Semi-continuous casting crystallizer for aluminum alloy near net shape cast ingot

A technology for casting crystallizers and aluminum alloys, which is applied in the field of semi-continuous casting crystallizers for near-net-shape ingots of aluminum alloys, and can solve problems such as structure and composition of unseen crystallizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

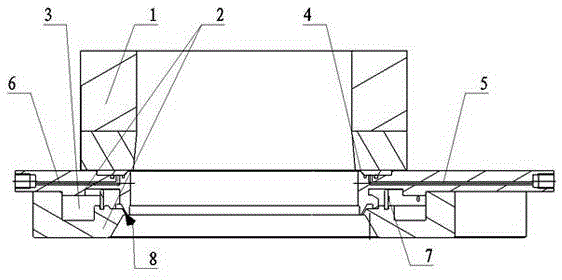

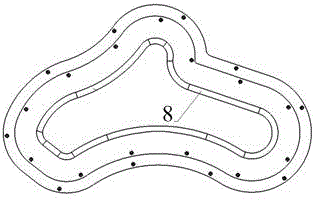

[0019] Such as figure 1 , figure 2 As shown, the semi-continuous casting crystallizer for near-net-shape aluminum alloy ingots includes a crystallizer body 2 and a thermal insulation roof 1. 2 is provided with an oil-gas distribution ring 4, and the oil-gas distribution ring 4 is evenly distributed with gas injection holes 6 and oil injection holes 5 along the circumferential direction. The crystallizer body 2 includes a cooling water cavity and a water spray structure connected with the water cavity. The water spray structure is a non-equal width water gap structure 8. The crystallizer body includes a cooling water cavity and a water spray structure connected with the water cavity. The water spray structure is a non-equal width water gap structure, so that The cooling water flow rate is non-equivalent distribution, which varies from 0 L / min×mm to 0.95 L / min×mm, and a water separator 7 is provided in the cooling water cavity.

[0020] The non-equal-width water gap structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com