Dielectric filter and 5G communication equipment

A dielectric filter and dielectric resonator technology, applied in the field of filters, can solve the problems of complex manufacturing process, great technological difficulty, easy breakage, etc., and achieve the effect of reducing insertion loss, realizing simple process and large capacitance loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

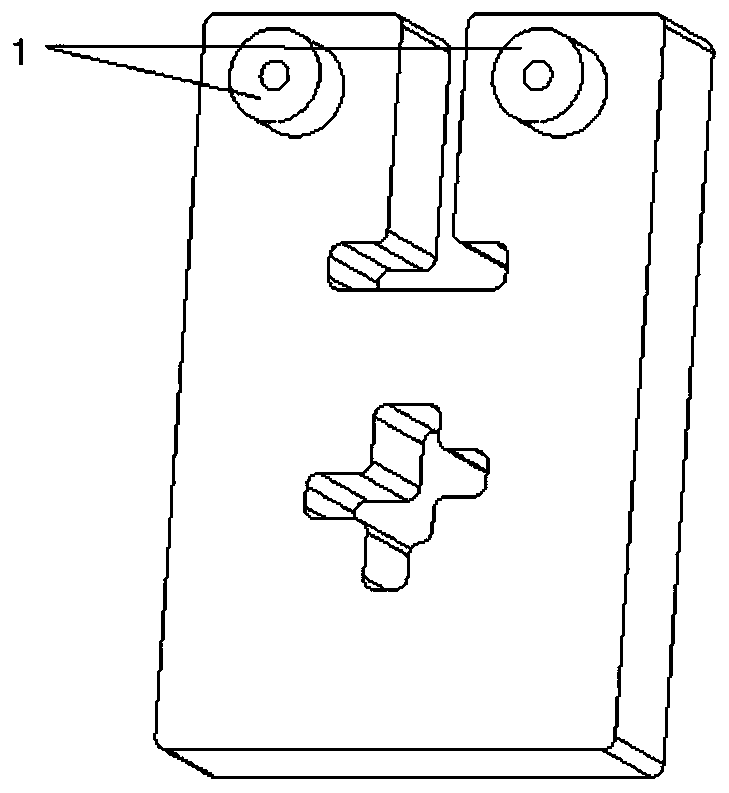

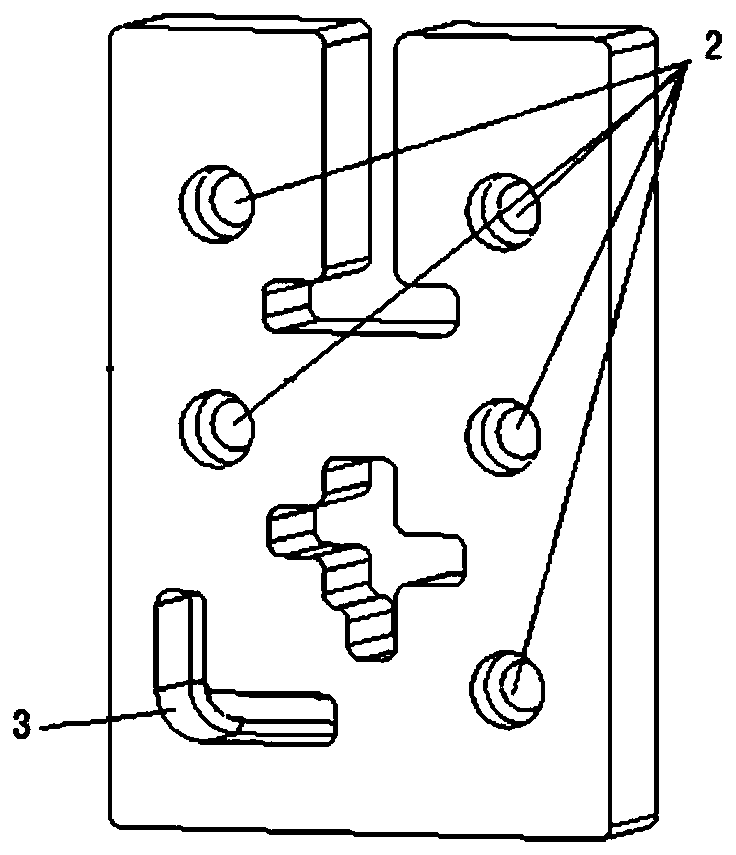

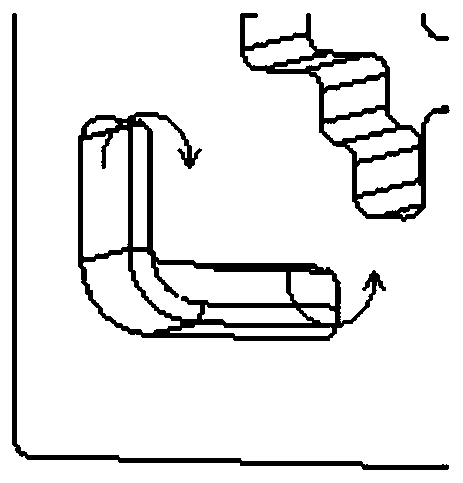

[0031] Aiming at the deficiencies of the prior art, the solution of the present invention is to realize the secondary mode resonant cavity by arranging a groove structure on the surface of the dielectric material body of the dielectric resonator, and use the secondary mode resonator technology to realize the capacitive crossover of the dielectric filter. Coupling, its realization process is simple, and the entire filter can be realized by one piece of dielectric processing, which is convenient for industrialized mass production; this scheme can realize larger capacitance loading, thereby greatly reducing the volume of the resonant cavity, while improving the Q value and reducing the insertion loss, and Does not affect the mechanical strength of the filter.

[0032] Specifically, the technical scheme of the present invention is as follows:

[0033] A dielectric filter, comprising at least three sequentially connected dielectric resonators, each dielectric resonator comprising a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com