Antigravity vacuum sucking cast apparatus for aluminium base composite material

An aluminum-based composite material and vacuum suction casting technology, which is applied in the field of equipment in the field of casting technology, can solve problems such as being unsuitable for the forming of aluminum-based composite materials, and achieve the goals of overcoming forming difficulties, less temperature drop, and avoiding particle settlement and agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

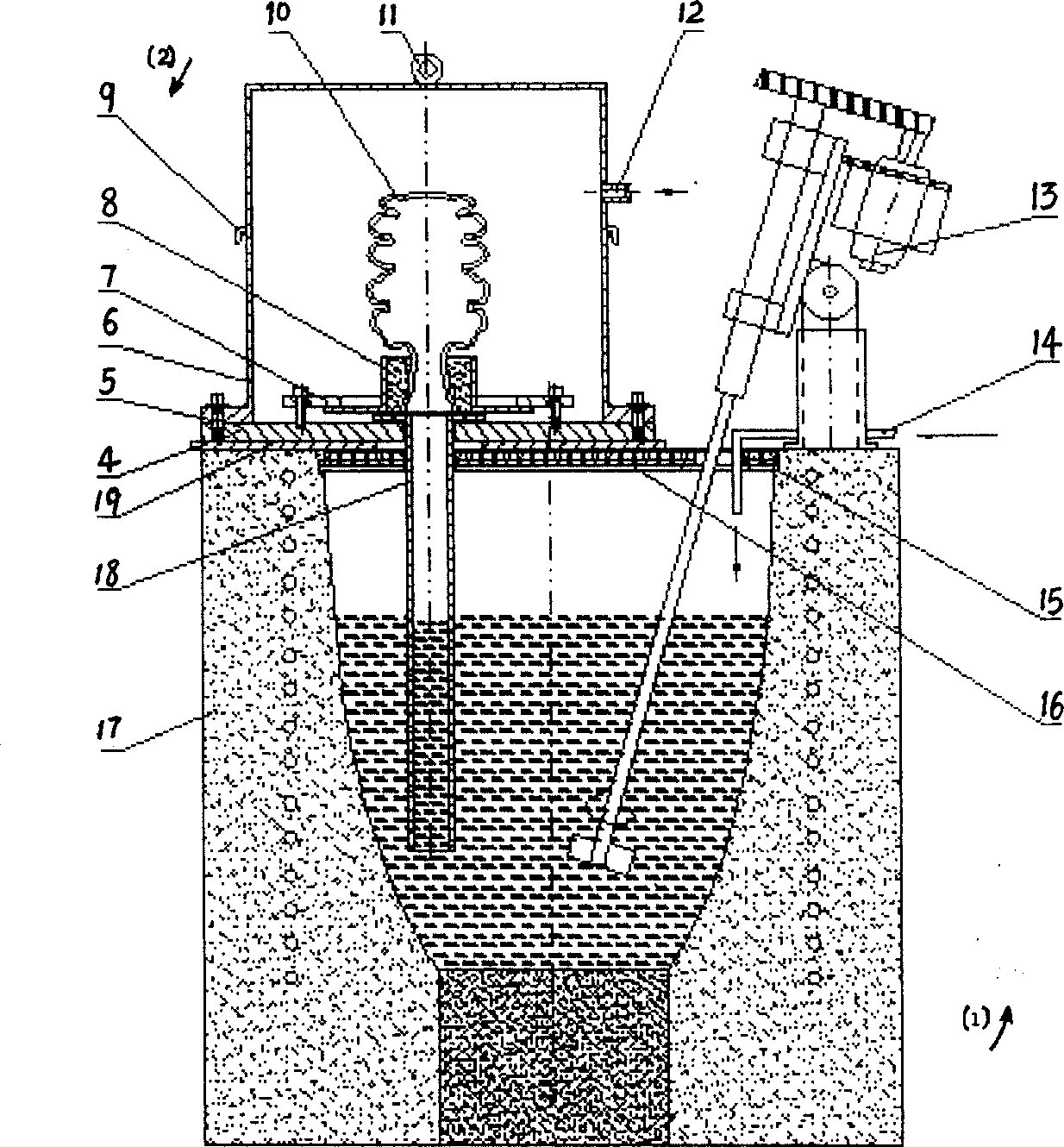

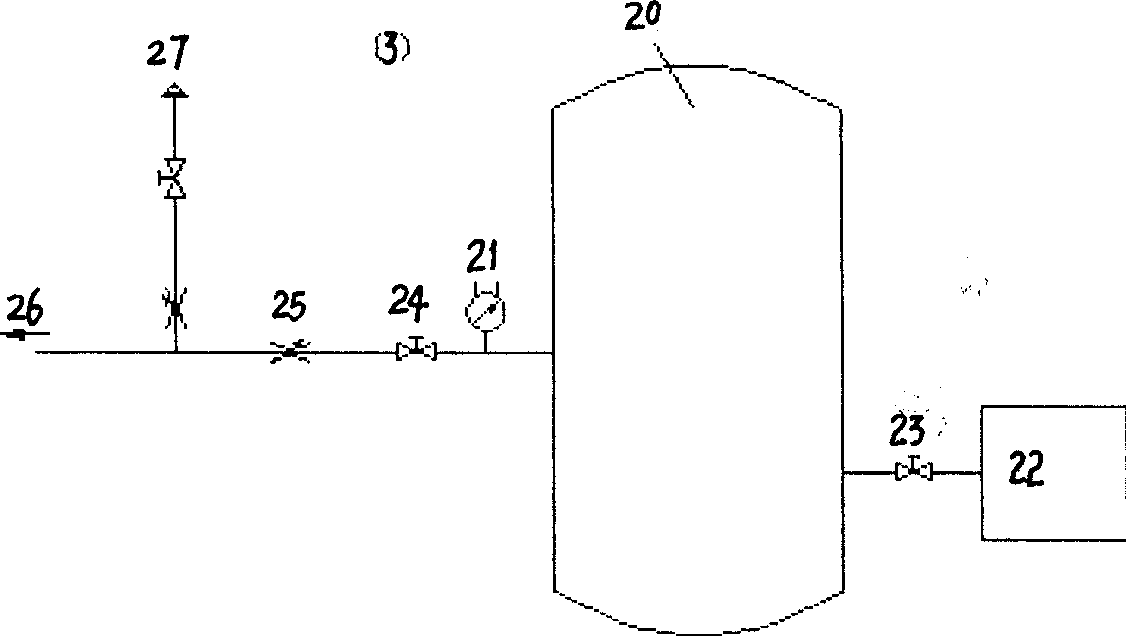

[0014] like Figure 1~2 As shown, the present invention includes a smelting device 1 , a vacuum suction casting device 2 and a gas path part 3 .

[0015] The smelting device 1 includes: a stirrer 13 , a protective gas channel 14 , a thermal insulation layer 15 , a radiation protection layer 16 , and a crucible 17 . The agitator 13 is arranged on the crucible 17, the protective gas channel 14 is arranged on the crucible 17, next to the agitator 13, the heat insulating layer 15 is placed on the radiation protection layer 16, and the heat insulation layer 15 and the radiation protection layer 16 are placed There are 17 crucibles.

[0016] The vacuum suction casting device 2 includes: a partition 4, a sealing gasket 5, a sealing sleeve 6, a pressure plate 7, a mold shell fixing sleeve 8, a hook 9, a mold shell 10, a lifting ring 11, a vacuum channel 12, and a lifting liquid Pipe 18, backing plate 19. The sealing sleeve 6, the riser pipe 18 and the sealing gasket 5 are all arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com