High alloy matrix metal-ceramic composite and preparation method thereof

A cermet and alloy matrix technology, which is applied in the field of wear-resistant materials, can solve the problems of inability to prepare high-alloy matrix cermet composite materials, etc., and achieve the effect of facilitating large-scale industrial production, high service life, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A high-alloy matrix metal-ceramic composite material can be used to prepare specific wear-resistant parts. The thickness of the working area of the wear-resistant part, that is, the thickness of the high-alloy matrix metal-ceramic composite material, is 3 / 4 of the thickness of the overall part.

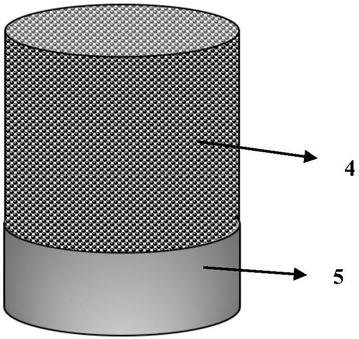

[0071] The high-alloy matrix metal-ceramic composite material is based on a cylindrical high-toughness metal substrate 5 as a toughening area, and the working area is a cylindrical high-alloy matrix metal-ceramic composite material 4; its structural diagram is shown in figure 2 .

[0072] Among them, the cylindrical high-alloy matrix cermet composite material 4 includes cermet-reinforced particles and high-alloy matrix materials, wherein the cermet-reinforced particles are white corundum particles + SiC particles, as the reinforcing phase, according to the volume ratio, the cermet-reinforced particles: High alloy matrix material = 1:1.

[0073] In the high-alloy matrix cerm...

Embodiment 2

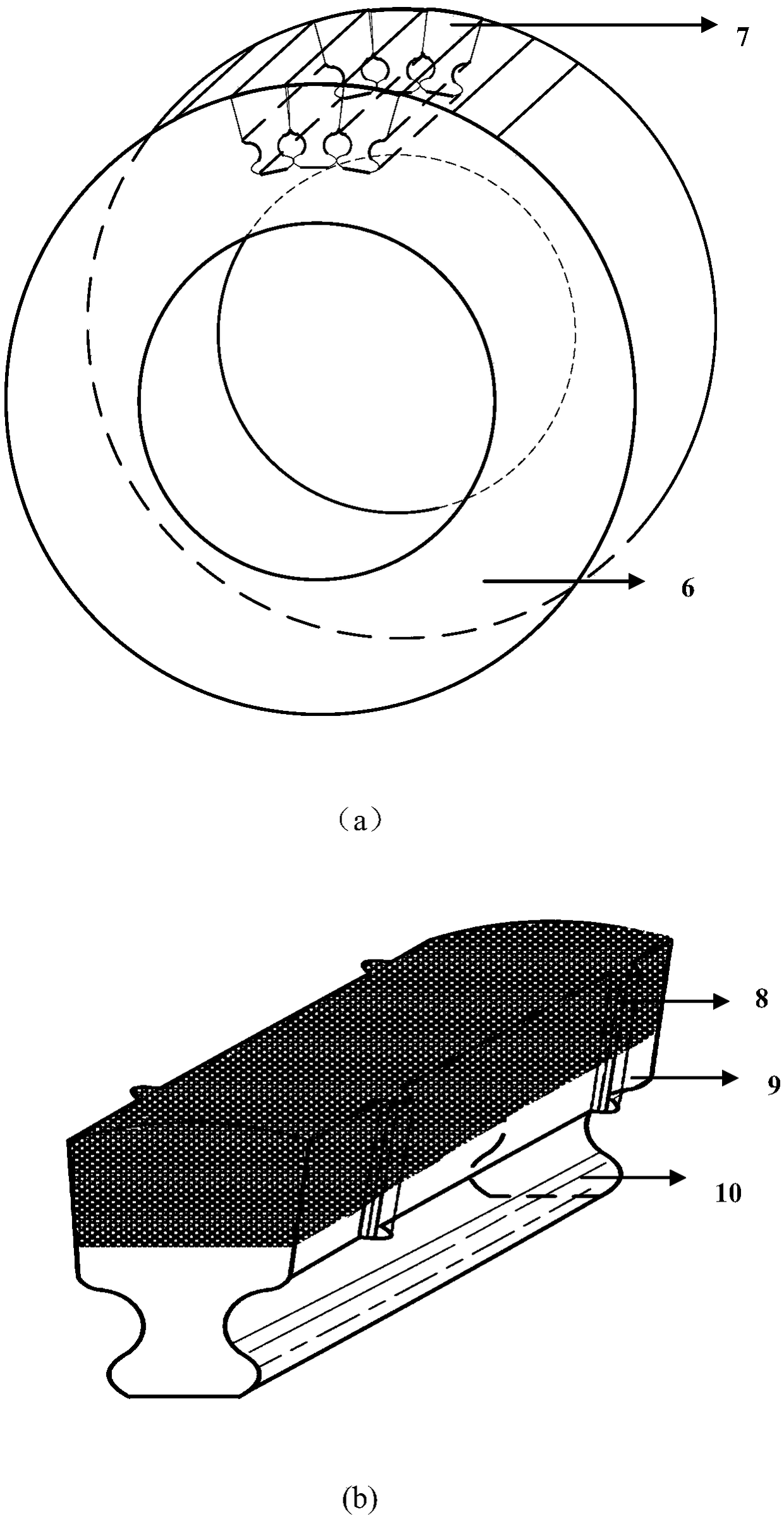

[0093] A high-alloy matrix metal-ceramic composite material, which is used to prepare high wear-resistant mosaic roller sleeves, its structure schematic diagram is shown in image 3 (a), the working area of the high wear-resistant mosaic roller sleeve, that is, the thickness of the mosaic block on the outer surface of the high wear-resistant roller sleeve is 1 / 2 of the thickness of the overall high wear-resistant mosaic roller sleeve.

[0094] The working area of the high wear-resistant inlaid roller sleeve 6 is the inlaid block 7 on the outer surface of the high wear-resistant roller sleeve;

[0095] The inlaid block 7 on the outer surface of the high-wear-resistant roller sleeve includes a high-alloy matrix cermet composite material 8, a high-alloy metal material 9, and a high-toughness metal substrate 10; the structure diagram of the inlaid block 7 on the outer surface of the high-wear-resistant roller sleeve is shown in image 3 (b);

[0096] Among them, the high-allo...

Embodiment 3

[0119] A high-alloy matrix metal-ceramic composite material is used to prepare wear-resistant parts. The thickness of the working area of the wear-resistant part, that is, the thickness of the high-alloy matrix metal-ceramic composite material is 1 / 3 of the thickness of the entire part.

[0120] The high-alloy matrix metal-ceramic composite material is a quadrilateral high-toughness metal substrate 12 as a toughening part, and the working area is set as a quadrilateral high-alloy matrix high-alloy matrix metal-ceramic composite material 11;

[0121] Among them, the quadrilateral high-alloy matrix metal-ceramic composite material 11 includes metal-ceramic reinforcing particles and high-alloy matrix materials, wherein the metal-ceramic reinforcing particles are ZrO 2 -Al 2 o 3 (ZTA), which acts as a reinforcing phase, by volume ratio, cermet reinforcing particles: high alloy matrix material = 1:3.

[0122] In the high-alloy matrix cermet composite material, the components co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com