Patents

Literature

55results about "Addressing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Social networking system and method for an online stationery or greeting card service

InactiveUS20110282942A1Input/output for user-computer interactionAddressing machinesPersonalizationUser input

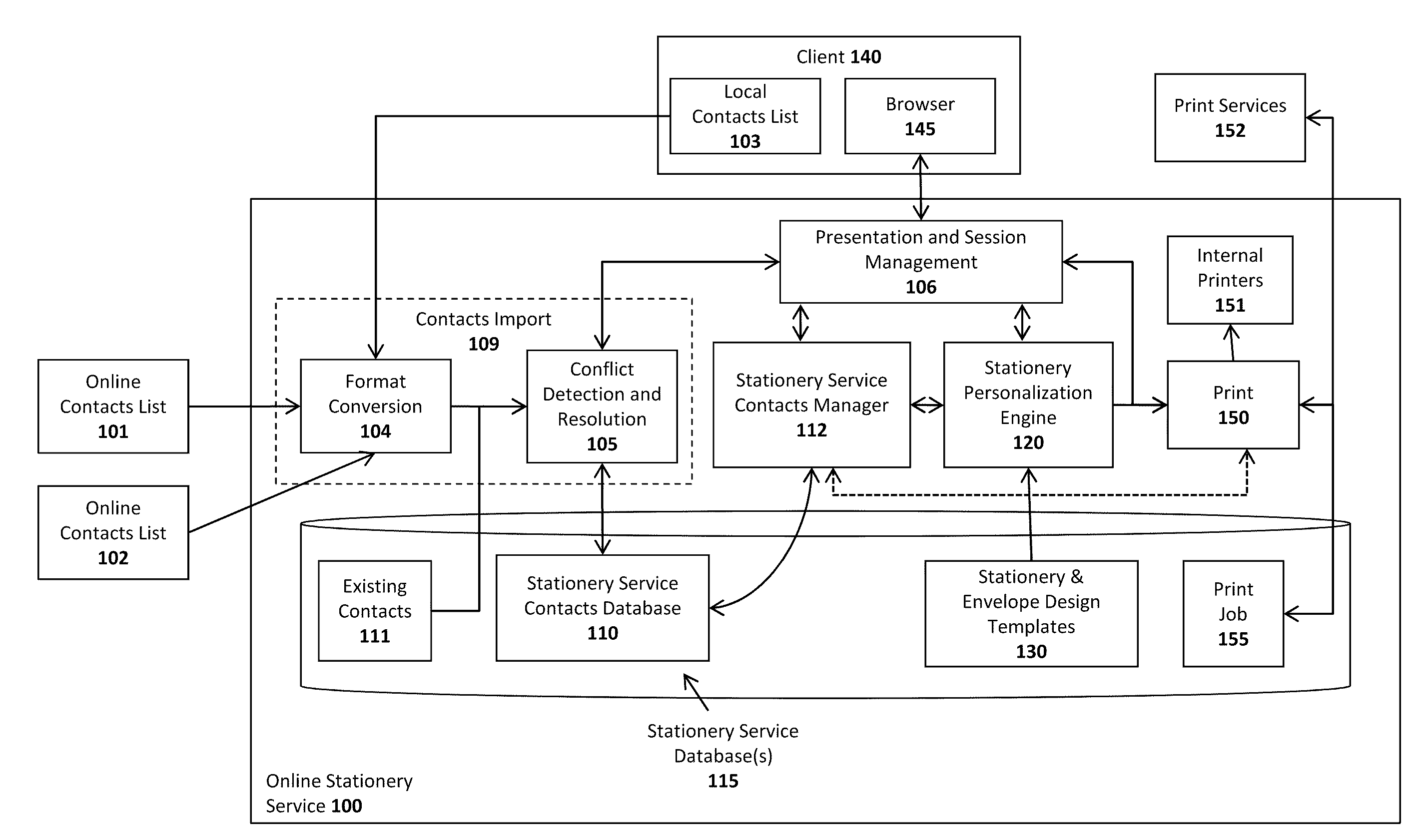

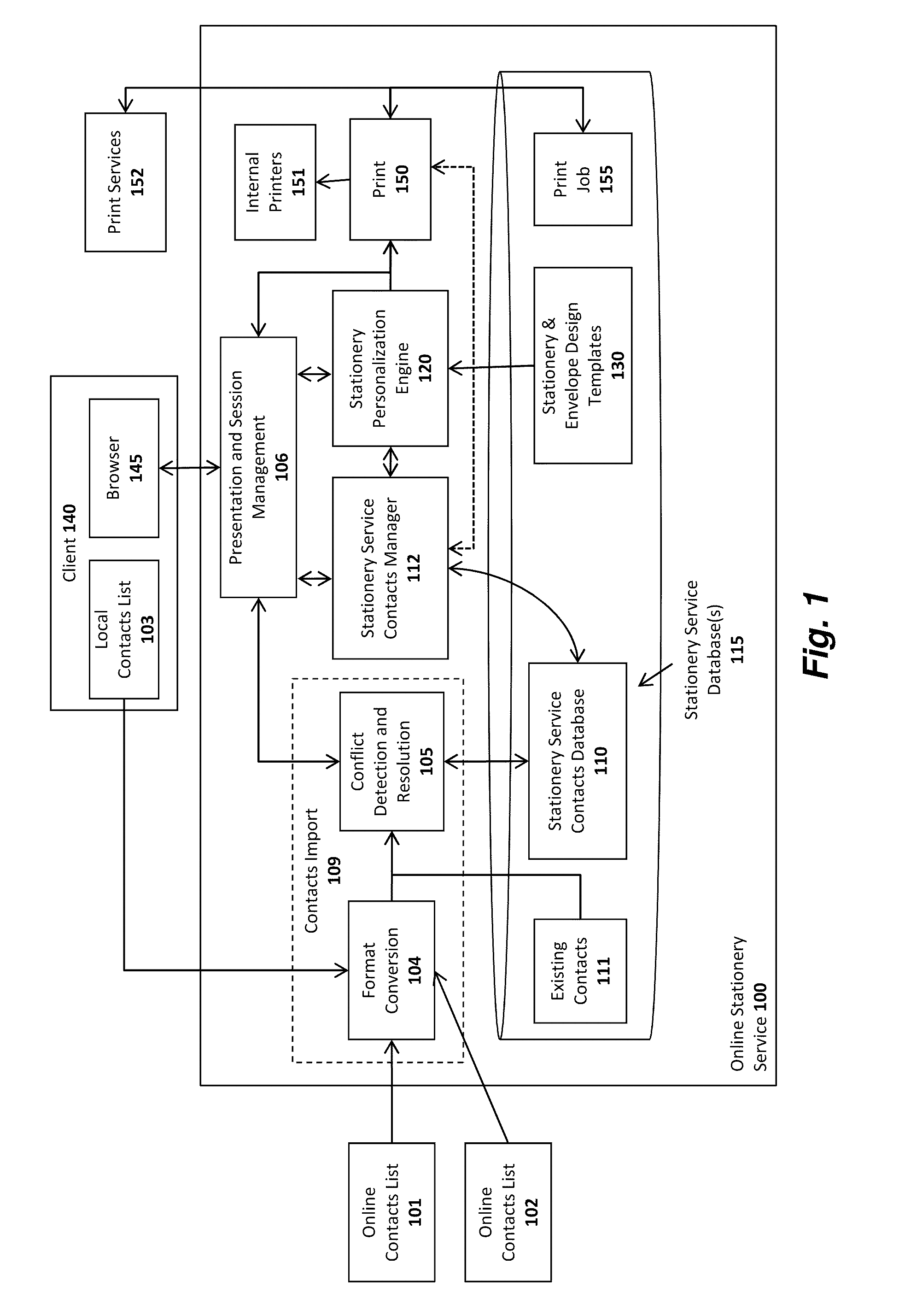

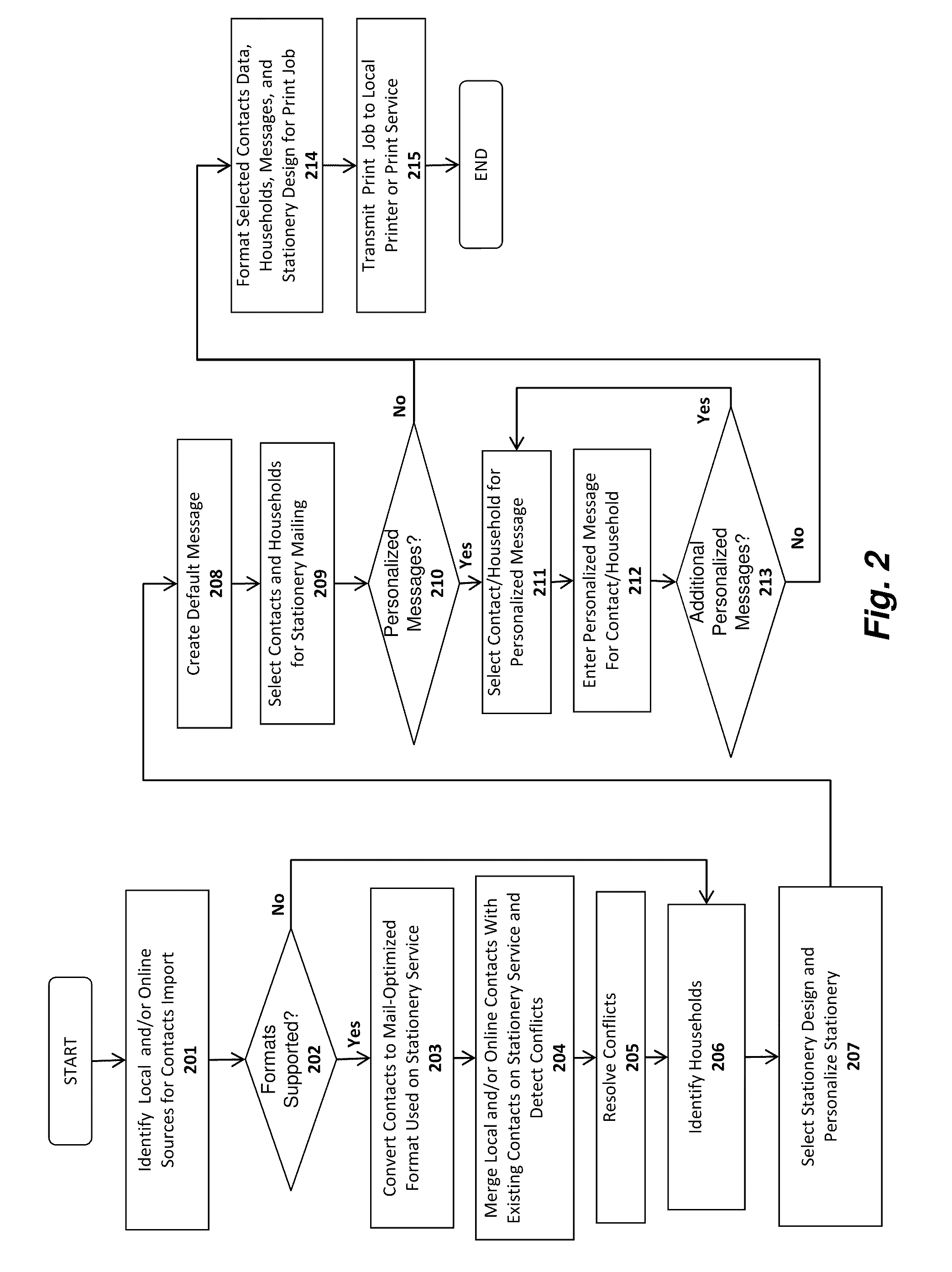

A system and method are described for managing friends within an online stationery / card service. For example, a method according to one embodiment comprises: connecting to an external social networking service on behalf of a user; retrieving the user's friend data from the external social networking service, the friend data specifying friends of the user; filtering the friend data to arrive at an inner circle of friends based on user input; associating address data with one or more friends retrieved from the external social networking service; creating a personalized item in response to input from the user; and mailing the personalized item with one or more of the friends in the inner circle of friends.

Owner:SHUTTERFLY

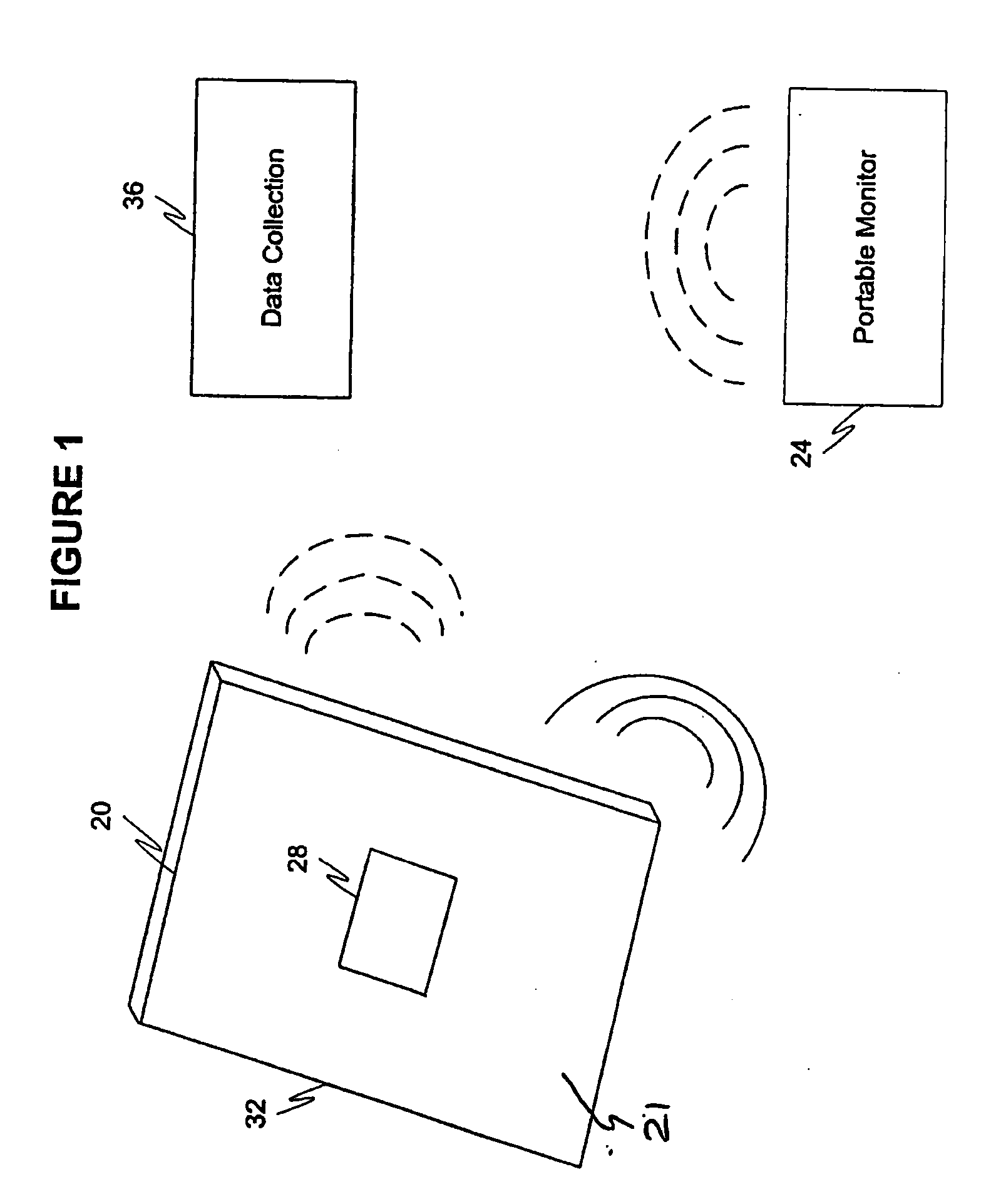

Gathering data concerning publication usage

ActiveUS20050268798A1Analogue secracy/subscription systemsStructural/machines measurementTransducerLibrary science

Owner:NIELSEN HLDG NV +1

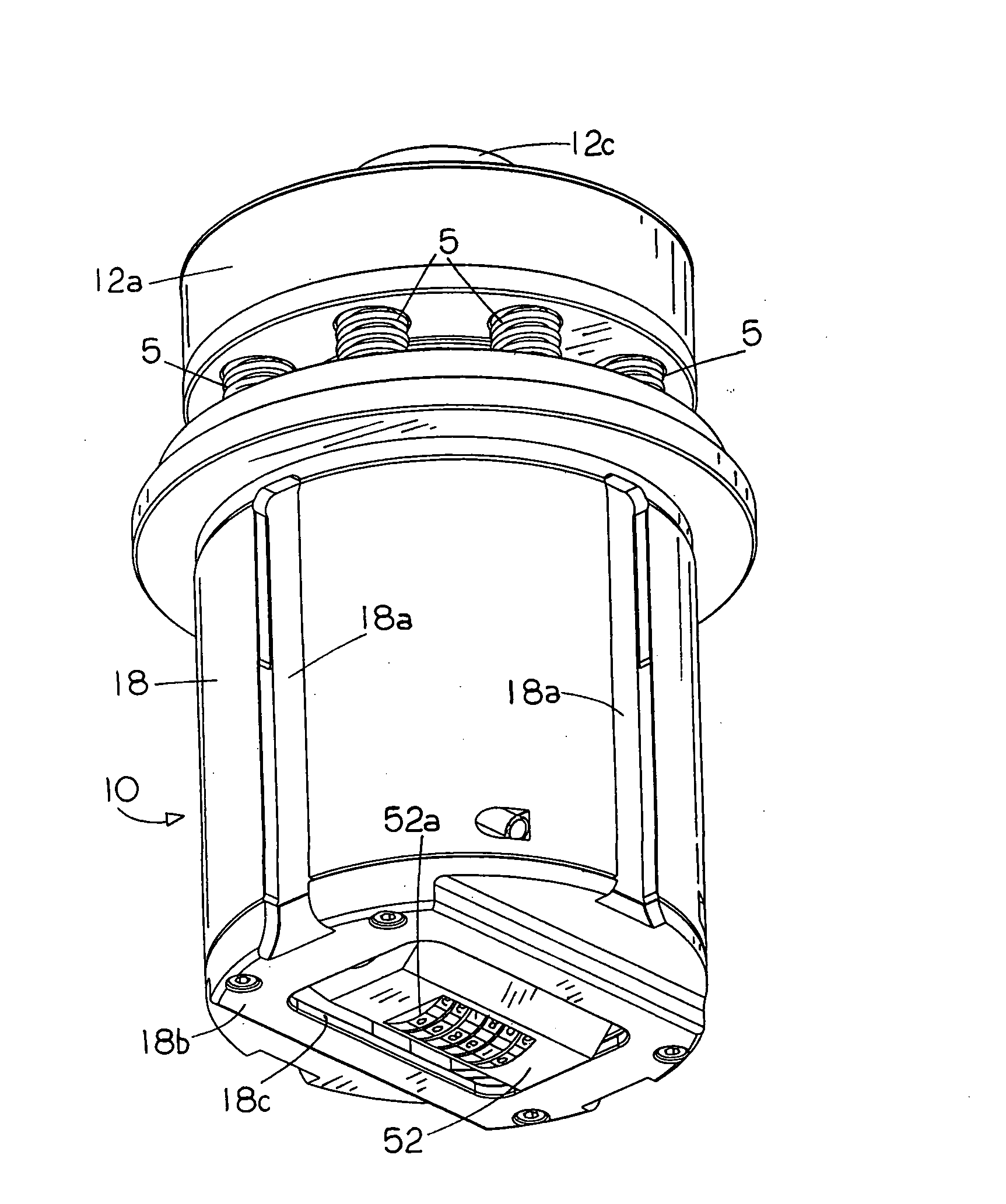

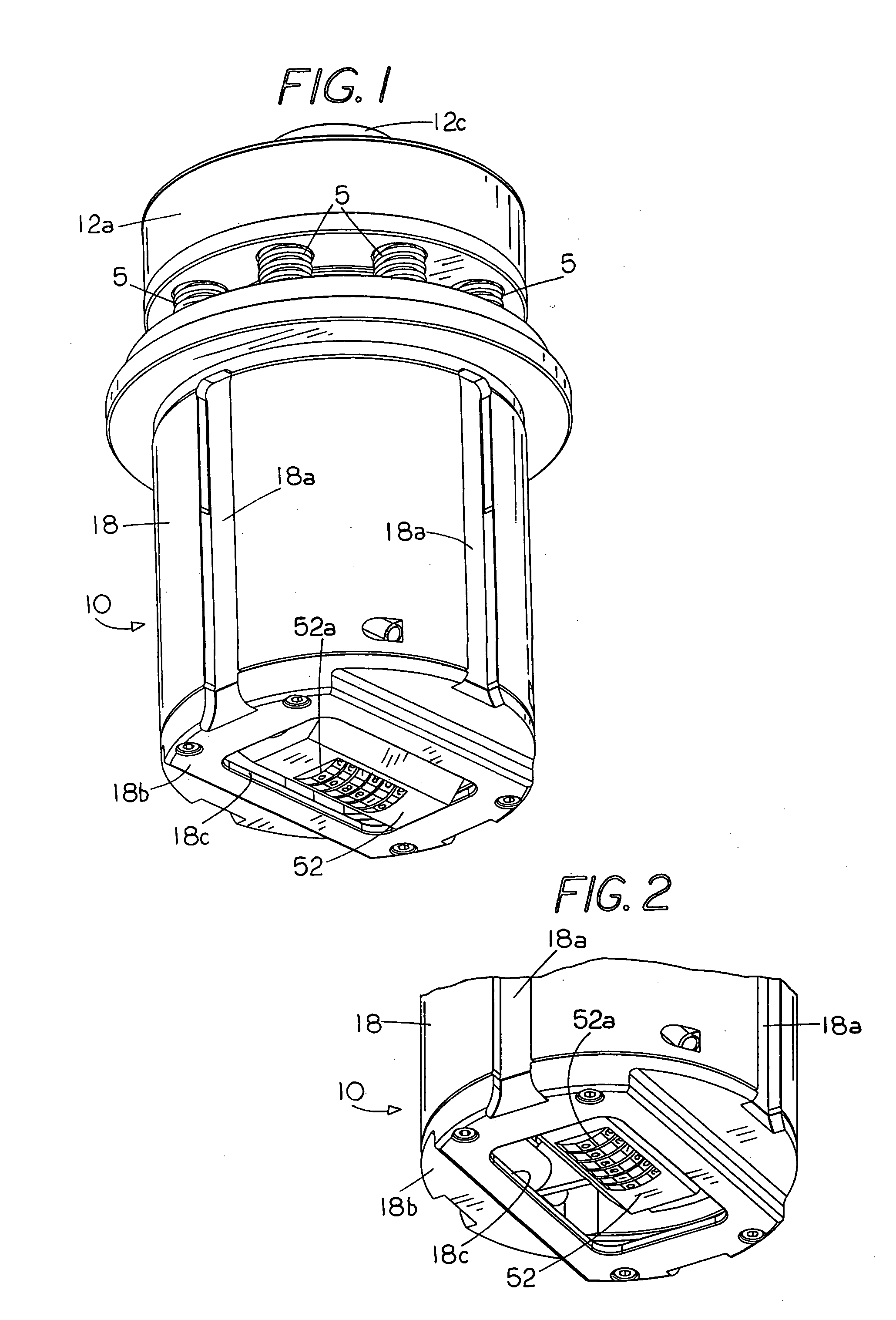

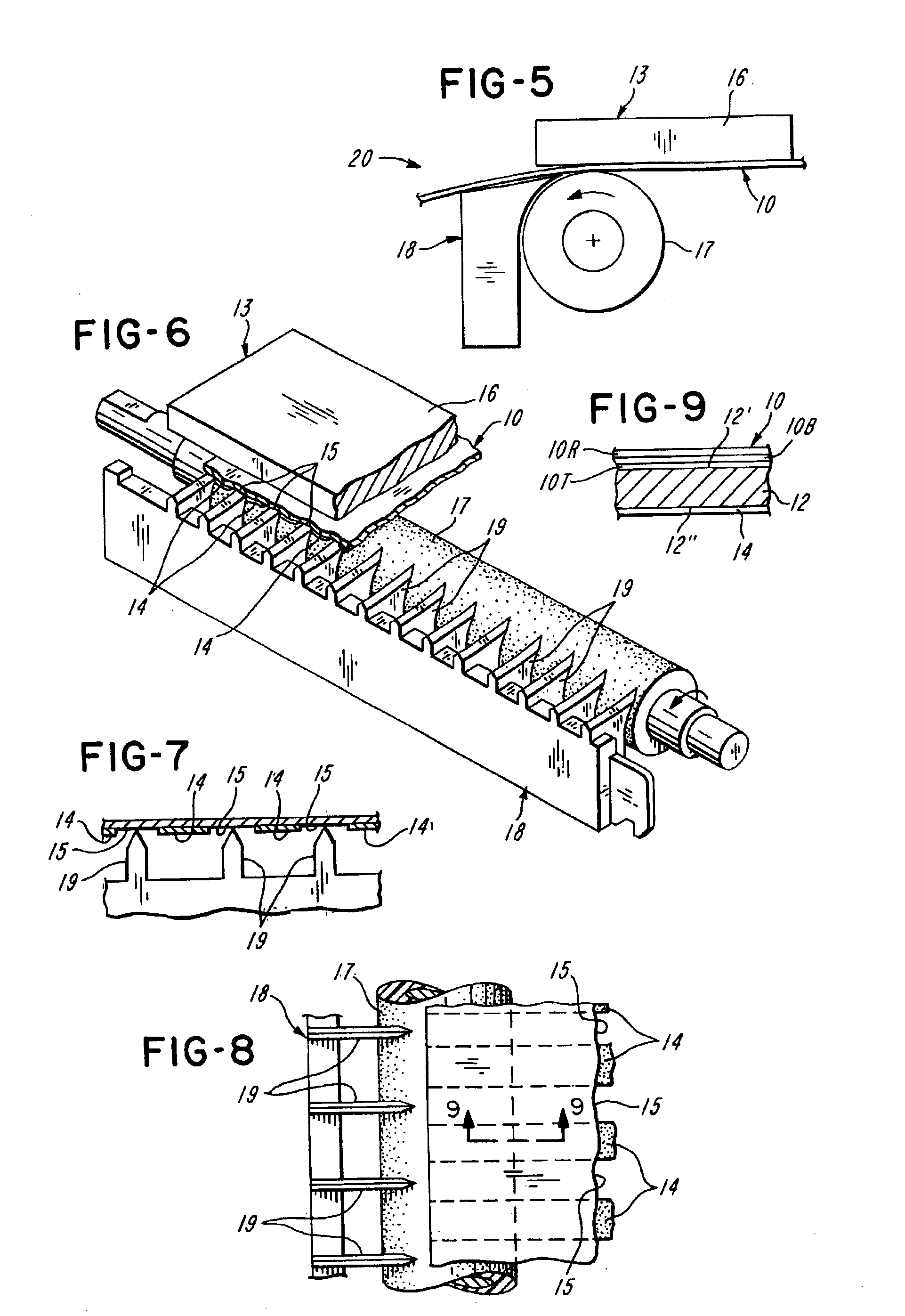

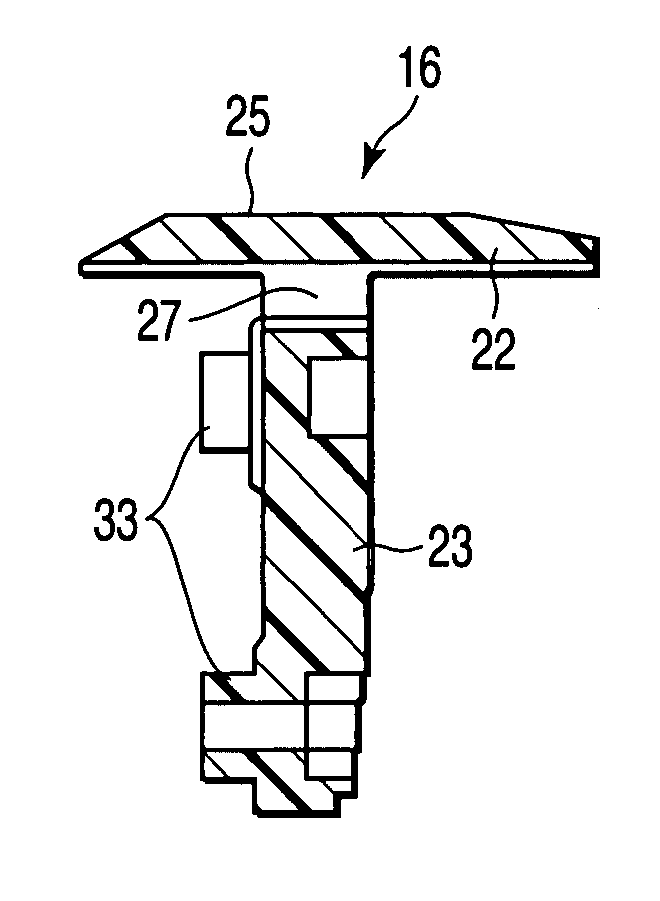

Punch press tool for stamping successive multicharacter impressions into a workpiece

ActiveUS20080314220A1Addressing machinesMechanical working/deformationPunch pressReciprocating motion

A punch press tool for stamping successive multicharacter impressions into a workpiece such as a piece of steel, sheet metal, or other workpiece, includes a guide body in which a stamp driver is slidably mounted for being driven downwardly toward the workpiece by a punch press ram which is a standard part of a high speed commercial punch press. A multicharacter marking stamp is supported at the lower end of the stamp driver for reciprocal movement therewith. The marking stamp includes multicharacter wheels that are rotated automatically during operation for advancing characters in sequence responsive to the movement of a character advancing arm. At least one character stamp operating lever is operatively associated with the punch press tool for articulation responsive to motion imparted to the tool by the ram. The lever has an operating element that is operatively associated with the character advancing arm of the multicharacter stamp for indexing the arm to enable successive characters thereof to be placed in an operating position responsive to a stroke of the punch press ram.

Owner:MATE PRECISION TOOLING

Method and system for handling a linerless label web

There is disclosed a linerless label web roll wherein the label web has a patterned coating of pressure sensitive adhesive on its underside between marginal side edges and at marginal side edges of the label web. The adhesive is provided in longitudinally extending laterally spaced stripes of adhesive with intervening adhesive-free zones. The label web can be supported and / or guided by support or guide elements which contact the adhesive-free zones in a suitable utilization device such as a printer or label applicator.

Owner:AVERY DENNISON CORP

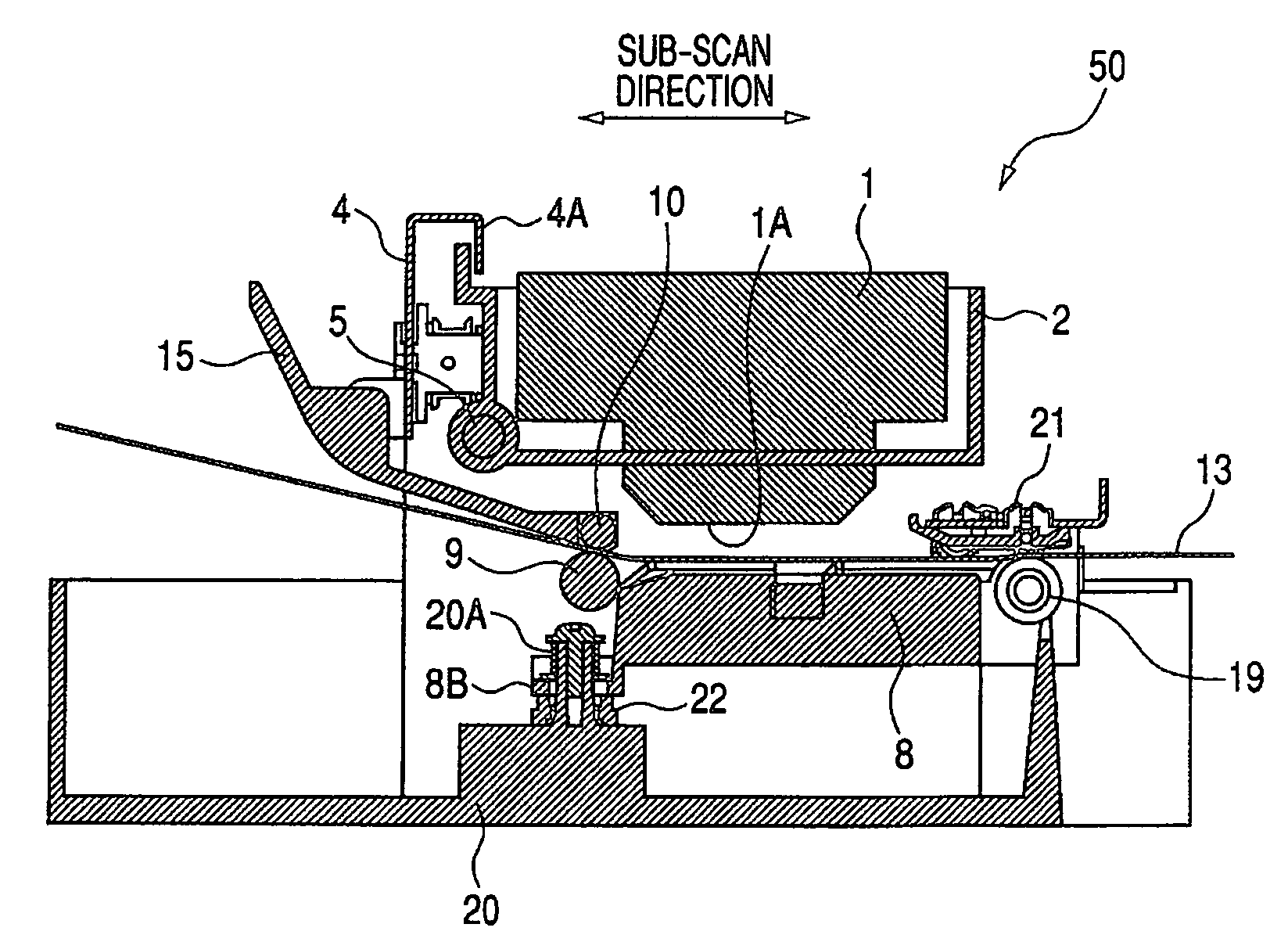

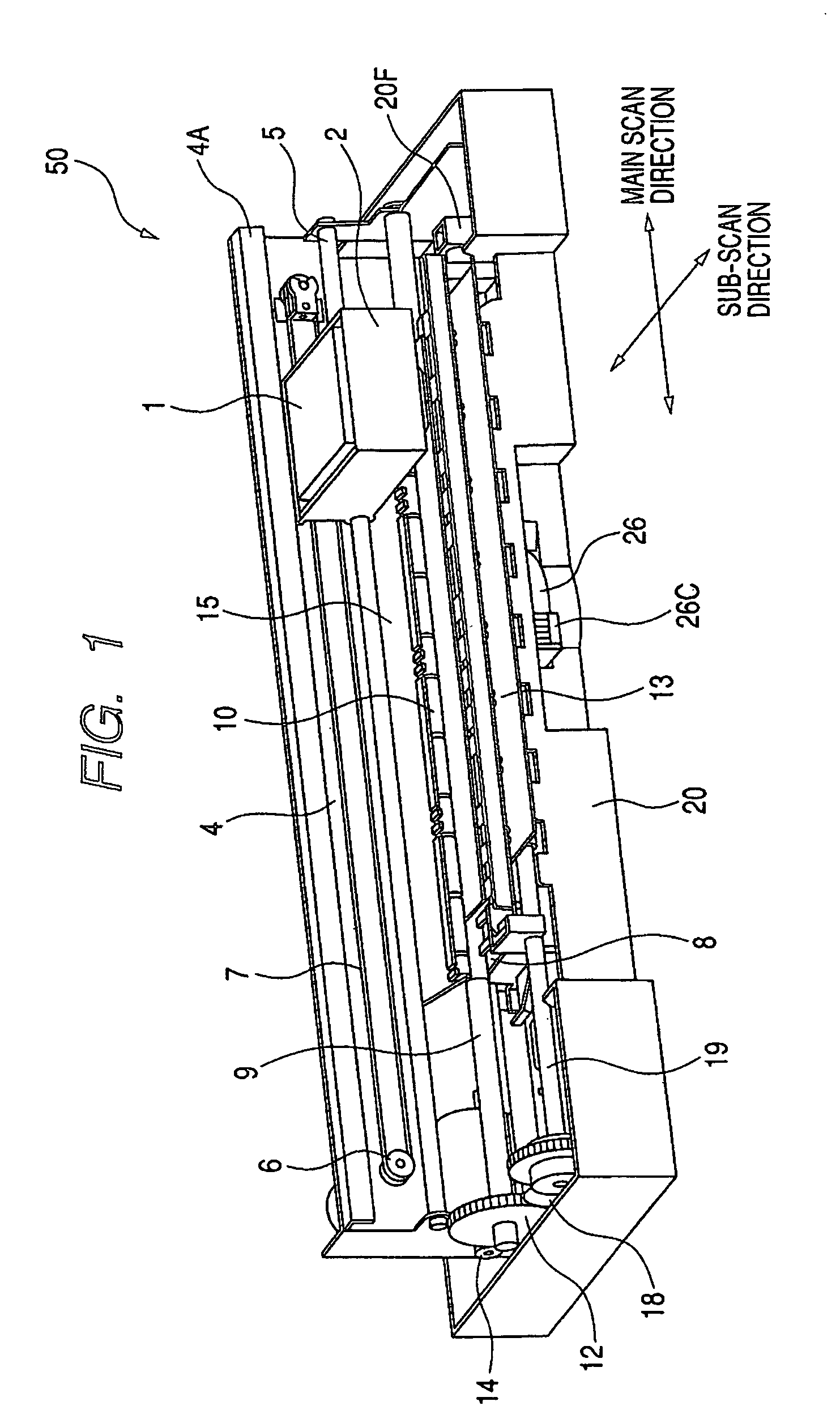

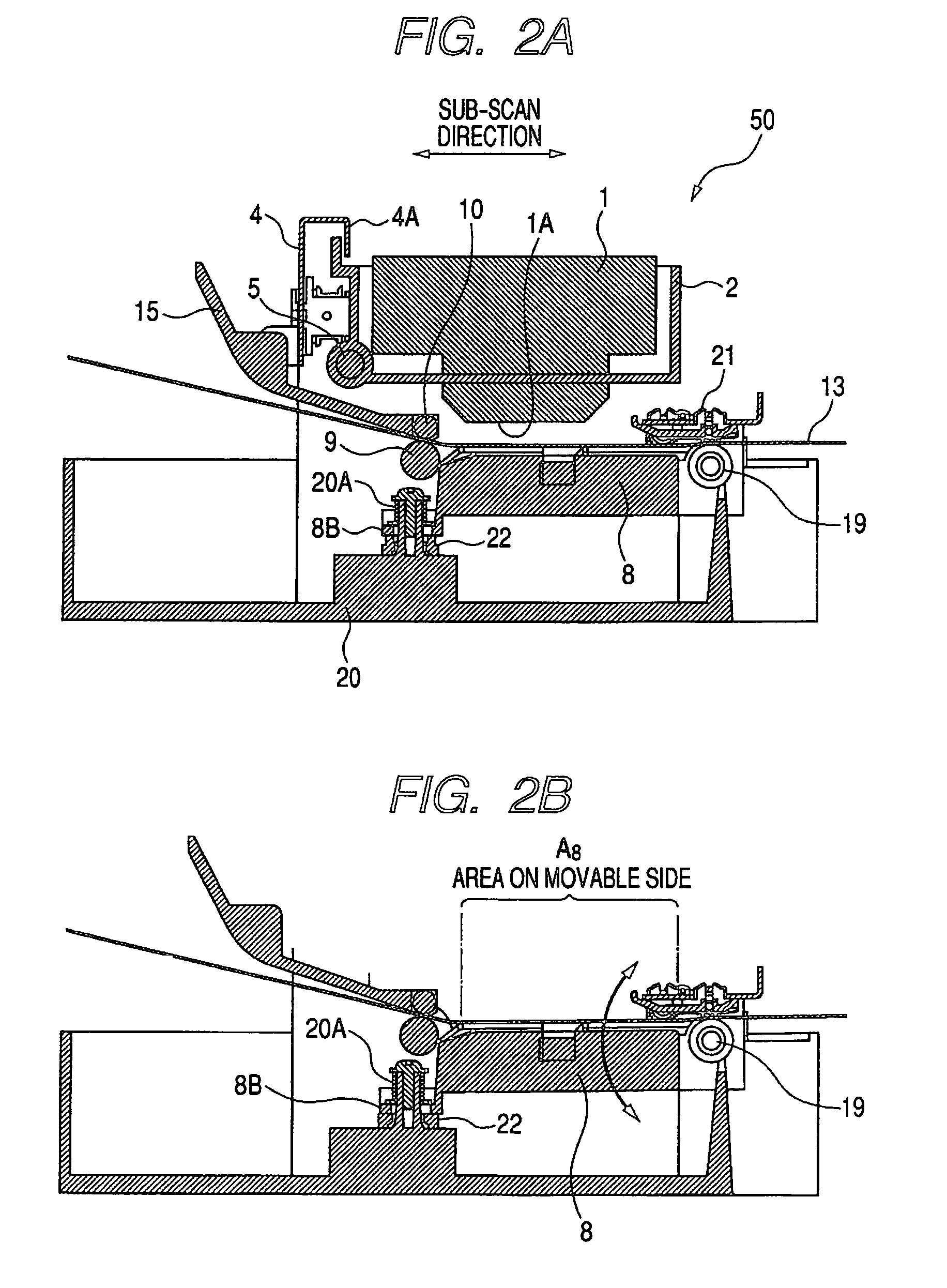

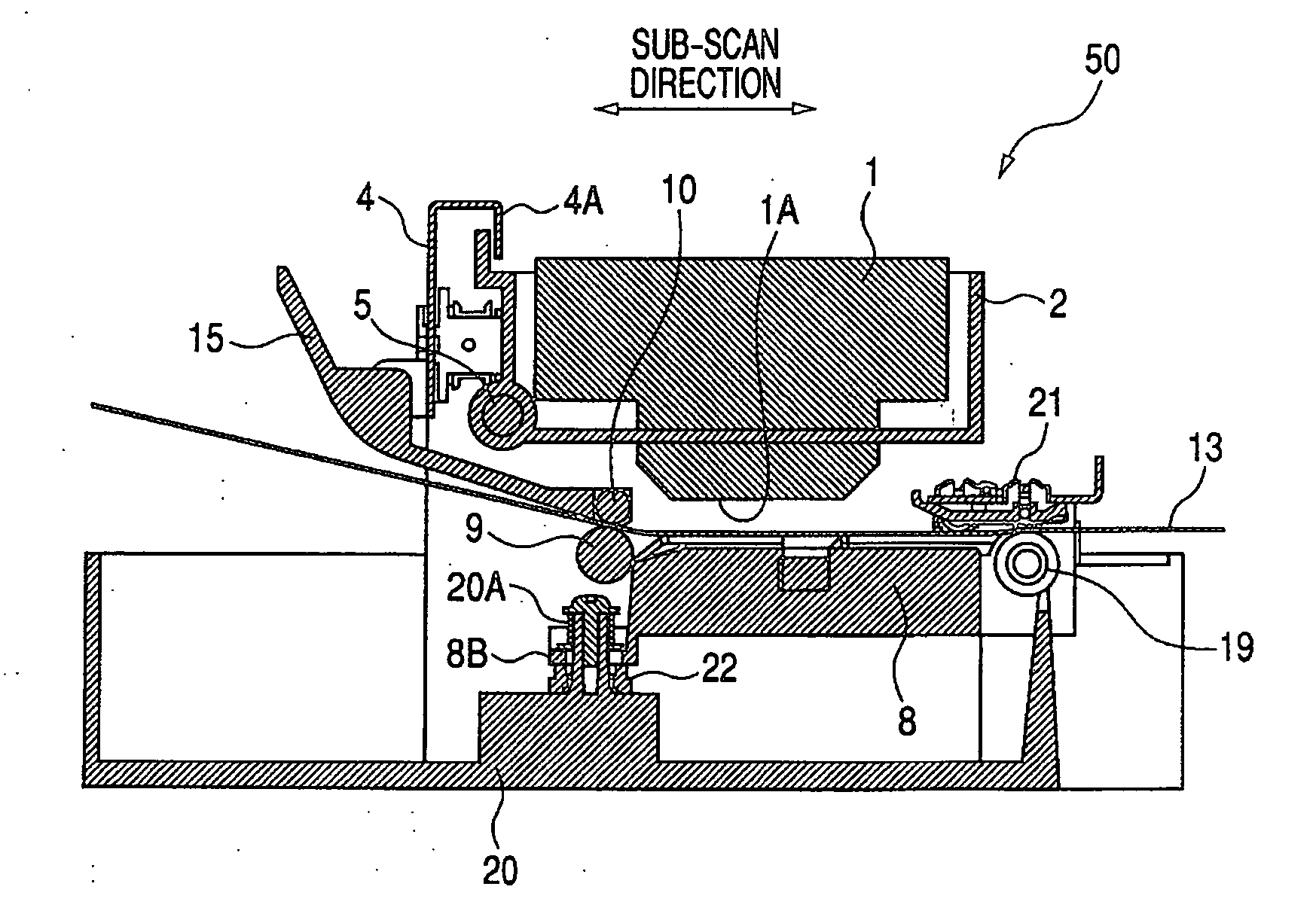

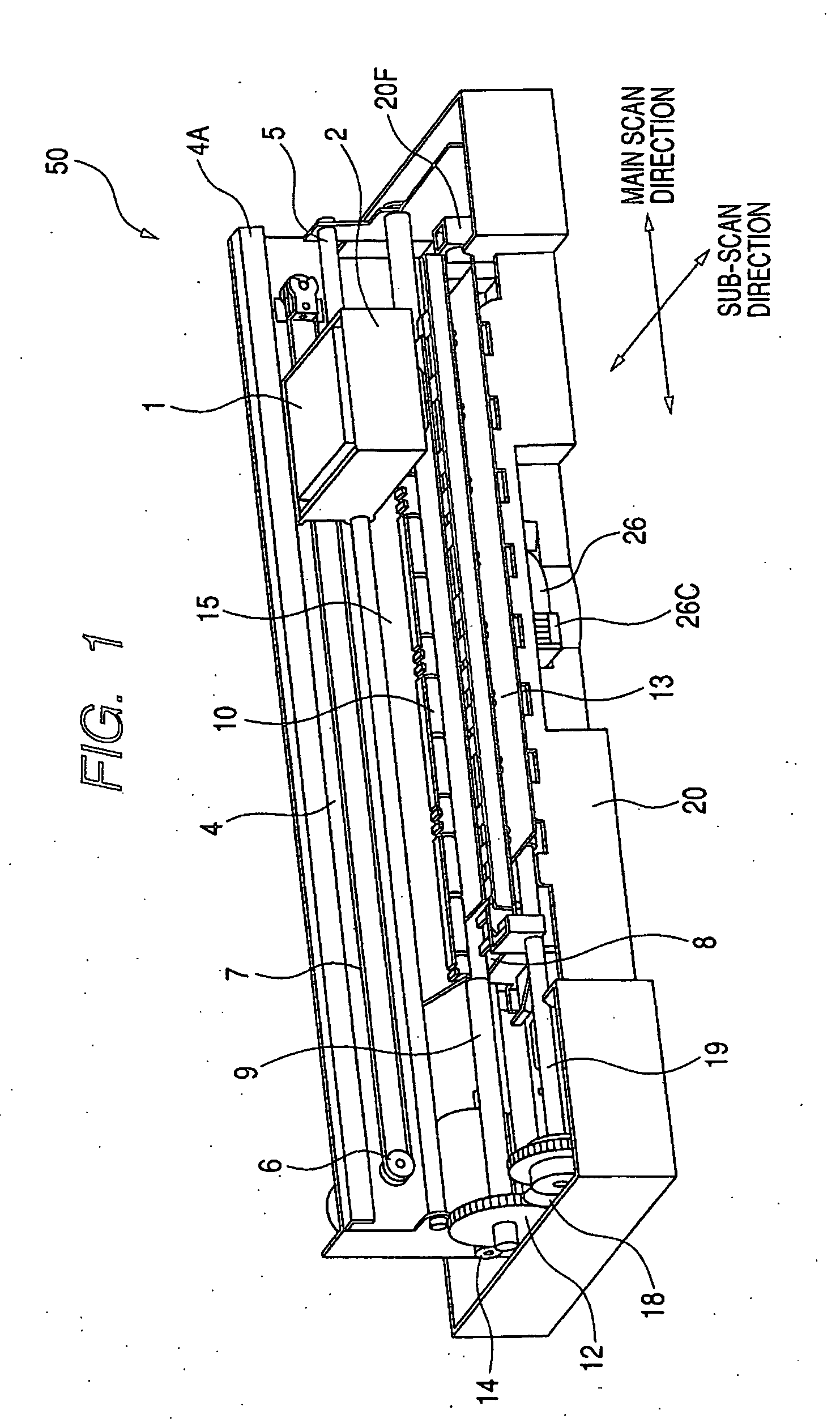

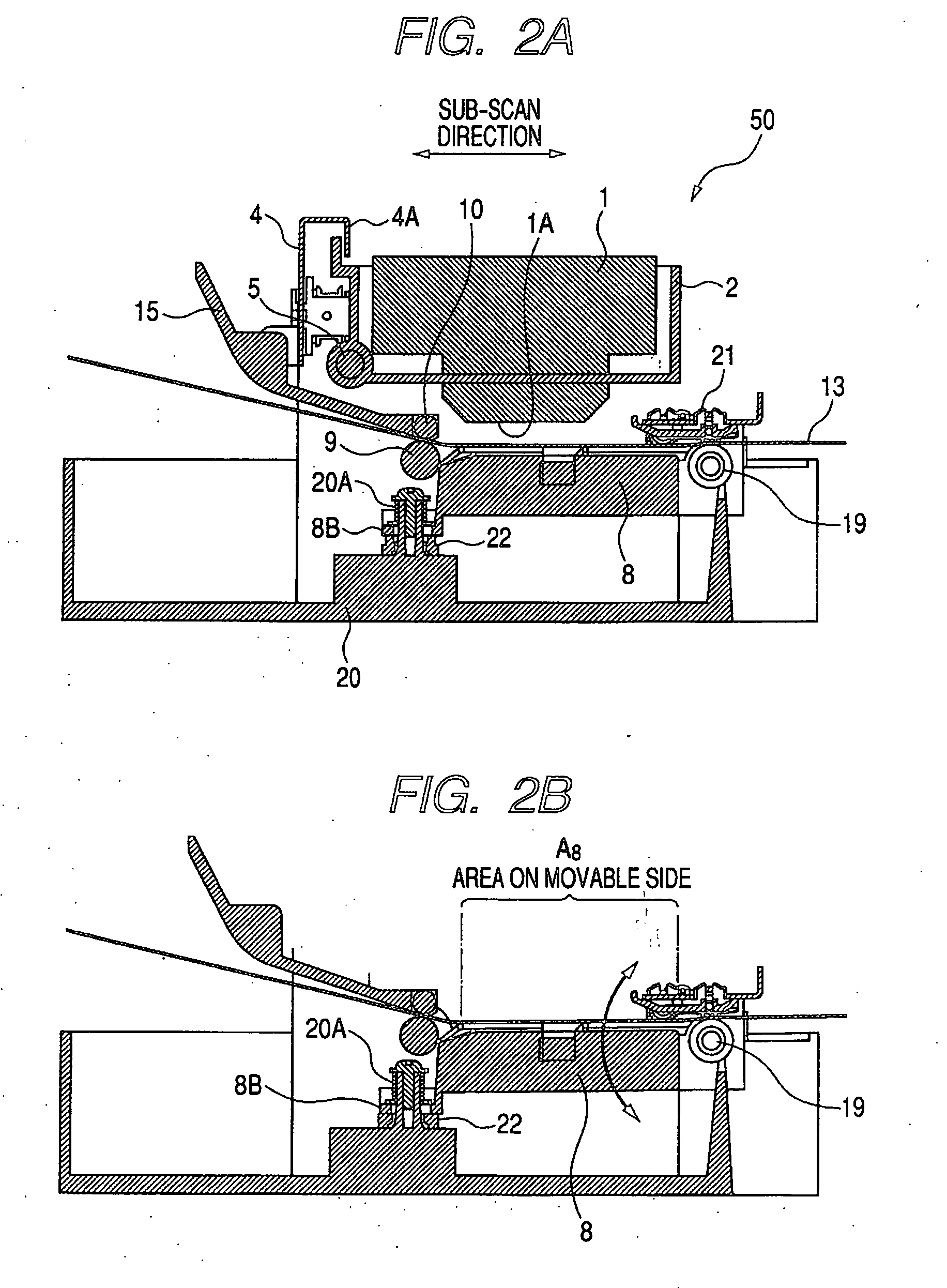

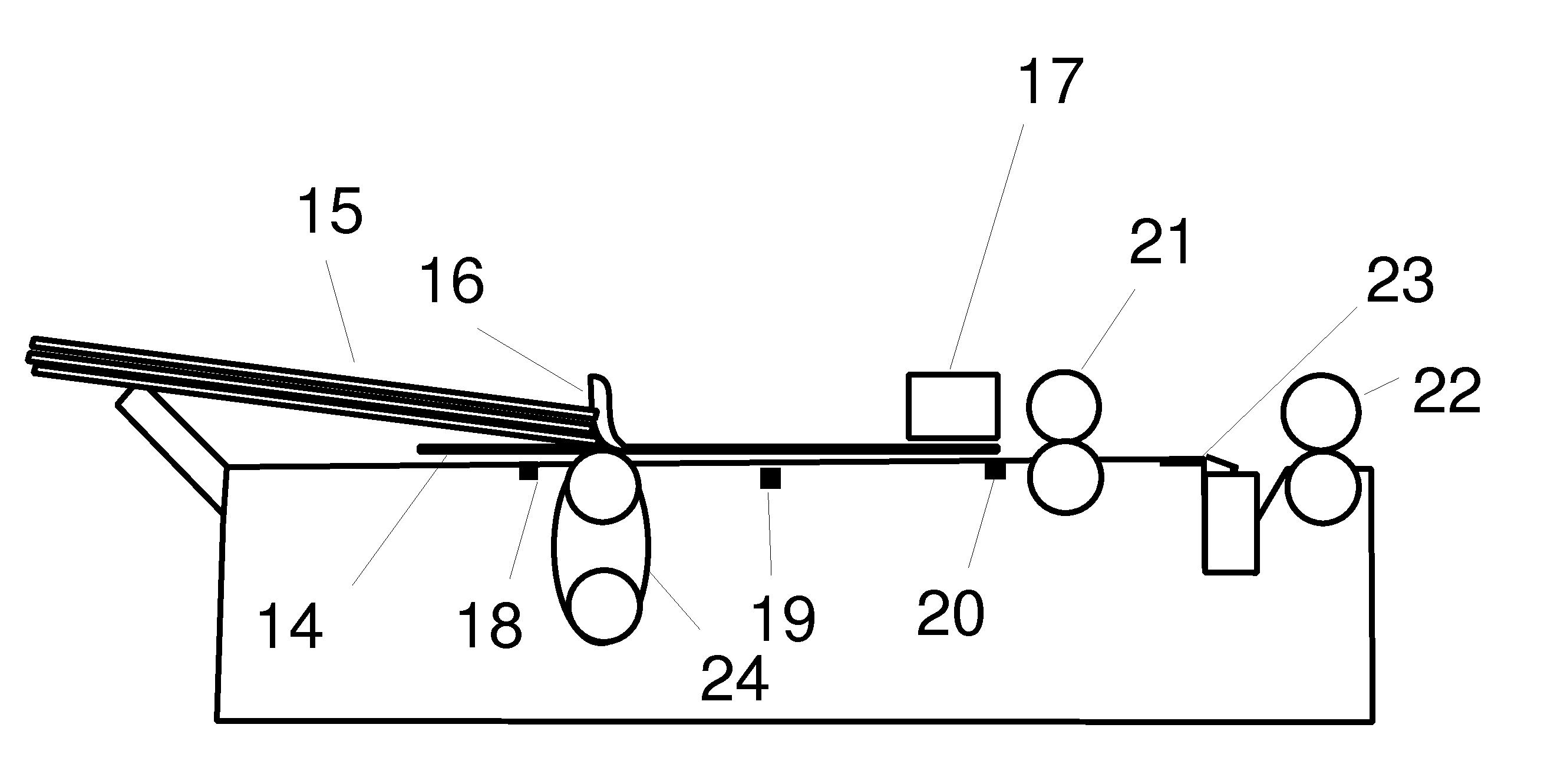

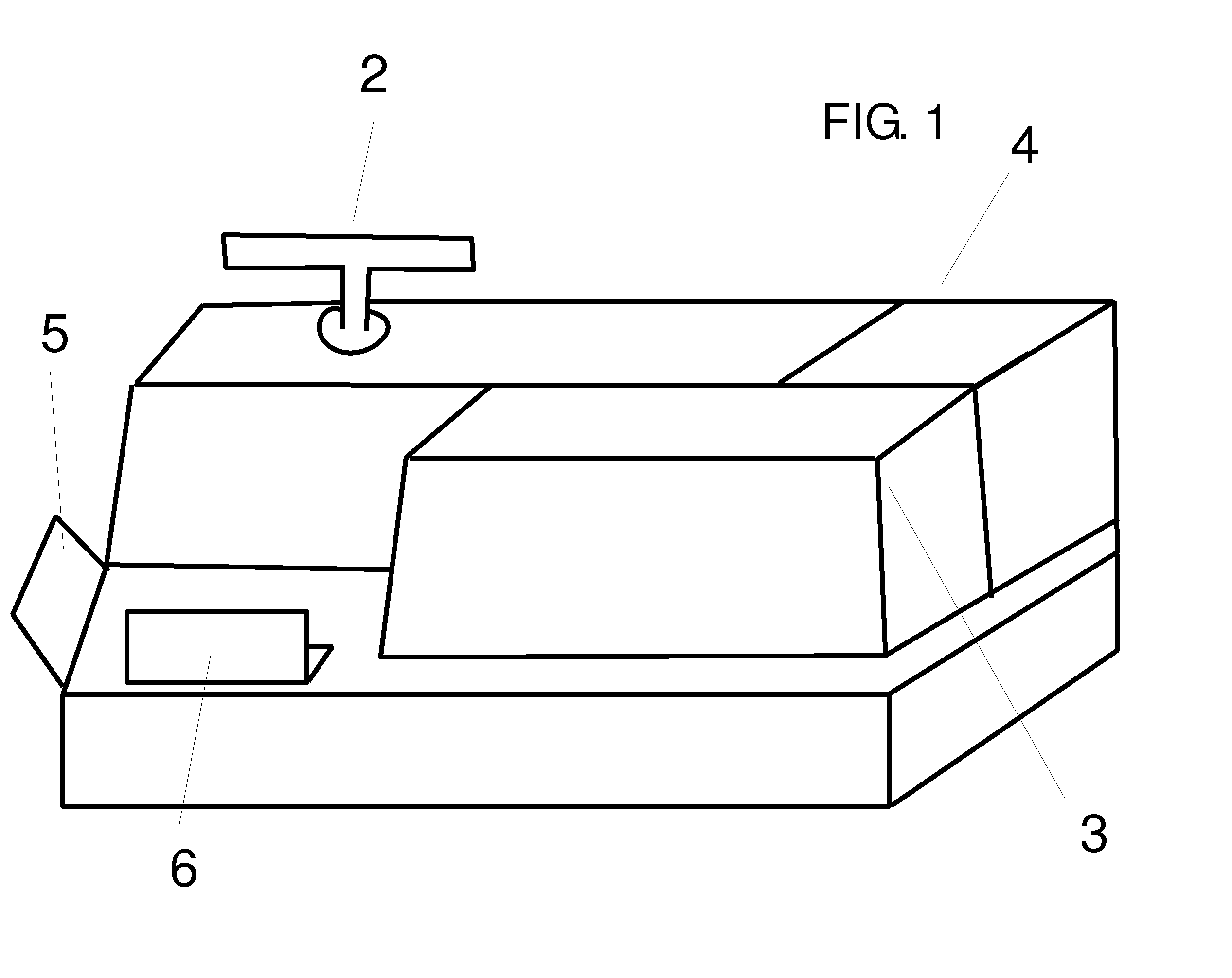

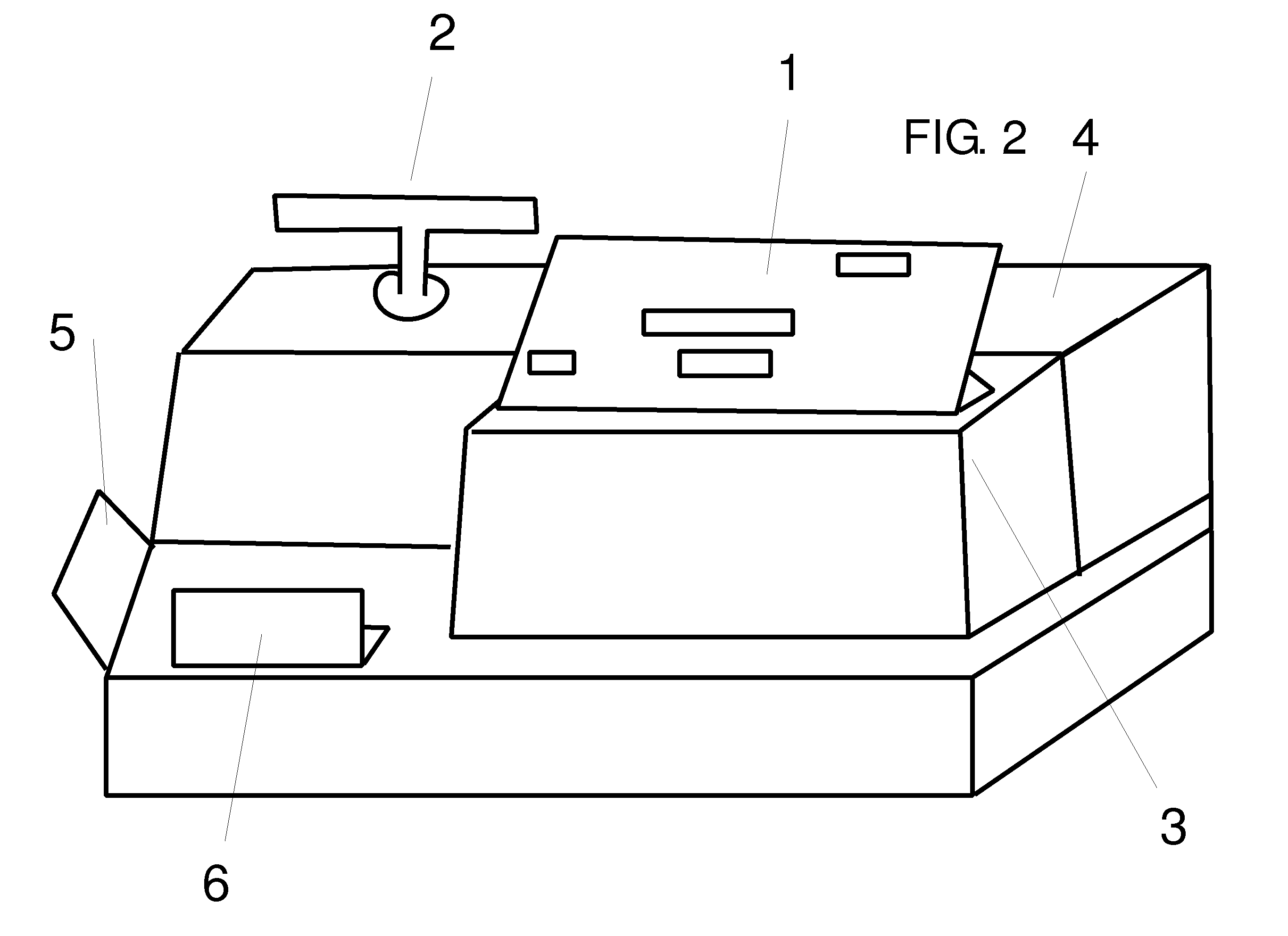

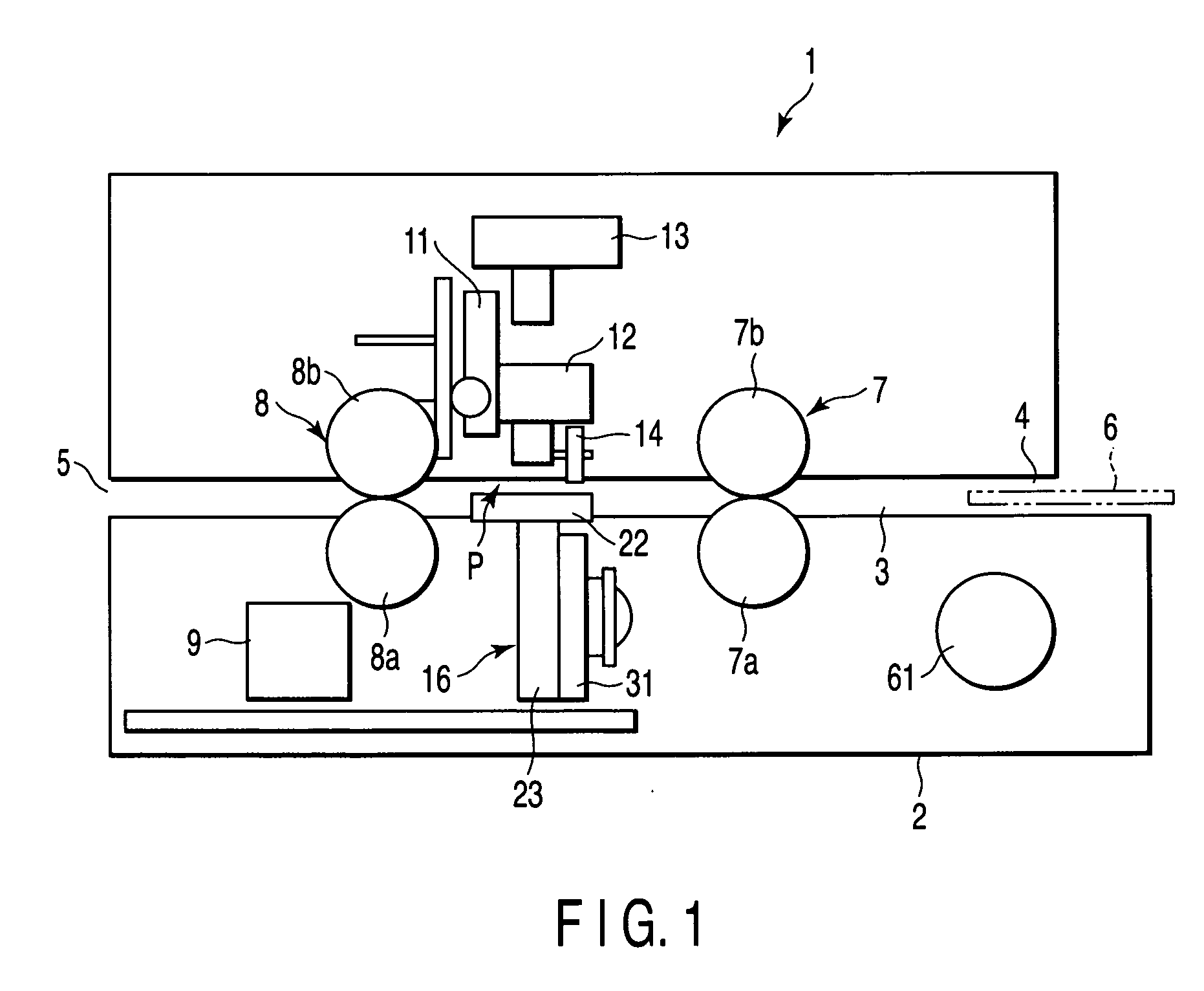

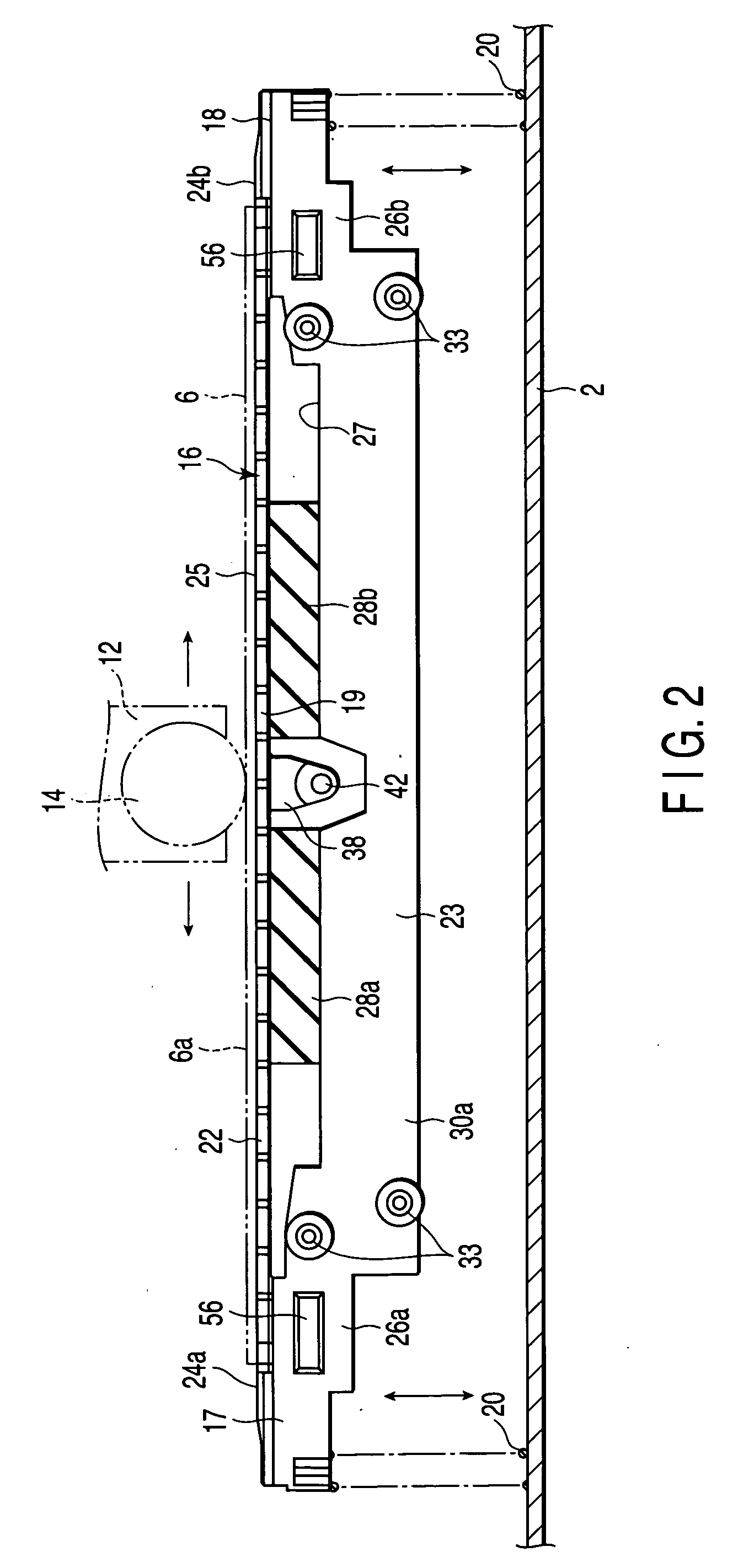

Recording apparatus

InactiveUS7735991B2AdvantageousMiniaturizationInk ribbon cartridgesRecording apparatusMiniaturizationEngineering

A recording apparatus is advantageous in miniaturization even though a mechanism for adjusting a head gap is included. The recording apparatus includes a carriage for detachably holding a cartridge, a platen for supporting one surface of a recording medium, and a conveying roller and an eject roller for conveying the recording medium. The platen is constructed so that it is rockable with an axis of the eject roller as a rotation center and is switchable between at least two positions.

Owner:CANON KK

Recording apparatus

InactiveUS20060256180A1MiniaturizationAdvantageousInk ribbon cartridgesRecording apparatusMiniaturizationEngineering

Provided is a recording apparatus which is advantageous in miniaturization even when a mechanism for adjusting a head gap is included. The recording apparatus includes a carriage for detachably holding a cartridge, a platen for supporting one surface of a recording medium, and a conveying roller and an eject roller for conveying the recording medium. The platen is constructed so that it is rockable with an axis of the eject roller as a rotation center and is switchable between at least two positions.

Owner:CANON KK

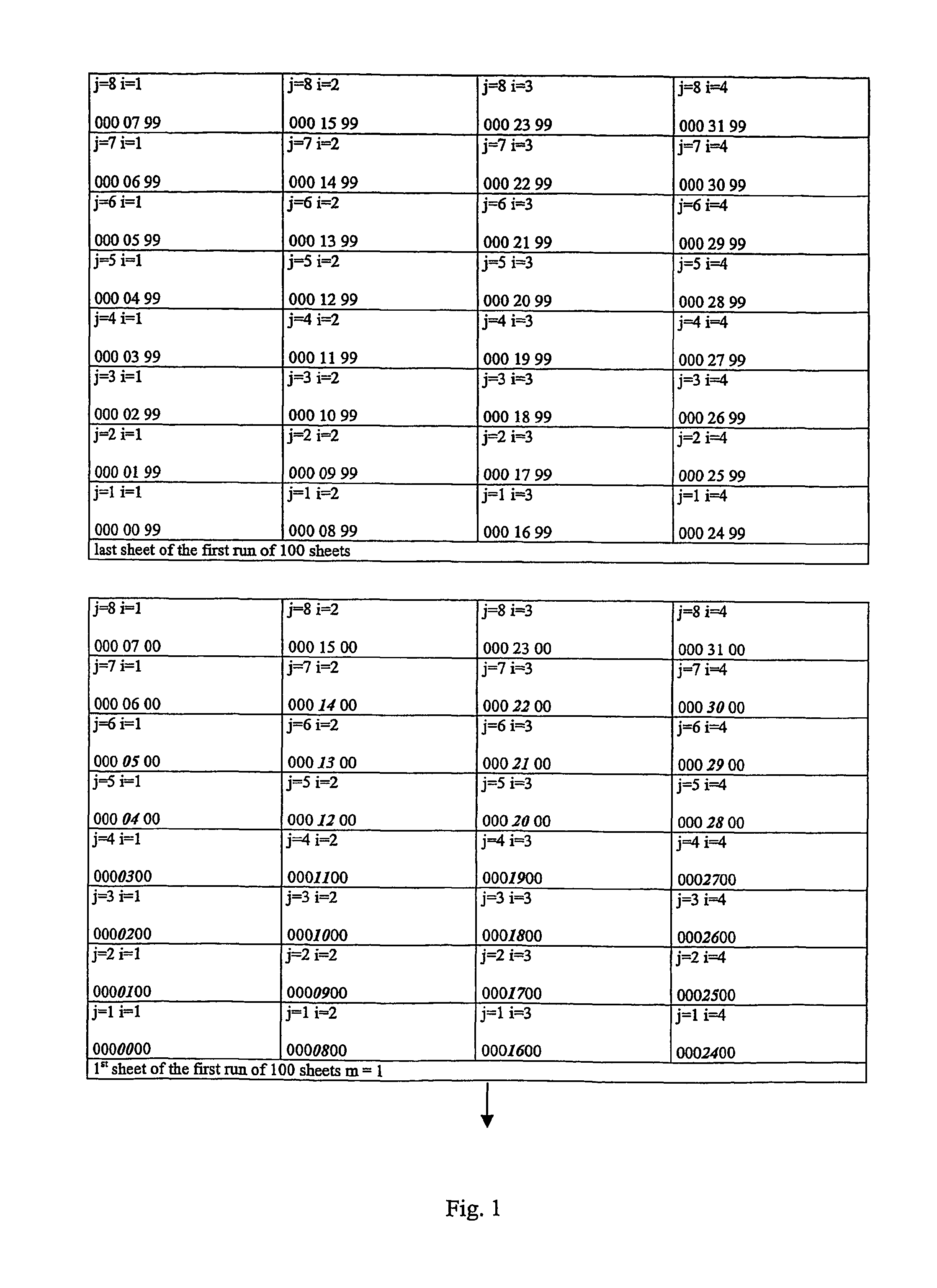

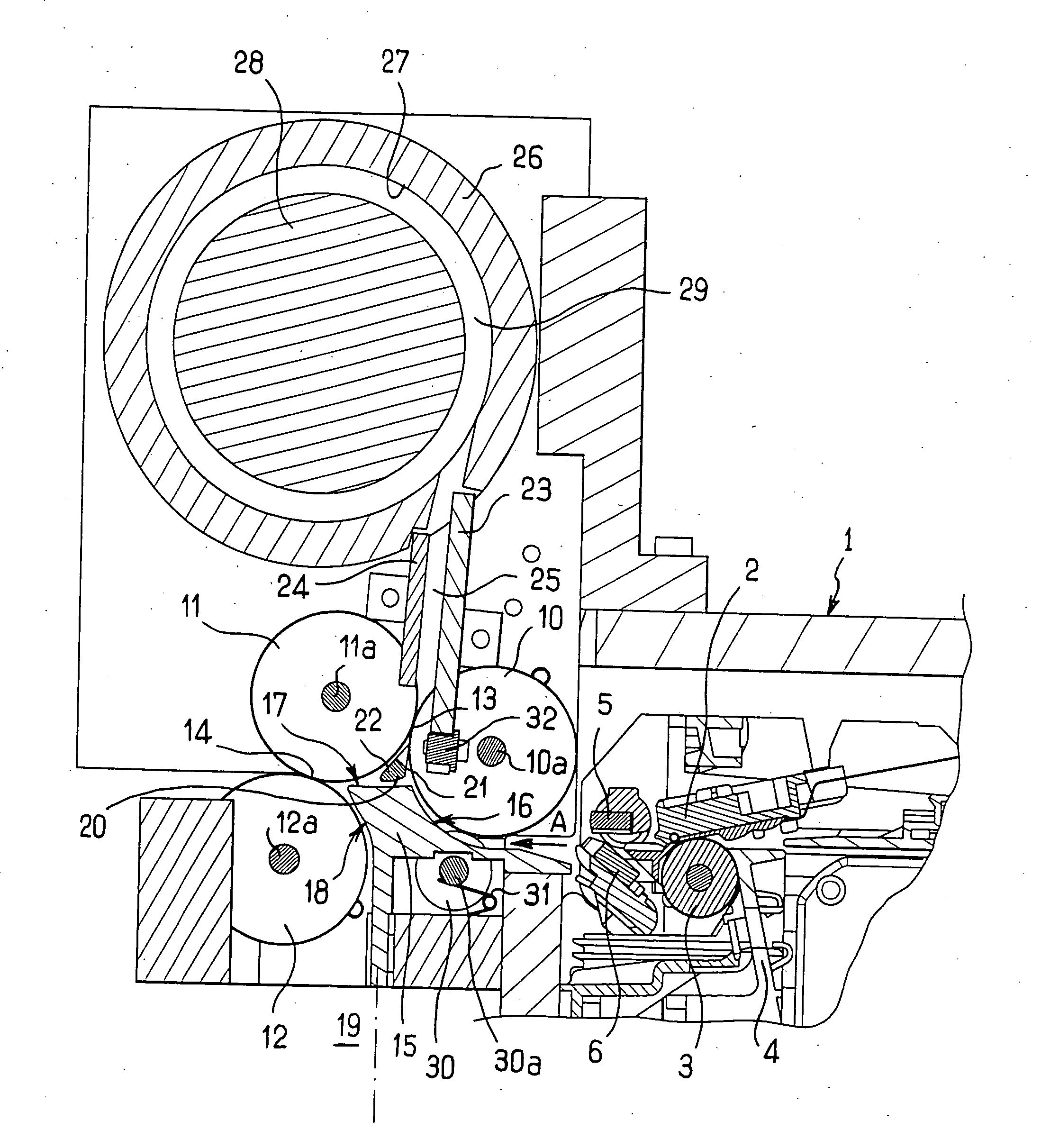

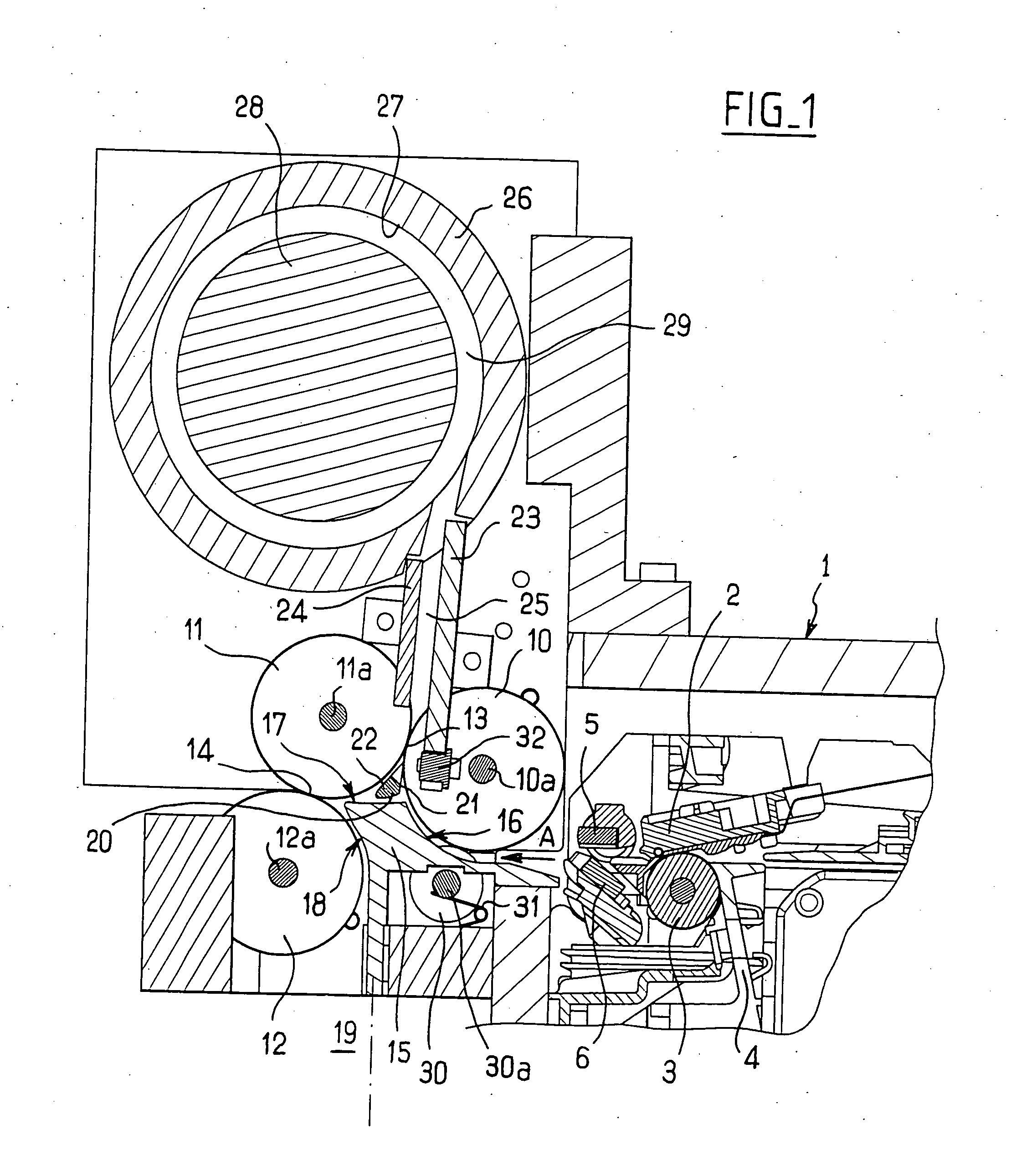

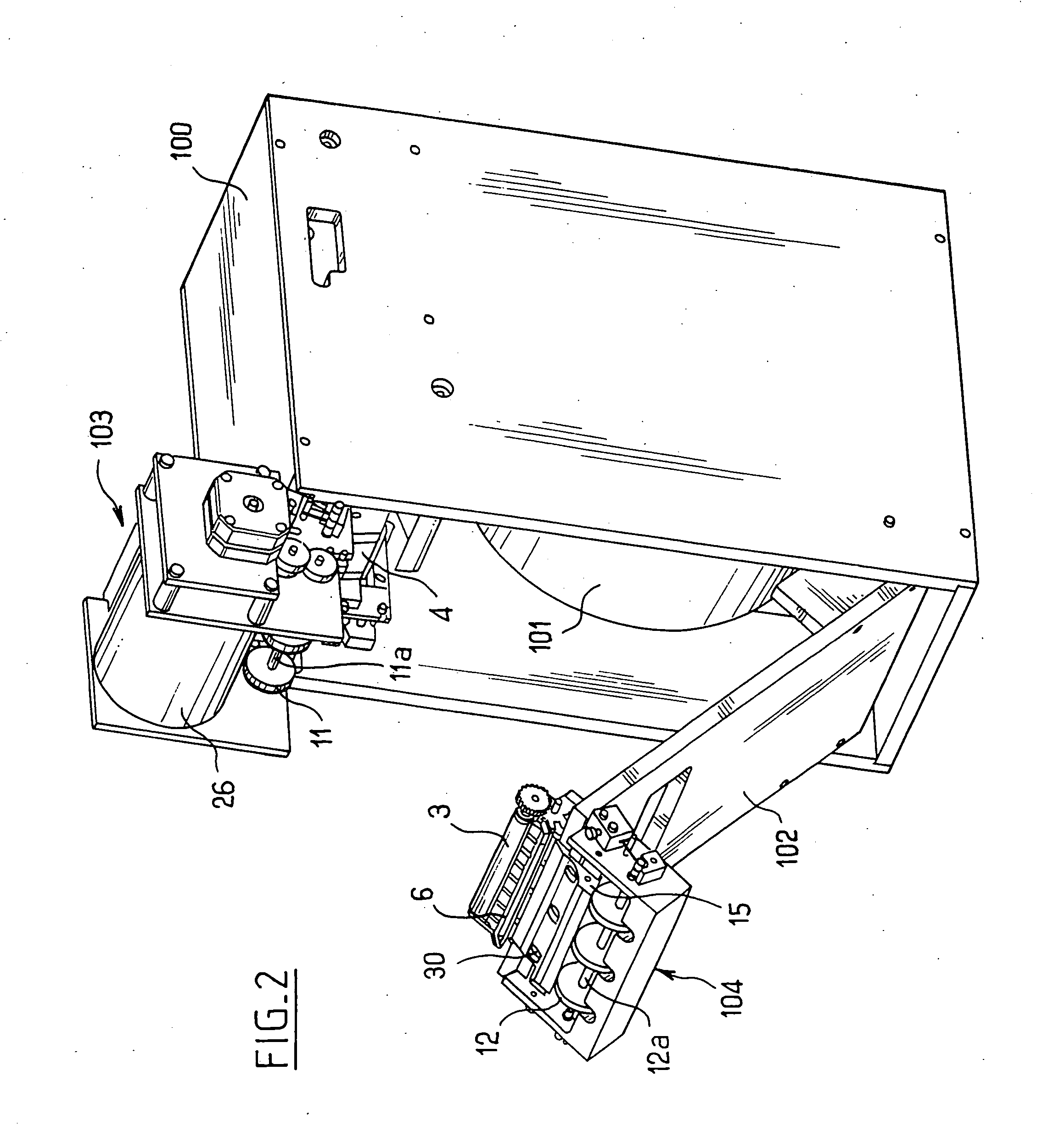

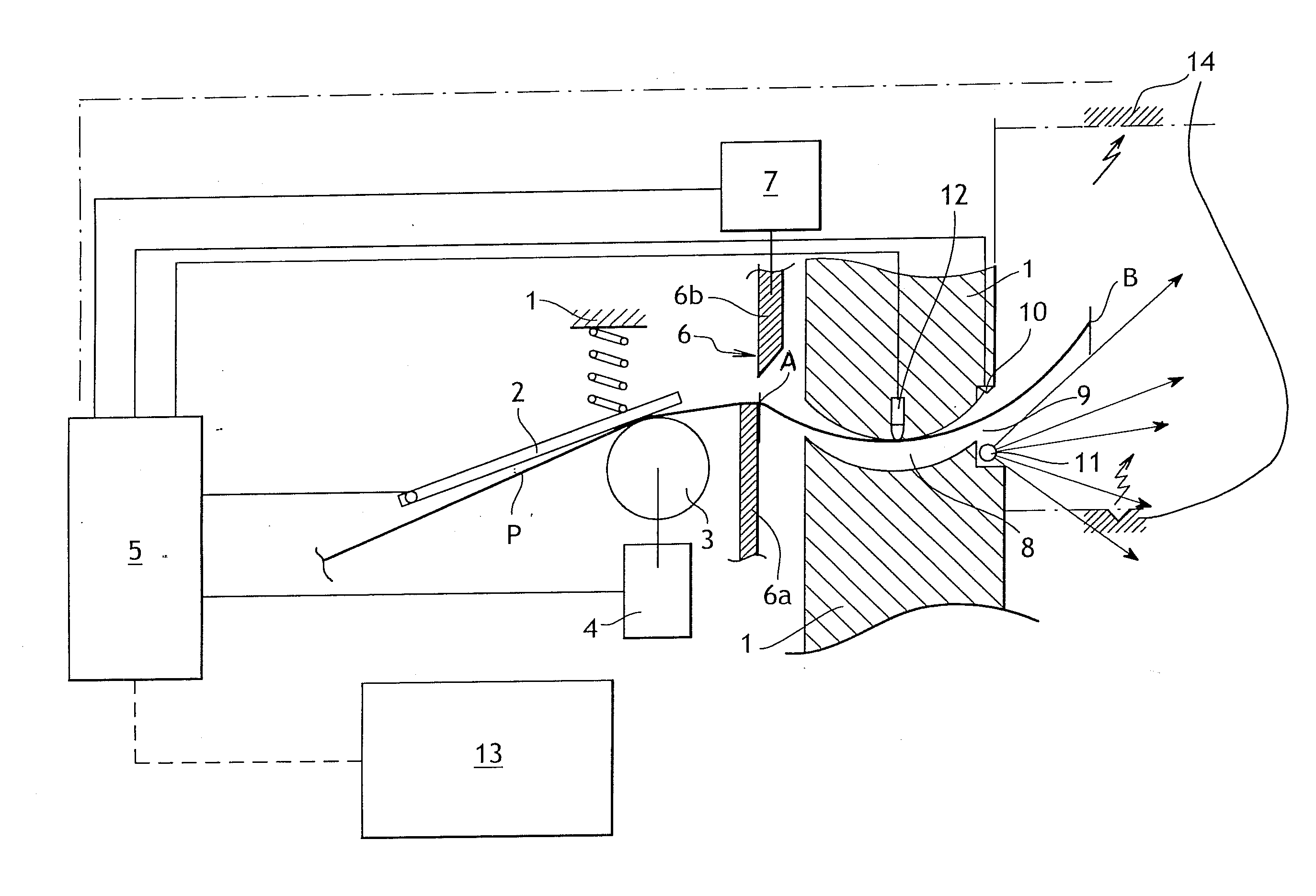

Numbering process and numbering box to carry out the process

ActiveUS7216583B2Easy to manufactureAddressing machinesDigitally marking record carriersEngineeringPrinting press

The numbering box for typographic numbering in sheet or web fed printing machines, said box numbering with p digits k*n items on said sheets or web for allowing a sequential collecting of said items in the finishing and collating process of layers of q sheets or of web cut into layers of q sheets, wherein said box carries out a purely sequential actuation for digits 1 to s, where 10S is smaller or equal to q, a purely individually settable actuation for digits s+1 to r, where the maximum number printable by digits 1 to s and s+1 to r is smaller or equal to k*n*q, and a sequential actuation for digits r+1 to p.

Owner:KBA NOTASYS SA

Method of printing unique prints or individually assembled printed products on rotary printing machines

InactiveUS6755129B2Low production costCheap productionAddressing machinesAddressographsEngineeringPrinting press

Owner:MANROLANAD AG

Device for making a printed ticket available

InactiveUS20060137549A1Addressing machinesApparatus for meter-controlled dispensingMechanical engineeringEngineering

A device for making a printed ticket available, the device being comprising at least three rollers or lines of wheels rotatable about respective parallel axes extending substantially transversely across the path of the ticket and situated, in end view, at the vertices of a triangle and defining two ticket pinch lines, one between a first roller and a second roller, and the other between said second roller and a third roller, a first deflector surface co-operates with the first roller to define a first guide for guiding the ticket from a ticket supply source to a first pinch line, a second deflector surface co-operates with the second roller to define a second guide for guiding the ticket from the first pinch line to a second pinch line, and the third roller co-operates with a third deflector surface to define a third guide for guiding the ticket from the second pinch line to a ticket collection channel, the three guides being inscribed within the above-mentioned triangle.

Owner:AXIOHM

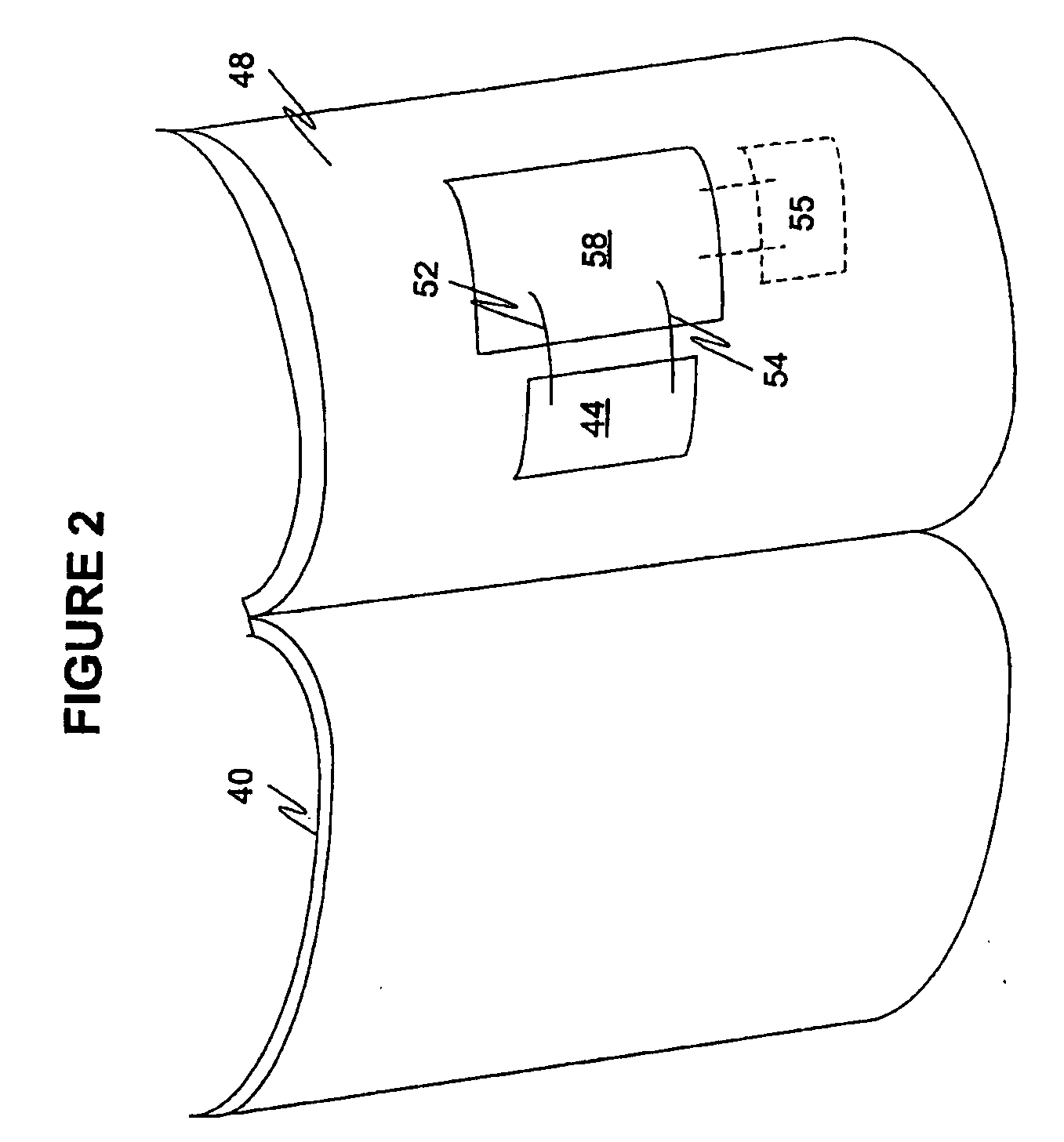

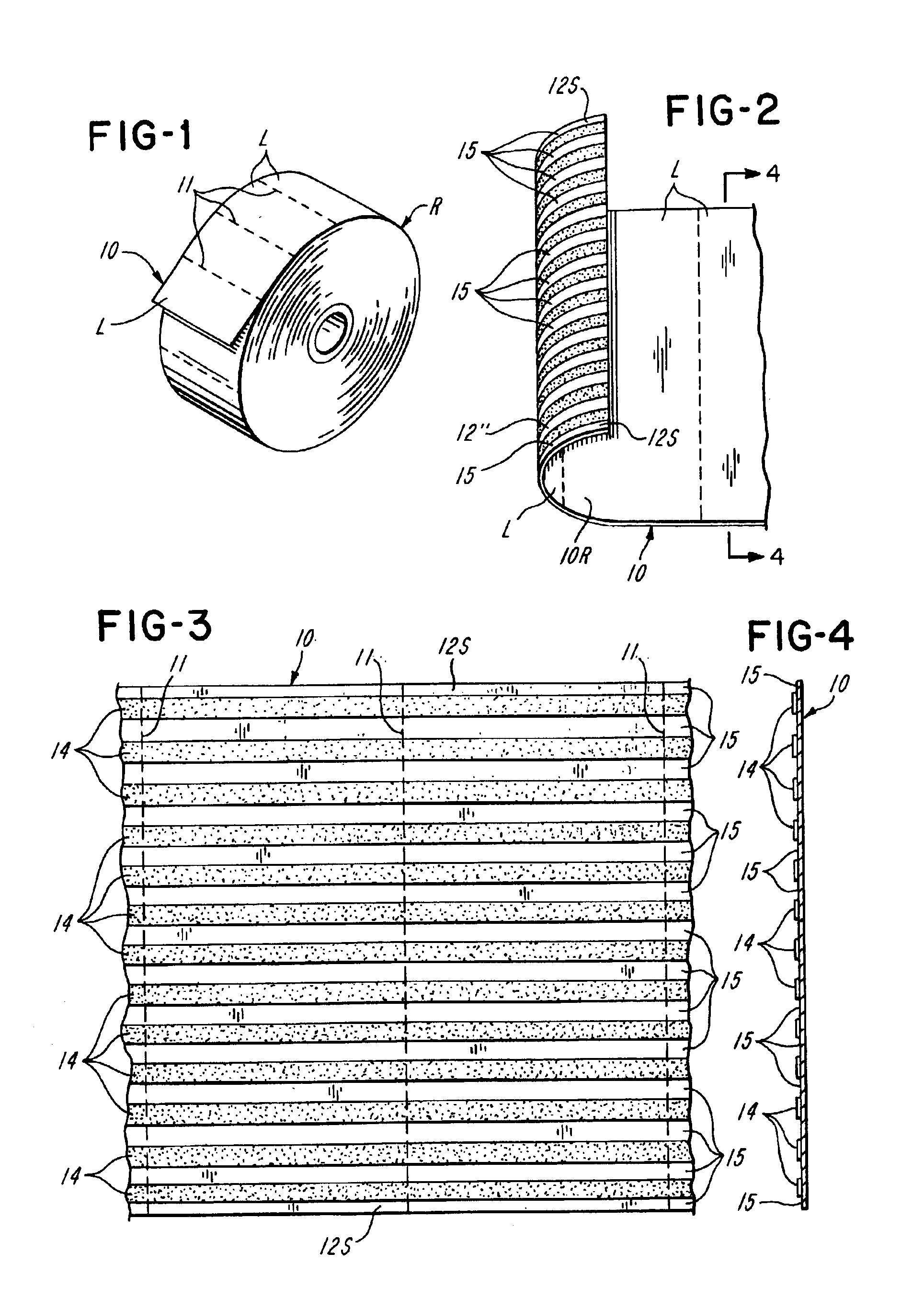

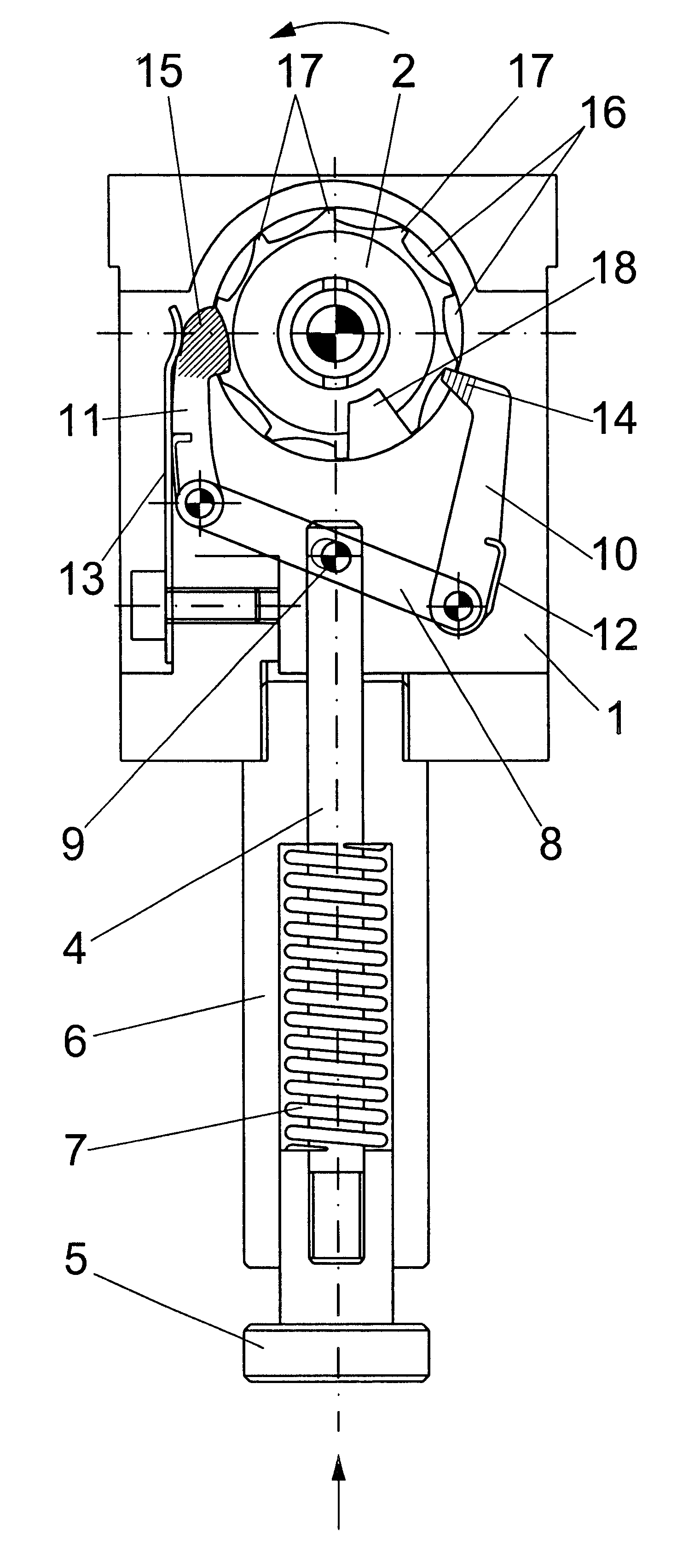

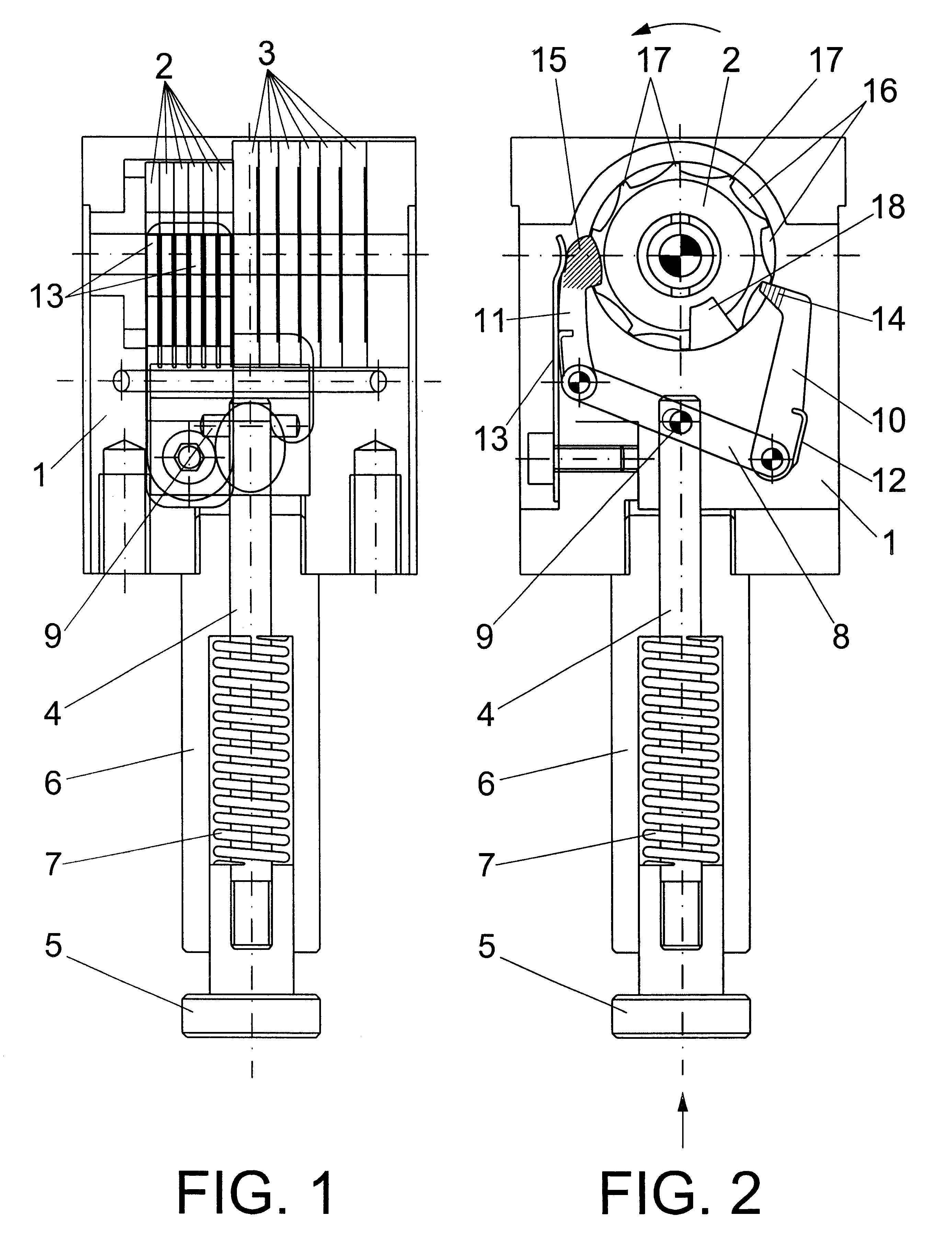

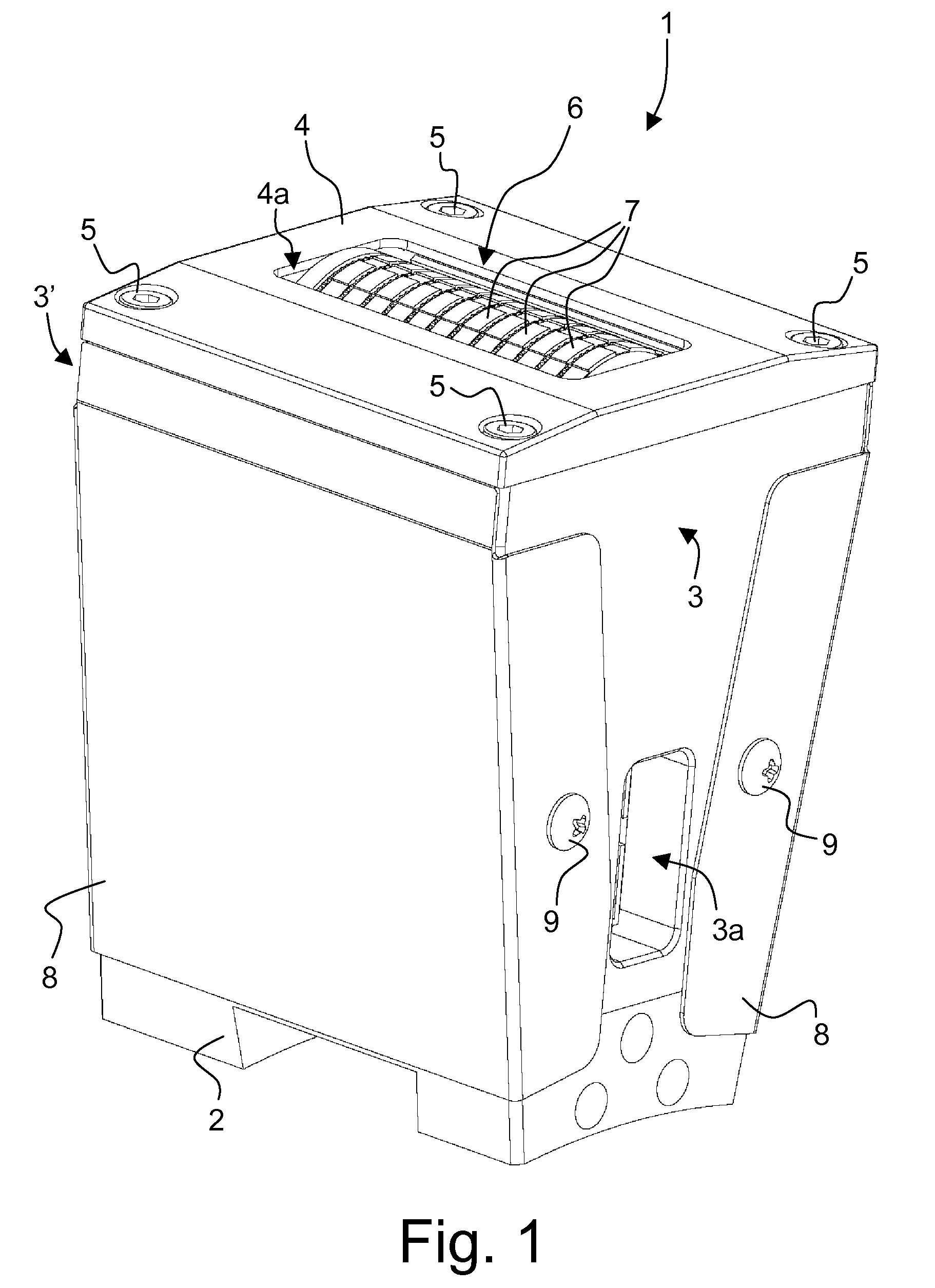

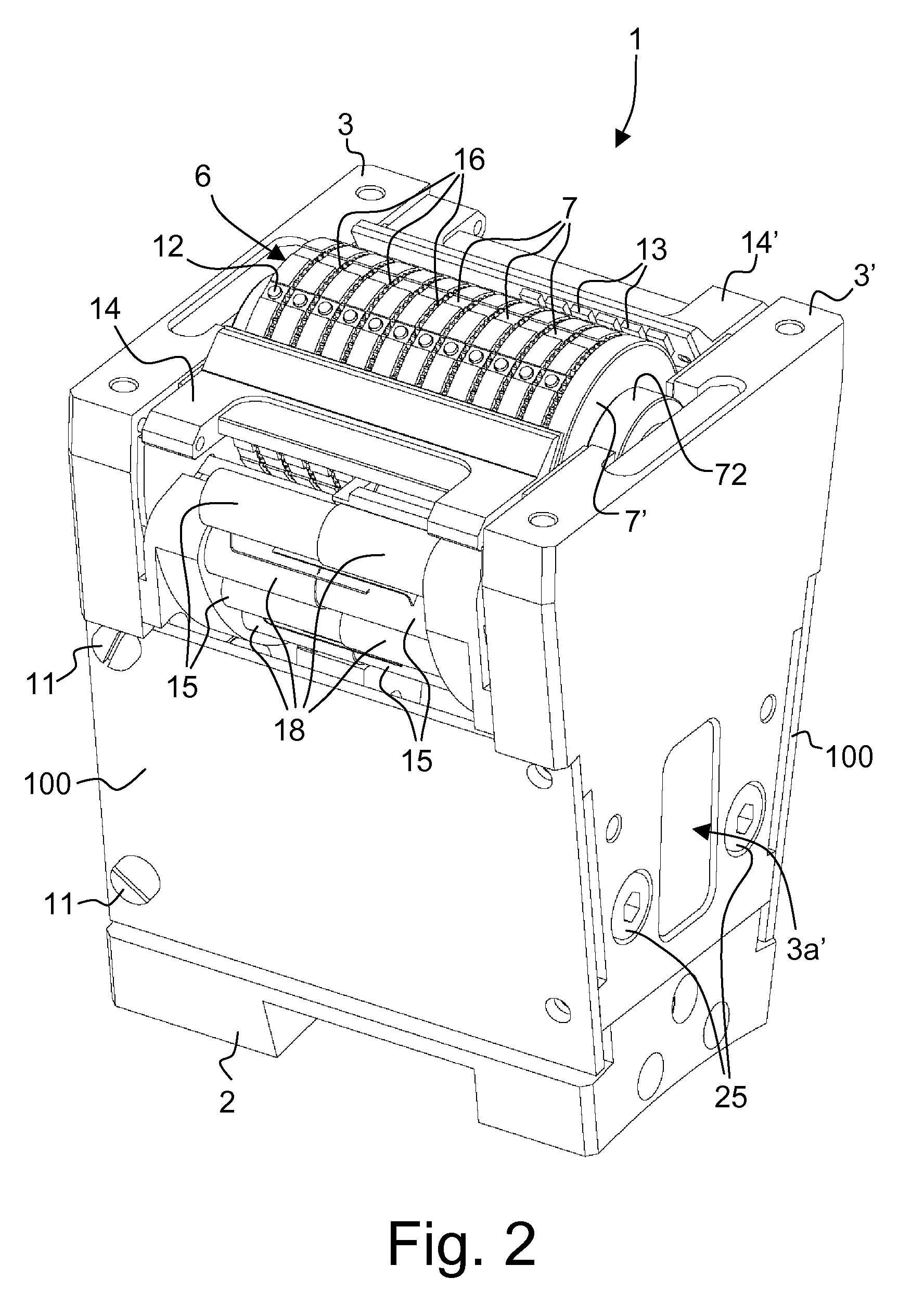

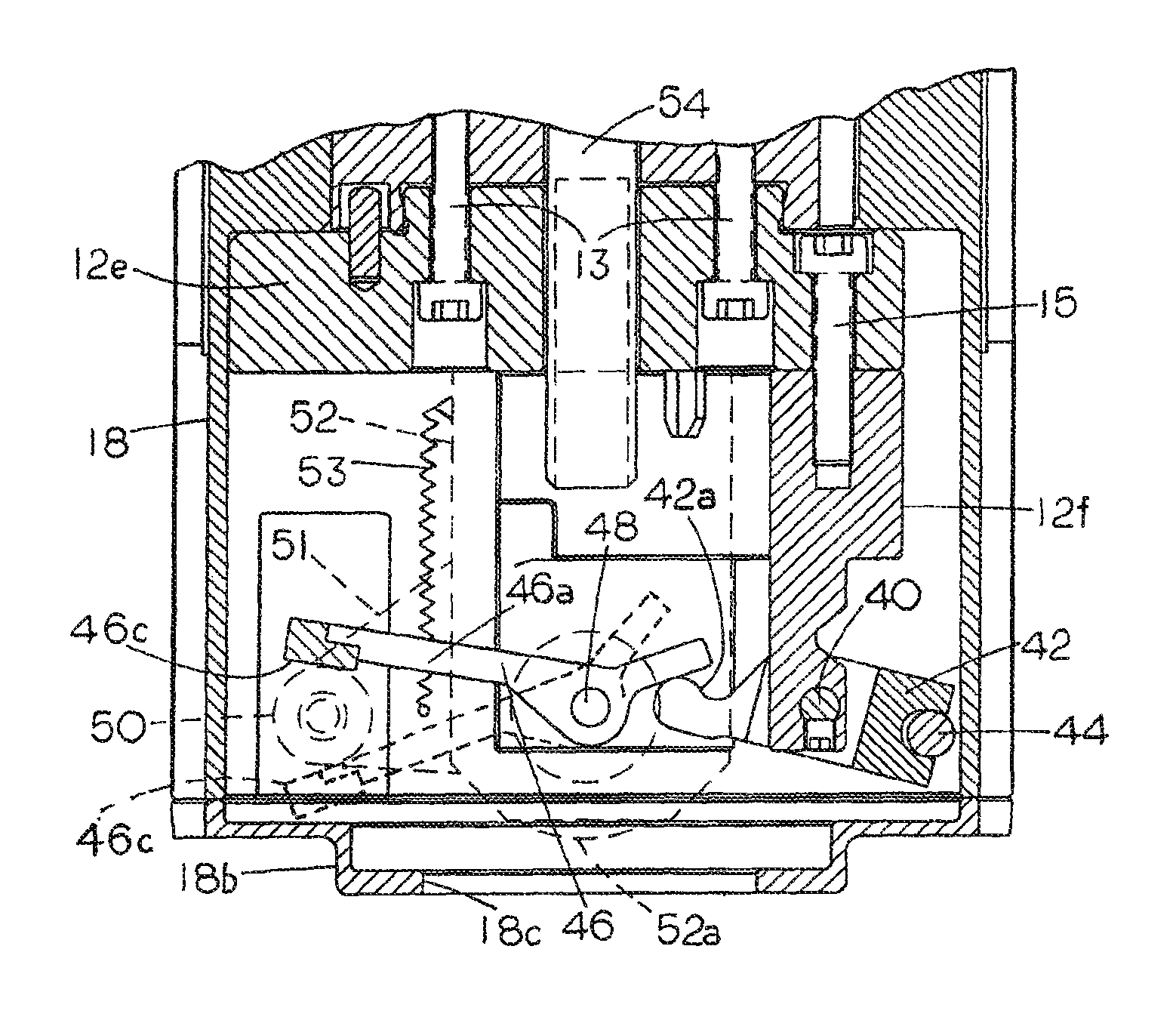

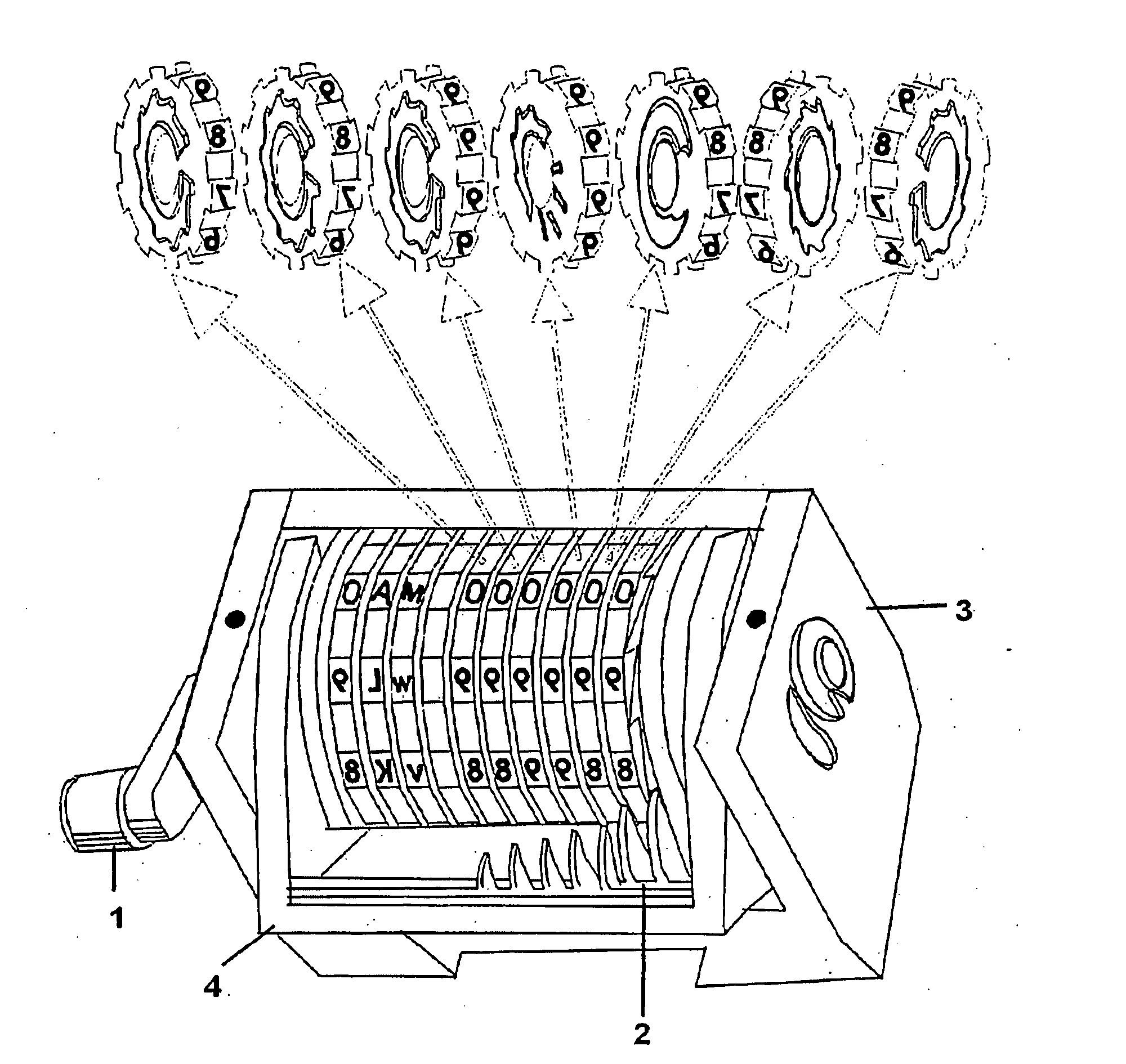

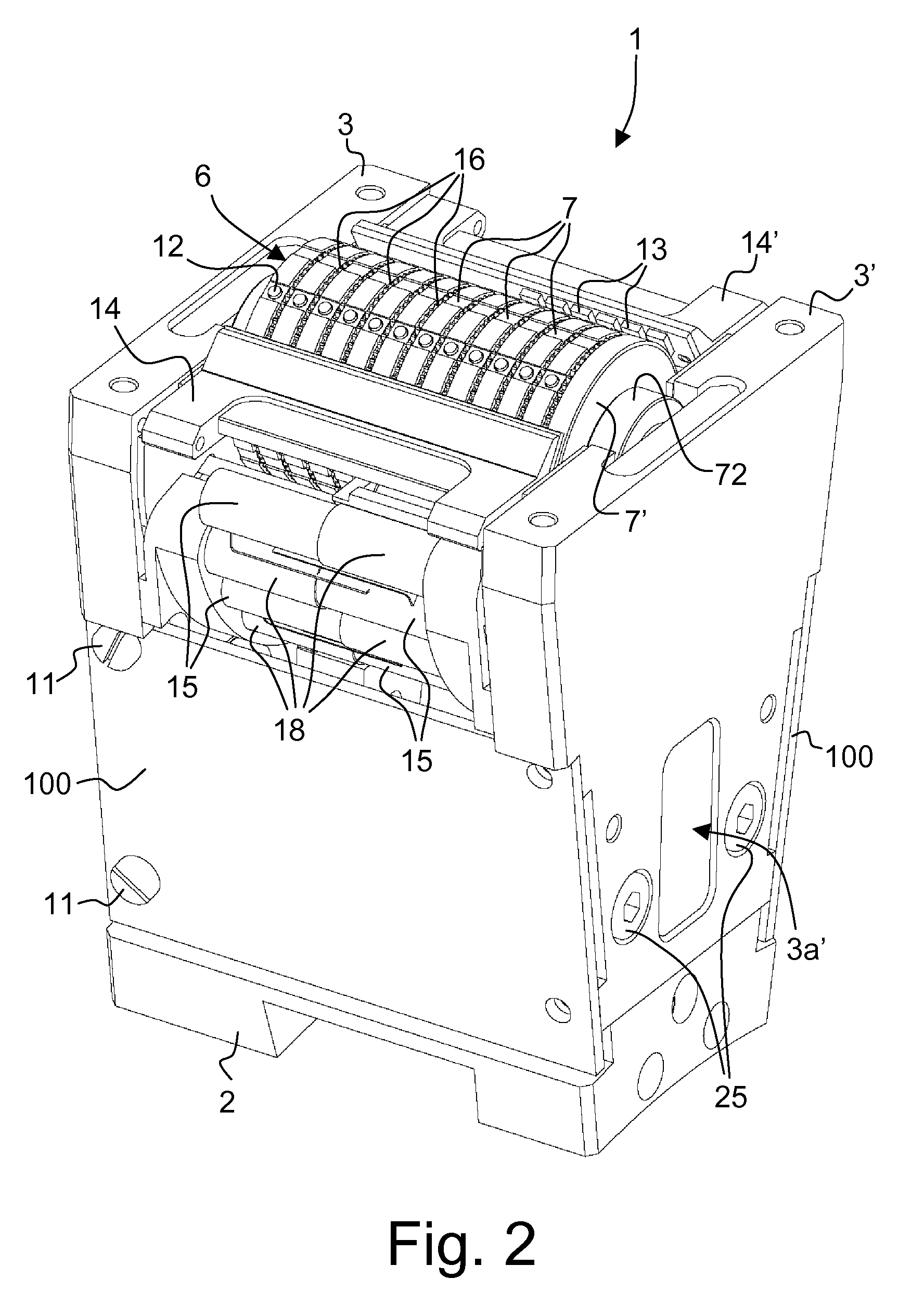

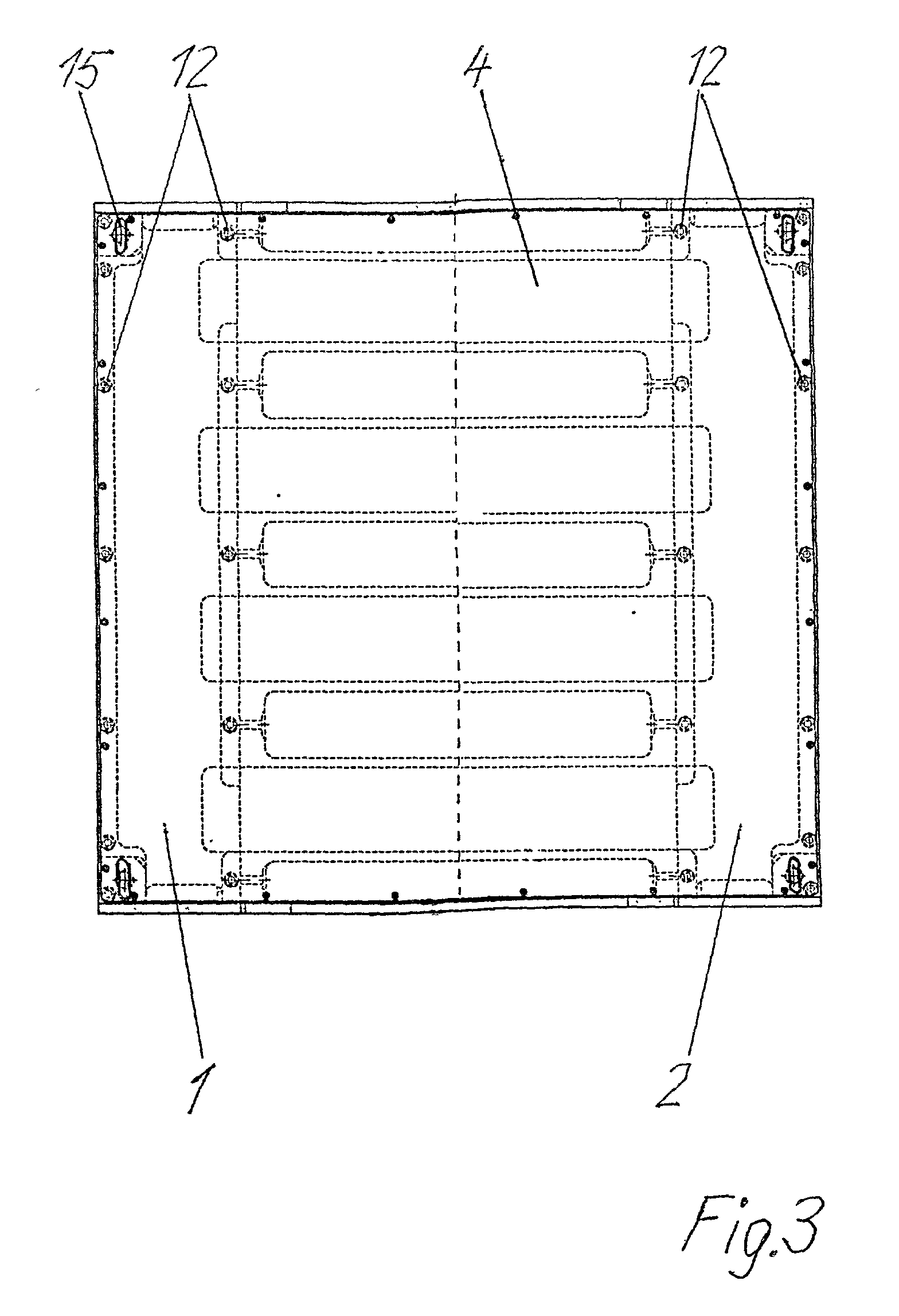

Sequential numbering machine for injection moulds

The numbering machine comprises a series of cams (2) and a series of wheels (3), each cam (2) being connected with a wheel (3), so that the turning of a cam (2) signifies the turning of a wheel (3). The cams (2) have on their periphery nine projections (17) and a recess or hollow (18), while each wheel (3) has on its periphery the digits corresponding to the first nine numbers. The assembly is mounted in an interior casing (1) from which a spindle (4) emerges operable sequentially in each process of injection of a piece, so that through that spindle (4) and by means of a lever (8) articulated thereto individual arms (10) and (11) are operated, the first of them having a toothed sector (14) the teeth of which are pushed for each tooth to press on a single cam (2) until the complete turn takes place, the interlocking taking place of a second tooth with the second cam (2) and so forth, so that in each sectorial turning of the cam (2) the sectorial turning of the respective wheel takes place (3) and therefore the sequential advance of the corresponding number. The arm (11) has a series of prongs (15) which maintain the wheels (3) immobilised with the exception of that which is operated by the corresponding cam (2). The numbering machine is foreseen for marking pieces obtained by injection.

Owner:COMML DE UTILES Y MOLDES

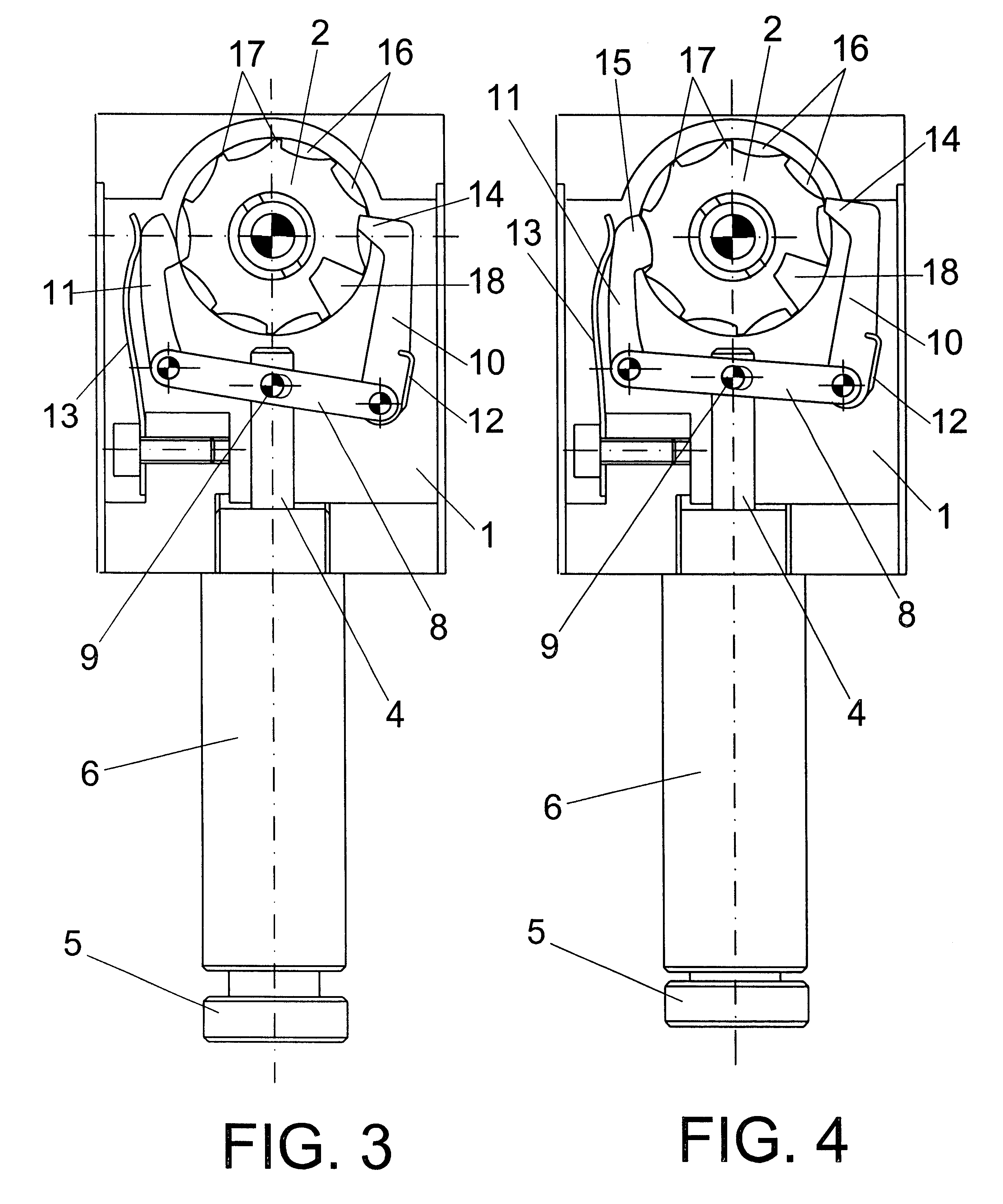

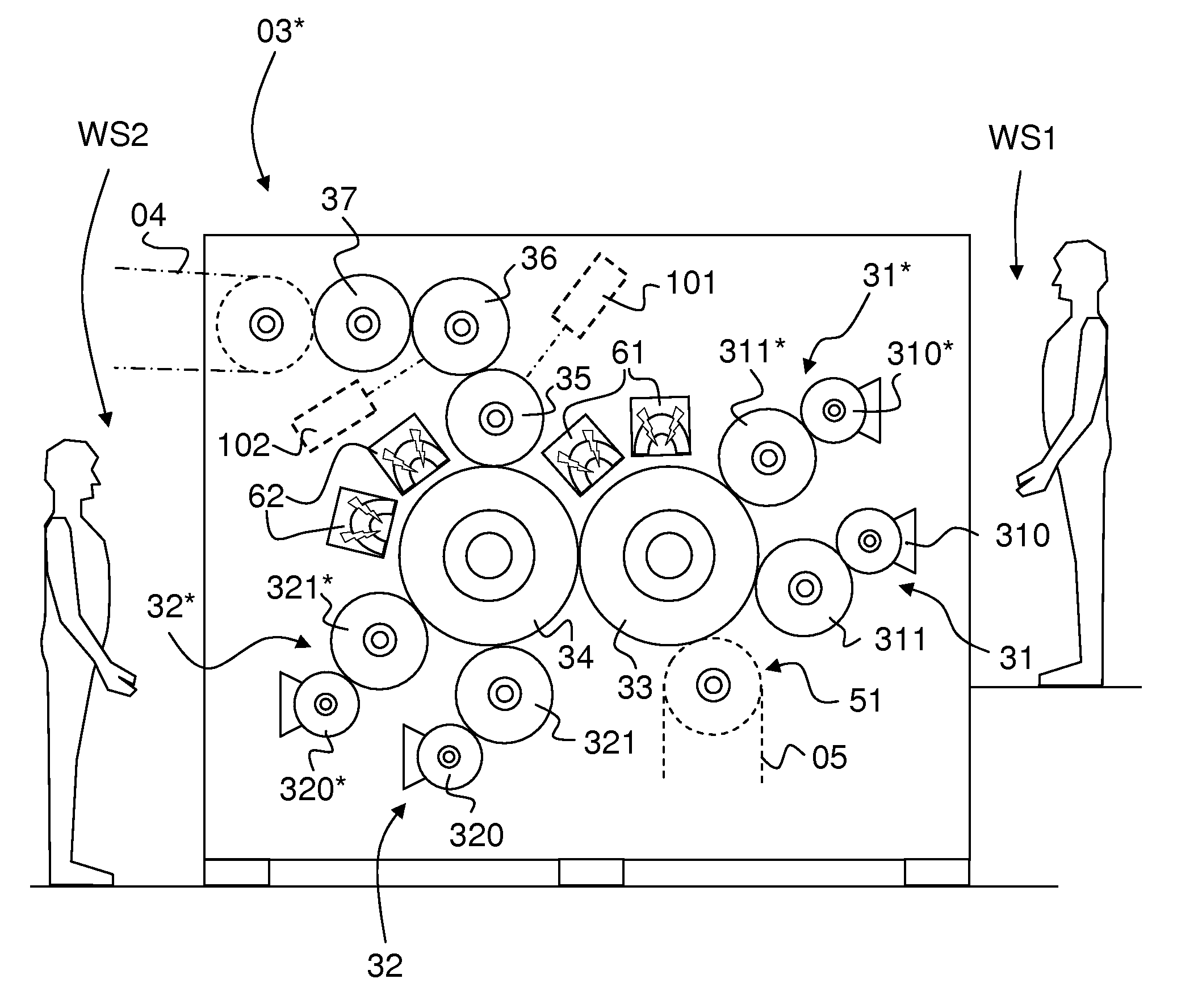

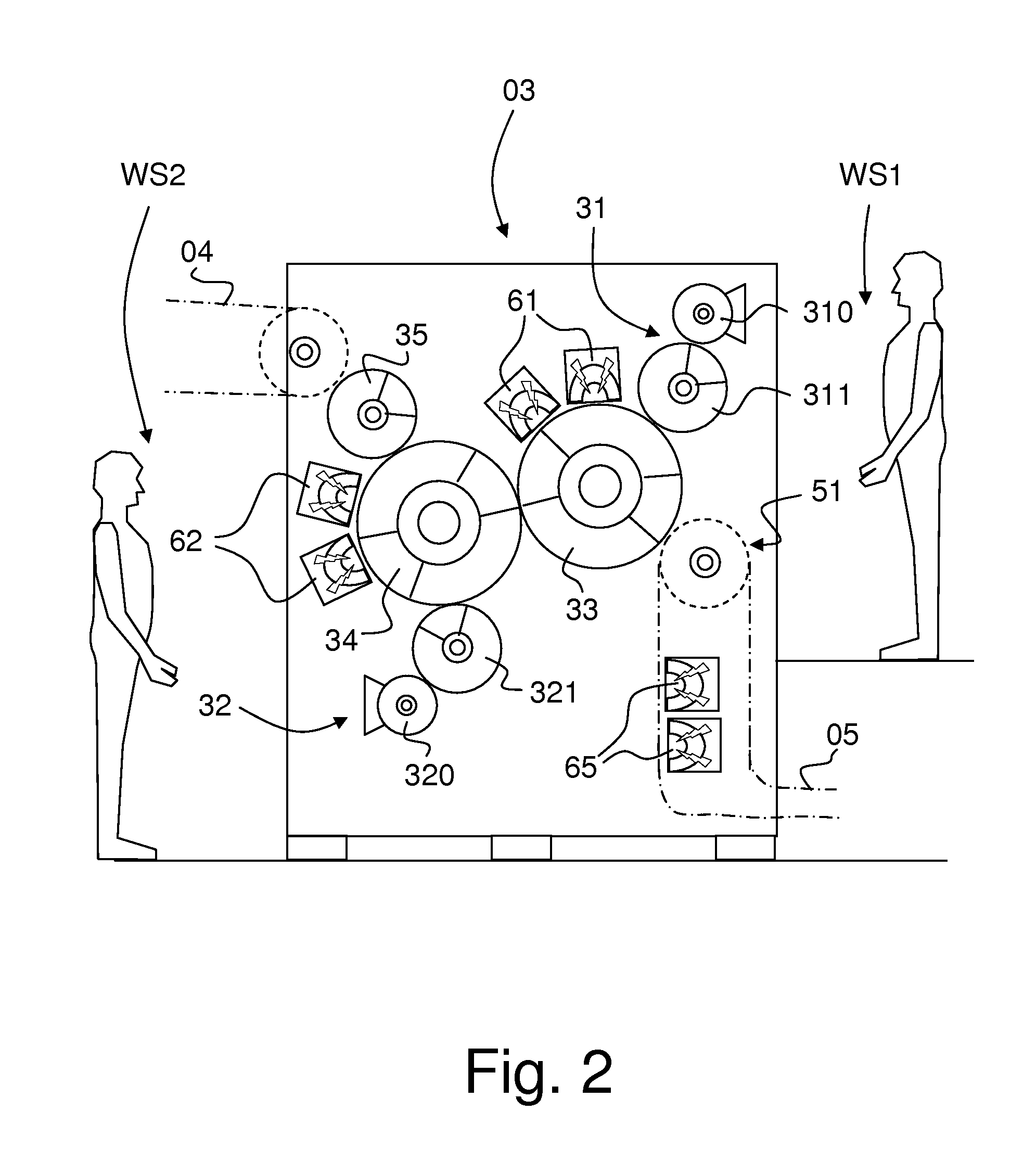

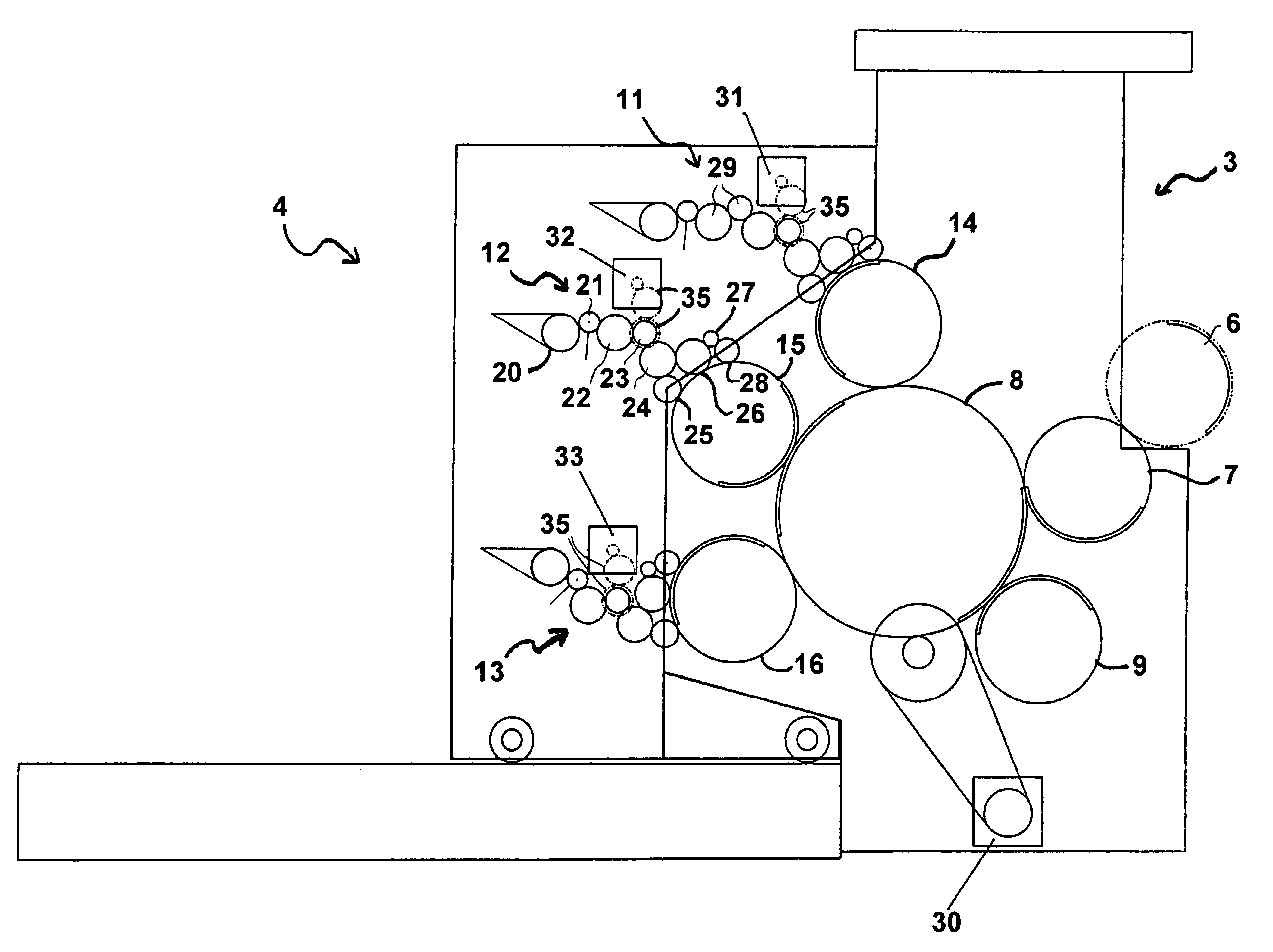

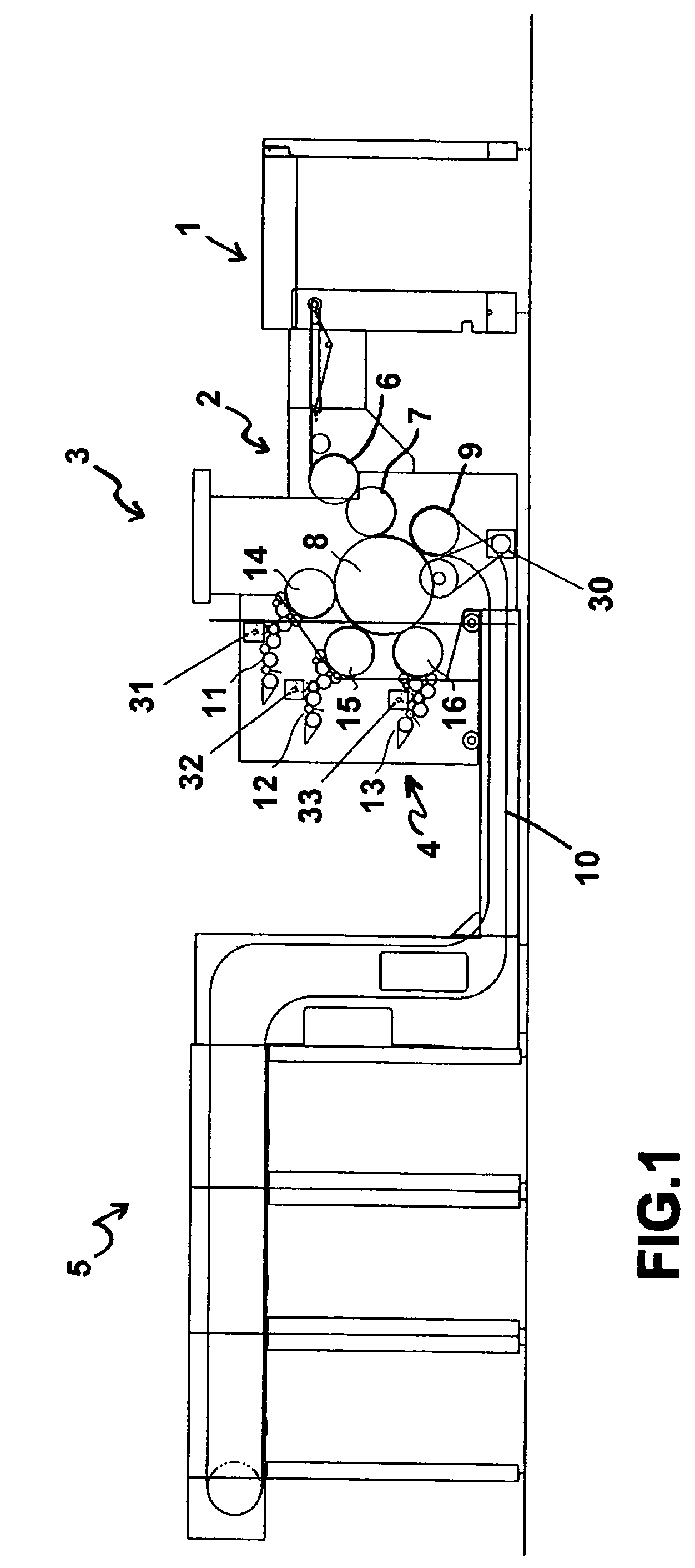

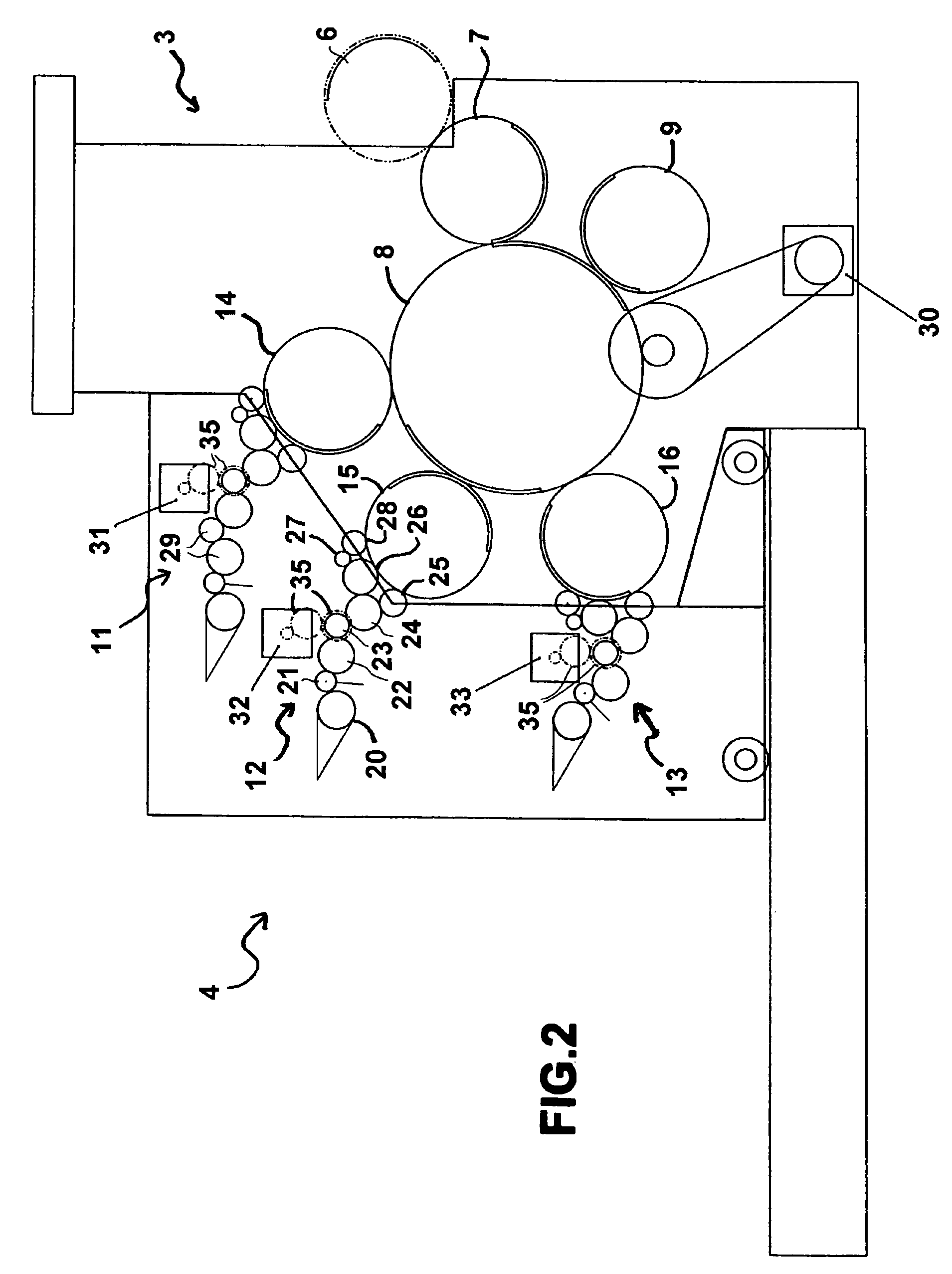

Printing press for numbering and varnishing of security documents, including banknotes

There is described a sheet-fed or web-fed printing press for numbering and varnishing of security documents, including banknotes, comprising:—a numbering group (02) comprising at least one numbering unit (21, 22) for numbering printed material in the form of individual sheets or successive portions of a continuous web carrying multiple security imprints; and—a varnishing group (03; 03*) located downstream of the numbering group (02) for applying varnish onto recto and verso sides of the printed material, the varnishing group (03; 03*) comprising at least a first varnishing unit (31) disposed above a path of the printed material to apply varnish on the recto side of the printed material and at least a second varnishing unit (32) disposed below the path of the printed material to apply varnish on the verso side of the printed material.

Owner:KBA NOTASYS SA

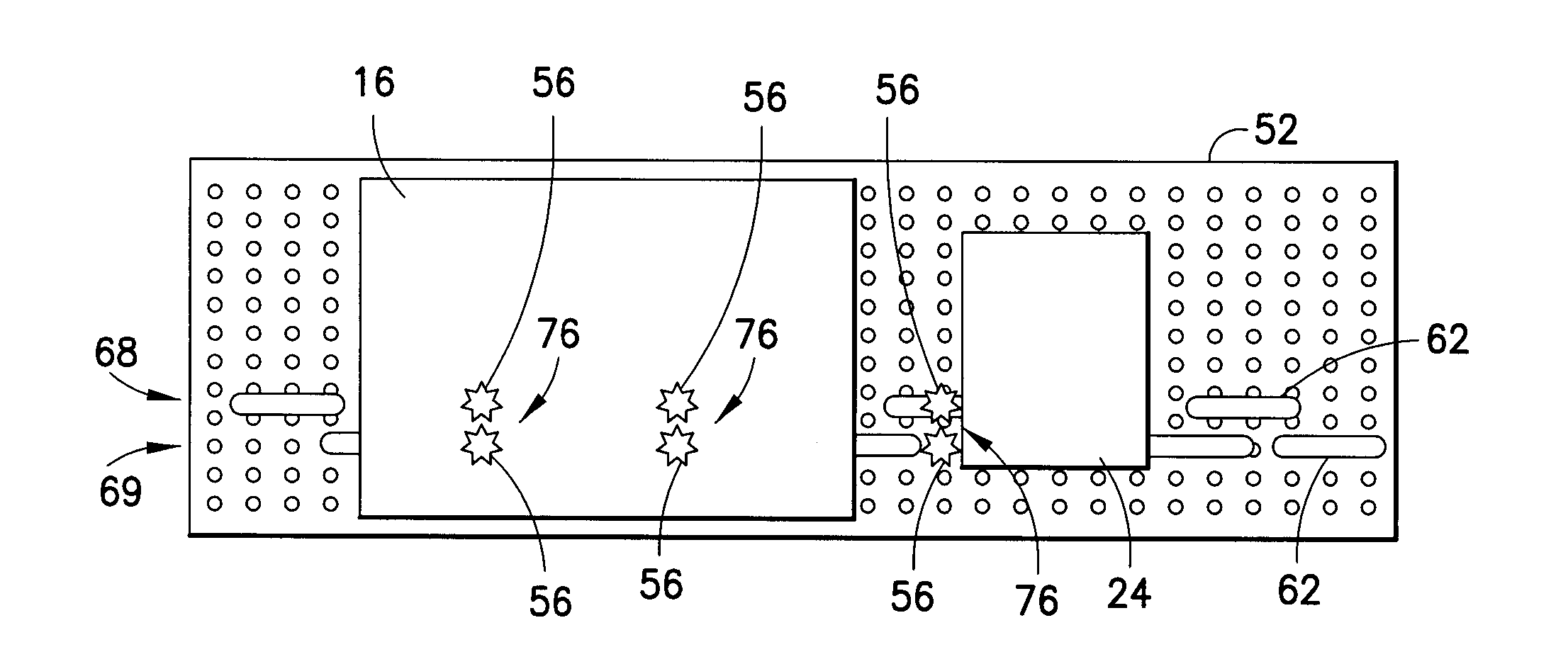

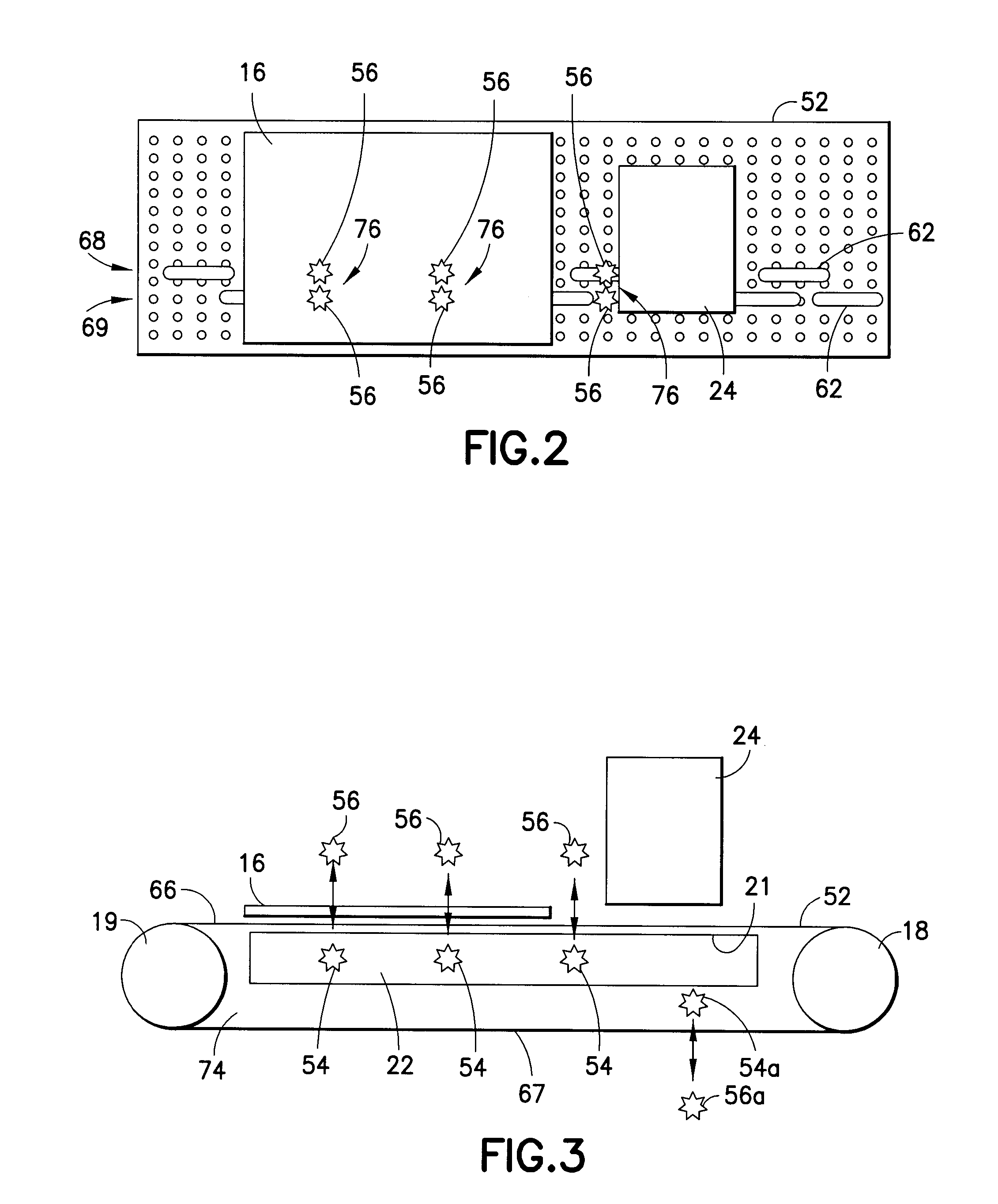

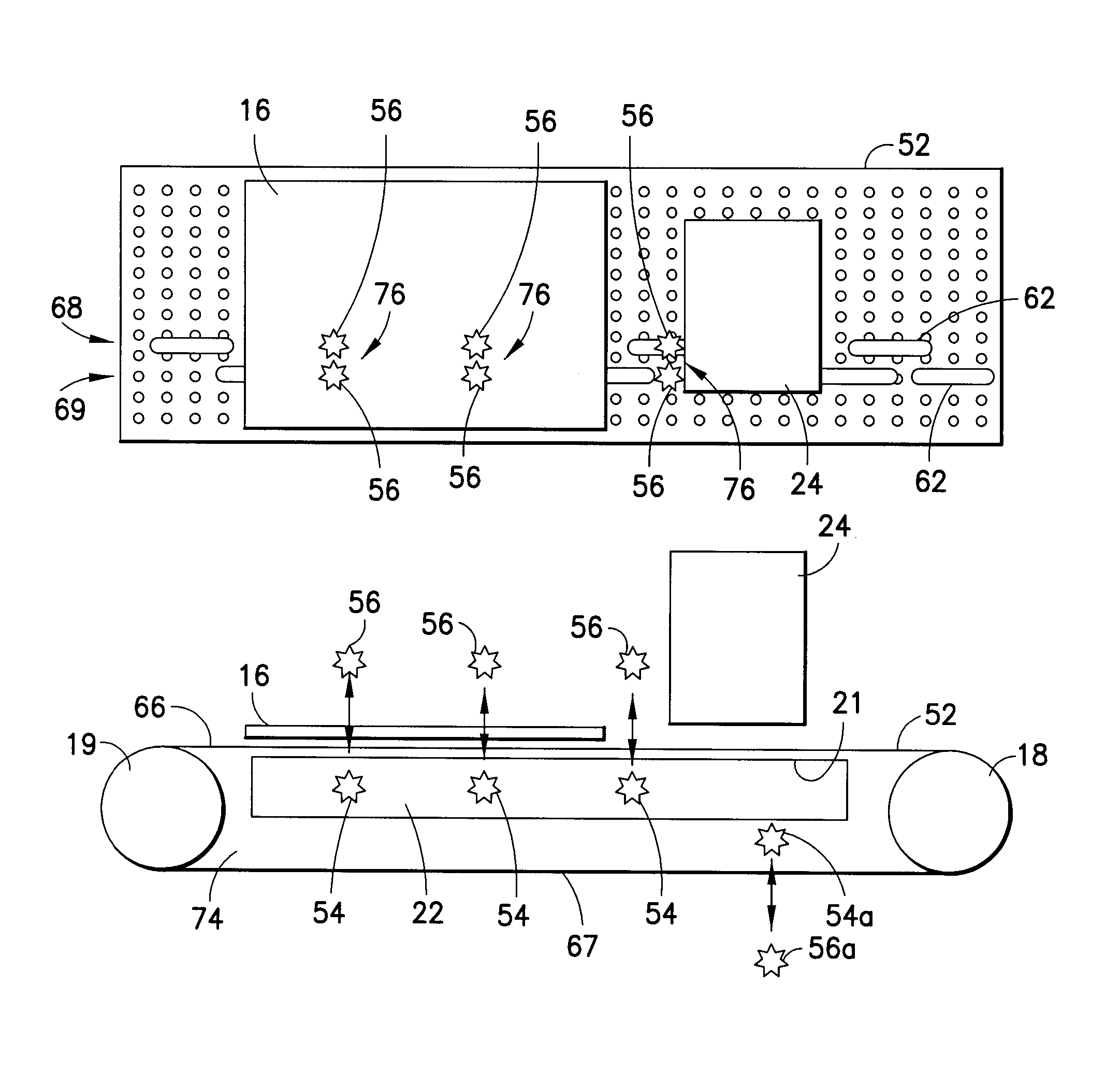

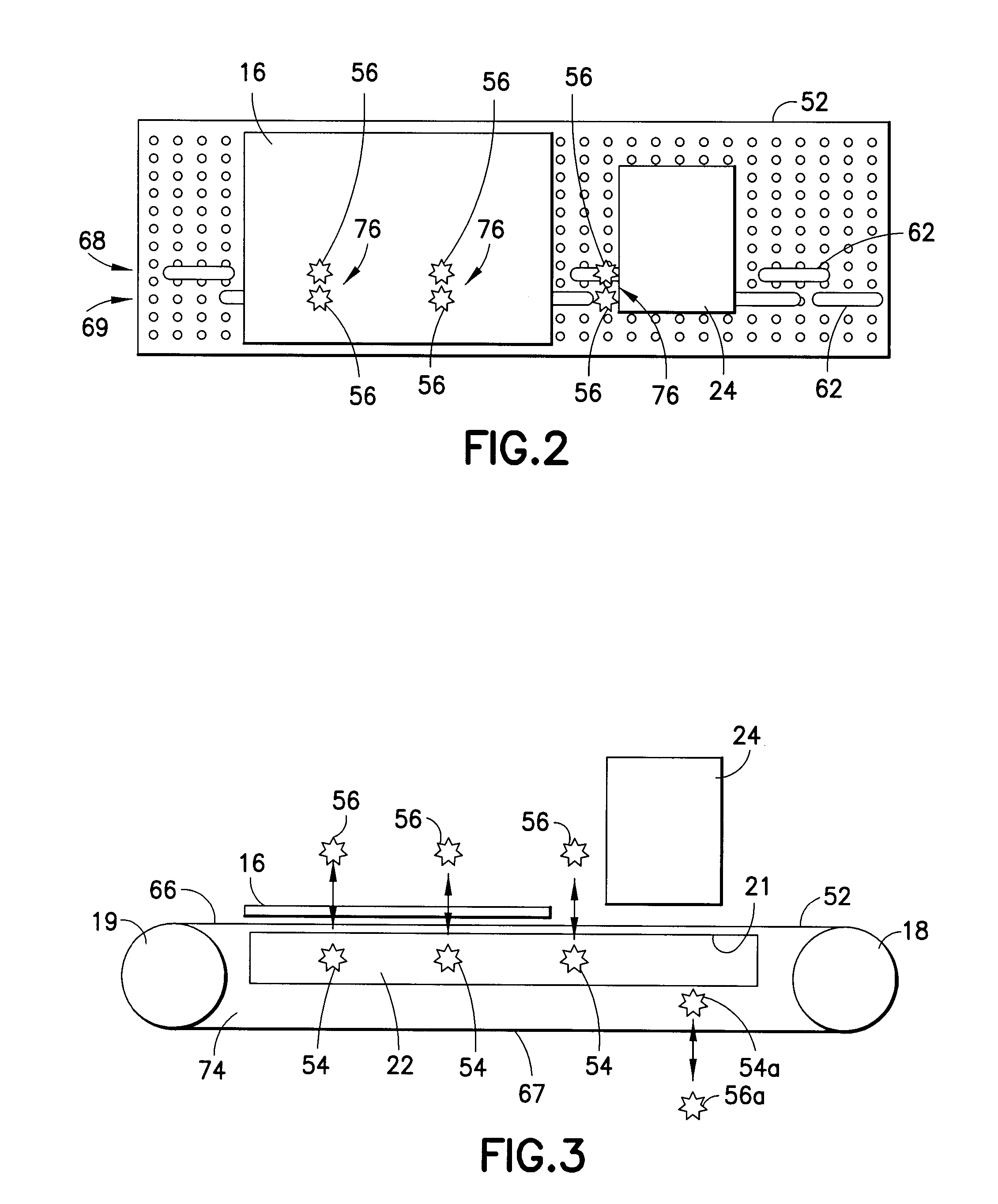

Item handling system with tracking

An item handling system includes a vacuum source, a transport element defining a plurality of vacuum openings in fluid communication with the vacuum source to create a securing force on an item proximate to the transport element for holding the item in contact with the transport element, and a drive element for driving the transport element to transport the item. The transport element further defines a plurality of sensor openings arranged in two substantially parallel arrays along a longitudinal direction of the transport element. The system further includes a sensor associated with each array of sensor openings for sensing energy passing through the sensor openings to thereby sense the item on the transport element. Each sensor is disposed at a common longitudinal position relative to the transport element. Sensing the item corresponds to a condition where the sensor associated with each array is blocked.

Owner:DMT SOLUTIONS GLOBAL CORP

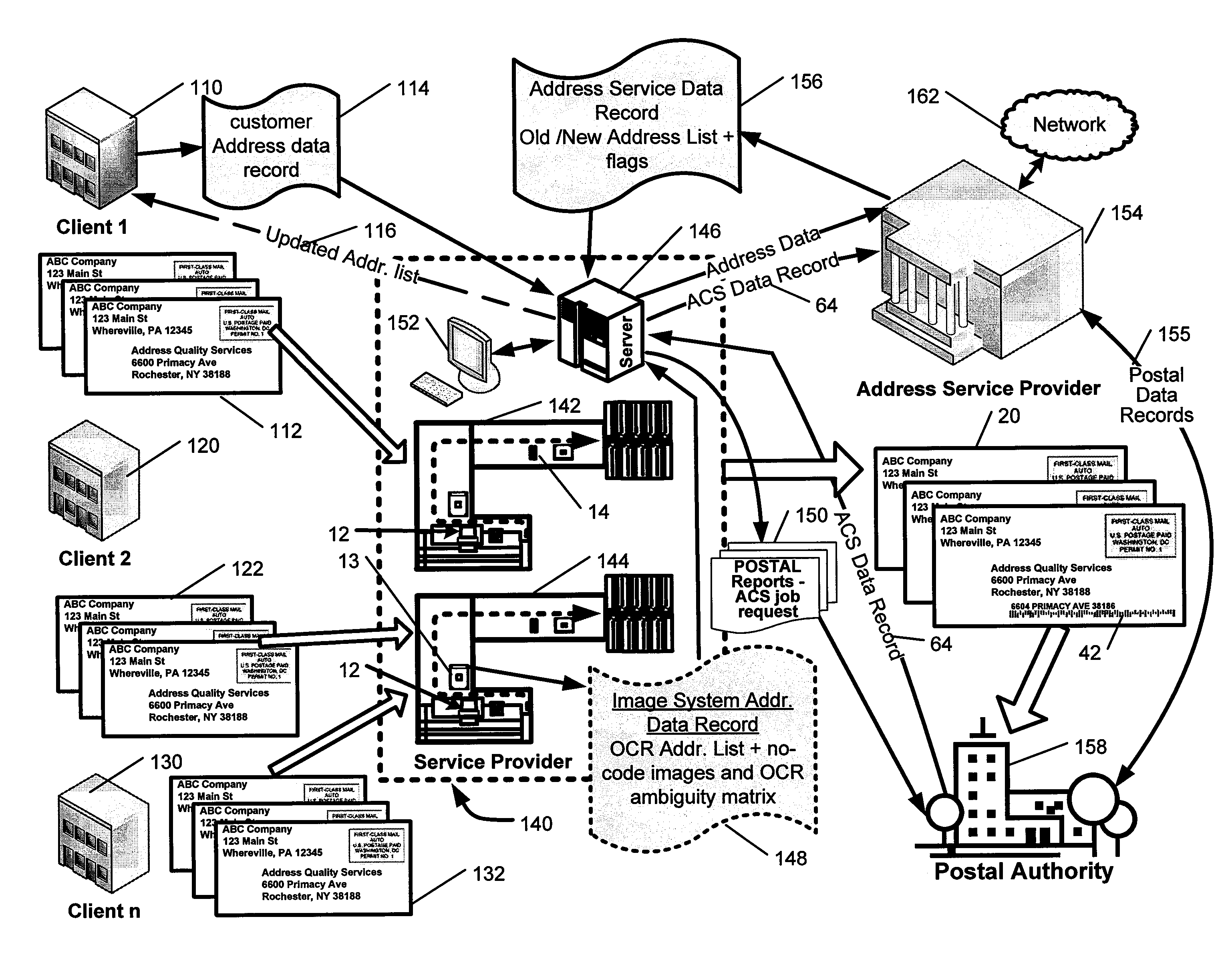

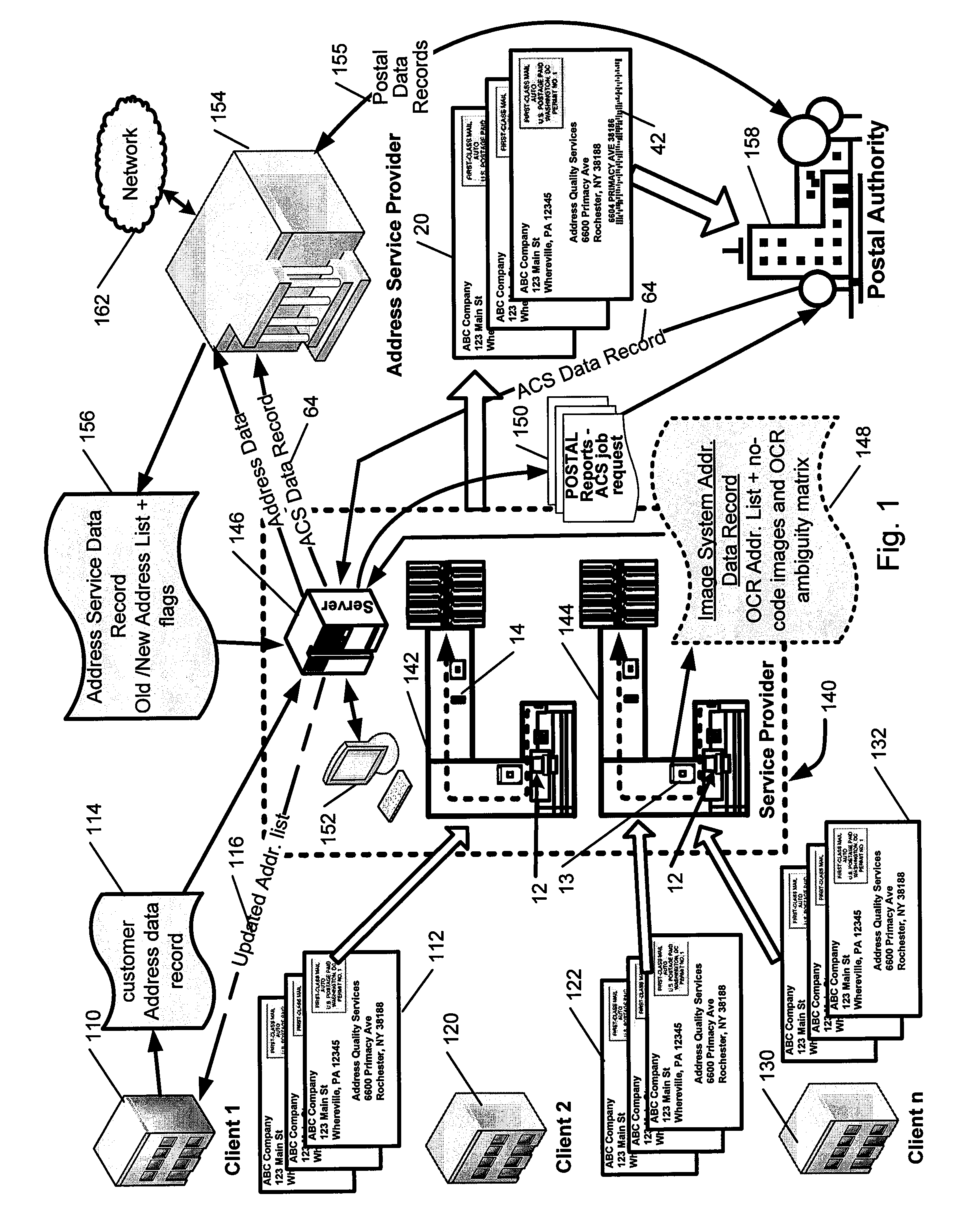

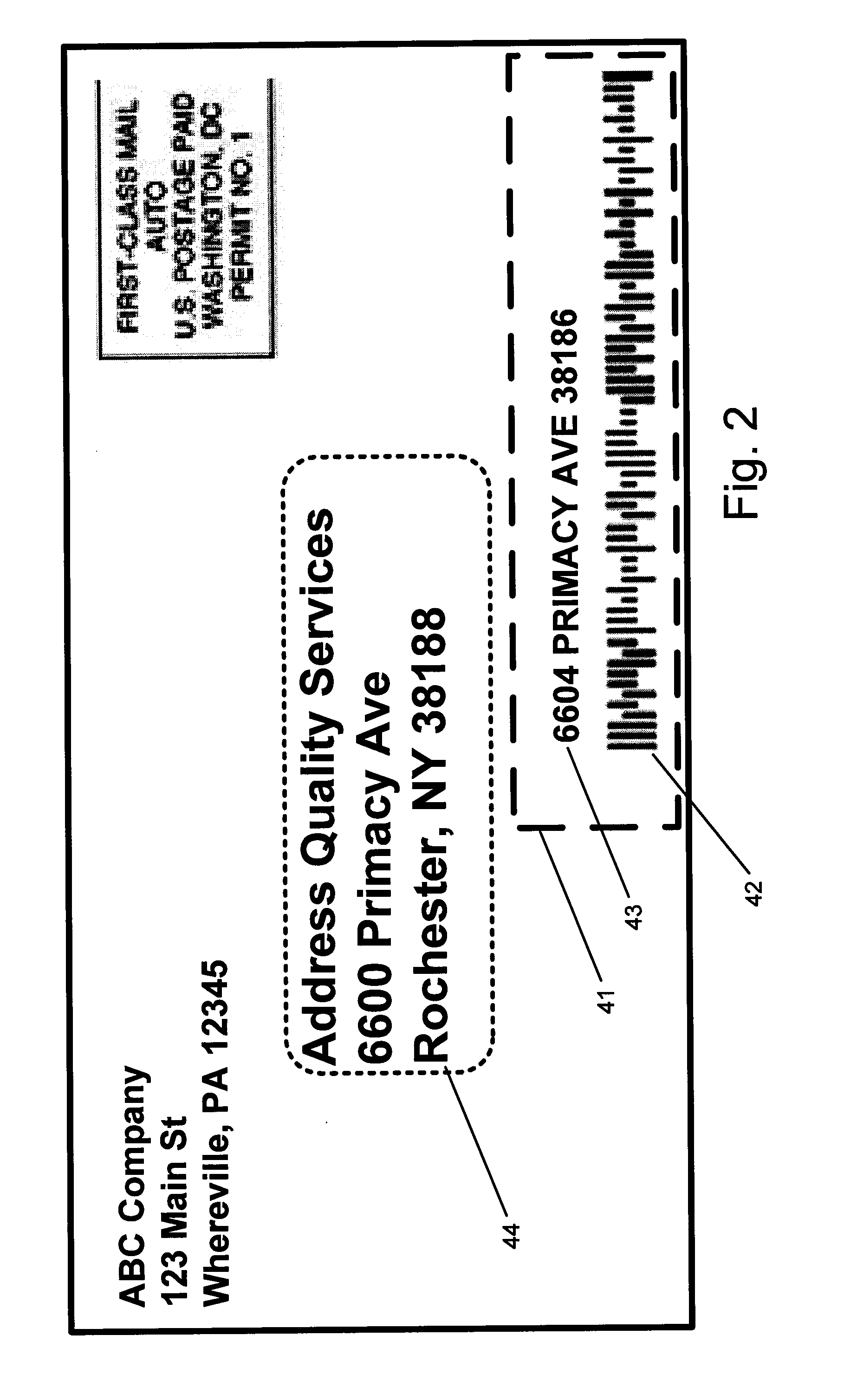

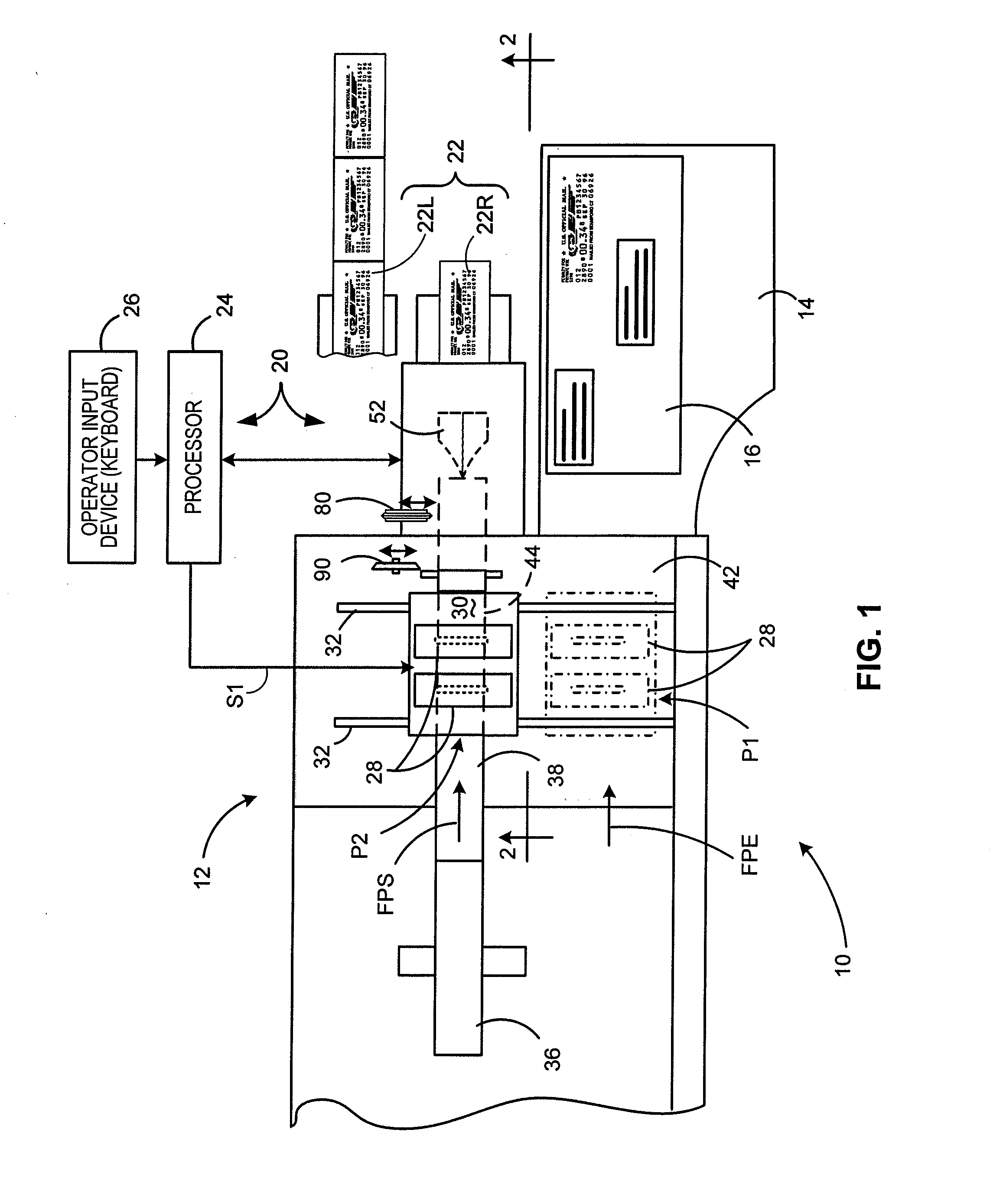

Method and system for run time directories for address services on a mail processing system

The present application generally relates to address data maintenance services using a mail processing system. The present application discloses techniques and equipment to update address information and usage of mail processing equipment to print delivery point barcodes that represent the current and accurate address information available for the addressee. The present application also provides a new approach for storing and searching address and name run time directories as part of a mail processing system using address reader technology.

Owner:DMT SOLUTIONS GLOBAL CORP

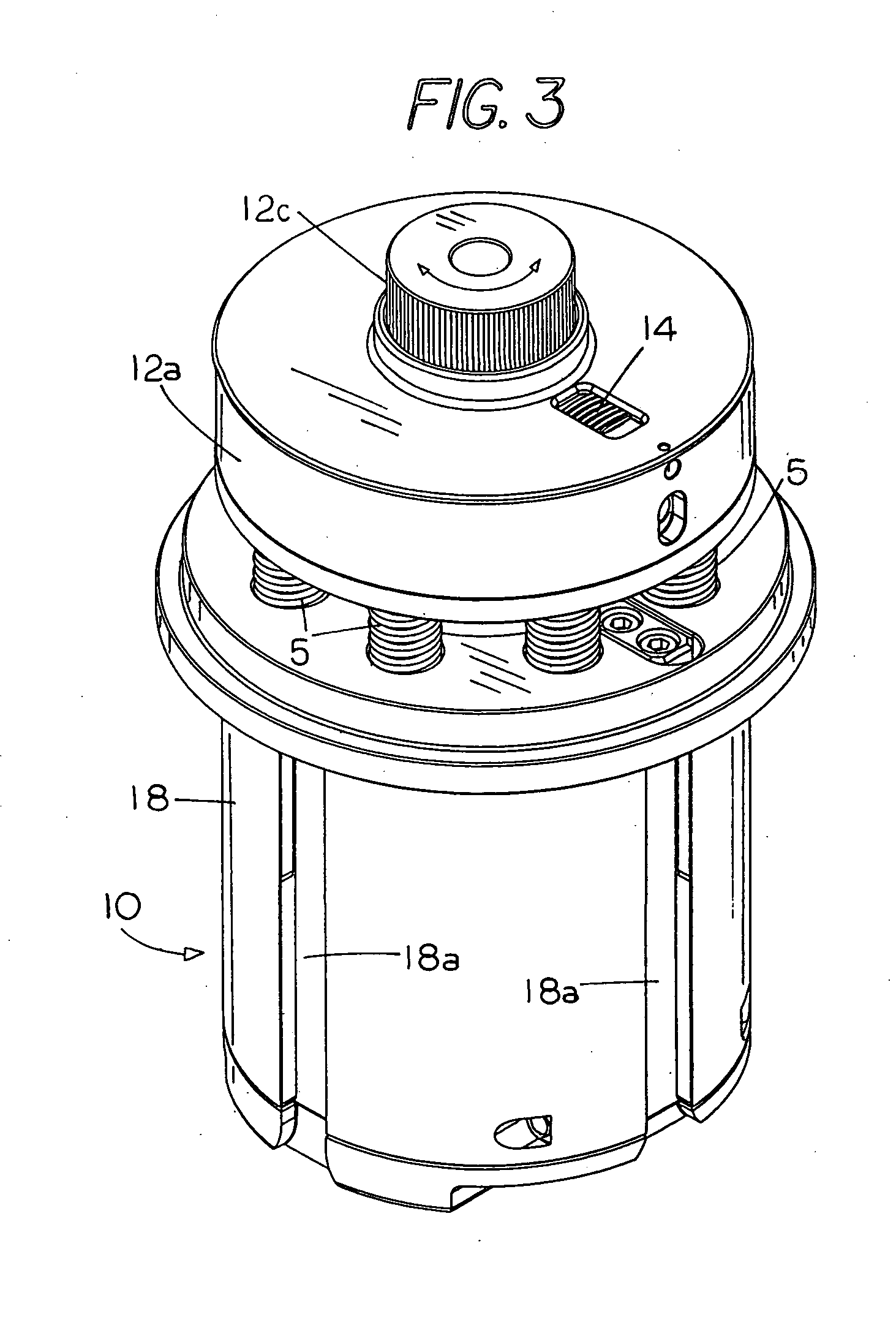

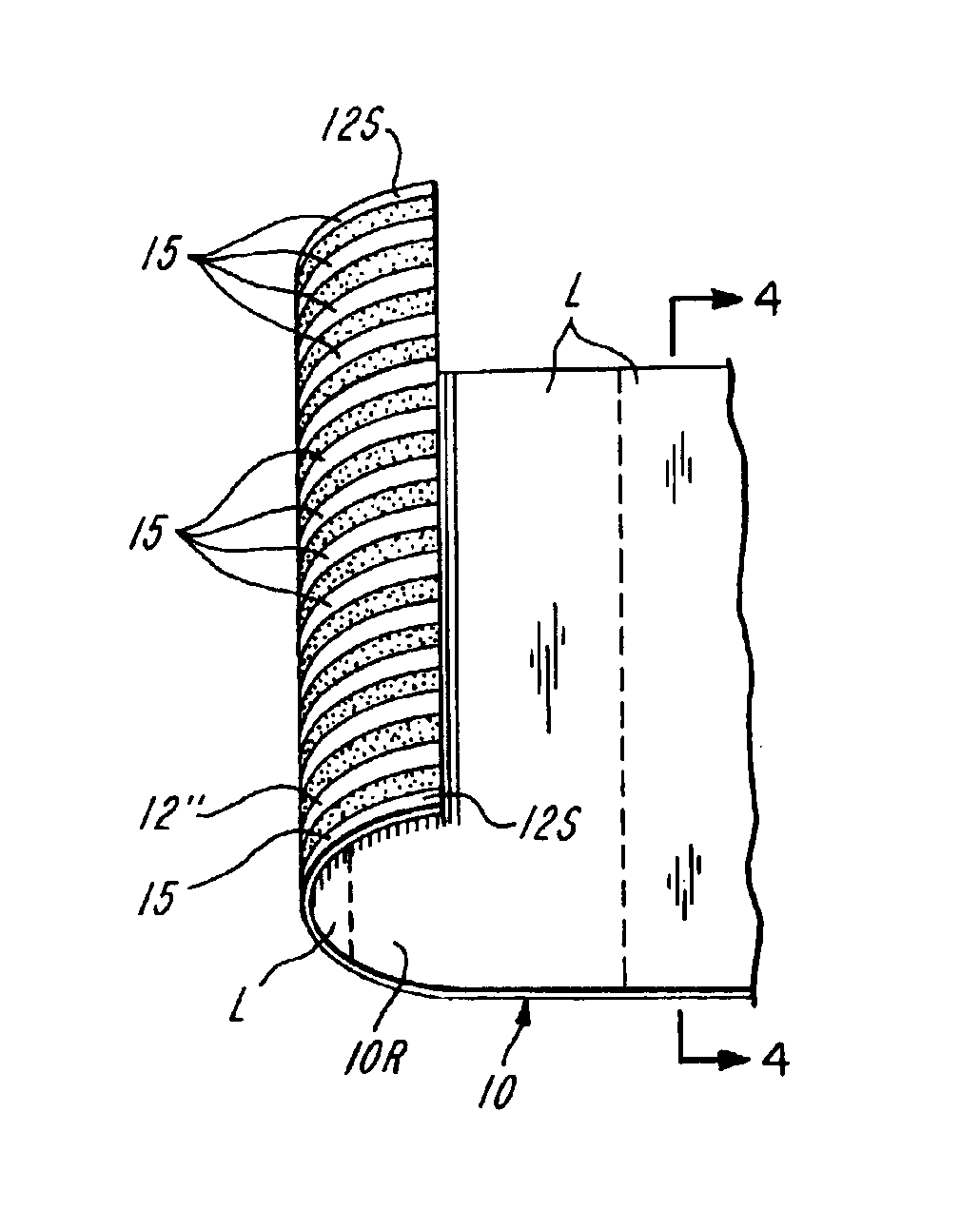

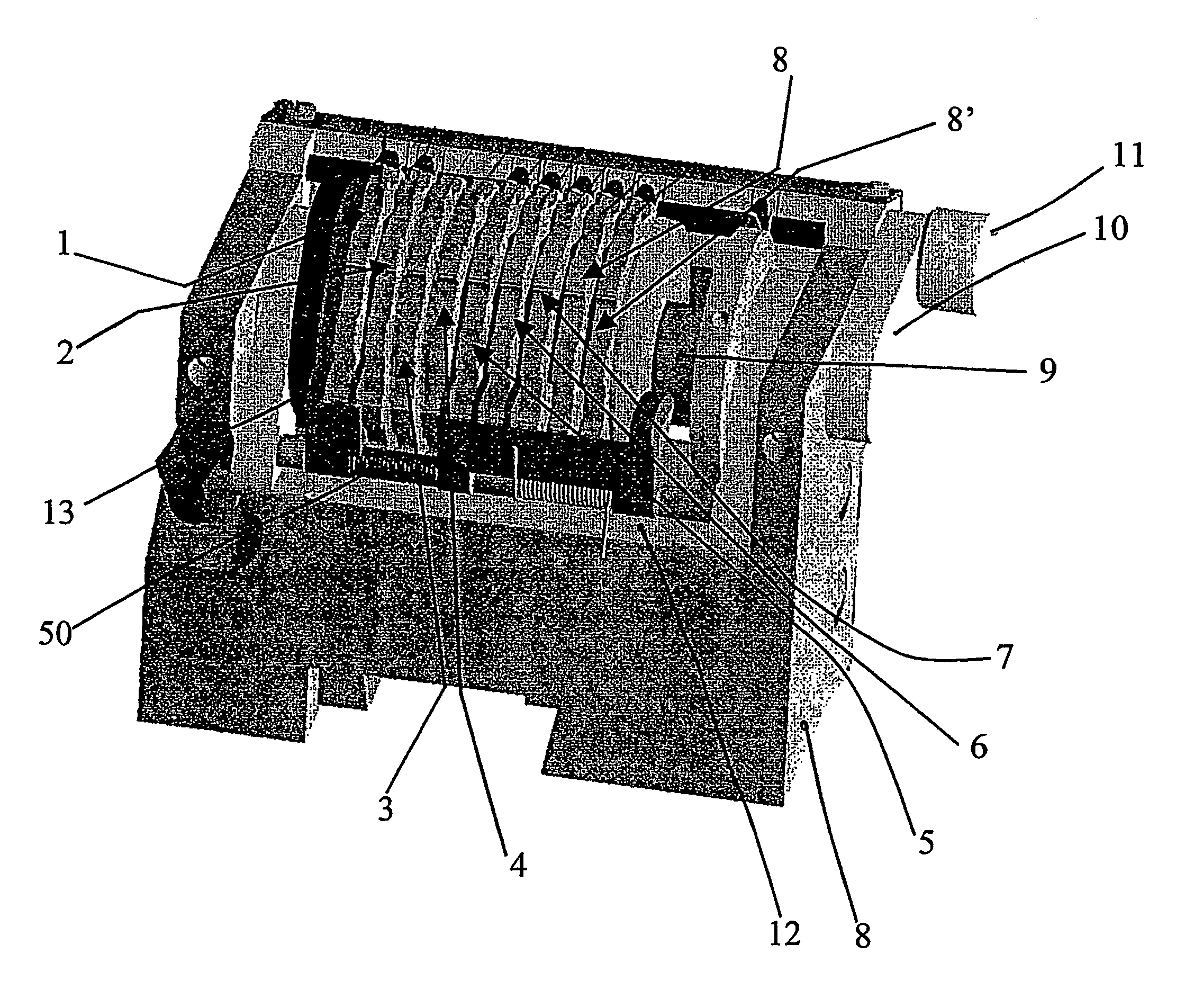

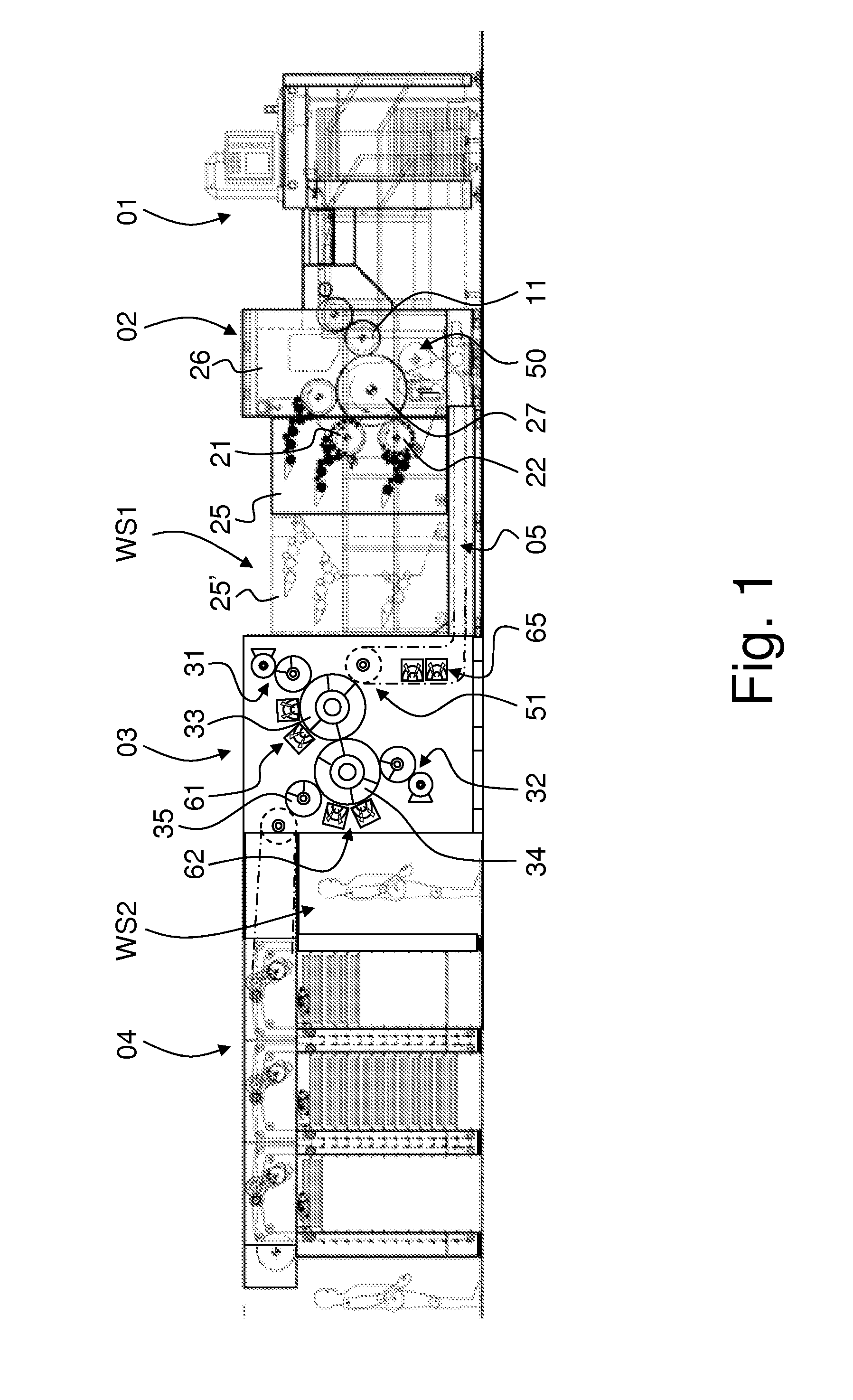

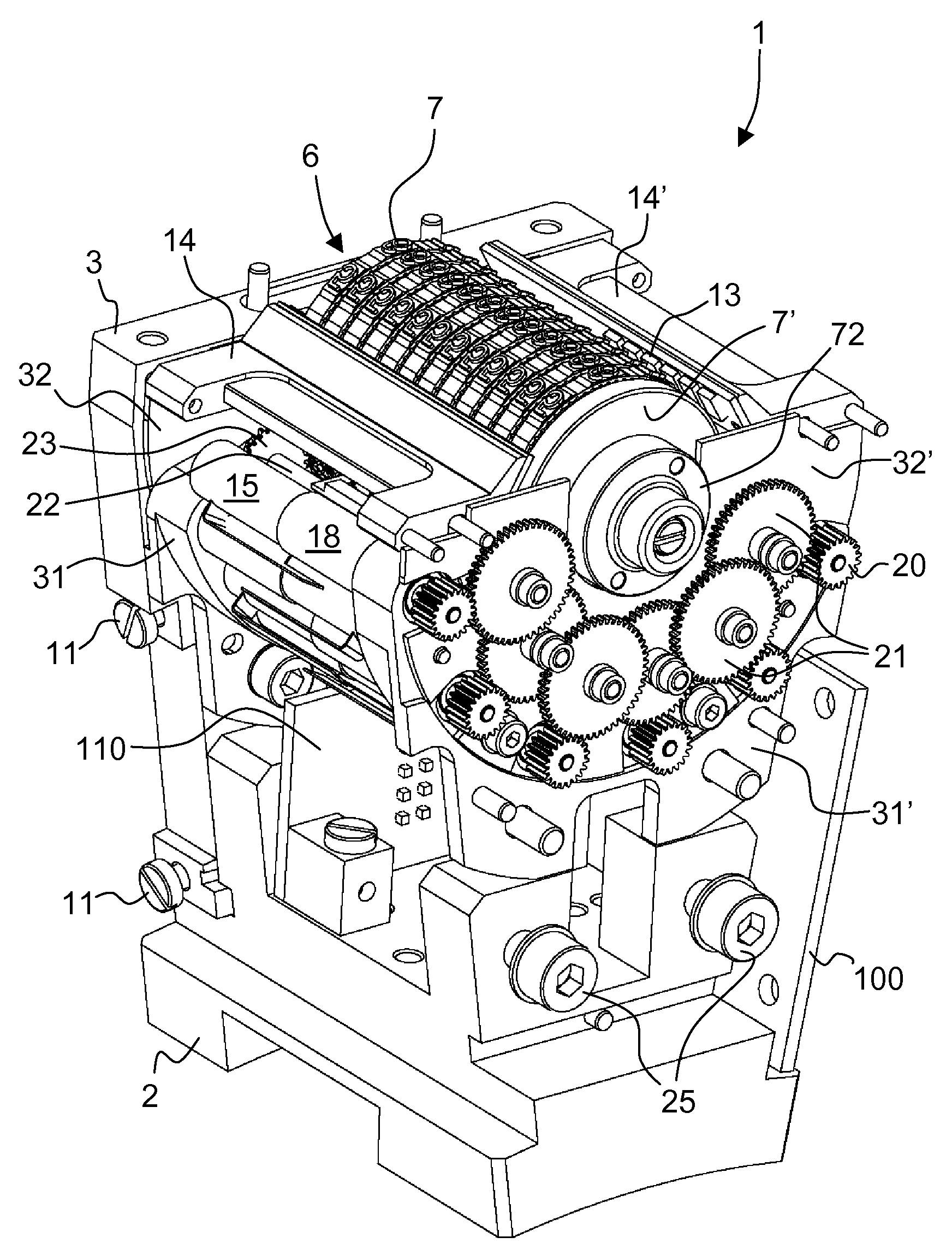

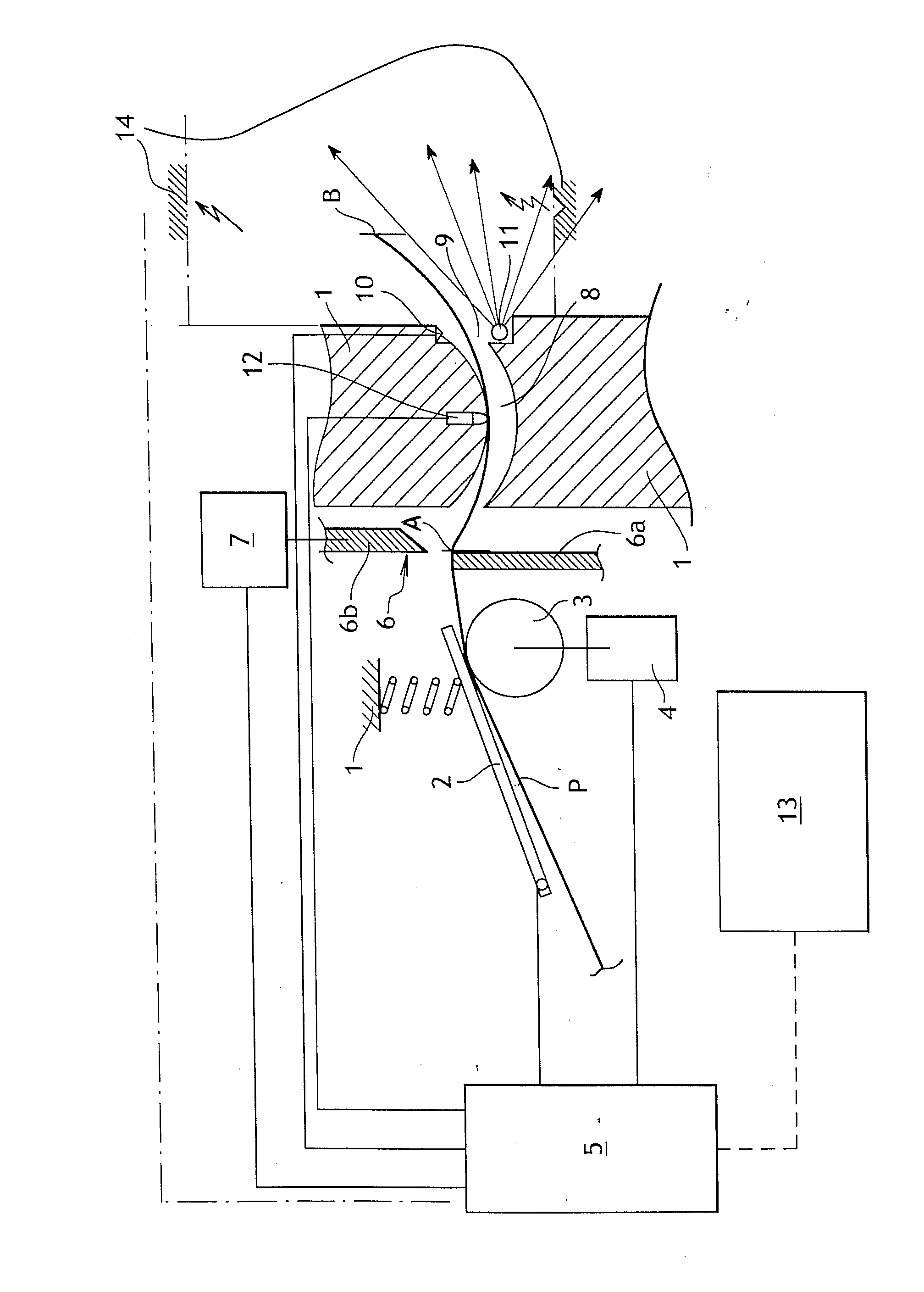

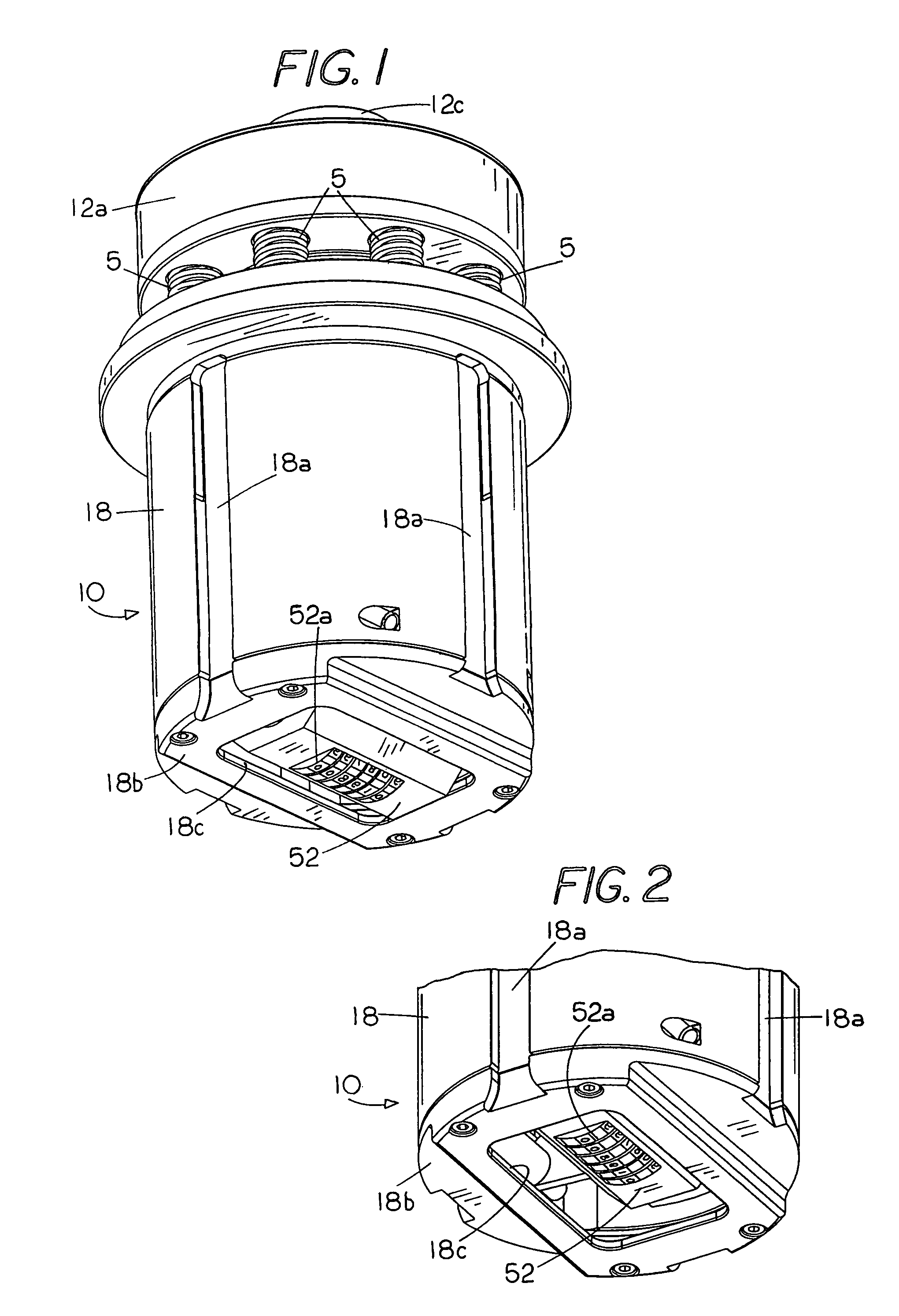

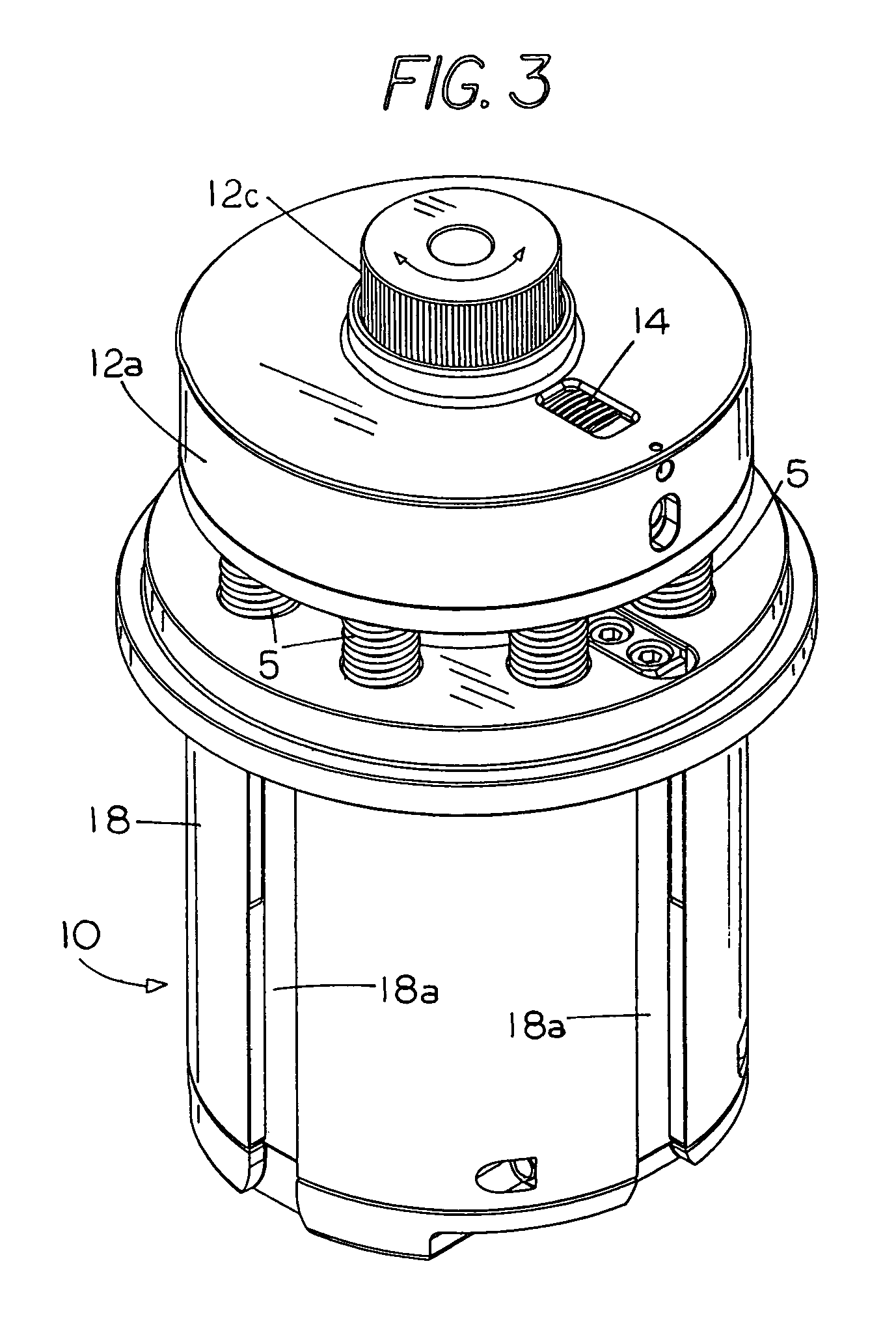

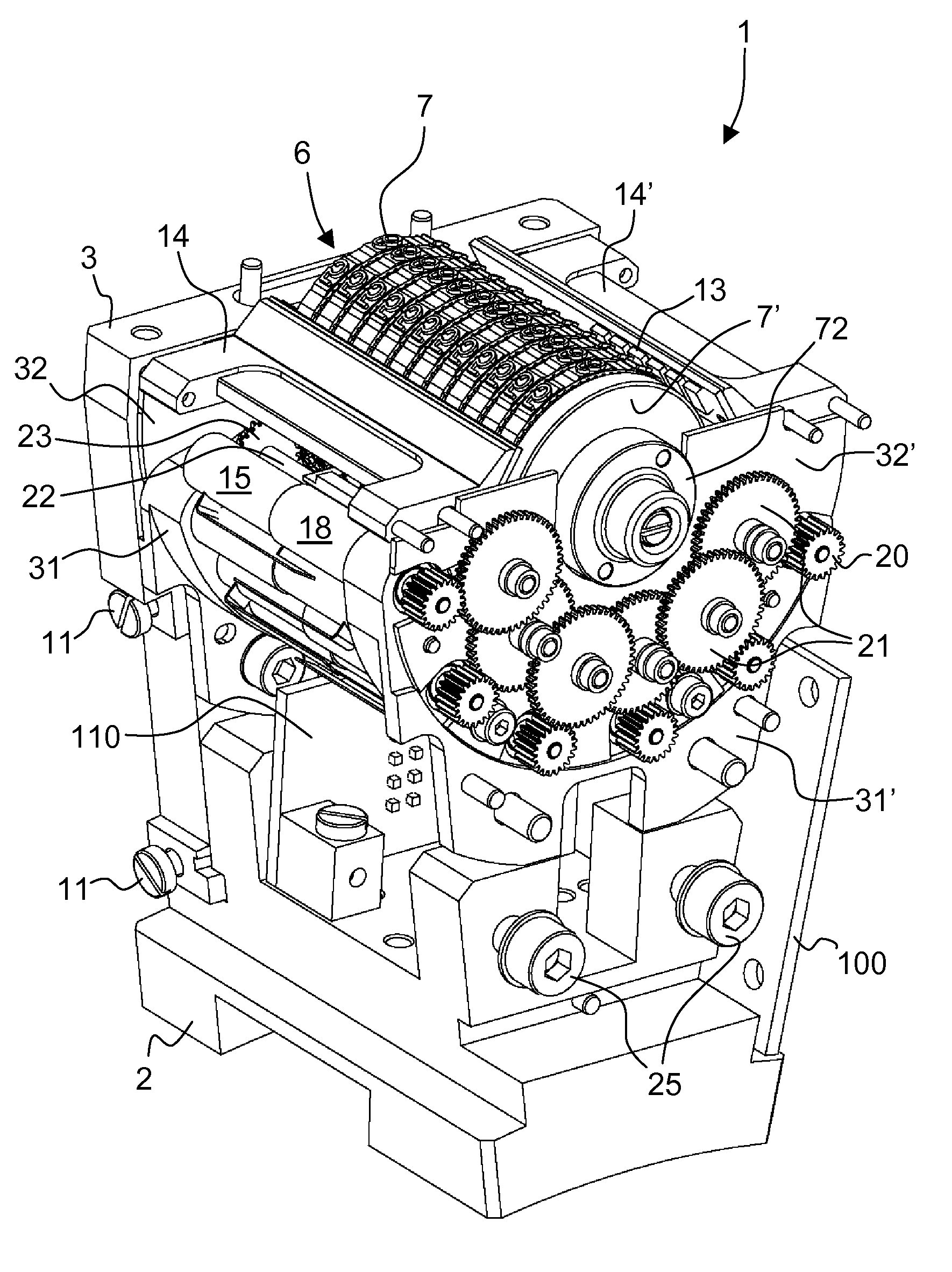

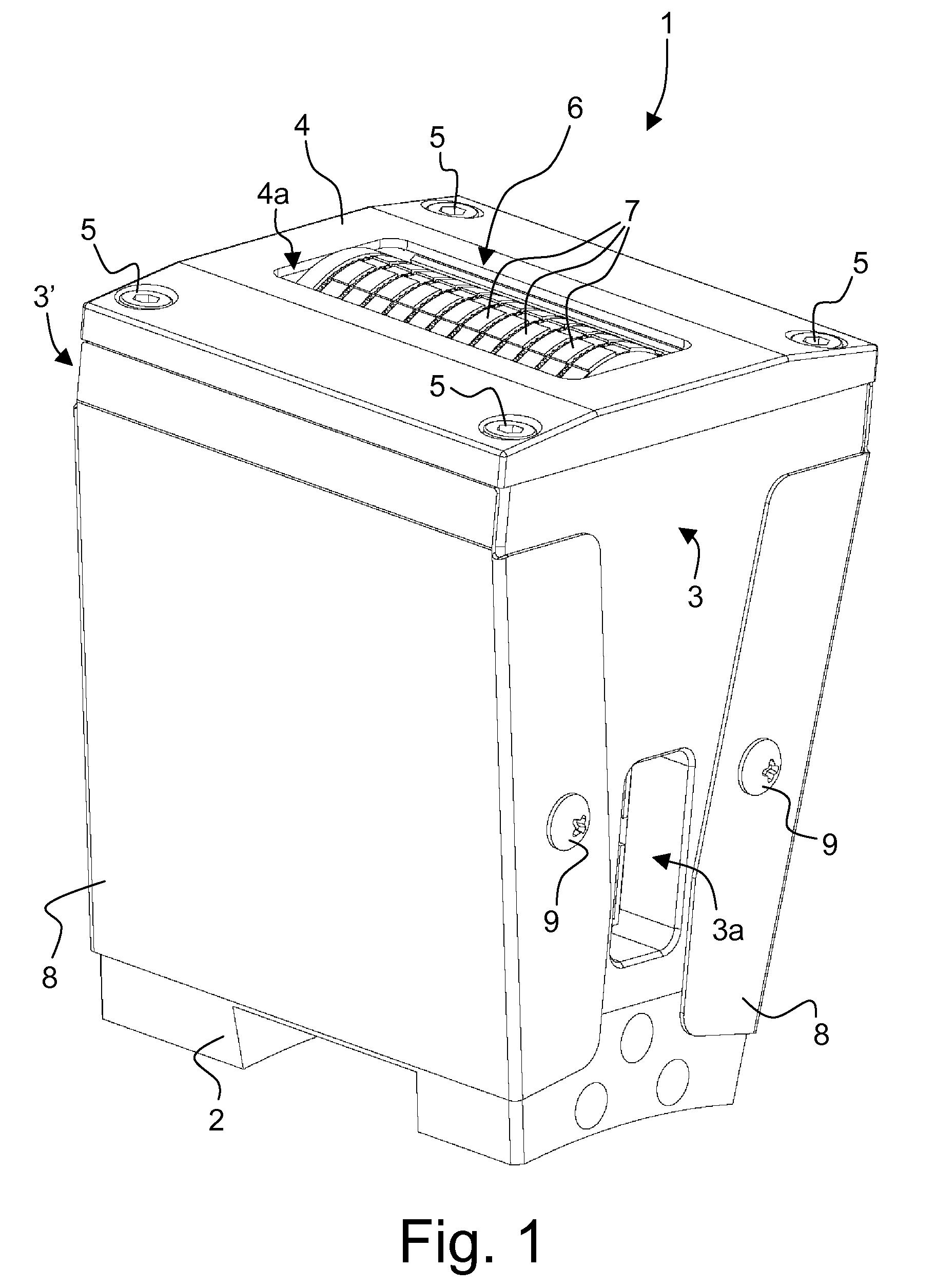

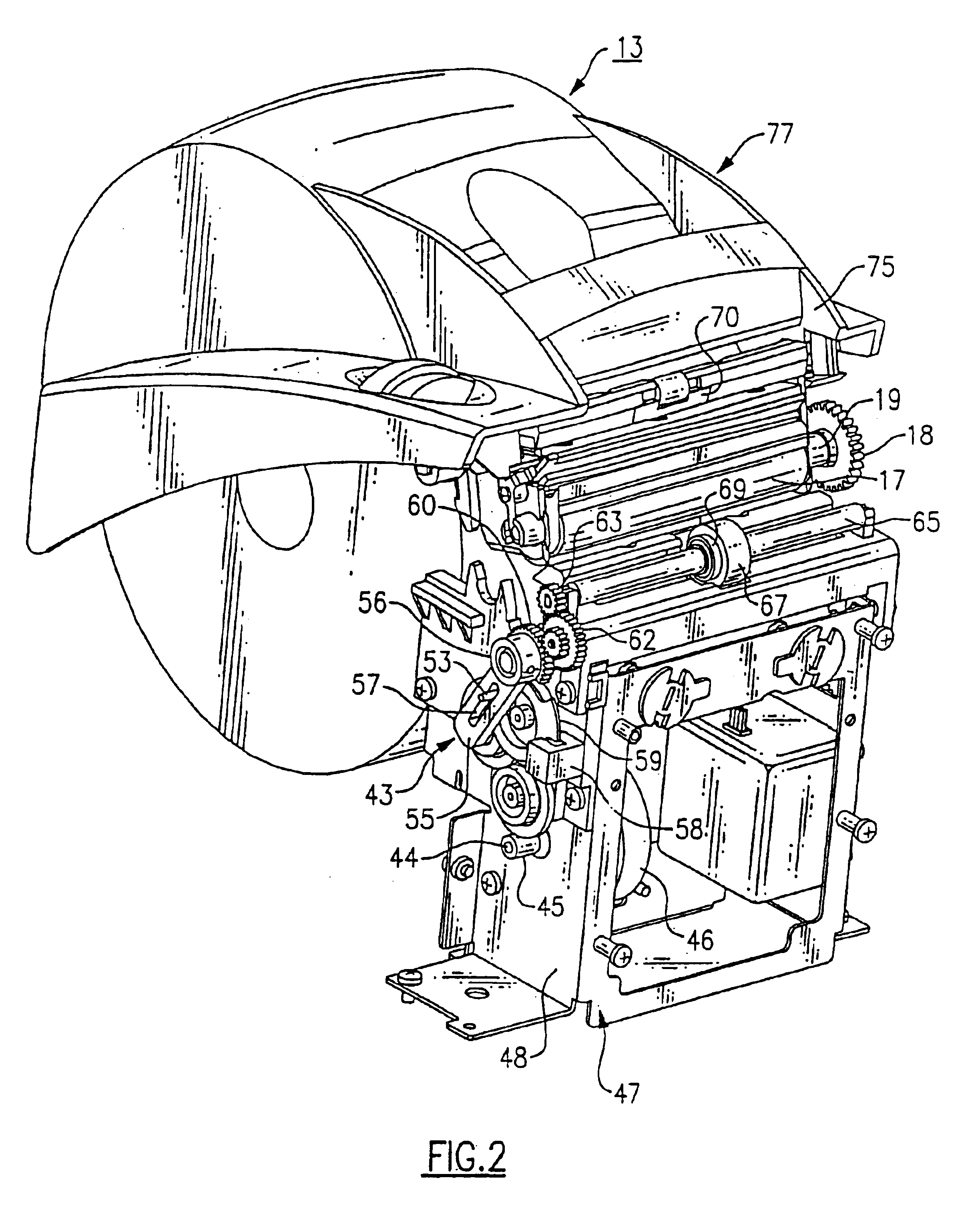

Numbering device for typographic numbering

ActiveUS20090235832A1Closely arrangedAddressing machinesRotary pressesNumbering unitGreek letter alpha

There is described a numbering device (1) for carrying out numbering in sheet-fed or web-fed numbering presses, the numbering device (1) comprising a numbering unit (6) with rotatable numbering wheels (7) carrying alpha-numerical symbols thereon, which numbering wheels (7) are disposed next to each other and rotate about a common rotation axis, the numbering device (1) further comprising electro-mechanical actuation means for setting the position of the numbering wheels (7). The electro-mechanical actuation means are entirely located within the numbering device (1) and are mechanically autonomous, the electro-mechanical actuation means comprising a plurality of independent driving means (15, 18-23; 23*) for actuating a corresponding plurality of the numbering wheels.

Owner:KBA NOTASYS SA

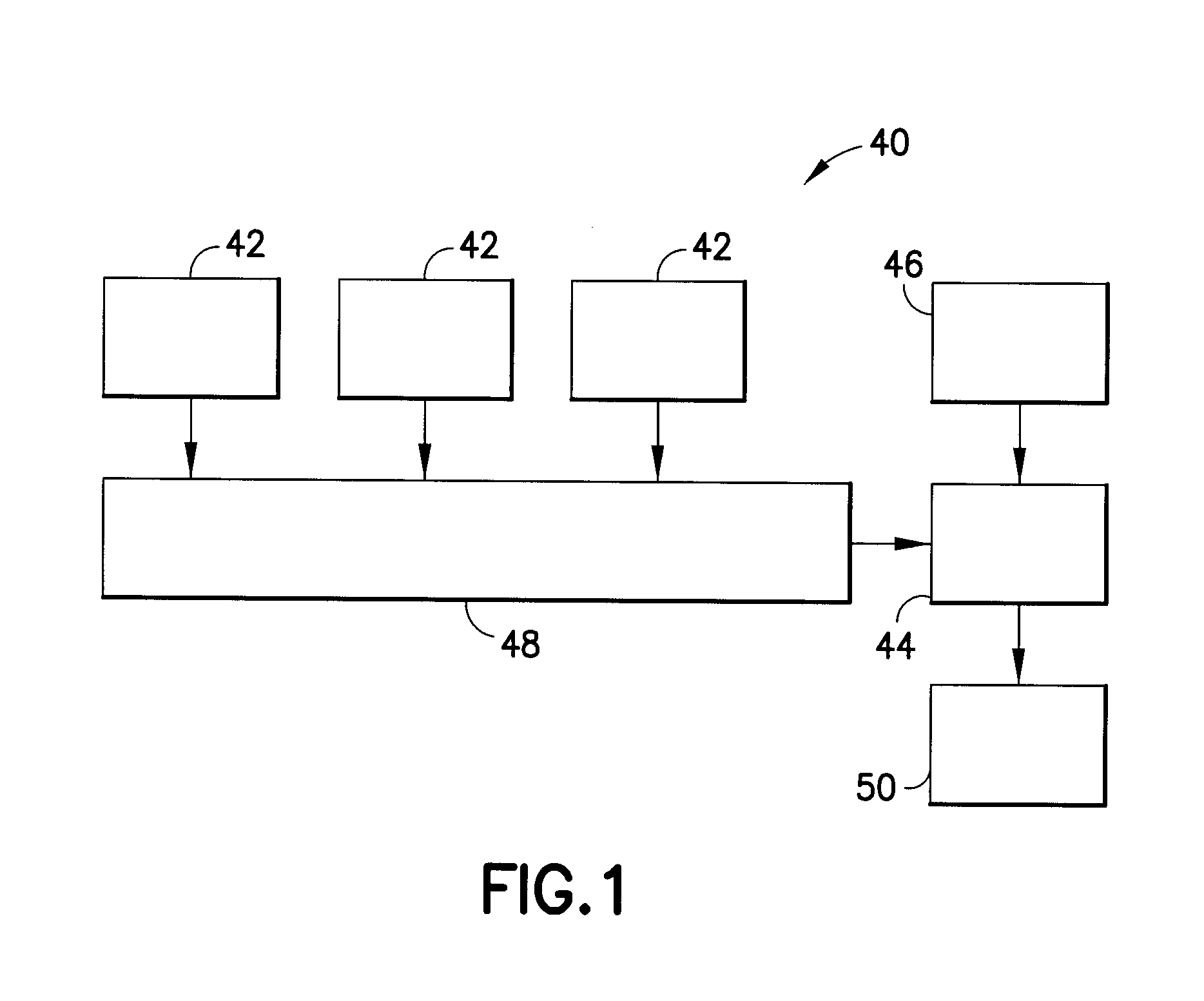

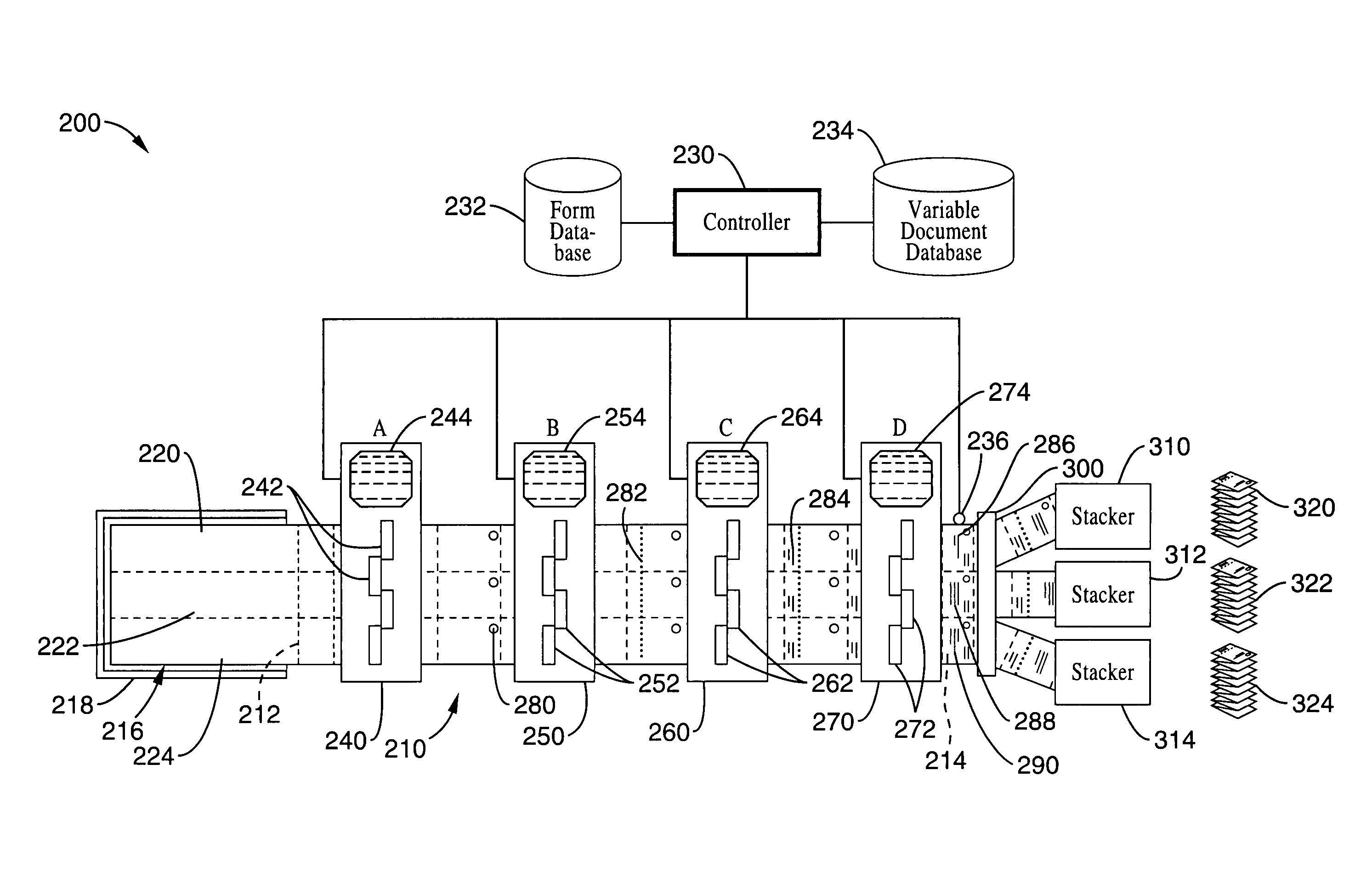

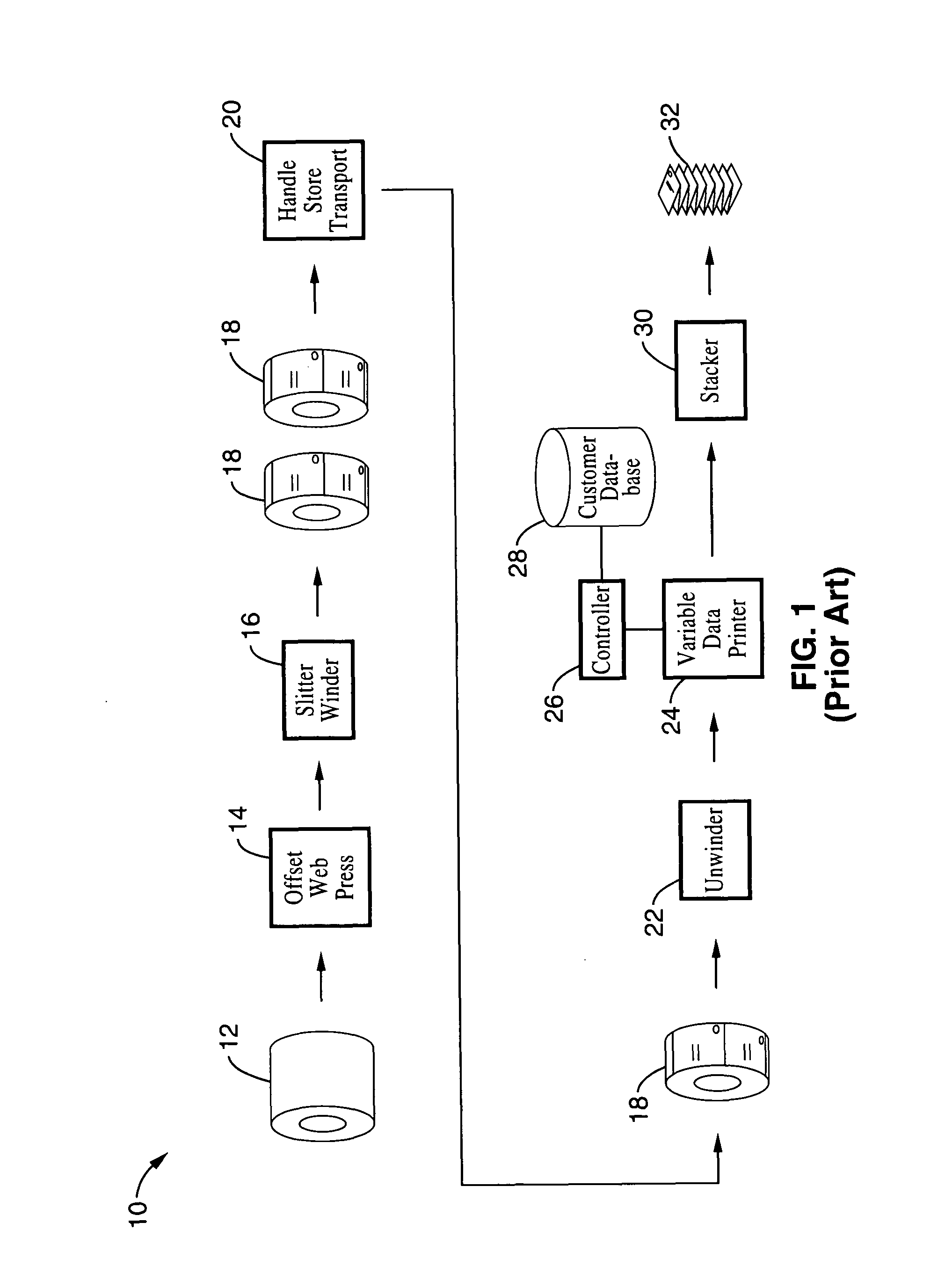

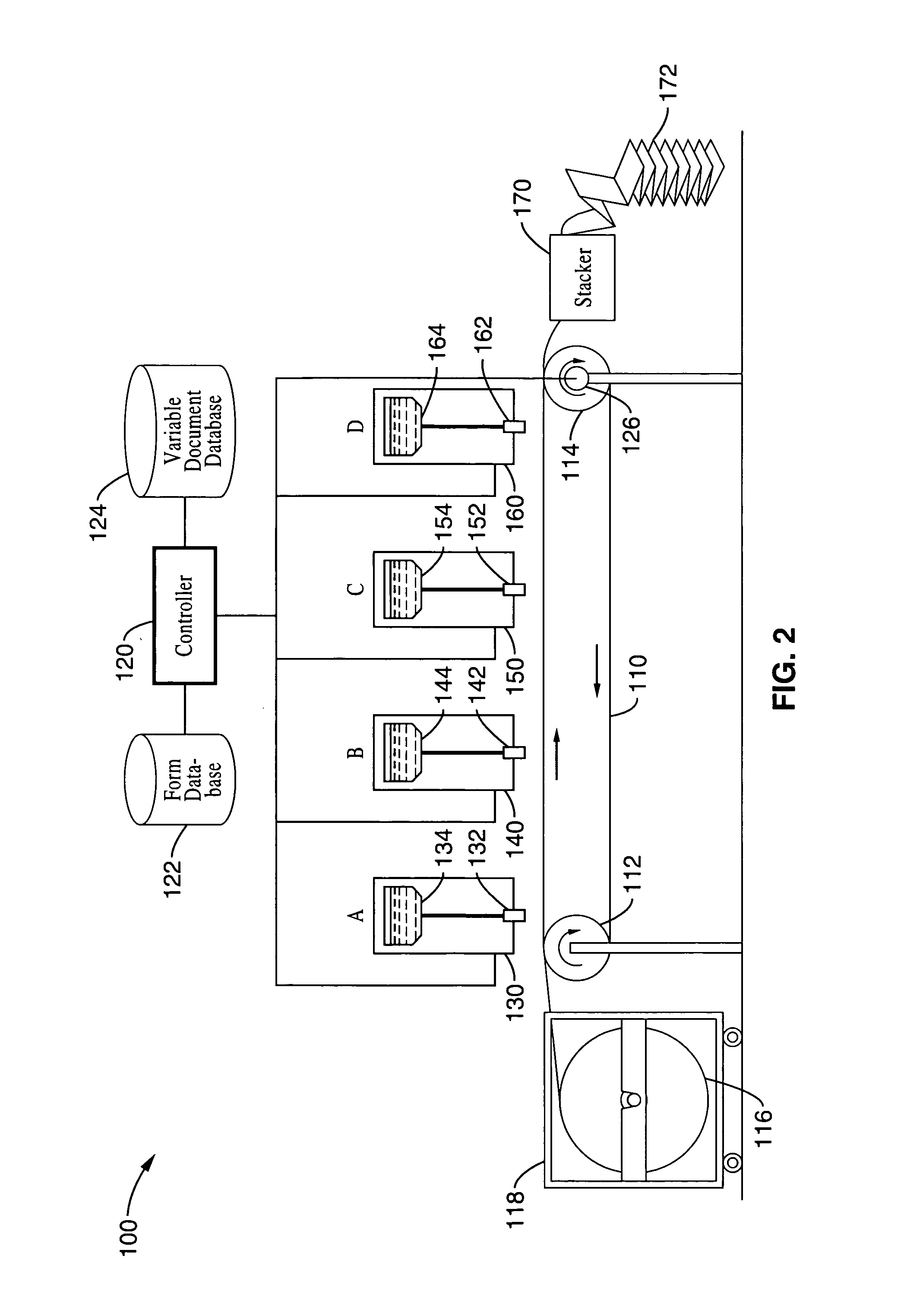

Apparatus and method for high speed printing of form and variable data

ActiveUS7978349B1Increase printing speedReduce handlingAddressing machinesPlaten pressesEngineeringDocumentation

A web platform has multiple print modules adapted to print form data and variable data in a continuous operation. A controller with access to a form image database and a variable document database is connected to the web platform. Each print module on the web platform uses single color, ink jet, print heads. Form data is printed by a plurality of single color print modules. Variable data is printed by a single color print module. Bulk paper in rolls is fed through the web platform to print the forms and customer statements. The controller can direct printing of multiple statements simultaneously in discrete lanes on the web platform. Printed customer statements are subsequently separated into individual finished documents for process and mailing.

Owner:DST OUTPUT

Internet Digital Mail System Inkjet Printer

This invention relates to a printer that can feed, seal, and print an indicia (Postage Stamp) directly on a mailpiece or tapesheet using an inkjet printhead. Printer will be capable of feeding mailpieces either by hand, semi-automatically or a stack of mailpieces automatically; sealing each mailpiece if needed, and printing an indicia directly on the mailpiece using Internet-Based USPS approved software.

Owner:CAUDLE JEFFERY SCOTT

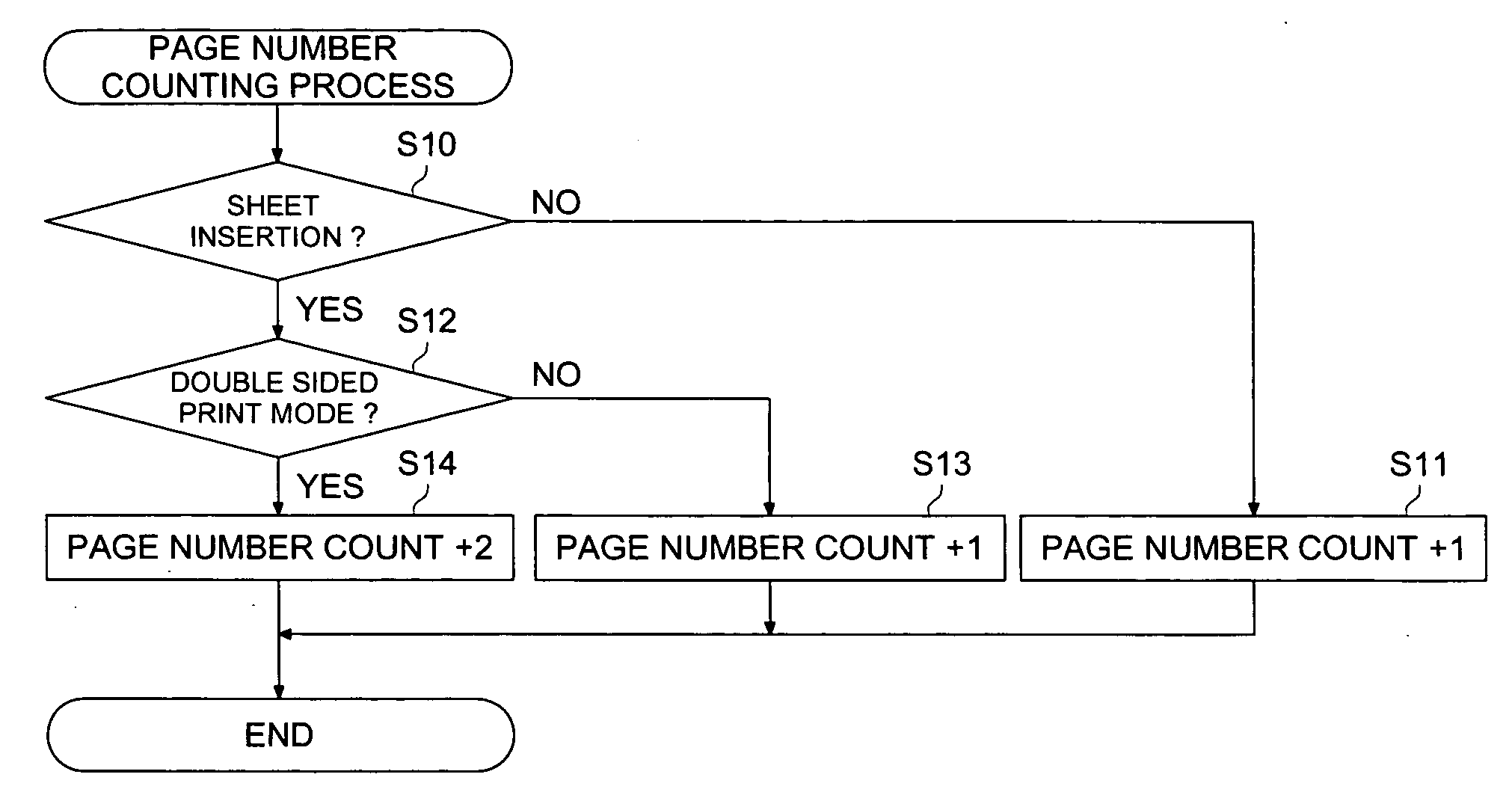

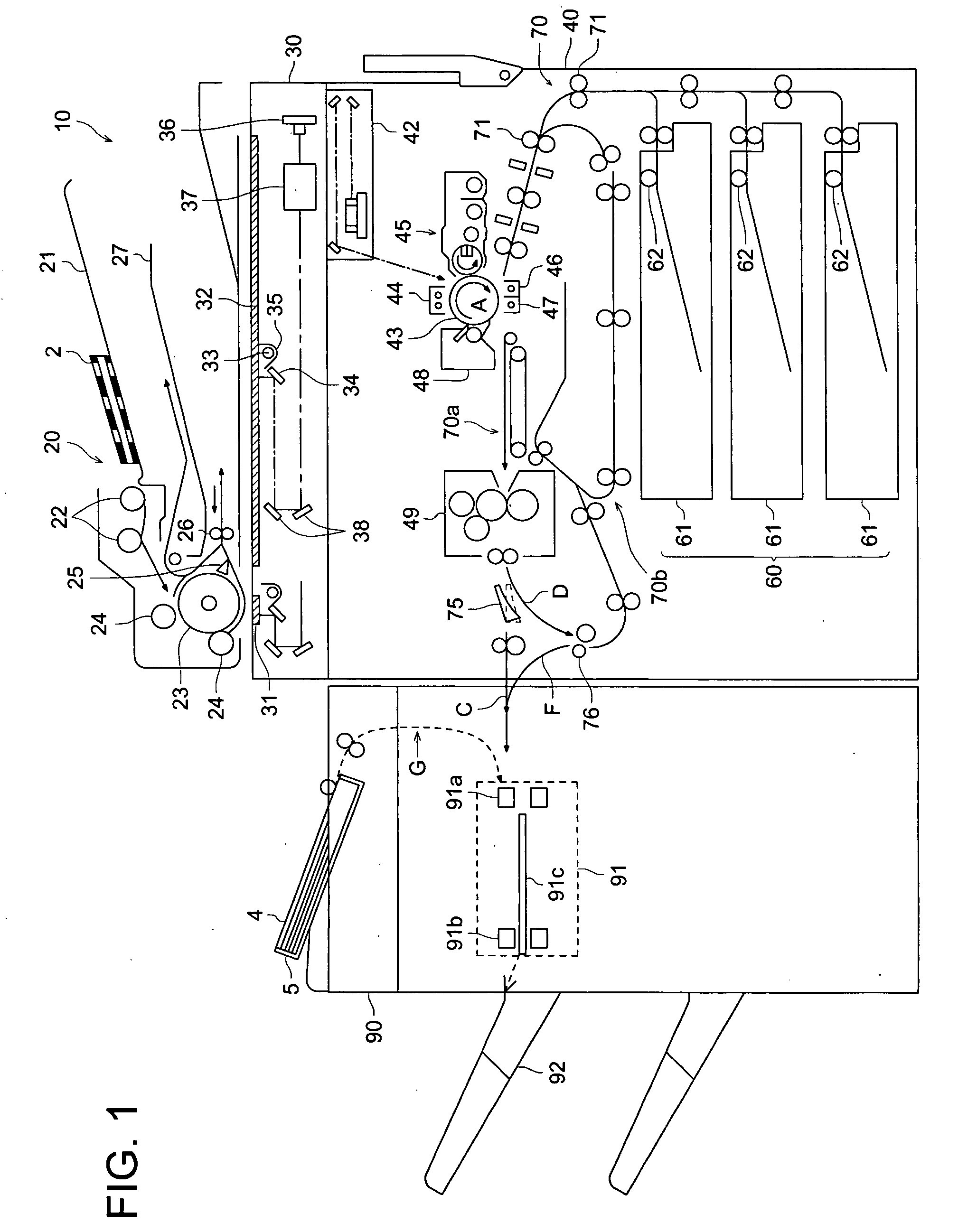

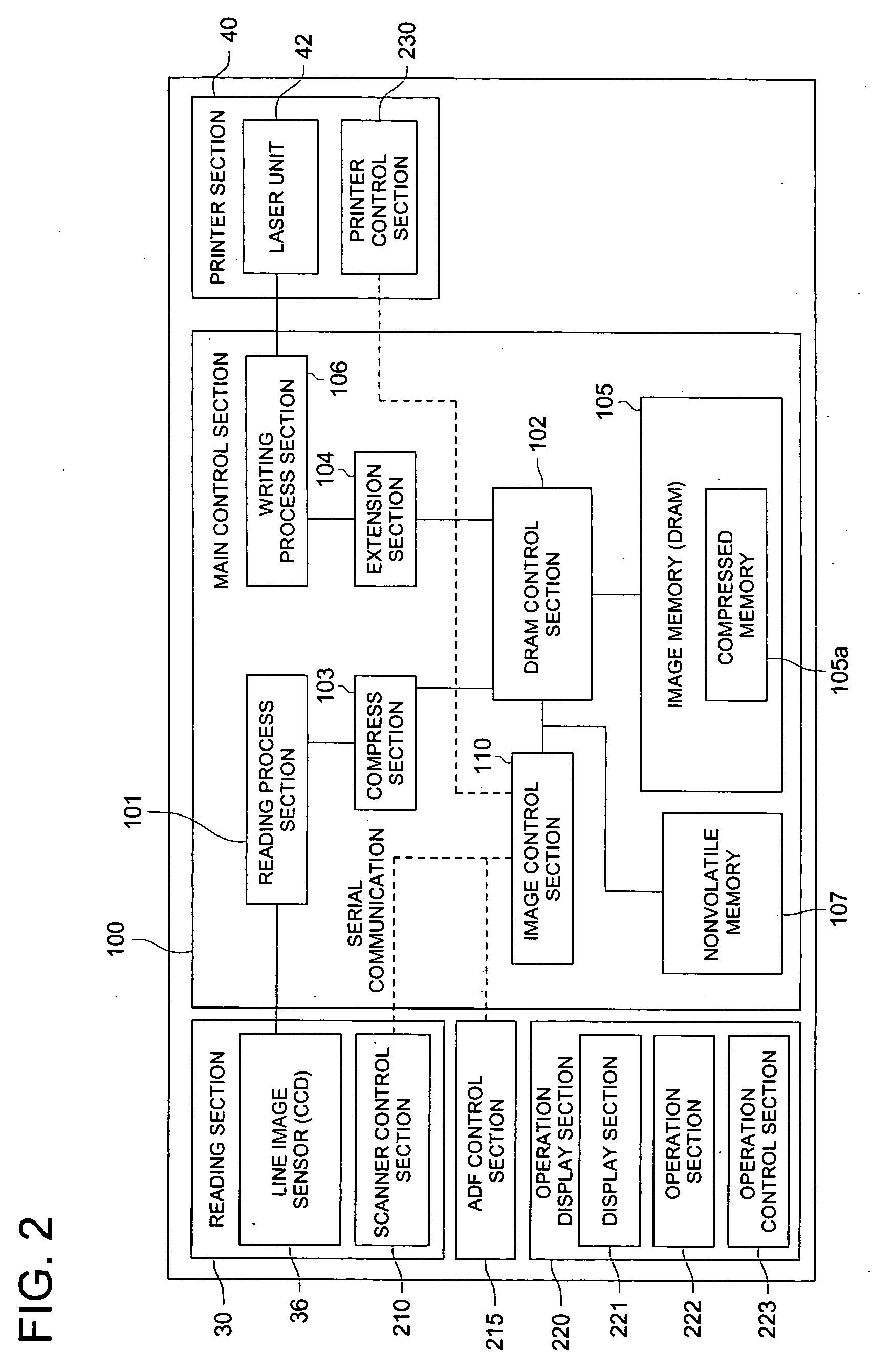

Image forming system

ActiveUS20050105930A1Function increaseDigitally marking record carriersCharacter printing data arrangement from carrierComputer printingImage formation

An image forming system, including: an image forming apparatus and a post processing device, wherein the image forming apparatus includes; a printer section, a control means, a selecting device to select one of a single sided print mode and a double sided print mode, and the post processing device includes; a sheet supplying tray, a conveyance route, and a post processing means, wherein the control means controls to count the page number to be assigned onto plural sheets of recording media, using a different counting value, based on the selected print mode.

Owner:KONICA MINOLTA BUSINESS TECH INC

Stand of printing unit

Owner:MANROLANAD AG

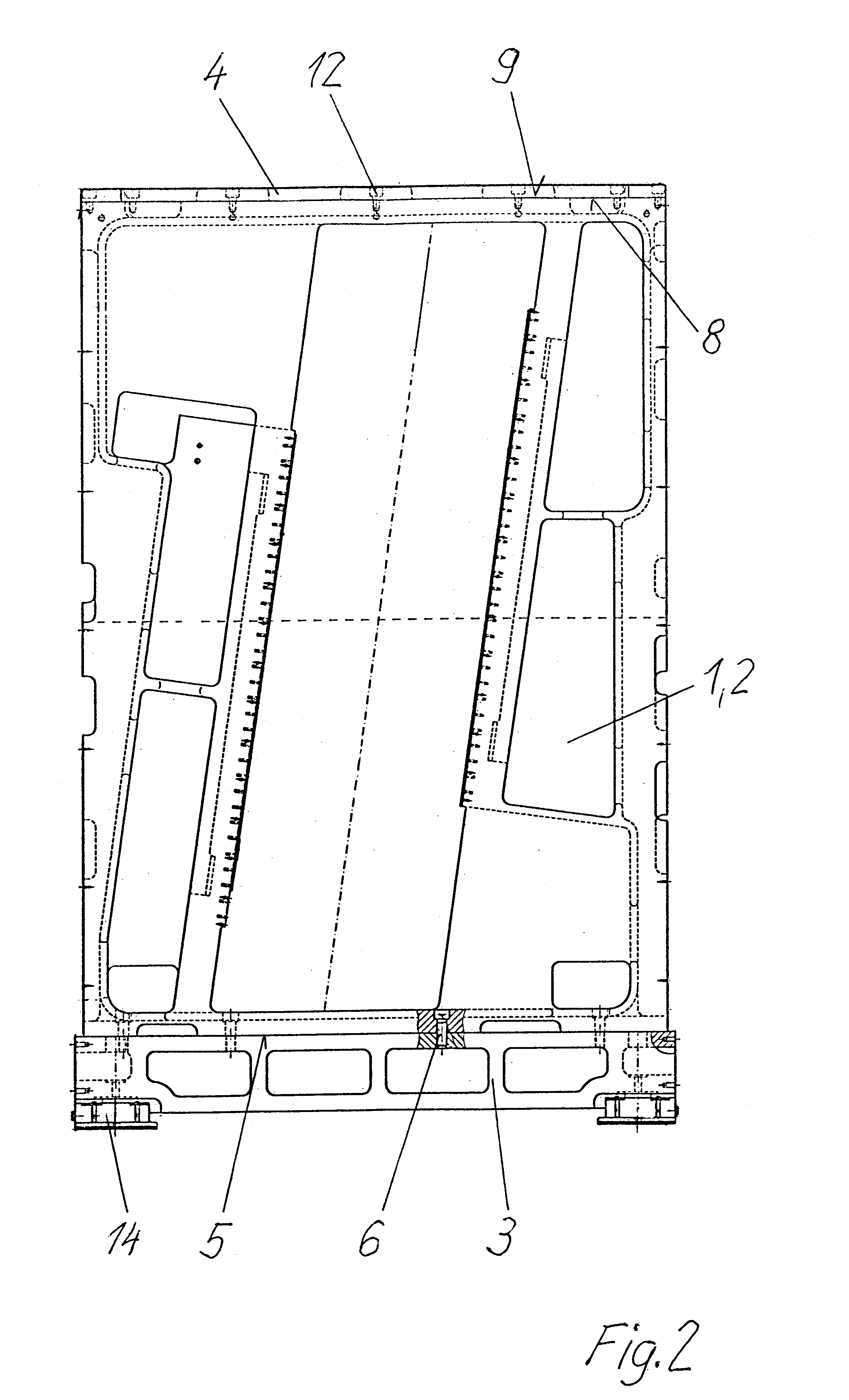

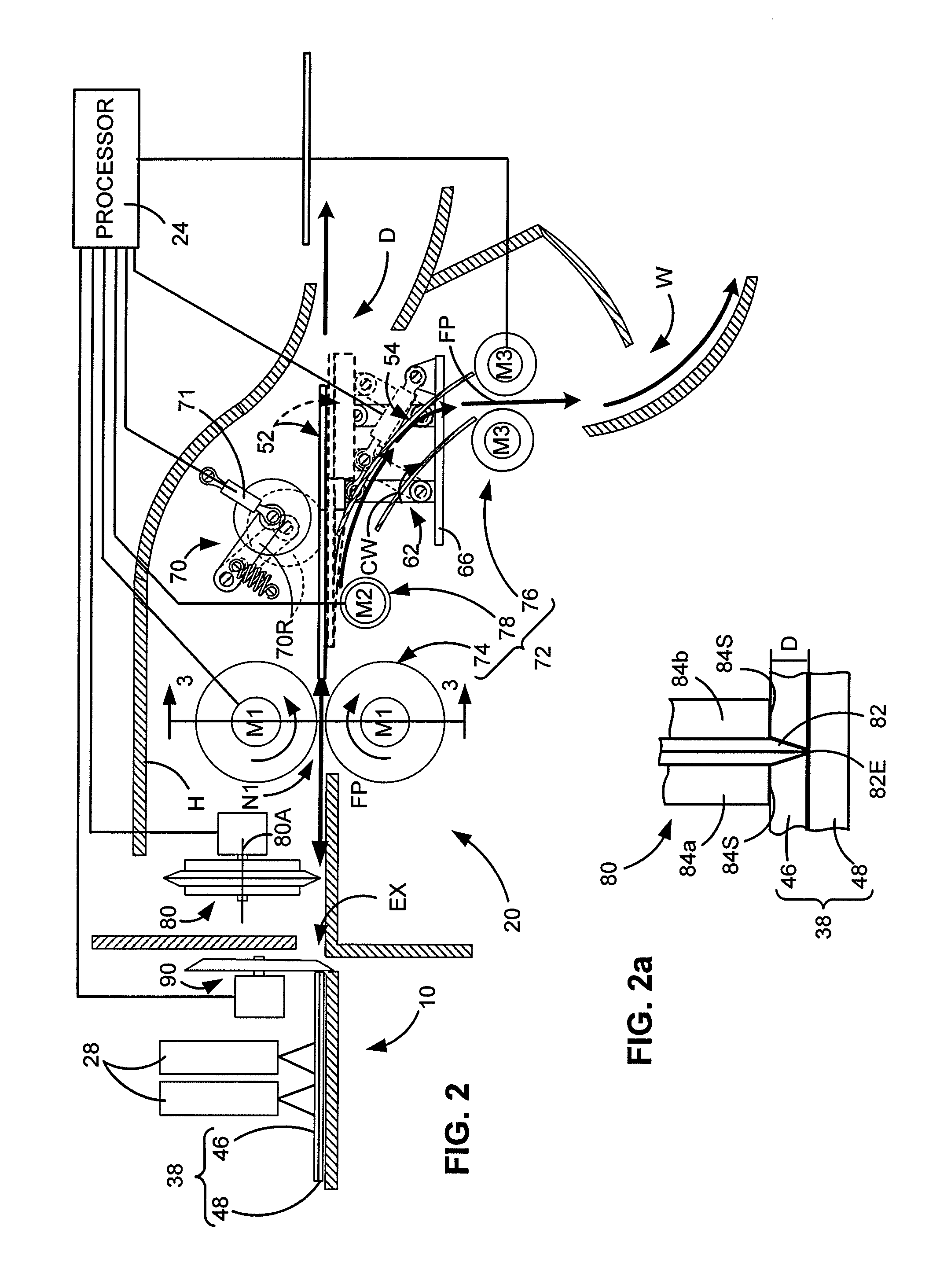

Postage Label Dispensing System Having A Peeler Plow For Dispensing Application Ready and/or Lined Postage Labels

A postage label dispensing system for dispensing adhesive-backed labels includes a conveyance system for displacing a supply of label material along a feed path wherein the label material includes a face material having an adhesive backing and a liner material detachably bonded to the adhesive backing. The adhesive backing defines a pair of longitudinal adhesive strips and a non-adhesive region disposed therebetween. The liner material has a longitudinal cut disposed adjacent to, and aligned with, the non-adhesive region to define a pair of liner strips. A peeler plow is disposed downstream of a bending means which induces a bend in the label material along an axis substantially parallel to the longitudinal cut, i.e., in an area corresponding to the non-adhesive region, which bend produces an opening between the face material and the liner strips. The peeler plow includes a tip portion operative to penetrate the opening between the face material and the liner strips, and an arcuate blade, disposed to each side of the tip portion, operative to peel the liner strips from the adhesive backing of the face material. A processor is operative to control the conveyance system such that the tip portion of the peeler plow penetrates the opening and the liner strips are peeled from the face material to dispense an application ready printed label. Alternatively, the peeler plow may be repositioned, from a first to a second position, such that the label material is conveyed over an upper surface of the peeler plow to dispense a plurality of lined labels.

Owner:PITNEY BOWES INC

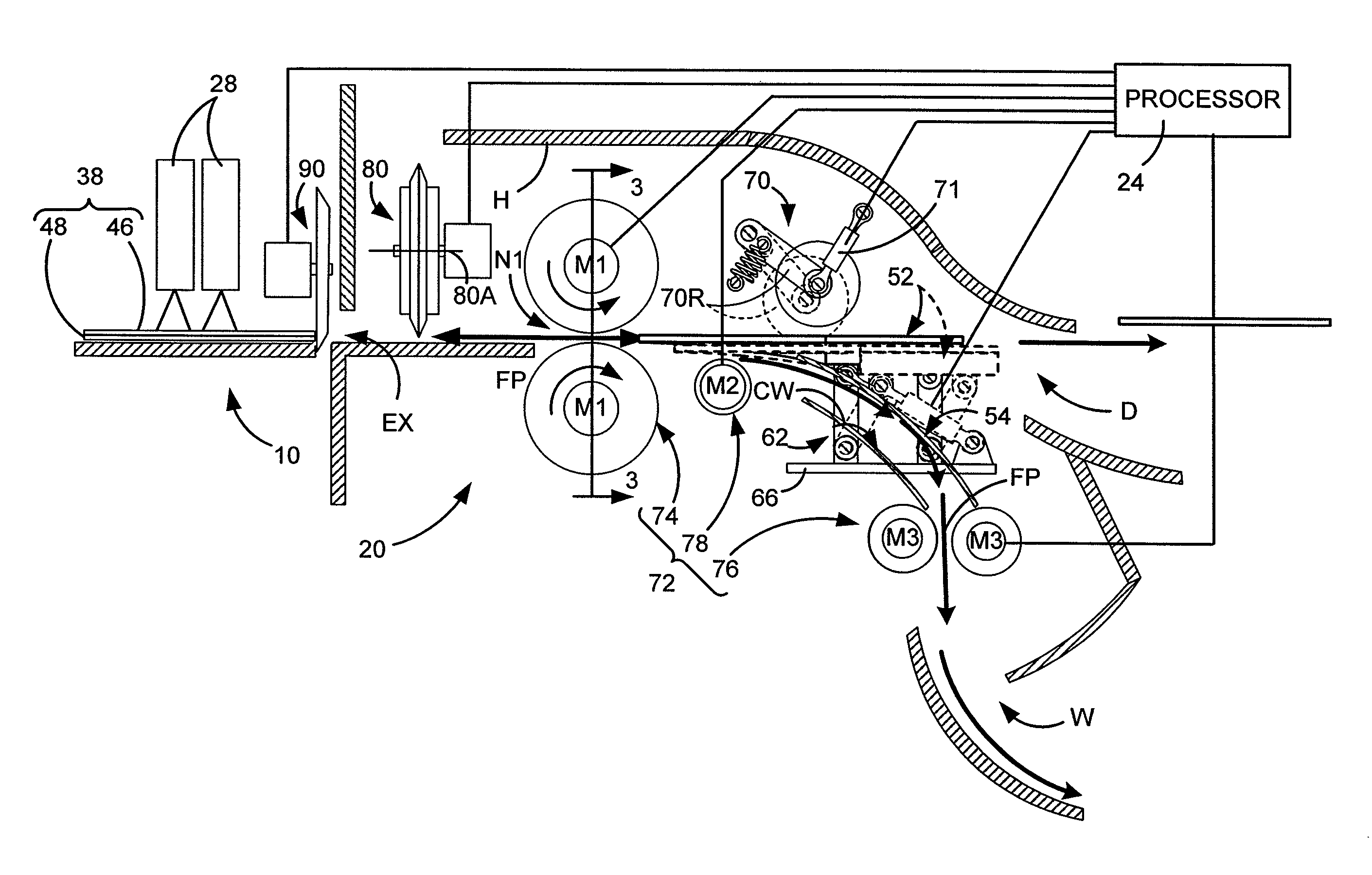

Method of issuing a printed ticket

InactiveUS20080310901A1Uselessly consumingAccelerated agingAddressing machinesApparatus for meter-controlled dispensingEngineeringThermal aware

The present invention relates to a method of issuing a printed ticket coming from a thermal printer, which printer comprises in a structure, a print head and a capstan for driving the ticket, a ticket travel guide being provided in the structure downstream from the print members, the method consisting in:a) storing in a memory of the printer the data for printing on the ticket;b) causing the ticket to advance by a determined amount so as to enable the user to grasp the ticket manually at the end of the guide;c) within a determined length of time from the end of step b), detecting the user applying a traction force to the ticket; andd) in response to said detection, simultaneously causing printing to take place on the ticket and the ticket to be ejected towards the user.

Owner:AXIOHM

Printer having a platen

ActiveUS20060210345A1Easily warpedConstantAddressing machinesTypewritersComputer printingEngineering

Owner:TOSHIBA TEC KK

Item handling system with tracking

An item handling system includes a vacuum source, a transport element defining a plurality of vacuum openings in fluid communication with the vacuum source to create a securing force on an item proximate to the transport element for holding the item in contact with the transport element, and a drive element for driving the transport element to transport the item. The transport element further defines a plurality of sensor openings arranged in two substantially parallel arrays along a longitudinal direction of the transport element. The system further includes a sensor associated with each array of sensor openings for sensing energy passing through the sensor openings to thereby sense the item on the transport element. Each sensor is disposed at a common longitudinal position relative to the transport element. Sensing the item corresponds to a condition where the sensor associated with each array is blocked.

Owner:DMT SOLUTIONS GLOBAL CORP

Punch press tool for stamping successive multicharacter impressions into a workpiece

A punch press tool for stamping successive multicharacter impressions into a workpiece such as a piece of steel, sheet metal, or other workpiece, includes a guide body in which a stamp driver is slidably mounted for being driven downwardly toward the workpiece by a punch press ram which is a standard part of a high speed commercial punch press. A multicharacter marking stamp is supported at the lower end of the stamp driver for reciprocal movement therewith. The marking stamp includes multicharacter wheels that are rotated automatically during operation for advancing characters in sequence responsive to the movement of a character advancing arm. At least one character stamp operating lever is operatively associated with the punch press tool for articulation responsive to motion imparted to the tool by the ram. The lever has an operating element that is operatively associated with the character advancing arm of the multicharacter stamp for indexing the arm to enable successive characters thereof to be placed in an operating position responsive to a stroke of the punch press ram.

Owner:MATE PRECISION TOOLING

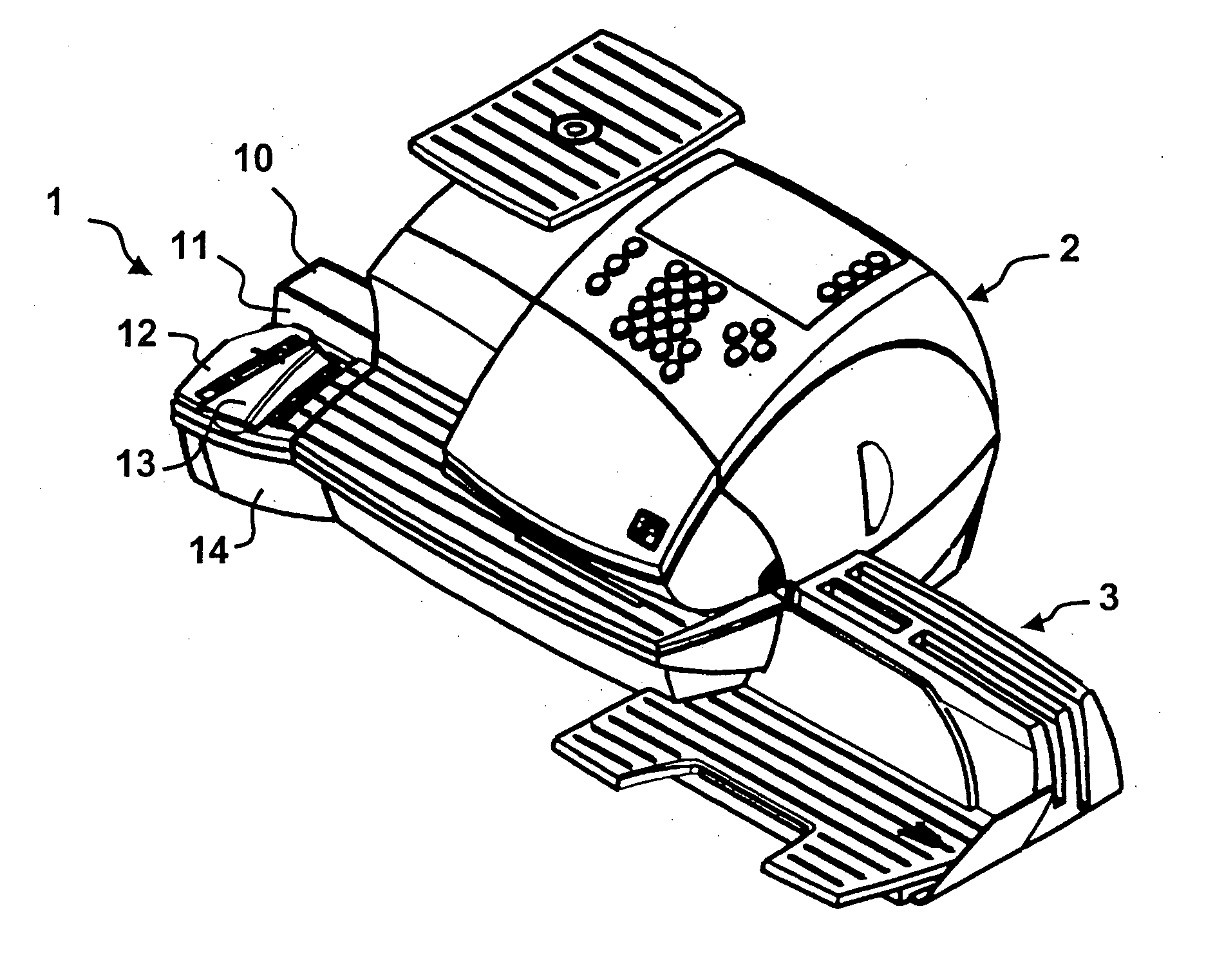

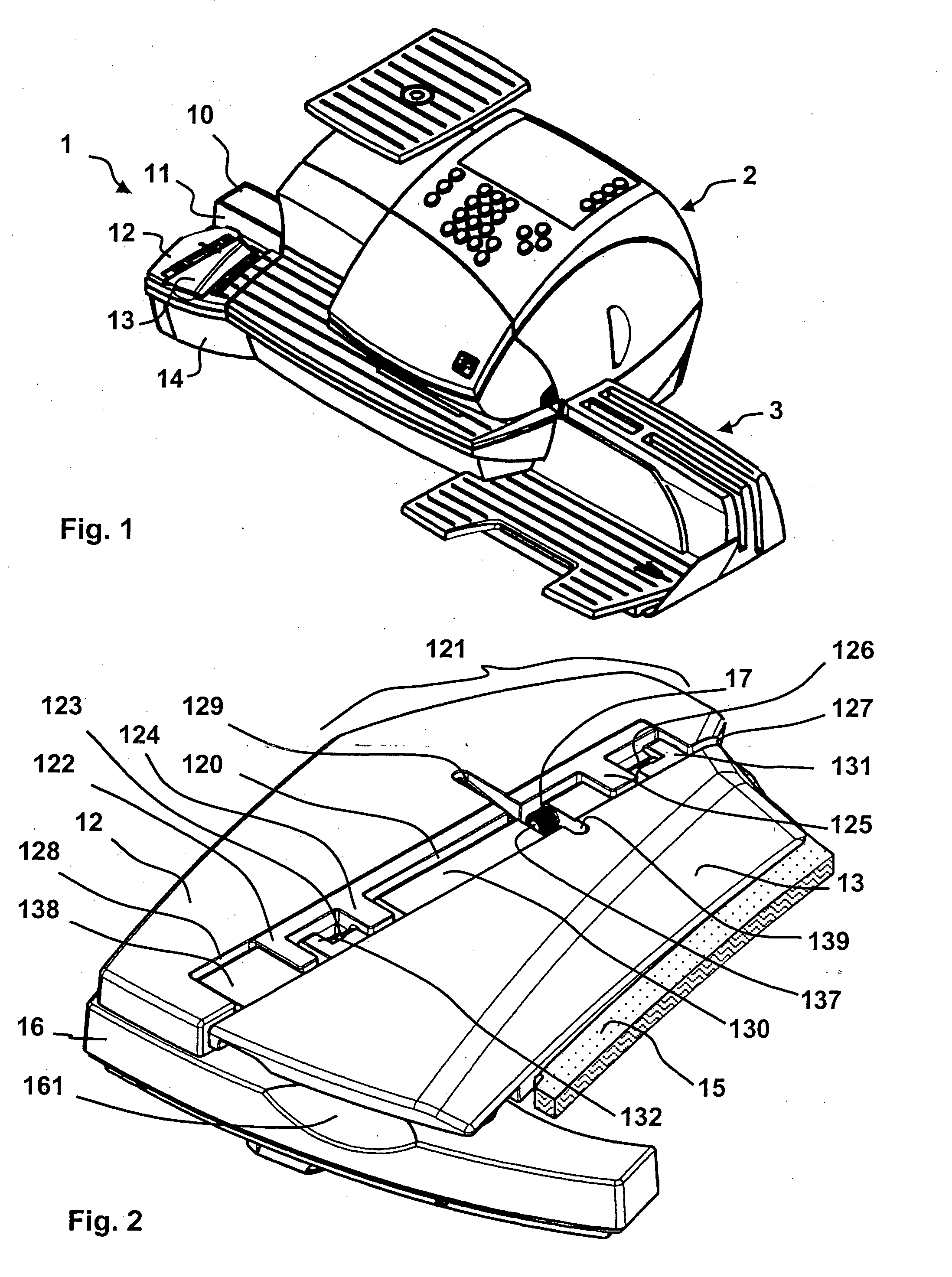

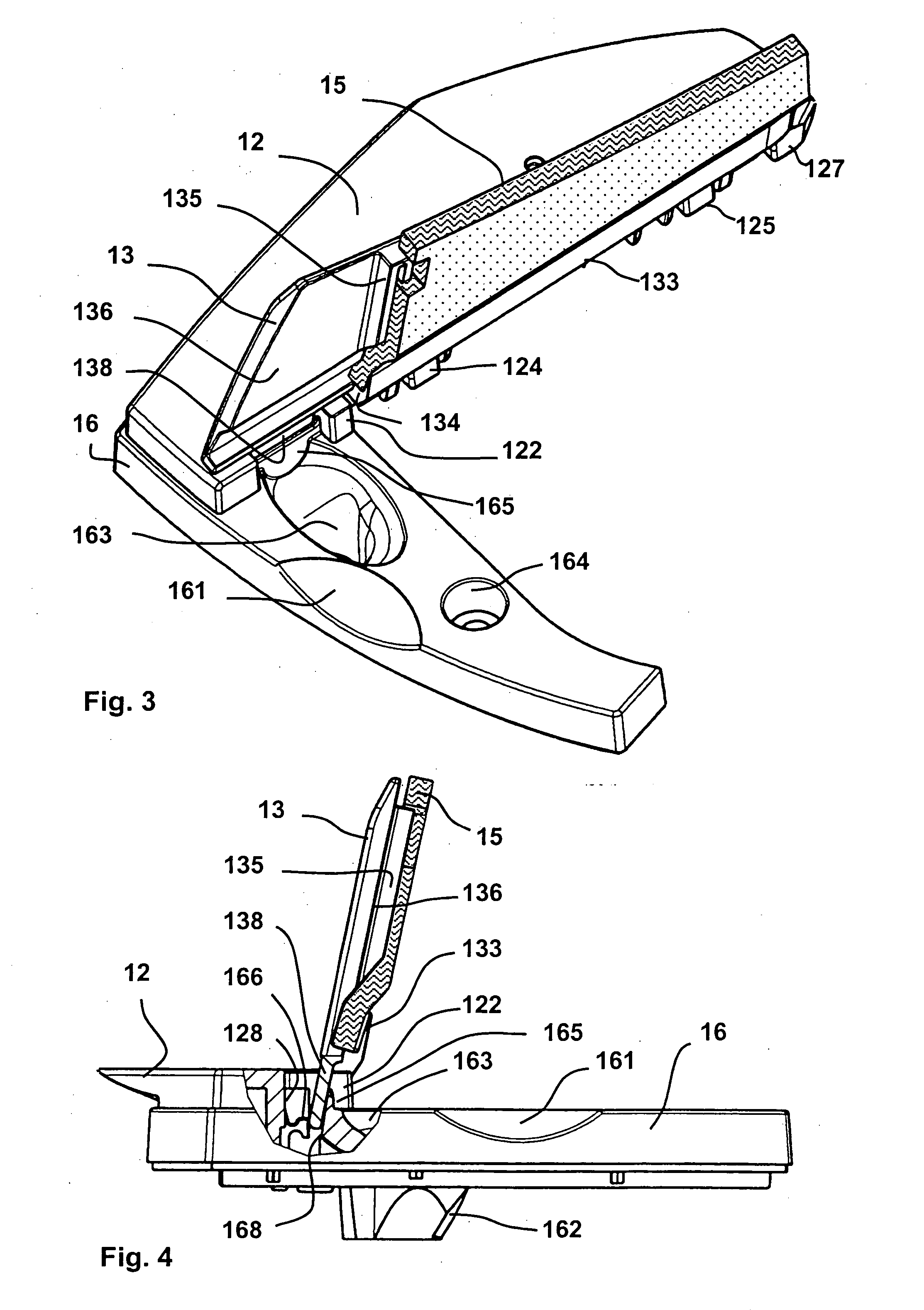

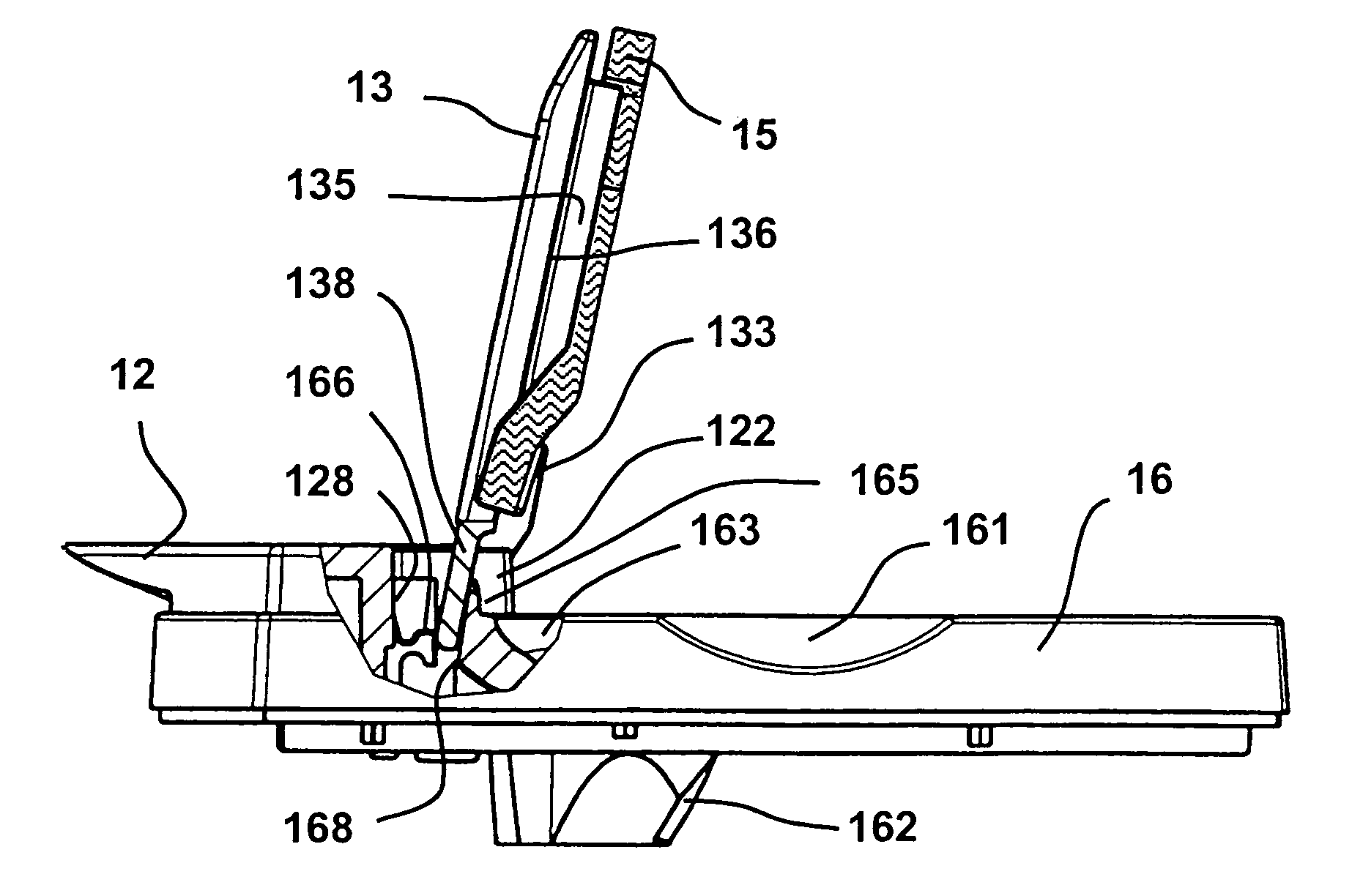

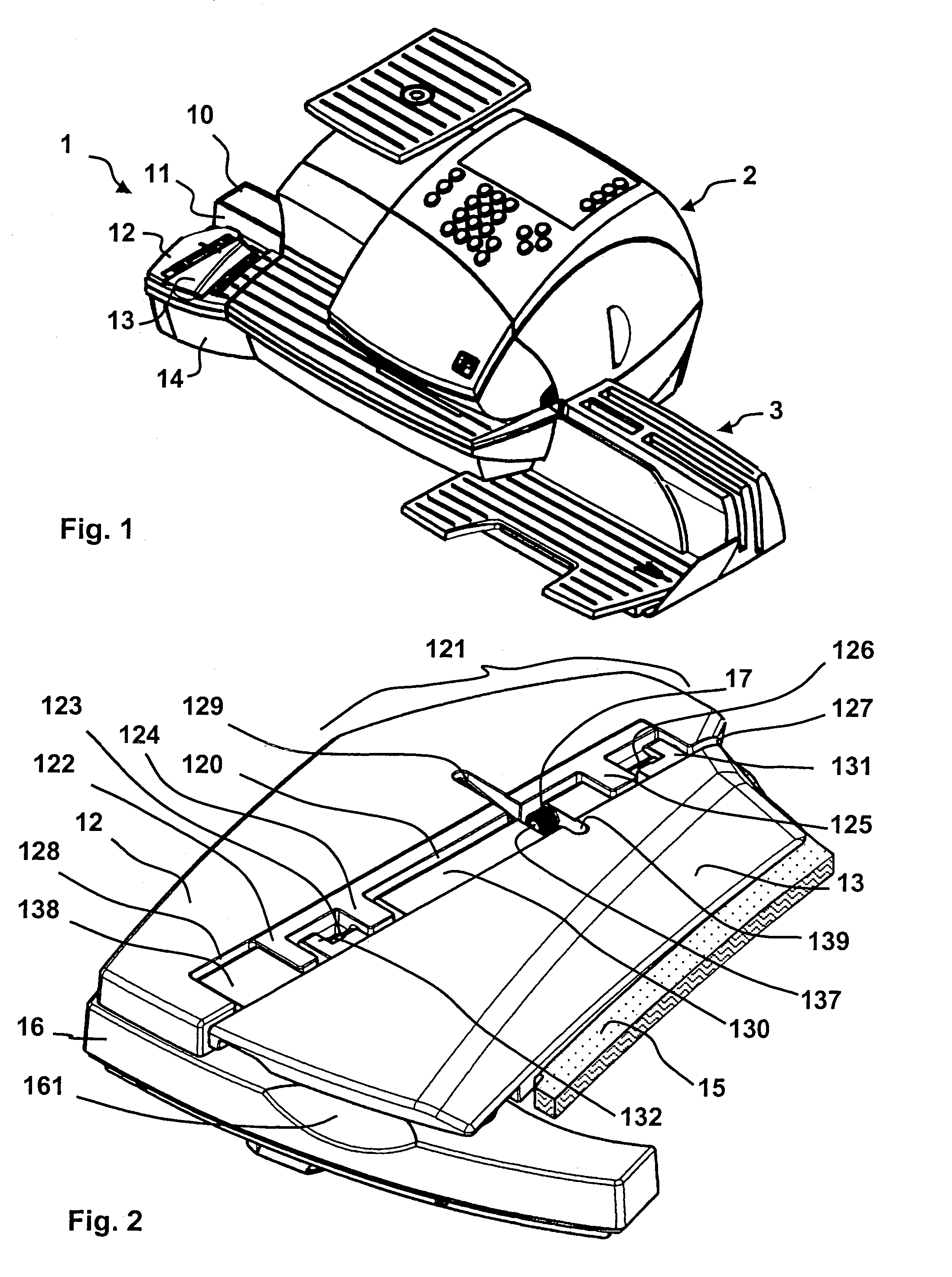

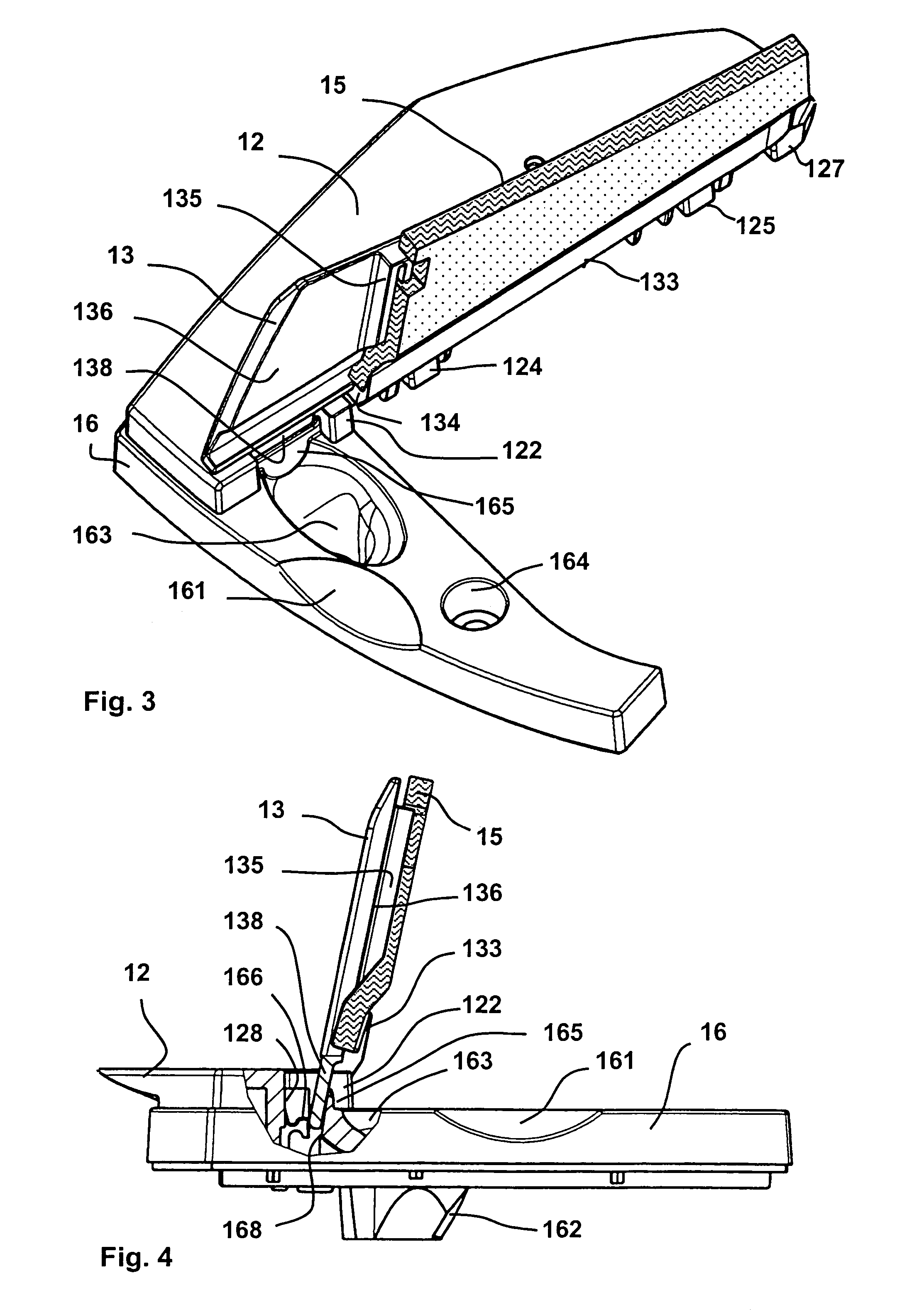

Manually operated moistener for items with a water-activated glue

InactiveUS20060011303A1Easy maintenanceReduce evaporationAddressing machinesLiquid surface applicatorsEngineeringWater transfer

A manually-operated moistener, to which a mail piece is supplied lying flat with a down-turned but not yet adhered flap on the underside of the envelope, has a blade in an upper part and a moistener rocker that can be opened upwardly and can be rotated with at least one locking contour on an associated hinge on the blade so as to be spring-supported as well as locked in a maintenance position. The upper part and a lower part of the moistener are connected by connection elements that can be detached only from above. An antibacterial upper moistening element is disposed in the upper part with a clamping region thereof in a clamping groove of the moistener rocker. A water transfer element protrudes into the lower part, which element is curved at its other, upper end. Both possess a shared contact surface for water transfer that is enlarged by the curvature.

Owner:FRANCOTYP POSTALIA

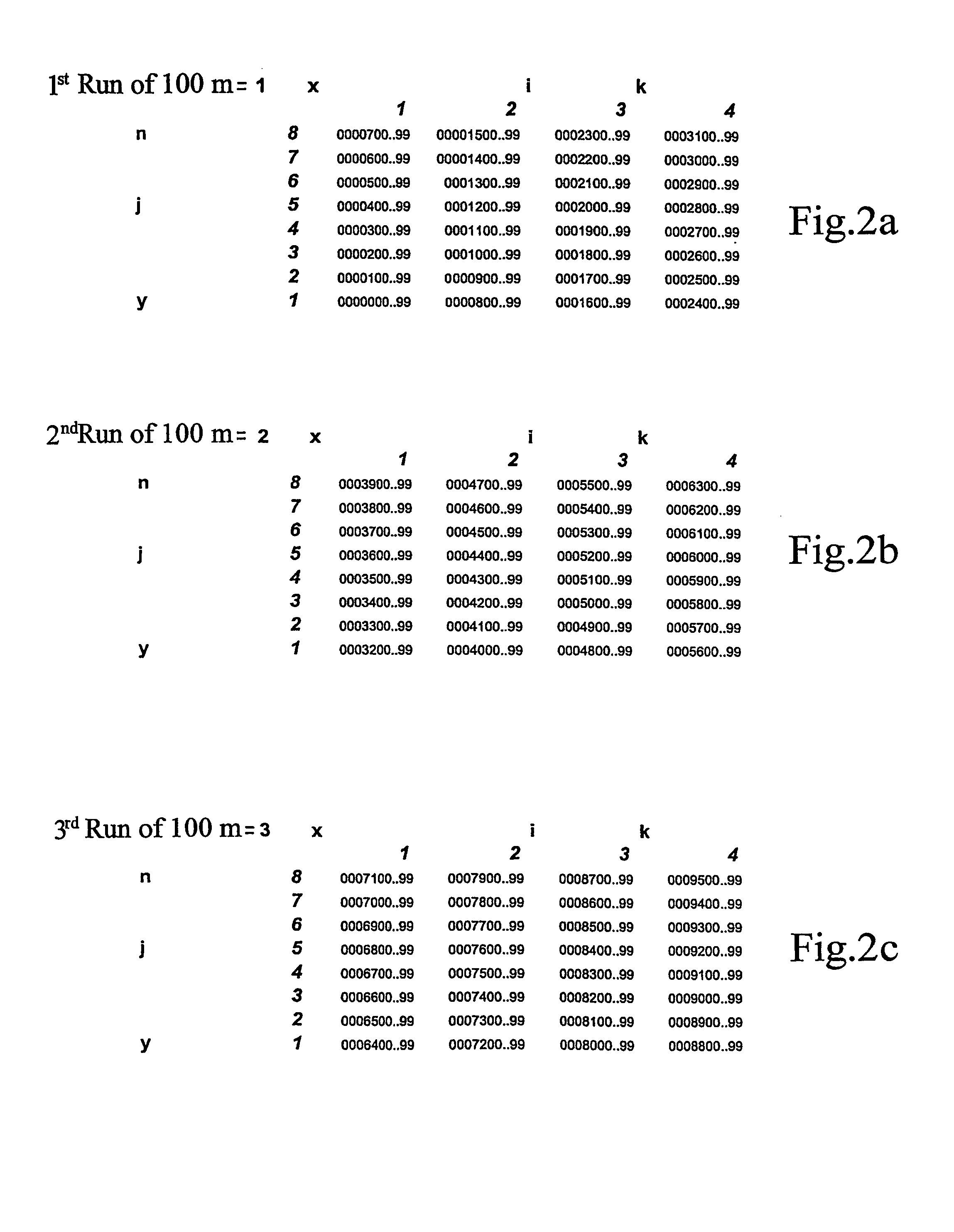

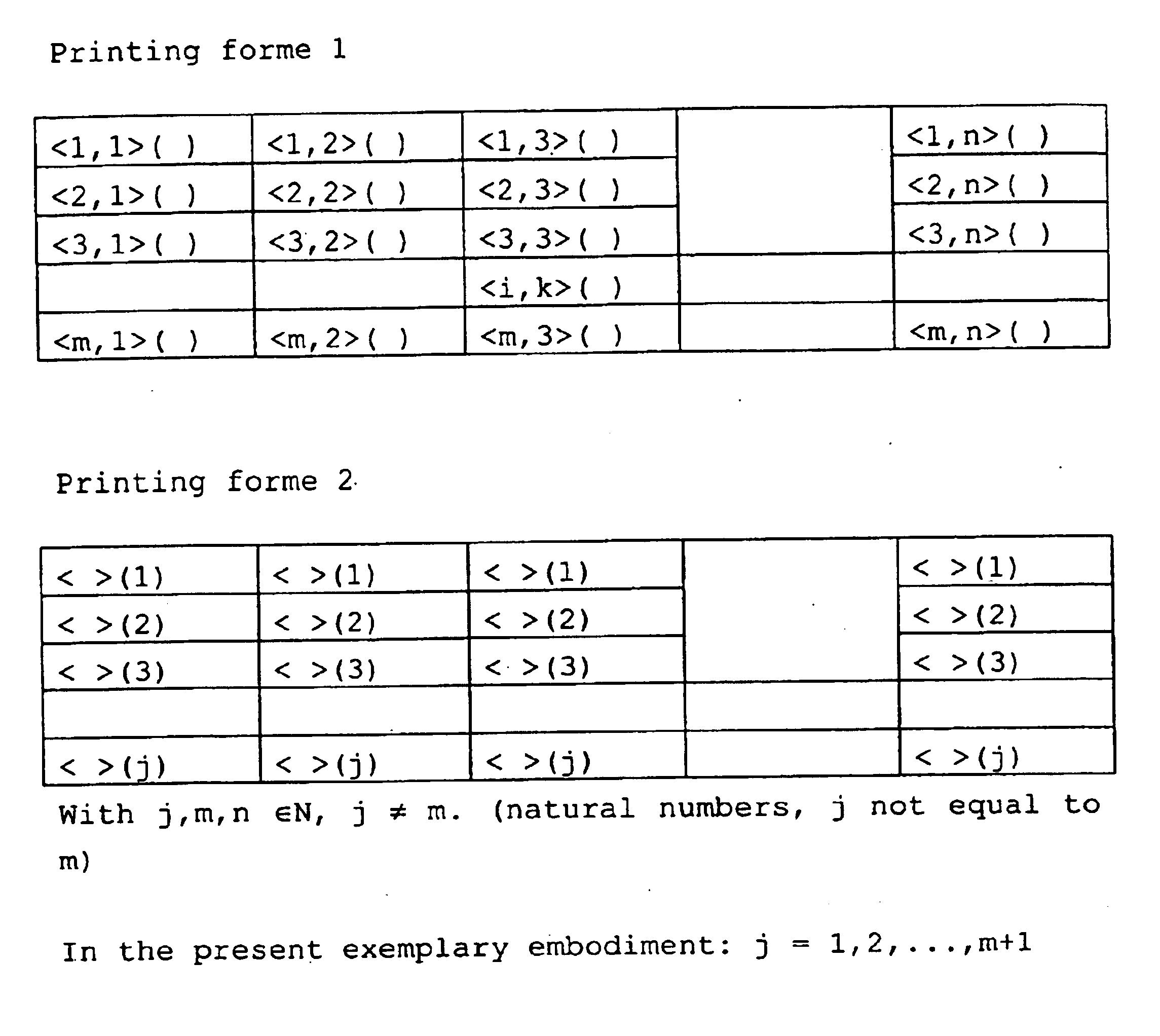

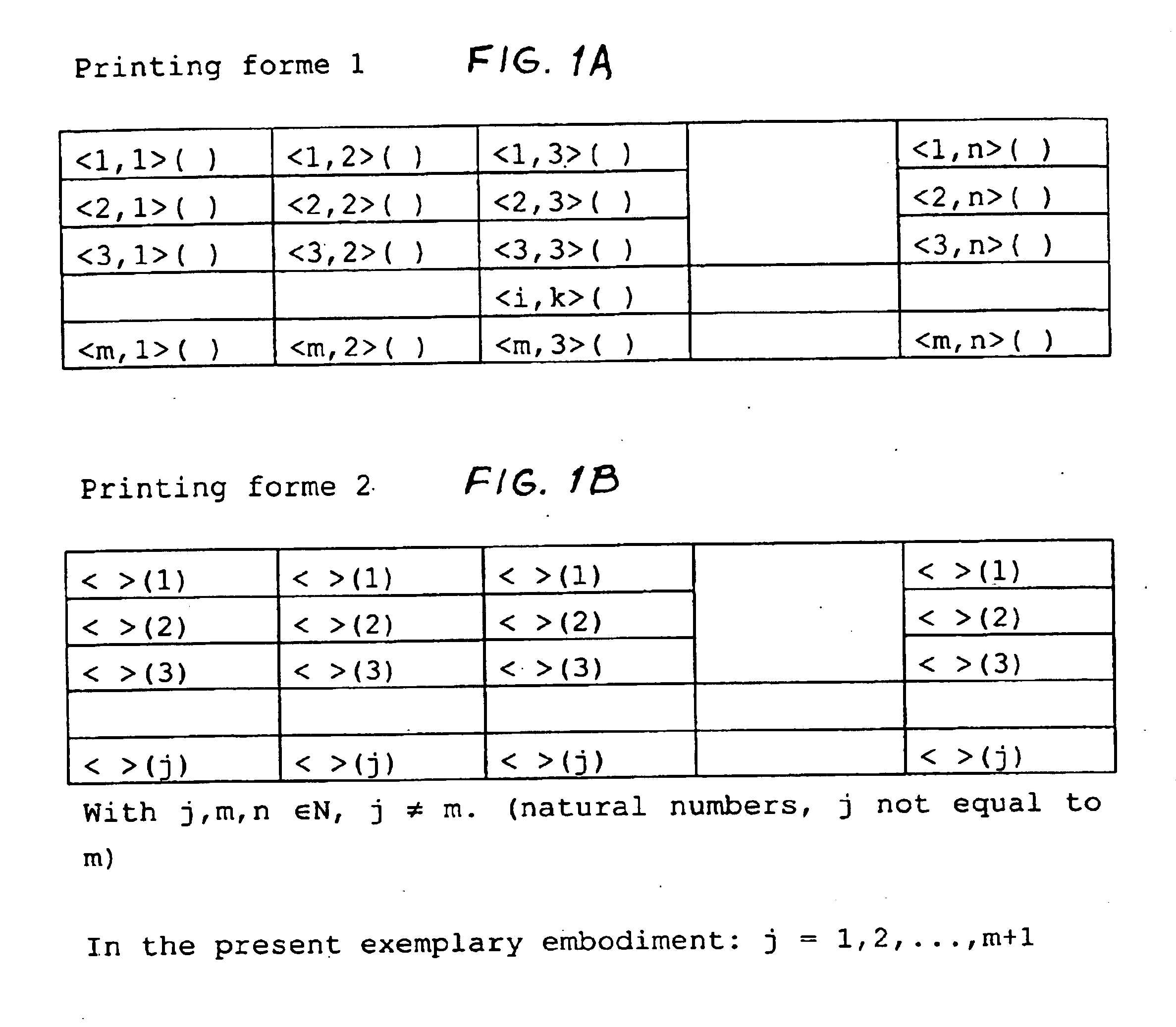

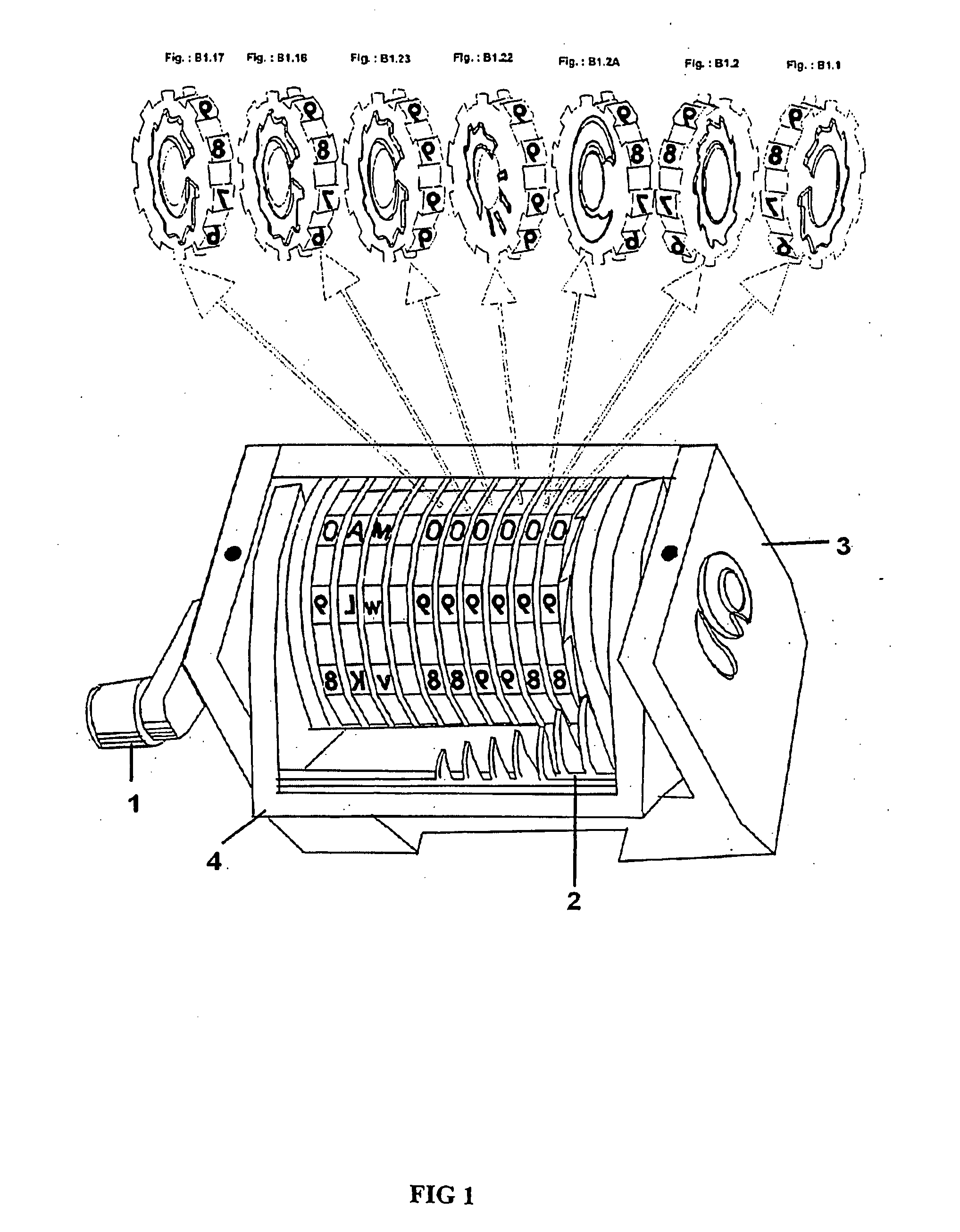

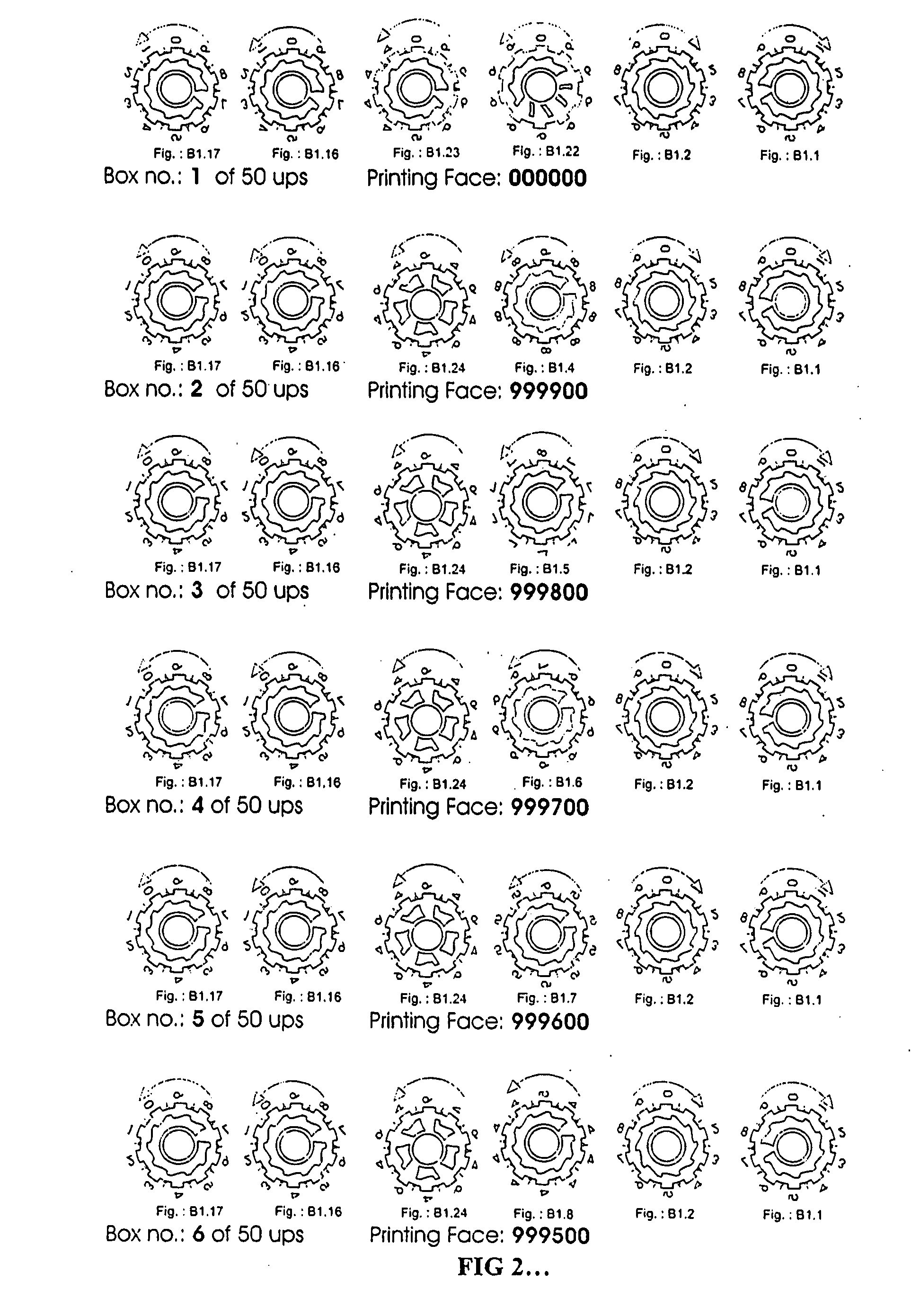

Method and an apparatus for printing sequential characters

InactiveUS20060225586A1Avoid any manual interferenceAddressing machinesHammer-impression mechanismEngineeringMechanical engineering

The present invention relates to a method and an apparatus for sequential printing of characters. The apparatus is a numbering box with a plurality of numbering wheels viz., unit wheel, tenth wheel, 100th wheel, 1000th wheel, 10000th wheel and 100000th wheel which are provided with a combination of ratchet and groove profiles on side-surfaces, numbers engraved on the periphery and are operably interconnected. The 100th and 1000th wheels provided with a combination of uniquely designed multiple grooves and ratchets. The numbering boxes are arranged in the form of a matrix of maximum rows (mr) and maximum columns (mc), to print first sheet. Thereafter, printing of characters on the second sheet till the next 99 sheets occurs. Finally printing from 101st sheet onwards till desired number of sheets is performed after assigning suitable value to first numbering box of 101st sheet by using the character profile of 100th and 1000th wheels.

Owner:KBA NOTASYS SA

Numbering device for typographic numbering

There is described a numbering device (1) for carrying out numbering in sheet-fed or web-fed numbering presses, the numbering device (1) comprising a numbering unit (6) with rotatable numbering wheels (7) carrying alpha-numerical symbols thereon, which numbering wheels (7) are disposed next to each other and rotate about a common rotation axis, the numbering device (1) further comprising electro-mechanical actuation means for setting the position of the numbering wheels (7). The electro-mechanical actuation means are entirely located within the numbering device (1) and are mechanically autonomous, the electro-mechanical actuation means comprising a plurality of independent driving means (15, 18-23; 23*) for actuating a corresponding plurality of the numbering wheels.

Owner:KBA NOTASYS SA

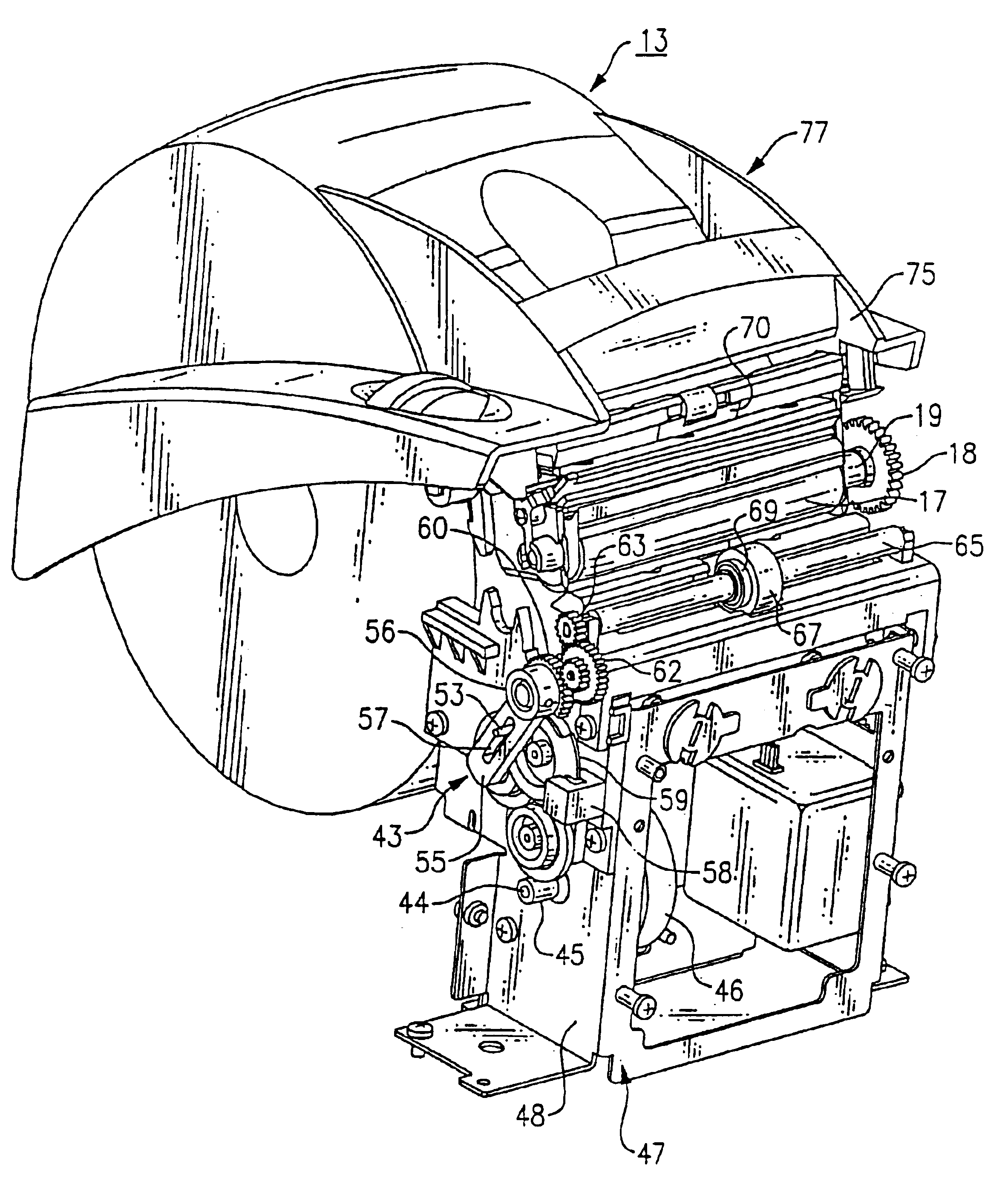

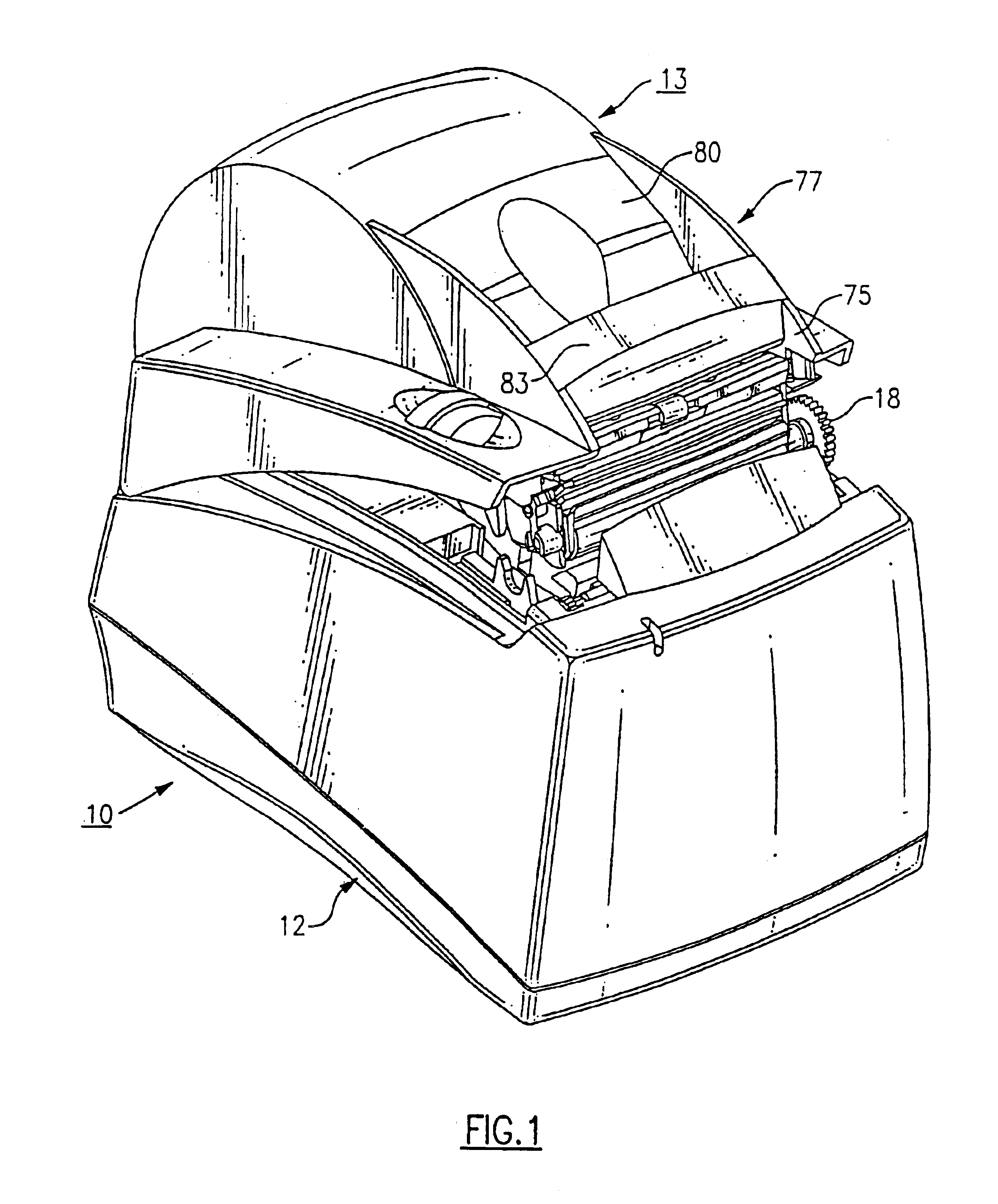

Stacker for a printer

InactiveUS6929416B2Speed saleImprove transaction-based printersAddressing machinesOther printing apparatusDot matrixEngineering

A transaction-based printer has a sheet drive for forwarding a sheet through a printing station to a cutting station where the sheet is severed from a spool by a rotary cutter. A kicker element is mounted in the cutting station. Movement of the kicker element is coordinated through the cutter drive with that of the rotary cutter so that the severed sheet is kicked into a bin located in the top cover of the printer. The printer can be, for example, an ink-jet, dot matrix, dye sublimation or thermal printer used to print tickets, vouchers, coupons or the like.

Owner:TRANSACT TECH

Manually operated moistener for items with a water-activated glue

InactiveUS7384500B2Reduce maintenanceEasy wetting capabilityAddressing machinesLiquid surface applicatorsEngineeringWater transfer

A manually-operated moistener, to which a mail piece is supplied lying flat with a down-turned but not yet adhered flap on the underside of the envelope, has a blade in an upper part and a moistener rocker that can be opened upwardly and can be rotated with at least one locking contour on an associated hinge on the blade so as to be spring-supported as well as locked in a maintenance position. The upper part and a lower part of the moistener are connected by connection elements that can be detached only from above. An antibacterial upper moistening element is disposed in the upper part with a clamping region thereof in a clamping groove of the moistener rocker. A water transfer element protrudes into the lower part, which element is curved at its other, upper end. Both possess a shared contact surface for water transfer that is enlarged by the curvature.

Owner:FRANCOTYP POSTALIA

Letterpress printing machine

ActiveUS8726805B2Improve accuracyEasy maintenanceAddressing machinesAddressographsLetterpress printingControl unit

Owner:KBA NOTASYS SA

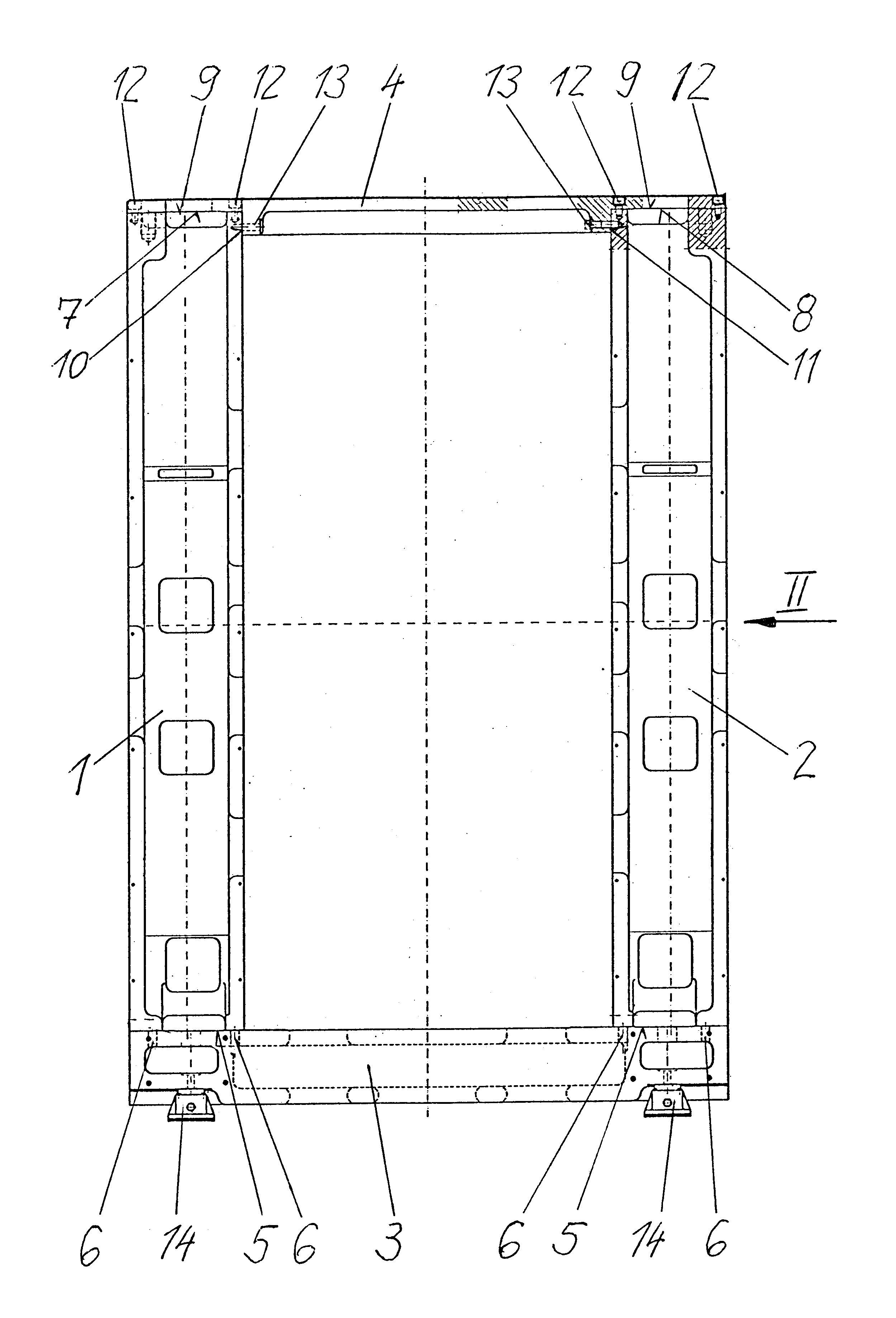

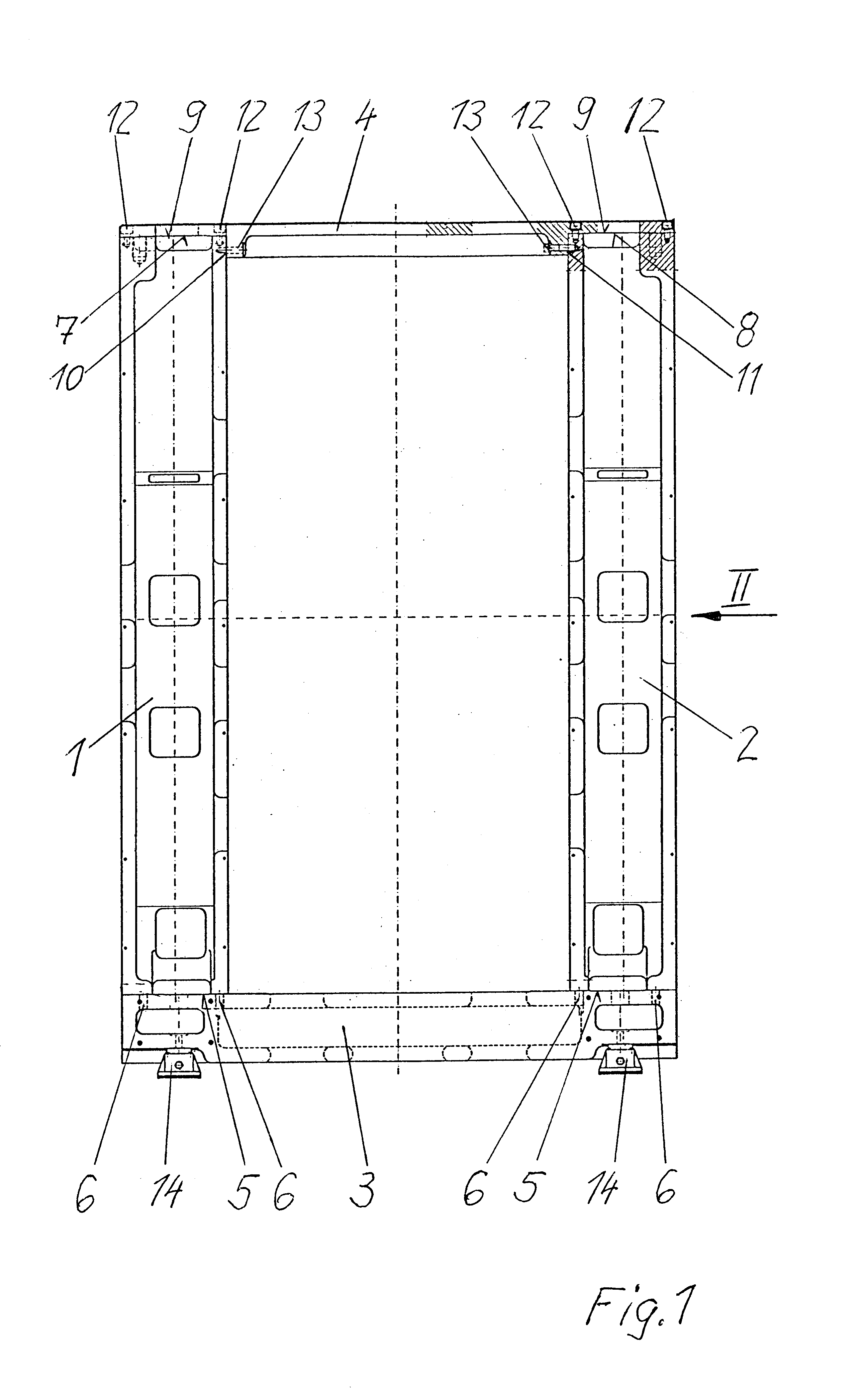

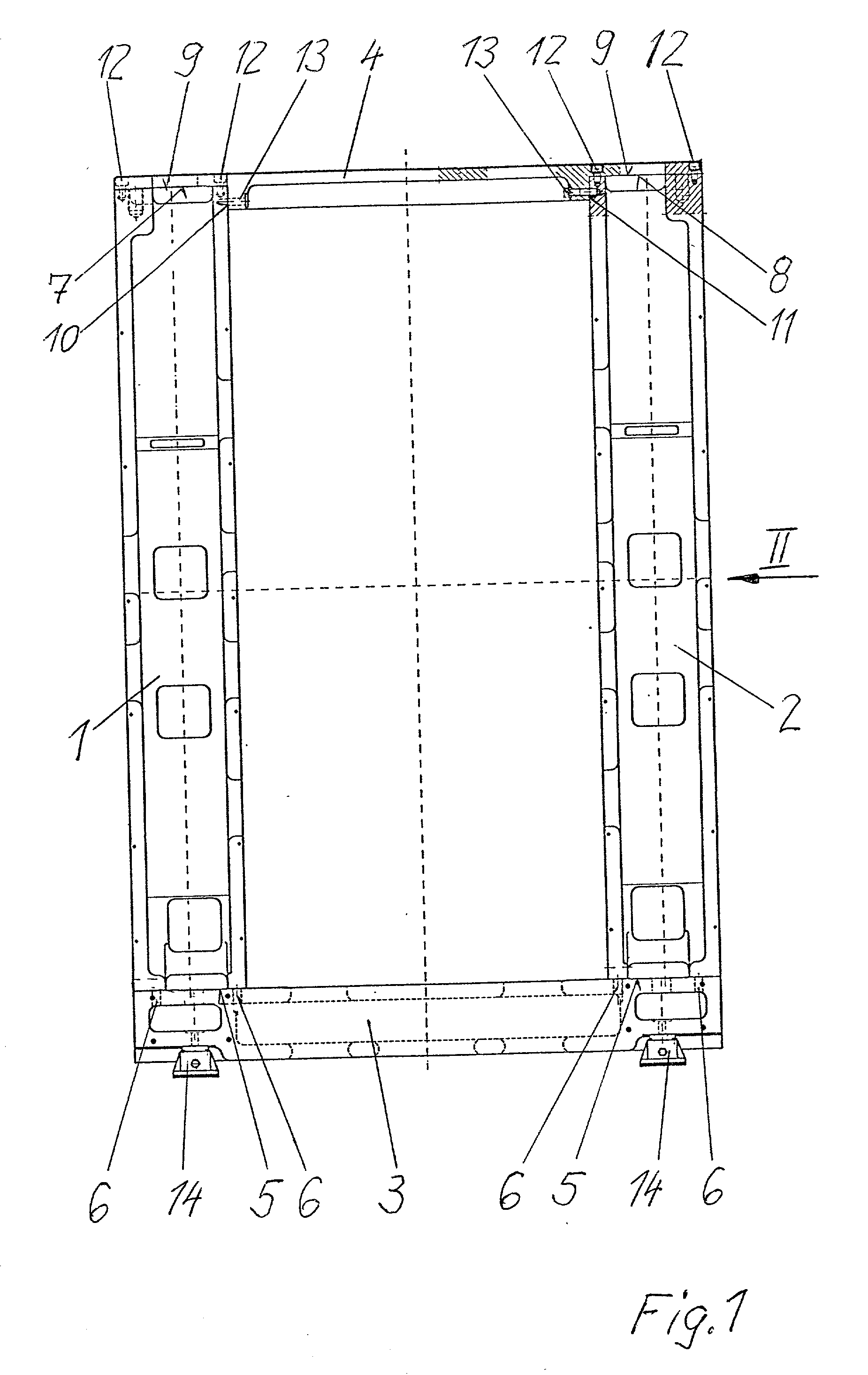

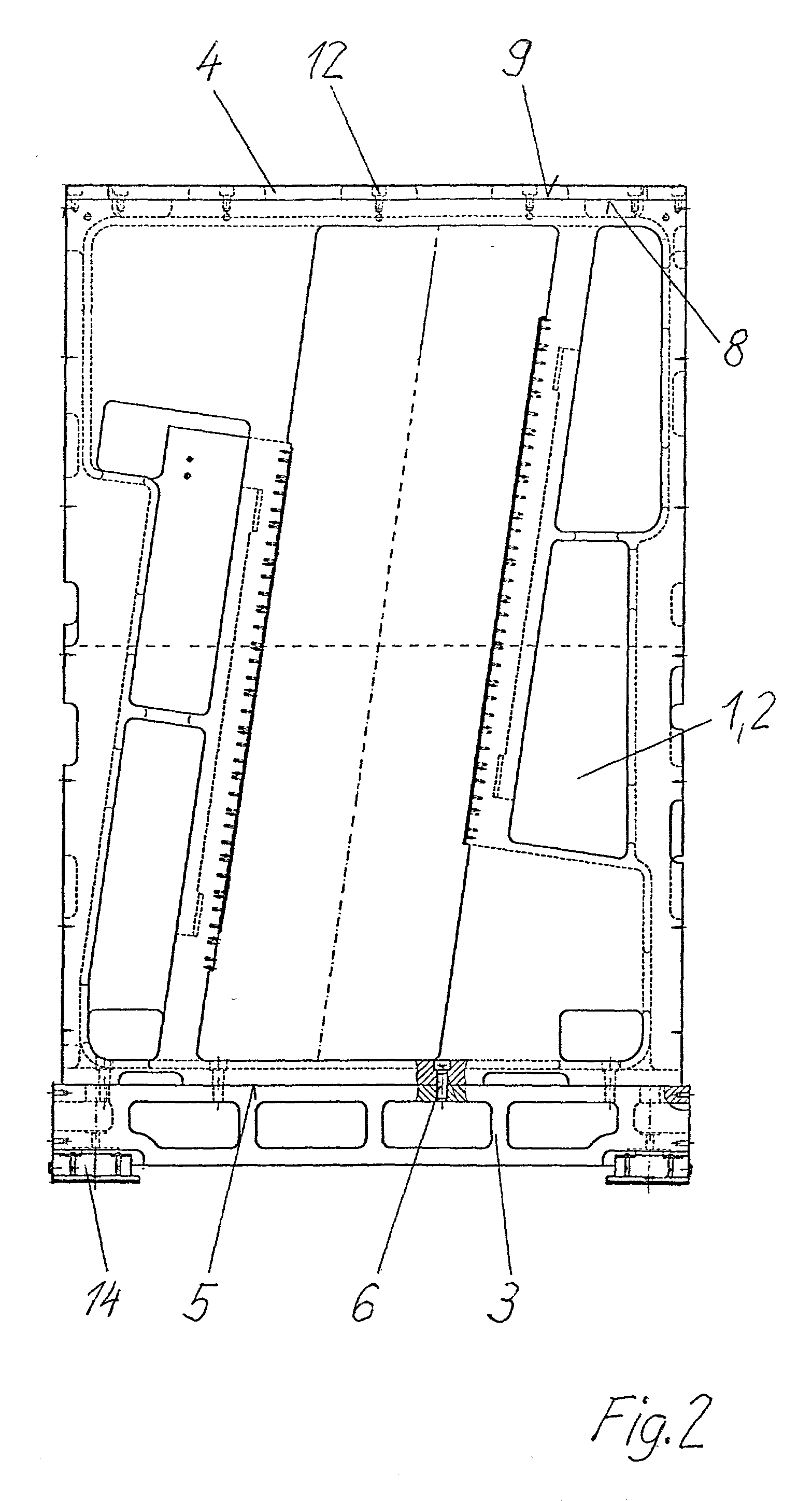

Stand of printing unit

In order to provide a stand of a printing unit of a rotary printing machine, said stand being capable of being produced cost-effectively and having high inherent rigidity, a left-hand and a right-hand side wall are placed onto a bottom plate and screwed to the latter and are also provided with a cover plate, the cover plate resting with first locating faces on the side walls and with second locating faces against the side walls, the cover plate being screwed to the side walls at all the locating faces.

Owner:MANROLANAD AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com