Electron beam welding method for TA15 and Ti60 dissimilar titanium alloy materials

A technology of electron beam welding and titanium alloy, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing material toughness, difficulty in welding large thickness titanium alloy materials, and prone to oxidation on the alloy surface. Achieve the effects of reducing deformation during welding, avoiding alloy oxidation and element burning, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

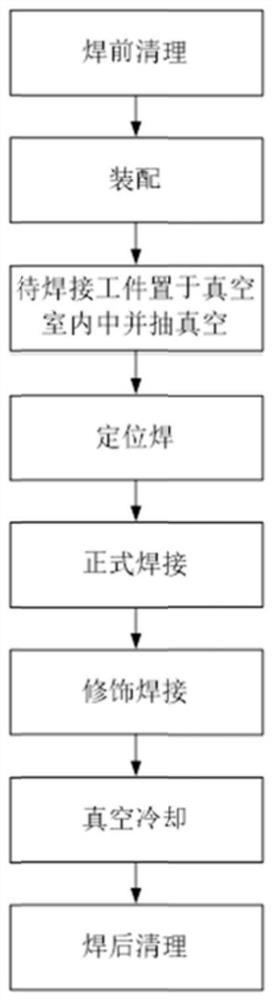

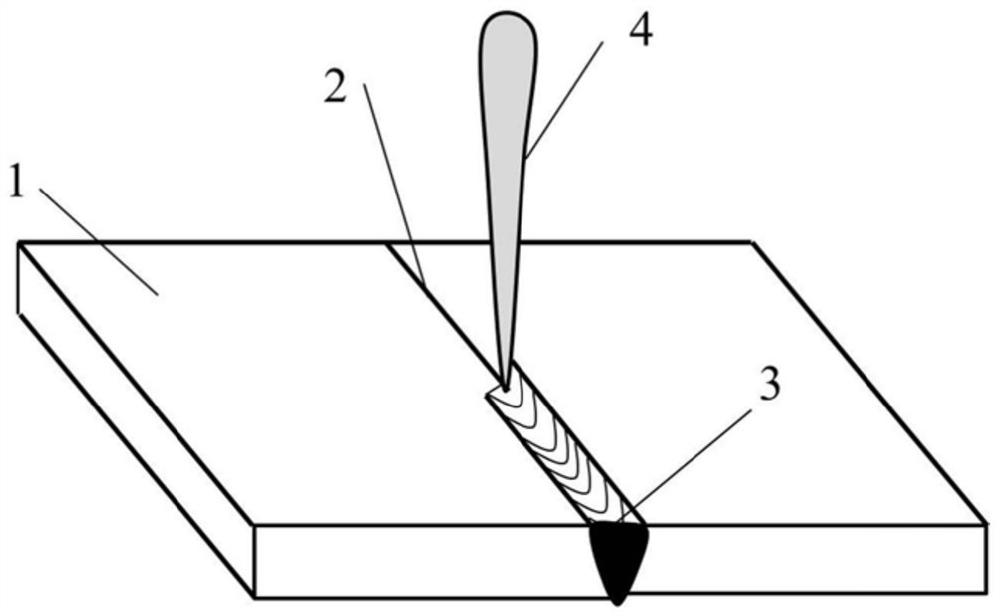

[0047] Butt welding of 2mm thick TA15 and Ti60 dissimilar titanium alloy plates. Such as figure 2 As shown, the structural form of the joint is a butt joint form, wherein, the number 1-welding base metal, 2-weld to be welded, 3-weld pool, 4-electron beam current. Specific welding process such as figure 1 shown.

[0048] Step (1), cleaning before welding, degreasing, pickling, drying, grinding and scraping the TA15 and Ti60 dissimilar titanium alloy plates;

[0049] Step (2), assembling, fixing the titanium alloy plate firmly, ensuring that the maximum butt joint gap of the weld is not greater than 0.15mm, and the step difference is not greater than 10% of the base metal thickness;

[0050] Step (3), put the assembled TA15 and Ti60 titanium alloy plates into the vacuum chamber and vacuumize, the vacuum degree of the vacuum chamber is 2×10 -2 Pa;

[0051] Step (4), when the vacuum degree meets the requirements, call the NC program and use a small electron beam current (2-4...

Embodiment 2

[0058] Butt welding of 3mm thick TA15 and Ti60 dissimilar titanium alloy plates. Such as figure 2 As shown, the structural form of the joint is a butt joint form.

[0059] Step (1), cleaning before welding, degreasing, pickling, drying, grinding and scraping of TA15 and Ti60 dissimilar titanium alloy plates

[0060] Step (2), assembling, fixing the titanium alloy plate firmly, ensuring that the maximum butt joint gap of the weld is not greater than 0.15mm, and the step difference is not greater than 10% of the base metal thickness;

[0061] Step (3), put the assembled TA15 and Ti60 alloy plates into the vacuum chamber and vacuumize, the vacuum degree of the vacuum chamber is 2×10 -2 Pa;

[0062] In step (4), when the degree of vacuum meets the requirements, the NC program is invoked, and a small electron beam current (2-4mA) is used to teach the weld trajectory. The teaching process ensures that the electron beam spot is always in the middle of the weld;

[0063] In step...

Embodiment 3

[0069] Butt welding of 10mm thick TA15 and Ti60 dissimilar titanium alloy plates. Such as figure 2 As shown, the structural form of the joint is a butt joint form.

[0070] Step (1), cleaning before welding, degreasing, pickling, drying, grinding and scraping the TA15 and Ti60 dissimilar titanium alloy plates;

[0071] Step (2), assembling, fixing the titanium alloy plate firmly, ensuring that the maximum butt joint gap of the weld is not greater than 0.15mm, and the step difference is not greater than 10% of the base metal thickness;

[0072] Step (3), put the assembled TA15 and Ti60 alloy plates into the vacuum chamber and vacuumize, the vacuum degree of the vacuum chamber is 2×10 -2 Pa;

[0073] In step (4), when the degree of vacuum meets the requirements, the NC program is invoked, and a small electron beam current (2-4mA) is used to teach the weld trajectory. The teaching process ensures that the electron beam spot is always in the middle of the weld;

[0074] In ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com