Lead-free bronze alloy and application thereof

A lead-free bronze and alloy technology, applied in the application field of drinking water system castings, can solve problems such as poor casting performance and application limitations, improve casting performance and mechanical properties, prevent segregation or reverse segregation, and resist seawater corrosion The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

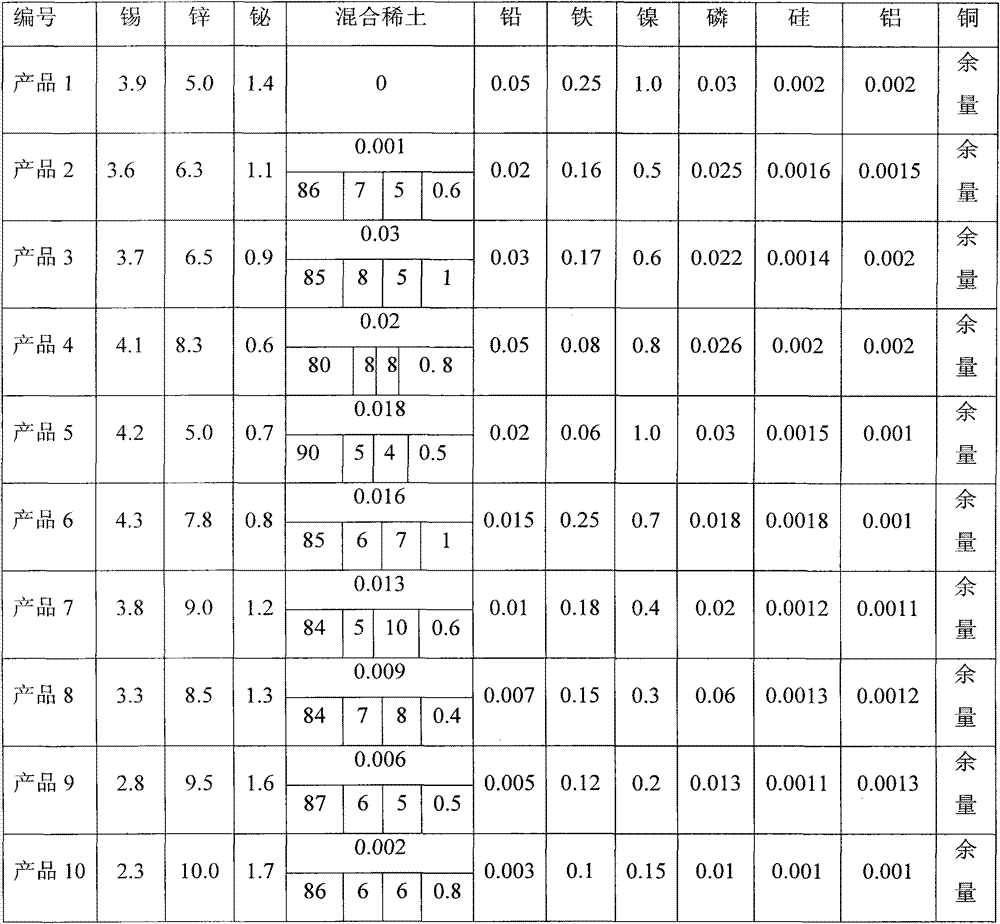

[0036] Embodiment one: product and preparation method

[0037] The manufacturing method of lead-free environment-friendly bronze alloy includes the following steps:

[0038] Copper+charcoal→melting→adding zinc, bismuth, tin→stirring→deoxidation→stirring→refining→mixing rare earth additives→stirring→sampling analysis→adjusting composition→removing slag→standstill→casting out of the furnace, specifically:

[0039] The first step is to heat the induction furnace, add electrolytic copper to cover the charcoal, and heat up to fully melt the copper.

[0040] In the second step, add 0# zinc, refined bismuth and refined tin at a furnace temperature of 1150°C and stir.

[0041] The third step, add CuP 14 Phosphor copper deoxidizer stirring.

[0042] Step 4: adding refining agent, the composition percentage of refining agent is: 50% of fluorite, 20% of cryolite, 10% of borax, and 20% of copper oxide.

[0043] The fifth step is to add mixed rare earths, which contain 80%-90% of lanth...

Embodiment 2

[0054]Embodiment two: casting performance test

[0055] The casting properties of the lead-free bronze alloy products 1, 2, 3 and ZQSn5-5-5 bronze are compared, product 1, no mixed rare earths are added, the casting performance is not improved, and the casting performance of product 2 is not improved by adding 0.001% of the mixed rare earths Significantly improved, the casting performance of products 1 and 2 has no obvious difference from ZQSn5-5-5 alloy, the addition of product 3 mixed rare earth is 0.03%, the castability can be significantly reduced, indicating that the excessive addition of mixed rare earth is harmful to casting performance, product 4-10 mixed The amount of rare earth added is in the range of 0.002%-0.02%, and its casting performance is significantly better than that of products 1, 2, 3, and ZQSn5-5-5 alloys. The production practice shows that due to the addition of an appropriate amount of mixed rare earths, the casting performance is significantly improved...

Embodiment 3

[0058] Embodiment three: Cutting performance test

[0059] The evaluation method of cutting performance: when turning on a general lathe, use a unified turning tool and turning method with a turning speed of 960r / min, a feed rate of 0.1mm / r, a cutting depth of 0.4mm, and a turning process with a rake angle of 4 degrees. Carry out the cutting performance test comparison of products 1, 2, 3, 4, 5, and the comparative example ZQSn5-5-5, collect 100 chips respectively, measure the average length of the chips, and use the average length of the chips of ZQSn5-5-5 Divide by the average chip length of products 1, 2, 3, 4, 5, and each sample as the evaluation index. The above experiments prove that the cutting performance of products 1 and 2 has not been improved, and the cutting performance of product 3 has declined instead. Due to the addition of appropriate amount of mixed rare earths in 4 and 5, the cutting performance of products 1, 2 and 3 is significantly better than that of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com