Patents

Literature

47results about How to "No defects such as cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

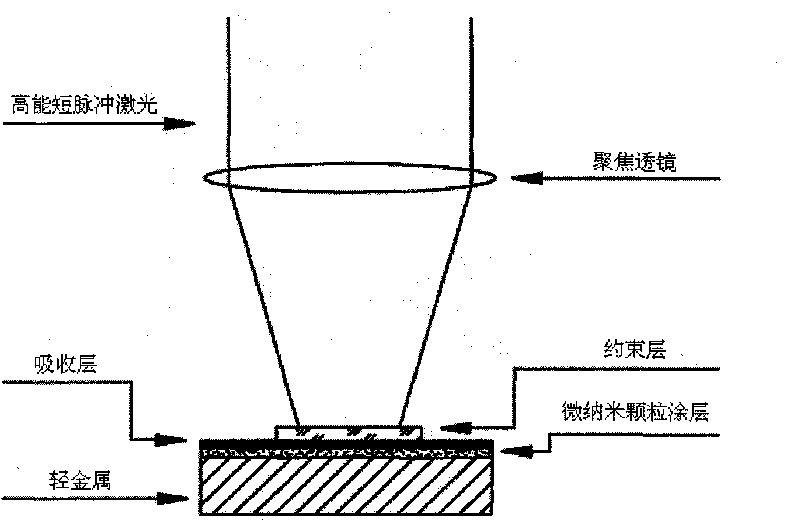

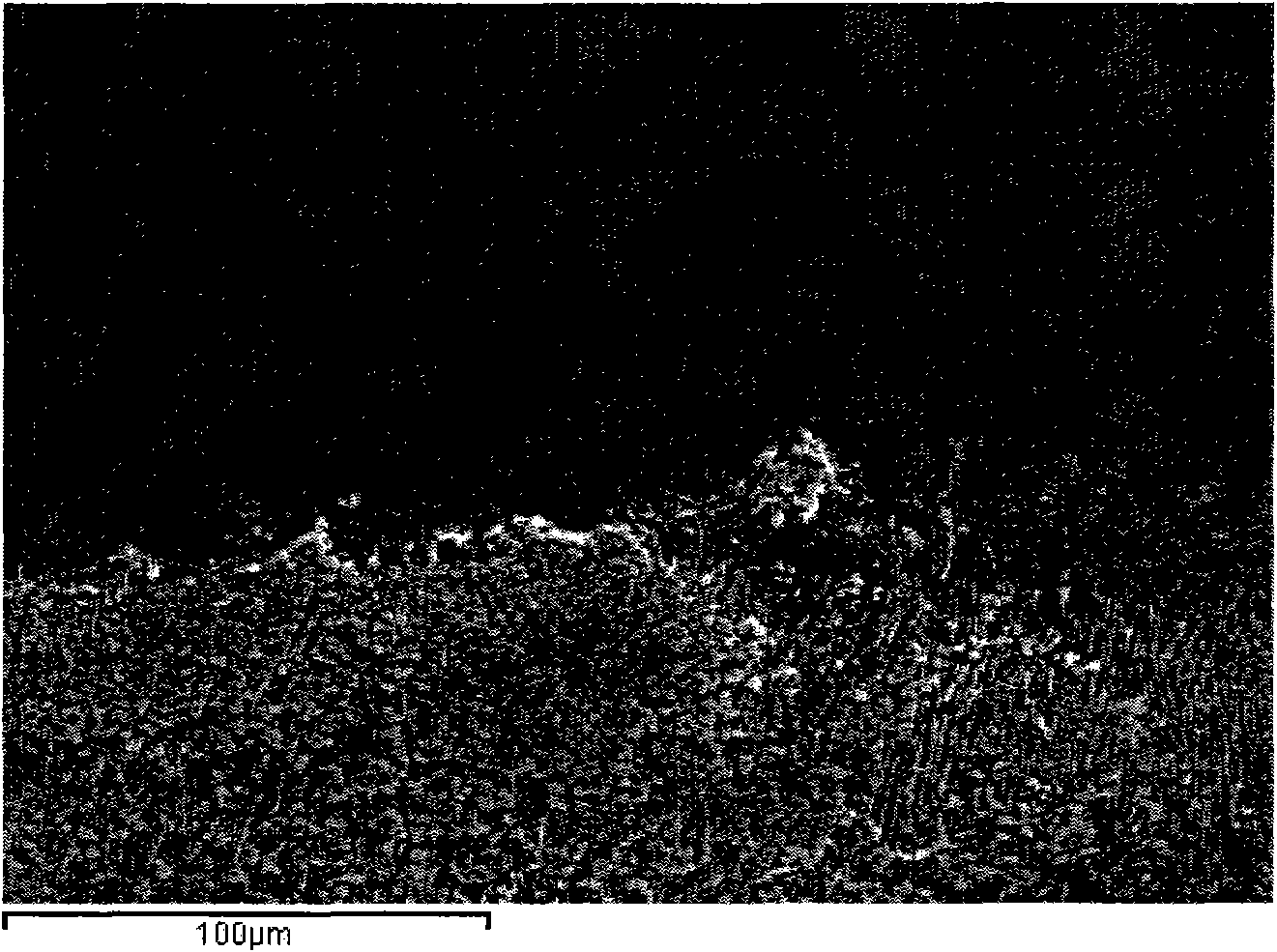

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

Alloy coating for crystallizer surface laser cladding and preparation method thereof

The invention relates to the field of laser cladding, in particular to an alloy coating for crystallizer surface laser cladding and a preparation method thereof. The componenst of the alloy coating are prepared according to the mechanical property and effectiveness condition of the crystallizer and the characteristics of crystallizer surface laser cladding. The alloy coating is prepared from nickel-based self-melt alloy powder comprising the following elements in percentage by mass: Ni 55-57, Cr 16-19, W 8-10, Mo 8-10, Al 0.8-1.0, Ti 2.5-3.5, C 0.2-0.3, Si 2.5-3.5 and B 2-2.5. After being cladby laser, the crystallizer surface has a high-quality coating, thereby meeting the requirements of a crystallizer on a basic performance of quick heat conduction on one hand and increasing the wear resistance and hot erosion resistance of the crystallizer surface.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

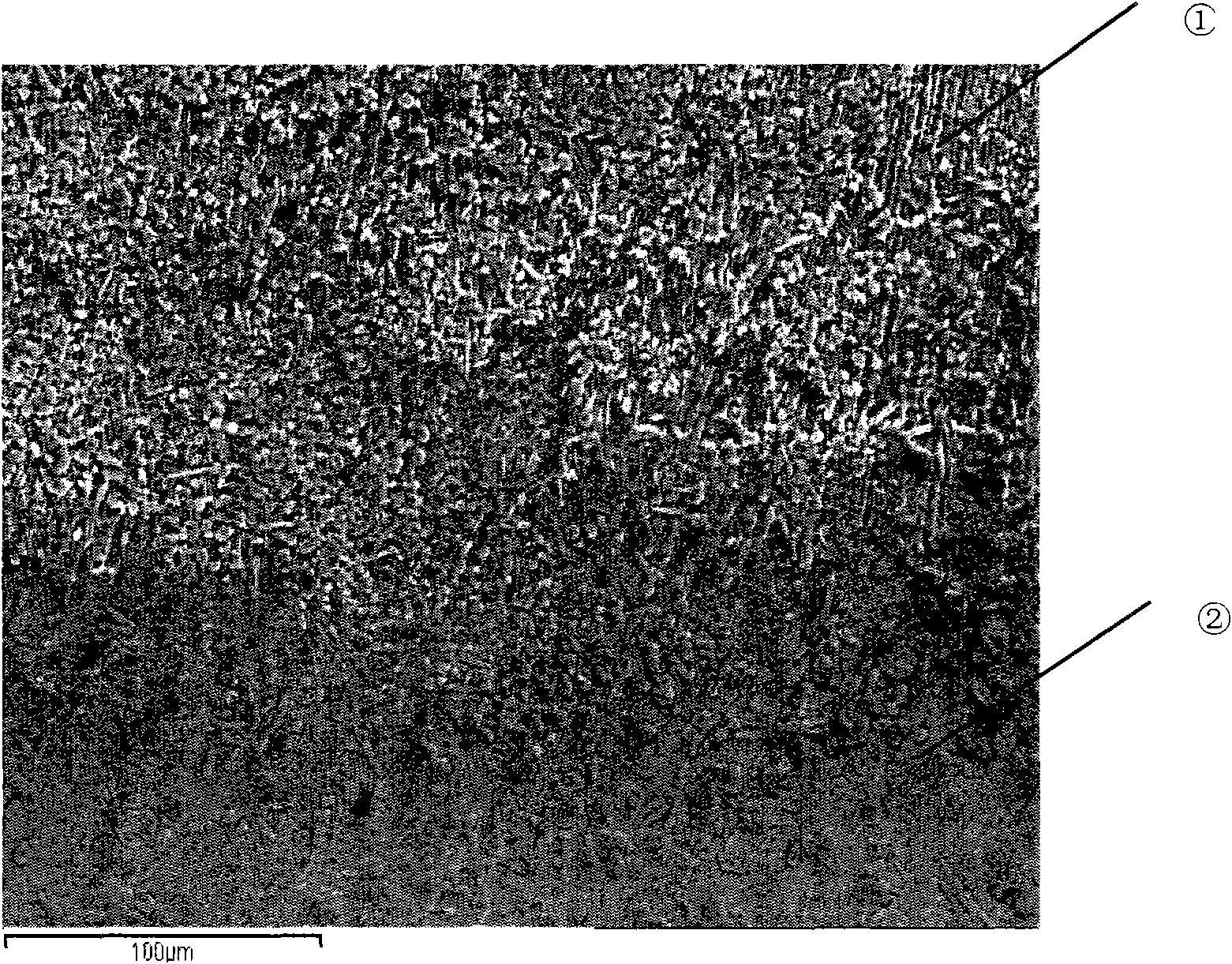

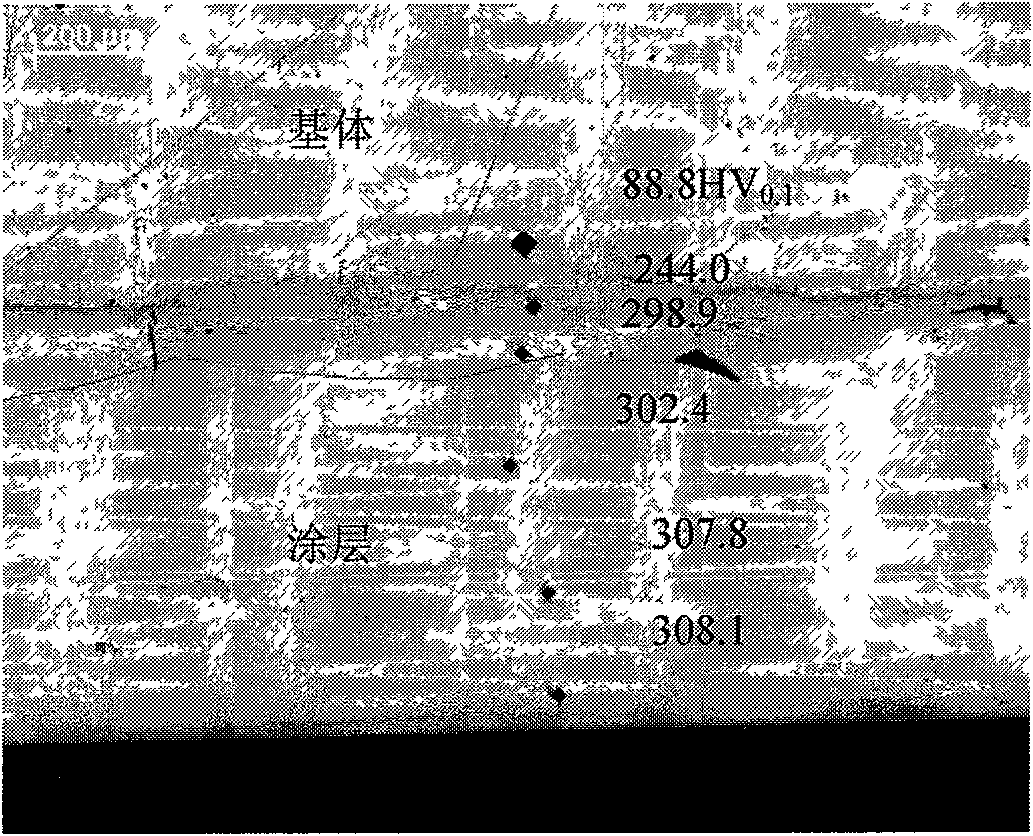

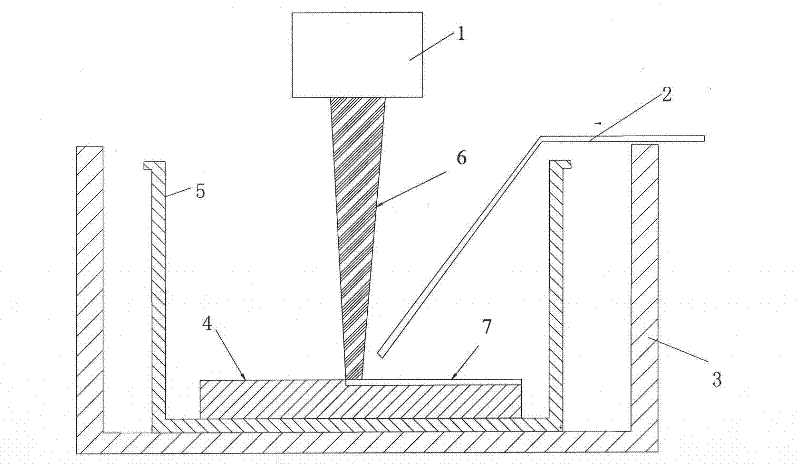

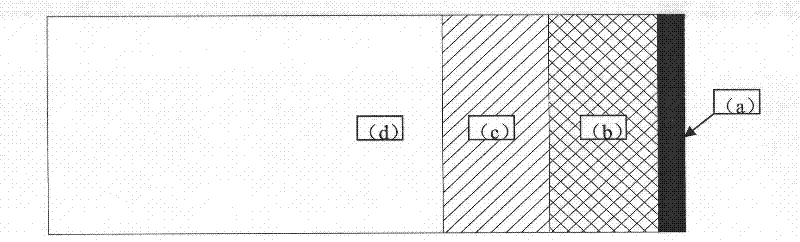

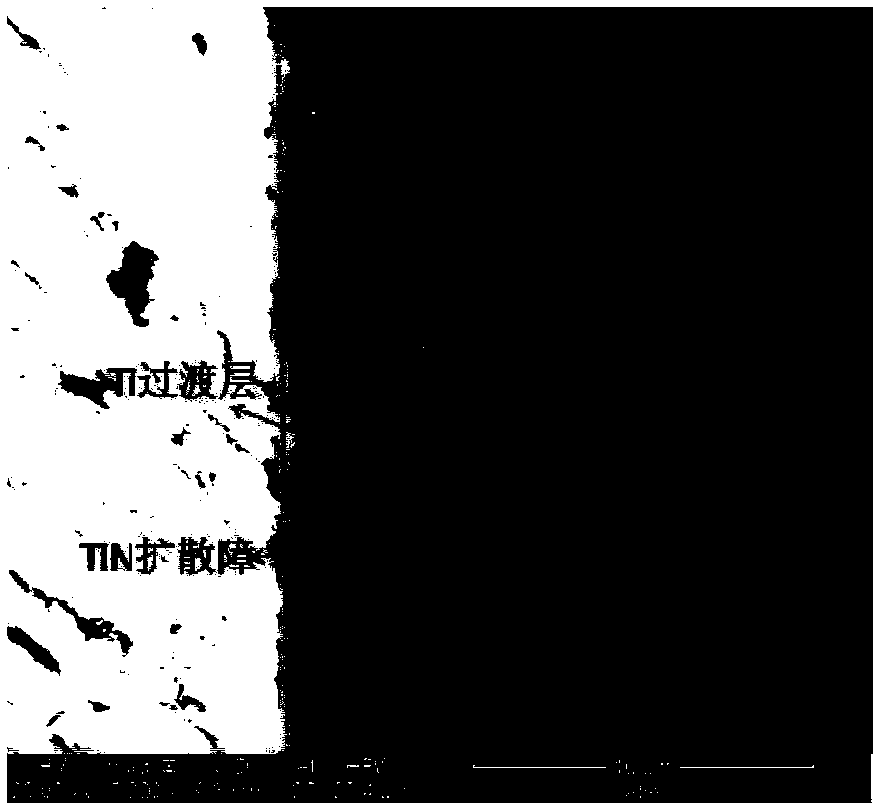

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

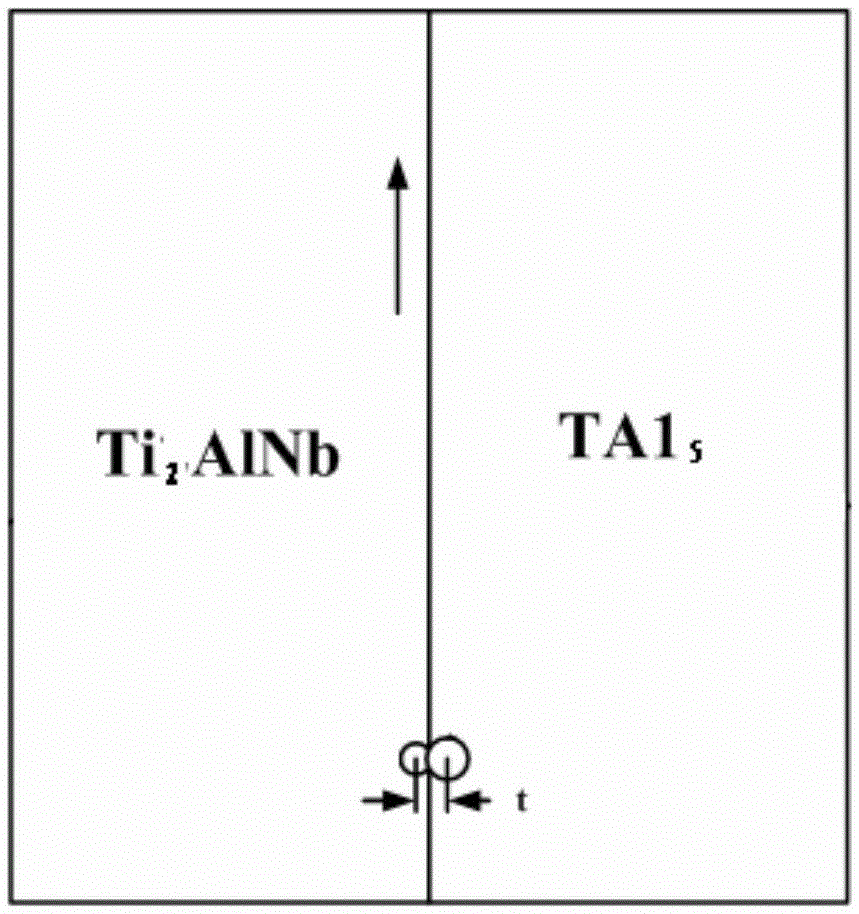

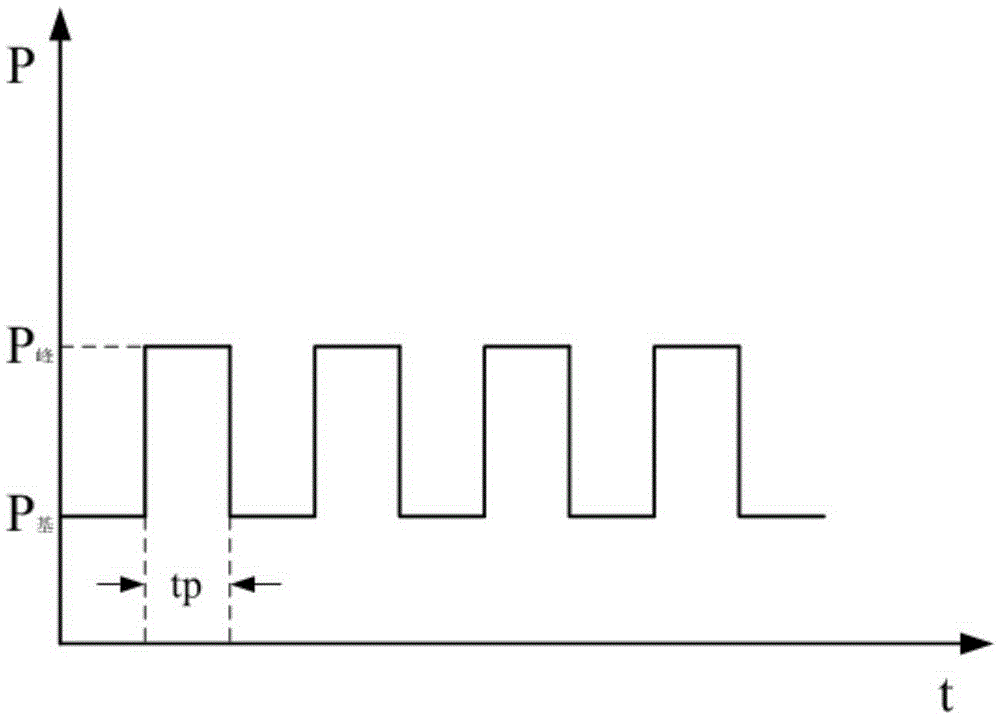

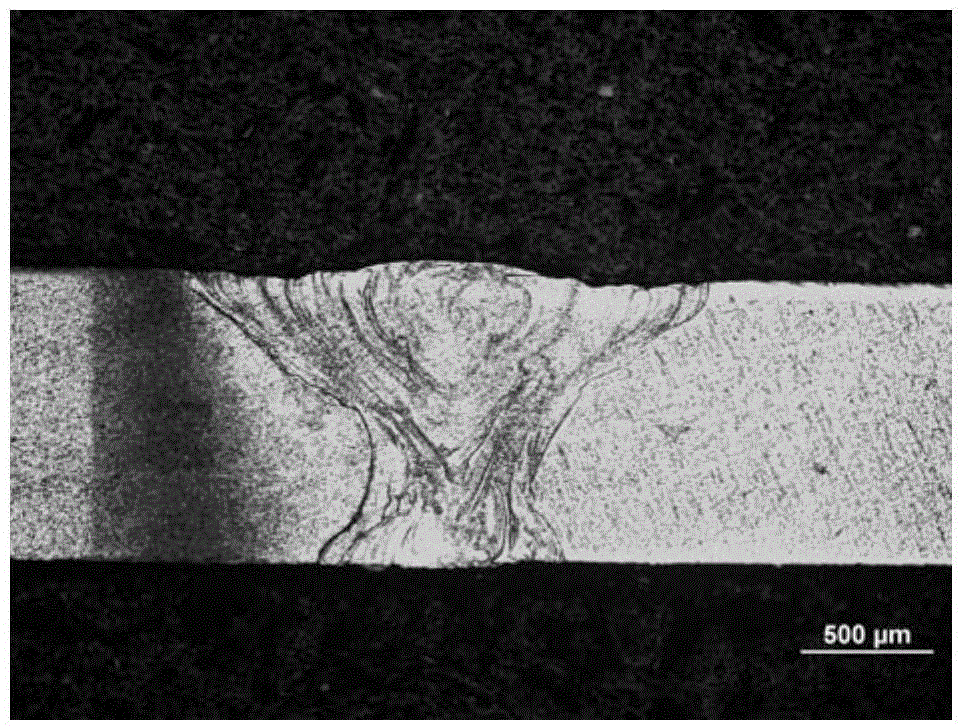

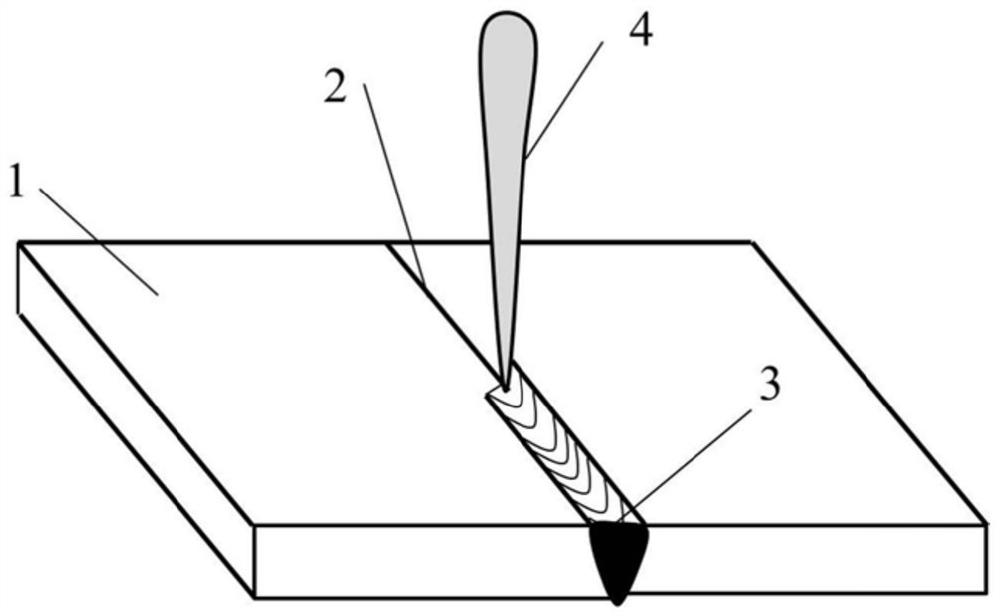

Laser welding method for TA15/Ti2AlNb dissimilar material

ActiveCN105397292AReduce weld cold crack susceptibilityLow costWelding/soldering/cutting articlesLaser beam welding apparatusPulsed modeTitanium alloy

The invention discloses a laser welding method for a TA15 / Ti2AlNb dissimilar material. The laser welding method comprises the following steps: before welding, washing TA15 titanium alloy and a Ti2AlNb inter-metallic compound by using acid; drying and mechanically grinding; clearing away impurities such as surface scales and oil dirt; before welding, guaranteeing that the abutting assembling clearance of the TA15 titanium alloy and the Ti2AlNb inter-metallic compound is smaller than 0.05mm; afterwards, welding by using a Nd:YGA solid laser device in a pulse mode; protecting the front and rear surfaces of a welding line by adopting high-purity argon of which the purity is 99.99% in a side-by-side double-light-spot mode; gradually shrinking and closing a welding arc crater during repeated melting and solidification processes by adopting continuously-damped saw-toothed laser output. The laser welding method has the advantages that the cold crack sensitivity of the welding line of the TA15 / Ti2AlNb dissimilar material is effectively reduced; good internal quality and appearance quality of the welding line are obtained; the joint of the welding line is flat and good-looking and free of defects such as oxidation and cracks; relatively good comprehensive performances are obtained; the cost is lowered.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

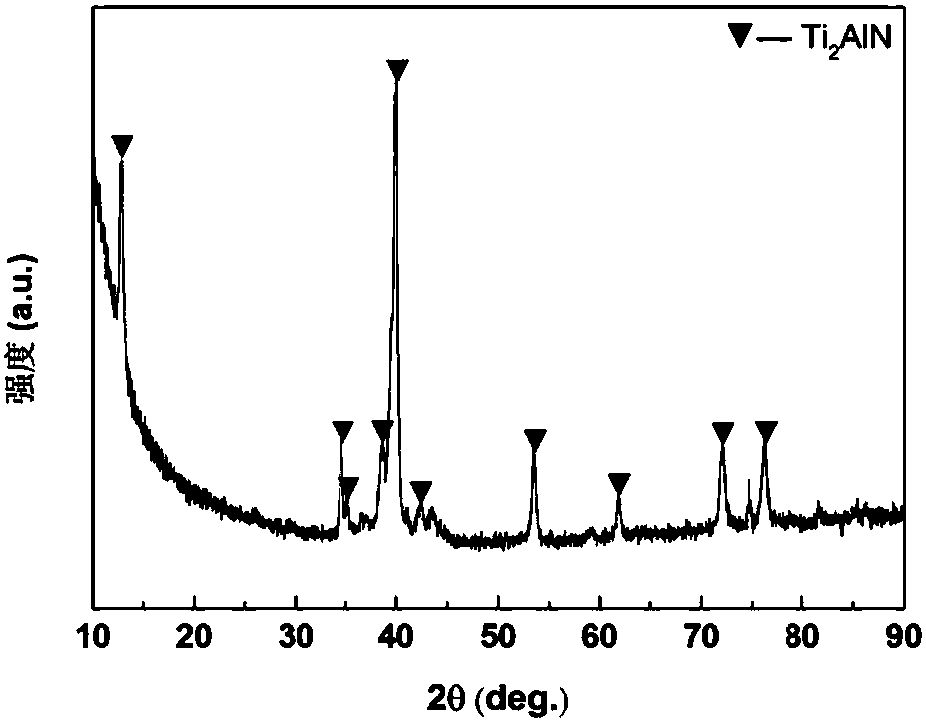

Preparation method for high-purity high-density MAX phase coating

ActiveCN107620033AEasy to controlEasy to homogenize large area depositionVacuum evaporation coatingSputtering coatingHigh densityNitrogen

The invention provides a preparation method for a high-purity high-density MAX phase coating. According to the method, an arc ion plating technology is combined with a magnetron sputtering technology,an M-position element is provided for the arc, an A-position Al element is provided for magnetron, nitrogen or hydrocarbon as reaction gas is introduced for deposition, then thermal treatment is adopted, and the high-purity high-density MAX phase coating is prepared. The prepared MAX phase coating is high in purity, good in compactness, free of a microdefect, high in preparation efficiency, low in cost and capable of overcoming the defects that large particles on the surface of a MAX phase coating prepared through a single arc method are excessive, the density is low, the efficiency is low bymeans of a magnetron sputtering method, and the defects are obvious and has the wide application prospects on the aspects of high-temperature protection, corrosion-resistant application and the like,and the industrial production of the MAX phase coating can be achieved easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

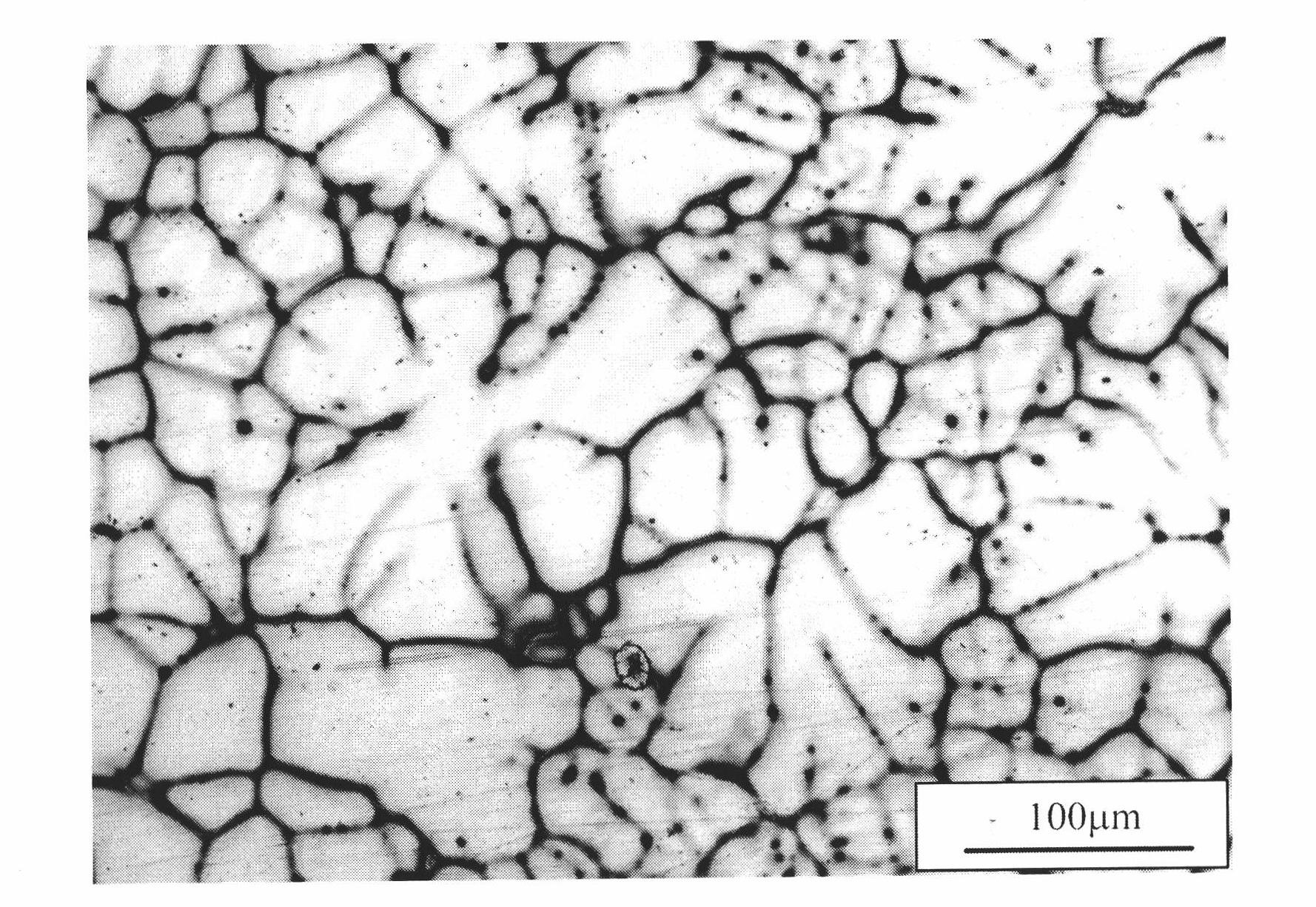

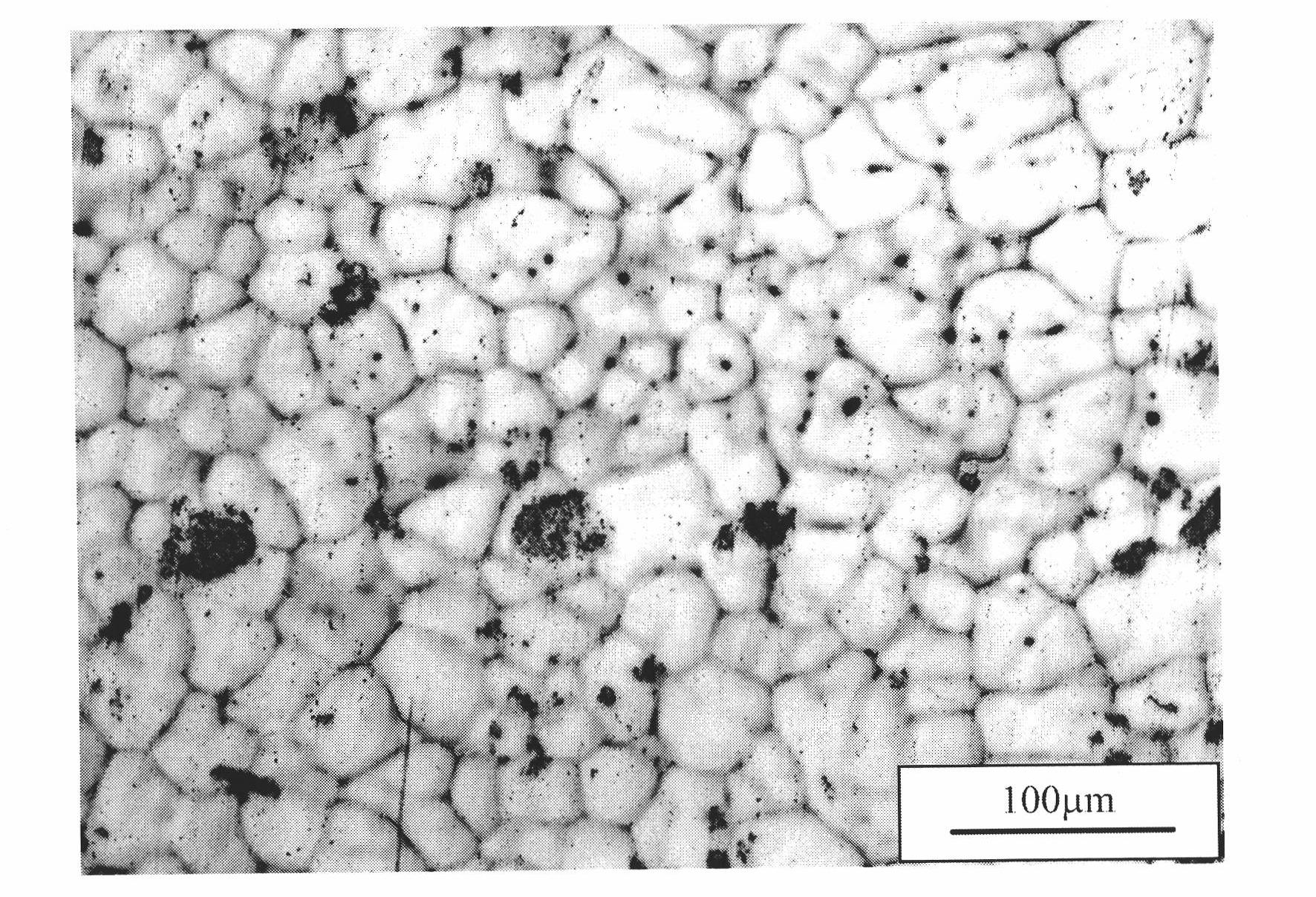

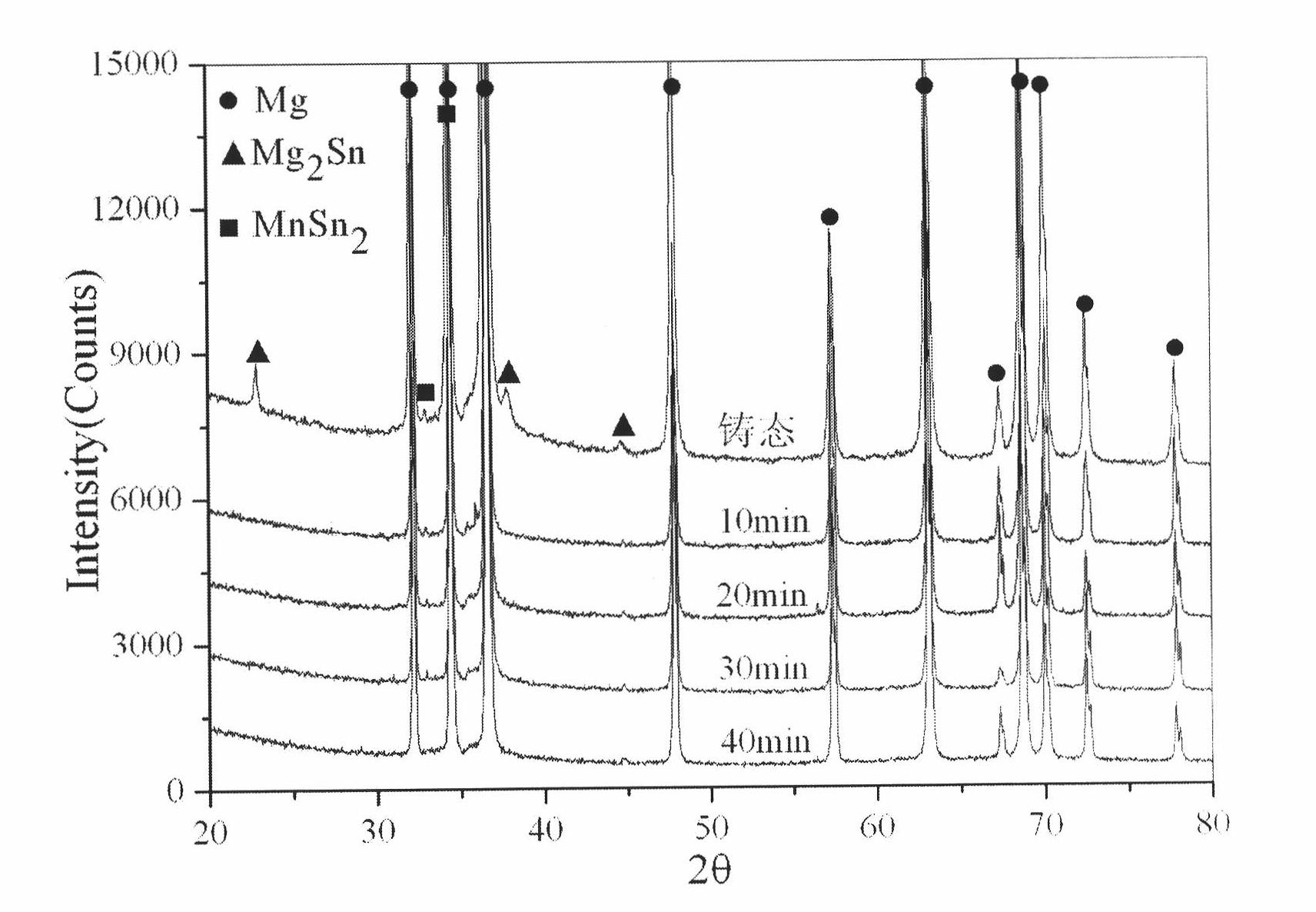

Biomedical Mg-Sn-Mn series magnesium alloy and plate rolling process thereof

ActiveCN101831580AImprove corrosion resistanceRaise the allowable limitTemperature control deviceMetal rolling arrangementsInternal fixationImpurity

The invention provides a biomedical Mg-Sn-Mn series magnesium alloy and a plate rolling process thereof. The process is characterized in that: an Mg-Sn-Mn series magnesium alloy ingot comprising 1 to 3 percent of Sn, 0.15 to 1.0 percent of Mn, less than 0.002 percent of impurity element Fe or less than or equal to 0.02 percent of Fe / Mn, less than 0.002 percent of Cu, less than 0.002 percent of Ni and the balance of Mg is selected; a uniform thermal treatment process combining high-temperature short-time solid solution treatment and traditional solid solution treatment is adopted before rolling the ingot, wherein the temperature of the high-temperature short-time solid solution treatment is 550 to 560 DEG C and the treatment time is 1 to 2 hours, and the temperature of the traditional solid solution treatment is 300 to 450 DEG C and the time is 20 to 30 hours; and variable temperature large-deformation rolling is adopted during rolling. The Mg-Sn-Mn series magnesium alloy obtained by the rolling process has the advantages of no toxicity, full degradation and high toughness, and can be used as an orthopedic surgery internal fixation and implant material for intravascular stents, bone lamellas, bone nails and the like.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

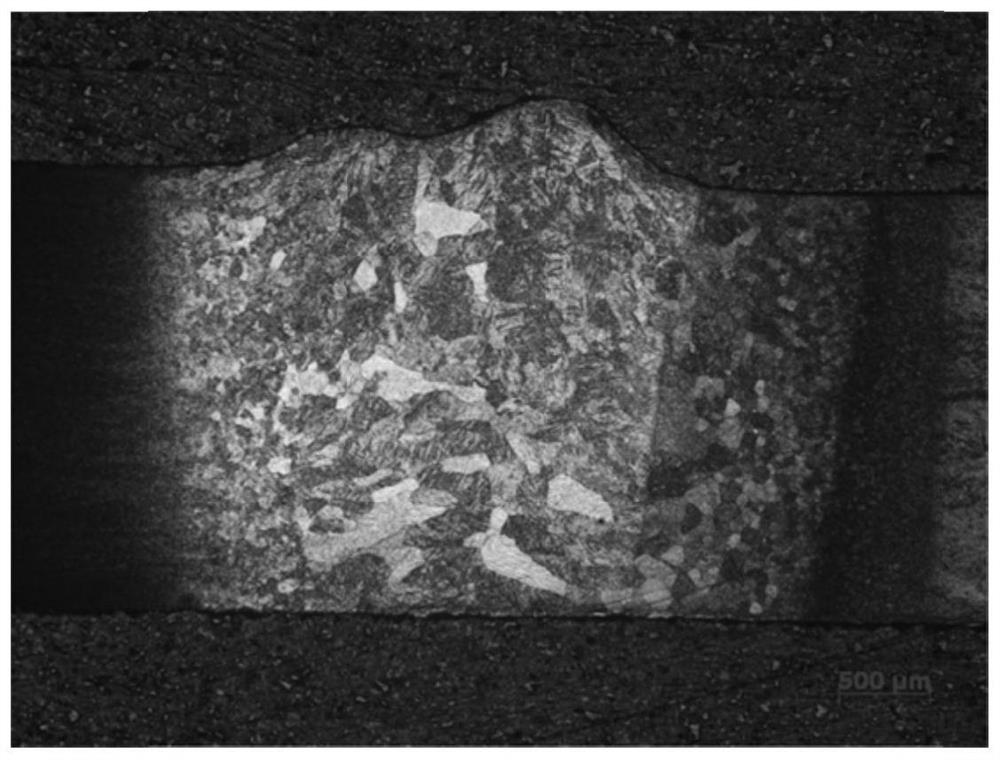

High alloy matrix metal-ceramic composite and preparation method thereof

The invention discloses a high alloy matrix metal-ceramic composite and a preparation method thereof, and belongs to the field of wear-resistant materials. According to the high alloy matrix metal-ceramic composite, the volume ratio of high alloy matrix materials to metal-ceramic reinforced particles is (1-10):1; the high alloy matrix materials comprise 1-8% of C, main alloying elements, minor additive elements and the balance Fe and unavoidable impurities; the main alloying elements comprise 0-60%of Ni, 0-60% of Mo, 0-40% of Cr, 0-30% of Mn, 0-20% of V, 0-20% of Ti, 0-15% of W and 0-15% of Nb; and the minor additive elements are one or more of B, Si, Zr, Cu, Co, Al and rare earth. The preparation method adopts a programmed temperature-controlled liquid phase sintering method for preparation and can be used directly for wear-resisting materials, or for wear-resisting materials after subsequent heat treatment; and the metallurgical bonding interface between the reinforced phase and thehigh alloy matrix in the composite reaches 40[mu]m-1mm, no cracks occurs after the integral heat treatment, and the service conditions in the wear-resistant material field are met.

Owner:NORTHEASTERN UNIV

Process for surfacing stainless steel sealing face on ductile cast iron valve base

InactiveCN102785004AImprove work efficiencyStrong heat resistanceArc welding apparatusWelding/soldering/cutting articlesButt weldingGas metal arc welding

The invention discloses a process for surfacing a stainless steel sealing face on a ductile cast iron valve base. The process includes firstly preheating and cleaning up the valve base; adopting pulse gas metal arc welding; performing full-automatic welding, pulsed direct current, anode reversed connection, and protection through argon and carbon dioxide mixed gas, wherein the flow is 18-25L / min and the welding speed is 8-15cm / min; cladding a stainless steel welding cladding with the thickness of 2.5-6mm at a to-be-welded position of the valve base after the welding; and then placing the valve base at the temperature of 350-400 DEG C for 2 hours. The process has the advantages that the welded sealing face is reliable in strength and stable in performance, and has no defects such as air holes and cracks; the utilization rate of welding materials is high, the process is simple, convenient to operate, and capable of achieving automation; and compared with spinning, boxing and stainless steel ring embedding processes, a plurality of processes such as marking, blanking, plate rolling, butt welding and spinning are omitted, and the process is suitable for automatic welding and batch production.

Owner:ZHENGZHOU ZHENGDIE VALVE CO LTD

Process for clearing metal grinding materials for derusting by using special steel wires for steel wire rope

The invention discloses a process for clearing metal grinding materials for derusting by using special steel wires for a steel wire rope, which is carried out according to the following steps: (1), disassembling the steel wire rope into single steel wires and classifying according to the diameters; (2), cutting the steel wires into cylindrical steel wire cutting segments by using a steel wire segment cutting machine; (3), putting the cylindrical steel wire cutting segments into a round casting machine, and repeatedly and circularly casting for 30-100 minutes at a speed of 75meter / second until the cutting segments are round to form steel grits; (4), carrying out roundness separation on the steel grits in a round separation machine; (5), screening the steel grits subjected to the screening by the round separation machine to screen scraps; and (6) packaging and putting in storage. With the adoption of the process method, the produced metal grinding materials have high quality and long service life and are suitable for surface clearing and derusting of various workpieces.

Owner:TIANJIN XINCHAO AST STEEL & ABRASIVE FOUNDRY

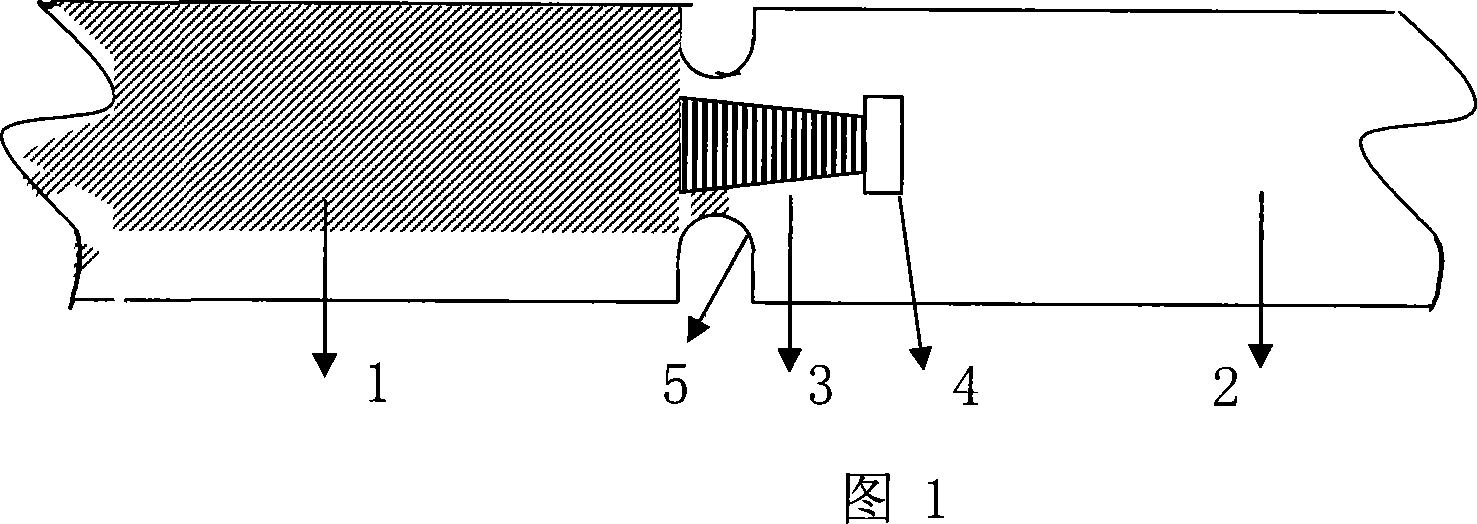

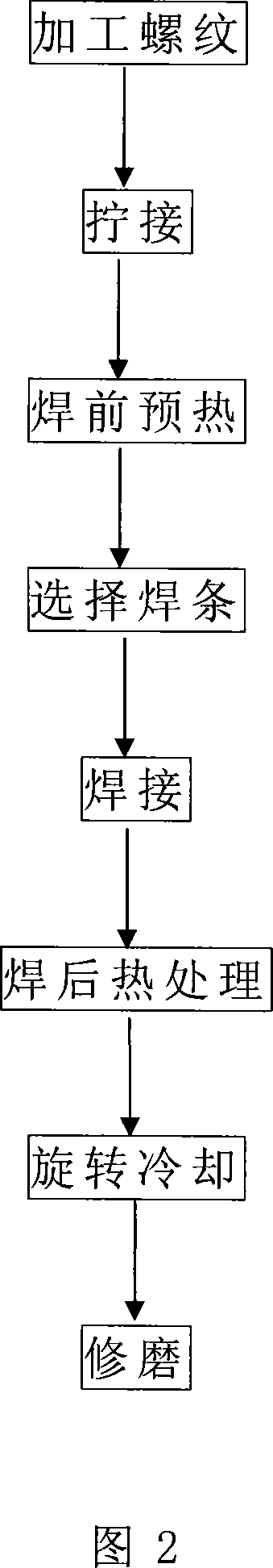

Welding technology for broken and waste core rod

ActiveCN101058139AService life reachedService life reaches or exceedsMandrelsMetal rolling arrangementsWorking environmentEngineering

The invention relates to a broken core bar welding process that comprises the thread processing and extension, preheating and welding bar selection, heat treatment after the welding, rotary cooling and grinding. In the process of preheating and welding bar selection, it welds continuously at one time to maintain the temperature between layers. In after welding heat treatment, it is cooled gradually using heat insulating material covering the welding spot under working environment lower than 5deg.C. It uses broken core bar to weld into qualified core bar blank, after lathe processing to reach the durability of the imported ones. If there isn't any crack occur, it means that the welding has reached expectation. It reduces the imported core bar blank with reduced capital and improved productivity.

Owner:TIANJIN PIPE GROUP CORP

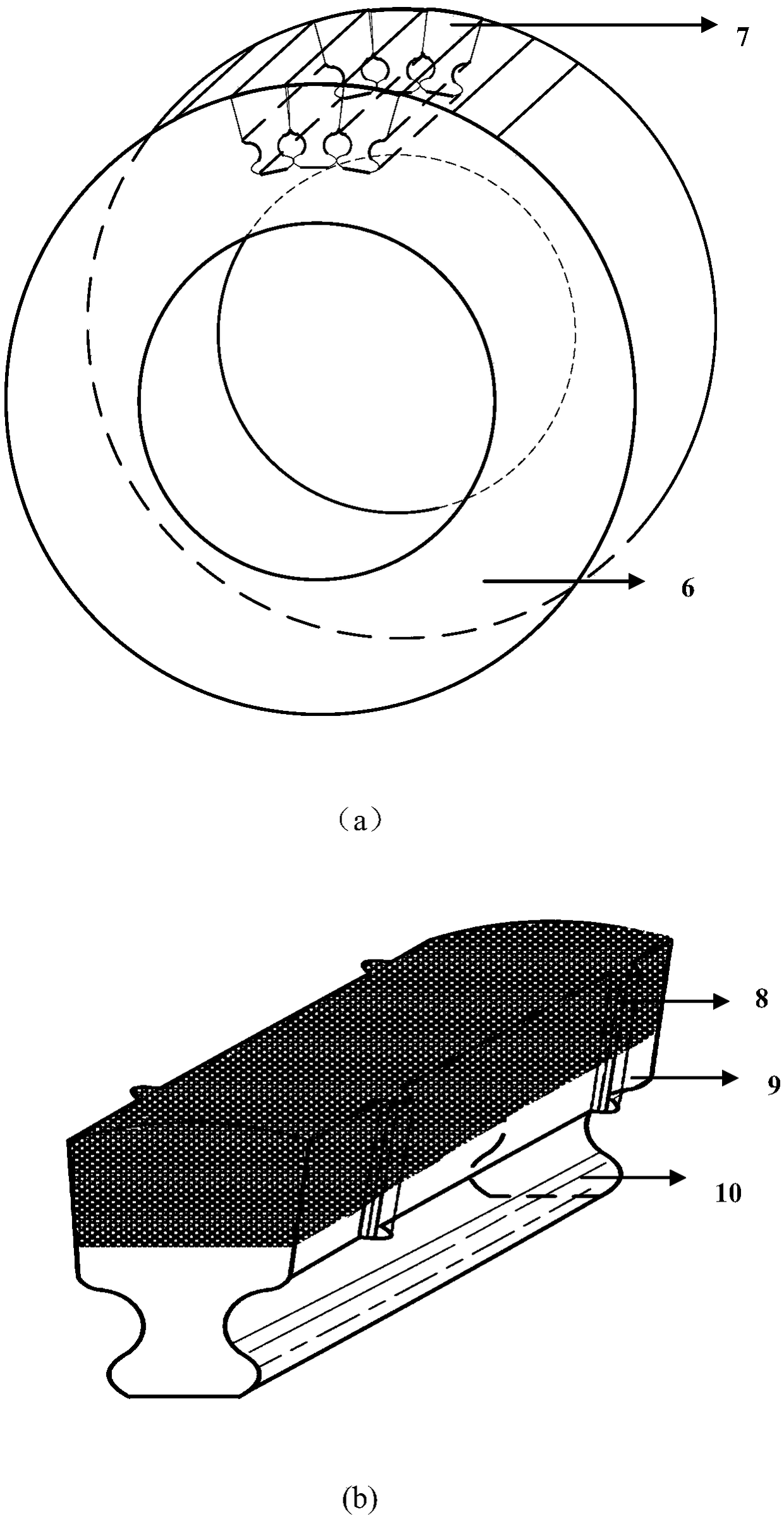

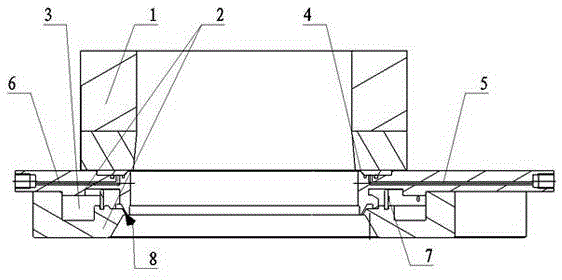

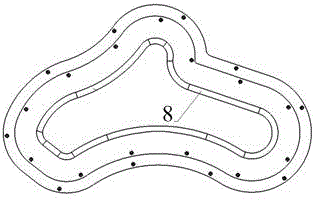

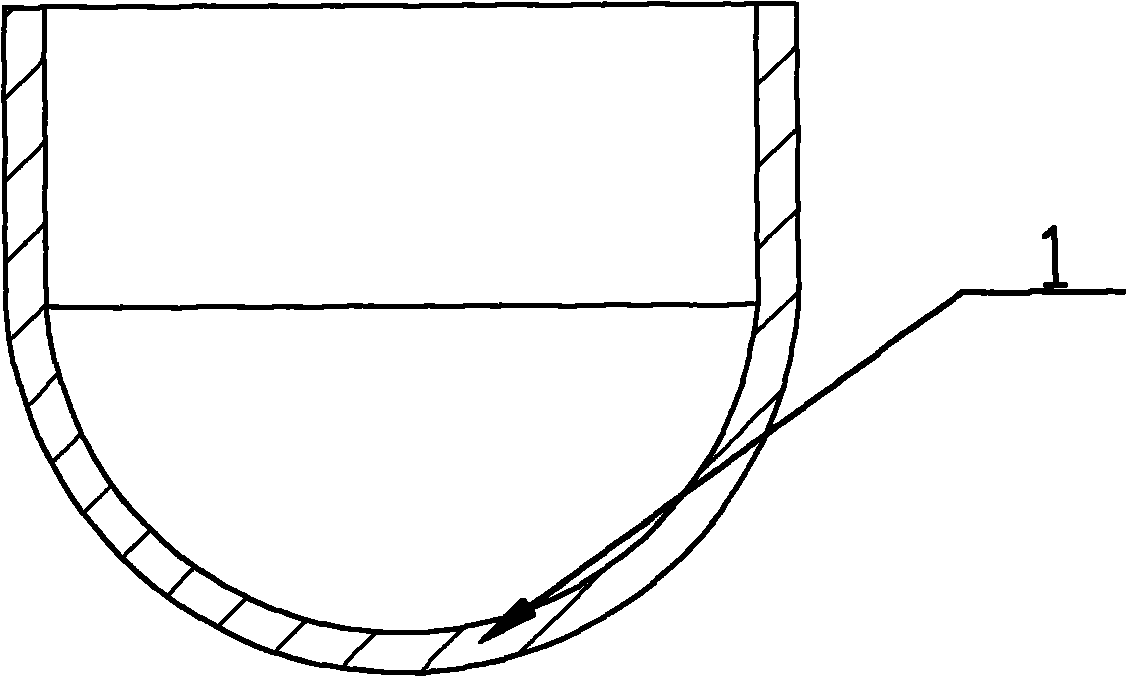

Semi-continuous casting crystallizer for aluminum alloy near net shape cast ingot

The invention relates to a semi-continuous casting crystallizer for an aluminum alloy near net shape cast ingot. The semi-continuous casting crystallizer comprises a crystallizer body and a thermal insulation hot top, wherein the thermal insulation hot top is arranged on the crystallizer body, an oil-gas distribution ring is arranged between the thermal insulation hot top and the crystallizer, gas injection holes and oil injection holes are uniformly distributed in the oil-gas distribution ring along the circumferential direction, the crystallizer body comprises a cooling water cavity and water spray structures communicated with the water cavity, the water spray structures are water seam structures with unequal widths, so that the cooling water flow in the circumferential direction of the crystallizer is a non-equivalent value. According to the crystallizer, liquid metal can be restrained, so that the liquid metal is condensed to a required shape of the cast ingot, and the cast ingot has a smooth surface and consistent quality to meet the dimensional requirements on subsequent thermal forming of the cast ingot. The cast ingot has stable forming condition, smooth surface and no defects, such as a drawing stamp and a gap.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Iron chromium aluminum alloy vacuum melting technology

The invention discloses an iron chromium aluminum alloy vacuum melting technology. The overall technological process mainly comprises a fusion stage, a primary refining stage, a primary alloying stage, a secondary refining stage, a secondary alloying stage and an electrification pouring stage; and a top pouring type mother alloy pouring system is adopted, and a round bar is poured. The iron chromium aluminum vacuum melting technology solves the problems that in the iron chromium aluminum alloy production process, aluminum elements are greatly lost under the oxidation, a large quantity of cracks exist inside a steel ingot, and a central shrinkage hole has defects, and meanwhile, the chemical component of an iron chromium aluminum alloy can be accurately controlled.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Brazing connection method for W/CuCrZr poling module

The invention belongs to the technical field of metal materials and relates to a brazing connection method for a W / CuCrZr poling module. The method is implemented through the following steps that firstly, oil stains, impurities and oxide films on the to-be-welded surface of a tungsten block with a drilled hole are removed; secondly, a layer of oxygen-free copper is cast onto the inner hole of the tungsten block by using a graphite casting die; a CuCrZr alloy pipe, solder and a tungsten block composite block are assembled, the solder is placed between pure copper liners of the CuCrZr alloy pipe and the tungsten block composite block, and then an assembly is put into a vacuum brazing furnace for welding; after completion of brazing, the assembly is quickly cooled to 470-480 DEG C and then is subjected to heat preservation at the temperature for 2-3h, and the W / CuCrZr poling module is formed, wherein the W / CuCrZr poling module comprises the CuCrZr alloy pipe, a brazing layer, a pure copper layer and the tungsten block in sequence from inside to outside. By means of the method, the efficiency is high, and a weld joint is combined well. The method has the advantages that the process is simple, and the preparation cost is low, and is suitable for large-scale industrial production.

Owner:SOUTHWESTERN INST OF PHYSICS

Welding technology

The invention discloses a technology, and particularly discloses a welding technology. The welding technology is characterized by comprising the following steps of material obtaining, clearing before welding, preheating before welding, positioning welding and postweld treatment. The welding technology has the advantages that the steps are simple, operation is convenient, time and labor are saved, safety and reliability are achieved, the stability is good, gas hole weld beading is avoided, concave and undercut phenomena are avoided, forming is good, non-welding defects, cracks and the like are avoided, the requirements for resisting intergranular corrosion and embrittlement are completely met, welding engineering quality is ensured, and the working efficiency is greatly improved.

Owner:刘振宇

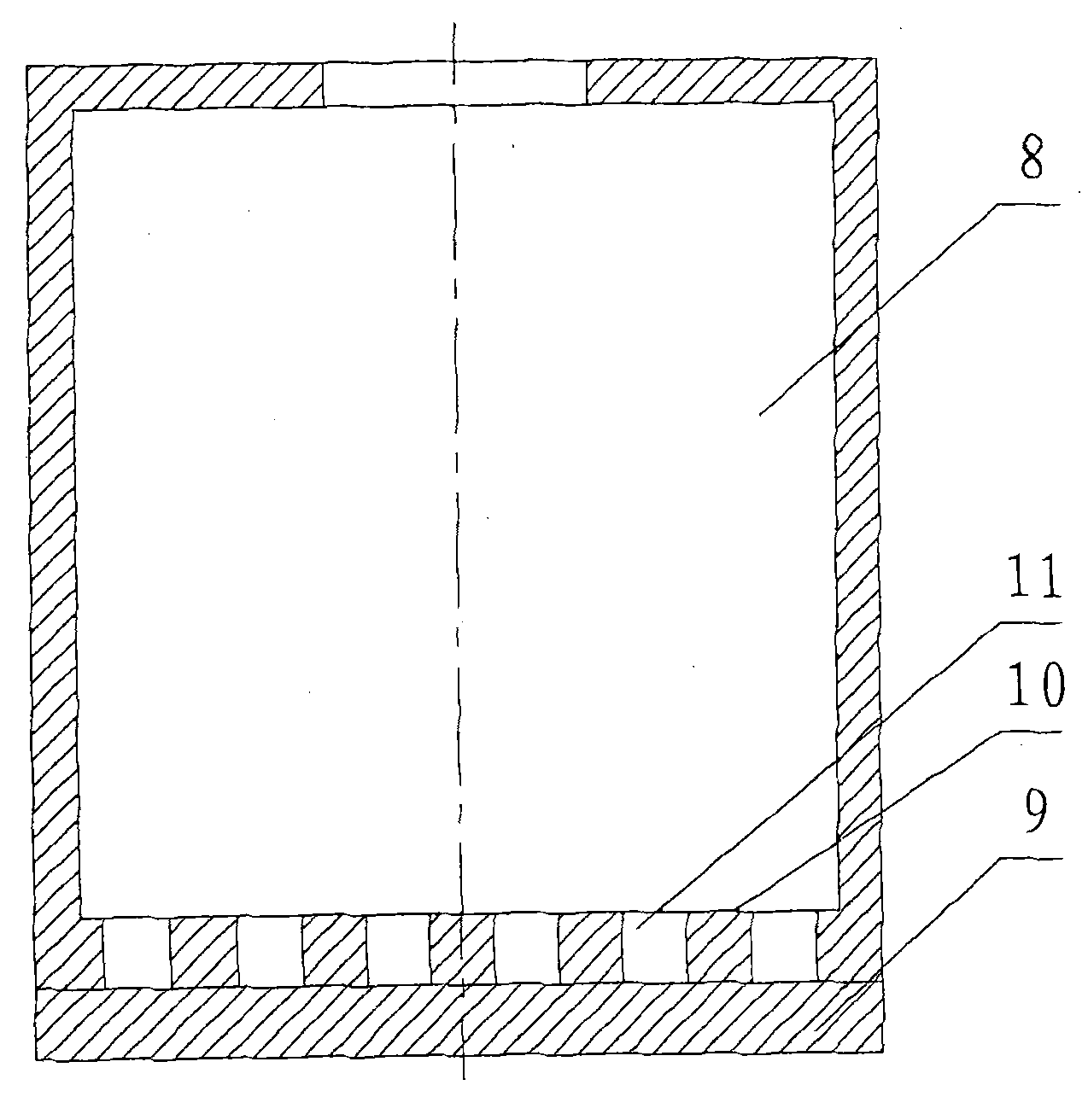

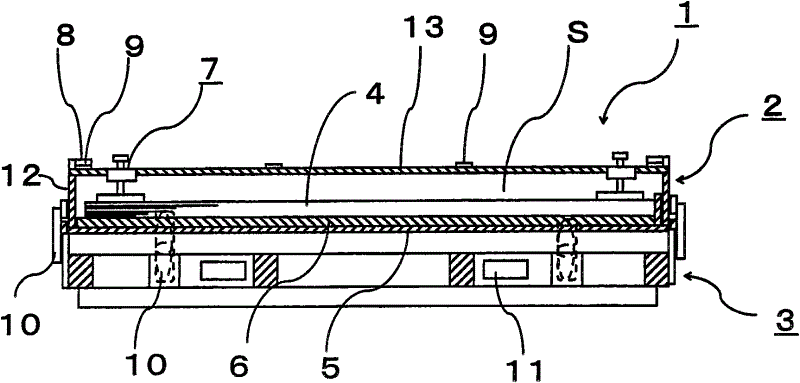

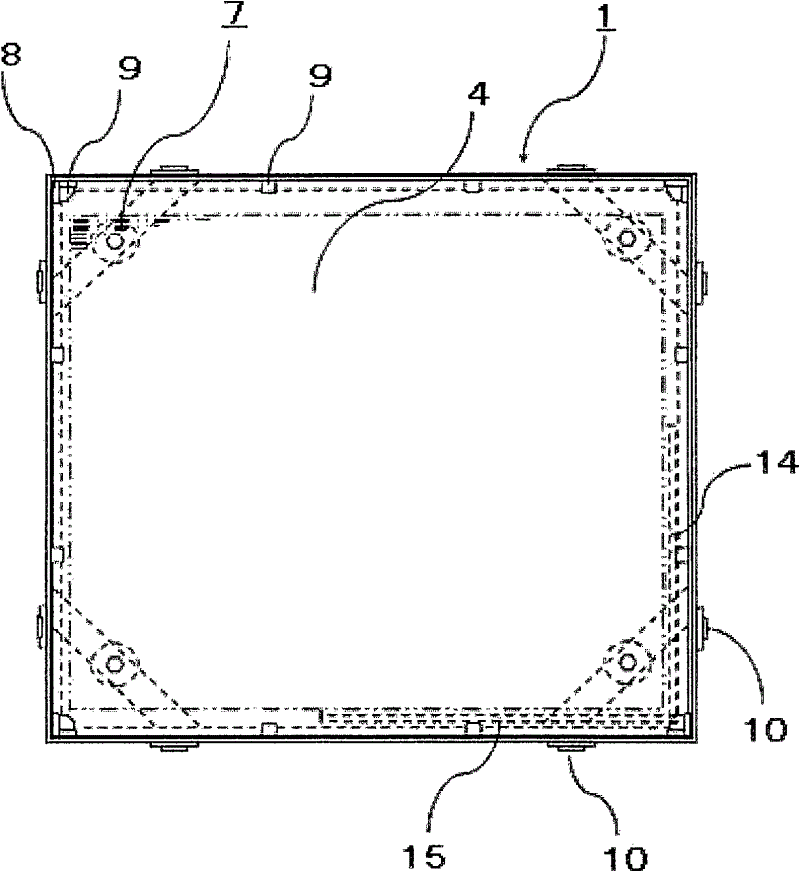

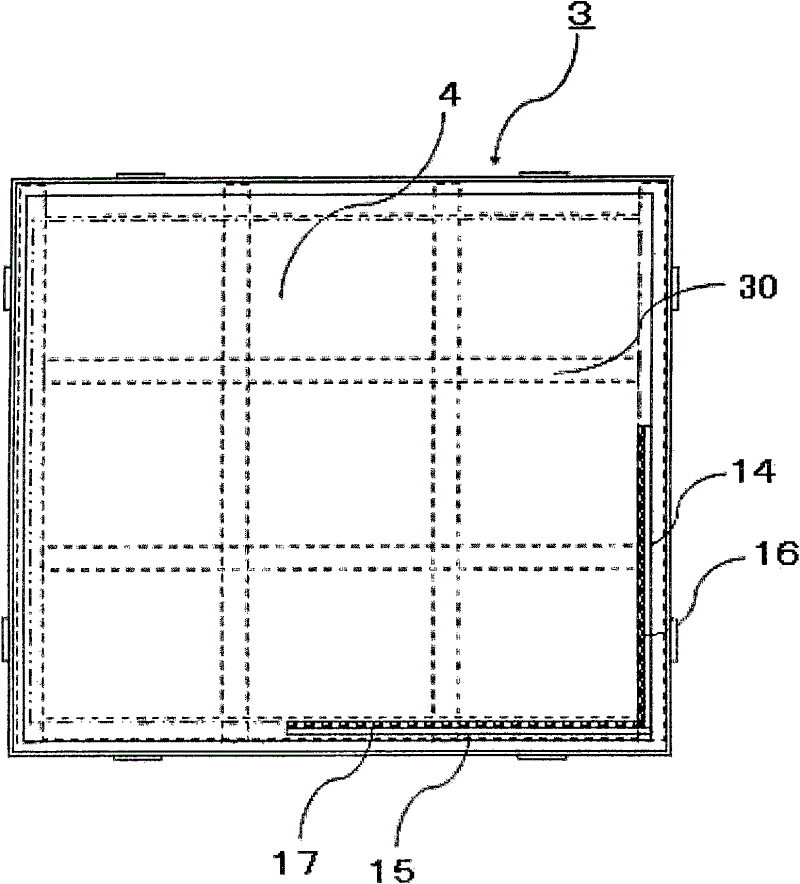

Large plate-shaped body packaging box

InactiveCN102616487ALower the altitudeNo incisionContainers to prevent mechanical damageRigid containersEngineering

The invention provides a large plate-shaped body packaging box, a method for transporting plate-shaped bodies by using the plate-shaped body packaging box, a method for loading the plate-shaped bodies, and a method for taking the plate-shaped bodies out. Dust is prevented from invading the packaging box, height during conveying is reduced, the packaging box can be easily stored in a storage room with a low top, and the plate-shaped bodies are efficiently and stably stored and transported. The plate-shaped body packaging box comprises a pedestal (3) with a veneer material, a plate-shaped body packaging box body (1) loaded on the pedestal (3), and an upper cover (2) which encircles the plate-shaped bodies (4) loaded on the pedestal (3) and can be assembled and disassembled relative to the pedestal (3), wherein the pedestal (3) is a supporting body with an open upper surface and comprises plate-shaped body protection materials (6) and side plates (14 and 15), a plurality of plate-shaped bodies (4) are fixed on the upper surface of the veneer material (5) in an approximately horizontally laminated state, and the side plates (14 and 15) are arranged on two sides in an L shape in the four sides; and the upper cover (2) consists of a top cover (13) which covers the upper surface of the plate-shaped body packaging box body (1) and side covers (12) on the four sides, has a shape of a box body with an open lower surface, and is provided with pressing pieces (7) which press the upper parts of the plate-shaped bodies.

Owner:ASAHI GLASS CO LTD

Humic acid slow release fertilizer suitable for long-term improvement of secondary salinization land

InactiveCN106396867AReduce alkalinityPromote reductionCalcareous fertilisersBioloigcal waste fertilisersAzotobacter chroococcumSlag

The invention discloses a humic acid slow release fertilizer suitable for long-term improvement of secondary salinization land. The humic acid slow release fertilizer comprises, by mass, 120-180 parts of crop wastes, 250-400 parts of humic acid, 160-200 parts of urea, 120-160 parts of nanometer calcium carbonate, 80-120 parts of mineral slag, 30-60 parts of high viscosity attapulgite clay powder, 8-20 parts of Azotobacter chroococcum, 800-1200 parts of a binder and 10-14 parts of a microbial fermentation agent. The above scientific and reasonable formula of the humic acid slow release fertilizer suitable for long-term improvement of secondary salinization land is obtained through a large amount of experiment researches carried out by the applicant, and the humic acid slow release fertilizer has fertilizing effect slow release and water retention functions, provides nutrient components needed by growth of plants, keeps no loss of nutrient components in a powdery saline and alkaline land water retention slow release fertilizer, and is in favor of realizing normal growth of the plants.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

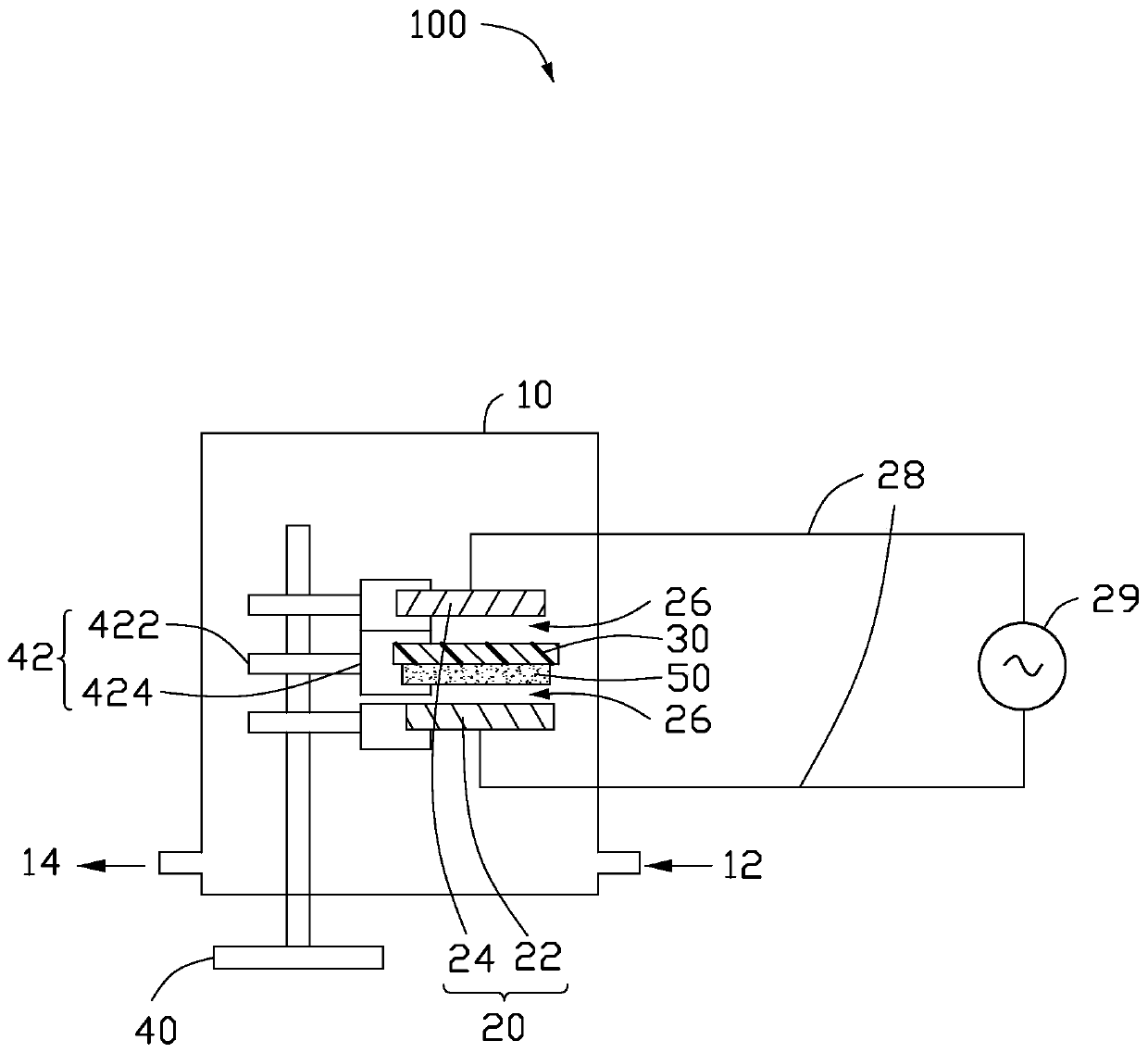

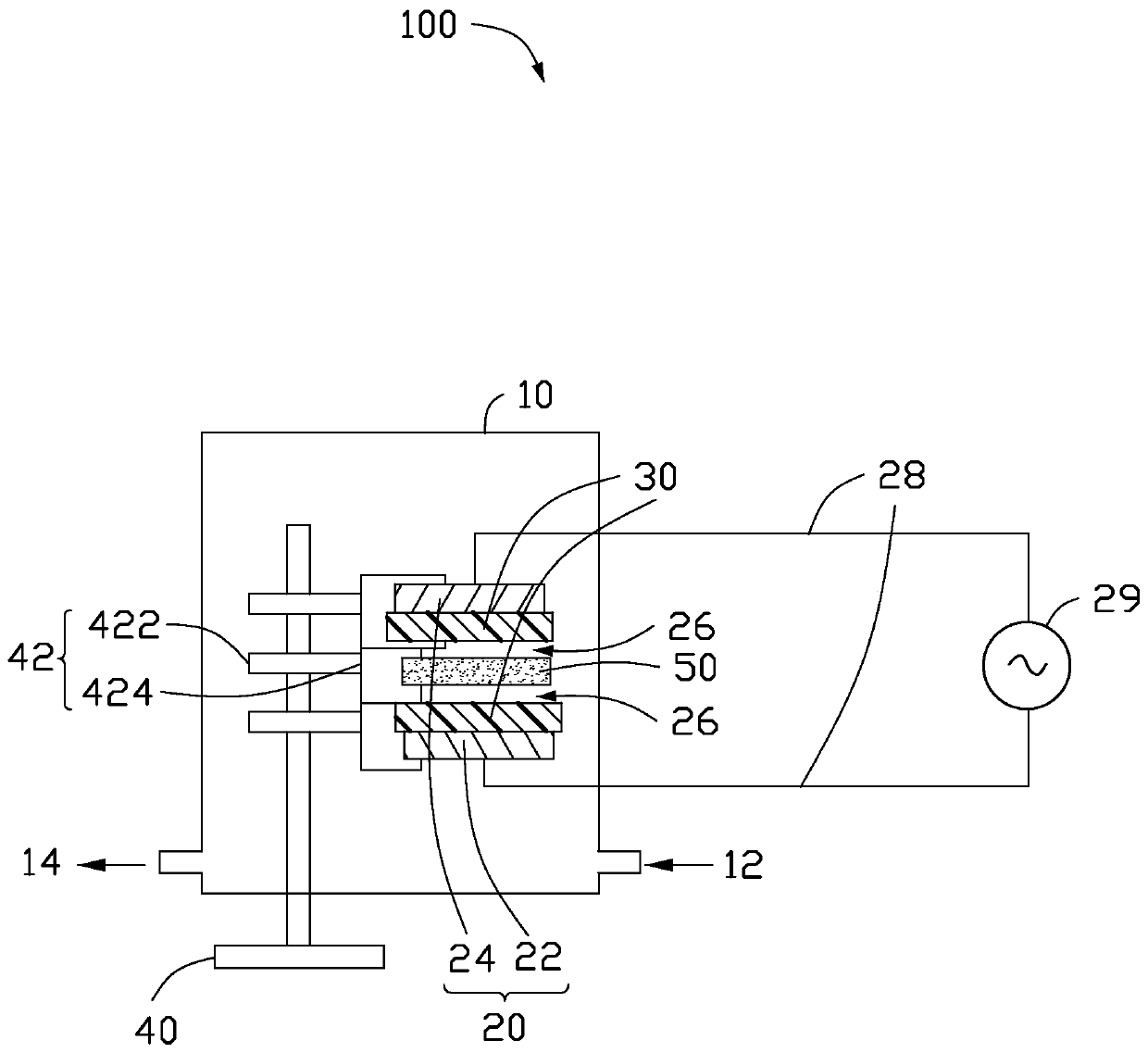

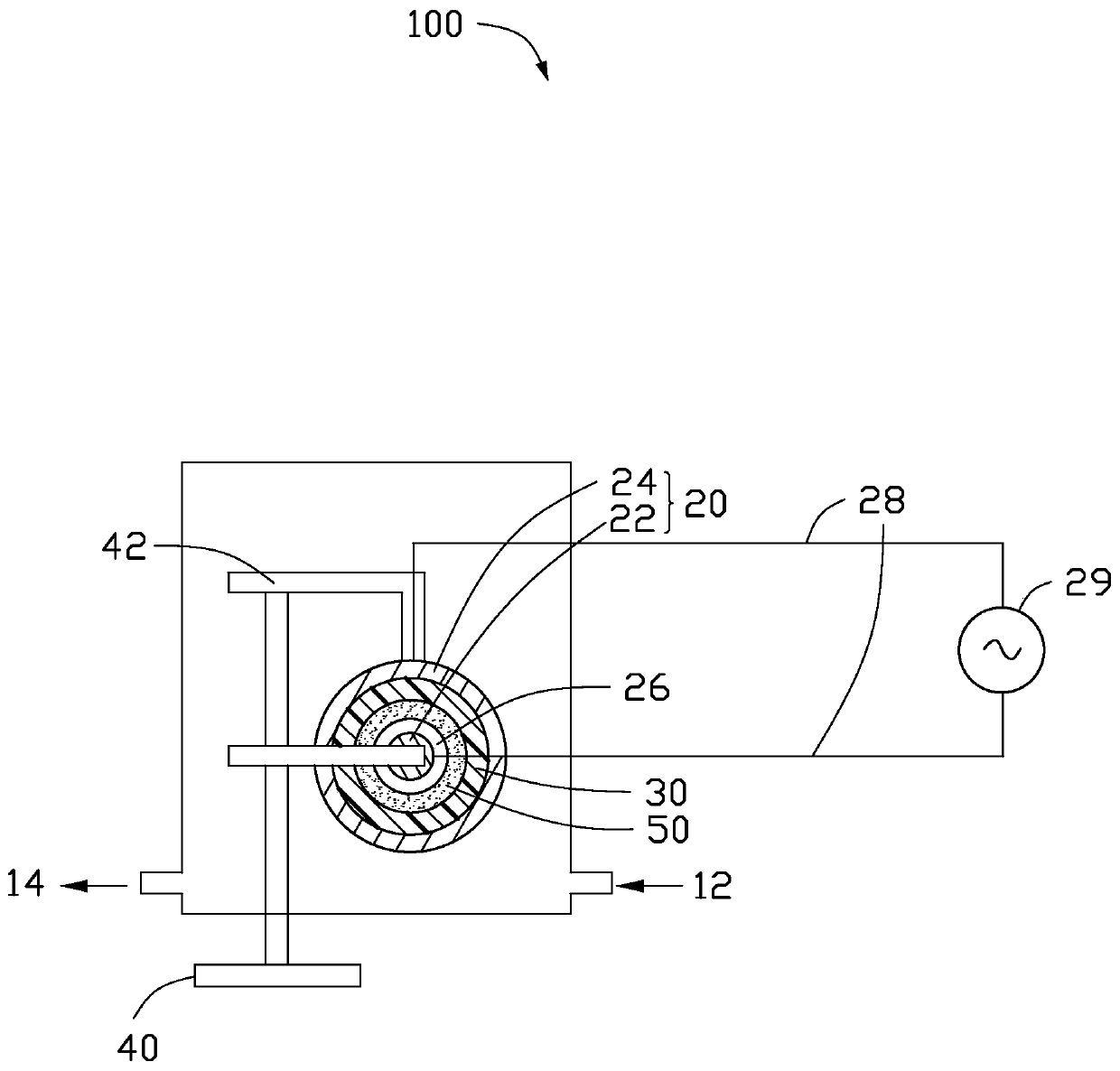

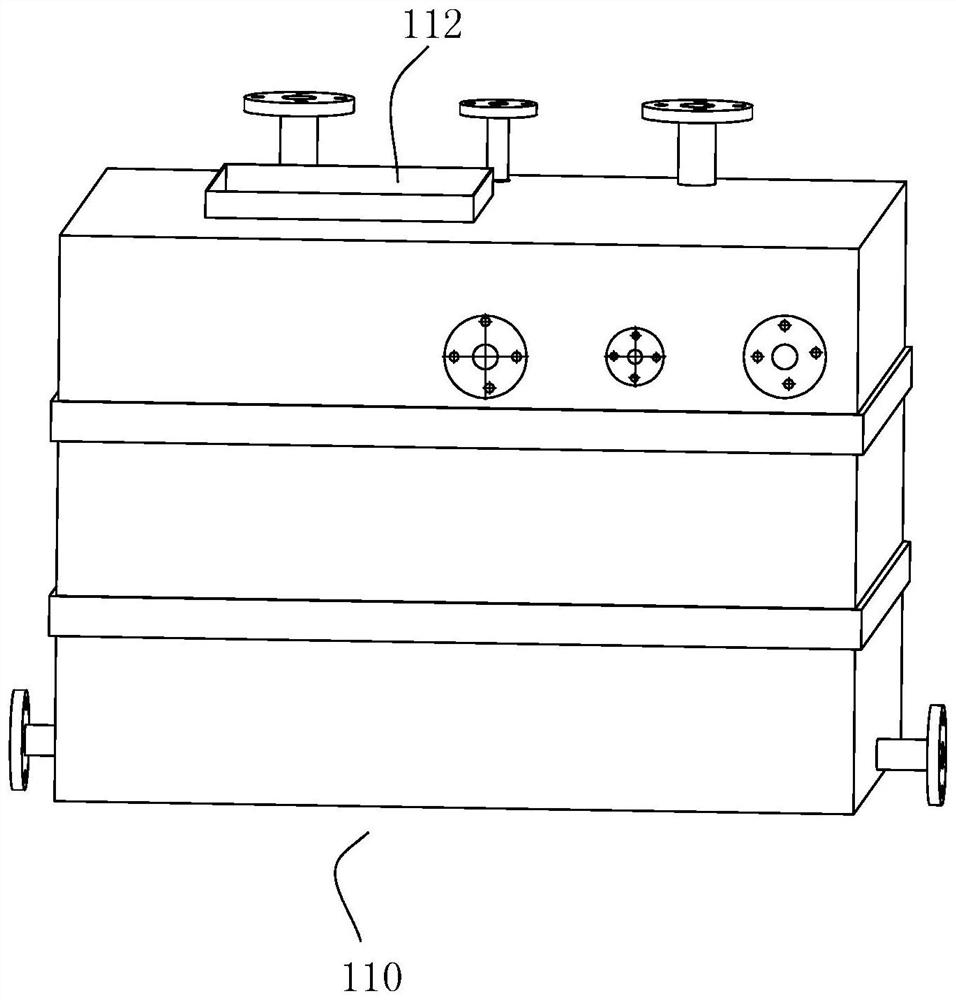

Ceramic sintering device and ceramic sintering method

InactiveCN110425877ASimple processEasy to operateFurnace typesElectric heating for furnacesCeramic sinteringMetallurgy

A ceramic sintering device is used for sintering a ceramic raw blank and comprises a box, an electrode, a stop medium and a fixing support. The electrode and the stop medium are arranged in the box through the fixing support. The electrode comprises a first electrode body and a second electrode body which are arranged in a spaced manner. The stop medium is arranged between the first electrode bodyand the second electrode body and is spaced from the first electrode body and / or the second electrode body. The fixing support is further used for fixing the ceramic raw blank between the first electrode body and the second electrode body, and the ceramic raw blank and the stop medium are arranged in an interval or spaced manner. The invention further provides a ceramic sintering method of the ceramic sintering device.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

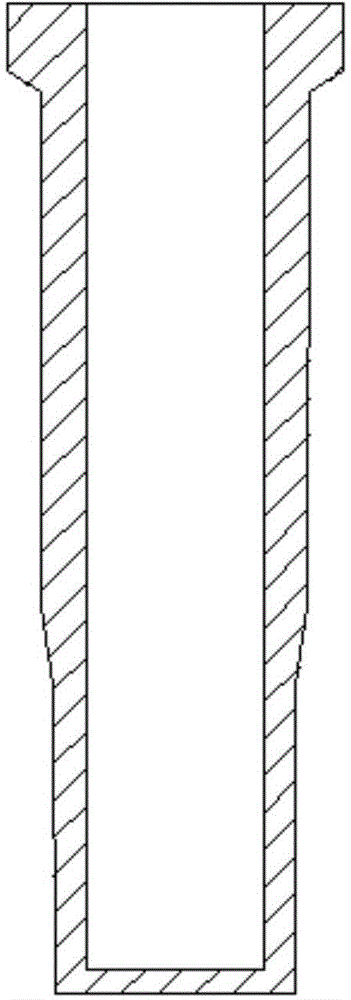

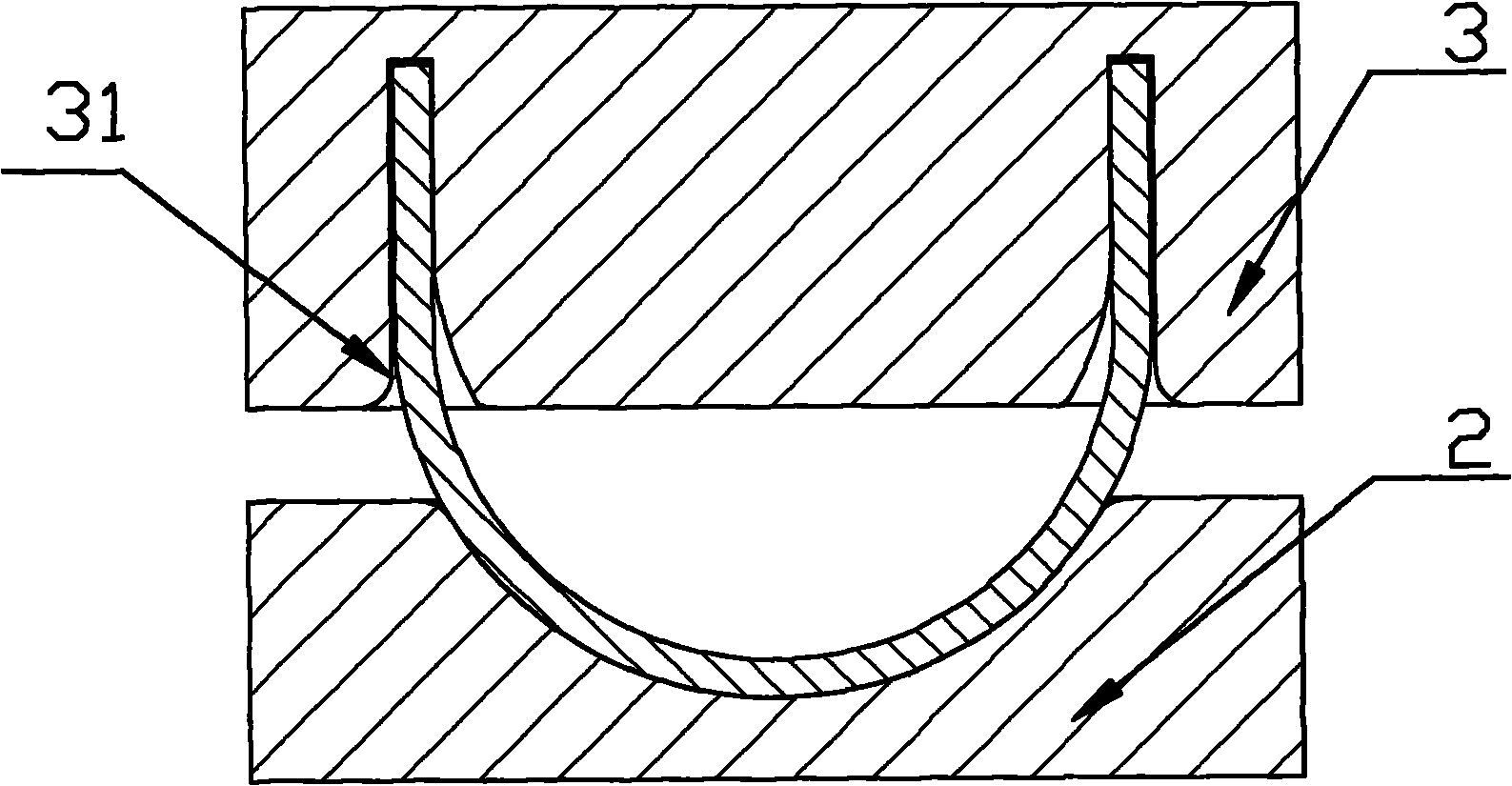

Inverted extrusion molding process of high pressure cylinder and inverted extrusion die adopted in inverted extrusion molding process

InactiveCN105478508AGuaranteed highly uniform inner diameterAvoid stickingExtrusion diesHeating furnaceHigh pressure

The invention discloses an inverted extrusion molding process of a high pressure cylinder and an inverted extrusion die adopted in the inverted extrusion molding process. The process includes the steps that a blank is heated to 800 DEG C after being blanked and is kept at the temperature for 90 minutes, and then the blank is heated to 1180 + / - 10 DEG C and kept at the temperature for 9 minutes; and the die is heated to 250-350 DEG C, a flange is subjected to upsetting in advance, then subjected to inverted extrusion molding, heated in a heating furnace to 910+ / -10 DEG C and kept at the temperature for 3.5 h, then air cooling is carried out, and finally a sample is fetched and subjected to physical and chemical inspection. A circle of outwards protruding annular extrusion belt is formed at the lower end of an upper die punch of the inverted extrusion die, a cylinder barrel female die is fixedly arranged on a lower die cushion plate, and the punch corresponds to a female die cavity of the cylinder barrel female die. A female die outer ring and a female die inner ring of a lower die make contact through a taper plane. An ejector rod of the lower die stretches into a penetrating hole of the cushion plate. A discharging device on the lower die can just be located over a workpiece in the female die cavity in a blocking mode. By means of the inverted extrusion molding process of the high pressure cylinder and the inverted extrusion die adopted in the inverted extrusion molding process, extrusion molding and demolding of a cylinder barrel with no draft bevel angle are achieved, the product structure is compact, the intensity is high, and usage is reliable and safe.

Owner:SUZHOU KUNLUN HEAVY EQUIP MFG

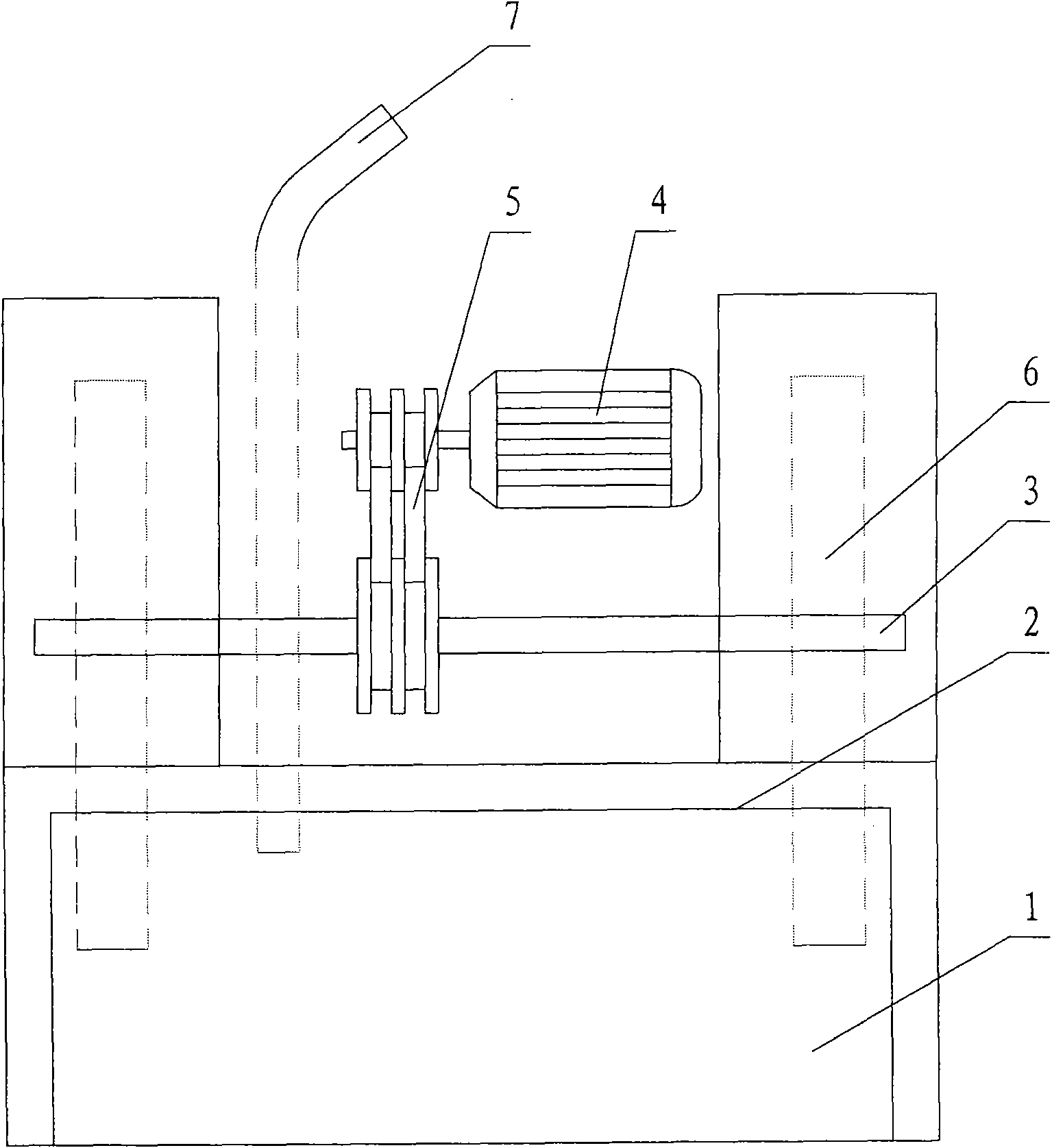

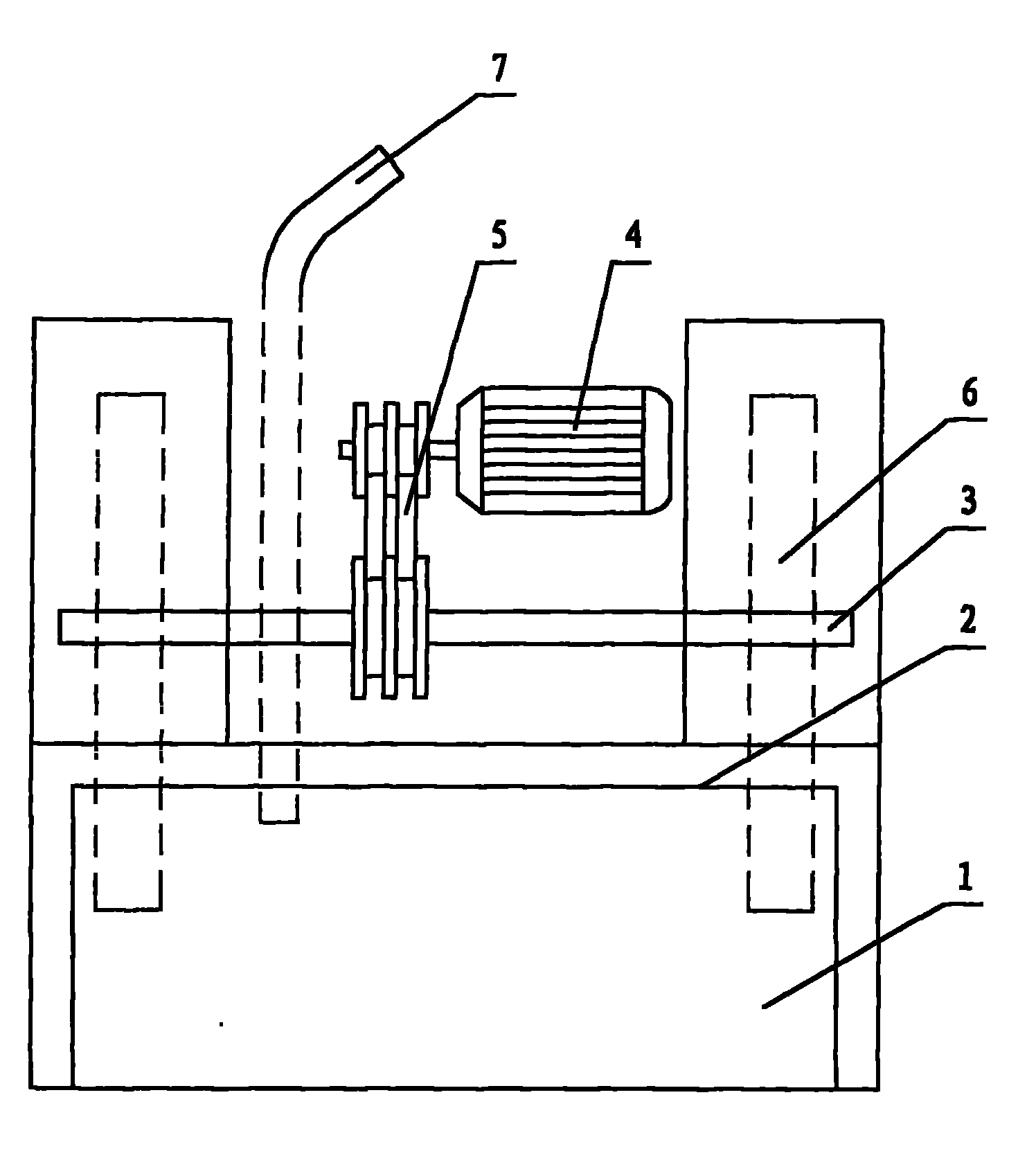

Method for laser manufacture of low speed heavy-duty ship diesel engine piston ring groove

InactiveCN106480447AExtended service lifeHigh hardnessMetallic material coating processesMelting tankLow speed

The invention relates to a method for laser manufacture of a low speed heavy-duty ship diesel engine piston ring groove. The method comprises: preparing required powder materials according to the components of alloy powder; before carrying out laser cladding work, cleaning a piston ring groove to ensure the absence of oil stains, impurities and the like; selecting a DL-HL-T5000 type CO2 gas lasers, using a synchronous powder conveying method, directly conveying alloy powder into a melting pool by using a gas carrying powder conveying device, and carrying out laser cladding on the end surface of the piston ring groove, wherein the thickness of the powder is 1.5-2 mm; and when the laser cladding is performed on the end surface of the piston ring groove, making a laser beam be obliquely incident into the piston ring groove, and coaxially blowing argon during the cladding process so as to protect, wherein the angle between the laser beam and the bottom surface of the ring groove is 35-38 DEG C. According to the present invention, the process parameters of the laser cladding and the ration of various elements in the powder material are optimized and designed, such that the cladding layer of the low speed heavy-duty ship diesel engine piston ring groove has characteristics of compact and uniform structure, and no defects such as gas holes, impurities, cracks, and the like.

Owner:沈阳大陆激光工程技术有限公司

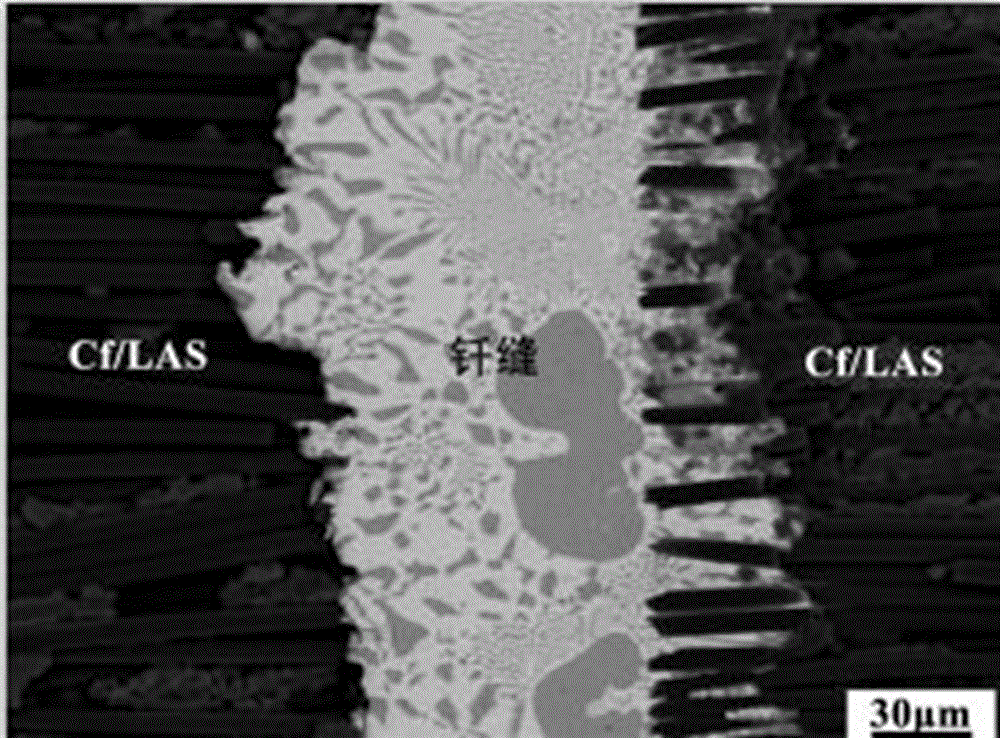

Method for connecting Cf/LAS composite material via AgCuTi brazing filler metal

InactiveCN104690386ARealize distributed controlImprove mechanical propertiesSoldering apparatusWelding/soldering/cutting articlesHeating furnacePumping vacuum

The invention discloses a method for connecting Cf / LAS composite material via an AgCuTi brazing filler metal. The method for connecting Cf / LAS composite material via the AgCuTi brazing filler metal comprises the following steps: step 1, machining the Cf / LAS composite material; step 2, processing the connection surface of the Cf / LAS composite material obtained in the step 1, placing the connection surface of the Cf / LAS composite material in the acetone solution and ultrasonic cleaning; step 3, placing the AgCuTi brazing filler metal between the connection surfaces of the Cf / LAS composite material to be connected, assembling the assembling piece with Cf / LAS composite material / AgCuTi brazing filler metal / Cf / LAS composite material overlapped in sequence; step 4, placing the assembling piece obtained in the step 3 in a vacuum heating furnace, pumping vacuum, electrically heating and cooling; the method for connecting Cf / LAS composite material via the AgCuTi brazing filler metal is mainly used for connecting the Cf / LAS composite material parts being smaller in size or simpler in shape together for obtaining the member being larger in size or complex in shape, the creep resistant property and thermal shock resistance of the high temperature structure can be improved and great application prospect can be achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

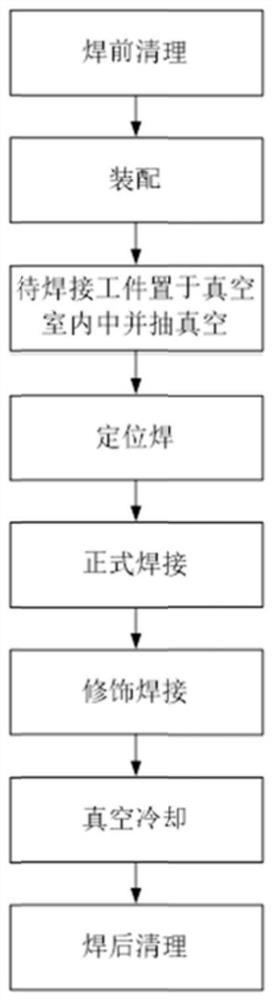

Electron beam welding method for TA15 and Ti60 dissimilar titanium alloy materials

PendingCN112676691AImprove the protective effectAvoid burnsElectron beam welding apparatusButt jointTitanium alloy

The invention provides an electron beam welding method for TA15 and Ti60 dissimilar titanium alloy materials. The electron beam welding method for the TA15 and Ti60 dissimilar titanium alloy materials comprises the following steps: a butt joint of a workpiece to be welded is fixed, and placed in a vacuum environment; positioned welding is carried out, wherein the parameters of the positioned welding are as follows: the length of each section of a weld joint is 20-25mm, the working distance is 400mm, the acceleration voltage is 50-60kV, the focusing current surface focus is +(0.01-0.03)A, the welding beam current is 10-25mA, and the welding speed is 600-800mm / min; formal welding is carried out, wherein the parameters of the formal welding are as follows: the working distance is 400 mm, the acceleration voltage is 50-60 kV, the focusing current surface focus is (-0.01 to +0.02) A, the electron beam current is 40-85 mA, and the welding speed is 600-800 mm / min; modified welding is carried out, wherein the parameters of the modified welding are as follows: the working distance is 400mm, the acceleration voltage is 50-60kV, the focusing current surface focus is +(0.02-0.04) A, the electron beam current is 30-50mA, and the welding speed is 600-800mm / min; and vacuum cooling and postwelding cleaning are carried out. According to the invention, the weld joint formed by welding is continuous, uniform and good in forming, defects such as air holes and cracks are avoided, and excellent mechanical property of the weld joint is achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

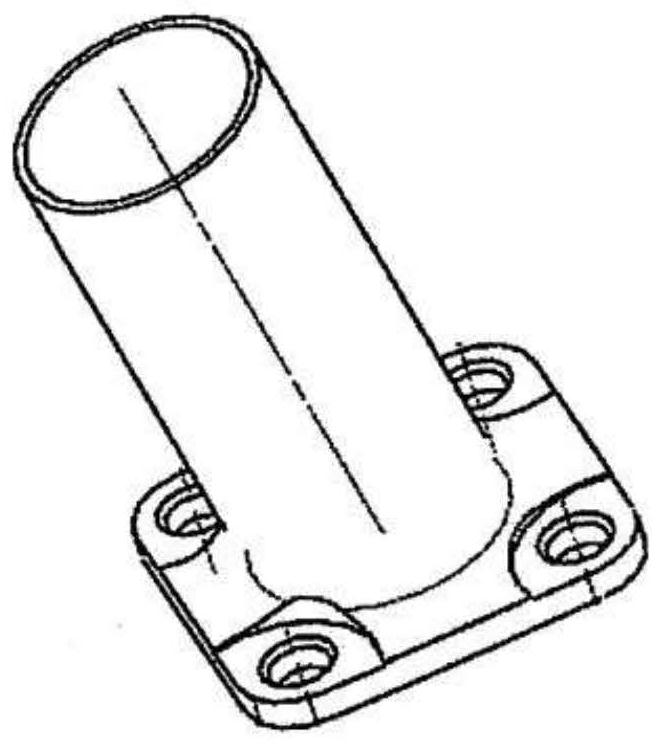

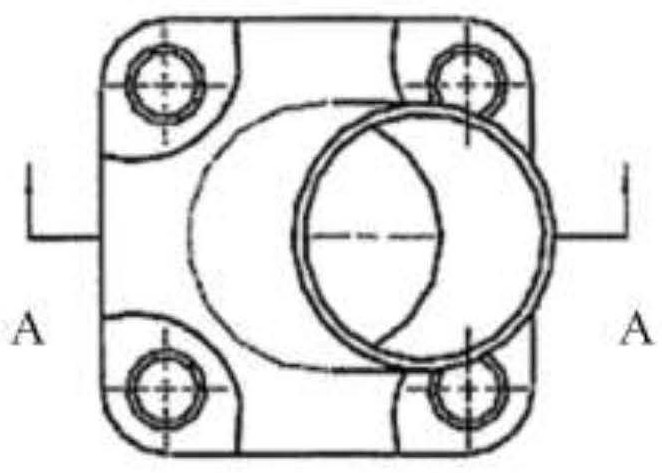

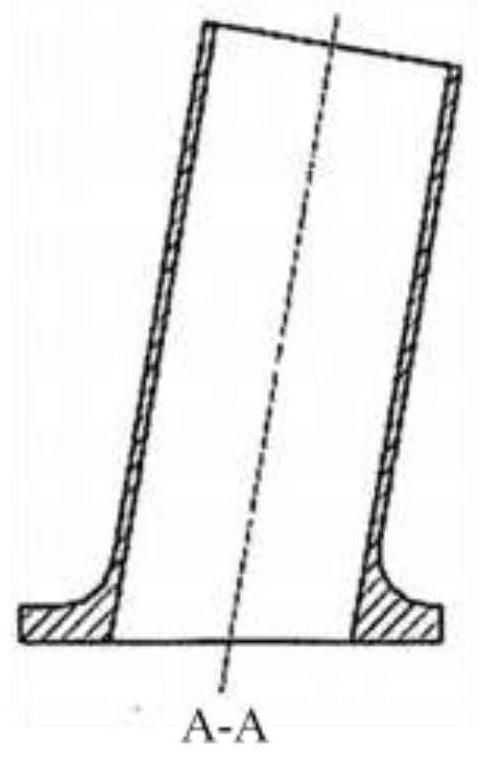

Method for forming 05Cr17Ni4Cu4Nb stainless steel air entraining pipe through selective laser melting

ActiveCN113560575AImprove performanceEasy to controlAdditive manufacturing apparatusFurnace typesSelective laser meltingManufacturing technology

The invention provides a method for forming a 05Cr17Ni4Cu4Nb stainless steel air entraining pipe through selective laser melting. The method comprises the following steps of weighing 05Cr17Ni4Cu4Nb stainless steel raw material powder which comprises the following components of, in percentage by mass, 3.0%-5.0% of Ni, 3.0%-5.0% of Cu, 15.0%-17.5% of Cr, 0.15%-0.45% of Nb, less than or equal to 0.07% of C, less than or equal to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.025% of S, and the balance Fe; (2) establishing a three-dimensional model of the 05Cr17Ni4Cu4Nb stainless steel air entraining pipe, slicing the three-dimensional model, and importing a slicing file into selective laser melting equipment; and (3) conducting selective laser melting forming of the air entraining pipe on the raw material powder, and the 05Cr17Ni4Cu4Nb stainless steel air entraining pipe is obtained after heat treatment. The problems that a traditional manufacturing process is large in tool consumption, long in manufacturing period, difficult to form complex special-shaped structural parts and the like are solved, and rapid forming and direct manufacturing of the parts made of the material are achieved; and the selective laser melting forming part manufactured through the method is excellent in mechanical property, few in defect, high in density and good in internal quality, and the design and use requirements of aero-engines are met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

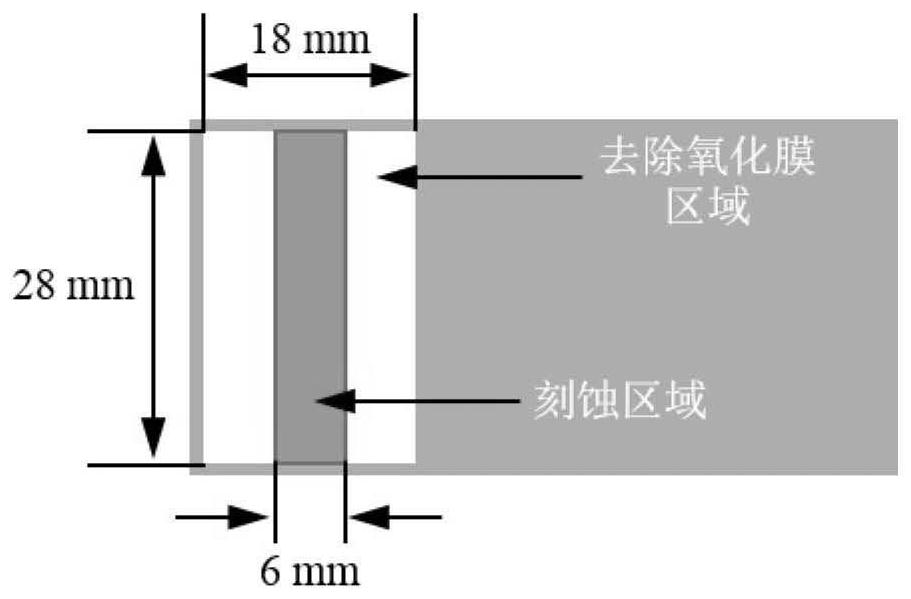

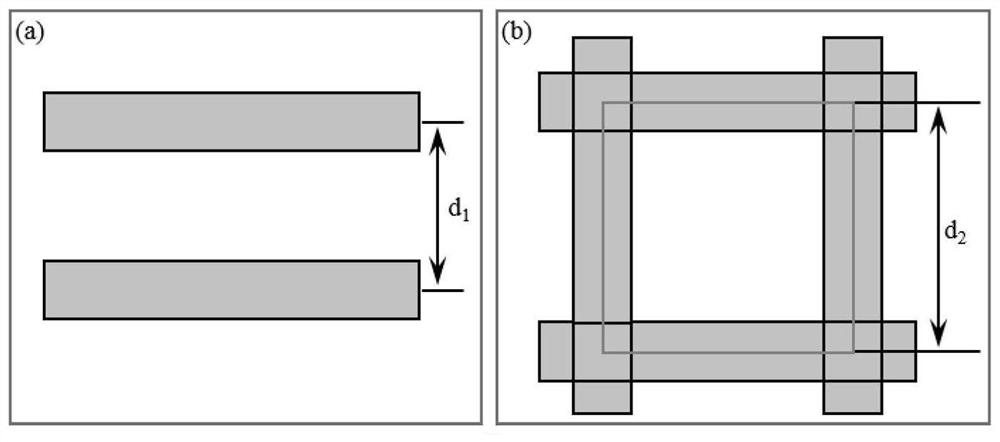

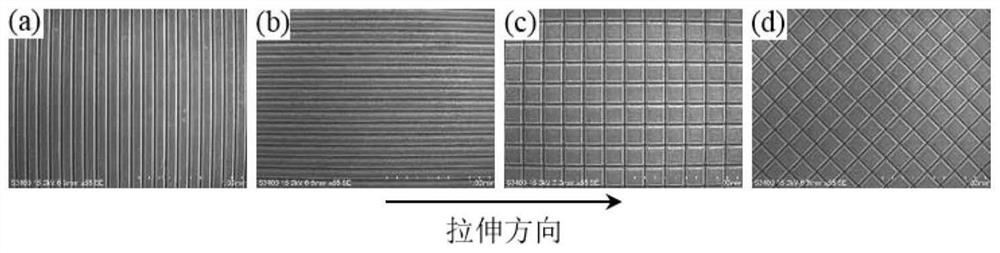

Method for treating connection strength of reinforced composite material and metal through ultrafast laser

PendingCN113414496AStrong structural controllabilityImprove efficiencyLaser beam welding apparatusHeterojunctionMetallic materials

The invention provides a method for treating the connection strength of a reinforced composite material and metal through ultrafast laser. According to the method, firstly, the purpose of effectively removing the oxide film thin layer of the metal material is achieved by controlling process parameters such as ultrafast laser scanning line spacing, laser power and a scanning speed, then a microstructure is etched on the metal surface without the oxide film through the ultrafast laser, by increasing an actual connecting area of the fiber reinforced composite material and the metal material, the mechanical anchoring effect of a heterostructure joint is improved, and the shearing strength of a connecting joint is greatly improved. The method has the advantages of being high in structural controllability, high in efficiency, free of pollution and the like, and has good industrial application prospects.

Owner:BEIJING UNIV OF TECH

Fusion refining agent for 5-series high-magnesium aluminum alloy welding wire blank and preparation method thereof

The invention discloses a fusion refining agent for a 5-series high-magnesium aluminum alloy welding wire blank. The agent comprises, in parts by weight, the following components of, 18-32 parts of potassium chloride, 35-55 parts of magnesium chloride, 5-14 parts of potassium fluoaluminate, 3-8 parts of potassium fluosilicate, 3-8 parts of potassium carbonate, 0.5-4 parts of fluorinated rare earth, 1-5 parts of potassium fluorotitanate, 1-5 parts of potassium fluoroborate, 2-8 parts of manganese chloride, and 2-6 parts of barium sulfate. According to the agent, the contents of hydrogen, inclusions and impurity element Fe of welding wire blank melt are reduced, meanwhile, grains are refined, and produced welding wires are guaranteed to be free of welding defects.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Manufacturing method of ceramic PCD grinding wheel

InactiveCN104526591ANo defects such as cracksHigh mechanical strengthAbrasion apparatusGrinding devicesAluminum borate whiskersBorosilicate glass

The invention discloses a manufacturing method of a ceramic PCD grinding wheel. The manufacturing method comprises the following steps that borosilicate glass is added to diamond grinding particles, aluminum borate whiskers are added to the mixture, and the mixture is sintered under the sintering temperature ranging from 650 DEG C to 950 DEG C. By means of the method, the purposes of effectively improving the mechanical strength and tensile strength of the grinding wheel can be achieved.

Owner:廖云建

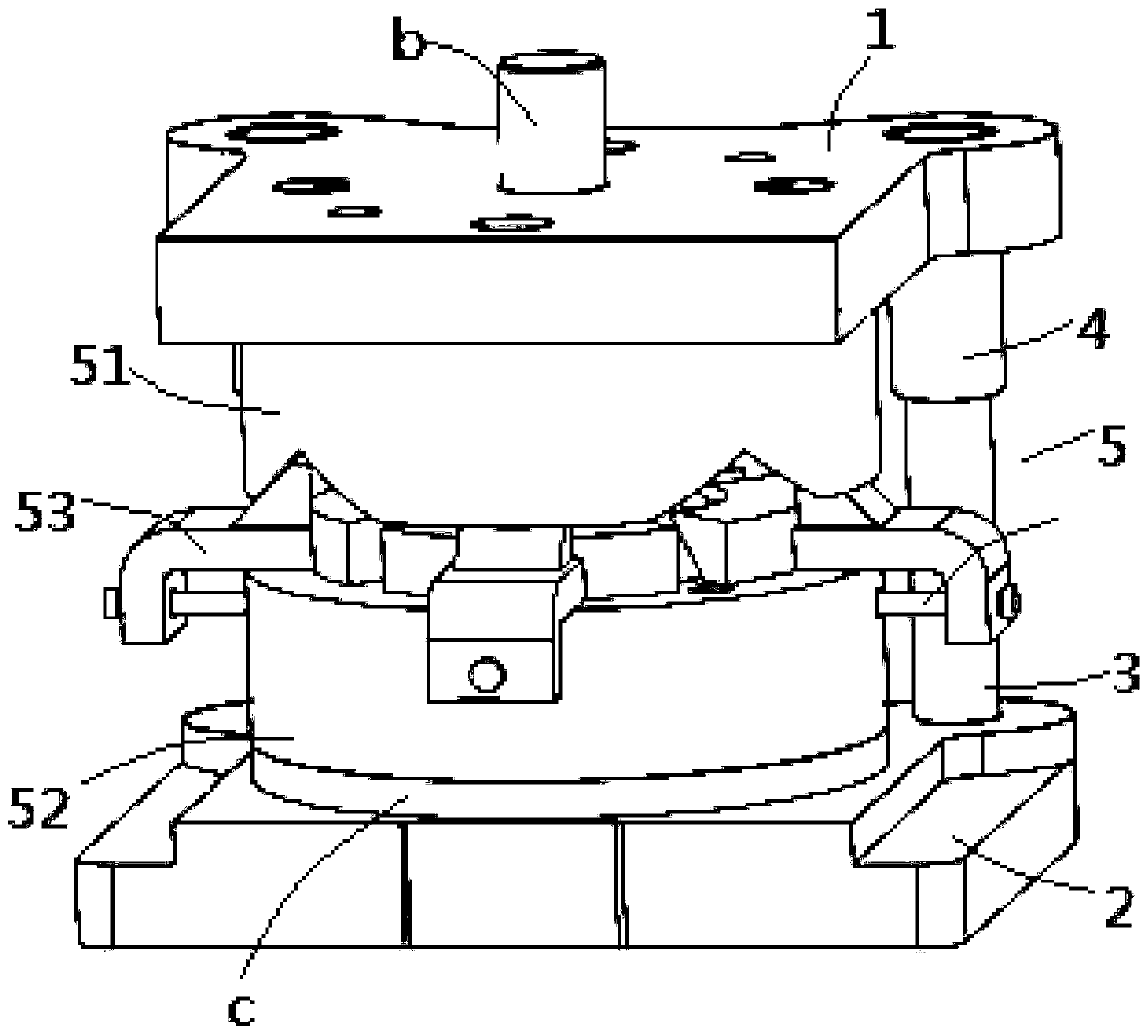

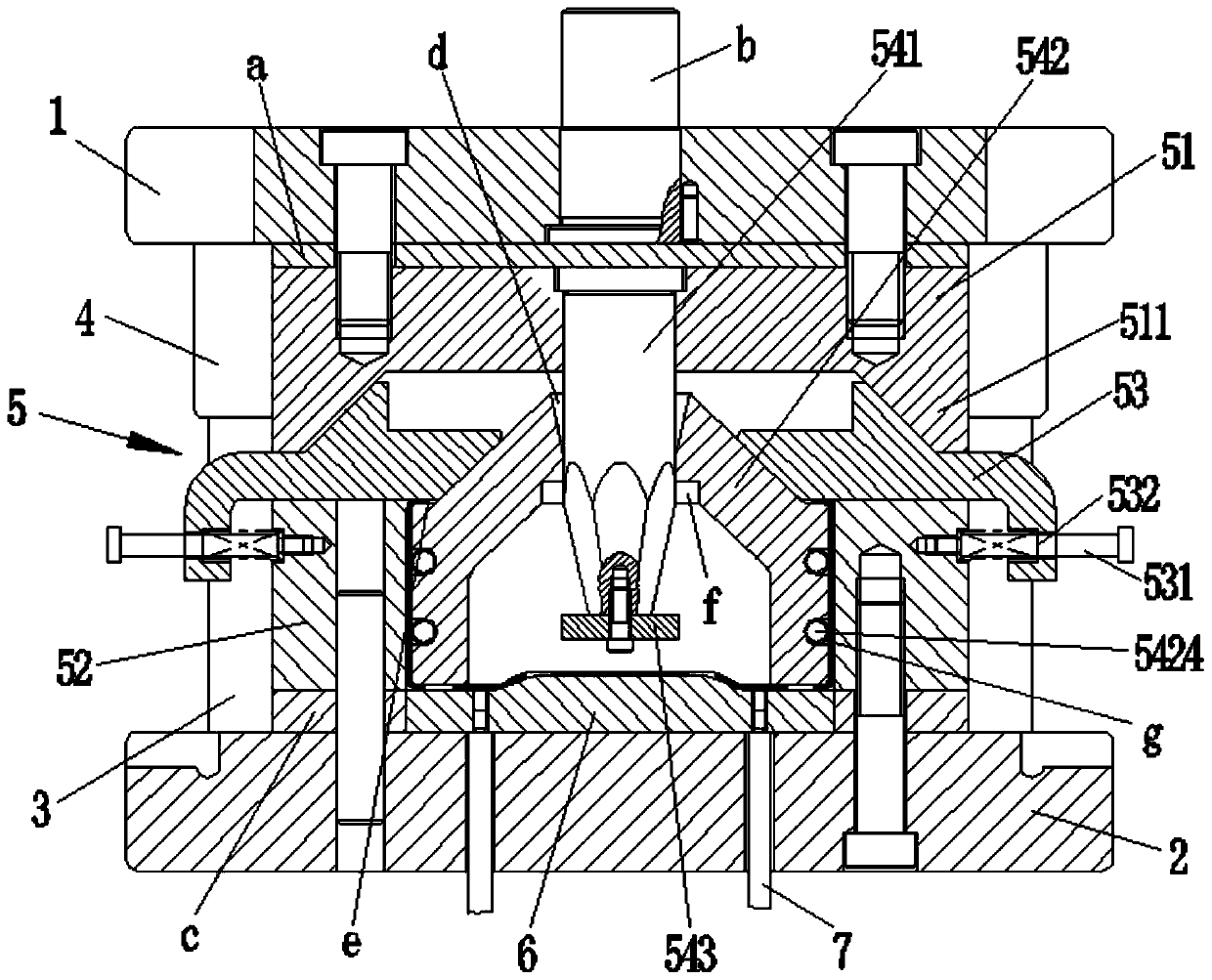

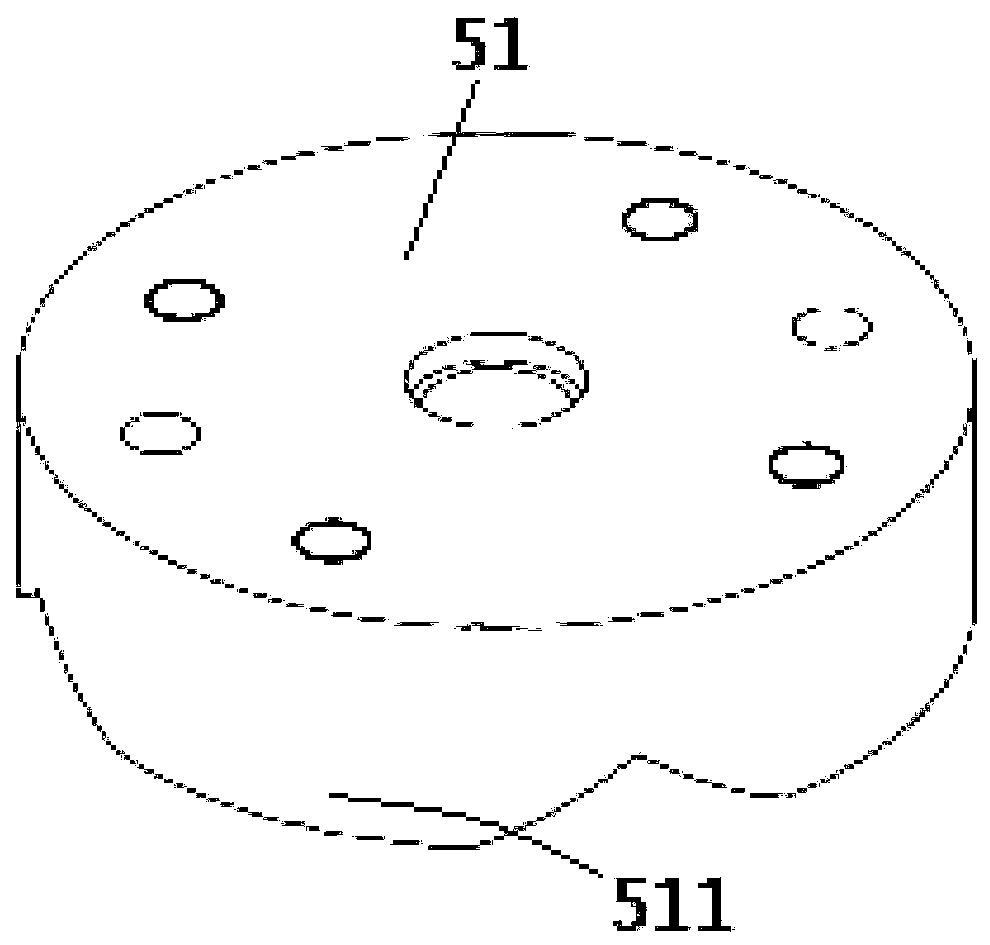

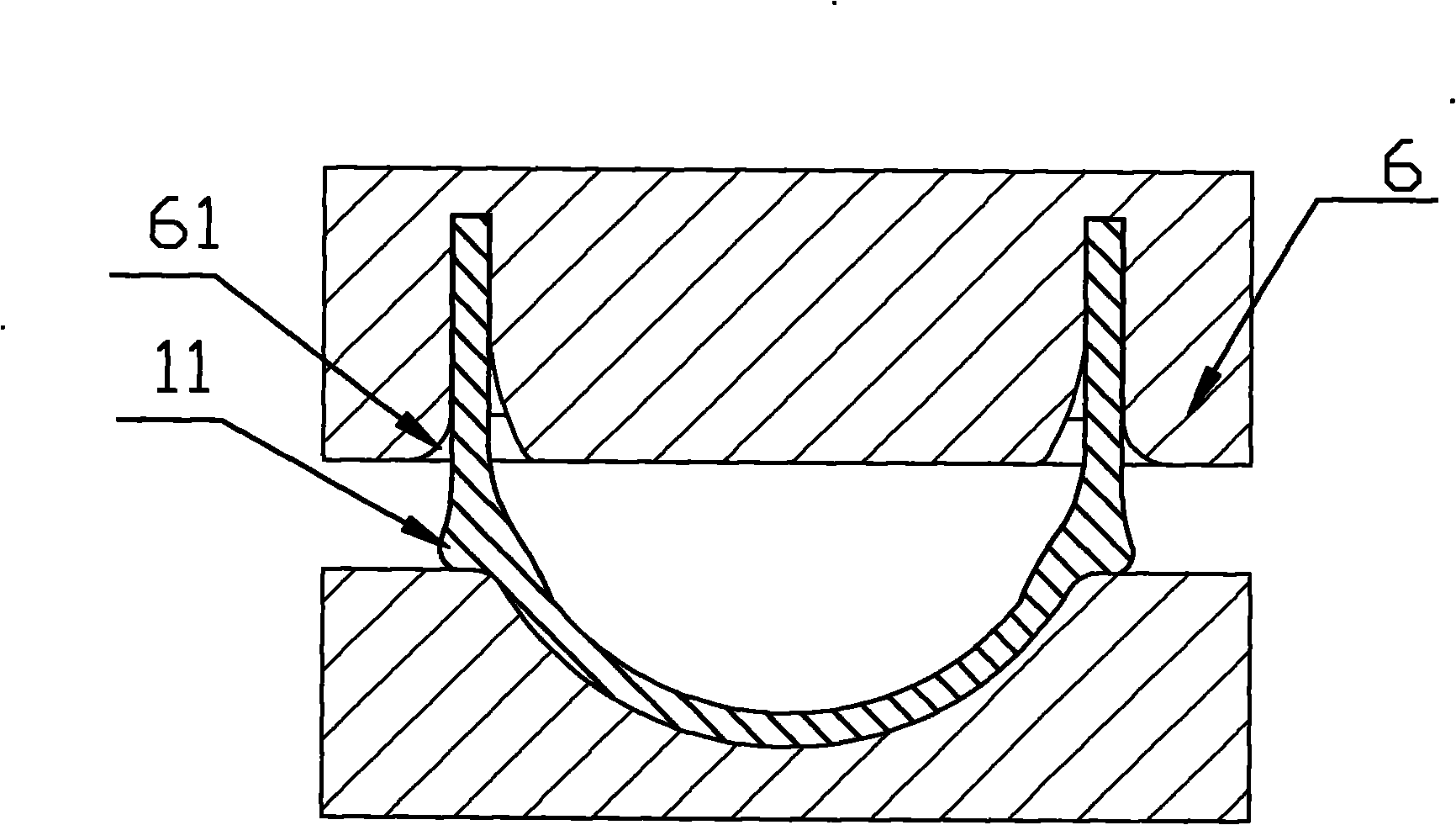

Thrust bearing block stamping die

PendingCN110640023AReduce production processDense tissueShaping toolsBearing componentsStampingThrust bearing

The invention relates to a thrust bearing block stamping die. The thrust bearing block stamping die comprises an upper die base, a lower die base, guide posts connecting the upper die base and the lower die base and guide sleeves, and further comprises a necking part pushing module. The necking part pushing module comprises a cone fixing push block and a cone expansion structure, wherein the conefixing push block is fixedly connected with the upper die base; the lower surface of the cone fixing push block is uniformly provided with a plurality of first protrusions with slope surfaces; a locating sleeve is fixedly connected with the lower die base; a plurality of necking part pushing devices are movably connected to the outer wall of the locating sleeve through stripper bolts; the cone expansion structure comprises a cone, an expansion module and a clamping plate; and the upper end of the cone is arranged on the locating sleeve, and the lower end of the cone is provided with the clamping plate. The thrust bearing block stamping die conducts necking stamping on the upper edge of a thrust bearing, the technological process is greatly reduced, the manufacturing time is shortened, pollution to the environment is reduced, and the operating cost is reduced. A workpiece stamped through the thrust bearing block stamping die is compact in structure, free of the defects such as shrinkagecavities, pores, residues and cracks. The stamping mechanical performance of the workpiece is improved, and the quality of the workpiece is greatly improved.

Owner:杨晓东 +1

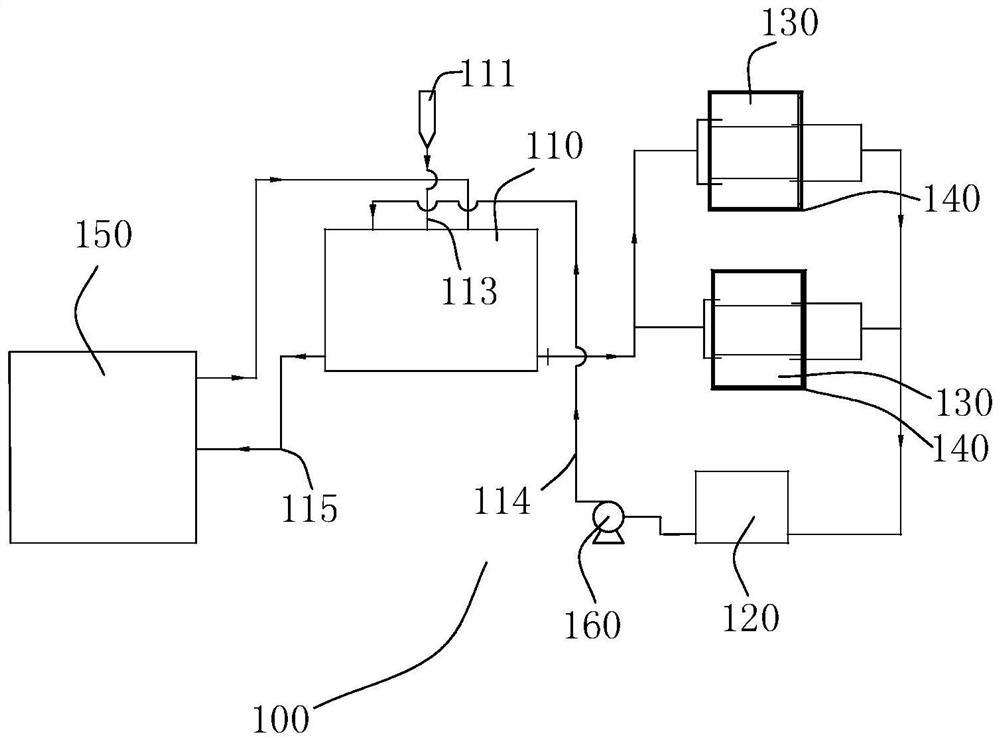

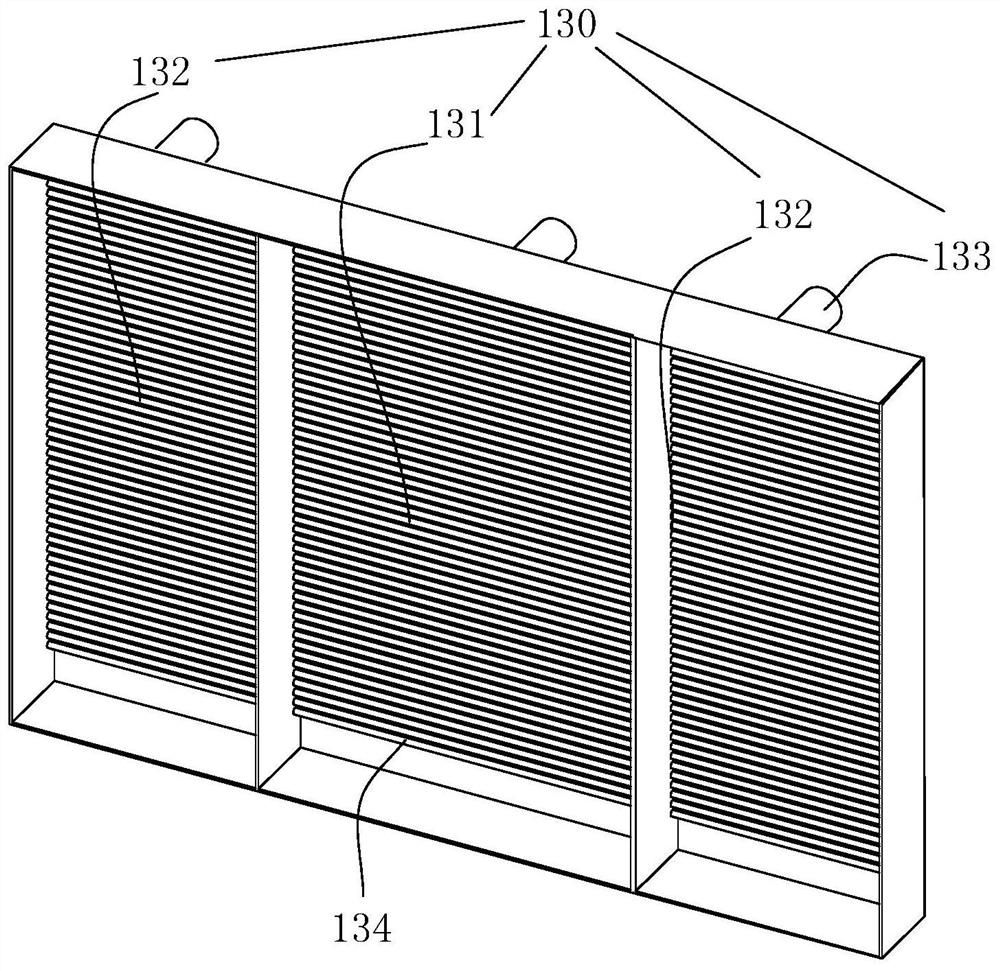

Water cooling device and method for indium casting

The invention relates to a water cooling device for indium casting. The device comprises an elevated tank, a lower tank, a plurality of cooling discs and a plurality of cooling water collecting tanks,the elevated tank is provided with a cooling water inlet, indium is cast and cooled in the cooling discs, and the cooling water collecting tanks are in one-to-one correspondence to the cooling discsand are positioned below the cooling discs. The elevated tank conveys low-temperature cooling water into each cooling disc through a pipeline by using gravity or a centrifugal pump, the cooling discscollect the cooling water into the cooling water collecting tanks through holes in the bottoms of the discs, the cooling water collecting tanks convey the cooling water to the lower tank through a pipeline, and the lower tank conveys the cooling water to the elevated tank through the centrifugal pump. According to the cooling device and method, an automatic circulating water cooling manner is adopted for casting an indium ingot, the indium ingot can be rapidly cooled, compared with a cooling manner of natural cooling in the prior art, the purity of the indium ingot is guaranteed while the production efficiency is improved, and the indium ingot obtained after demolding is smooth in appearance and free of undesirable phenomena such as holes, shrinkage cavities and cracks.

Owner:广东先导稀贵金属材料有限公司

Welding process

InactiveCN106808119AQuality assuranceSimple stepsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIndustrial engineering

The invention discloses a process, in particular to a welding process. The welding process is characterized by comprising the following steps: material taking, pre-welding cleaning work, pre-welding preheating, positioning welding and post-welding treatment. The welding process has the beneficial effects that the steps are simple, the operation is convenient, the time and labor are saved, the safety and reliability are good, the stability is good, air holes and overlaps are avoided, the phenomena of denting and undercutting are avoided, formation is good, defects such as incomplete welding and cracks are avoided, the requirements of intergranular corrosion resistance and embrittlement resistance are completely met, the quality of a welding project is guaranteed, and the working efficiency is greatly improved.

Owner:侯霞

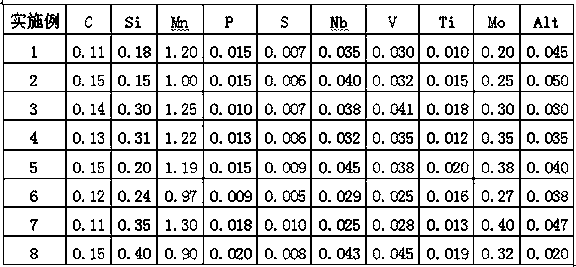

Production method of NR400ZL steel plates used for equipment converter shells

InactiveCN109957701AIngredient control precision and excellent internal qualityGood surface quality and internal stress reliefFurnace typesHeat treatment furnacesSteel platesSlag

The invention discloses a production method of NR400ZL steel plates used for equipment converter shells. The production method comprises the procedures including steel-making, continuous casting, heating, rolling and heat treatment. According to the production method, by limiting the contents of the element components of C and Si, by controlling the steel ladle baking temperature and C content ofthe converter steel making process and controlling the white slag holding time and vacuum soft blowing time of the LF refining process, by adopting protective casting and controlling the steel plate rolling process and return-red temperature, the obtained steel plates are good in compactness, high in strength and good in welding performance, the steel plate thickness is 60-160 mm, the steel plateyield strength is greater than or equal to 320 MPa, the tensile strength is greater than or equal to 420 MPa, the ductility is greater than or equal to 24%, 0 DEG C impact force is greater than or equal to 60 J, the 350 DEG C high-temperature tensile strength is greater than or equal to 230 MPa, standards and safety requirements are met completely, and the production method meets requirements forsteel used for the equipment converter shells.

Owner:WUYANG IRON & STEEL

Process method for forming integral top cover and heading die thereof

The invention discloses a process method for forming an integral top cover and a heading die thereof. The process method comprises that: high temperature steel ingots are distributively extruded into a drum blank and then fixed in a heading lower die, the side wall of the upper end of the heading lower die is rightly accommodated in a longitudinal annular opening of a heading upper die, the heading upper die moves downwards to make the drum blank form a circle of annular protrusions at the upper end of the outer side wall of the heading lower die, a shaping upper die moves downwards to flatten the inner surface of the drum blank, and finally, the upper ends of the annular protrusions on the side wall of the drum blank are rightly accommodated in an annular forming opening of a forming upper die, and the forming upper die moves downwards to extrude the annular protrusions of the drum blank into a circle of annular flange in set specification. The integral top cover is formed integrally, does not have welding lines and cracks, and is safe and stable; the heading lower die of the heading die for the integral top cover is a drum-shaped cylinder with an opening at the upper end, and the upper end face of the side wall and the inner side wall are in arc transition; and the lower end of the heading upper die is longitudinally provided with a circle of longitudinal annular opening, and the side wall at the lower end of the longitudinal annular opening and the end face of the lower end of the longitudinal annular opening are in arc transition.

Owner:苏州昆仑先进制造技术装备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com