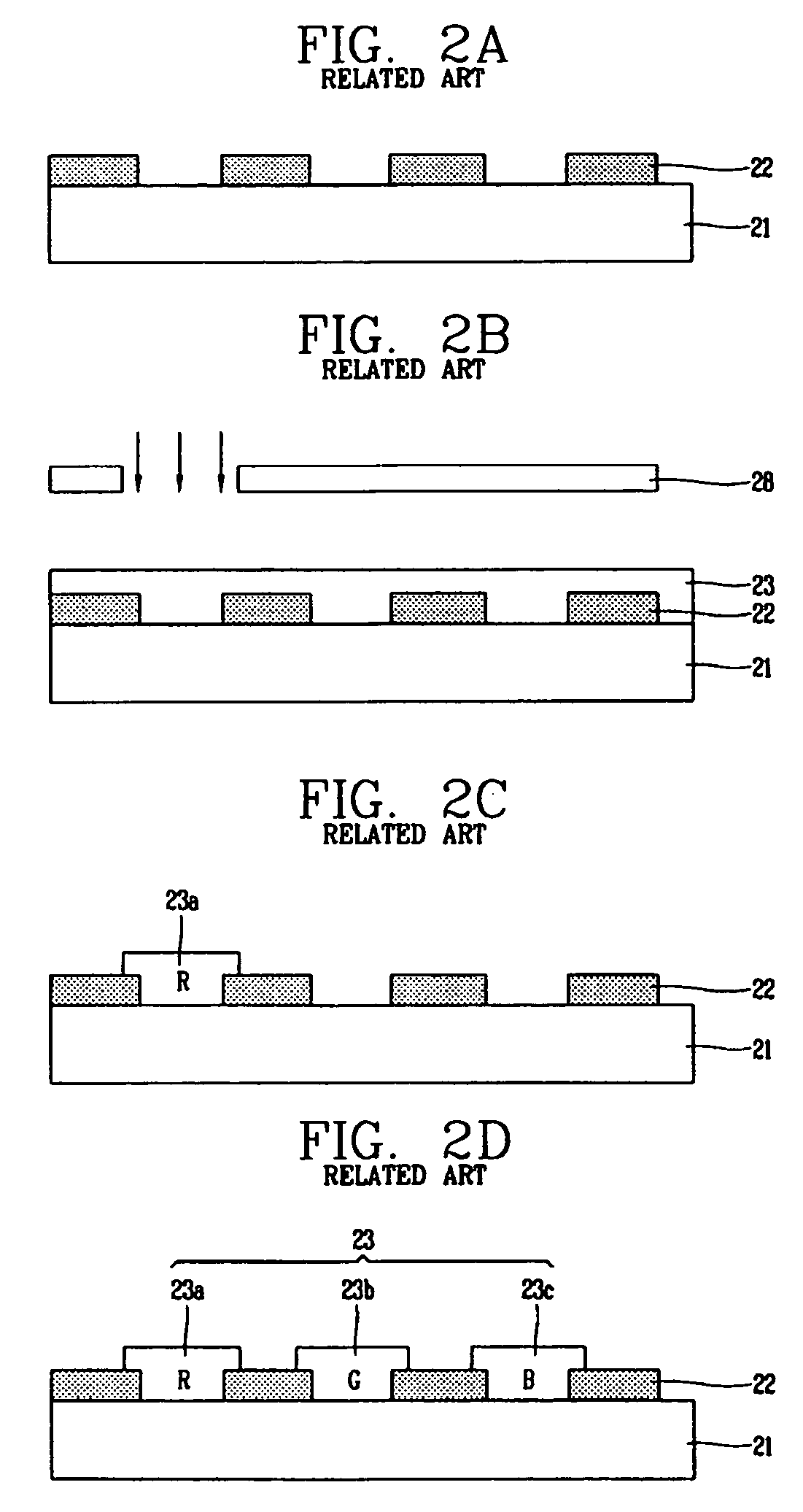

Method of fabricating color filter in display device

ActiveUS20040123753A1Cylinder pressesMechanical working/deformationLiquid-crystal displayDisplay device

A method of fabricating a color filter in a liquid crystal display device includes providing a plurality of clichés in which grooves are formed, filling color inks and a black resin in the grooves of the clichés, applying the color inks in the clichés onto a substrate to form a color filter, and applying a black resin in one of the clichés onto the color filter. The color inks and black resin are transferred to the clichés from an ink supply container via an ink supplying roller and from the clichés to the substrate via a printing roller.

Owner:LG DISPLAY CO LTD

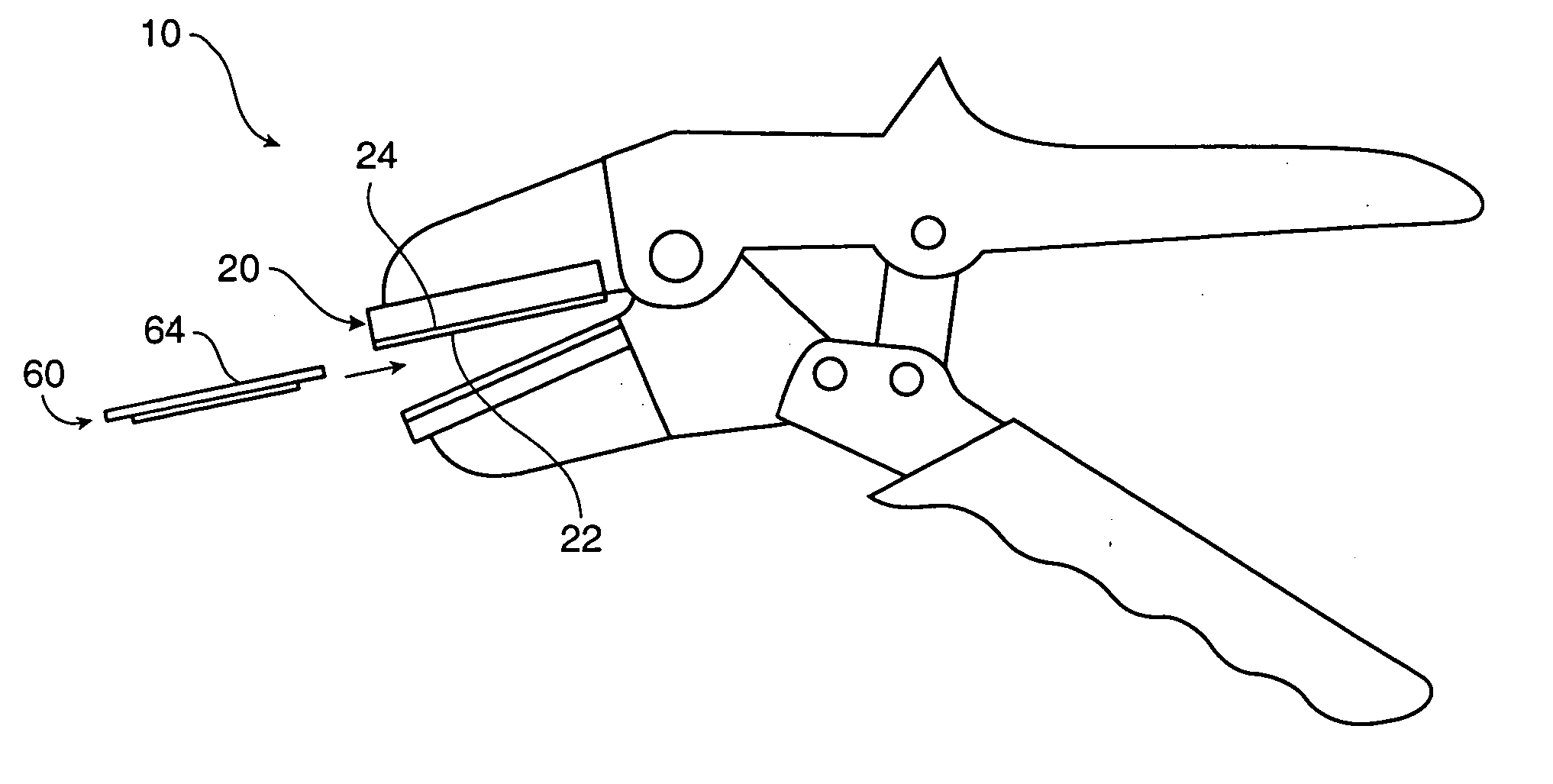

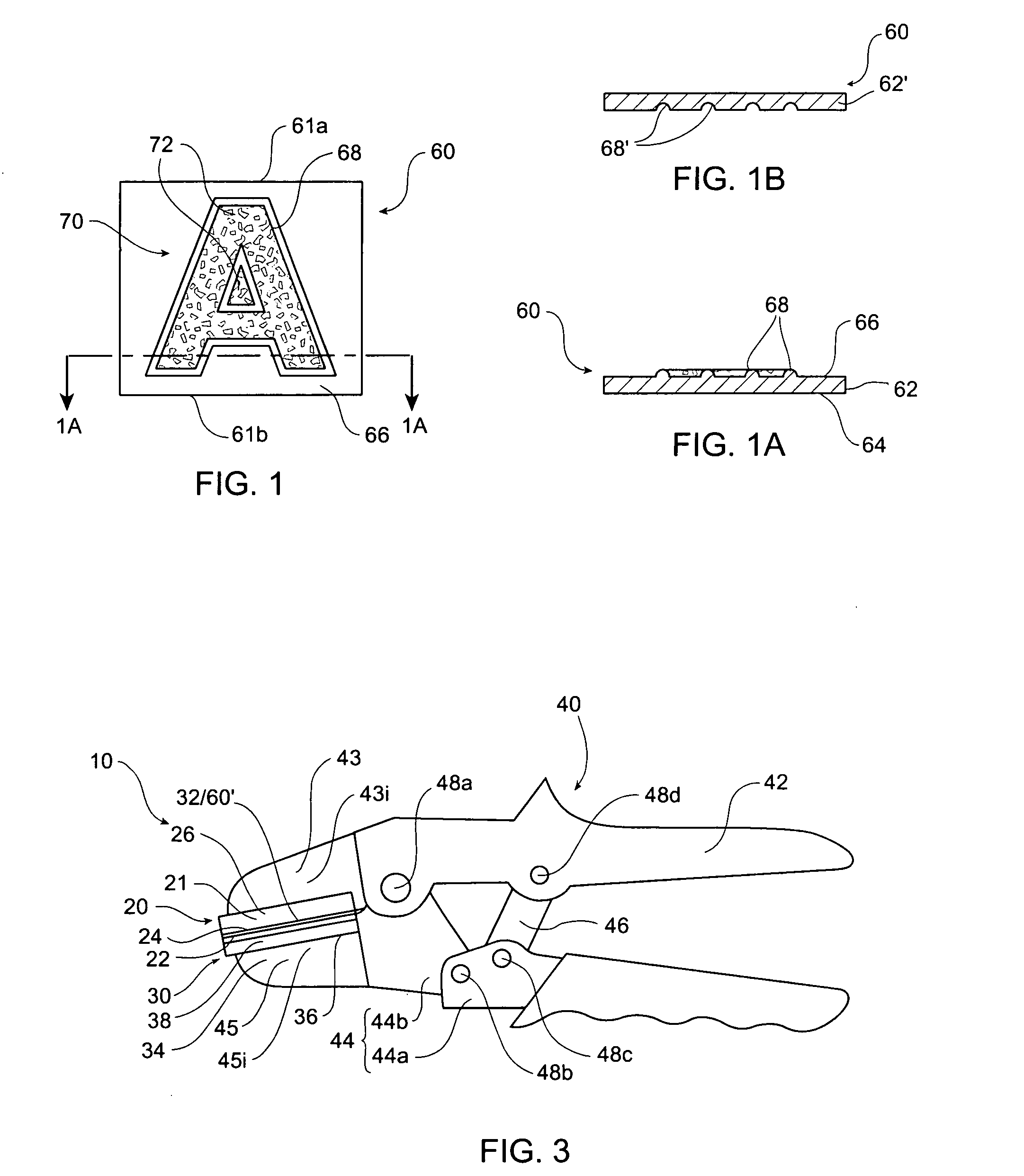

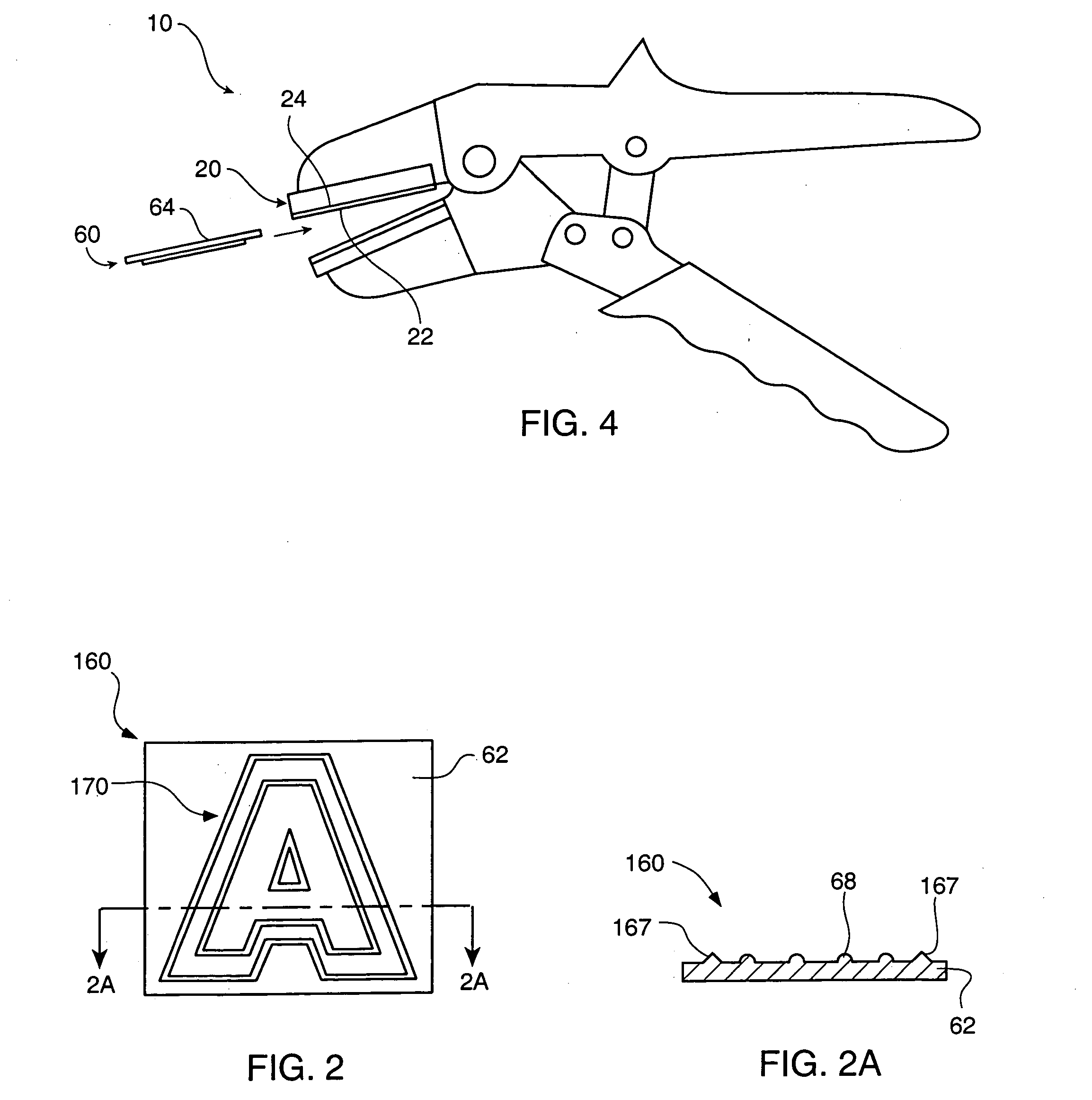

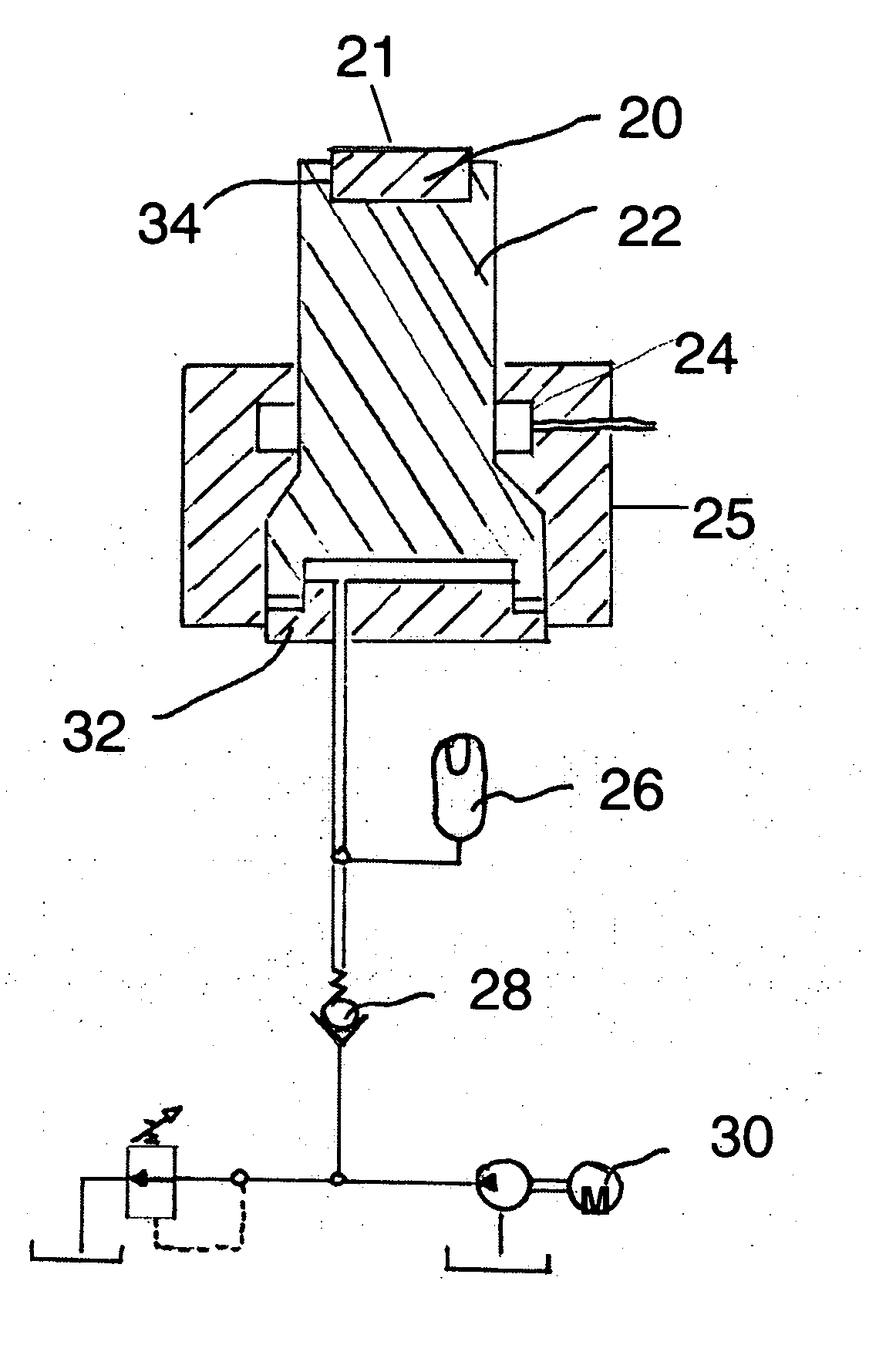

Embossing system,components thereof, and methods

InactiveUS20050126407A1Easy to useMechanical working/deformationRotary pressesHand heldMachine press

An embossing die includes a plate and at least one embossing element protruding from a surface thereof. The embossing die may also include at least one cutting edge protruding from the surface of the plate. An embossing system that includes the embossing die may also include a press. The press may be manually operated and may be hand-held or supported upon a flat surface, such as a tabletop. A first member of the press receives the embossing die, while a second member of the press provides support for a sheet of material into or from which the embossing die will form a pattern upon biasing the die against the sheet of material. Manually operated presses and die embossing methods that employ teachings of the invention are also disclosed.

Owner:QUICKUTZ

Nano-optical color embrossing

InactiveUS20050211114A1Rapid productionMechanical working/deformationDecorative surface effectsNano structuringEngineering

An apparatus for embossing a surface with a nano-optical color structure includes a monolithic material. The monolithic material is mounted to a carrier and has an active area facing away from the carrier and, in use, towards a surface to be embossed. The active area has a surface structure with at least one predetermined nano structure that causes in the surface to be embossed a structure that generates a predetermined color structure when exposed to visible light.

Owner:FAHRENBACH JUERGEN +1

Method and apparatus for marking workpieces

InactiveUS7168364B2Reduce noiseNumberMechanical working/deformationTypewritersContact pressurePunch press

A method and an apparatus are provided for marking a sheet-shaped workpiece using a marking tool. The marking tool is mounted in a punch holder of a punch press and a counter-support is fixed in place on a side opposite of a marking surface of the workpiece to be marked. The surface of the workpiece is marked by displacing the workpiece in its plane while engaging the marking tool with the workpiece. In one form, a support roller provides counter-support. In another form, an elastic element is cooperatively associated with the punch stroke of the punch press to translate an exactly defined contact pressure force between the tool tip and the workpiece to be marked.

Owner:MATE PRECISION TOOLING

Apparatus for perforating a web material

ActiveUS8468938B2Easy to disassembleIncrease attractivenessMechanical working/deformationStock shearing machinesMechanical engineeringMaterial Perforation

Apparatuses are disclosed that include forming selected perforation designs and patterns. The perforation designs and patterns can be formed in linear or nonlinear fashion, can extend in the cross direction or the machine direction and can be formed to complement or match an embossed or printed design on the web. The perforation designs and patterns can be formed utilizing various mechanical perforating techniques.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com