Ink gun manufacturing method, ink gun and printing equipment

A manufacturing method and technology for an inkjet head, which are applied in the field of inkjet head and printing equipment, and inkjet head manufacturing, can solve the problems of increasing the manufacturing cost, affecting the mechanical strength and performance of the substrate, and thinning the side wall, so as to improve the yield of finished products. , The effect of improving manufacturing efficiency and manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

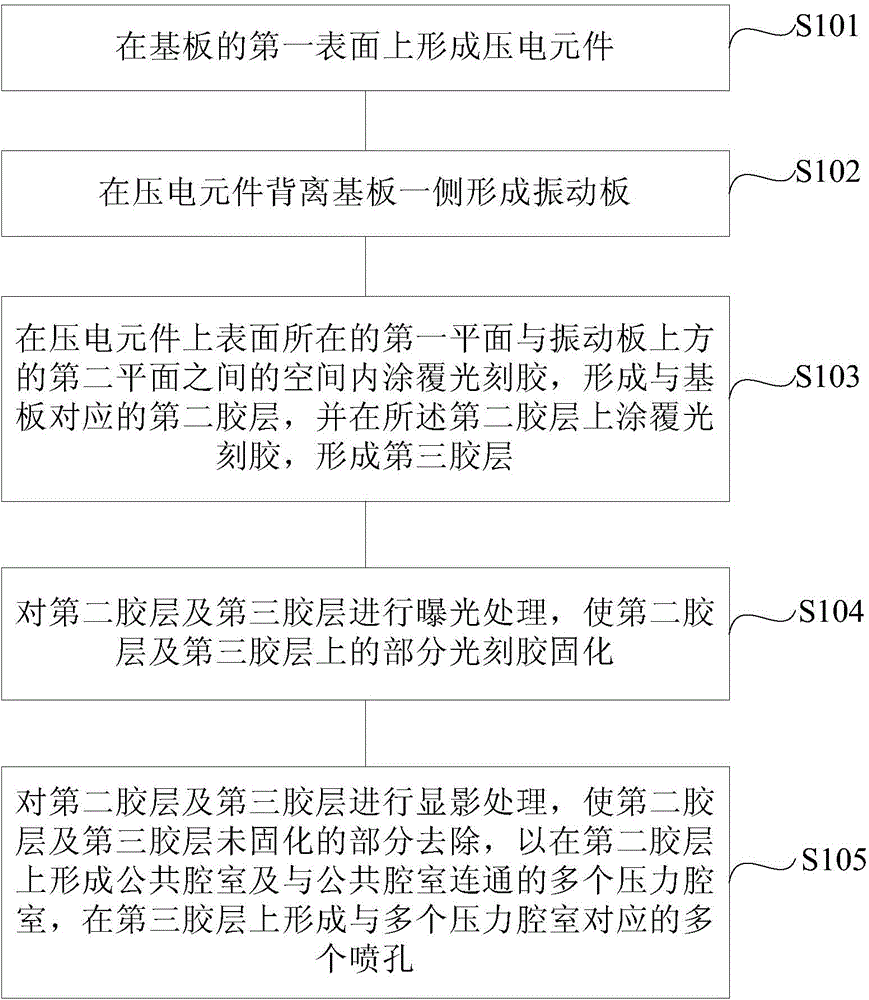

[0033] Embodiment 1 of the present invention provides a method for manufacturing an inkjet head, specifically as figure 2 As shown, the method includes the following steps:

[0034] S101, forming a piezoelectric element on the first surface of the substrate;

[0035] In this embodiment, the formation of the piezoelectric element specifically includes: sequentially forming a lower electrode layer on the first surface of the substrate by sputtering, forming a piezoelectric layer on the lower electrode layer by a sol-gel method, and The upper electrode layer is formed by sputtering.

[0036] S102, forming a vibrating plate on a side of the piezoelectric element away from the substrate;

[0037] In this embodiment, the vibrating plate can be formed by low pressure chemical vapor deposition or plasma enhanced chemical vapor deposition.

[0038] S103. Coating photoresist in the space between the first plane where the upper surface of the piezoelectric element is located and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com