Patents

Literature

334results about How to "Facilitate industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-doped lithium-rich anode material for lithium ion batteries and preparation method of material

ActiveCN103413931AMinimal dosageHigh tap densityOxygen/ozone/oxide/hydroxideElectrode thermal treatmentElectrical batteryPhysical chemistry

The invention discloses a boron-doped lithium-rich anode material for lithium ion batteries and a preparation method of the material. The chemical formula of the material provided by the invention is Li[LiaMnbCocNidBx]O2, wherein the sum total of a, b, c, d, and x equals 1, a, b and x are greater than 0, c is greater than or equal to 0, and the sum total of c and d is greater than 0. The material, provided by the invention and prepared through a coprecipitation method and a sol-gel method, is doped with a relatively small amount of boron element but achieves a very remarkable effect, and the stability of the material can be greatly improved just by doping 2% boron; meanwhile, the tap density of the material is increased due to the doping of boron; the coprecipitation method for synthesizing the material is convenient for industrial mass production; the sol-gel method has simple steps, the granules of the synthesized product are uniform and fine.

Owner:PEKING UNIV

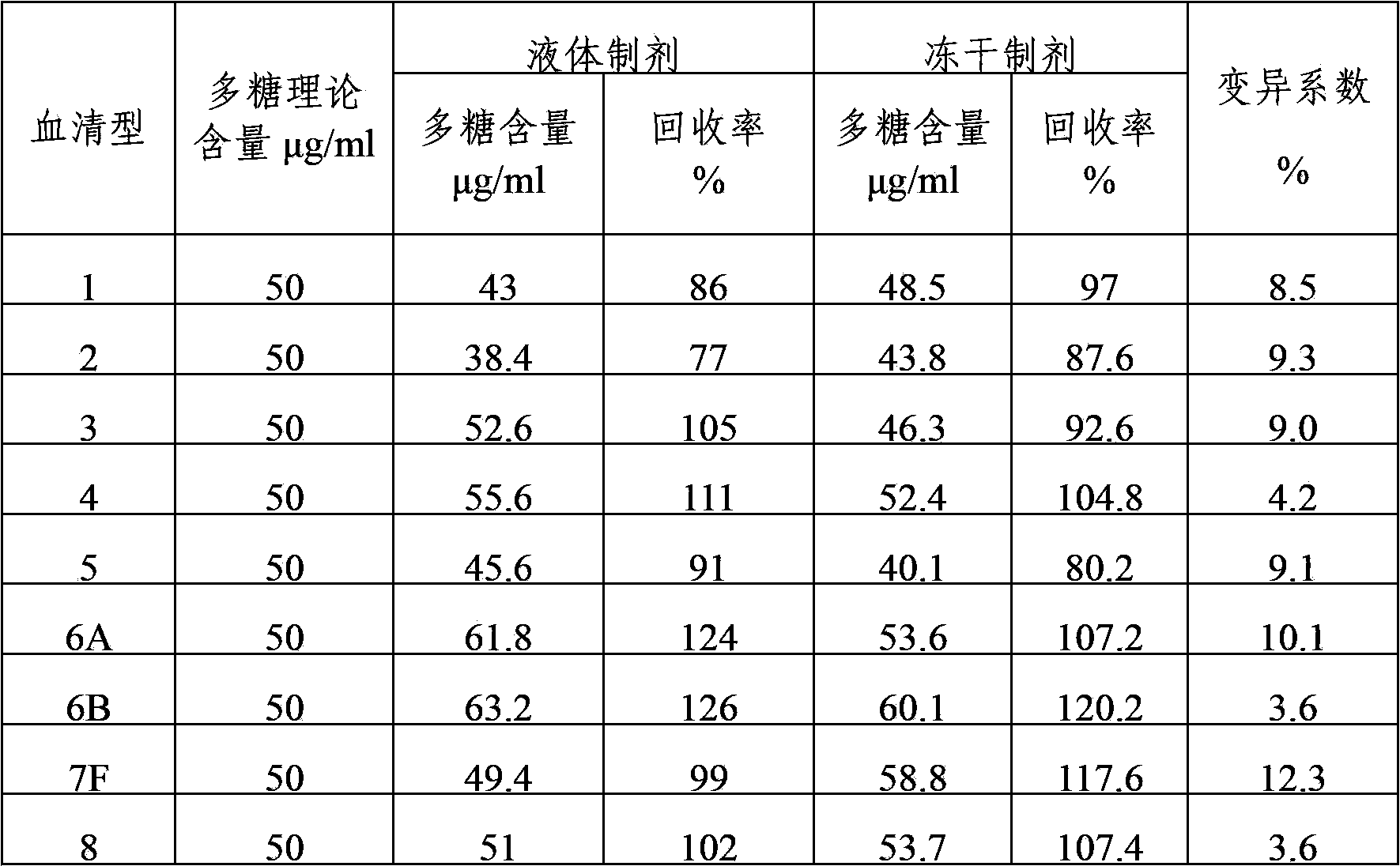

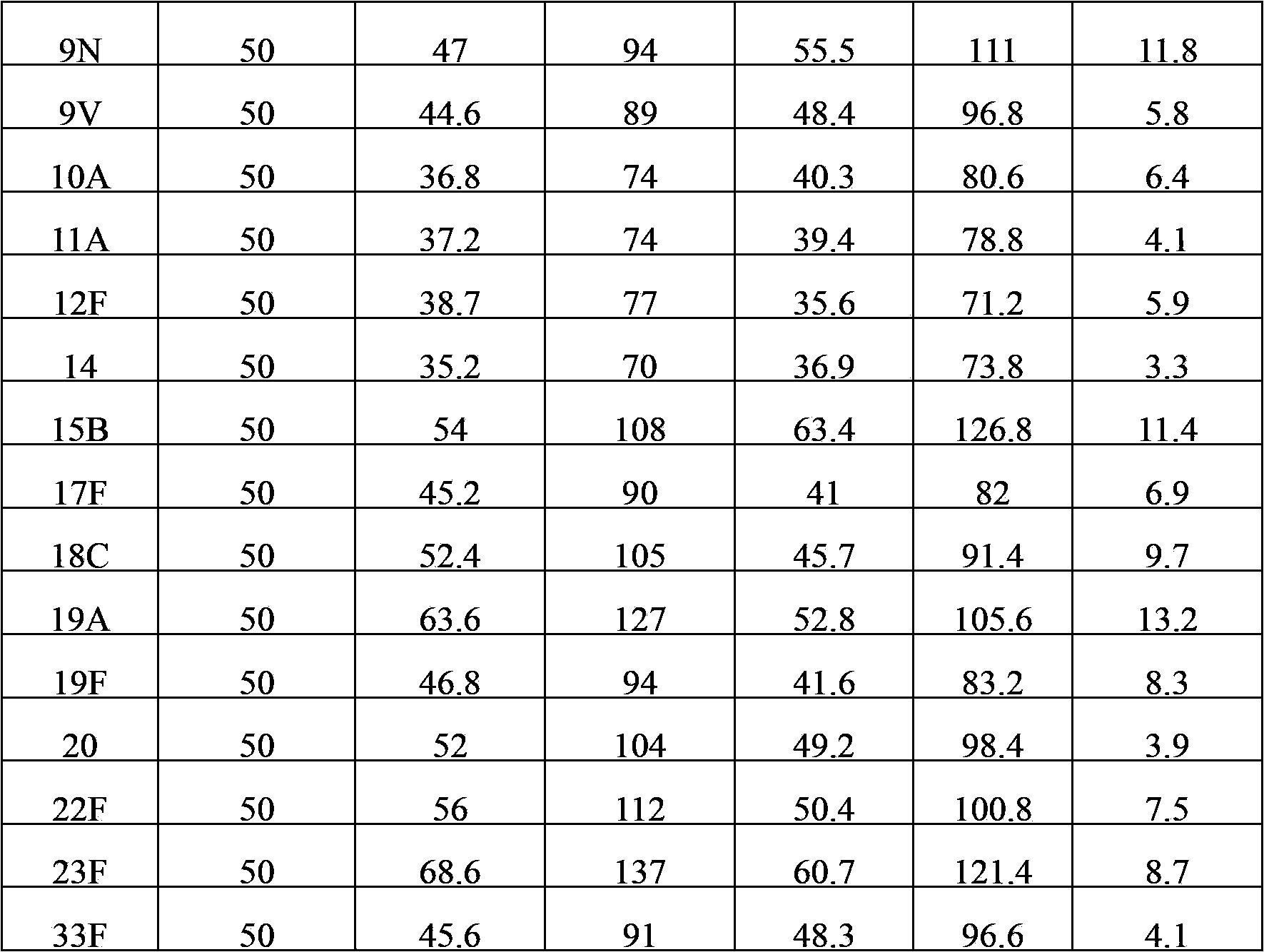

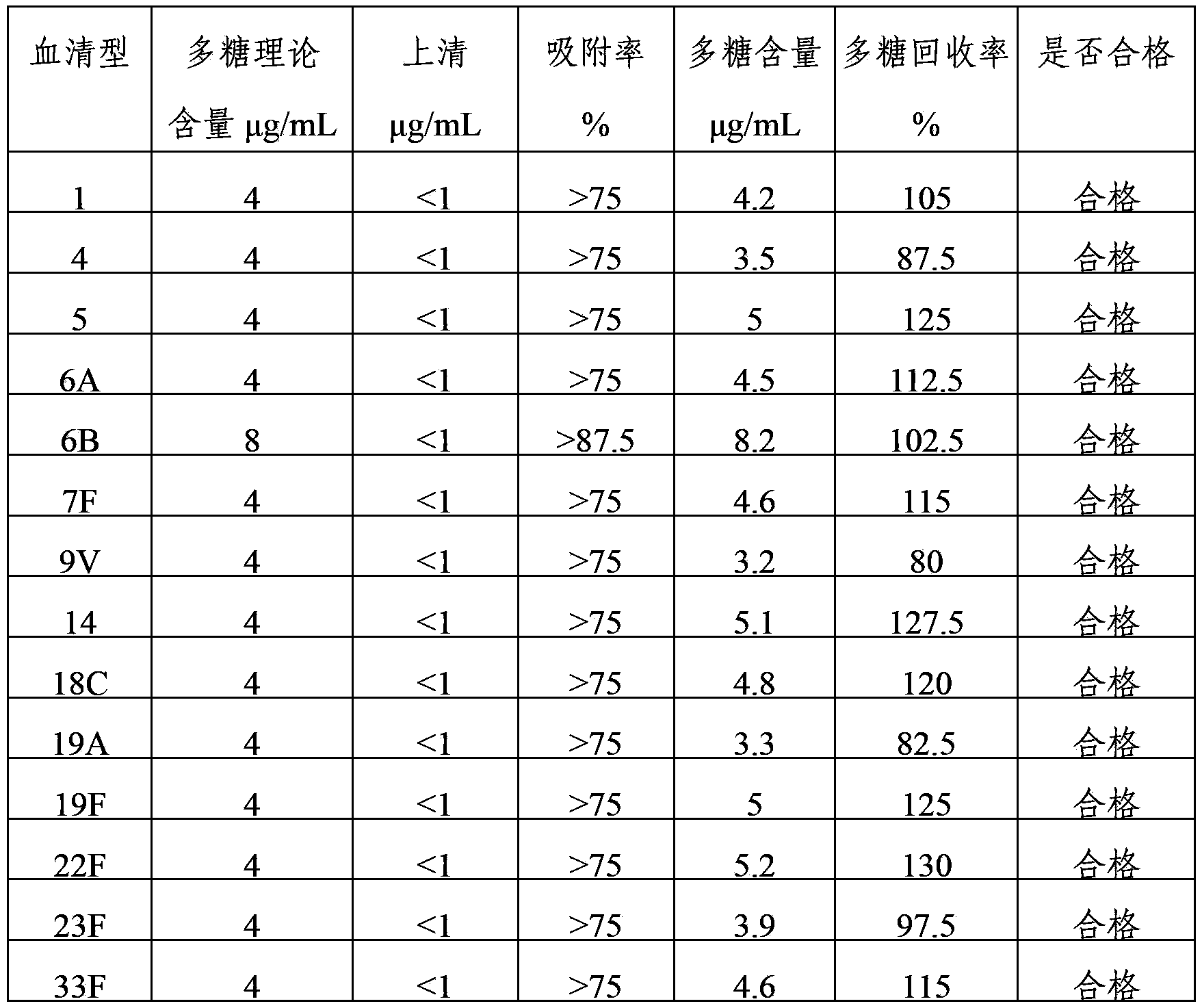

Multivalent pneumococcal capsular polysaccharide composition as well as preparation method and application thereof

ActiveCN103656632AStable physical and chemical propertiesPrevent diseaseAntibacterial agentsBacterial antigen ingredientsConjugate vaccineStreptococcus pneumoniae capsular polysaccharide

The invention provides a multivalent pneumococcal capsular polysaccharide composition as well as a preparation method and application thereof. The multivalent pneumococcal capsular polysaccharide composition contains a serotype 6A and at least one extra serotype selected from the group consisting of 1, 2, 3, 4, 5, 6B, 7F, 8, 9N, 10A, 11A, 12F, 14, 15B, 17F, 18C, 19A, 19F, 20, 22F, 23F and 33F. The multivalent pneumococcal capsular polysaccharide composition provided by the invention can be used for inducing an organism to generate humoral immunity, can generate a relatively good protecting effect for infectious diseases caused by the 24 common serotype pneumococcuses and is wide in immunity coverage rate and better in effect as comparison with various existing pneumococcal polysaccharide vaccines and conjugate vaccines sold on the market.

Owner:SINOVAC RES & DEV

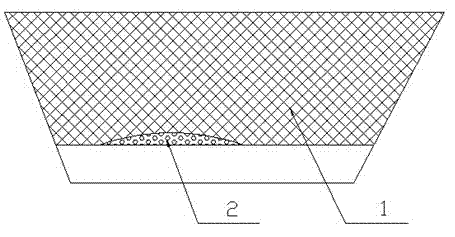

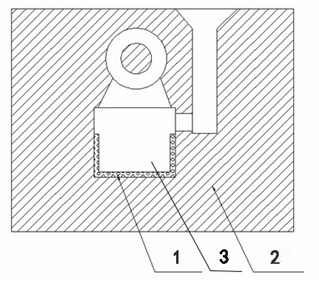

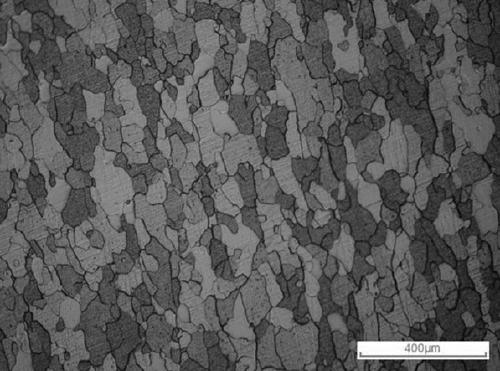

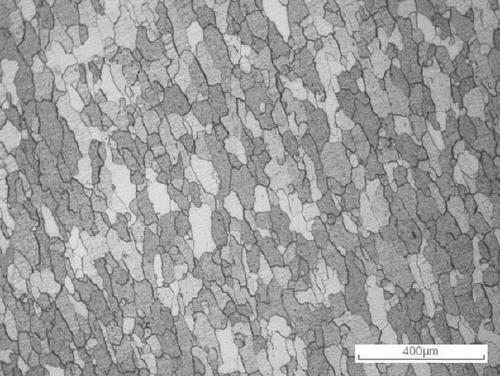

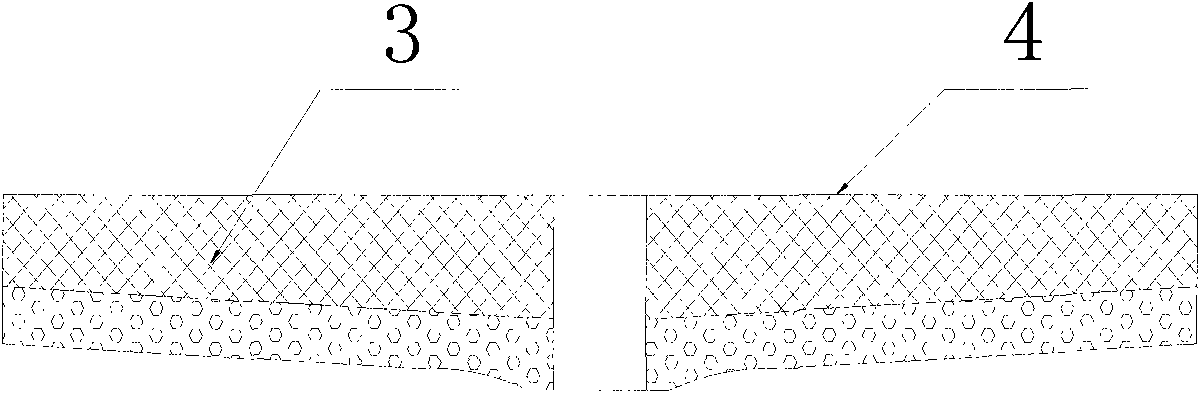

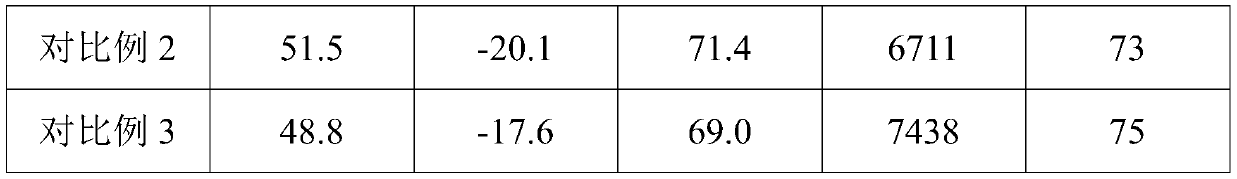

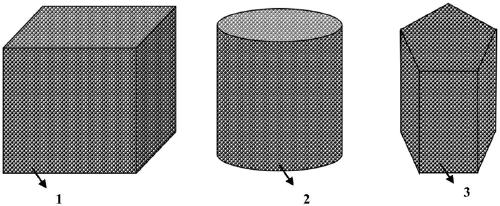

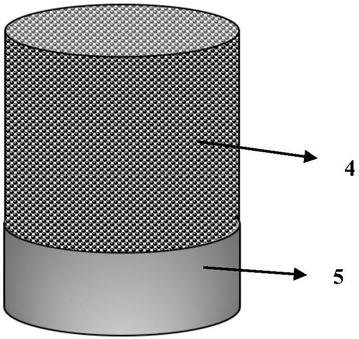

Method for preparing heat-fatigue-resistance wear-resistance laminated particle reinforced composite material

The invention provides a method for preparing a heat-fatigue-resistance wear-resistance laminated particle reinforced composite material. The method prepares the wear-resistance laminated particle reinforced composite material consisting of a heat-fatigue-resistance laminated composite wear-resistance layer, a metallurgical transitional layer and a substrate metal layer by the following steps: mixing nickel-based self-melting alloy powder and hard ceramic particle uniformly, adding an adhesive, and forming a prefabricated block; and performing common sand mold coating or lost foam casting, namely melting a substrate metal material to a pouring temperature, pouring the molten substrate metal material into a molding cavity in which the prefabricated block is placed, allowing the molten substrate metal material to cool and condense at room temperature, and removing sand. The combined preparation process disclosed by the invention has the characteristics of high controllability, simple operation, high yield, high overall performance and stable production quality; and the heat-fatigue-resistance laminated composite wear-resistance layer and the substrate metal layer are metallurgically combined, and the composite material can be used in heat-fatigue-resistance and wear-resistance fields of mines, power, metallurgy, coal, building materials and the like. The method is suitable for industrial large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

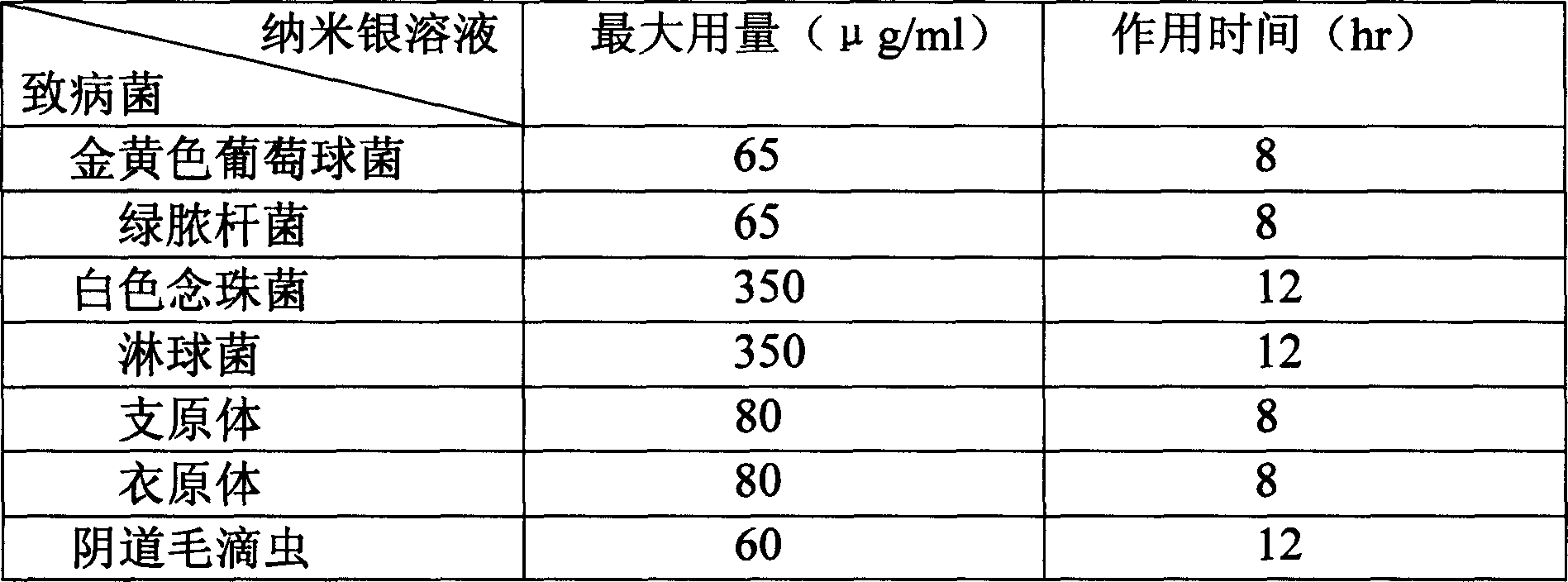

Nano-silver aqueous solution preparation and its preparation method, use and using method

InactiveCN1569366AEasy injectionNo stimulationInorganic active ingredientsMixing methodsReducerInto bladder

The invention relates to a nanometer silver aqueous solution preparation. Its components and weight percentage are: nanometer silver 0.05-1.5, the dispersant 0.5-1.5, the reducer 0.05-0.2, the stabilizer is nanometer silver 0.5-1.5, the dispersant 0.5-1.5, the reducer is 0.05-0.2, the stabilizer is 0.5-10, and the deioned water is 1000. The invention also relates the manufacturing method for above mentioned nanometer silver aqueous solution preparation, and the usage for curing man social disease, and the using method for ejecting the medicine into bladder through urethra. The reducer and stabilizer in the solution accord with the standards of America FDA or china sanitary department.

Owner:杨漓 +1

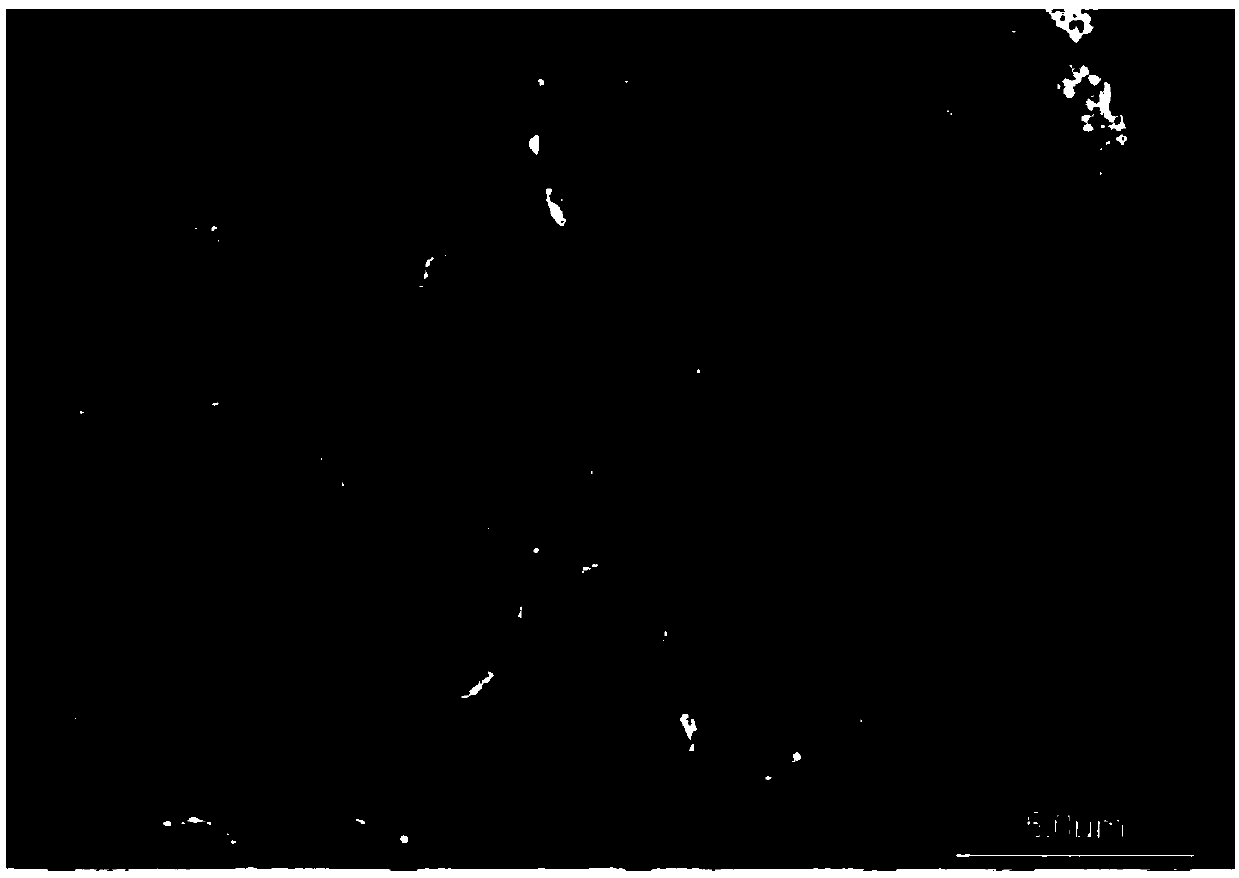

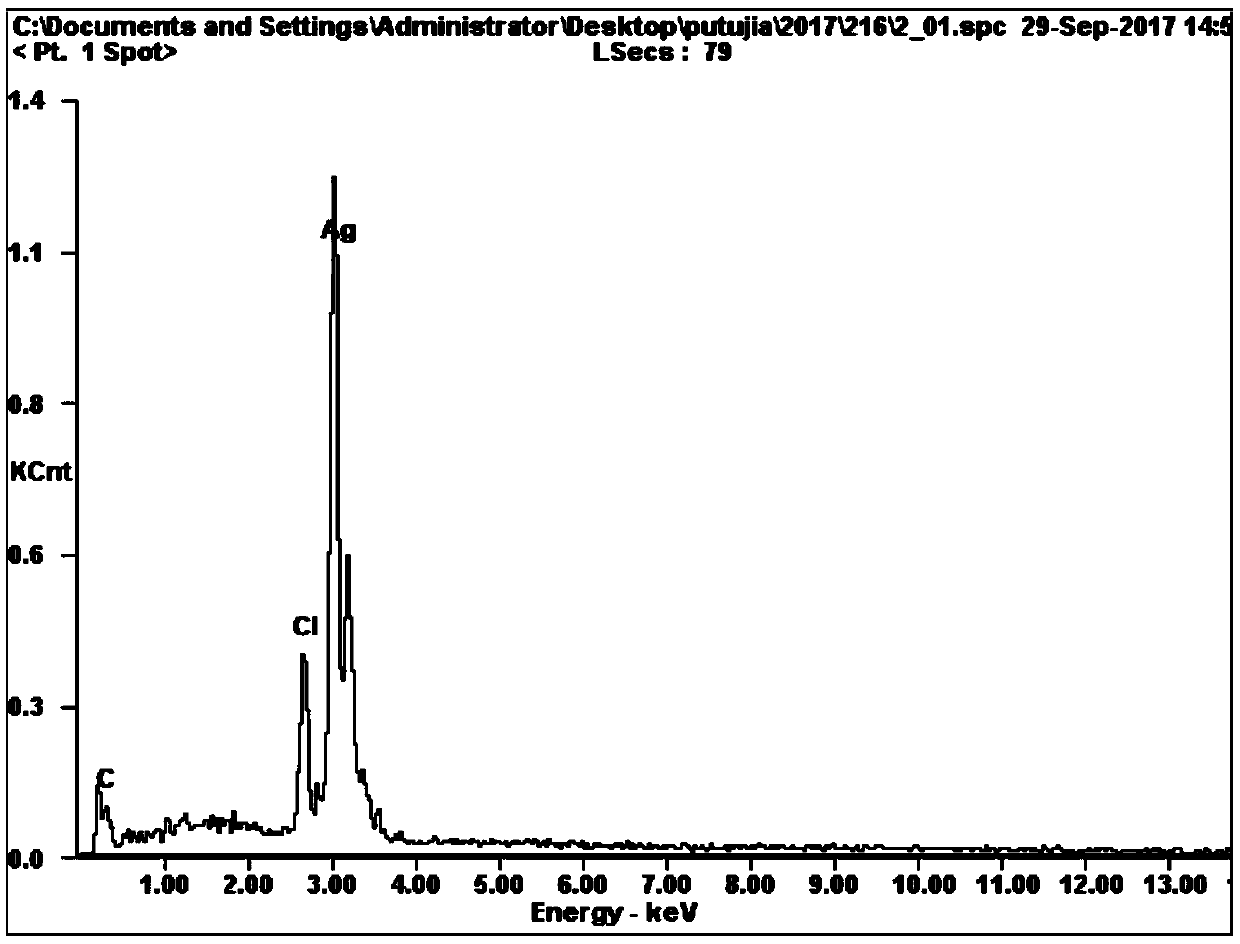

Silver/silver chloride electrode material, method for manufacturing same and electrode

ActiveCN103192070AEasy to processReduce manufacturing costMaterial analysis by electric/magnetic meansSilver chloride electrodeEther

The invention discloses a silver / silver chloride electrode material and a method for manufacturing the same. The electrode material comprises, by weight, 15%-70% of silver / silver chloride powder, 1%-15% of adhesion agents and 15%-70% of alcohol and ethers diluents. The method for manufacturing the electrode material includes firstly, manufacturing the silver / silver chloride powder; secondly, adding the adhesion agents and the alcohol and ethers diluents into the silver / silver chloride powder to mix the adhesion agents, the alcohol and ethers diluents with the silver / silver chloride powder to obtain a mixture; and thirdly, mechanically grinding the mixture to obtain slurry with certain consistence for standby application. The silver / silver chloride electrode material and the method have the advantages that the adding proportion of the adhesion agents to the diluents is controlled, so that the inky or pasty silver / silver chloride slurry can be manufactured, has a high-dispersion electrochemical interface and is convenient to process, and a silver / silver chloride electrode which can meet different requirements can be manufactured by a process for coating the slurry on a substrate and molding at low pressure or hand pressure.

Owner:SUZHOU GREENTEK

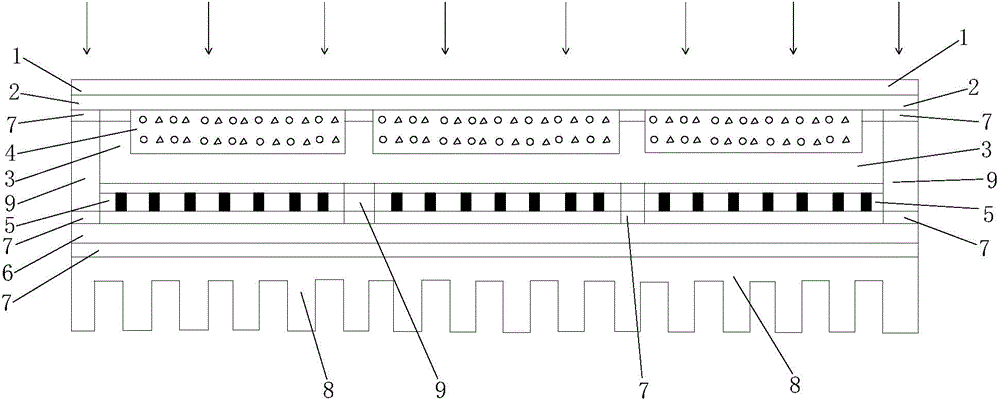

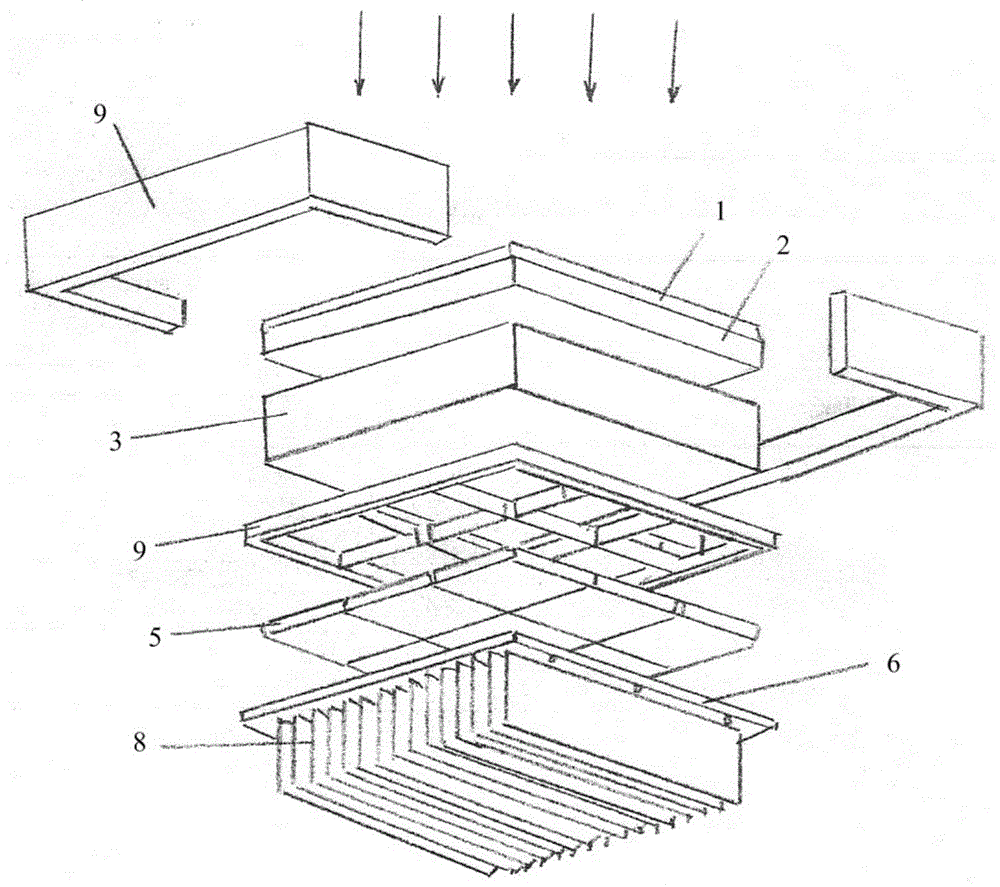

Solar phase-change energy storage thermoelectric power generation device and lighting system

InactiveCN104022689AImprove thermal conductivityImprove power generation efficiencyGenerators/motorsEngineeringLighting system

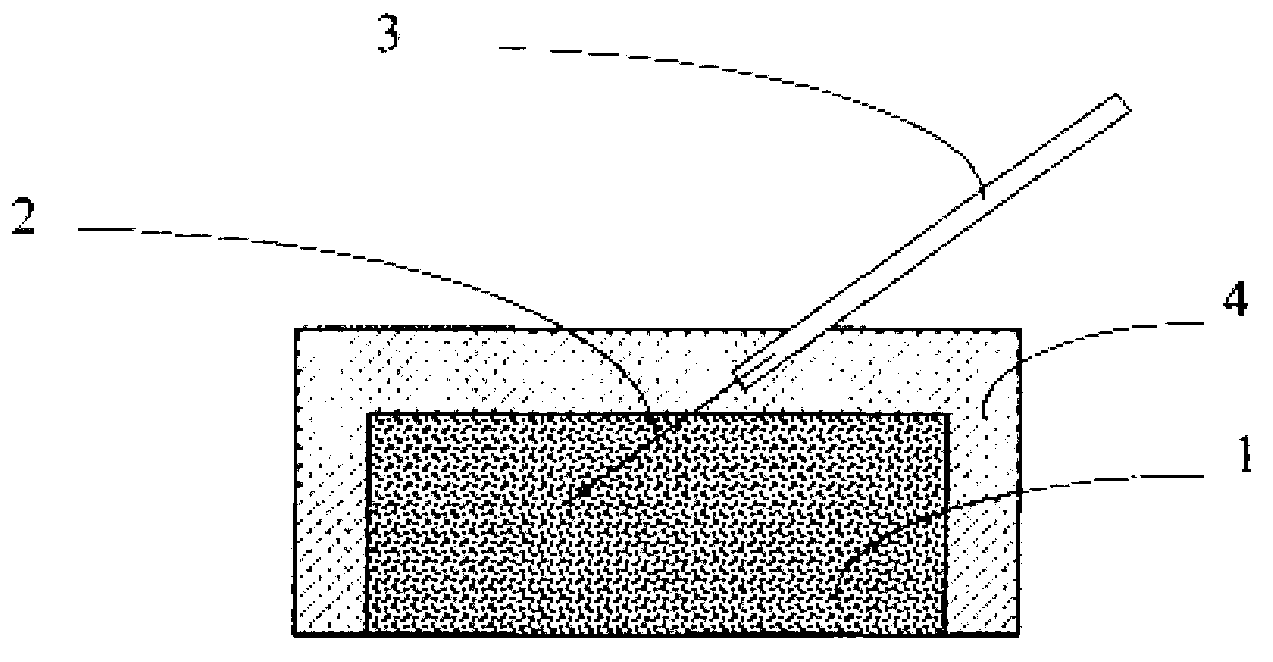

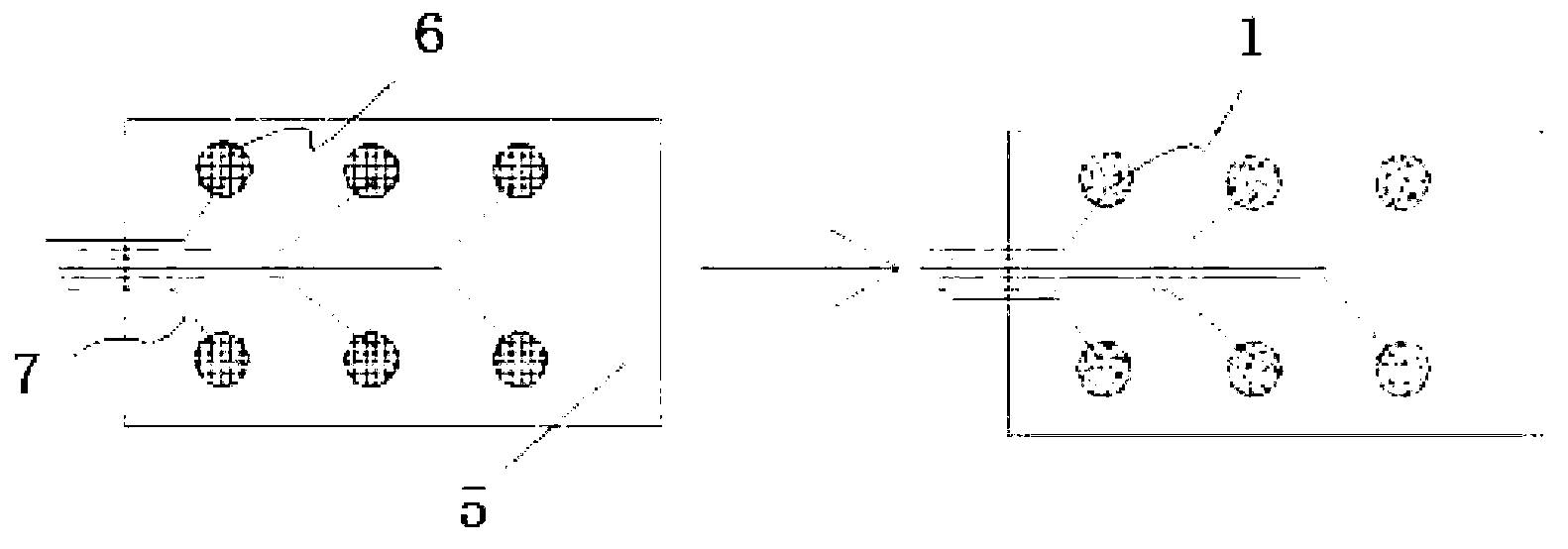

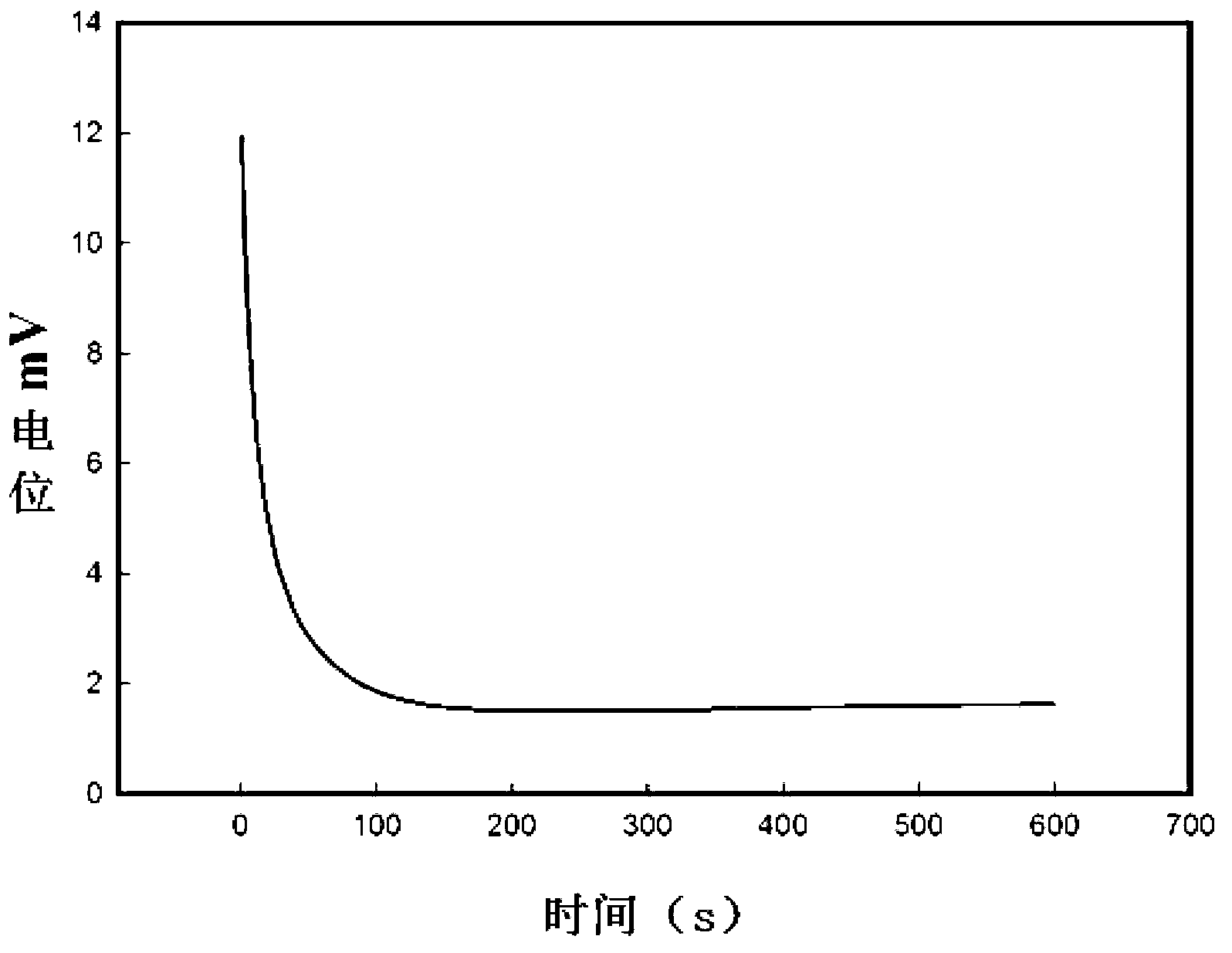

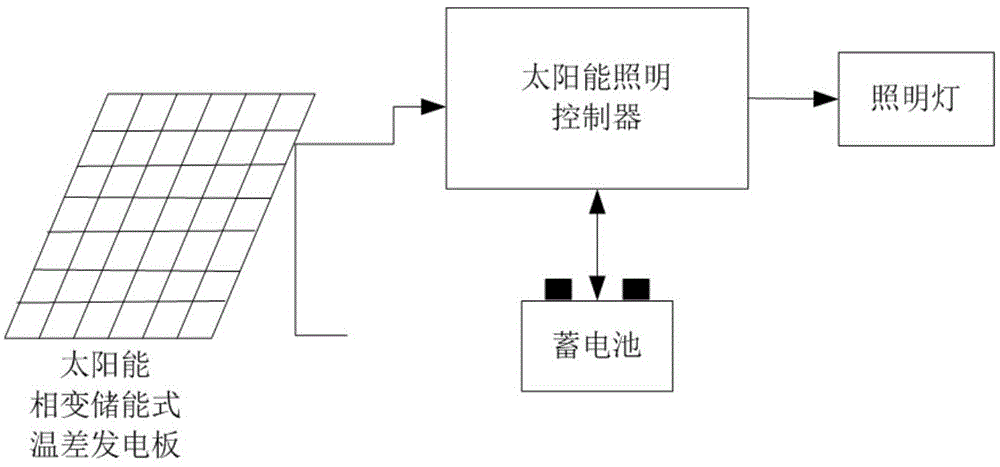

The invention relates to a solar phase-change energy storage thermoelectric power generation device and a lighting system. The power generation device comprises a thermoelectric power generation plate, and the thermoelectric power generation plate comprises a heat absorption groove-type groove substrate, a thermoelectric power generation module and cooling fins. Grooves of the heat absorption type groove-type substrate are filled with phase-change energy storage material. A heat conduction plate is encapsulated through heat conduction glue, and the outer layer of the heat conduction plate is coated with heat absorption material. The hot end of the thermoelectric power generation module tightly makes contact with the high-temperature end of the heat absorption groove-type substrate, and the cold end of the thermoelectric power generation module is connected with the cooling fins through the heat conduction plate and the heat conduction glue. The lighting system comprises the power generation device, a solar lighting controller, a storage battery and a lighting lamp. Due to the unique structure of the heat absorption groove-type substrate, the heat absorption groove-type substrate has excellent heat absorption and heat conduction effects on solar radiation, the heat absorption groove-type substrate can be combined with the phase-change energy storage material to improve temperature stability of the hot end of the thermoelectric power generation module of the system, and thermoelectric power generation efficiency is improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Process for manufacturing high-density molybdenum-niobium alloy sputtering target material

InactiveCN110257784ALow oxygenHigh purityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityMixed materials

The invention belongs to the field of manufacturing high-temperature refractory metal target materials, and particularly relates to a process for manufacturing a high-density molybdenum-niobium alloy sputtering target material. The process comprises the steps of mixing raw materials; loading mixed material powder in a rubber sleeve; performing cold isostatic pressing operation, after the pressure is increased to a certain pressure, maintaining the pressure for a period of time, then depressurizing, and finally taking out a pressed blank from the rubber sleeve; carrying out vacuum sintering or hydrogen protection sintering; carrying out hot isostatic pressing operation directly on the sintered blank; performing hot rolling operation, namely performing metal sleeve rolling on a molybdenum-niobium alloy, and annealing after hot rolling to remove stress; and carrying out machining operations such as grinding to obtain the final required product size. The process is simple in processing steps and convenient to operate, the purity and the relative density of the manufactured molybdenum-niobium alloy sputtering target material all meet the use requirements in the film coating field of high-end electronic products; and the process is low in production cost, wide in production size range, and convenient for industrial batch production.

Owner:LUOYANG SIFON ELECTRONICS

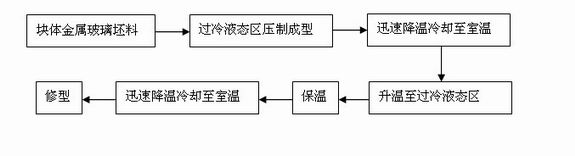

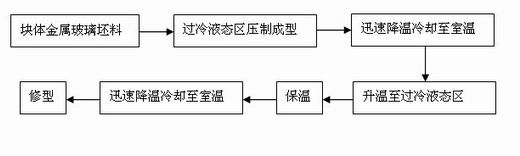

Processing and forming method for workpieces made of blocky metal glass or composite material of blocky metal glass

The invention discloses a processing and forming method for workpieces made of blocky metal glass or a composite material of the blocky metal glass, which is used for carrying out processing and forming on the workpieces made of the blocky metal glass or the composite material of the blocky metal glass. The method comprises the following specific steps: procedure of selecting blanks, procedure of die pressing, procedure of heat treatment, and procedure of modification. In the method, the preparation technique is simple, the operation process is short, the workpiece products, which are made of the blocky metal glass or the composite material of the blocky metal glass, can be produced in batches and are high in shape complexity and excellent in combination property, the production efficiency of products is improved and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

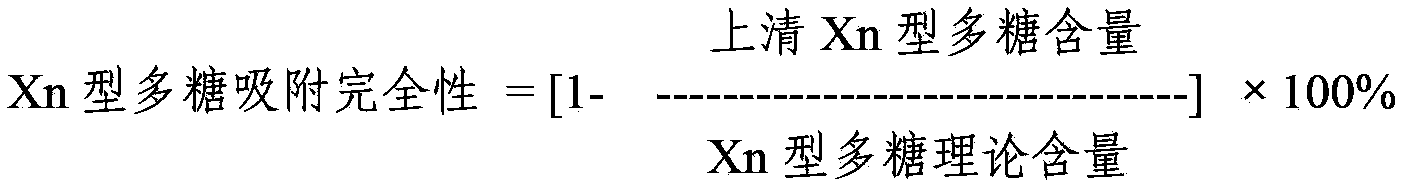

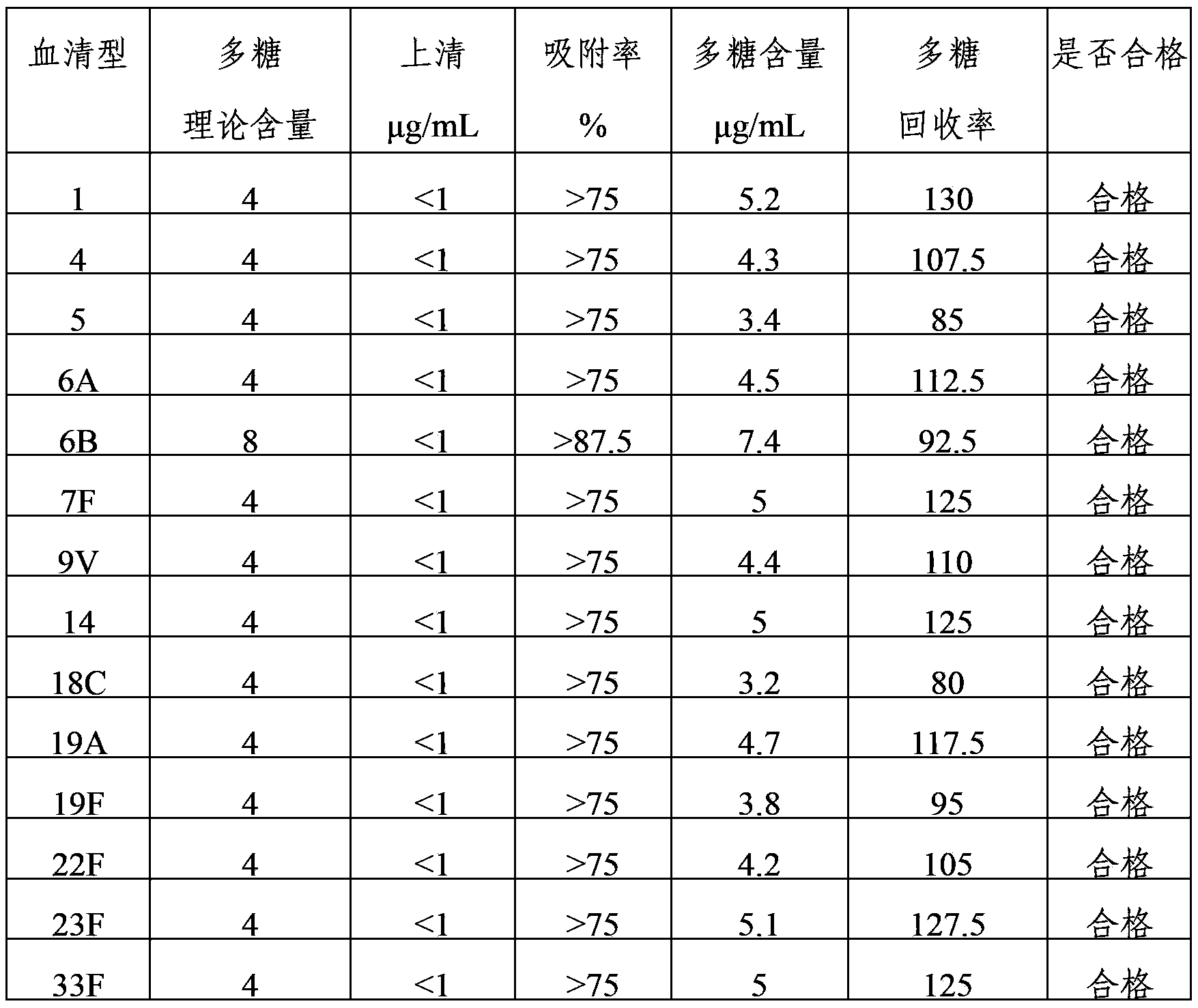

Multivalent pneumococcus capsular polysaccharide-protein conjugated composition and preparation method thereof

InactiveCN104069488AImprove adsorption capacityImprove stabilityAntibacterial agentsBacterial antigen ingredientsDiseaseConjugate vaccine

The invention provides a multivalent pneumococcus capsular polysaccharide-protein conjugated composition and a preparation method thereof. The conjugated composition is formed by covalent linkage of multivalent pneumococcus capsular polysaccharides of 14 different serotypes and carrier protein, wherein the 14 serotypes include 1, 4, 5, 6A, 6B, 7F, 9V, 14, 18C, 19A, 19F, 22F, 23F and 33F. The conjugated composition has good adsorption effect and good stability, has multiple immunogenicity and protective performance against invasion of the pneumococcus of 14 serotypes, is superior to on-sale low-valent pneumonia compositions, and the immune response of the conjugated composition disclosed by the invention is higher than that of an uncombined composition. The inoculating injection frequency can be reduced by using the multivalent pneumococcus capsular polysaccharide conjugate vaccine containing the conjugated composition, the immune process can be simplified, and diseases of human and animals caused by the 14 serotypes of pneumococcal bacteria can be effectively prevented. The conjugated composition has wider coverage and better immune effect.

Owner:SINOVAC RES & DEV

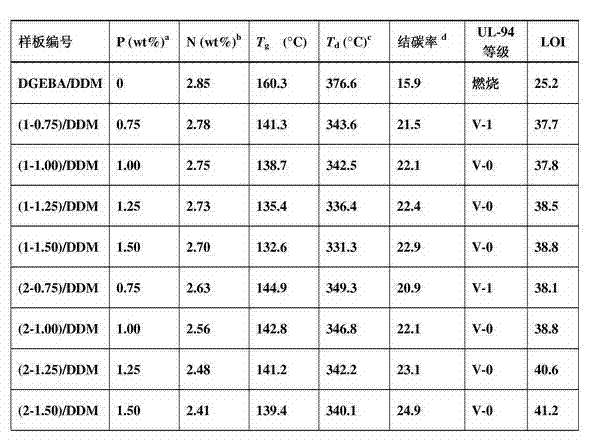

High-efficiency N/P flame retardant, as well as preparation method and application thereof

InactiveCN103044708AThe process steps are simpleImprove flame retardant performanceGroup 5/15 element organic compoundsAldehydeFlame resistance

The invention provides a high-efficiency N / P flame retardant, as well as a preparation method and application thereof. The method comprises the following steps: firstly performing condensation reaction of 4,4'-diaminodiphenylmethane (DDM) with aromatic aldehydes, and then adding DOPO into the resulting mixture for reaction, to obtain the N / P flame retardant. The flame retardant has higher activity, can promote curing of epoxy resins, and is added to epoxy resin for curing to form a cured epoxy product which has higher flame retardancy. When the phosphorus content of the cured epoxy system reaches 1.0 wt% to 1.5 wt%, the vertical combustion level reaches the grade UL94V-0, the limited oxygen index reaches 37.8-41.2, and the char yield reaches 22.1%-24.9% at 800 DEG C.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

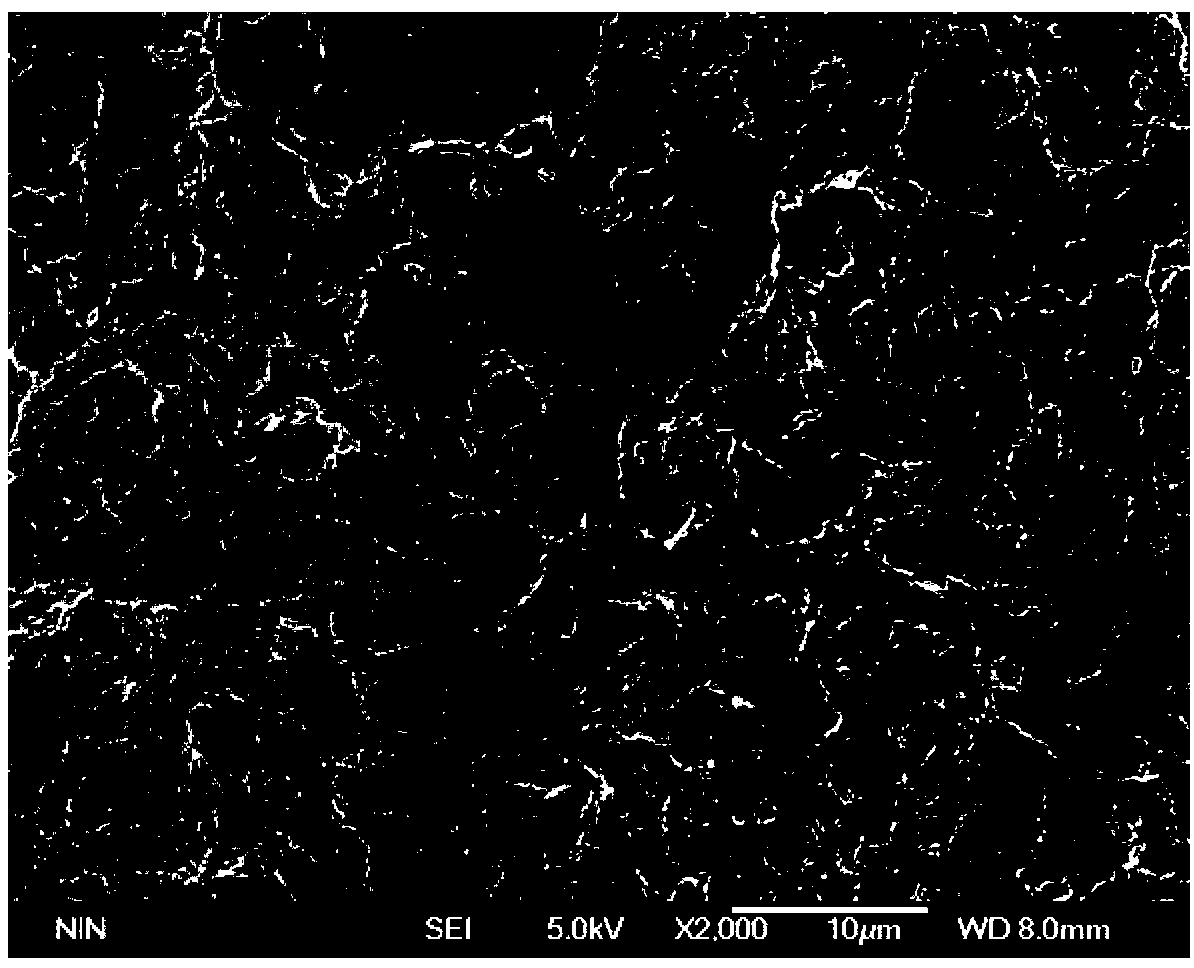

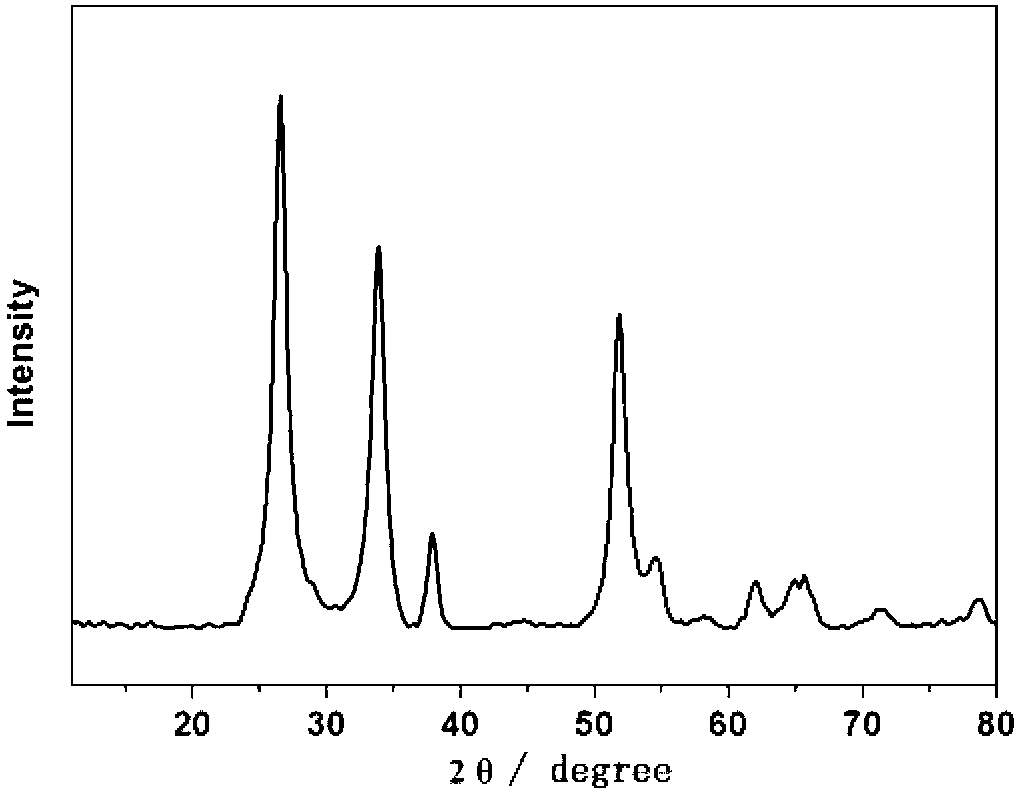

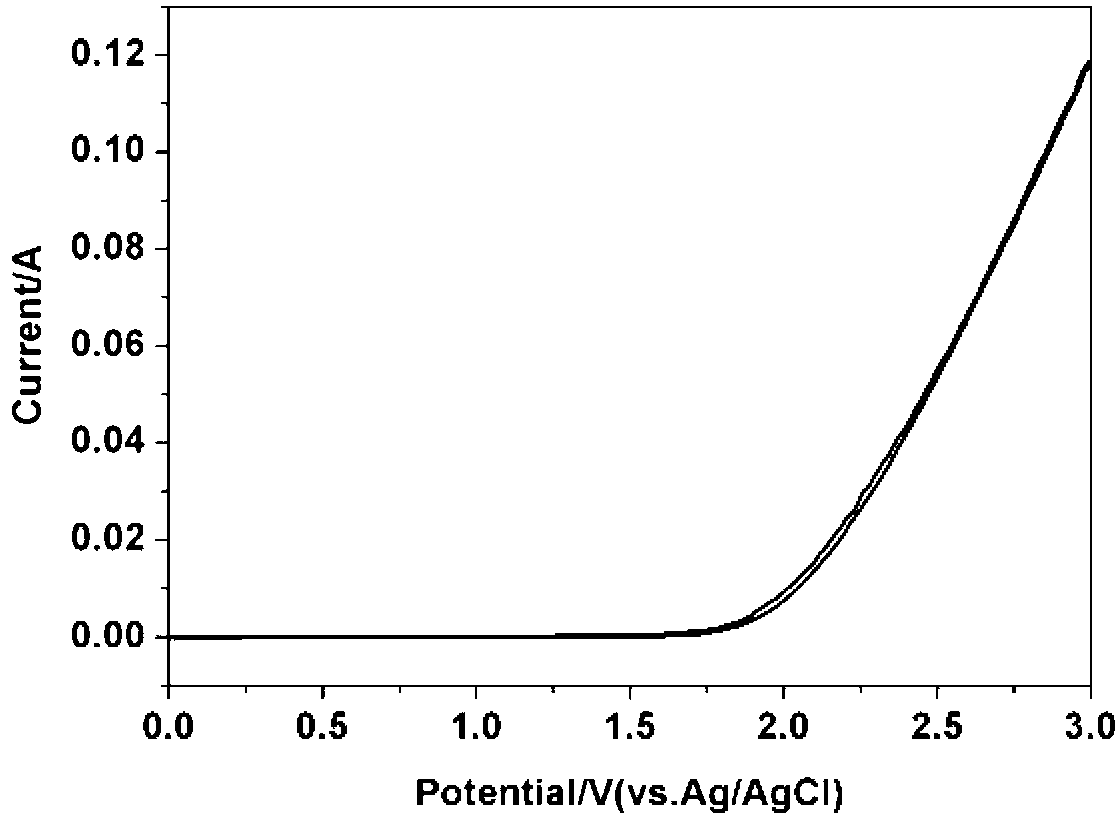

Fabrication method of long-life titanium base electrode

The invention discloses a fabrication method of a long-life titanium base electrode, which comprises the steps of fabricating a titanium oxide layer on a titanium substrate by a dipping-thermal decomposition method, reducing the titanium oxide layer in a reducing atmosphere, synchronously depositing a tin metal simple substance and an antimony metal simple substance in proportion on the surface of the titanium oxide layer by an electrodeposition method, and conducting thermal oxidation to allow an antimony doped tin oxide layer to be tightly combined with the titanium oxide layer connected with the titanium substrate to form a solid solution structure. The prepared titanium base tin dioxide electrode has the advantages of long service life, high oxygen evolution potential, high electrocatalytic activity, high generation efficiency of ozone from electrolyzed water, and the like. In addition, the cost of the fabrication process is low, the requirement of equipment is low, the operation is easy to control, and industrial mass production is facilitated.

Owner:XI AN JIAOTONG UNIV

High-oil pollution resistant oil/water separation membrane and preparation method thereof

ActiveCN104607060AImprove stabilityGood oil resistanceSemi-permeable membranesLiquid separationChemical solutionRoom temperature

The invention discloses a high-oil pollution resistant oil / water separation membrane and a preparation method thereof, the preparation method is as follows: polyvinylidene fluoride, a solvent and an additive are mixed at 50 to 150 DEG C, and dissolved to obtain a mixed solution; the weight ratio of polyvinylidene fluoride to solvent to additive is 10-20:60-70:15-30; the mixed solution is squeezed out by membrane making equipment, nonsolvent-induced phase separation is used for curing and membrane forming and rinsing, before or after the rinsing, a chemical solution is used for aftertreatment, and the membrane is dried in the air at room temperature. The method is simple and feasible, is convenient for industrialized mass production; the prepared oil / water separation membrane is large in flux, and has good stability and oil pollution resistance to achieve efficient processing of kitchen garbage waste water and residual oil deep recovery.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

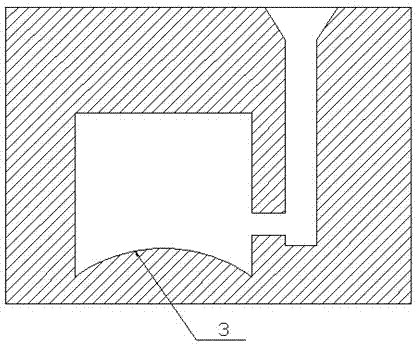

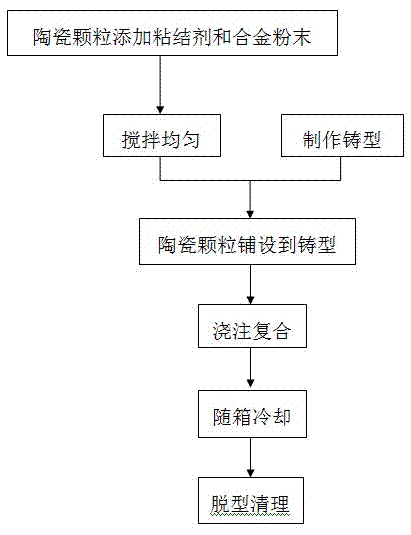

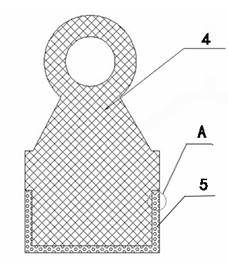

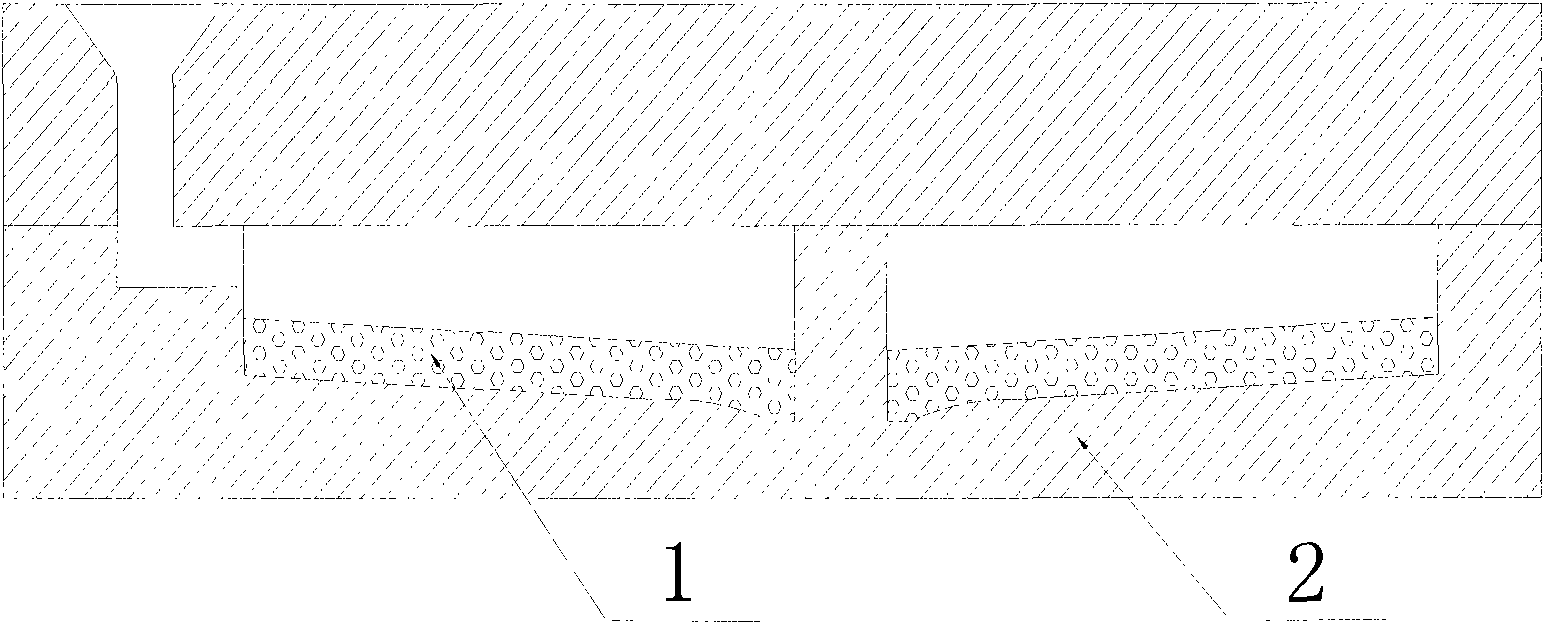

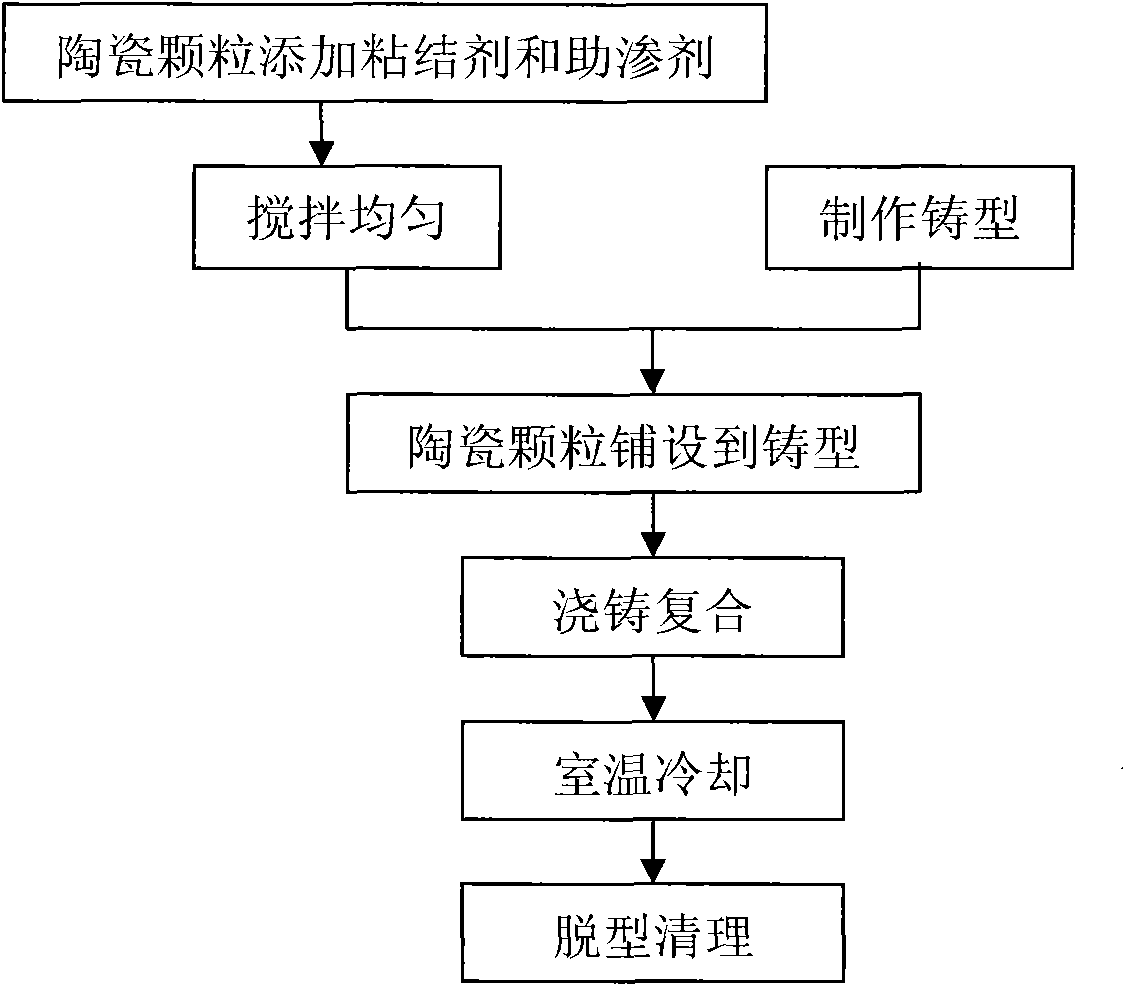

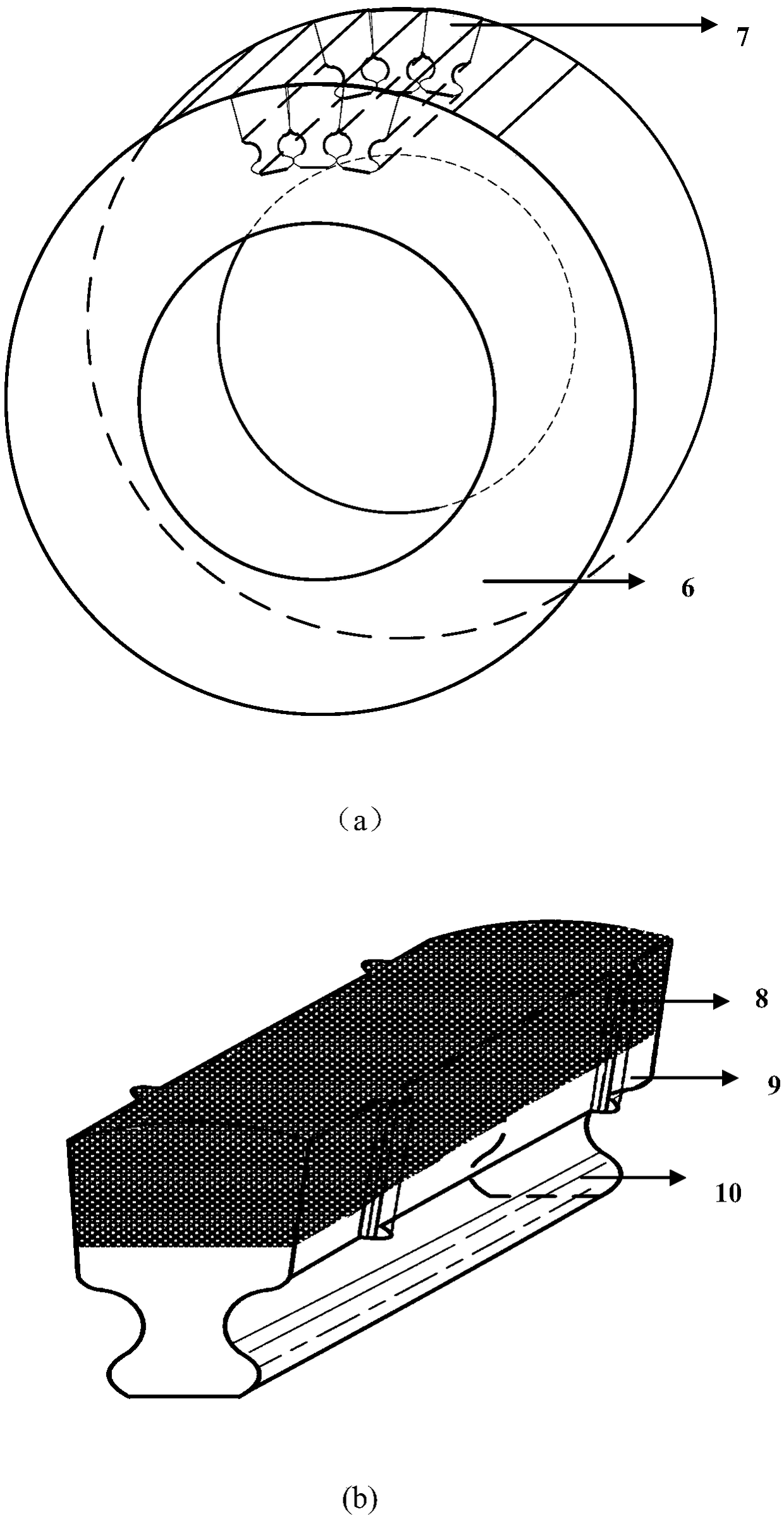

Composite lining plate of ball mill and preparation method thereof

ActiveCN101884948ASimple manufacturing processHigh hardness and wear resistanceGrain treatmentsSlagBall mill

The invention relates to a composite lining plate of a ball mill and a preparation method thereof. A layer of hard ceramic grains are compounded on a wear surface of the composite lining plate of the ball mill to form an anti-wear hard phase, so that the wear resistance is improved. The preparation method comprises the following steps of: adding an adhesive and a permeation-promoting agent into the ceramic grains; stirring the mixture uniformly; paving the mixture in a cast of the lining plate of the ball mill according to the design requirements; casting a matrix metal; and cooling, demoulding and cleaning to obtain the composite lining plate of the ball mill. The composite lining plate of the ball mill and the preparation method thereof have the advantages that: one layer of the hard ceramic grains are compounded on the wear surface of the composite lining plate of the ball mill to form the anti-wear hard phase and the matrix metal is filled in the gap of the ceramic grains, so the composite surface has the wear resistance of the ceramic grains and the plasticity and the fatigue resistance of the matrix metal; the hard phase is difficult to drop off; the controllability of process parameters is high; the defects of slag inclusion and the like do not exist in the organization; the processing operation is convenient; industrialized mass production is facilitated; and the service life of the lining plate is prolonged by 5 to 8 times compared with that of the common metal lining plate.

Owner:KUNMING UNIV OF SCI & TECH

Low-temperature curing silver/silver chloride slurry for flexible bioelectrode and preparation method thereof

ActiveCN109645986AReduce square resistanceGood adhesionDiagnostic recording/measuringSensorsBiocompatibility TestingBlood glucose testing

The invention discloses a low-temperature curing silver / silver chloride slurry for a flexible bioelectrode and a preparation method thereof. The silver / silver chloride slurry comprises, by weight, 38-70wt% of silver / silver chloride powder and 30-62wt% of an organic carrier, wherein the silver / silver chloride powder is composed of 40-90wt% of silver powder and 10-60wt% of silver chloride powder. The prepared flexible bioelectrode is low in square resistance, good in adhesion, good in electrode potential stability, high in anti-interference capability and good in biocompatibility, specific shapes can be formed for different use environments, the cost is low, and mass production is easy. The obtained flexible bioelectrode can highly fit the human tissue, especially the skin, can meet the wearing requirements of different parts of the human body, can measure more accurate and reliable bioelectrical signal data, and can be applied to the fields of biosensor electrodes, ECG electrodes, electrochemical reference electrodes, blood glucose test reference electrodes, environment test electrodes and the like.

Owner:KUNMING INST OF PRECIOUS METALS

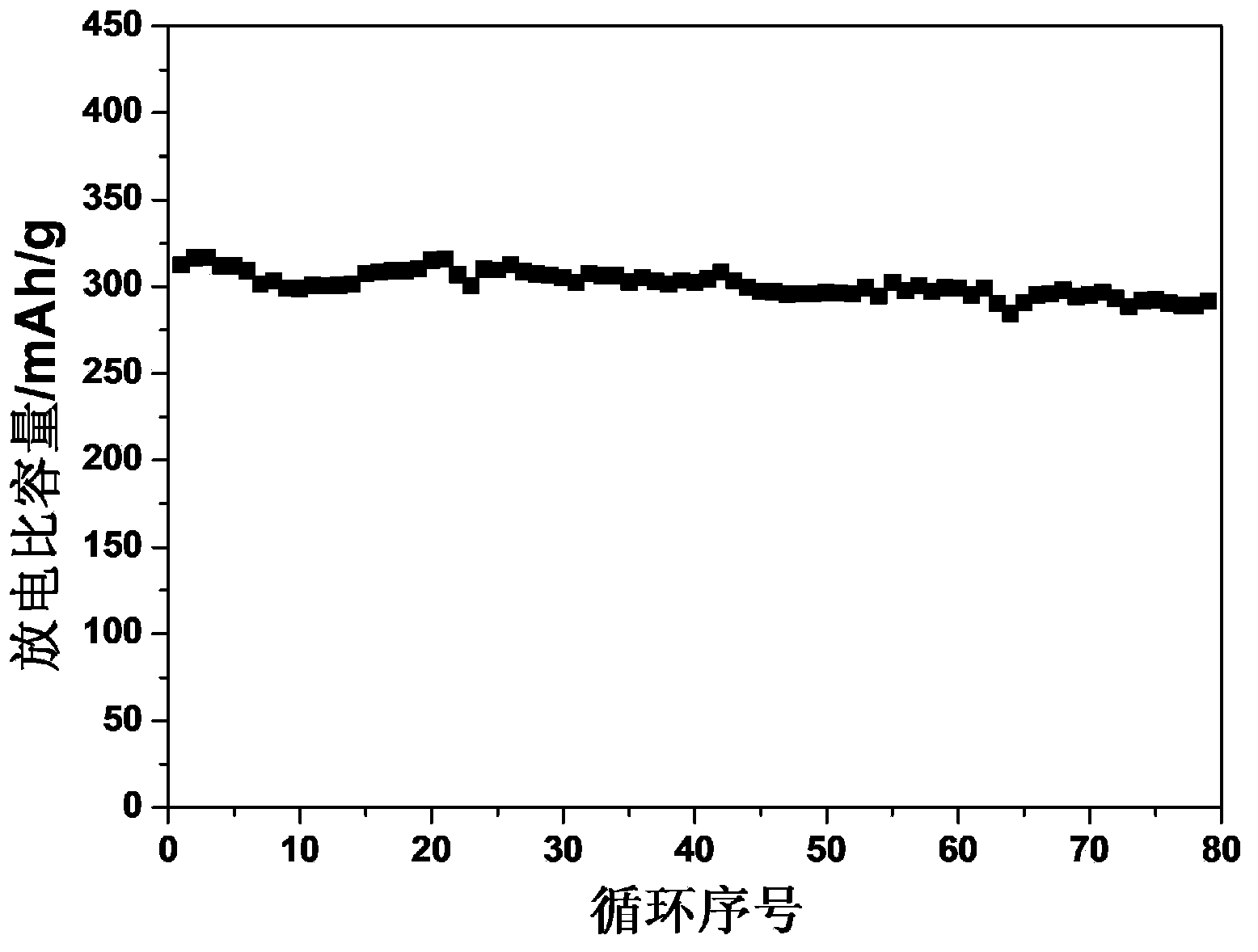

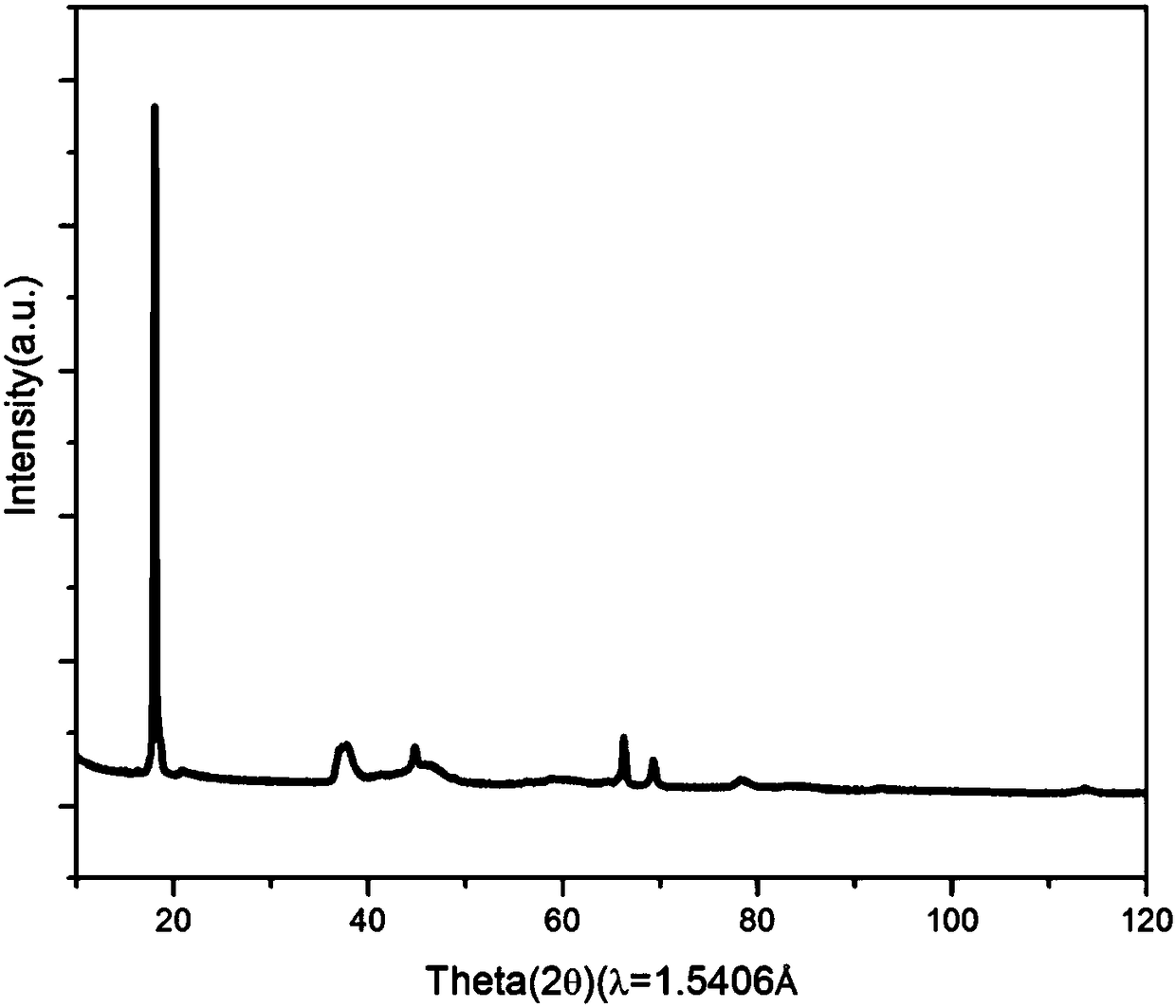

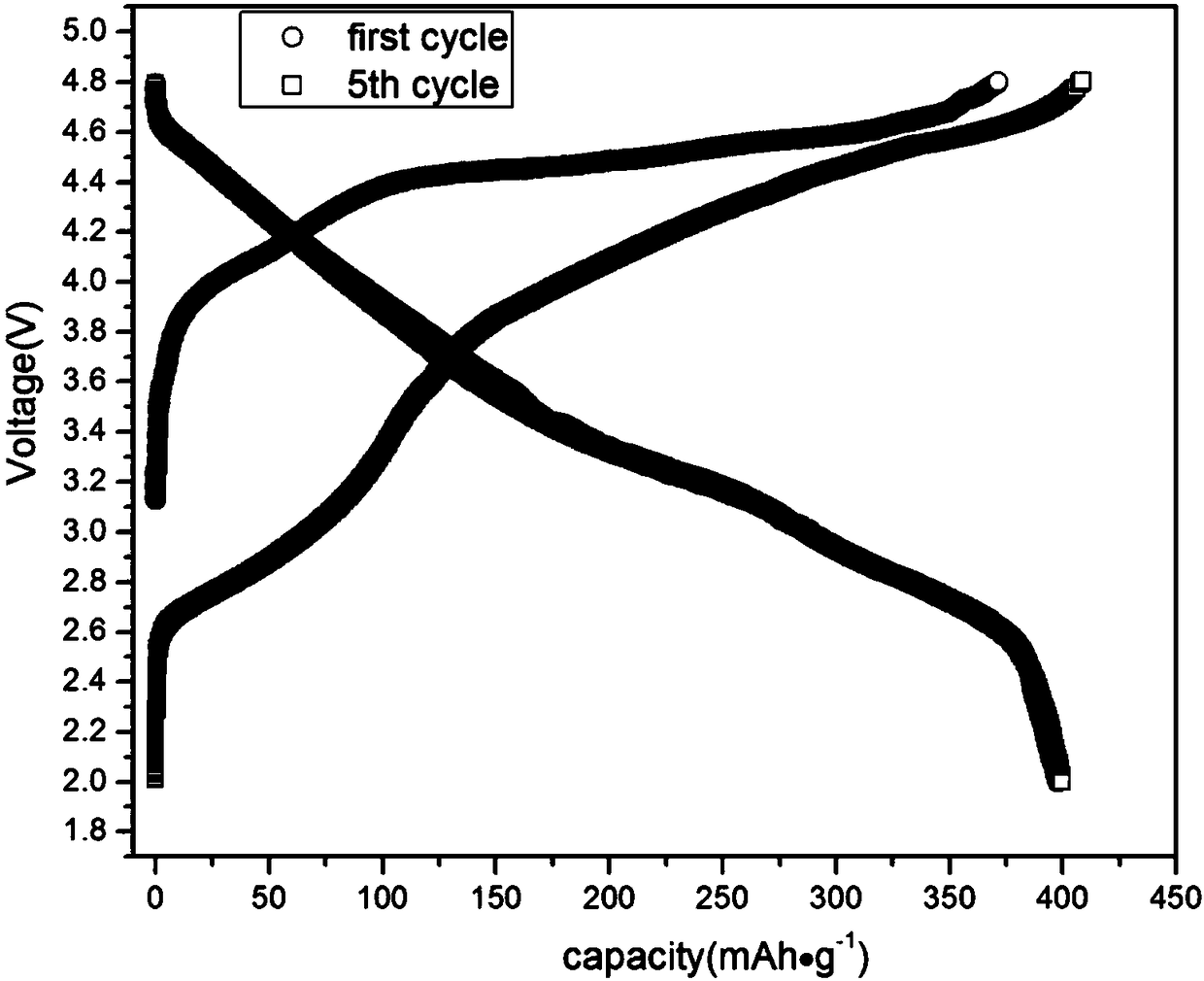

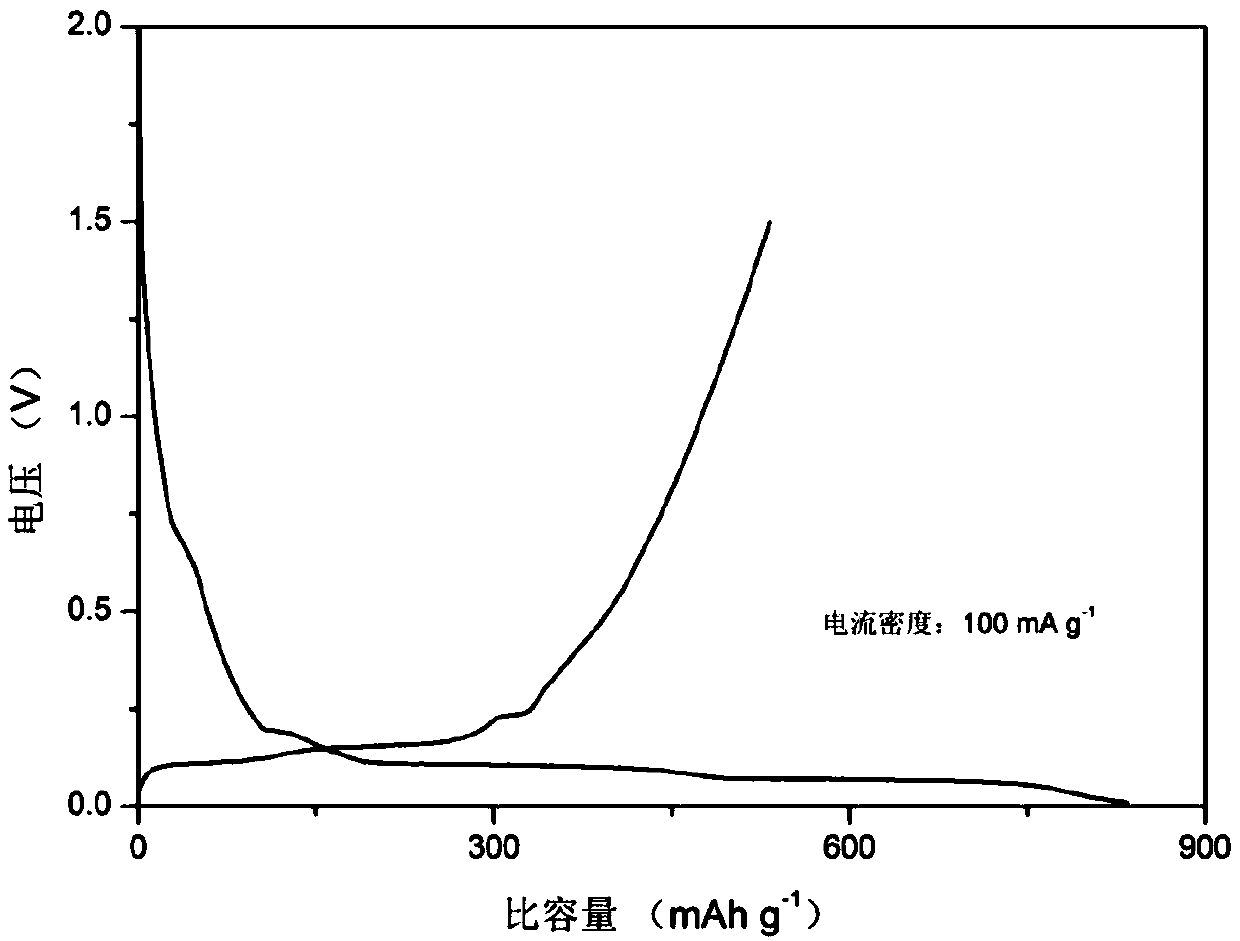

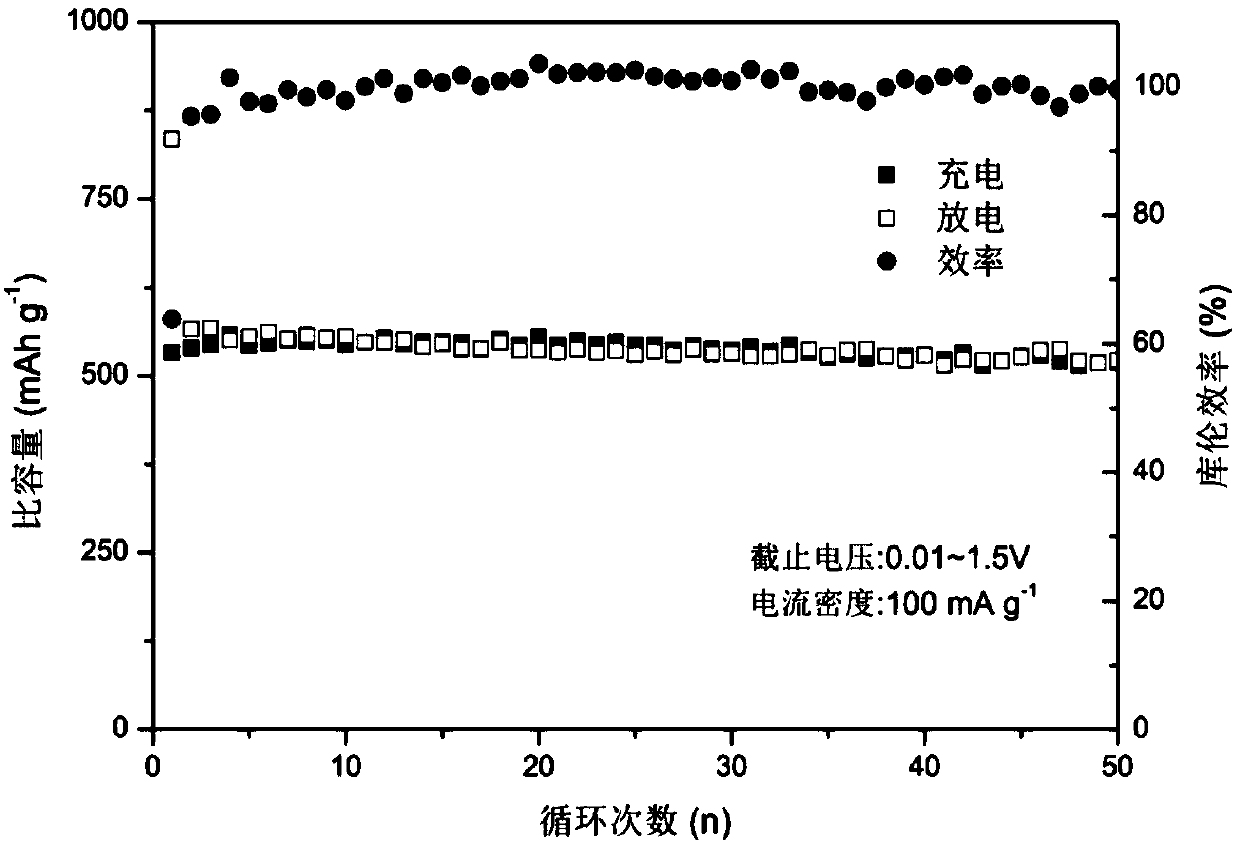

O2 configured lithium battery positive electrode material and preparation method thereof

ActiveCN108123115AHigh tap densitySimple stepsCell electrodesSecondary cellsPhysical chemistryPhase change

The invention discloses an O2 configured lithium battery positive electrode material and a preparation method thereof. The material is mainly of an O2 configured stratified structure, and comprises lithium ion layers, transitional metal layers and oxygen atom layers, wherein the oxygen atom layers are arrayed periodically by taking the interval of the two transitional metal layers as a period; andthe chemical formula is Lia(LixMy)O2, wherein M is selected from one or more of Mn, Ni, Co and Fe, a is more than or equal to 5 / 6 and smaller than or equal to 1, x is more than or equal to 0.2 and smaller than or equal to 0.35, and x+y is equal to 1. The performance is extremely excellent, first coulombic efficiency is between 95%-105%, the reversible capacity is up to 398mAh / g under 10mA / g multiplying power, the phase change from a stratified phase to a spinel phase cannot occur in the circulation, and the synthetic method is simple and convenient for industrialized mass production.

Owner:PEKING UNIV

Method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution

InactiveCN102181886AImprove current efficiencyIncrease current densityNanotechnologyElectrolysisHigh energy

The invention provides a method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution, relating to the production technology of flake zinc powder. The method is characterized by firstly preparing zinc-containing strong alkaline solution, wherein the solution contains 1-100g / L of Zn, 10-200g / L of OH<->, 5-70mg / L of additive A and 10-110mg / L ofadditive B; secondly taking a stainless steel plate as an anode and a magnesium plate as a cathode to electrolyze the solution for 1-180min under the following conditions: the distance between the two plates is 0.5-5cm; the current density is 100-2500A / m2; and the solution temperature is 10-100 DEG C, then stopping electrolysis, rapidly taking out the electrodeposit and washing the electrodepositwith water until the pH value of the water is lower than 8; and finally, rapidly vacuum-drying the washed electrodeposit, thus obtaining the one-dimensional nanometer flake zinc powder, wherein the electrolysis waste liquor is returned to be used for preparing the zinc-containing strong alkaline solution. The method has the following advantages and effects: the produced zinc powder has high activity, is flaky and is 10-100nm thick; the method is low in production cost and energy consumption, is simple to operate and is convenient for mass production; and the defects of high cost, high energy consumption, low capacity, difficulty in controlling quality and the like in the traditional production methods are thoroughly overcome.

Owner:TONGJI UNIV

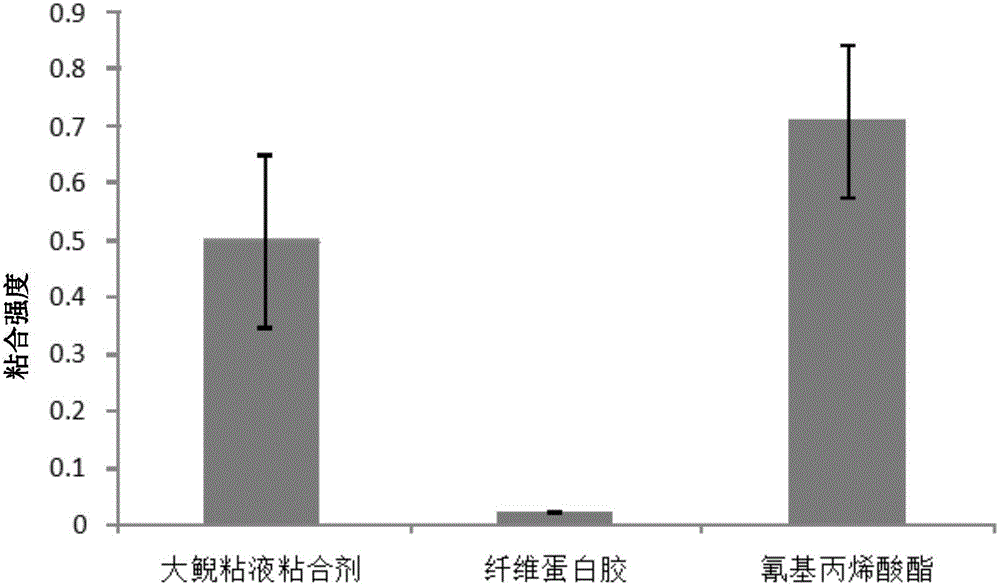

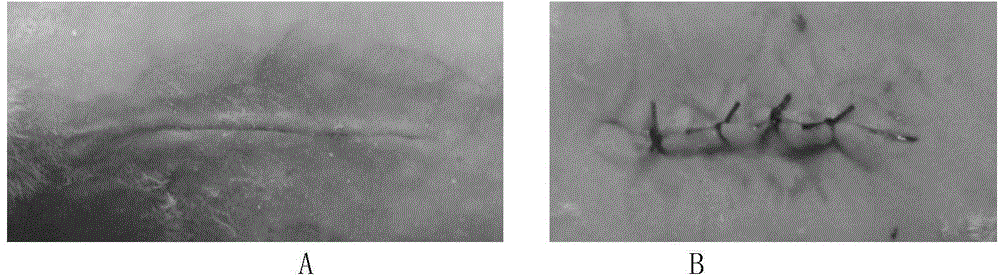

Binder prepared from giant salamander mucus and preparation method thereof

The invention discloses a binder prepared from giant salamander mucus and a preparation method thereof. The binder is freeze-dried powder of giant salamander mucus. The preparation method comprises the following steps of freezing giant salamander mucus to obtain solids, carrying out refrigeration vacuum drying to remove water, crushing the dried giant salamander mucus and carrying out disinfection. The preparation method has simple processes. The binder has good viscidity and can be directly used as a tissue binder for operation wound bonding and bone bonding. The binder is prepared from giant salamander, contains pure natural components, has good safety and biocompatibility, can be degraded and has a wide application prospect.

Owner:CHONGQING KUIXU BIOLOGICAL SCI & TECH +2

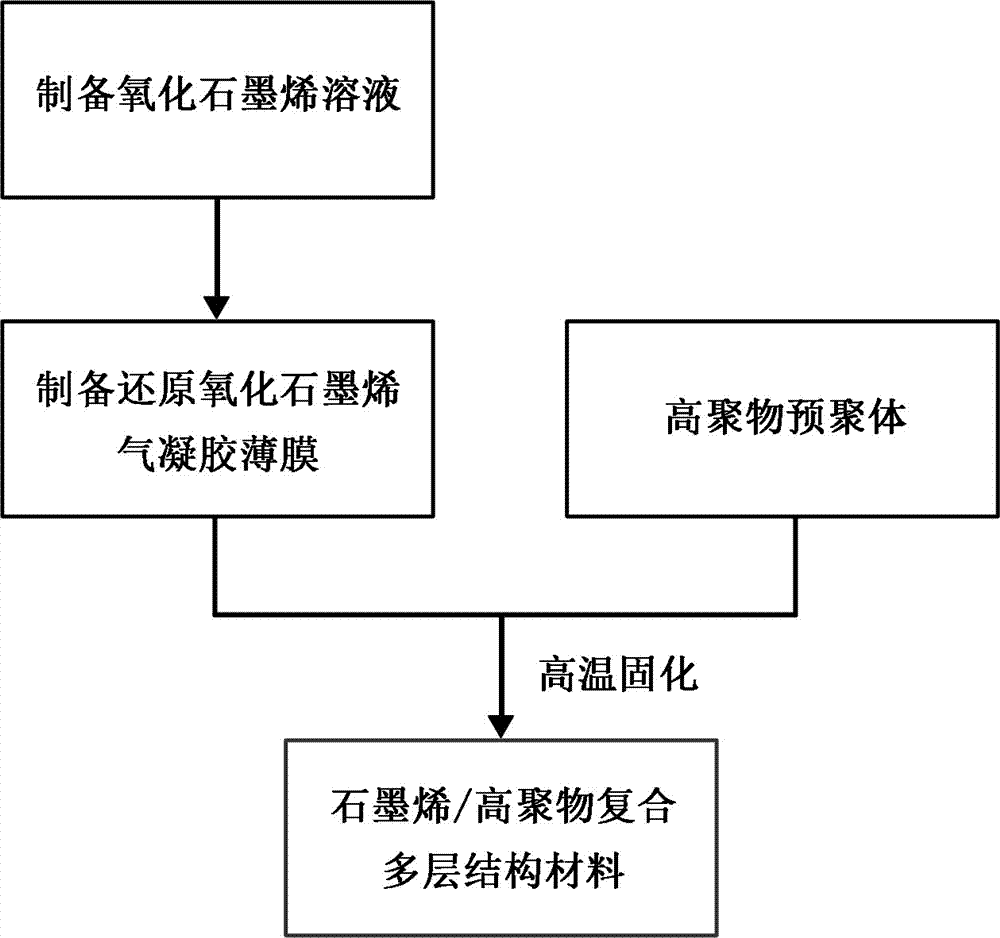

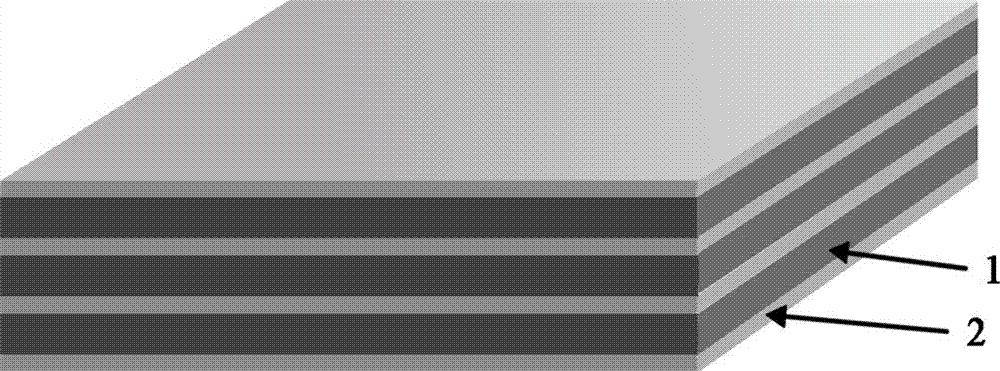

Preparation of graphene/superpolymer multilayer material with high electromagnetic shielding performance

InactiveCN107283949AWide variety of sourcesHigh strengthLamination ancillary operationsSynthetic resin layered productsMetallic foilFreeze-drying

The invention provides a preparation method of a graphene / superpolymer multilayer material with high electromagnetic shielding performance, and belongs to the field of electromagnetic shielding material preparation. The method comprises the following steps: firstly preparing an oxidized graphene solution by adopting a liquid-phase stripping method; then carrying out freeze drying on a graphene thin film reduced by metallic foil under a vacuum condition so as to obtain a graphene aerogel thin film; and finally infiltrating a thin superpolymer layer on the surface of the thin film, laminating thin film layers together to prepare the graphene / superpolymer multilayer material. The method is simple in technological conditions, the flow is easy to control, the source of the raw materials is wide, the cost is low, and the method is convenient for industrial production. Due to the fact that graphene sheets are assembled to form a certain structure before the graphene is mixed with the superpolymer, and agglomeration in the mixing process of the graphene sheets and the superpolymer is avoided, the composite material has the characteristics of high strength, high conductivity, corrosion resistance, high electromagnetic shielding performance and the like, and can be widely applied to civil and military fields such as consumer electronics, communication equipment, information transfer and security.

Owner:PEKING UNIV +1

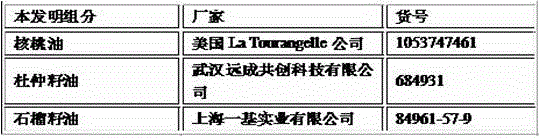

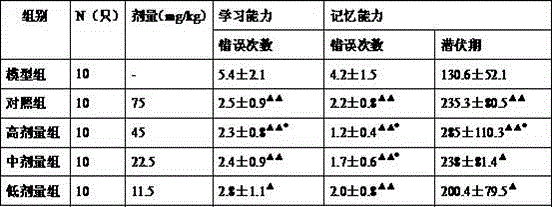

Vitamin D3 soft capsule and preparation method thereof

ActiveCN105476020AEnhance immune functionPromote absorptionFood ingredient as antioxidantFood shapingPOMEGRANATE SEED OILVegetable oil

The present invention belongs to the field of health food, and in particular relates to a vitamin D3 soft capsule and a preparation method thereof. The vitamin D3 soft capsule includes an internal contained substance and a capsule shell, the internal contained substance comprises the following components in parts by weight: vitamin D3, vitamin D2, walnut oil, eucommia ulmoides seed oil, pomegranate seed oil, amino acids, calcium citrate, an antioxidant and a stabilizer; and the capsule shell comprises the following components in parts by weight: gelatine, glycerol, titanium dioxide, and purified water. The vitamin D3 soft capsules contains a variety of vitamins and vegetable oils, can be used for supplement of a sufficient amount of vitamin D and promotion the absorption of calcium and phosphorus, can provide a variety of nutrients for the human body, and has the effects of enhancing brain function, enhance human immune function, promoting the development of the brain and nervous system, eliminating free radicals in the body, preventing a variety of chronic diseases, and the like.

Owner:富诺健康股份有限公司

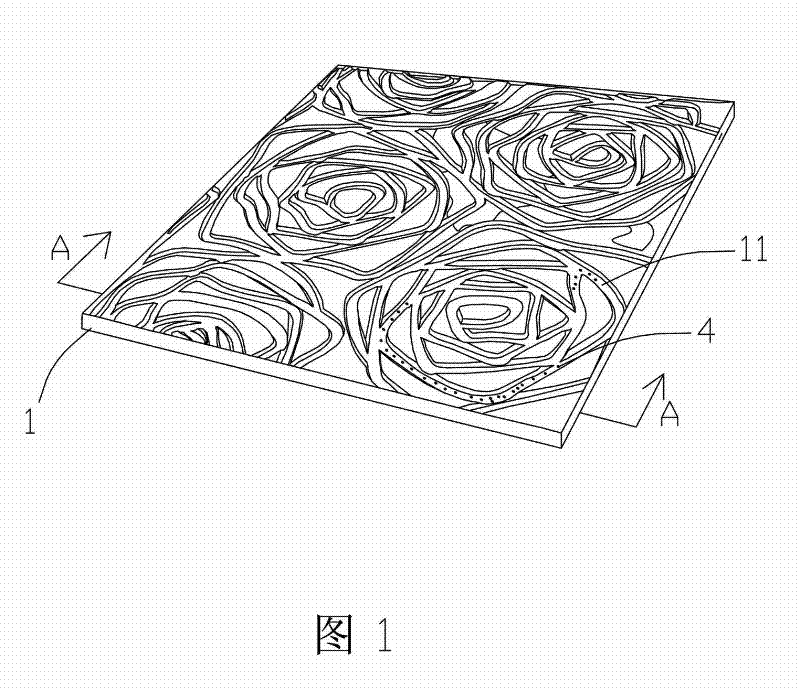

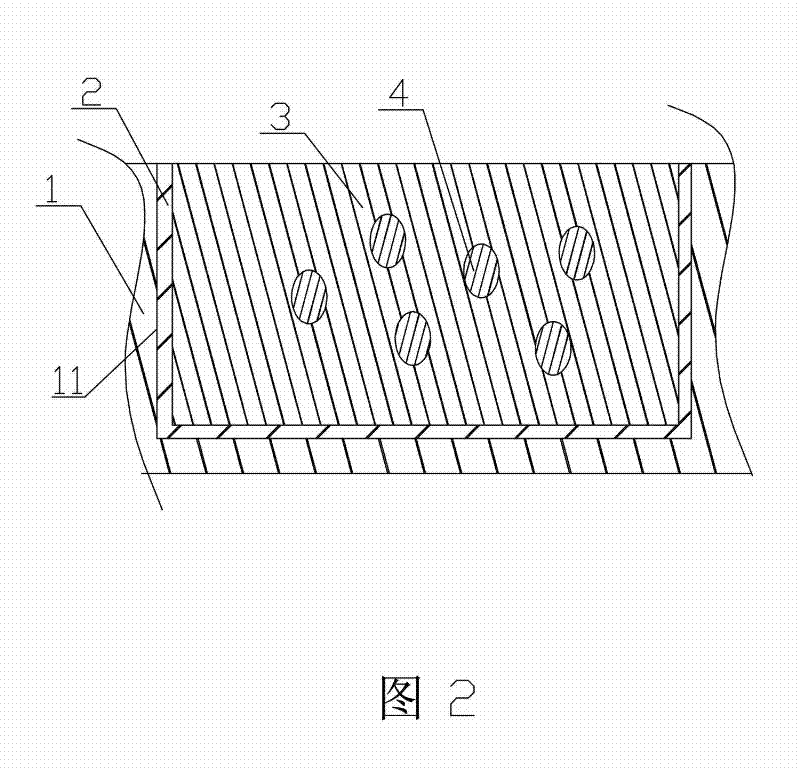

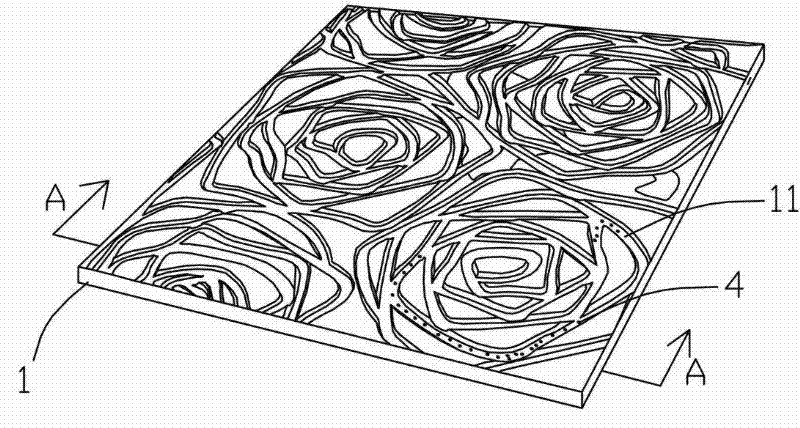

A kind of decorative board and its production process

InactiveCN102259547AExtended service lifeInhibit sheddingDecorative surface effectsData filePulp and paper industry

A decorative board, comprising a decorative board body, the decorative board body is provided with a concave texture engraved by a numerical control engraving machine, and a pattern decorative layer formed by a numerical control inkjet printer is arranged in the concave texture, and the concave texture is filled with Has a transparent protective layer. The decorative board completely covers the pattern in the texture through a transparent protective layer, which can avoid color fading, and can be applied to decorative occasions such as outdoors with harsh natural conditions. Simultaneously, the present invention also provides the production process of the decorative panel, which combines the CNC engraving machine and the CNC inkjet printer well, through the input of data files including patterns, the positioning and data of the CNC engraving machine and the CNC inkjet printer equipment. The CNC engraving machine engraves the corresponding concave texture on the surface of the decorative plate, and the CNC inkjet printer prints the corresponding pattern in the concave texture, which overcomes the limitation that the existing inkjet printer can only print flat patterns and improves production efficiency. Reduced production costs.

Owner:NANAN BESTTIME STONE

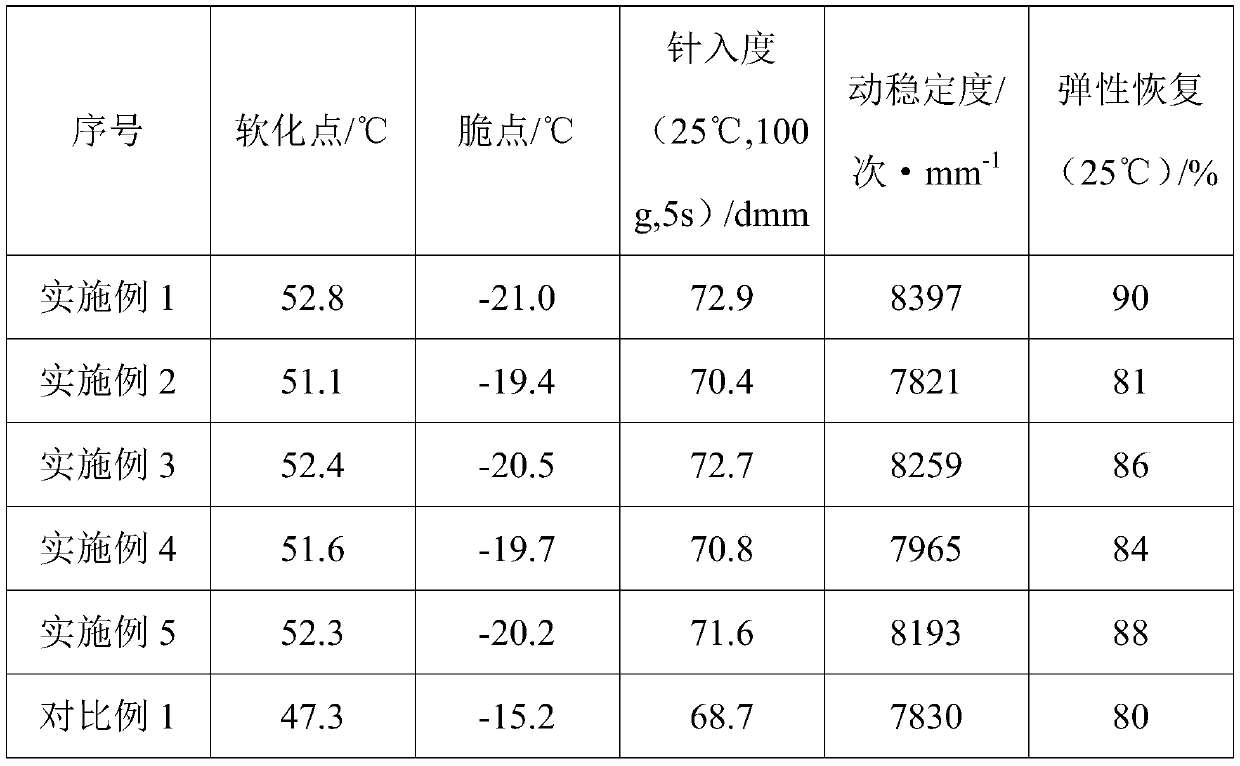

Modified biological asphalt material, preparation method thereof and application of material

InactiveCN109735120AImprove carrying capacityGood deformation recoveryBuilding insulationsFiberSolvent

The invention belongs to the technical field of asphalt, and discloses a modified biological asphalt material, a preparation method thereof and an application of the material. The modified biologicalasphalt material comprises, by weight, 30-78 parts of biological asphalt, 10-15 parts of modified agents, 0.2-0.6 part of mineral fibers, 1-3 parts of stabilizing agents and 10-25 parts of solvents. According to the modified biological asphalt material, special modified agents are selected, softening points and viscosity of the biological asphalt are improved, high-temperature stability of the biological asphalt is improved, mineral fibers have excellent performances of high strength, corrosion resistance and high-temperature resistance and the like, and deformation resistance of the biological asphalt is improved by the mineral fibers. According to the modified biological asphalt material, the biological asphalt is modified by adding the modified agents, the mineral fibers and the stabilizing agents, and high-temperature stability, low-temperature stability and deformation resistance of the biological asphalt are improved, so that the prepared modified biological asphalt material hasgood bearing capacity, deformation recovery capacity and high-temperature rut resistance.

Owner:NANJING COMM INST OF TECH

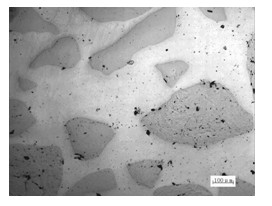

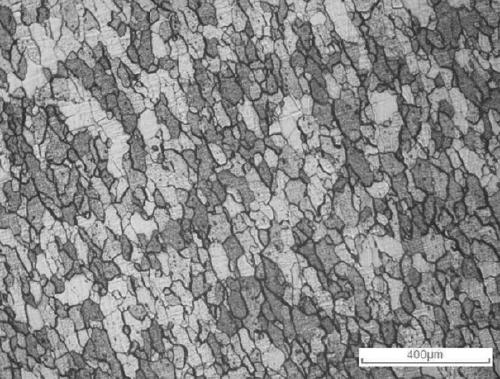

High alloy matrix metal-ceramic composite and preparation method thereof

The invention discloses a high alloy matrix metal-ceramic composite and a preparation method thereof, and belongs to the field of wear-resistant materials. According to the high alloy matrix metal-ceramic composite, the volume ratio of high alloy matrix materials to metal-ceramic reinforced particles is (1-10):1; the high alloy matrix materials comprise 1-8% of C, main alloying elements, minor additive elements and the balance Fe and unavoidable impurities; the main alloying elements comprise 0-60%of Ni, 0-60% of Mo, 0-40% of Cr, 0-30% of Mn, 0-20% of V, 0-20% of Ti, 0-15% of W and 0-15% of Nb; and the minor additive elements are one or more of B, Si, Zr, Cu, Co, Al and rare earth. The preparation method adopts a programmed temperature-controlled liquid phase sintering method for preparation and can be used directly for wear-resisting materials, or for wear-resisting materials after subsequent heat treatment; and the metallurgical bonding interface between the reinforced phase and thehigh alloy matrix in the composite reaches 40[mu]m-1mm, no cracks occurs after the integral heat treatment, and the service conditions in the wear-resistant material field are met.

Owner:NORTHEASTERN UNIV

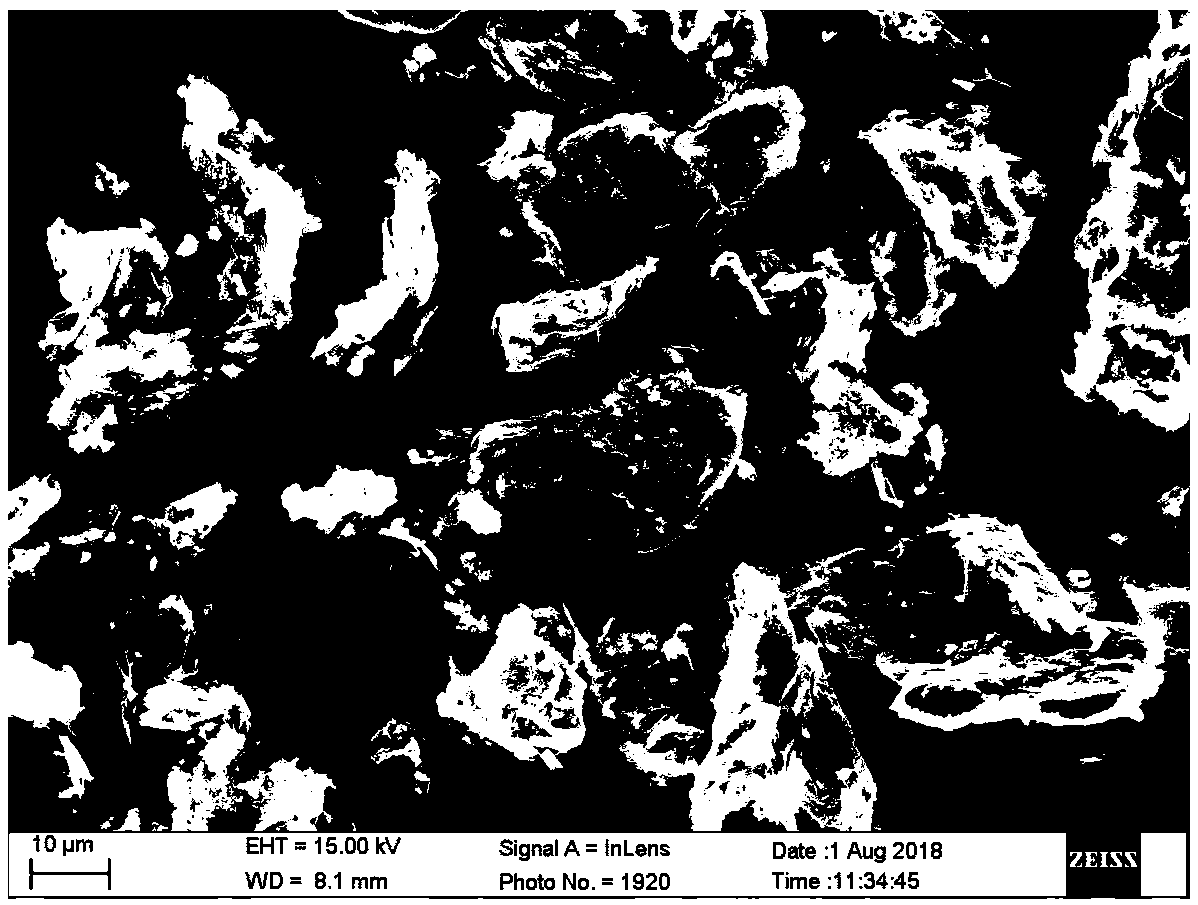

Preparation method of lithium ion battery negative electrode material silicon oxide-carbon/graphite

ActiveCN109560278AImprove electronic conductanceCoulombic efficiency is highCell electrodesSecondary cellsSucroseSilicon oxygen

The invention relates to a preparation method of a lithium ion battery negative electrode material silicon oxide-carbon / graphite. The preparation method comprises the steps of taking tetraethyl orthosilicate as a silicon source and sucrose as a carbon source, performing in-situ combination on a gel-state silicon oxide, the sucrose and the graphite by hydrolysis-condensation reaction of the tetraethyl orthosilicate, and performing ball-milling to disperse the graphite to obtain a uniform silicon-oxygen-sucrose-graphite precursor; and allowing the sucrose to split and reducing silicon oxide during the subsequent thermal treatment process so as to prepare the uniformly-combined silicon oxide-carbon / graphite material. The in-site process of the silicon oxide and the graphite is simple in process and low in cost, and the prepared silicon oxide-carbon / graphite material is uniform in combination; with the introduction of the graphite, the electron conductivity of the composite material can beimproved, the coulombic efficiency of the composite electrode material is effectively improved, so that the electrochemical performance of the electrode material is remarkably improved; and the silicon oxide-carbon / graphite material can be used as a potential high-performance lithium ion battery negative electrode material and is expected to be widely applied to the fields of various types portable electronic equipment, an electric automobile and aerospace.

Owner:UNIV OF SCI & TECH BEIJING

No-coating air bag fabric and its making process

InactiveCN1986927ASimplify processing costsThe preparation process is simple and scientificLoomsFibre treatmentBatch productionSizing

Owner:吴江祥盛纺织染整有限公司

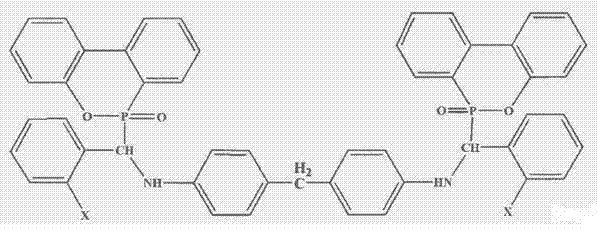

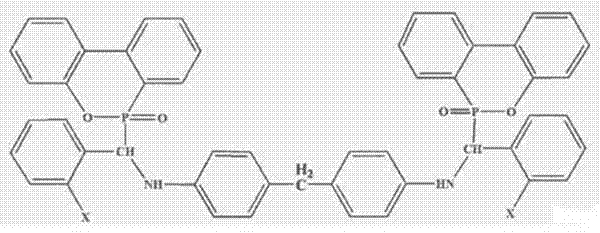

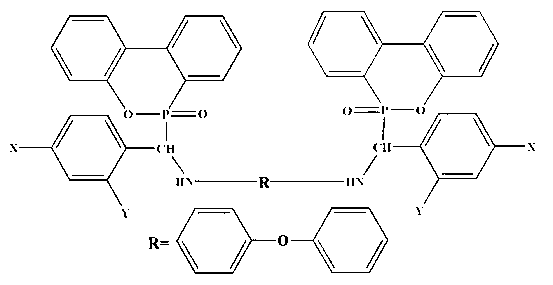

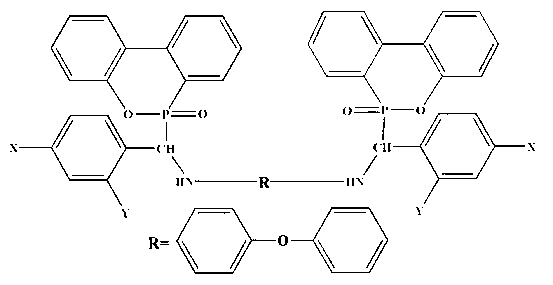

Efficient nitrogen and phosphorus fire retardant for epoxy resin and preparation method of efficient nitrogen and phosphorus fire retardant

InactiveCN103012847AThe process steps are simpleFacilitate industrial mass productionGroup 5/15 element organic compoundsEpoxyDiaminodiphenyl ether

The invention relates to an efficient nitrogen and phosphorus fire retardant for epoxy resin, and a preparation method of the efficient nitrogen and phosphorus fire retardant. The method comprises the steps of allowing 4,4'-diaminodiphenyl ether (DDE) and aromatic aldehyde to conduct condensation reaction, and adding DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) to a reacted mixture for reaction to prepare the nitrogen and phosphorus fire retardant. According to the method, an intermediate product is not required to be separated; the method has simplified processing steps, is efficient, safe and environment-friendly and facilitates industrial batch production. Molecules of the obtained fire retardant are higher in activity; the fire retardant can facilitate epoxy resin curing; after the fire retardant is added into the epoxy resin, a cured epoxy condensate has better flame resistance; when the phosphorus content of an epoxy curing system reaches 0.75-1.0wt%, the vertical burning grade reaches UL94V-0; the limit oxygen index is greater than 38; and the char yield reaches 21.2-22.7% at 800 DEG C.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid

The invention discloses a method for catalytic synthesis of a 4H-benzo[b]pyran derivative with a basic ionic liquid and belongs to the technical field of organic synthesis. The molar ratio of aromatic aldehyde to malononitrile to a 1,3-cyclohexanedione compound in a synthetic reaction is 1:1:1, the molar weight of a basic ionic liquid catalyst is 4%-7% of that of the used aromatic aldehyde, the volume dose of a reaction solvent ethanol aqueous solution in terms of milliliters is 4-6 times the molar weight of the aromatic aldehyde in terms of millimoles, the reaction pressure is one atmosphere, the reflux reaction is performed for 5-30 min, the mixture is cooled to the room temperature after the reaction is finished, a large quantity of solids are separated out, suction filtration is performed, filter residues are subjected to vacuum drying, and the pure 4H-benzo[b]pyran derivative is obtained. Compared with synthetic methods in which other basic ionic liquids are adopted as catalysts, the method has the characteristics that the catalyst is easy to biodegrade, simple to prepare, low in cost and easy to obtain, the utilization rate of raw materials is high in the whole synthetic process, the operation is simple and convenient and the like, and industrial mass production is facilitated.

Owner:山东润耀环保科技有限公司

Composite guide plate and preparation process thereof

The invention discloses a composite guide plate and a preparation process thereof. A layer of hard ceramic particles is compounded on the abraded surface of the composite guide plate to improve the abrasion resistance. The preparation process comprises the following steps of: adding adhesive and alloy powder into the ceramic particles, stirring uniformly, spreading the mixture into a guide plate casting mold according to the design requirement, pouring a base material metal, cooling, stripping and clearing to obtain the composite guide plate. The composite guide plate has the advantages that: the layer of hard ceramic particles is compounded on the surface of the guide plate to form an abrasion-resistant hard phase, and the base material metal is filled in the gaps of the ceramic particles, so that the compounded surface has the abrasion resistance of the ceramic particles and the plastic toughness and the fatigue resistance of the base material metal, the hard phase does not drop easily, the controllability of process parameters is strong, the defects of slag inclusion and the like do not exist in the tissues, the composite guide plate is convenient for machining operation and convenient for industrialized large-batch production, and the service life of the guide plate is prolonged by 5 to 8 times higher than that of a common guide plate.

Owner:KUNMING UNIV OF SCI & TECH

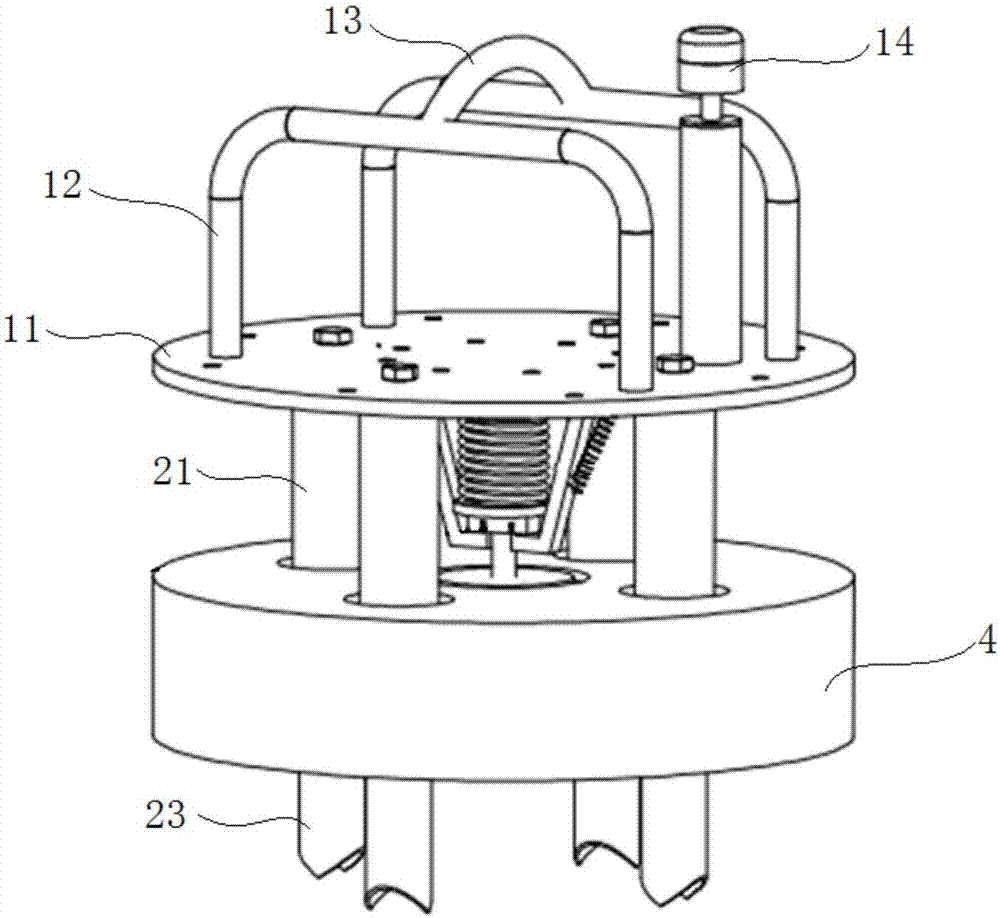

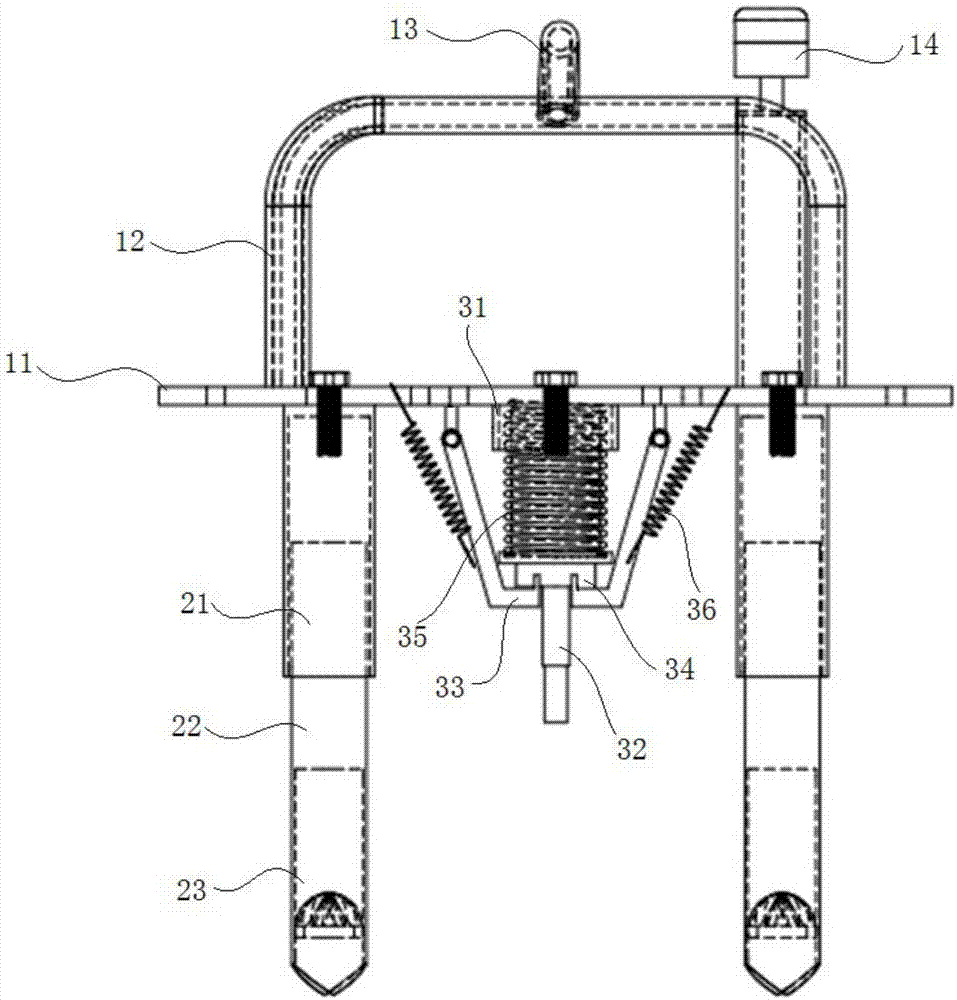

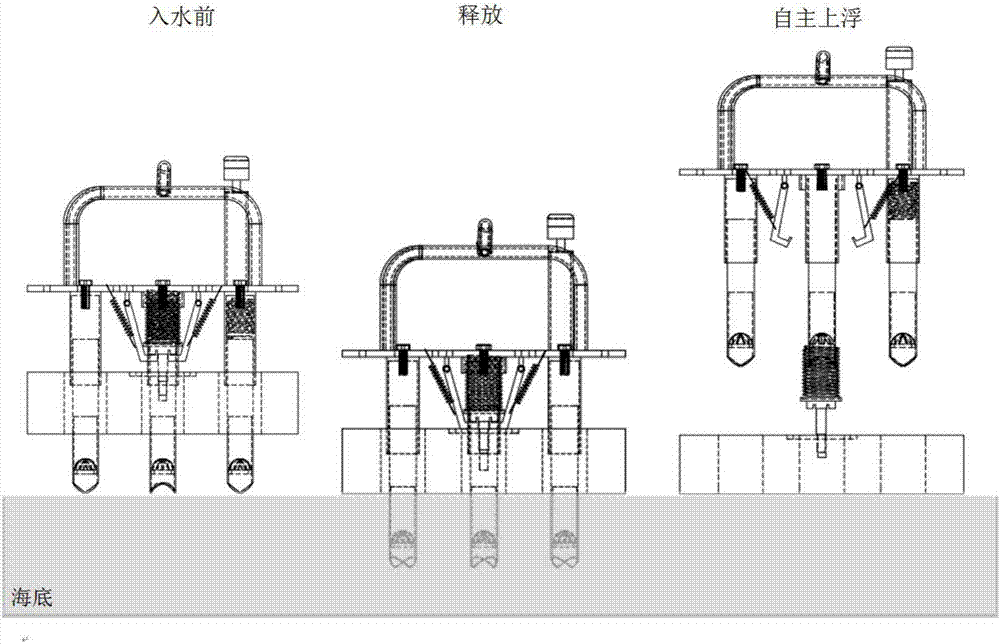

Undersea mechanical myriametre level light impact geological sampling device

ActiveCN107449629ASave human effortReduce wasteWithdrawing sample devicesLoad rejectionComputer module

The invention relates to the technical field of submarine geological prospecting equipment and in particular relates to an undersea mechanical myriametre level light impact geological sampling device which comprises a main supporting frame, a guide sampling mechanism, a grounding releasing mechanism and a load rejection counterweight mechanism. The main supporting frame comprises a connecting disc in the bottom. A floating block is arranged on the connecting disc. The undersea mechanical myriametre level light impact geological sampling device provided by the invention is designed modularly, is conveniently produced in batches and maintained, is low in production cost, simple to mount, efficient and safe and reliable, and solves the technical problems that in the prior art, a deep undersea sampling device is complex in structure, low in efficiency, high in cost, hard to operate and maintain and the like.

Owner:NAT DEEP SEA CENT

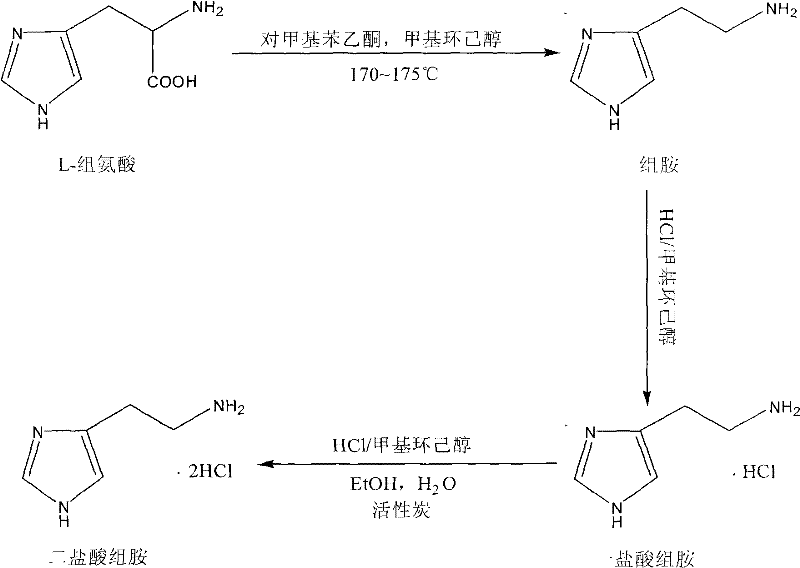

Preparation method of histamine dihydrochloride

ActiveCN102477014AFacilitate industrial mass productionEasy to recycleOrganic active ingredientsOrganic chemistrySolventHistamine Hydrochloride

The invention relates to an industrial preparation method of officinal histamine dihydrochloride. The preparation method comprises the following steps of: suspending histidine in hexahydrocresol which is used as a reaction solvent; carrying out a decarboxylation reaction at the temperature of 170 DEG C-175 DEG C; and then quantitatively dropwise adding the hexahydrocresol solution containing hydrochloric acid twice so as to synthesize histamine dihydrochloride. According to the invention, the content of the related substances in histamine dihydrochloride is less than 0.5%, and the content of a single impurity in histamine dihydrochloride is less than 0.1%, thus the histamine dihydrochloride completely meets officinal grade; and the preparation method is simple in equipment, easy and simple in process operation and safe and reliable in reaction; and the solvent can be recycled, thus the preparation method is environment-friendly and is beneficial to industrial large-scale production.

Owner:SHANDONG NEWTIME PHARMA

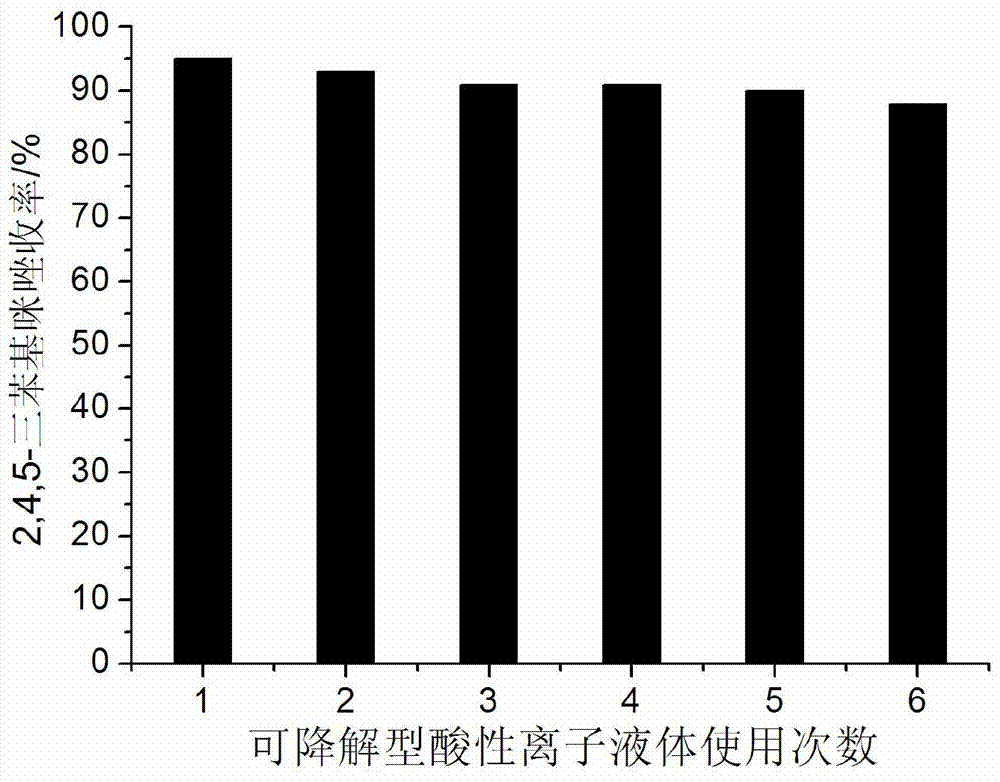

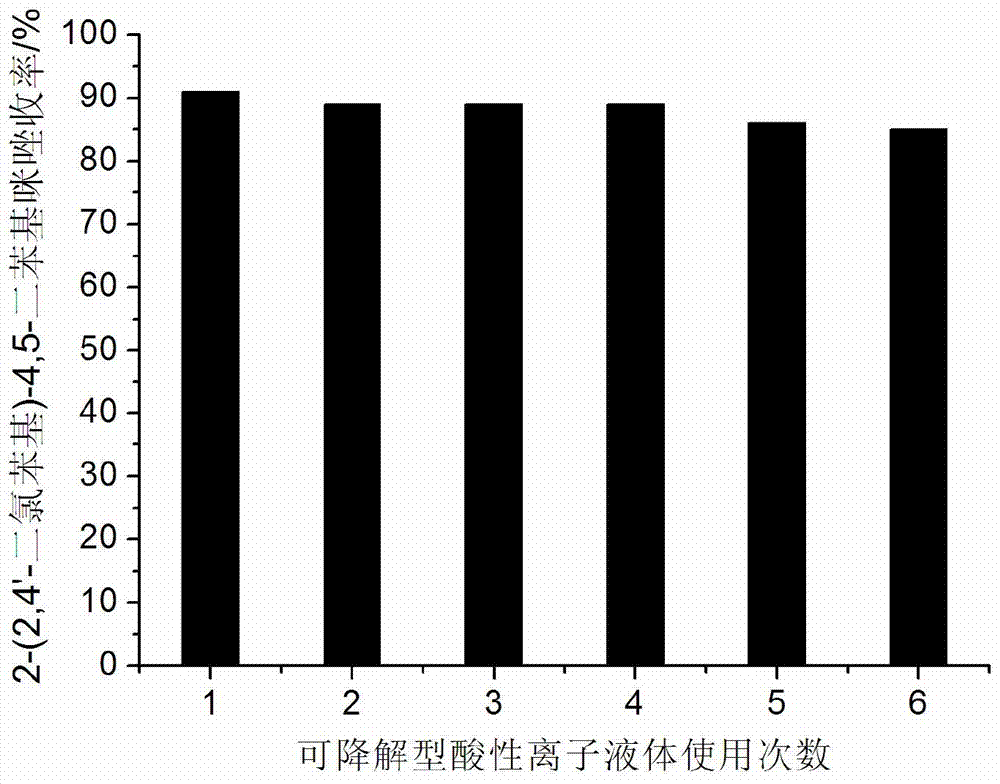

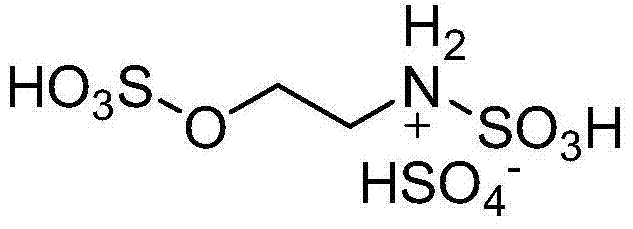

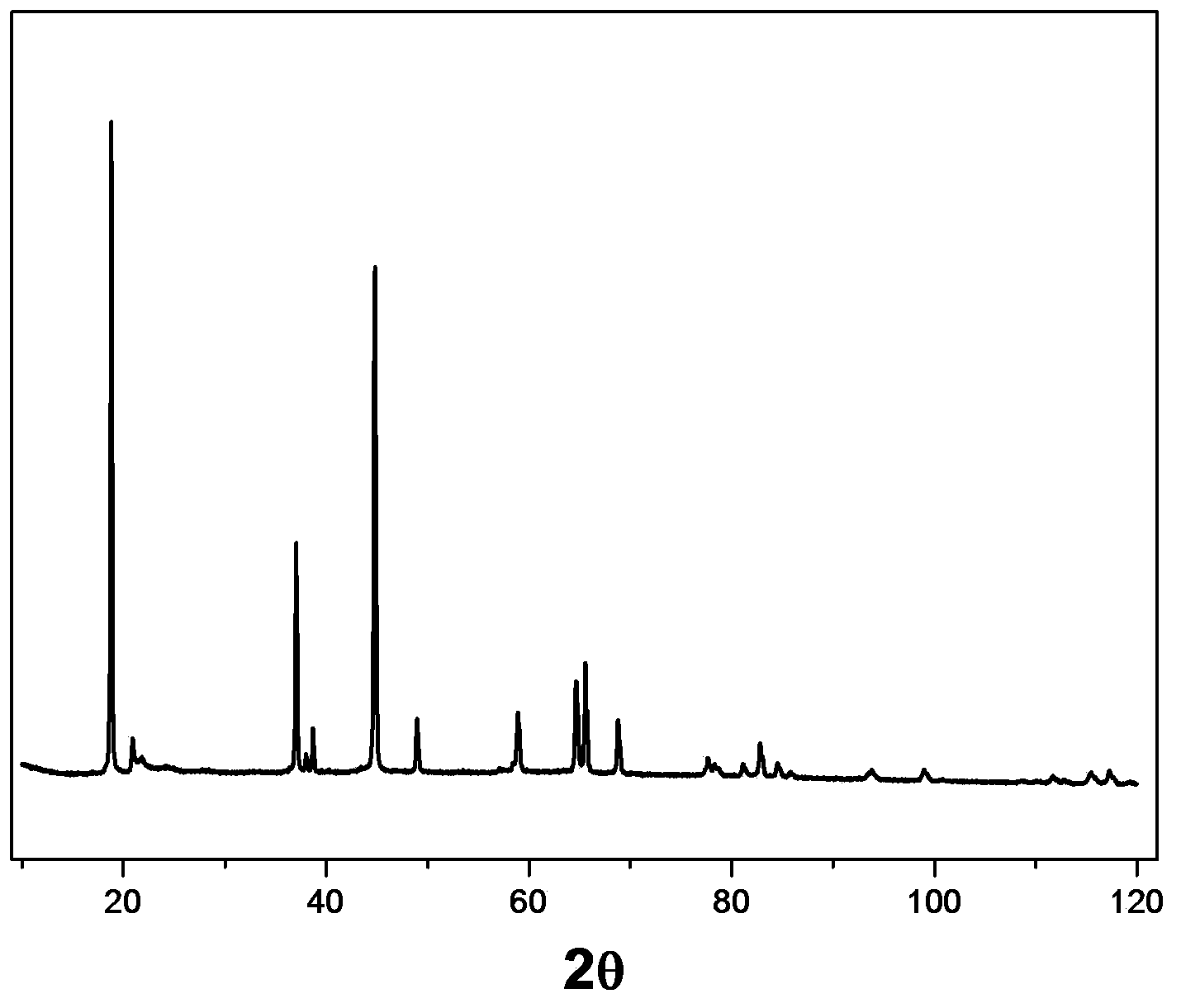

Method for preparing 2,4,5-triaryl substituted imidazole through catalysis of degradable acidic ionic liquid

The invention discloses a method for preparing 2,4,5-triaryl substituted imidazole through catalysis of a degradable acidic ionic liquid, belonging to the technical field of preparation of chemical materials. According to the preparation method, a mol ratio of dibenzoyl to aromatic aldehyde to ammonium acetate is 1:1:(2-4), the molar weight of a degradable acidic ionic liquid catalyst accounts for 3-5 percent of that of the used aromatic aldehyde, and the volume (ml) of alcohol as a reaction solvent is 1-3 times molar weight (mmol) of that of the aromatic aldehyde. The method comprises the steps: performing a reflux reaction for 0.5-2 hours, rotatably evaporating a solvent after the reaction is ended, separating out a large quantity of solids after adding water, grinding solids, standing, carrying out suction filtering, washing filter residue, recrystalizing by using alcohol after drying, and drying in vacuum to obtain 2,4,5-triaryl substituted imidazole. Compared with a preparation method of other acidic ionic liquid catalysts, the method has the advantages of good activity of the catalyst, simplicity, convenience and low cost in the whole preparation process, and the like, and is easy to degrade, and brings the convenience to industrialized large-scale production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid](https://images-eureka.patsnap.com/patent_img/57767ea6-20b4-474c-8501-820b82377553/HDA0000778861820000011.PNG)

![Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid](https://images-eureka.patsnap.com/patent_img/57767ea6-20b4-474c-8501-820b82377553/HDA0000778861820000012.PNG)

![Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid Method for catalytic synthesis of 4H-benzo[b]pyran derivative with basic ionic liquid](https://images-eureka.patsnap.com/patent_img/57767ea6-20b4-474c-8501-820b82377553/HDA0000778861820000021.PNG)