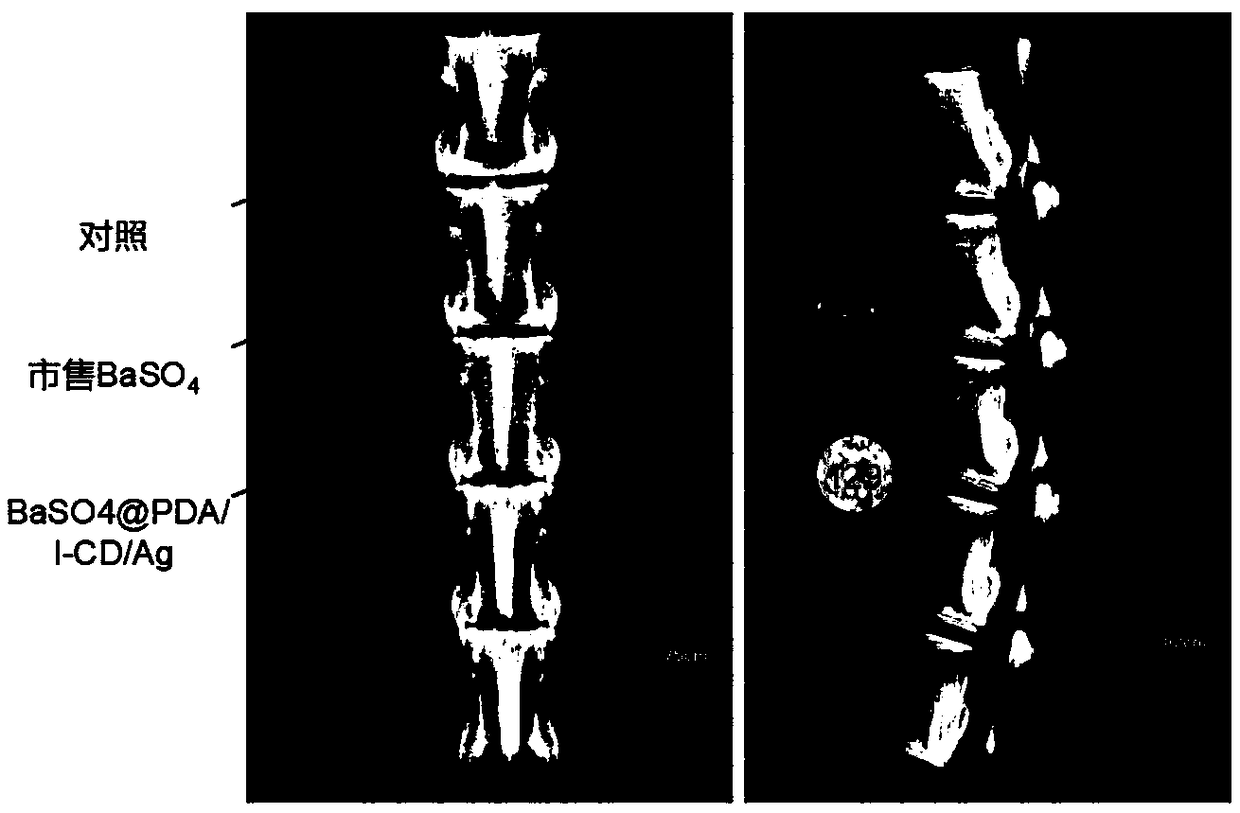

Coated barium sulfate nanoparticle, preparation method and use thereof

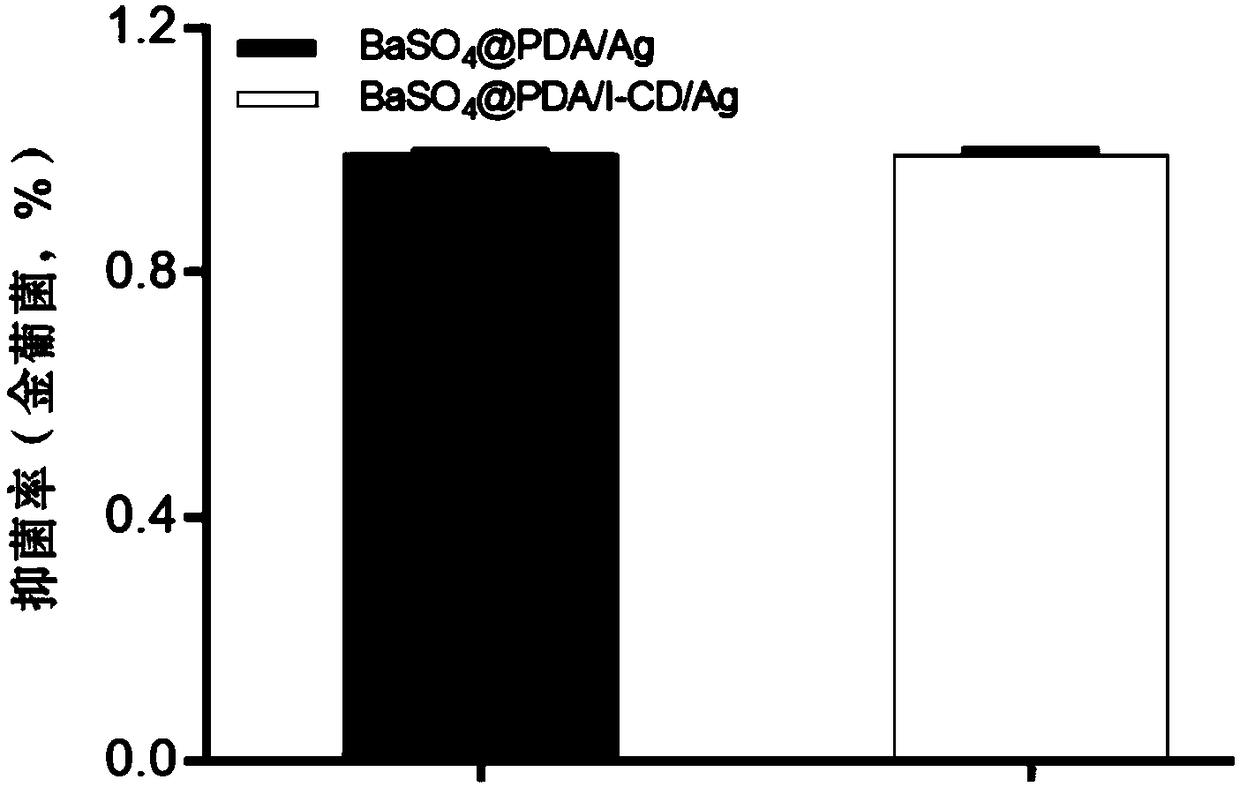

A barium sulfate and nanoparticle technology, applied in the field of nanomaterials, can solve the problems of infection, PMMA mechanical properties and biocompatibility decline, and achieve the effects of enhanced developing performance, excellent drug loading performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Add 5.2g BaCl 2Dissolve in 50mL deionized water, then mix with 50mL aqueous solution containing 3wt% polyvinyl alcohol, add 25mL containing 3.3g (NH 4 ) 2 SO 4 After the dropwise addition is complete, continue to stir for 3 minutes, then let it stand at room temperature for 5 hours, and centrifuge to obtain BaSO 4 The precipitation was washed three times with deionized water, dried at 80°C for 2h, and the BaSO4 precipitate was calcined in a muffle furnace at 600°C for 4h to obtain porous barium sulfate nanoparticles.

[0041] 2. Prepare 10mM Na 2 CO 3 / NaHCO 3 solution and 0.2M silver ammonia solution.

[0042] 3. Dissolve 100mg I-CD in 1mL N,N-dimethylformamide, then add to 150mL Na containing 300mgDOPA, pH=5, concentration 10mmoL / L 2 CO 3 / NaHCO 3 In the solution, 3g BaSO 4 Add 150mL of 0.2M silver ammonia solution, mix the two solutions under magnetic stirring, react at 25°C for 8h, then centrifuge to remove the supernatant, wash the precipitate with dei...

Embodiment 2

[0044] 1. Add 5.2g BaCl 2 Dissolve in 25mL deionized water, then mix with 25mL aqueous solution containing 1wt% polyvinyl alcohol, add 25mL containing 3.3g (NH 4 ) 2 SO 4 After the dropwise addition is complete, continue to stir for 3 minutes, then let it stand at room temperature for 5 hours, and centrifuge to obtain BaSO 4 Precipitated, washed three times with deionized water, dried at 80 °C for 2 h, and BaSO 4 The precipitate was calcined at 600° C. for 4 h in a muffle furnace to obtain porous barium sulfate nanoparticles.

[0045] 2. Prepare 20mM Na 2 CO 3 / NaHCO 3 solution and 0.4M silver ammonia solution.

[0046] 3. Dissolve 200mg I-CD in 1mL N,N-dimethylformamide, then add to 150mL Na 2 CO 3 / NaHCO 3 In the solution, 3g BaSO 4 Add 150mL of 0.4M silver ammonia solution, mix the two solutions under magnetic stirring, react at 25°C for 8h, then centrifuge to remove the supernatant, wash the precipitate with deionized water several times, and obtain multifunctio...

Embodiment 3

[0048] 1. Dissolve 20.8g BaCl2 in 50mL deionized water, then mix with 50mL aqueous solution containing 7wt% polyvinyl alcohol, add 25mL containing 13.2g (NH 4 ) 2 SO 4 After the dropwise addition is complete, continue to stir for 3 minutes, then let it stand at room temperature for 5 hours, and centrifuge to obtain BaSO 4 Precipitated, washed three times with deionized water, dried at 80 °C for 2 h, and BaSO 4 The precipitate was calcined at 600° C. for 4 h in a muffle furnace to obtain porous barium sulfate nanoparticles.

[0049] 2. Prepare 30mM Na 2 CO 3 / NaHCO 3 solution and 1M silver ammonia solution.

[0050] 3. Dissolve 500mg I-CD in 2mL N,N-dimethylformamide, then add to 150mL Na 2 CO 3 / NaHCO 3 In the solution, 9g BaSO 4 Add 150mL of 1M silver ammonia solution, mix the two solutions under magnetic stirring, react at 25°C for 8h, then centrifuge to remove the supernatant, wash the precipitate with deionized water several times, and obtain coated barium sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com