Patents

Literature

33results about How to "Solve forming difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

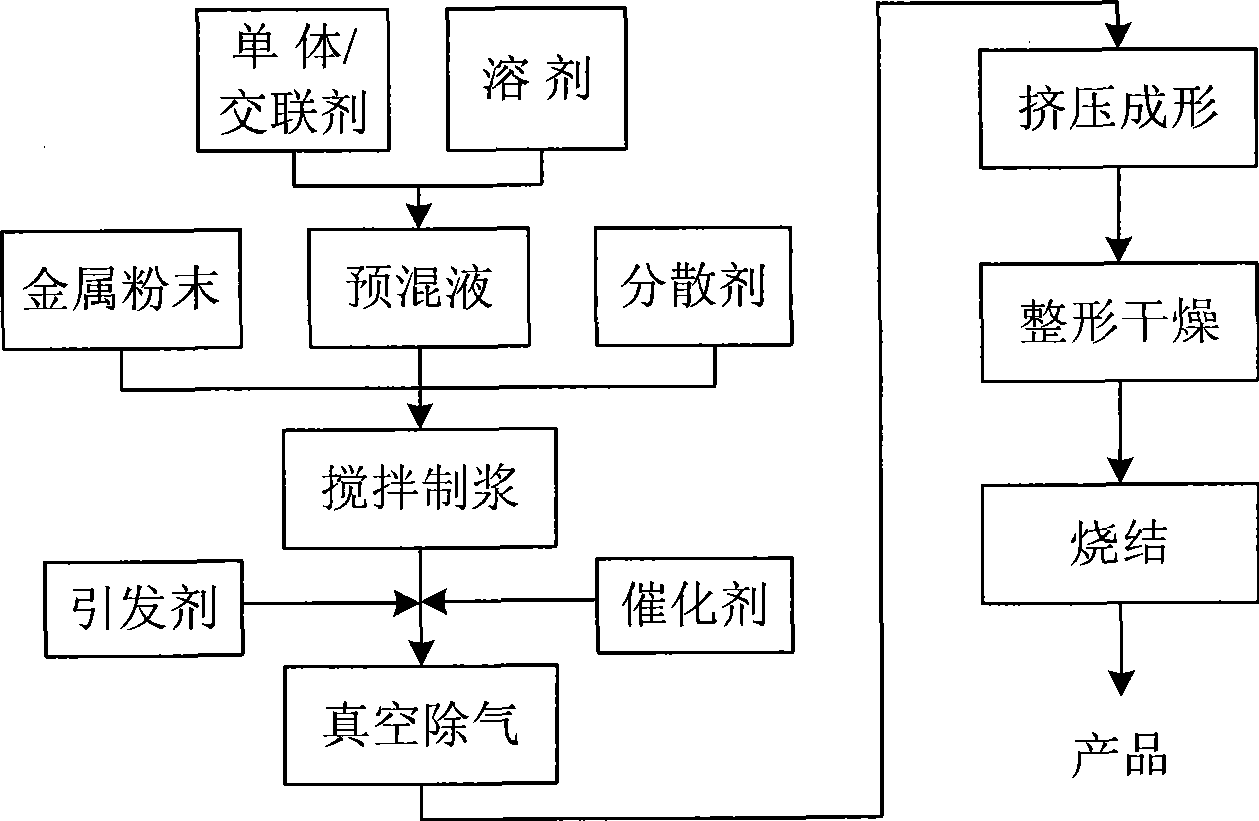

Method for extruding and molding metal powder gelatin

The invention relates to a method for extruding and molding metal powder gelatin, which belongs to the field of metal part preparation in powder metallurgic production technology. The method is characterized by comprising the steps: firstly, premixed liquid with finite concentration is prepared; then, metal powder is added into the premixed liquid to prepare a stable gelatin system; the stable gelatin system is extruded and molded to prepare a blank body; and finally, the blank body is sintered into a part. The invention breaks through the traditional molding technology and can prepare metal products with large sizes and complicated shapes. Compared with the pressure molding, the invention solves the problems of complicated shape limitation and energy consumption caused by overlarge pressure needed by molding, and greatly improves the molding condition. Compared with the injection molding and the hot pressure casting molding which need to be added with a lot of organic binding agents, the method does not need a special degreasing step, has simple technology and can greatly reduce the production cost.

Owner:UNIV OF SCI & TECH BEIJING

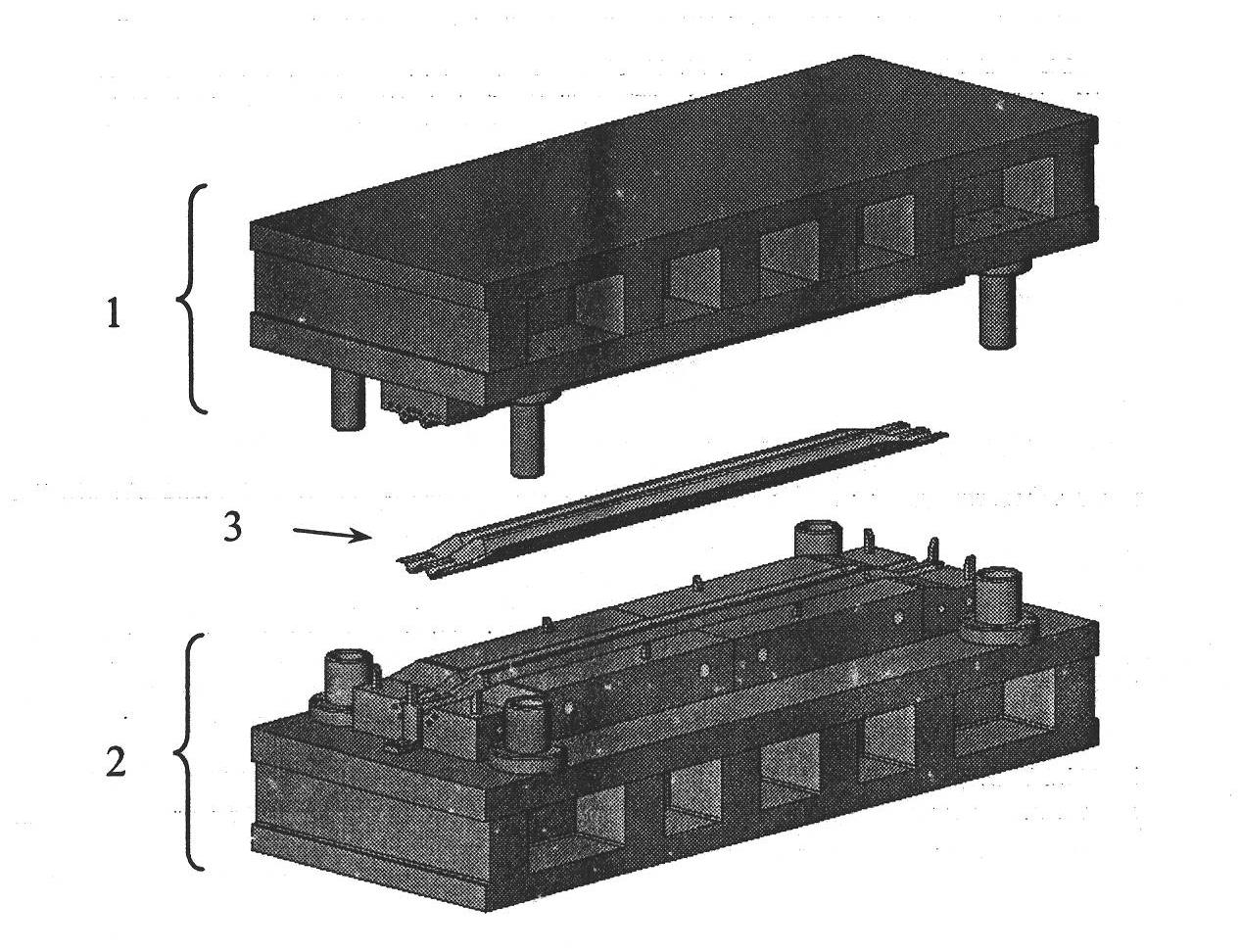

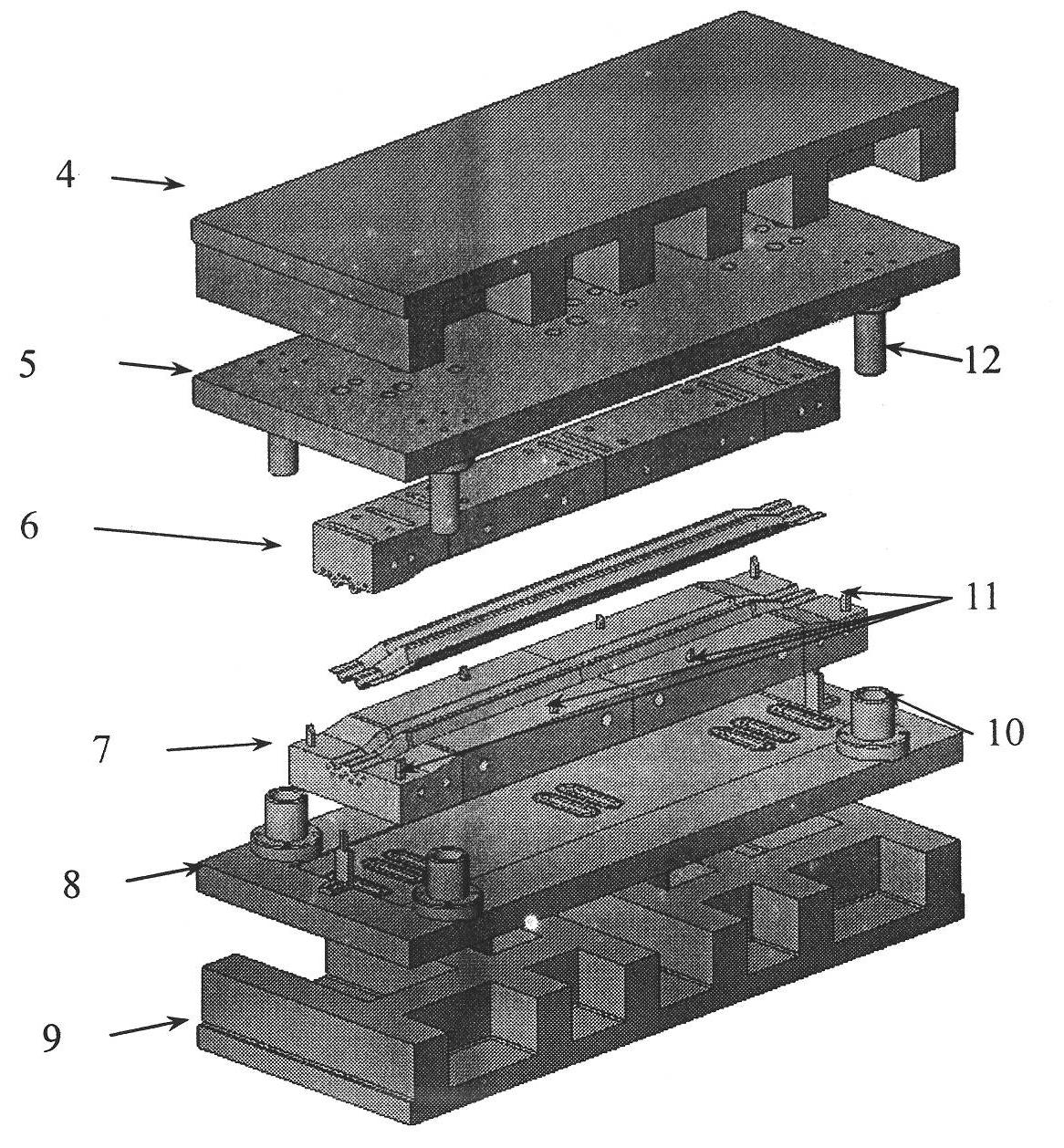

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

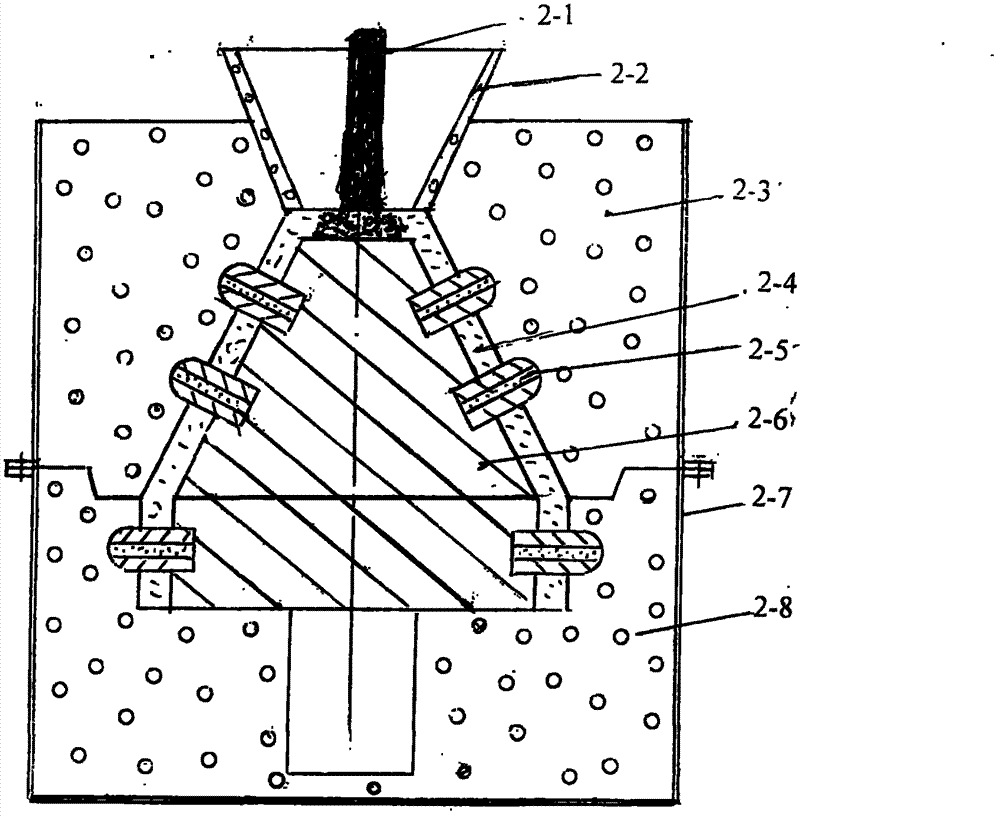

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

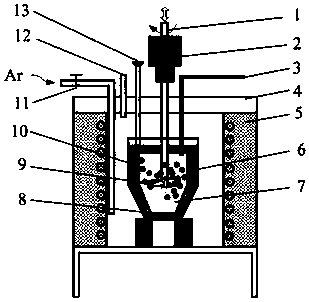

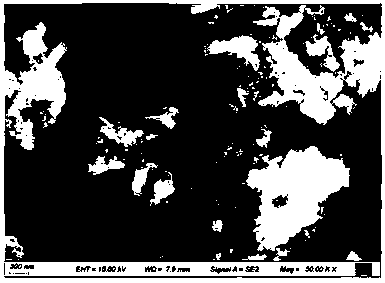

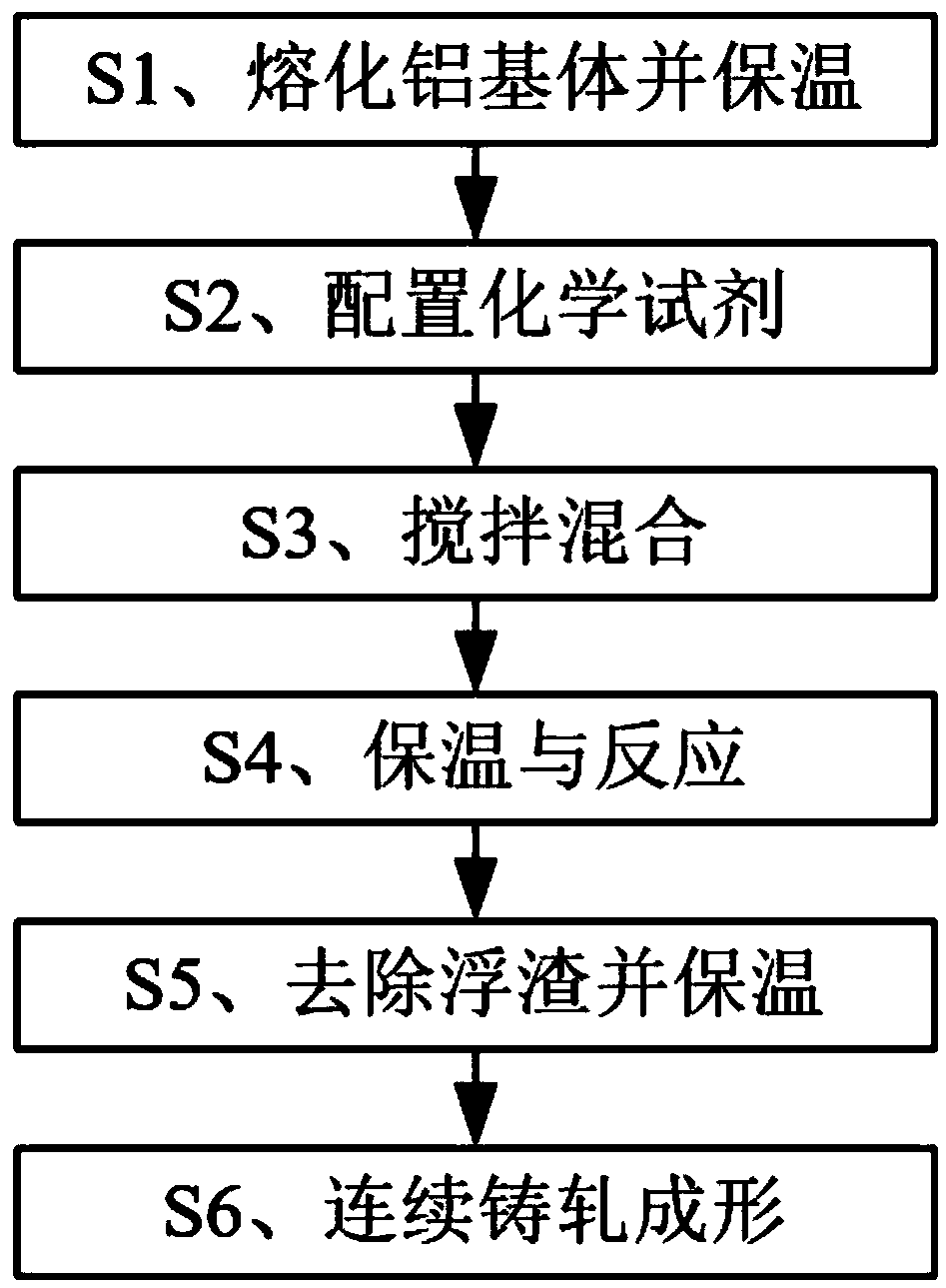

Casting-rolling method for aluminum matrix composite reinforced by in-situ generated TiB2 particles

InactiveCN108796266AImprove dispersion uniformityRefined grain structureMetal rolling arrangementsGeneration processChemical reaction

The invention provides a casting-rolling method for aluminum matrix composite reinforced by in-situ generated TiB2 particles. The casting-rolling method includes the following steps: S1 putting an aluminum ingot into a crucible and keeping the temperature constant for 20-60 min after the aluminum ingot is melted into molten aluminum; S2 preparing reagents KBF4 and K2TiF6 according to the stoichiometric ratio Ti / B = 1:2 and mixing the reagents with catalysts MgF2 and AlF6Na3 evenly; S3 dispersing evenly the chemical reagents dried in the step S2 into the molten aluminum obtained in the step S1and stirring the mixture evenly to prepare a melt mixture; S4 keeping the melt mixture obtained in the step S3 at 700-900 DEG C for a total time of 40-100 min and stirring the melt mixture once every5-20 min for 1-5 min to allow the KBF4 and the K2TiF6 in the melt mixture to react with each other to generate TiB2 particles during the period; S5 removing the scum and keeping the temperature constant; and S6 conducting continuous casting-rolling for formation. According to the casting-rolling method, a fine and uniformly-distributed TiB2-particle reinforcement is obtained by utilizing the in-situ generation process, so that the defects (such as poor wettability at the interface between particles and a matrix as well as uneven distribution of particles) arising when the particle reinforced aluminum matrix composite is prepared by using the traditional external addition process are removed.

Owner:YANSHAN UNIV

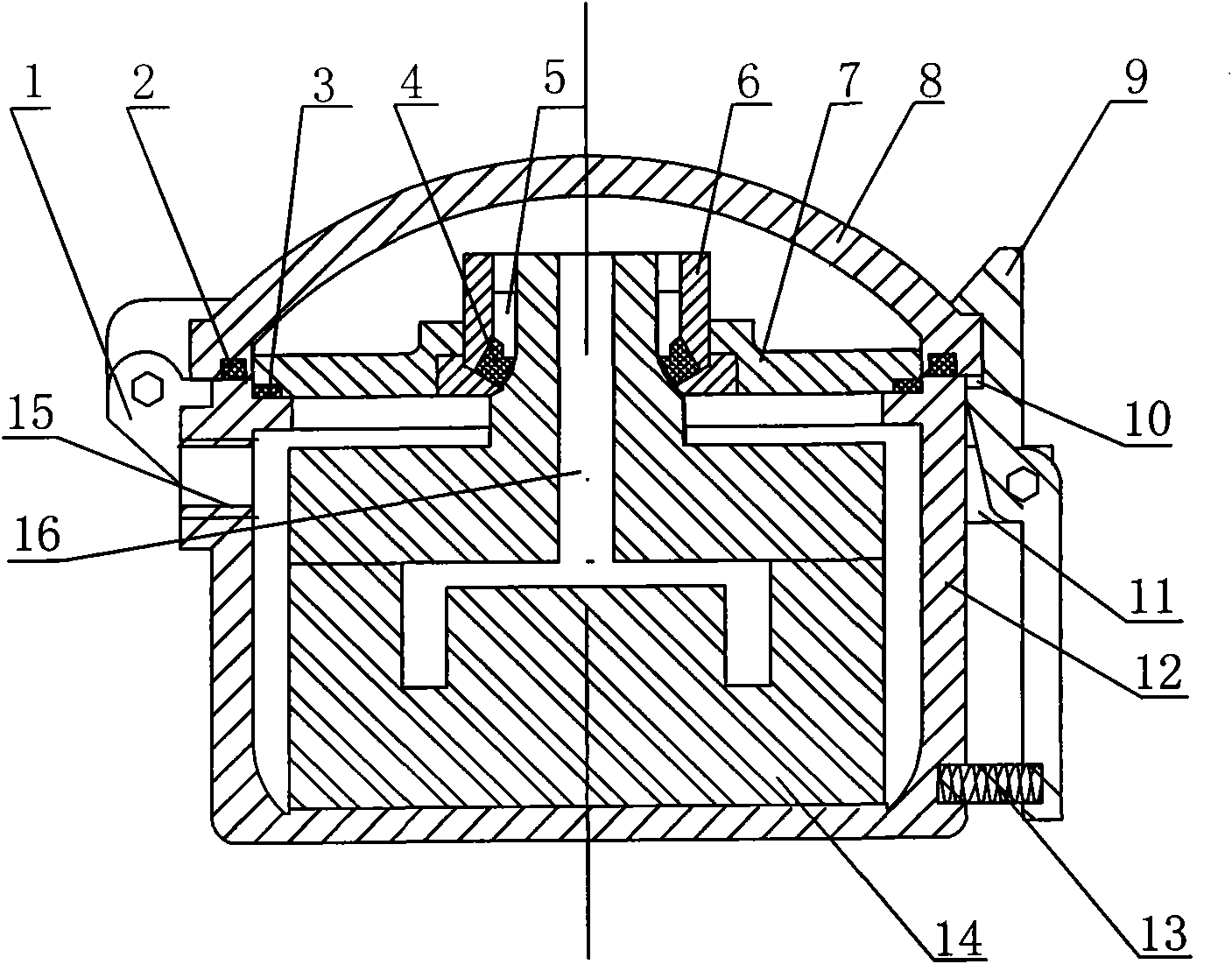

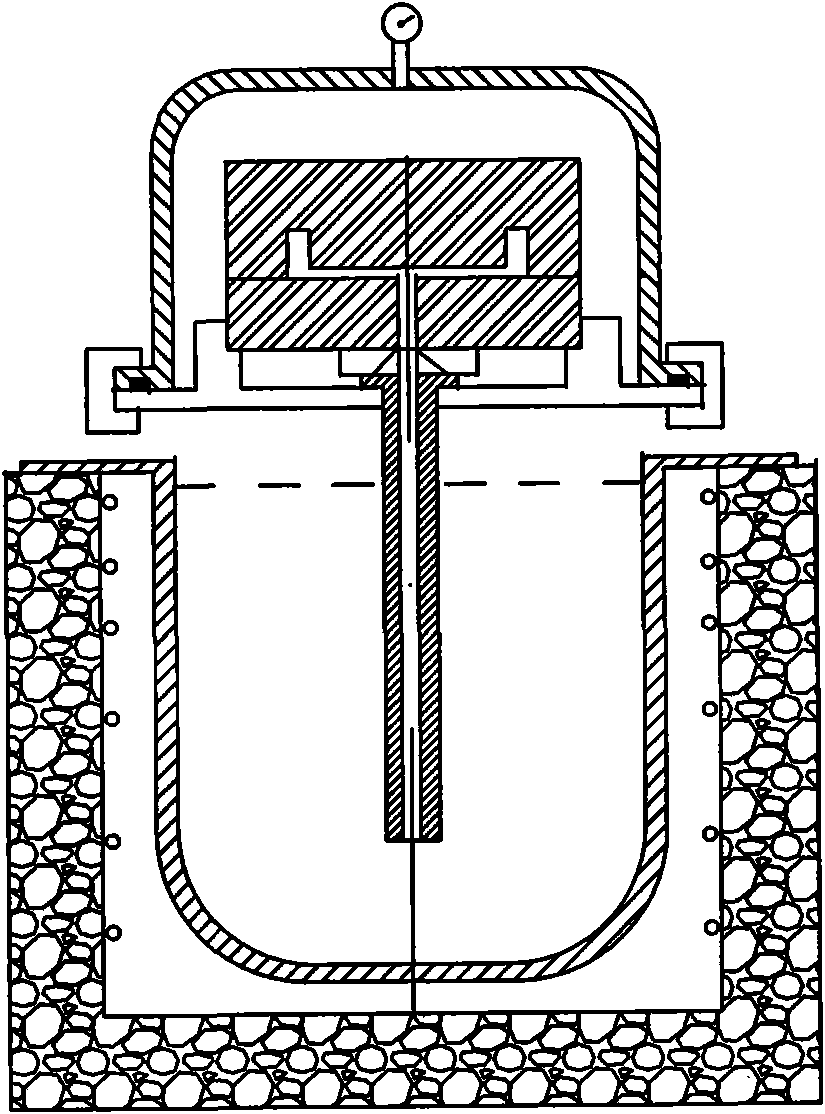

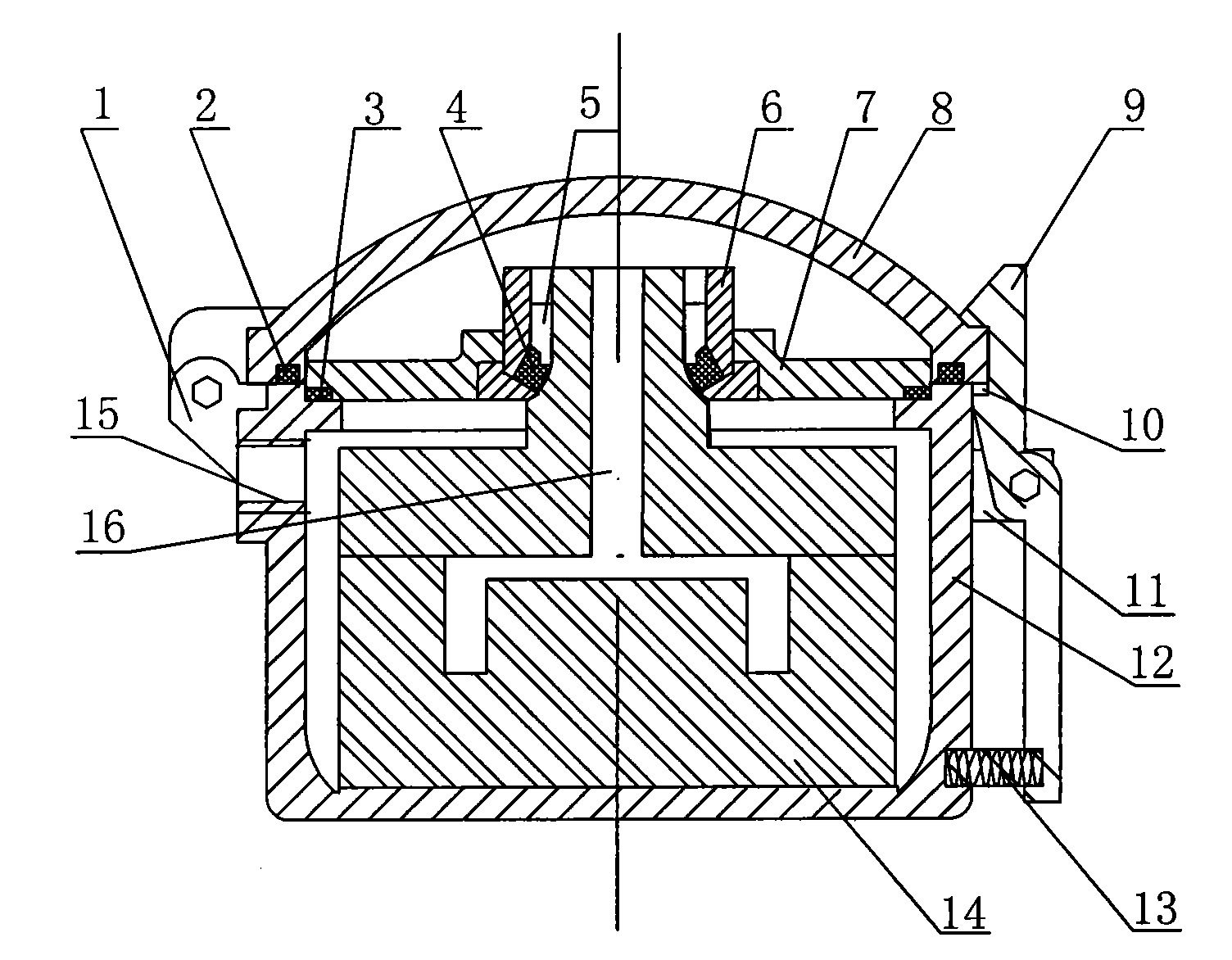

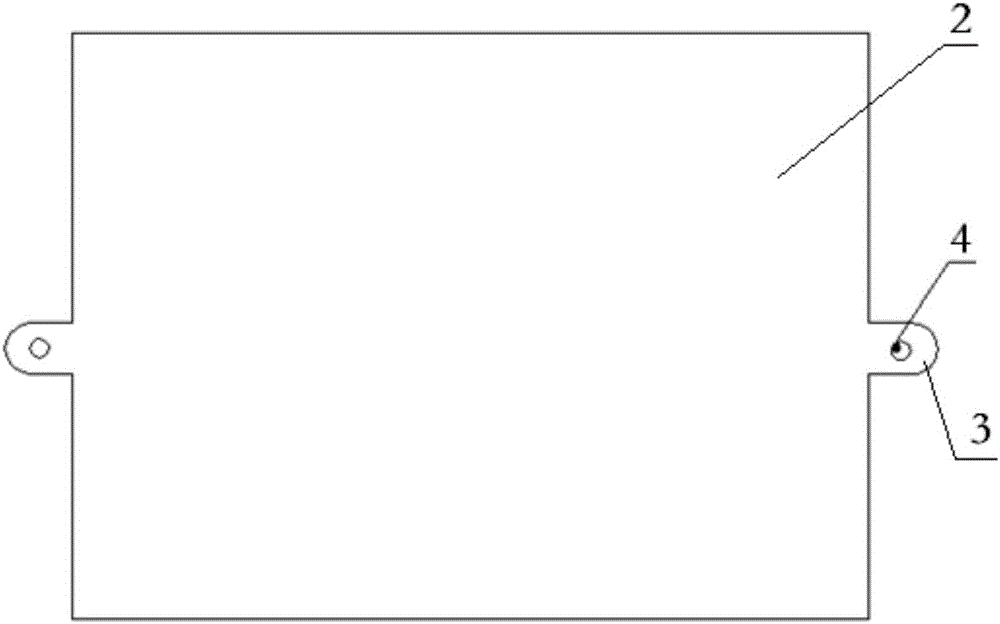

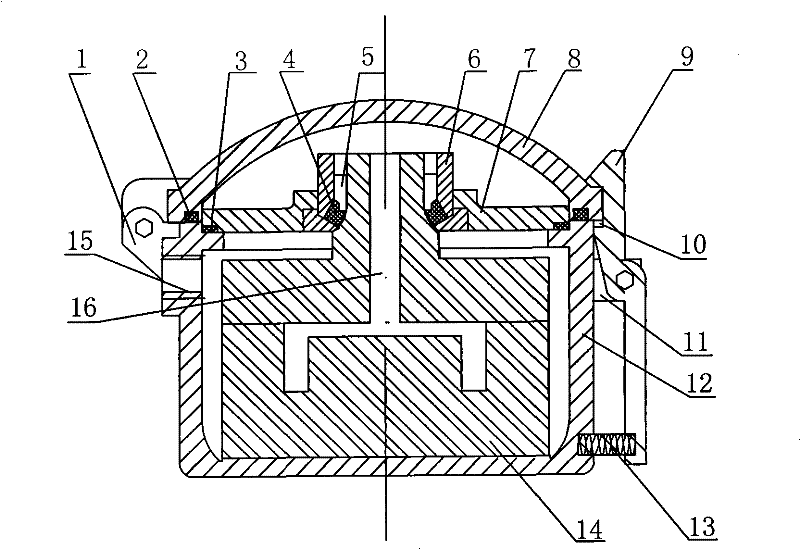

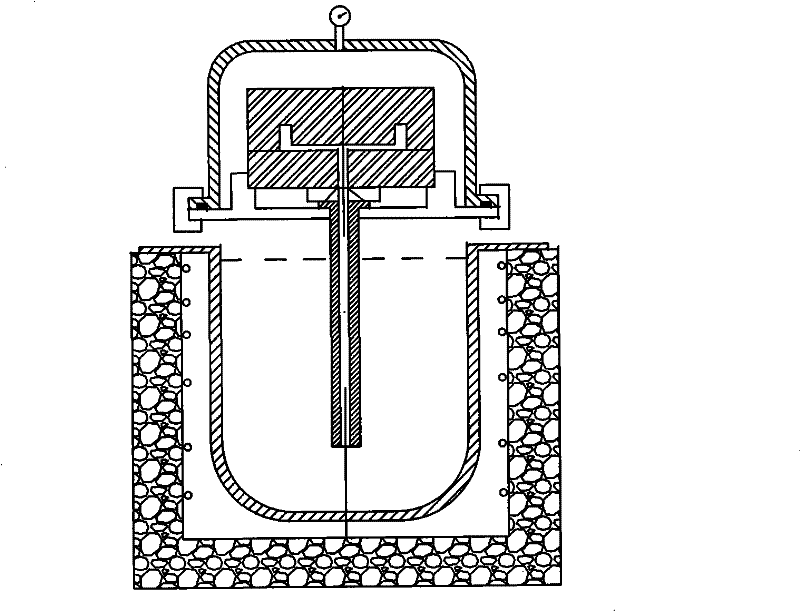

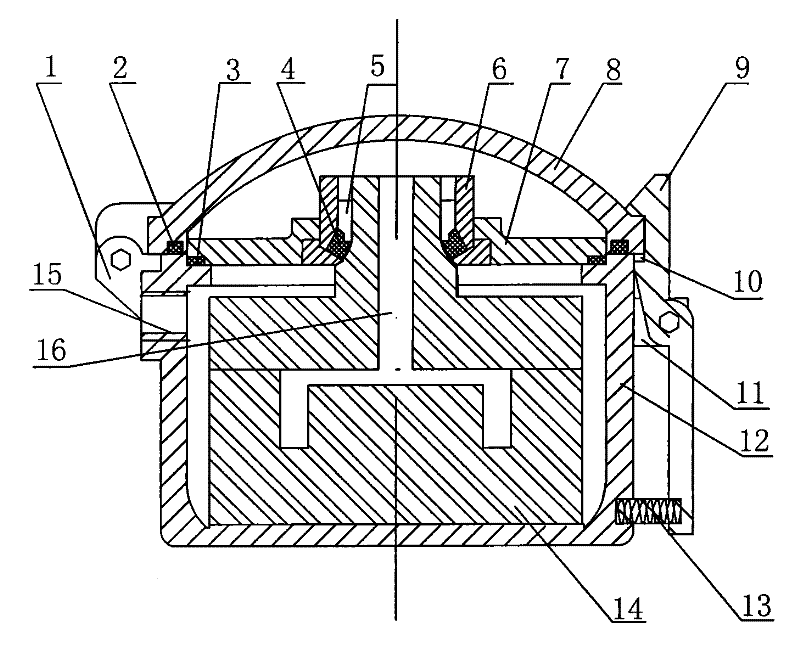

Quasi pressure adjusting casting machine and casting method thereof

The present invention relates to a quasi pressure adjusting casting machine comprising a casting kettle, a vacuum baffle, an upper cover, a rapidly locking mechanism, a sealing taper cylinder and a right-angle sealing ring, wherein The upper cover is hinged with an upper cover hinge ear arranged at one side of the casting kettle; the middle of the rapidly locking mechanism is hinged with a locking mechanism hinge ear arranged at the other side of the casting kettle; a groove locked with the upper cover is arranged on the upper end of the rapidly locking mechanism, and a swelling force spring connected with the casting kettle is arranged at the lower end; both ends of the swelling force spring are respectively fixed on the casting kettle and the rapidly locking mechanism; the right-angle sealing ring is arranged in the vacuum baffle, and the vacuum baffle is covered at an opening at the top of the casting kettle; and the sealing taper cylinder is internally sheathed in the right-angle sealing ring. The present invention solves that aluminum alloy thin wall pieces are difficult to form and the aluminum alloy thin wall pieces always appear the problems of microshrinkage, poor tightness and suppress leakage. The present invention has the advantages of that super-thin aluminum alloy casting pieces can be produced; the strength of casting pieces can be improved about 25%; the toughness of the casting pieces can be improved to 80 % to 100%; the production rate is high; and the equipment cost is tens times as low as pressure adjusting casting equipment.

Owner:SHENYANG LIGONG UNIV

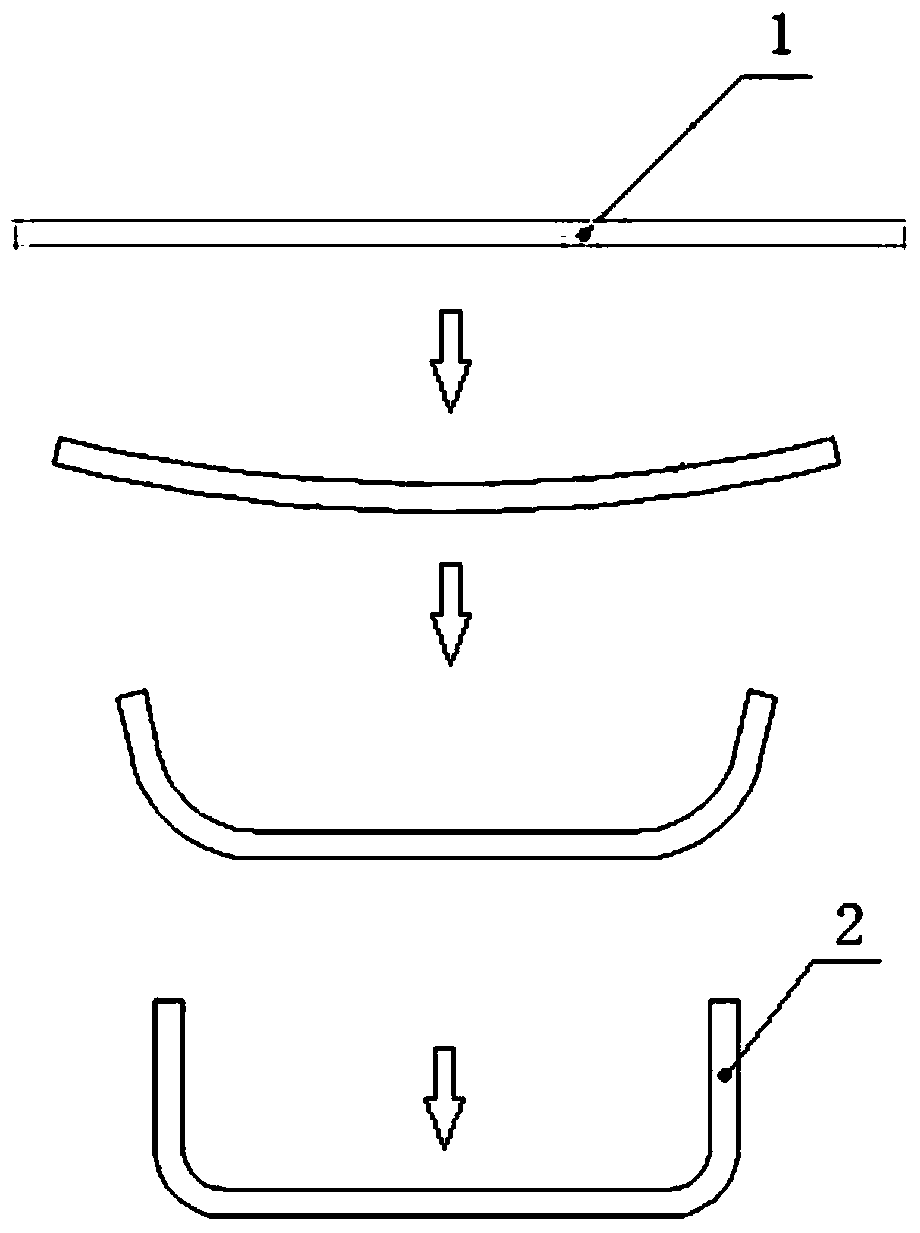

Forming method and forming mold of semi-closed sheet part

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

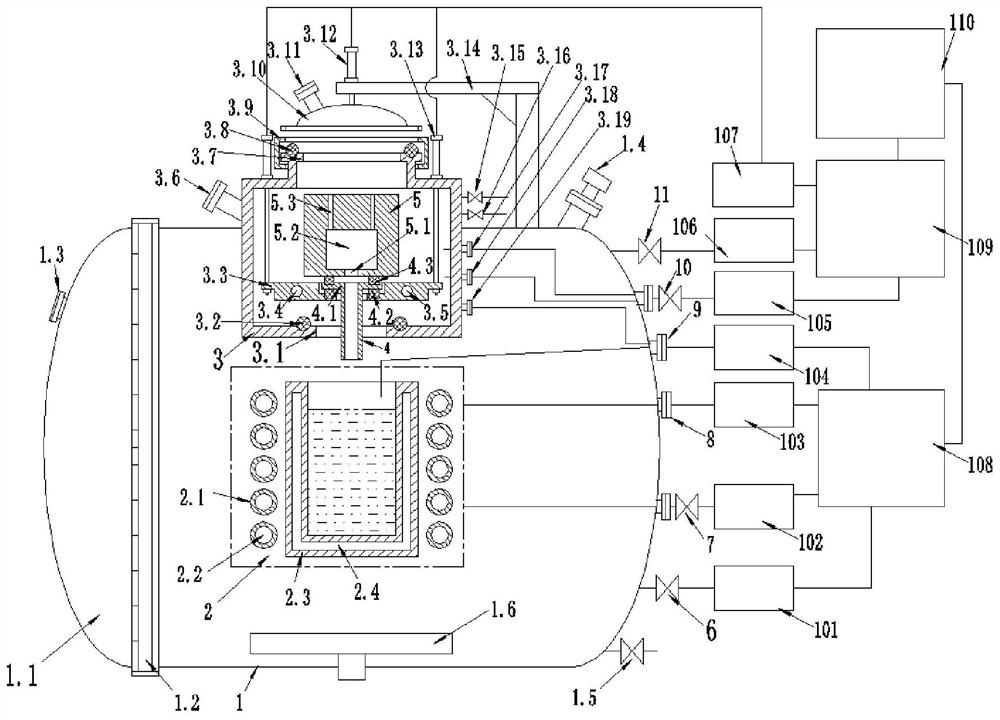

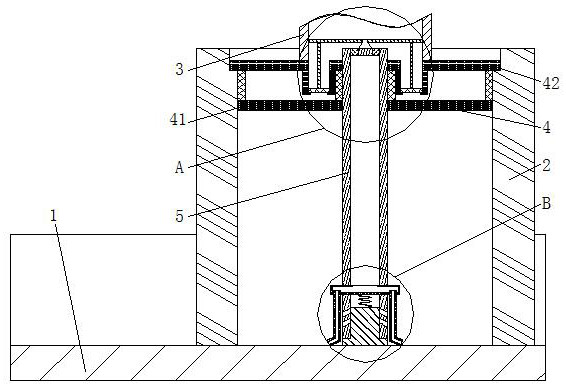

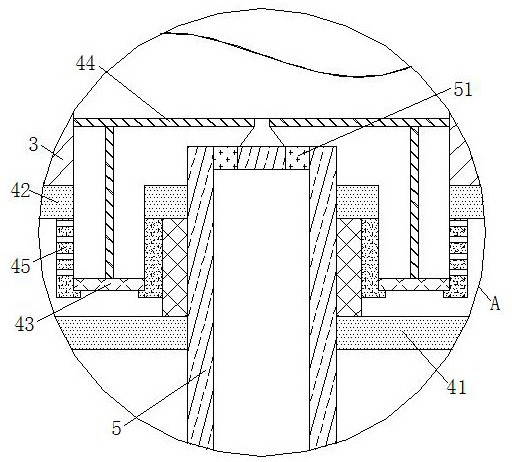

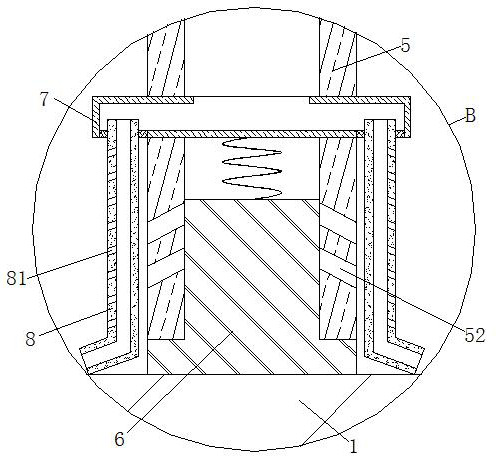

Inverse gravity filling forming device of large-size complex amorphous alloy component

ActiveCN113275541AGuaranteed Cooling RequirementsControl heating rateMolten metal conveying equipmentsAlloyActuator

The invention discloses an inverse gravity filling forming device of a large-size complex amorphous alloy component, relates to an amorphous alloy casting device, and aims to provide equipment for ensuring the purity of a smelted alloy, overcoming gravity constraint filling casting and realizing relatively rapid solidification and cooling. The inverse gravity filling forming device comprises a smelting cabin, an induction heating system, an inverse gravity filling cabin, an inverse gravity filling riser tube, an amorphous component forming die and a computer control actuator. The smelting cabin is a sealed tank body, the induction heating system is arranged in the smelting cabin, the inverse gravity filling cabin is arranged above the induction heating system and is installed on a shell at the top of the smelting cabin in a sealed manner, the inverse gravity filling riser tube is installed at the bottom of the inverse gravity filling cabin, the amorphous component forming die is installed at the position, above the inverse gravity filling riser tube, in the inverse gravity filling cabin, and the induction heating system, the inverse gravity filling cabin, the inverse gravity filling riser tube and the amorphous component forming die all communicate with the computer control actuator. The invention belongs to the field of casting forming.

Owner:HARBIN INST OF TECH

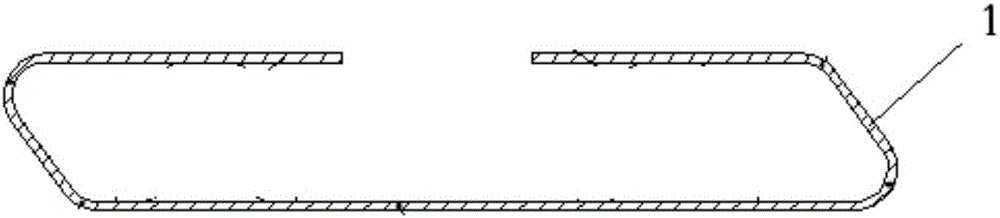

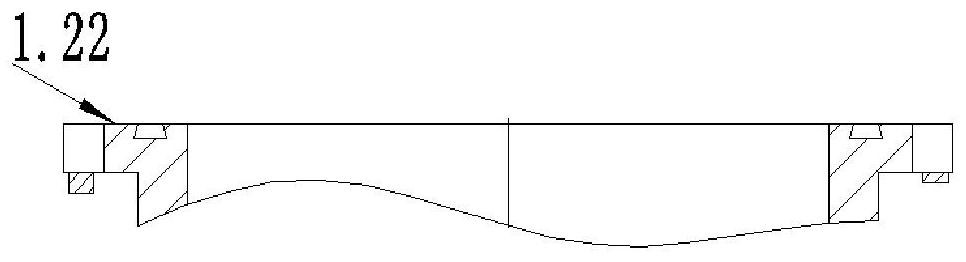

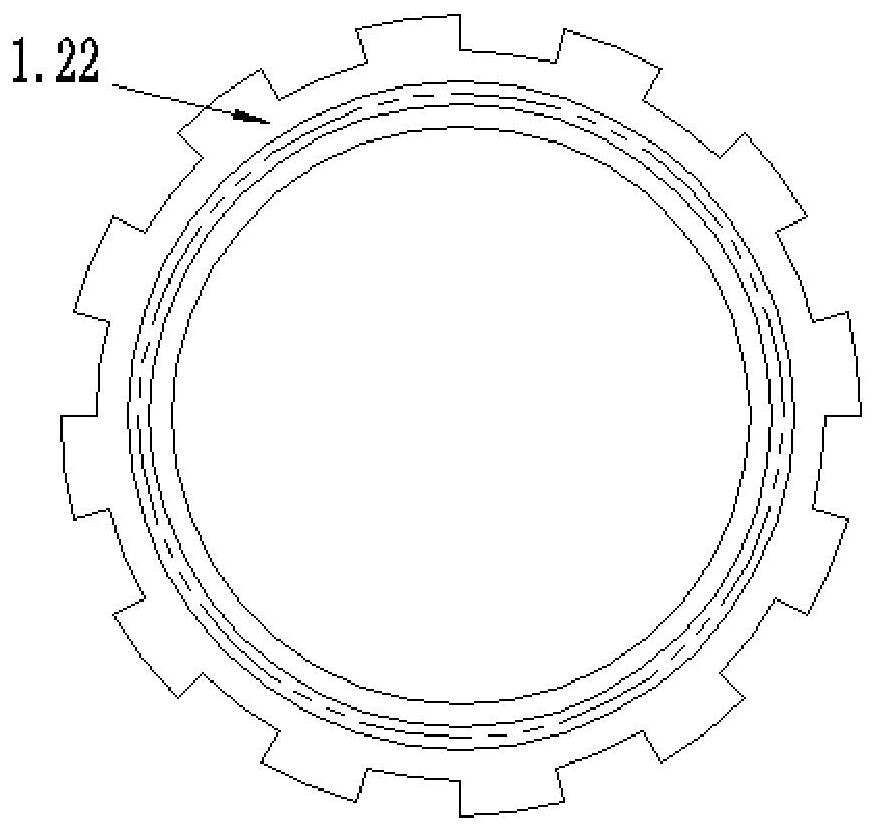

Machining method of split sleeve

The invention relates to the technical field of improvement of the strength of aircraft or high-speed locomotive structural fastener connecting holes and specifically relates to a method for intensifying the strength of an aircraft or high-speed locomotive structural fastener connecting hole in an extruding mode, in particular to a machining method of a split sleeve. The method comprises the following steps that raw materials are selected according to specification requirements of the required stainless steel split sleeve, wherein the raw materials are hard stainless steel plates which are subjected to no heat treatment when leave a factory; and the raw materials are subjected to annealing heat treatment and then subjected to rolling depression and leveled on a roller press according to needs, the thickness is adjusted, and after calculation and blank layout are completed, the raw materials are cut into bar-shaped to-be-machined raw materials. According to the machining method of the split sleeve, heat treatment is adopted for the excessively thicker stainless steel plates subjected to no heat treatment, firstly the thickness is adjusted, then punching blanking and bending and rounding linkage forming reinforcing are performed, and the problem that high-strength stainless steel sheets are difficult to form is solved in the mode that the thickness of the stainless steel plates subjected to heat treatment is adjusted firstly, and then punching blanking and bending and rounding linkage forming reinforcing are performed.

Owner:宗仁斌

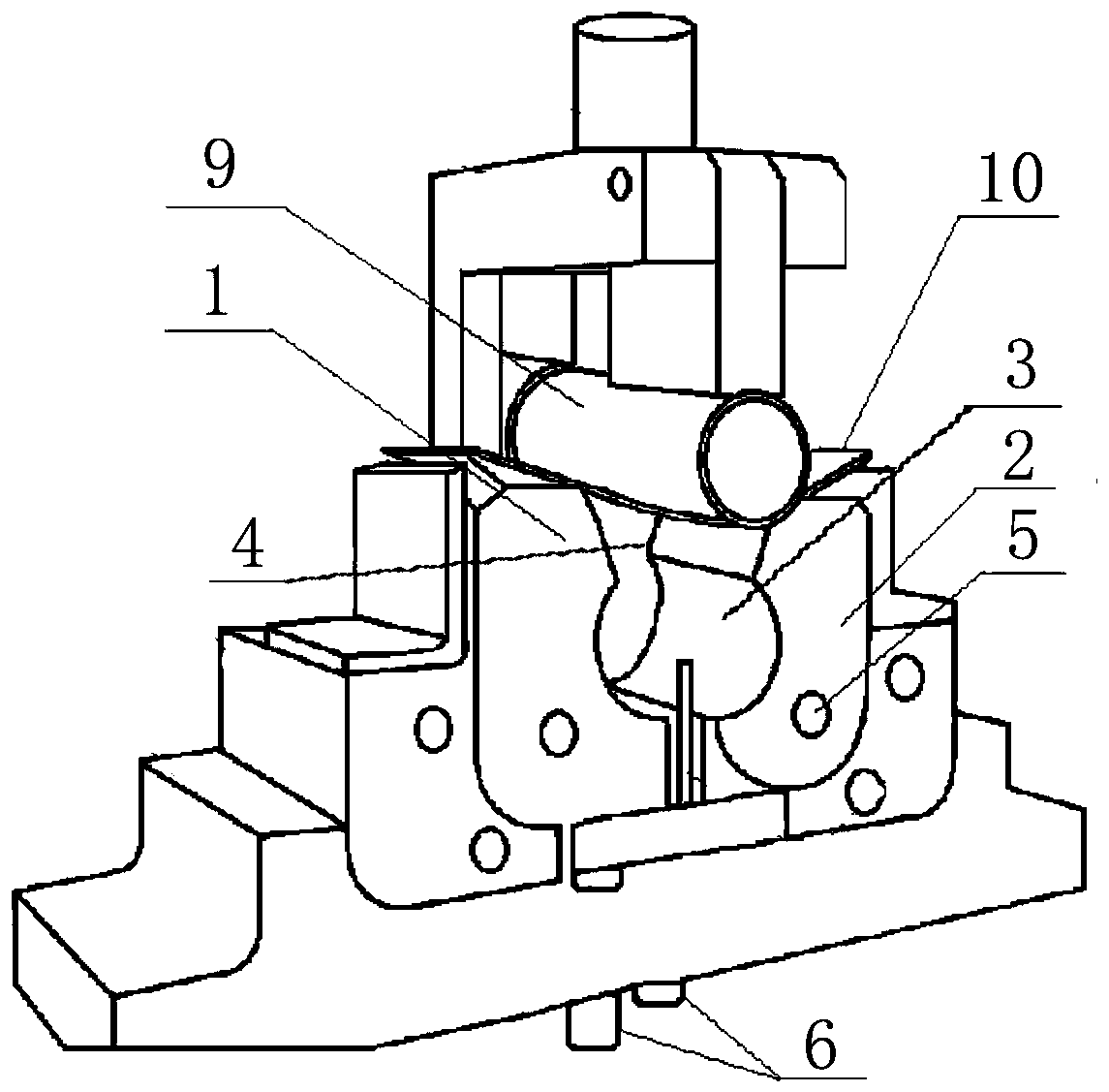

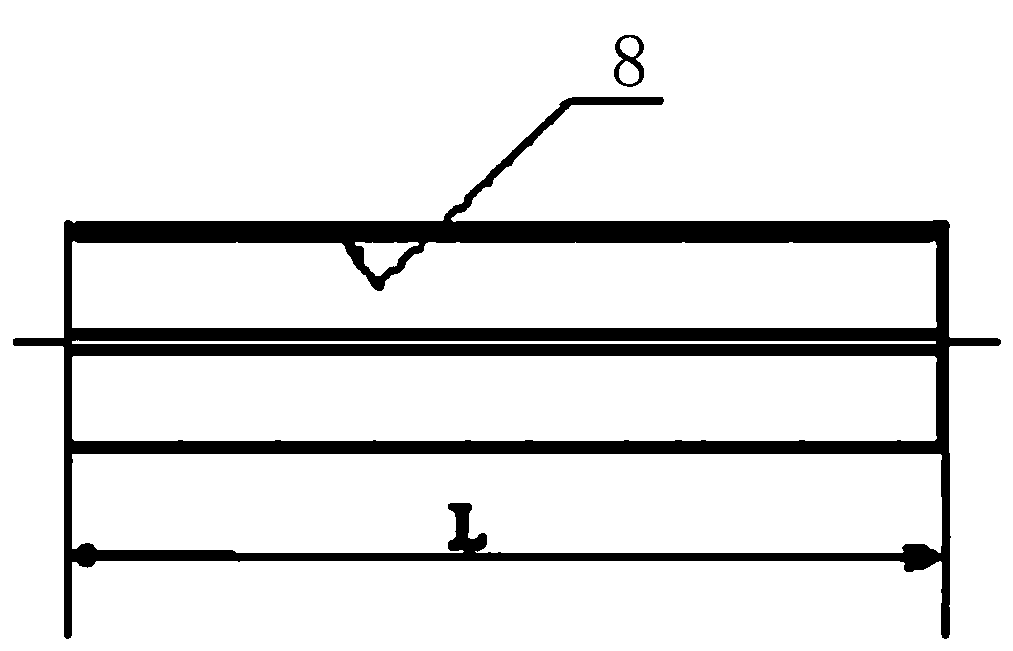

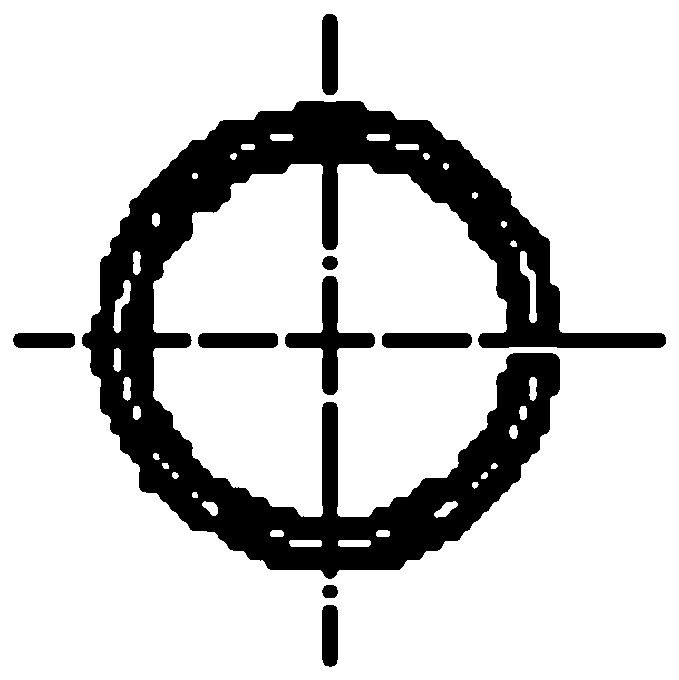

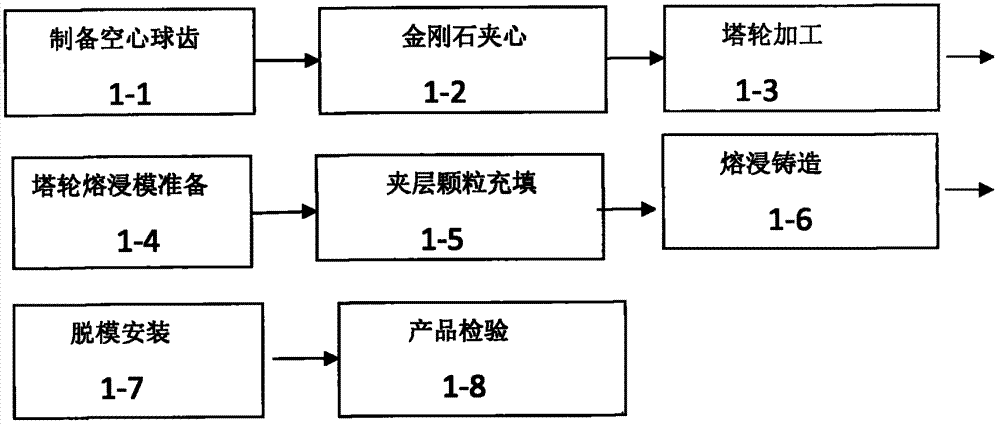

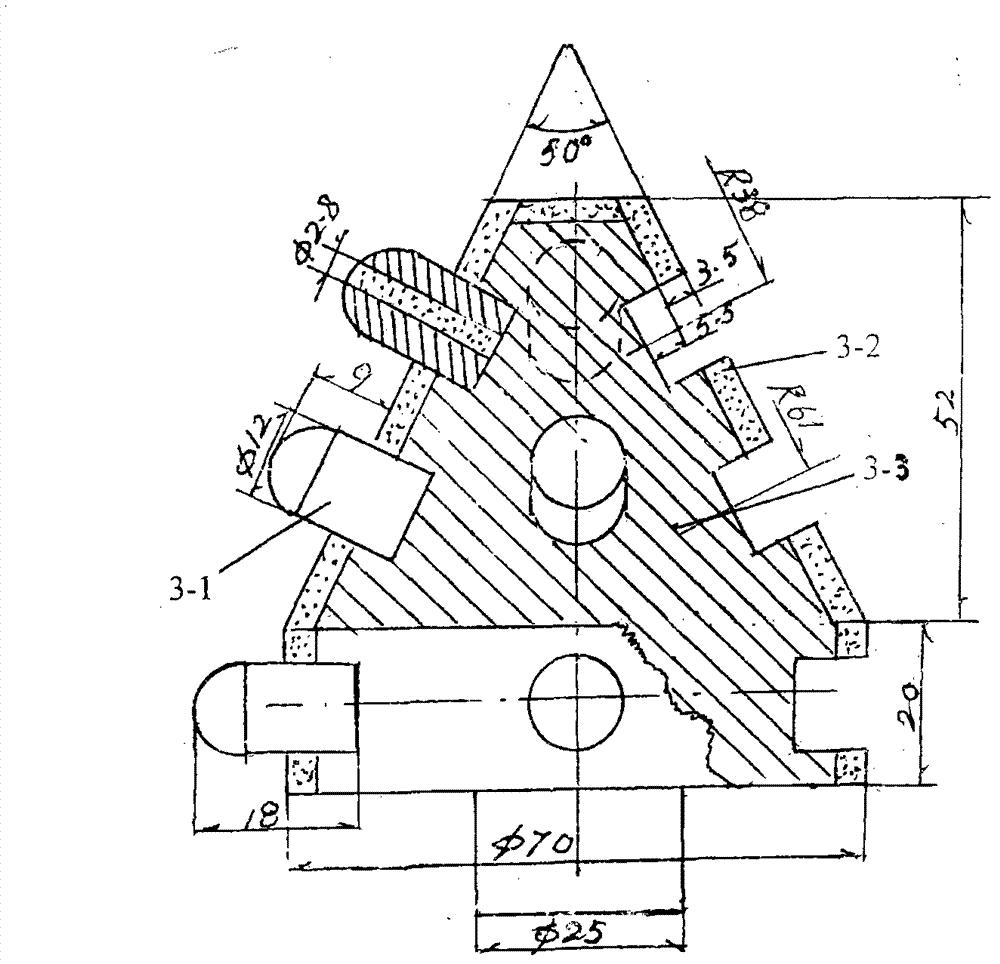

Preparation technology of novel roller bit used in geological and oil industry

InactiveCN103358103AIncrease overall densityImprove wear resistanceGearingCylindersSubmarineUltra fine

The invention belongs to the field of a preparation technology of a roller bit in the geological prospecting and oil exploitation industry, and particularly provides a production technology of novel diamond sandwich type ultra-fine grain sintered carbide ball teeth. Artificial diamond grains can be added to the centers of the sintered carbide ball teeth, and therefore machinability and abrasive resistance of the sintered carbide ball teeth are enhanced greatly. According to the preparation technology, the technology that the surface of a cone pulley is completely covered with a sintered carbide layer through the grain melting soaking casting technique is adopted, and therefore all the ball teeth can be reinforced by the sintered carbide layer and connected into a whole. Actually, materials and the overall structure of the roller bit are changed, the stress state of each ball tooth is greatly improved, and grinding force and impact force borne by part of the ball teeth are rapidly buffered and dispersed through the sintered carbide overall shell layer. Finally, the drilling speed of the roller bit can be promoted, the service life of the roller bit is prolonged, and the roller bit can show the excellent characteristics better when used during submarine oil drilling under the harsh conditions.

Owner:吴庆华 +2

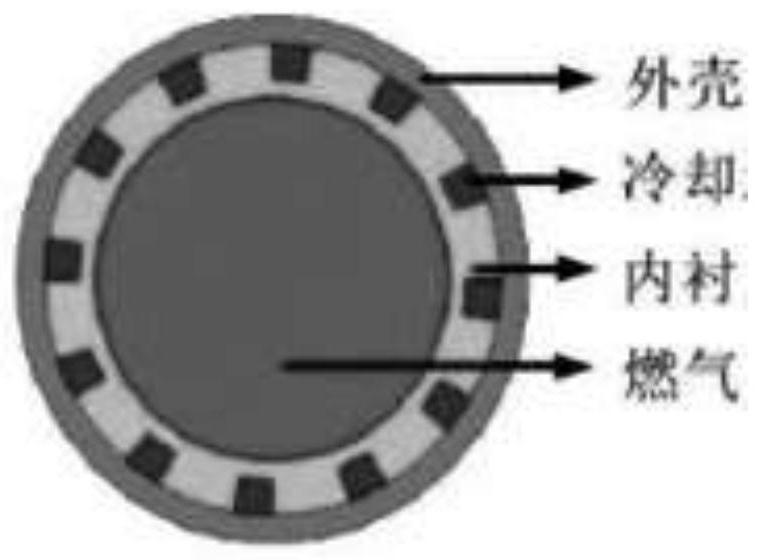

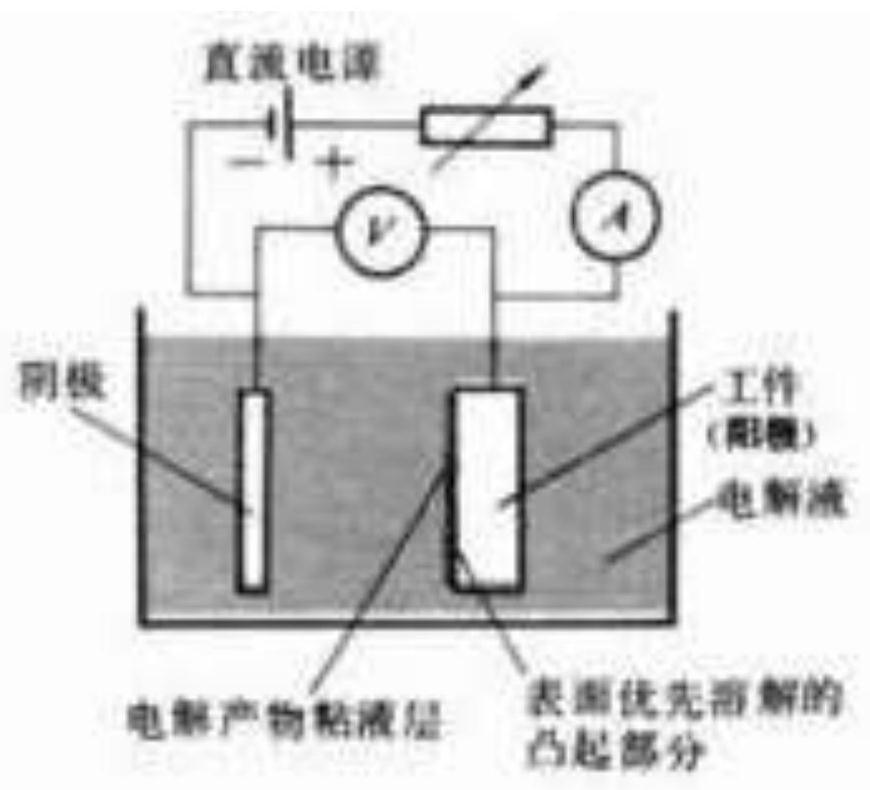

Method for reducing flow resistance of interlayer cooling structure of 3D printing thrust chamber

InactiveCN112359408ASmall flow resistanceReduce surface roughnessAdditive manufacturing apparatusElectrolytic agentThrust chamber

The invention discloses a method for reducing the flow resistance of an interlayer cooling structure of a 3D printing thrust chamber. The method comprises the following steps: firstly, the interlayercooling structure of the thrust chamber is optimally designed, and then a workpiece is formed by adopting a 3D printing technology; the formed interlayer cooling structure of the thrust chamber is treated by adopting an electrochemical polishing and plasma electrolytic polishing technology; and through cooperation of the two technologies, the needed workpiece can further reach the needed performance, rough polishing is conducted through the electrochemical polishing technology, and fine polishing is conducted through the plasma electrolytic polishing technology. According to the plasma electrolytic polishing technology, the surface quality of parts can be improved by adjusting the proportion of electrolyte and the magnitude of current and voltage, initiation and expansion of a crack sourceare effectively reduced, the flow resistance of the interlayer cooling structure of the thrust chamber is effectively reduced, the service condition of the interlayer cooling structure of the thrustchamber under specific conditions is achieved, the problem of workpieces at present is solved, and the application range of the 3D printing technology and a surface modification technology in the aerospace field is widened.

Owner:XIAN UNIV OF TECH +1

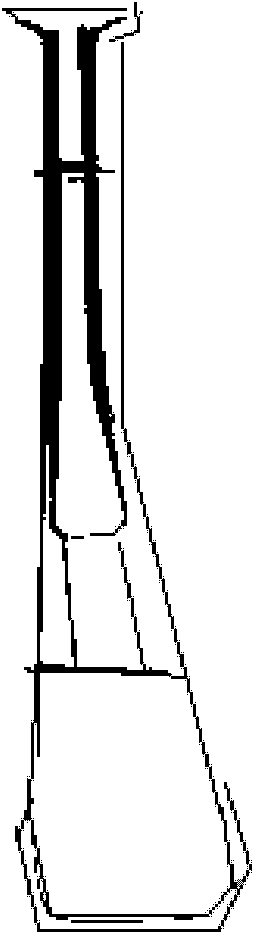

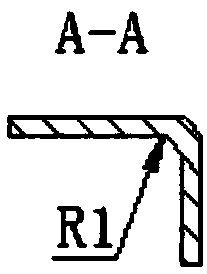

Novel hand-rail aluminium section hot-extrusion die

InactiveCN101362162ASufficient supplyGuaranteed surface qualityExtrusion diesRail profileCavity wall

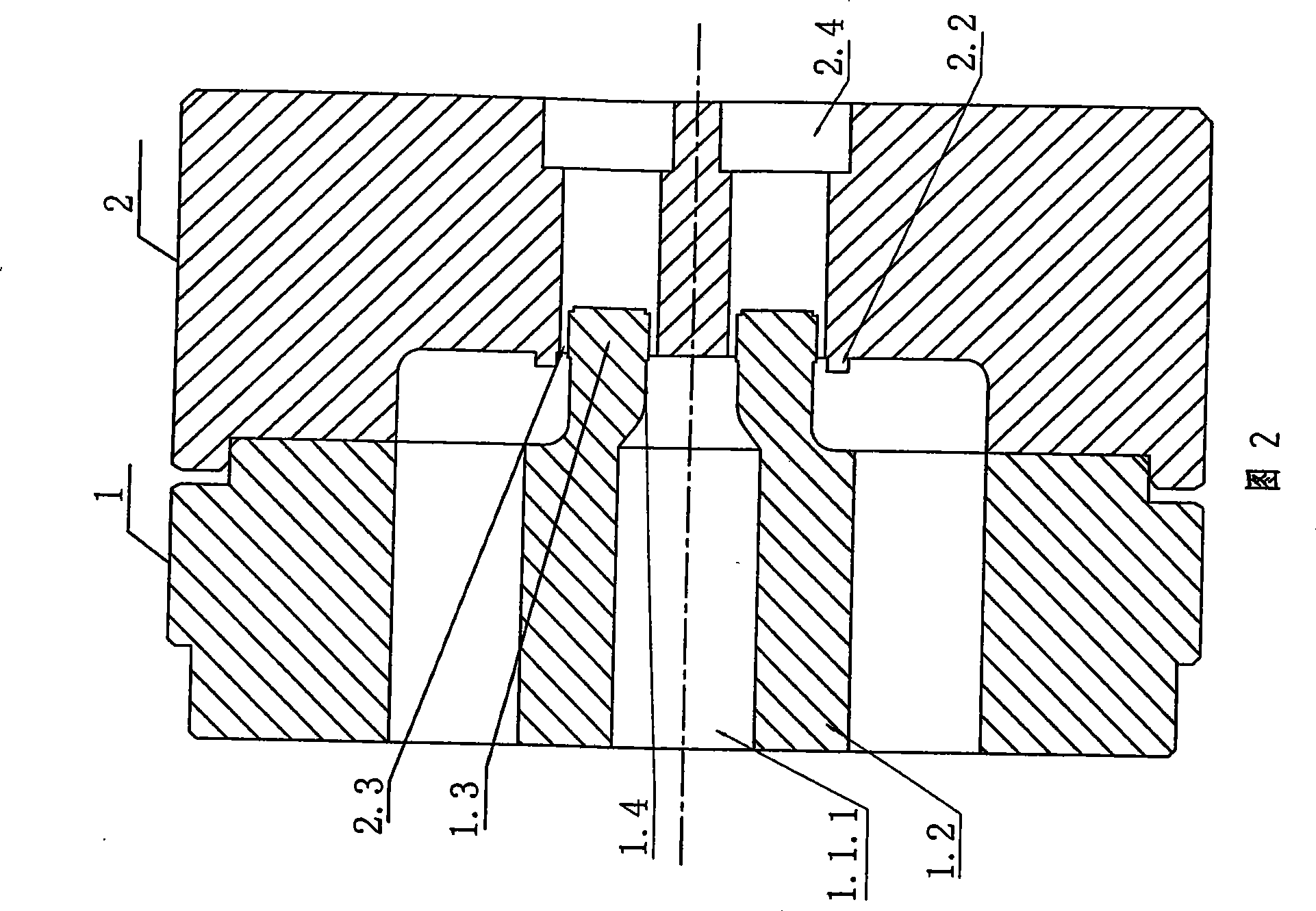

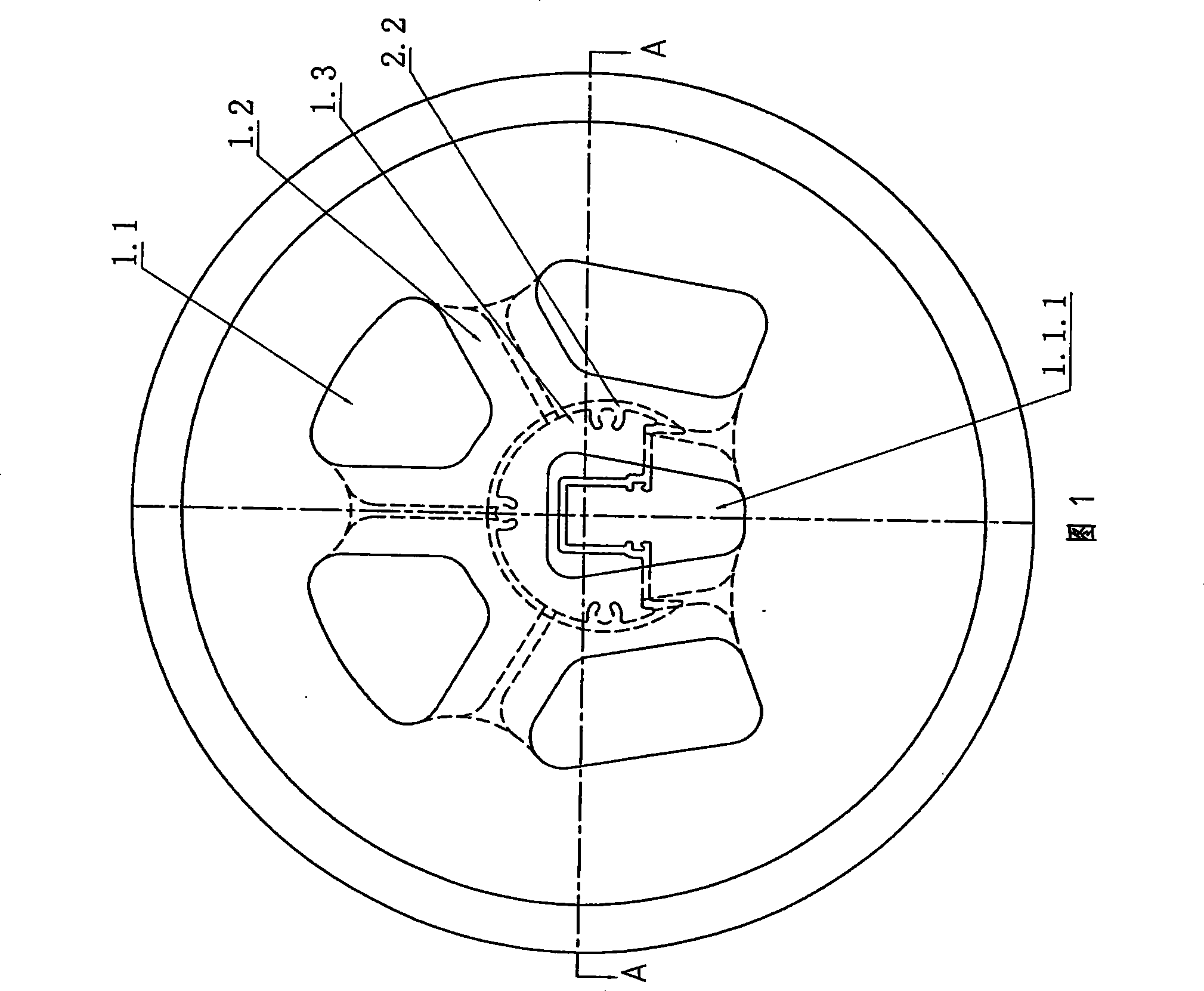

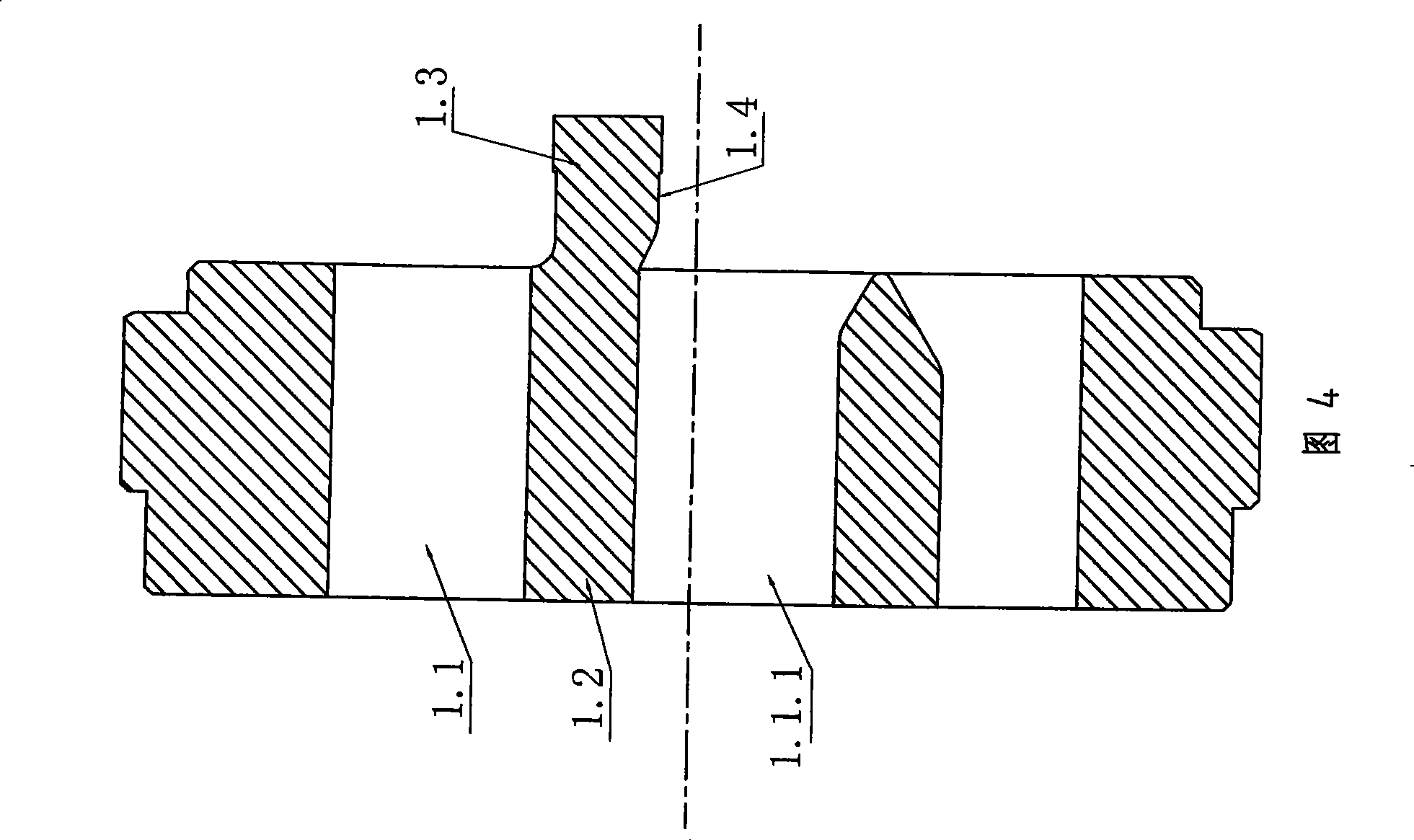

The invention relates to a novel aluminum profile hot extrusion mould for a hand rail, which is mainly used for the hot extrusion of building hand rail profile. The mould comprises an upper mold (1) and a lower mold (2) which are overlaid front and rear, the feeding surface of the upper mold (1) is provided with five flow-dividing bridges (1.2), five flow-dividing holes (1.1) are formed among the five flow-dividing bridges (1.2), the middle flow-dividing hole shrinks from large to small, thus forming a large head and a small head, furthermore, the large head is arranged in the center of the feeding surface of the upper mold (1), and the hole is called a direct impact groove flow-dividing hole (1.1.1). The feeding surface of the lower mold (2) is provided with a welding chamber (2.1), the rear of which is provided with a mold cavity (2.3), and the middle of the mold cavity (2.3) is provided with a groove position (2.3.1) which is arranged directly below the large head end of the direct impact groove flow-separating hole (1.1.1). The bottom of the welding chamber (2.1) is provided with an arc-shaped flow-blocking plate (2.3) in an upward convex way along the cavity wall of the mold cavity (2.2). The mould ensures adequate feeding at the groove part of the mold cavity of the lower cavity and the uniform discharging of the extruded aluminum profile, without the problems of hand feeling and welding strips, etc.

Owner:JIANGYIN GIANSUN MOLD

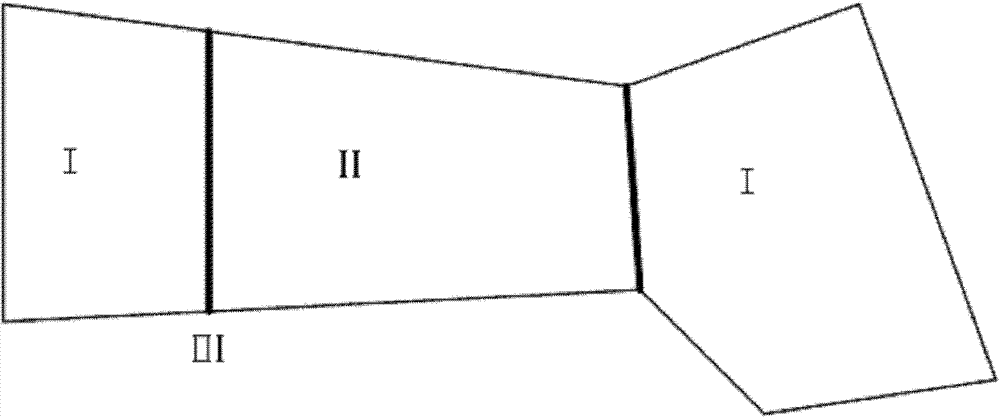

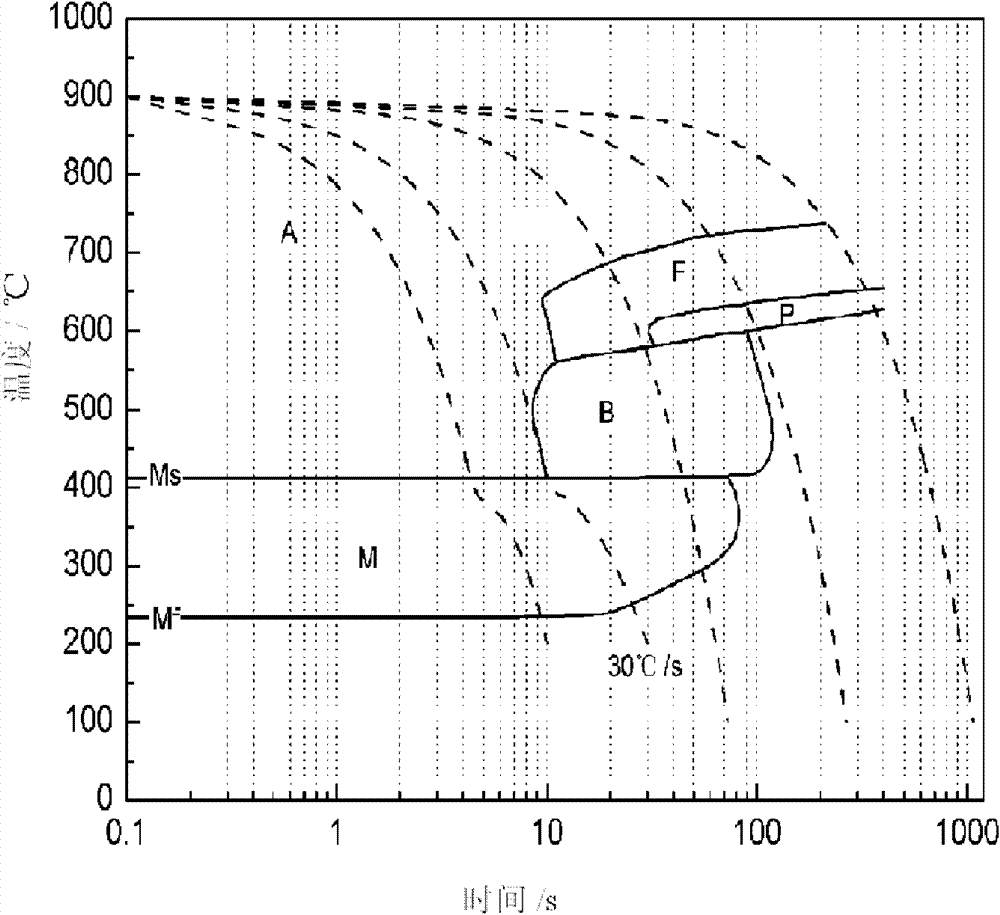

Ultrahigh-strength steel laser tailor welded blank and forming process thereof

InactiveCN102162574BGood formabilityReduce weightSheets/panelsLaser beam welding apparatusHot stampingShielding gas

The invention relates to an ultrahigh-strength steel laser tailor welded blank and a forming process thereof. The forming process provided by the invention comprises the following steps: carrying out the laser tailor welding on ultrahigh-strength steel and high-strength steel according to the needed shape; then, delivering the obtained welded blank to a furnace filled with a protective gas and heating to 920-940 DEG C to be continued for at least 5 minutes; fully austenitizing; transferring the austenitized welded blank to a press machine to be rapidly molded and formed; cooling to 100-150 DEG C through pressurization quenching; and cooling along room temperature to obtain the needed parts. The hot stamping process of the laser tailor welded blank provided by the invention has the double advantages of the forming and hot stamping forming of the laser tailor welded blank and simultaneously solves the problems that the ultrahigh-strength steel is difficultly applied to the production ofautomobile structural components / framework components in a laser tailor welded blank mode.

Owner:SHANDONG JIANZHU UNIV

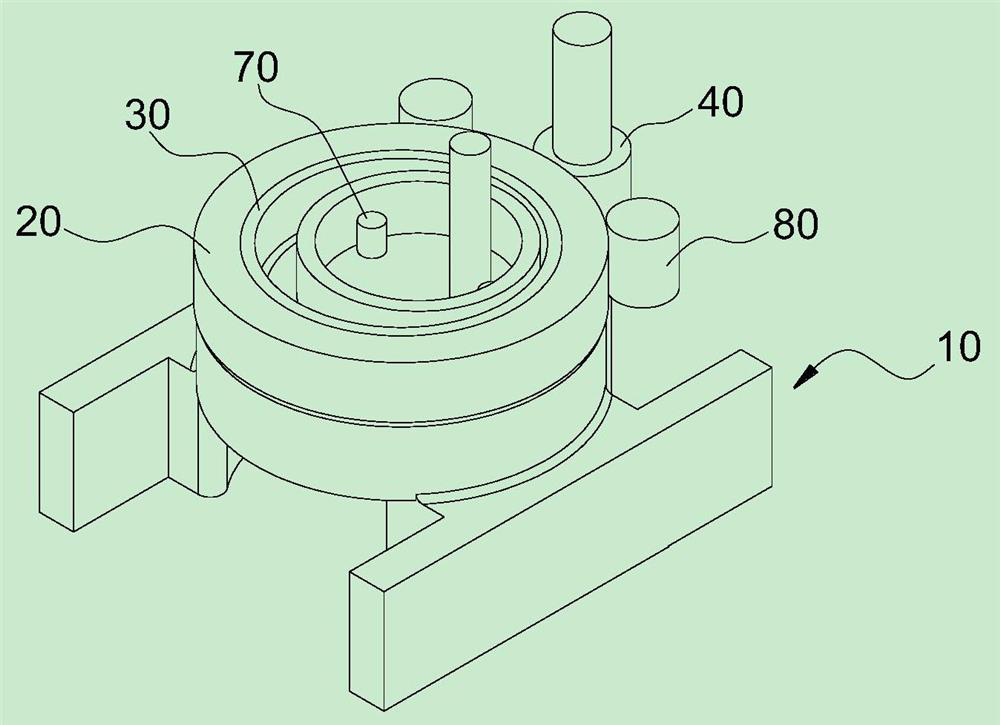

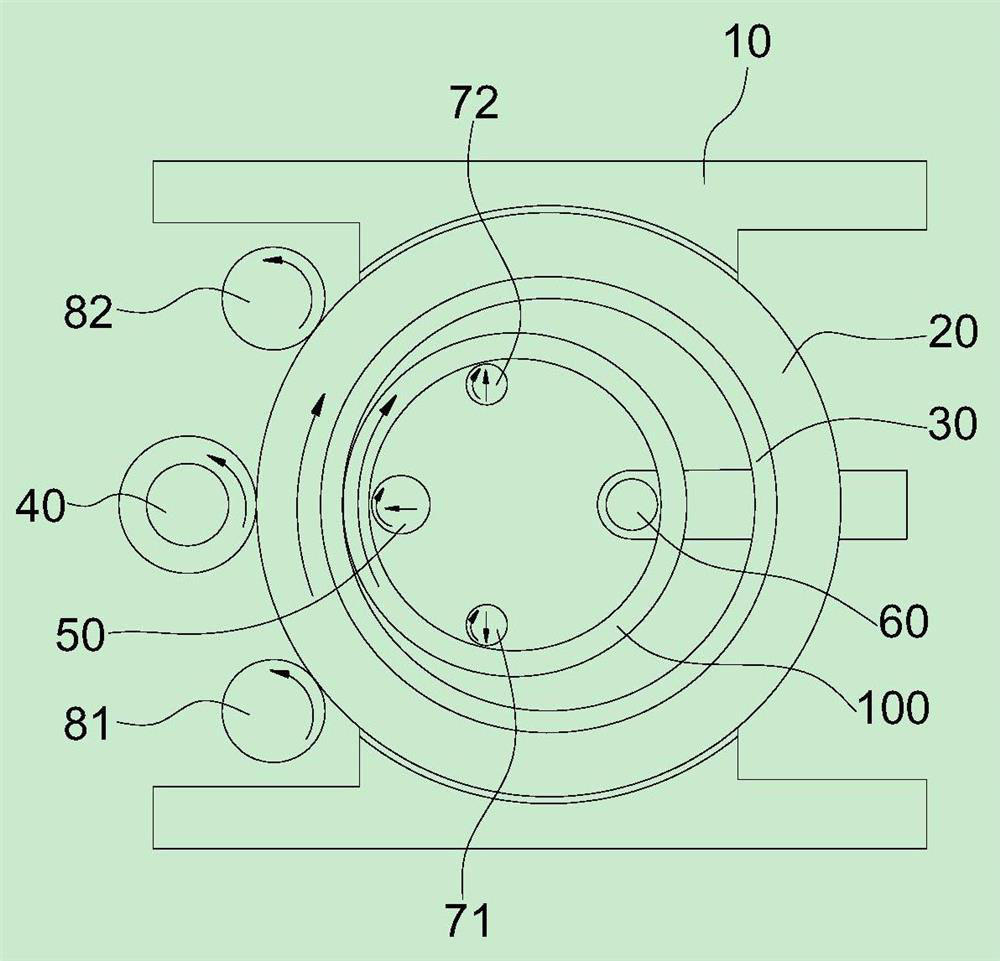

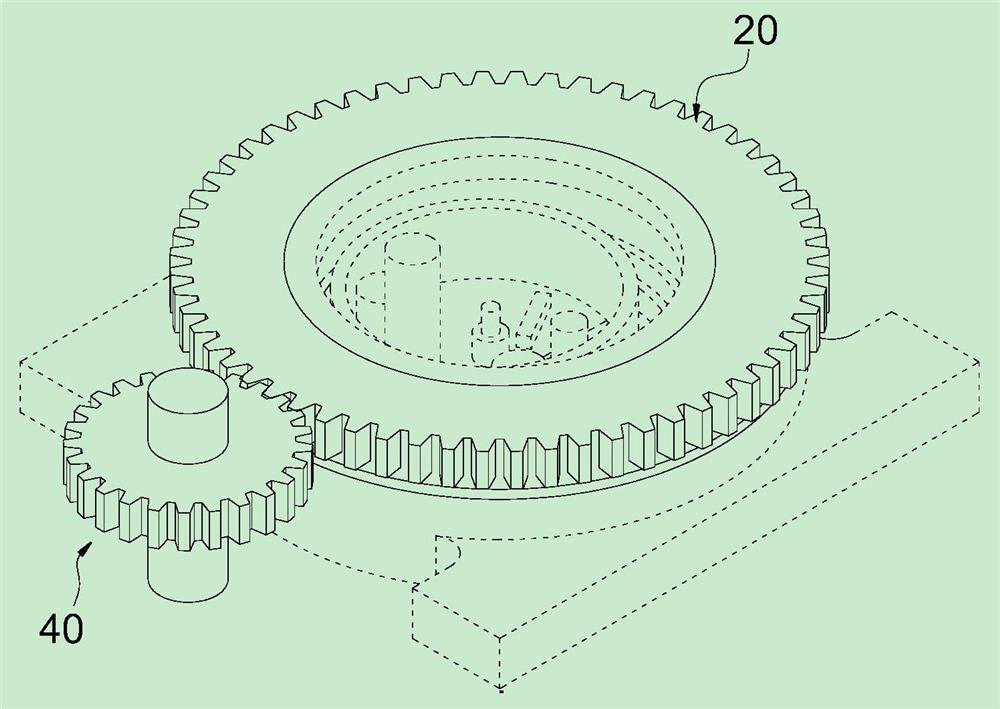

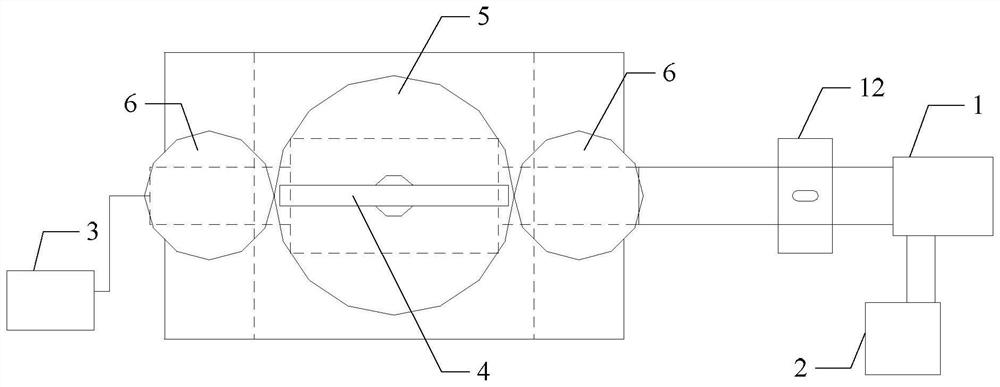

Forming device and forming method of annular part

PendingCN112496212AReduce process marginAccurate shapeMetal rollingMechanical engineeringThin walled

The invention relates to the technical field of manufacturing and forming, and provides a forming device and a forming method for a thin-walled annular part. The forming device structurally comprisesa fixed seat, a driving roller, a forming roller and a driving part, wherein the the driving roller and the forming roller are movably connected with the fixed seat, the forming roller is nested in aninner cavity of the driving roller, and the driving part is in driving connection with the forming roller through the driving roller; and the forming device further comprises a core roller which performs feeding motion in the radial direction of the forming roller. According to the forming device of a revolving body, the problem that a thin-walled revolving body is difficult to form is solved, the production of the thin-walled revolving body is realized, the problem of plastic instability is solved, and the limitation on the wall thickness of a thin-walled part is broken through.

Owner:重庆骄航科技有限公司

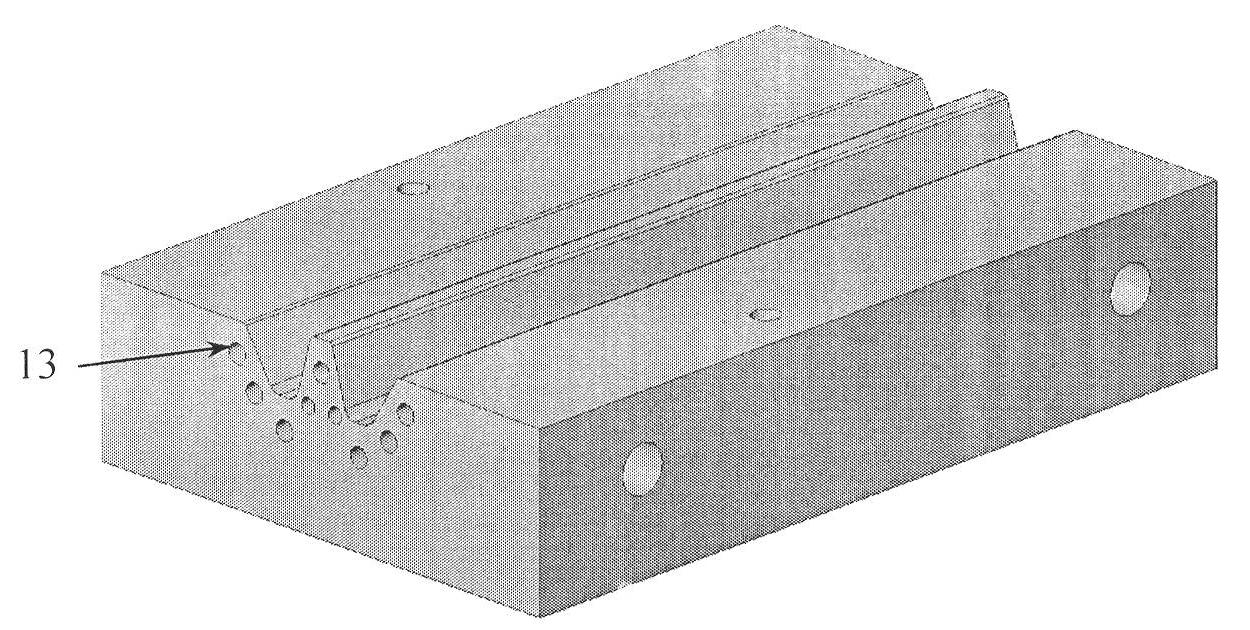

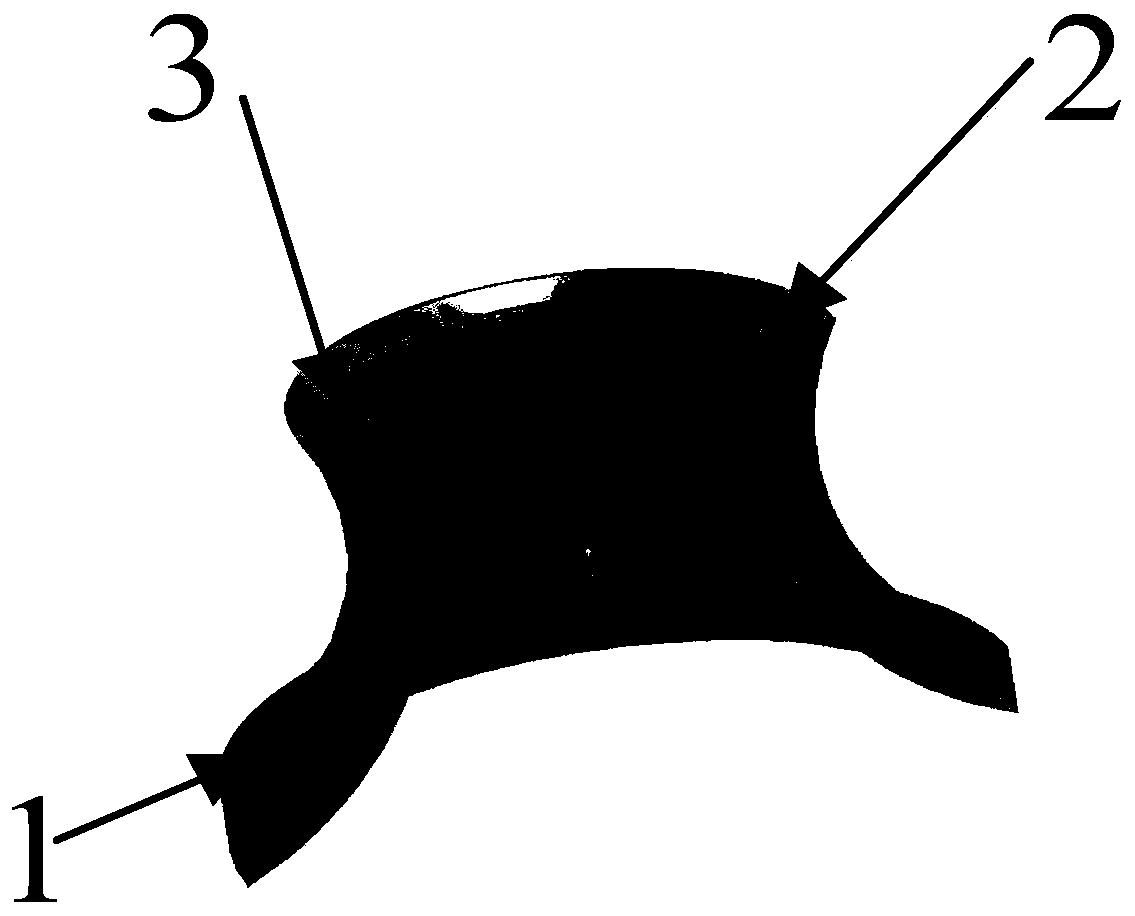

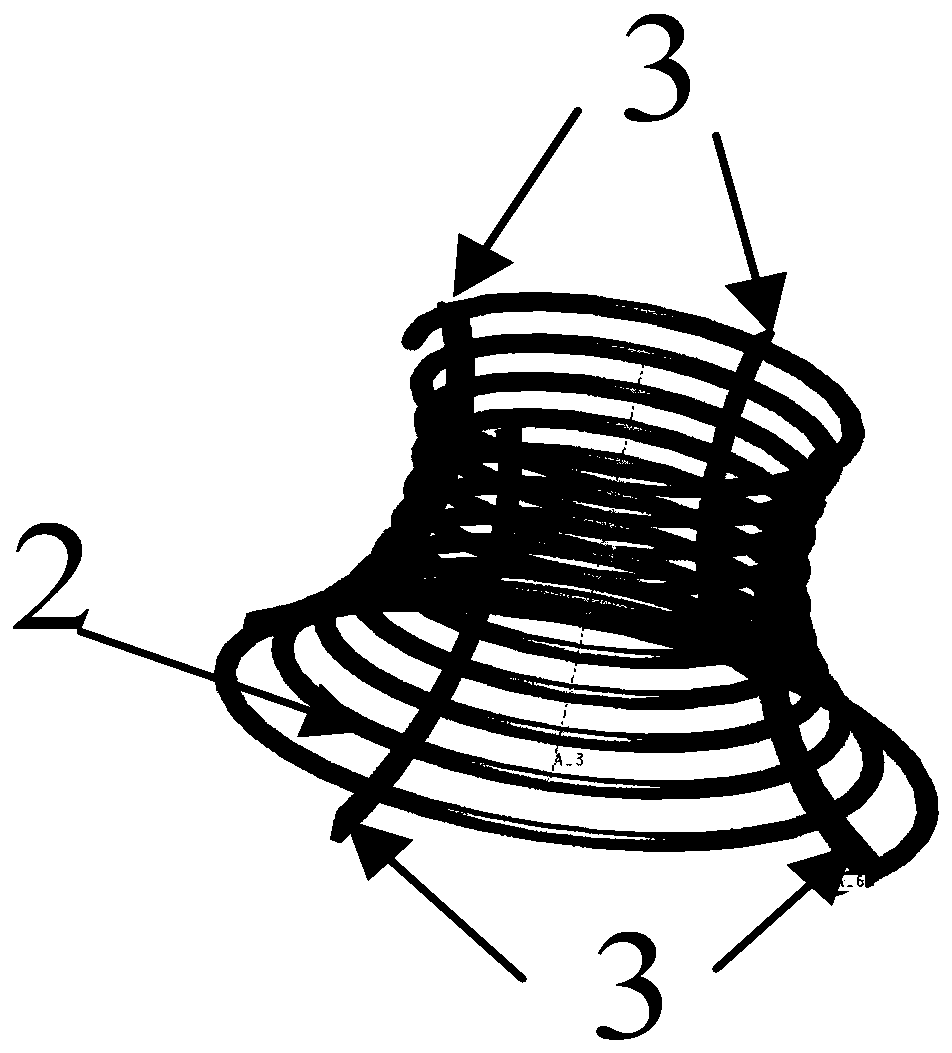

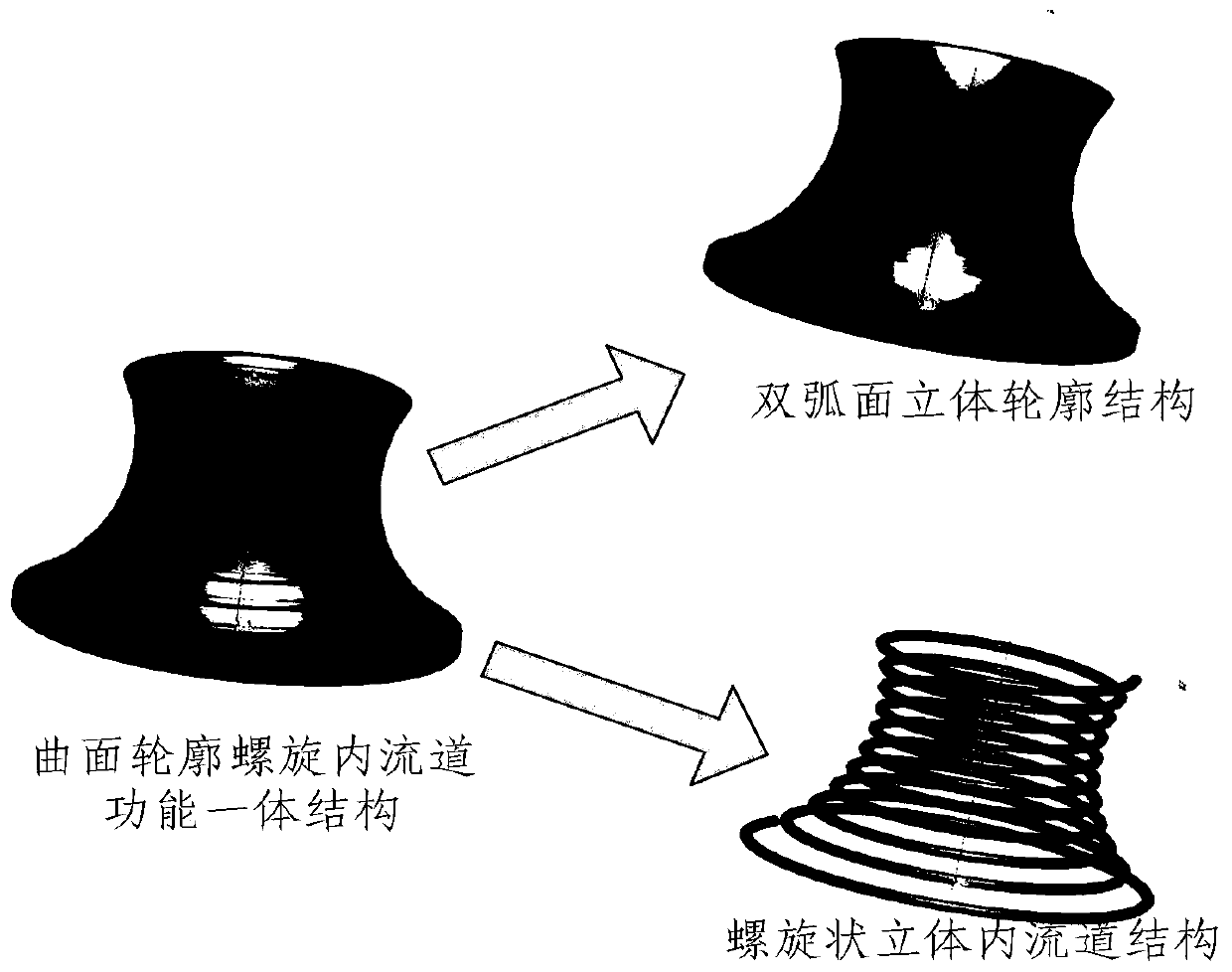

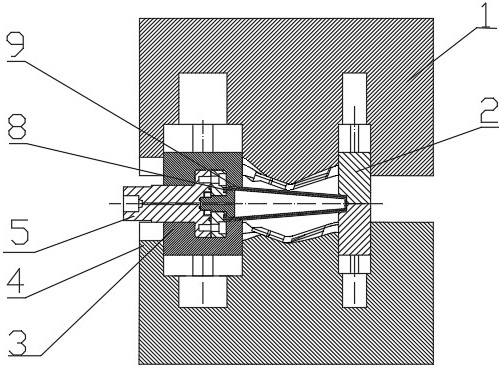

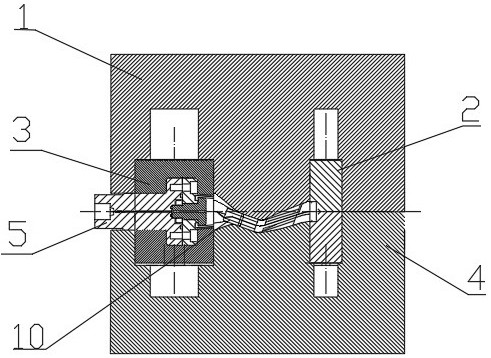

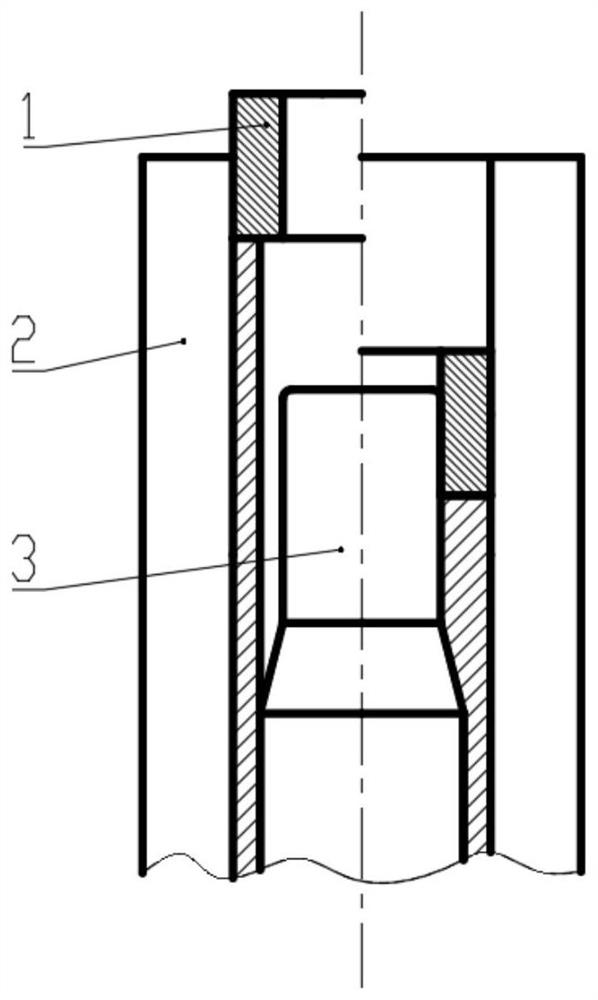

Precise molding method for complex internal flow passage structure

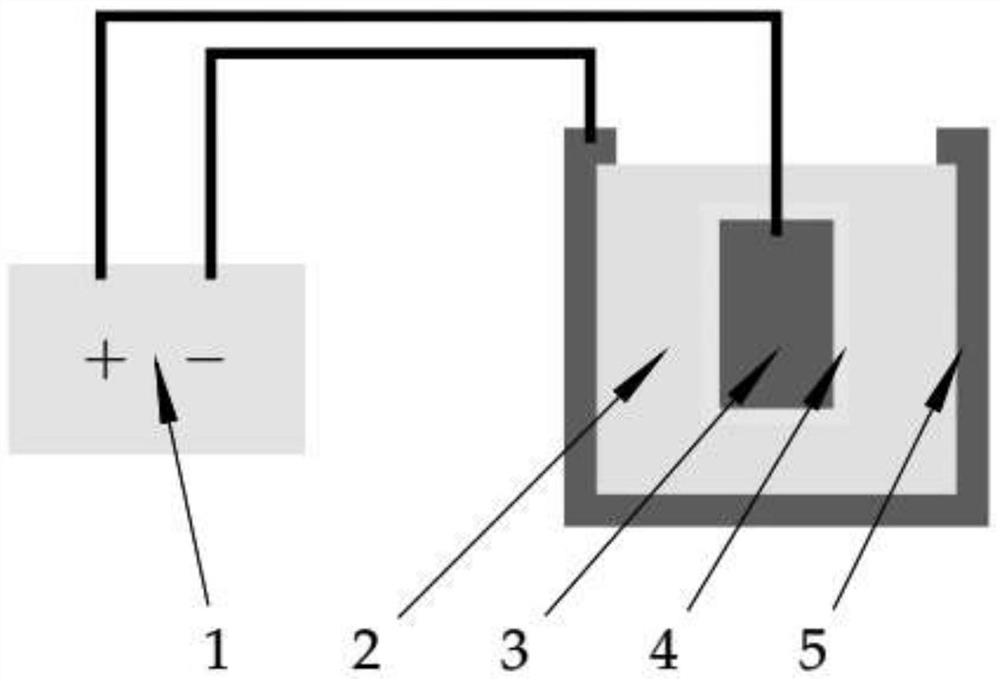

The invention discloses a precise molding method for a complex internal flow passage structure. By building a precise molding device for the complex internal flow passage structure and composed of a contour casting die (1), a prefabricated three-dimensional internal flow passage structure (2) and a fusible supporting frame (3), thin-wall metal pipes with high precision and smooth internal surfacesare adopted to be precisely wound into the three-dimensional internal flow passage structure, the high-precision fusible supporting frame is used for realizing precision positioning of a three-dimensional internal flow passage, and the structural position precision of the three-dimensional internal flow passage structure can be kept in the casting process. By utilizing differences between the three-dimensional internal flow passage structure and a three-dimensional outer contour structural material in melting points, erosion and deformation of the interior of the three-dimensional internal flow passage can be avoided. According to the precise molding method for the complex internal flow passage structure, the problems that in general manufacturing methods, the functionally integrated internal flow passage structure is difficult in a complex internal flow passage molding, low in percent of pass, poor in surface precision of the internal flow passage and the like are solved.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

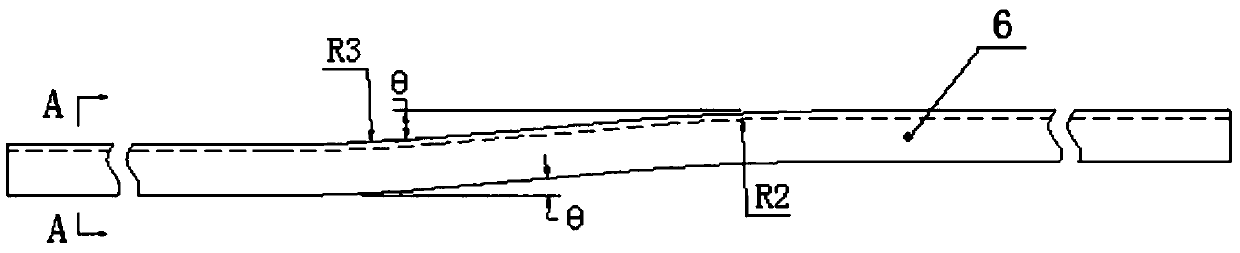

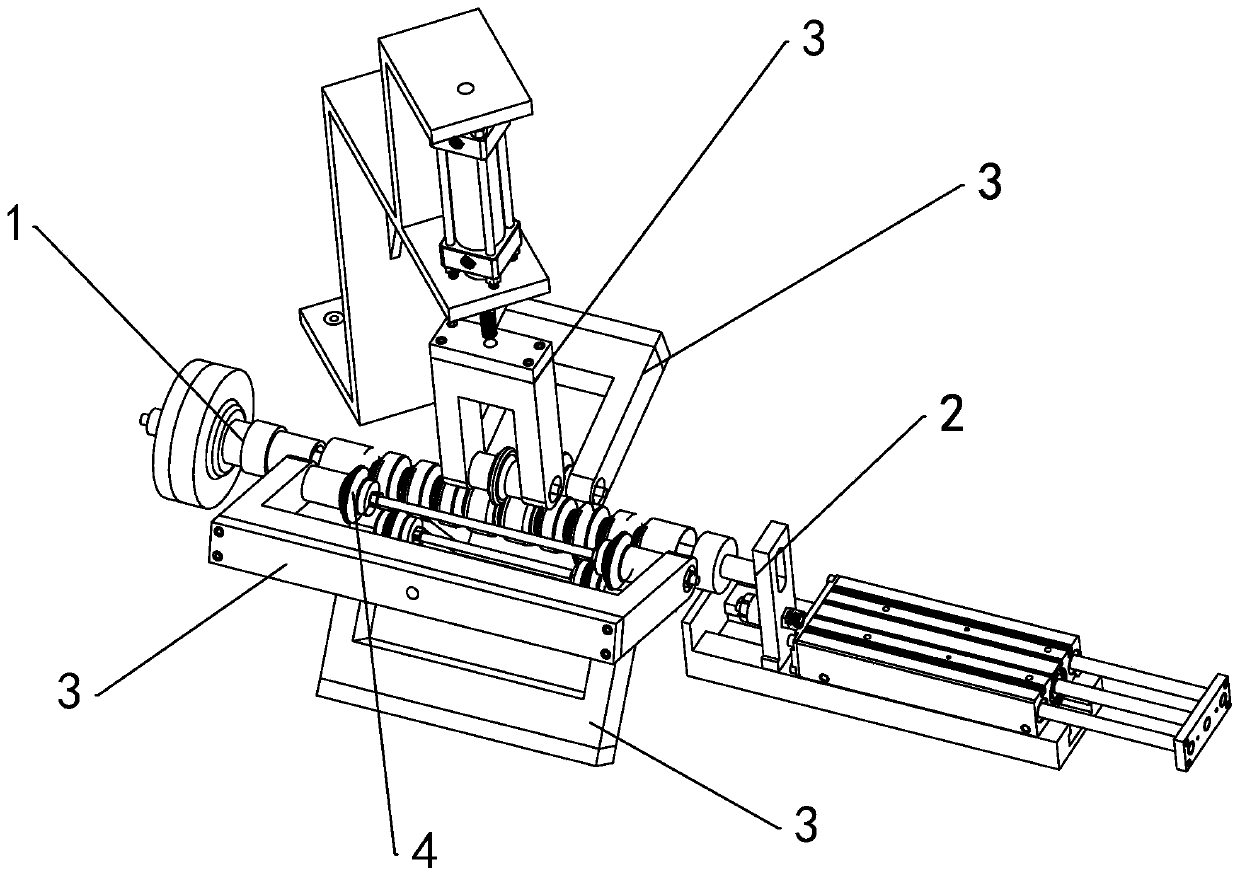

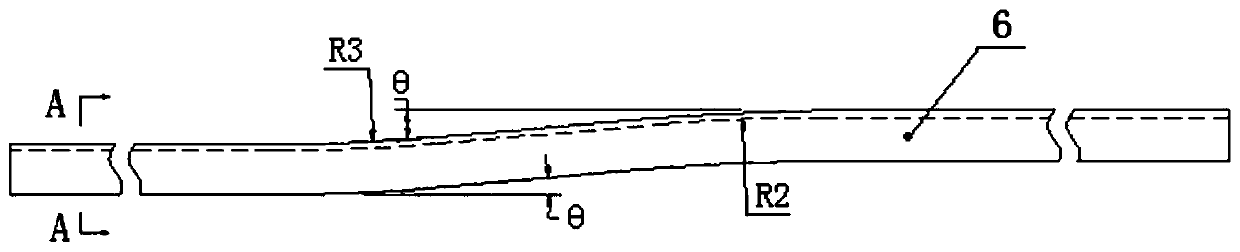

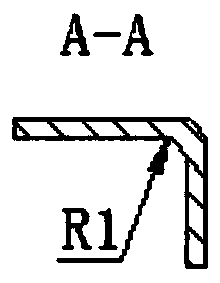

Cold stamping process of heavy-duty off-road vehicle frame reinforcing plate

ActiveCN109514201ASolve forming difficultiesReduce development costsVehicle componentsVehicle frameRoll forming

The invention discloses a cold stamping process of a heavy-duty off-road vehicle frame reinforcing plate. The reinforcing plate is a symmetric product, the section of the product is of an L-shaped structure, the bending circular bead radius is R1, two theta-degree bends are arranged in the longitudinal direction, the bending circular bead radii are R2 and R3, the material thickness ranges from 8 mm to 12 mm, the yield strength ranges from 450 MPa to 600 MPa, and the process comprises the steps of discharging, rolling forming, bending and separating. Flexible forming is achieved, product quality is improved, the problems that forming is difficult and cracking defects exist in the circuitous process can be solved, two products are formed at a time, production efficiency is improved, a general production device is adopted, mold development cost is saved, the product development period is shortened, and the advantages of being good in product quality, low in labor intensity, high in production efficiency, capable of saving cost and shortening product development period can be achieved.

Owner:SINO TRUK JINAN POWER +1

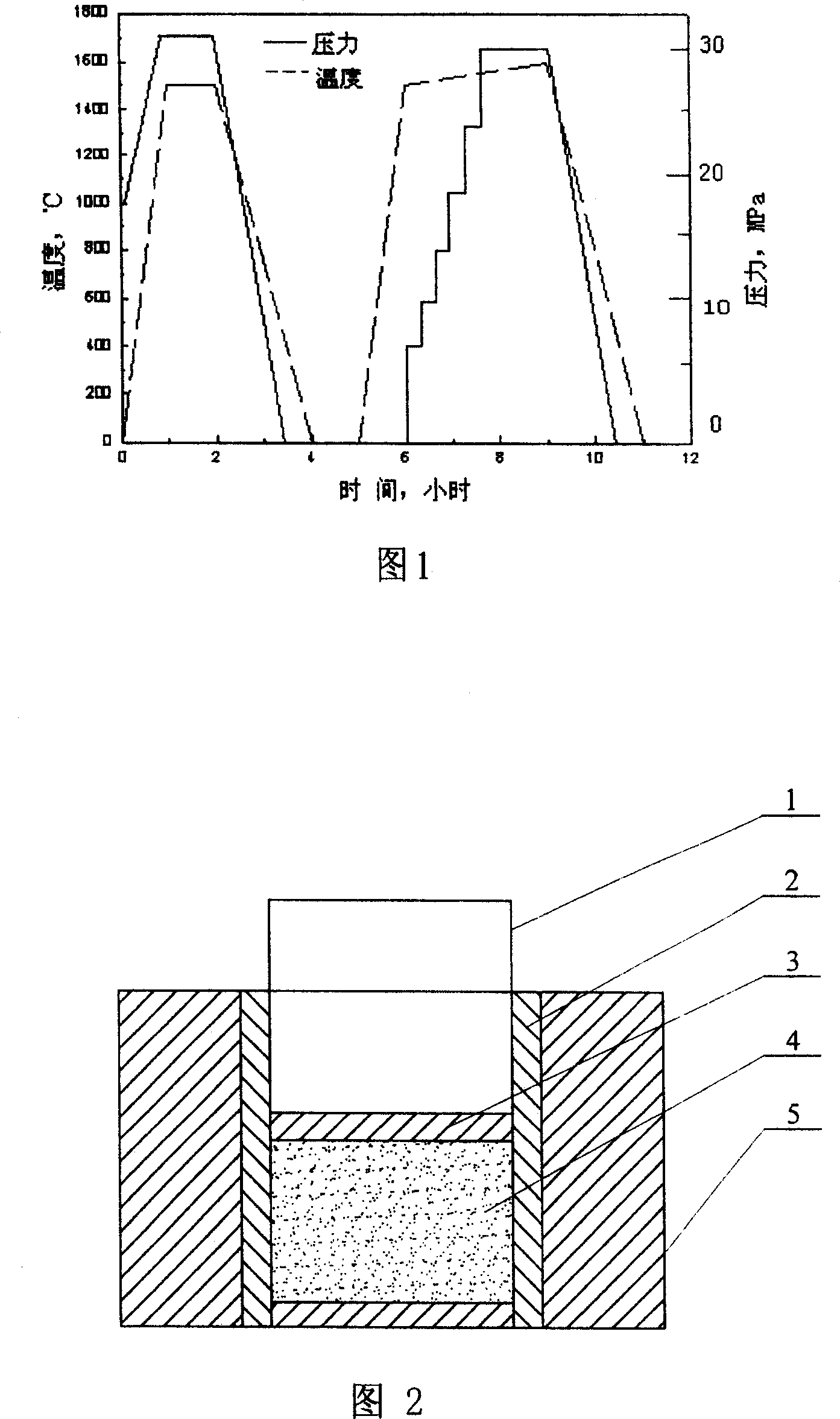

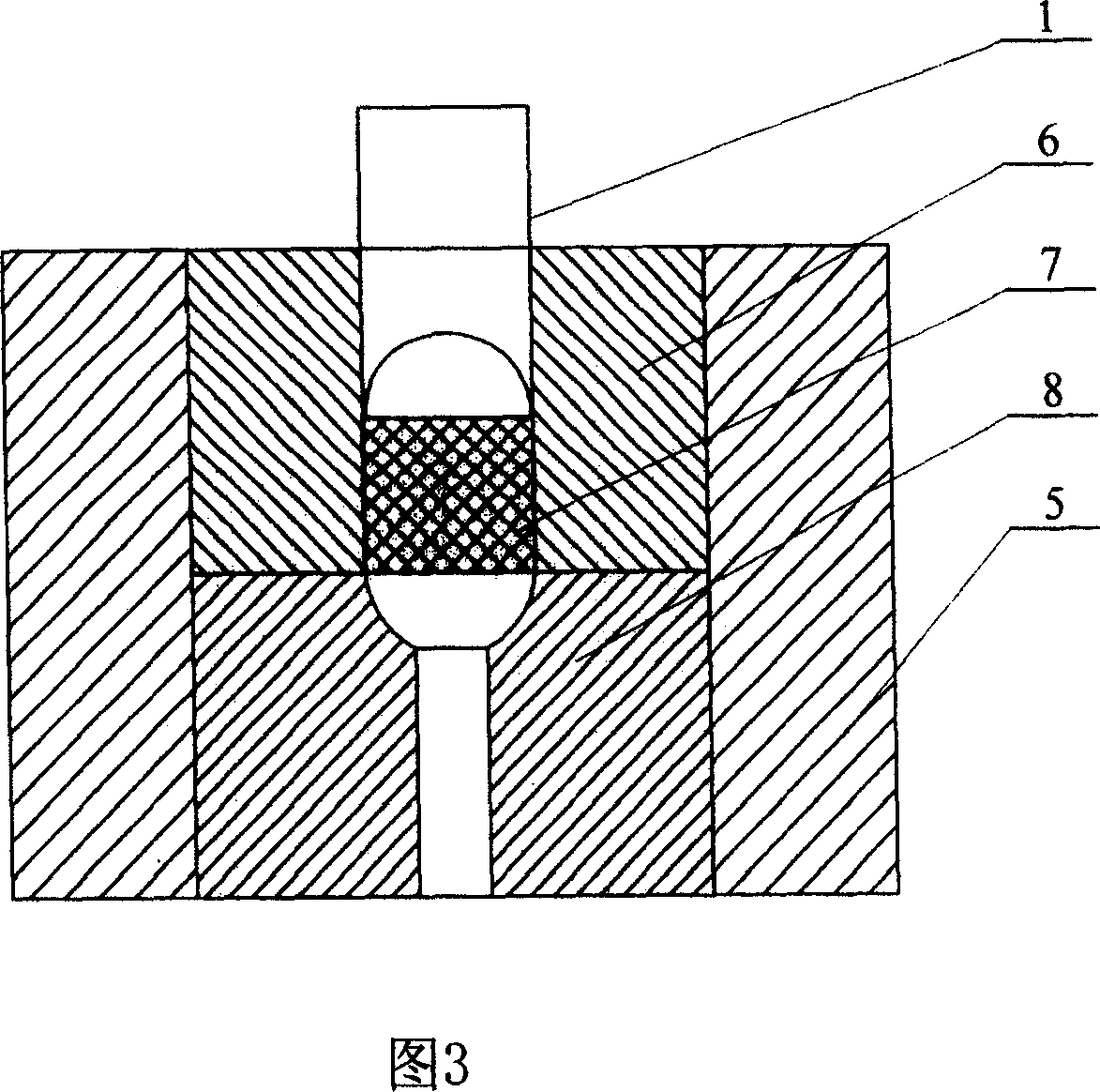

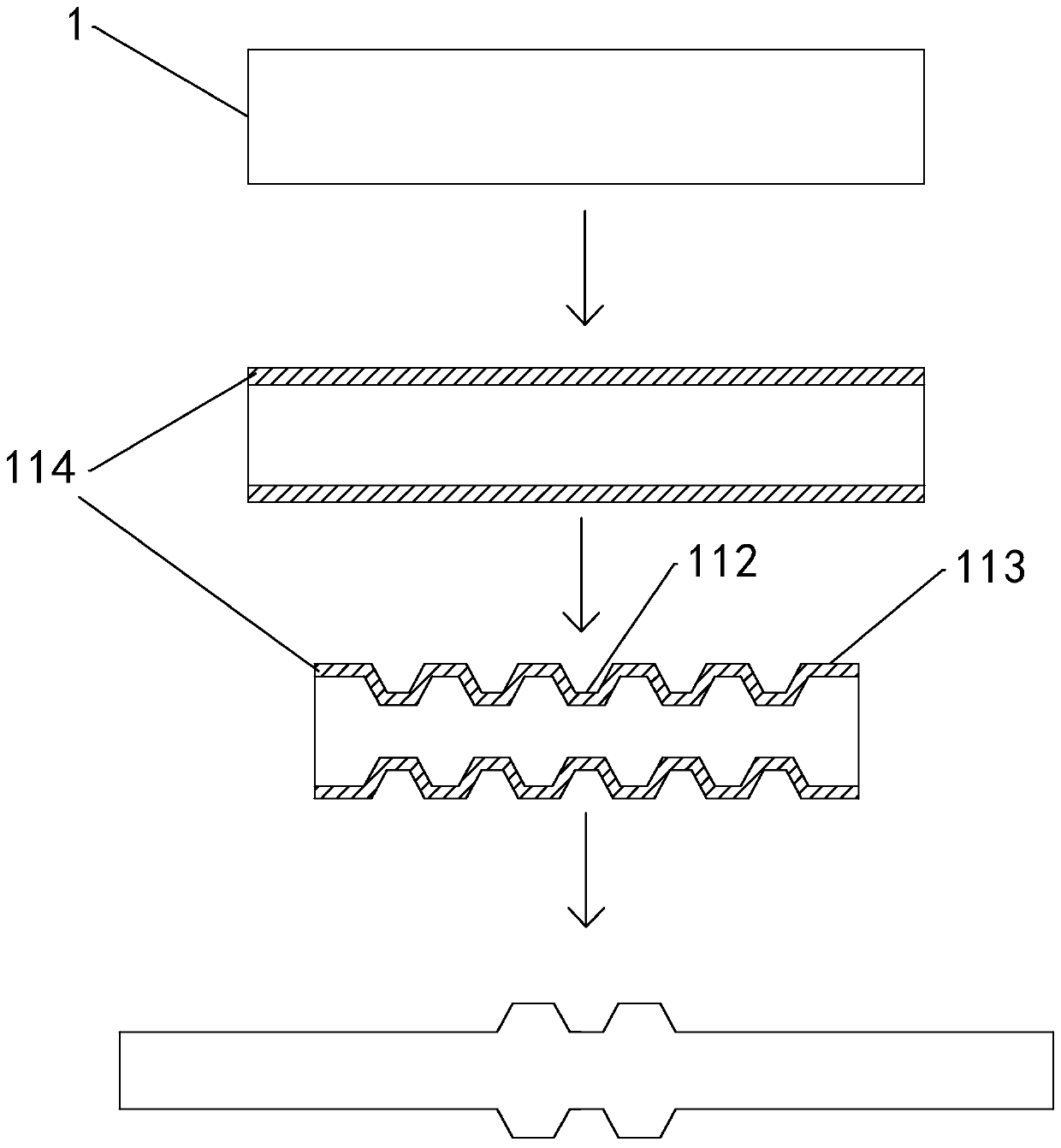

Shaping method of nanometer bioceramic artificial joint

The process of forming artificial joint of nanometer bioceramic relates to nanometer ceramic material forming technology, and aims at solving the problem of forming complicated shape ceramic product. The process includes the following steps: 1. hot pressing and sintering composite Al2O3 / ZrO2 powder or ZrO2 / HAP powder to prepare nanometer ceramic block; and 2. closed die forging to form ceramic product at high temperature. By means of the twice forming process, the present invention can form ceramic part of complicated shape. The present invention has the advantages of simple forming process, easy manufacture of mold, low cost, etc.

Owner:HARBIN MEDICAL UNIVERSITY

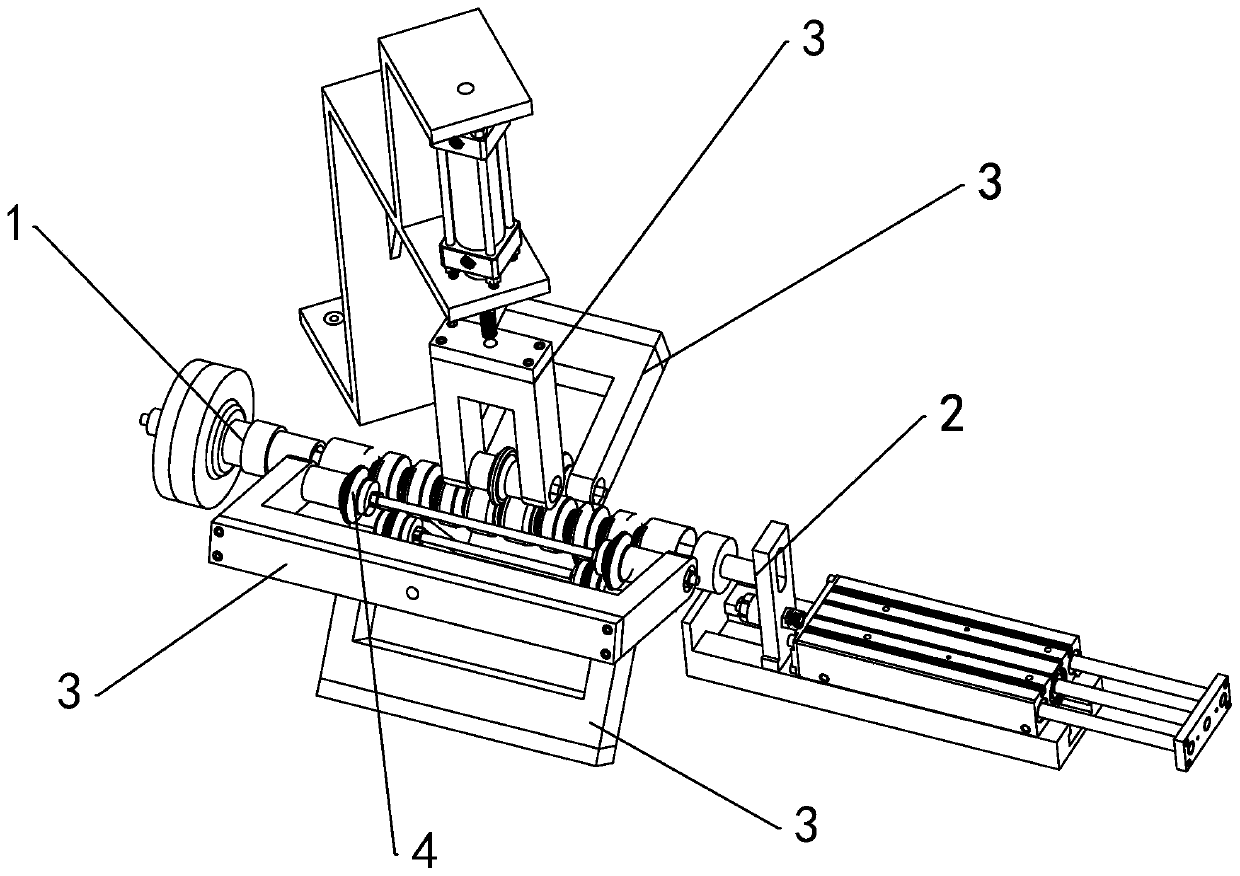

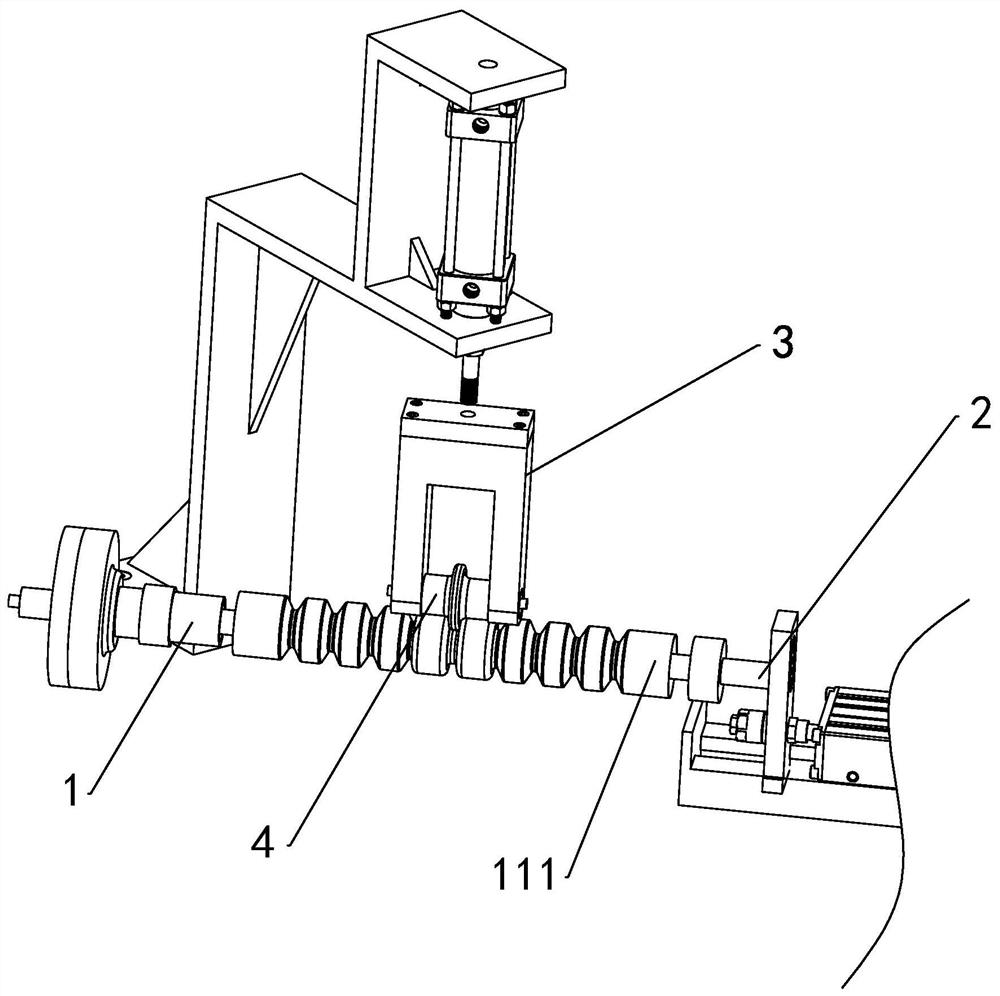

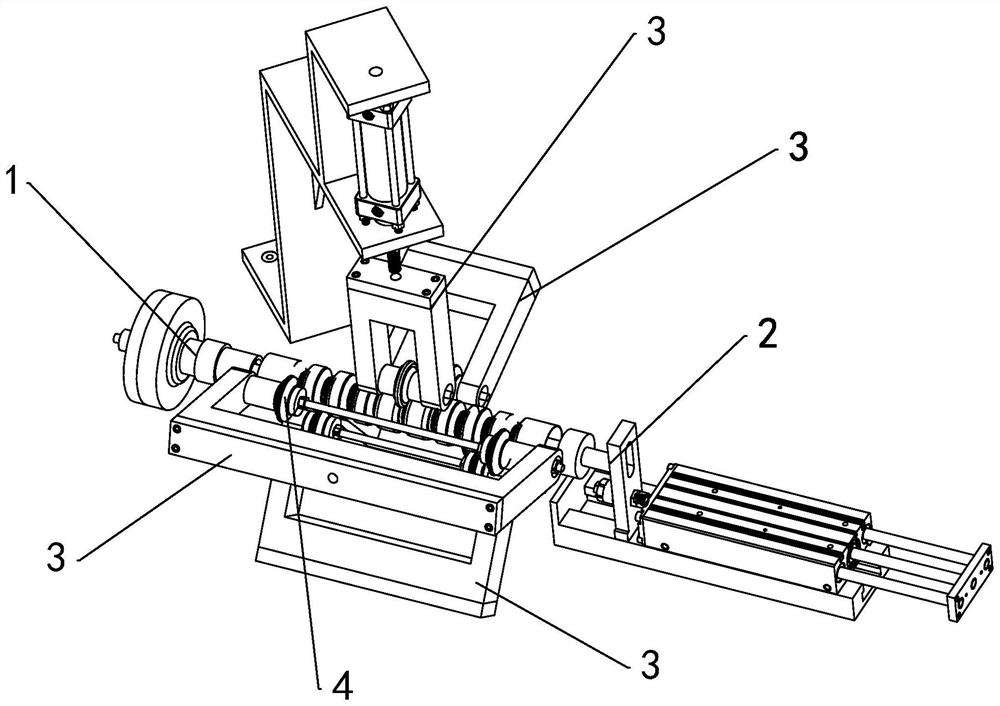

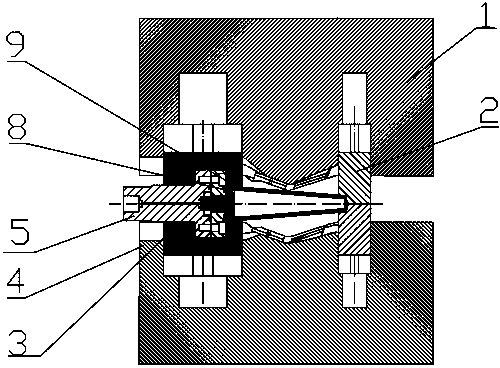

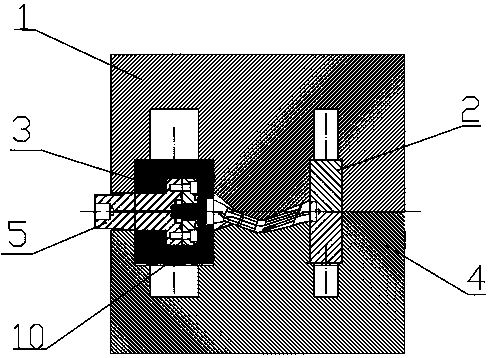

Roller press forming method of low-plastic alloy ultra-large deformation thin-wall pipe

The invention discloses a roller press forming method of a low-plastic alloy ultra-large deformation thin-wall pipe. The roller press forming method comprises a main shaft, a limiting support and a power device, and further comprises a roller-wave device and a shaping device, the roller-wave device comprises a plurality of roller-wave supports and a variable-diameter mandrel, and roller-wave diessare arranged on the roller-wave supports; the shaping device comprises a plurality of shaping supports, roller flat dies, a main shaft and the roller-wave supports are arranged on the shaping supports, and the shaping supports are connected with a power device. According to the roller press forming method, the step-by-step rolling mode is adopted in the pre-forming stage of a pipe blank, so thatthe problem that a traditional roller press is difficult to form is solved, and meanwhile, the problem that a traditional roller press tube blank is pressed by multiple waves in a synchronous roller is also solved, and the problem that the transition is thinned due to the fact that materials at the trough position cannot flow into the pipe blank is solved; and in the pipe blank shaping stage, a stepping rolling mode is adopted for machining, the flowing resistance of materials in the deformation process can be reduced, and the materials at each position of the shaped pipe wall can be uniformlydistributed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

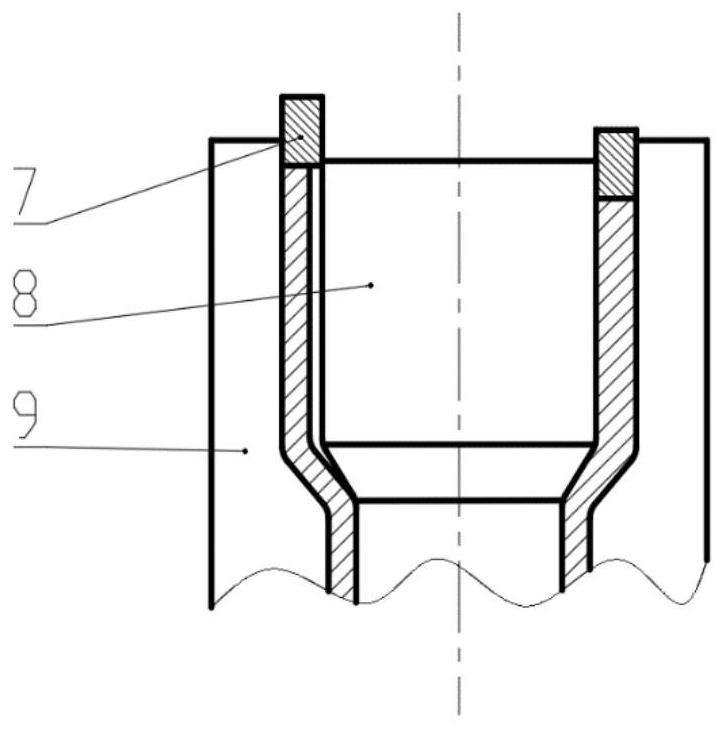

Method and device for forming parts with tapered rubber tube

The invention relates to a method for forming parts with a tapered rubber tube, which includes the following steps: Step 1: Put the tapered tube blank on the sealing assembly with the tapered rubber tube, and put the sealing assembly with the tapered tube blank into the lower mold In the floating block of the tire, make the axis of the two ends of the conical tube blank parallel to the working table of the equipment, and the equipment drives the upper mold tire to go down, so that the floating block of the upper mold tire is in contact with the floating block on the lower mold tire ;Step 2, forming stage: the upper mold tire continues to move down to lower the axis of the two ends of the conical tube blank to the preset position and maintain the preset tonnage. There is a liquid inlet on the sealing component, and the liquid finally enters through the inlet In the tapered rubber tube; the present invention also provides a device for forming parts of the tapered rubber tube.

Owner:天津天锻航空科技有限公司 +1

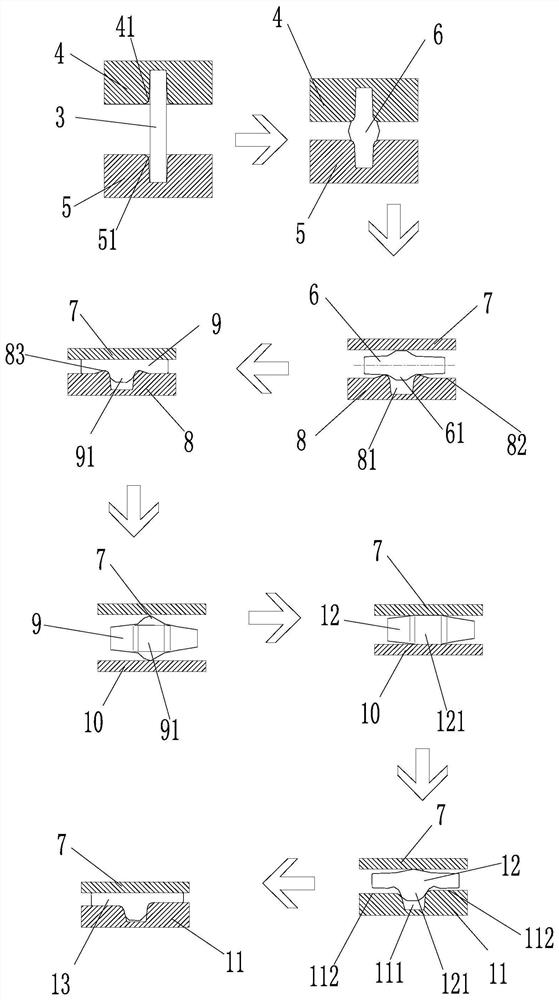

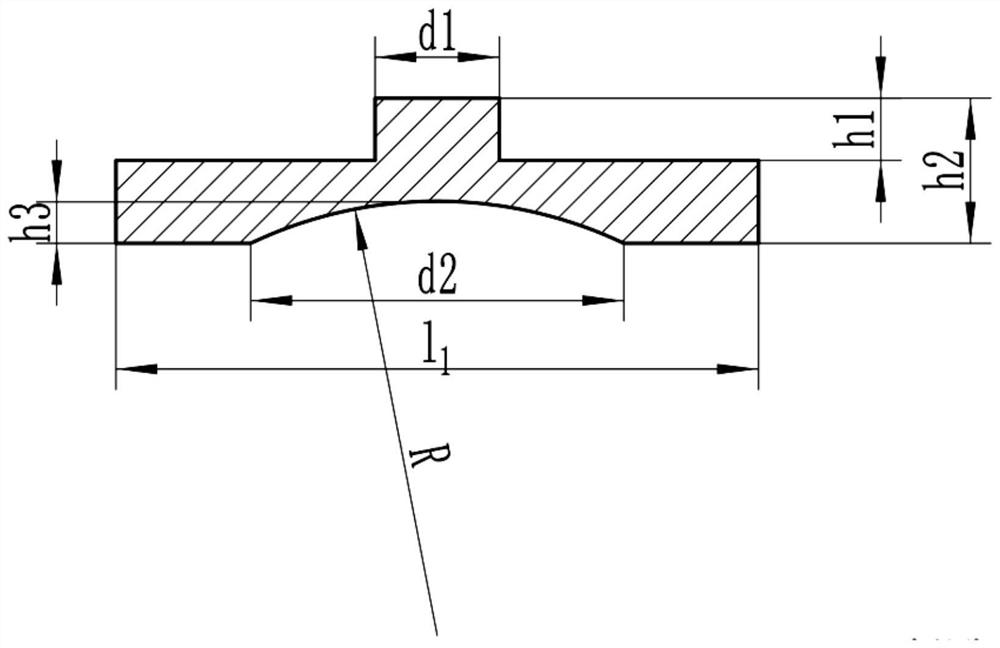

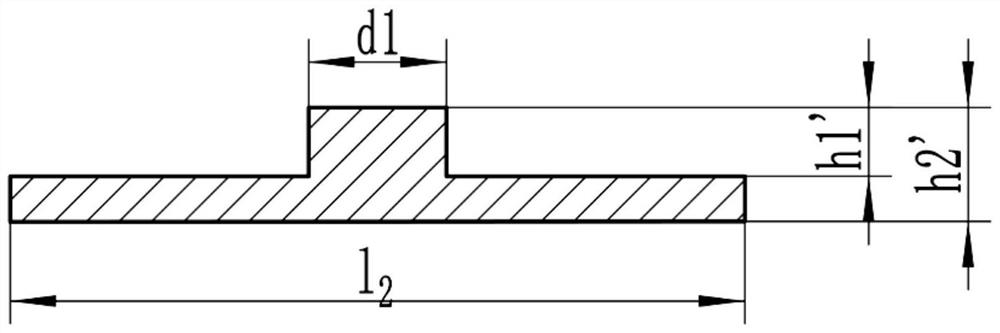

A Forging Method for Deformed Short T-shape Blank

ActiveCN110014105BSolve forming difficultiesFlat surfaceMetal-working apparatusAviationMechanical engineering

The invention provides a forging method for deformed short T-shaped blank, and the forging method solves the problem that forming of deformed short T-shaped blank is difficult, and relates to the technical field of forging-pressing. The forging method for the deformed short T-shaped blank comprises the following steps: a first step of placing the lower end part of rod-shaped blank into a heading lower mould cavity, placing the upper end of the rod-shaped blank into a heading upper mould cavity, pressing a heading upper mould along a heading lower mould until a bump part is formed between the upper end part of the rod-shaped blank and the lower end part of the rod-shaped blank, thereby forming first intermediate blank. The forging method solves the difficult forming problem of the deformedshort T-shaped blank. An inner metal flow line of the integrally formed deformed short T-shaped blank is good, and an aviation product processed by the inner metal flow line is good is in integral performance, so that weight of the aviation product can be relieved on the premise of meeting performance requirements, and therefore, product competitiveness is improved.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

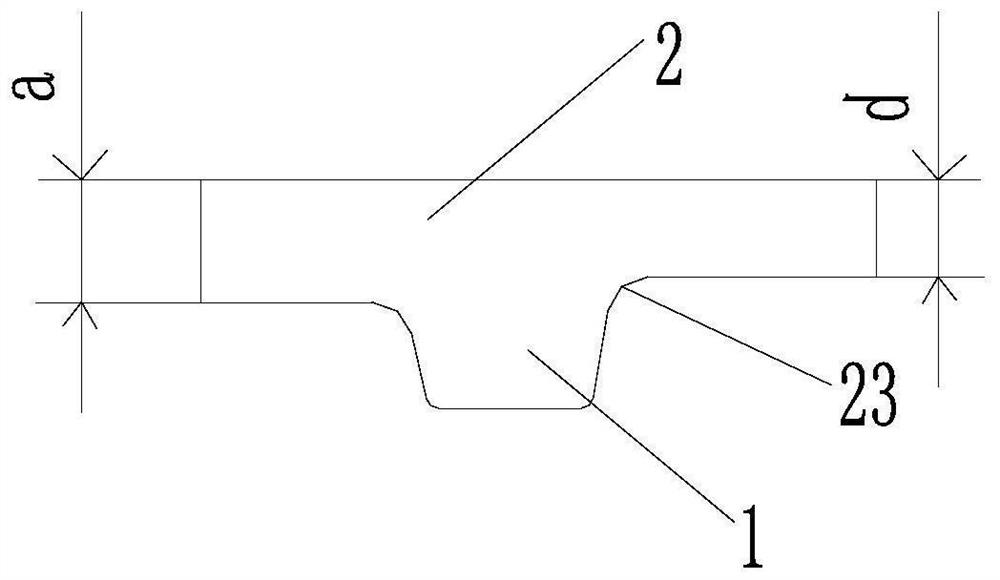

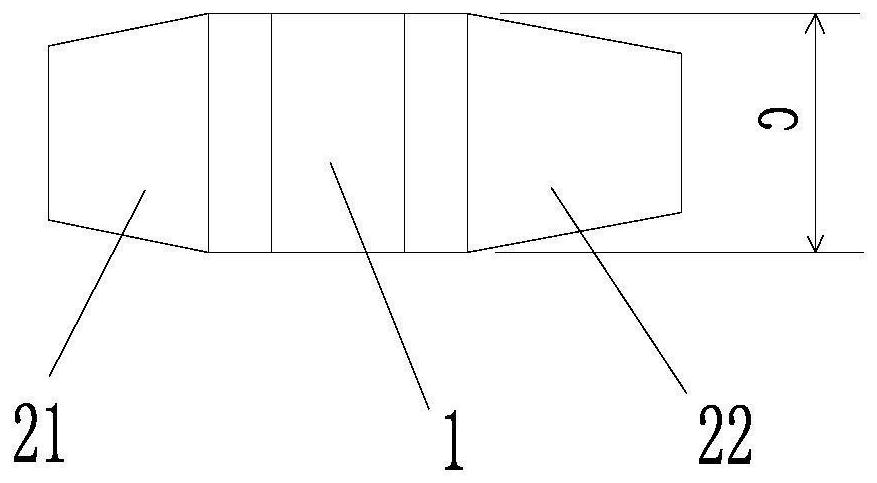

A flat rolling forming process with raised ribs

ActiveCN110170520BControl flow in all directionsSolve forming difficultiesMetal rolling stand detailsGuiding/positioning/aligning arrangementsStructural engineeringMechanical engineering

Owner:WUHAN UNIV OF TECH

Stepping roll-in forming method and device for supramaximal deformation thin-wall pipe

The invention discloses a stepping roll-in forming method and a device for a supramaximal deformation thin-wall pipe. The stepping roll-in forming method comprises pipe blank preforming and pipe blankshaping. The pipe blank preforming: rolling waves on the outer surface of a pipe blank to be processed in a stepping roll-in mode; and the pipe blank shaping: flattening the waves on the tube blank in the stepping roll-in mode. The pipe blank is processed in the stepping roll-in mode in the pipe blank preforming stage, so that not only the problem that the traditional roll-in forming is difficultis solved, but also the problem of transition thinning caused by the fact that materials at wave troughs cannot flow into the traditional rolling pipe blank when a plurality of waves are synchronously rolled is solved; and in the pipe blank shaping stage, the pipe blank is processed in the stepping roll-in mode, so that flow resistance of the materials in the deformation process is reduced, and the materials at each position of a shaped pipe wall is uniformly distributed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A Cold Stamping Process of Heavy Off-Road Vehicle Frame Reinforcing Plate

ActiveCN109514201BSolve forming difficultiesReduce development costsVehicle componentsOff-Road Motor VehicleVehicle frame

The invention discloses a cold stamping process of a heavy-duty off-road vehicle frame reinforcing plate. The reinforcing plate is a symmetric product, the section of the product is of an L-shaped structure, the bending circular bead radius is R1, two theta-degree bends are arranged in the longitudinal direction, the bending circular bead radii are R2 and R3, the material thickness ranges from 8 mm to 12 mm, the yield strength ranges from 450 MPa to 600 MPa, and the process comprises the steps of discharging, rolling forming, bending and separating. Flexible forming is achieved, product quality is improved, the problems that forming is difficult and cracking defects exist in the circuitous process can be solved, two products are formed at a time, production efficiency is improved, a general production device is adopted, mold development cost is saved, the product development period is shortened, and the advantages of being good in product quality, low in labor intensity, high in production efficiency, capable of saving cost and shortening product development period can be achieved.

Owner:SINO TRUK JINAN POWER +1

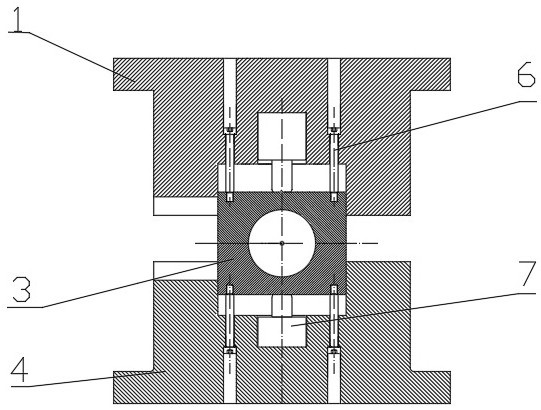

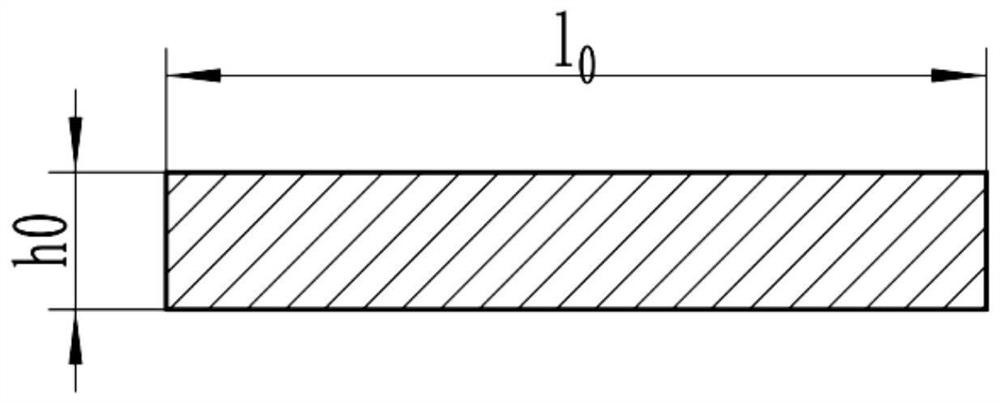

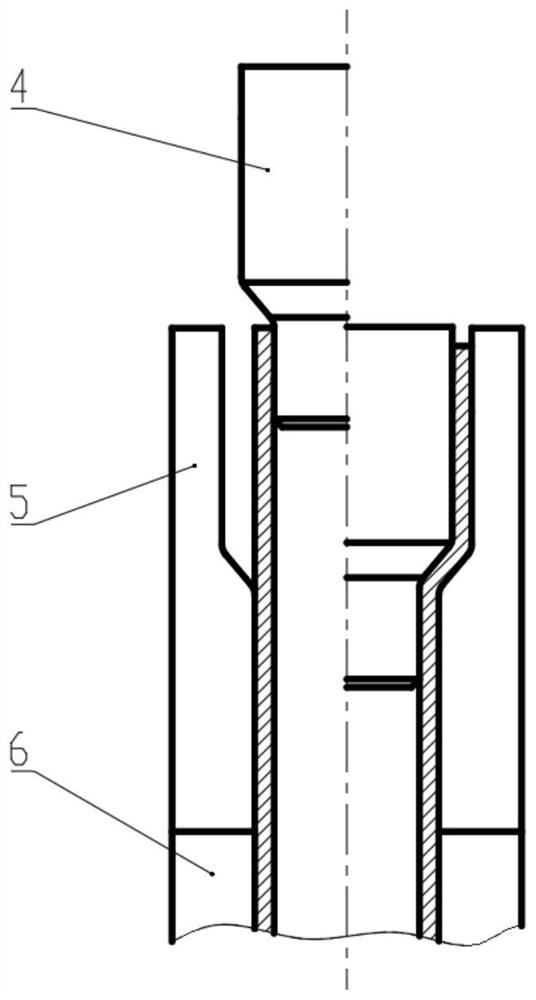

Forging forming method and die for unequal-thickness hollow part plate

PendingCN114515811AImprove mechanical propertiesSolve forming difficultiesRailway componentsForging/hammering/pressing machinesEngineeringMold removal

The invention provides an unequal-thickness hollow part plate forging forming die which comprises a forming male die, an outer side female die, a female die base plate, a floating mandrel and a detachable core. The invention further provides an unequal-thickness hollow part plate forging forming method which comprises the steps that firstly, one end of an original pipe blank with the outer diameter equal to the outer diameter of a target part is placed in the female die; then the male die slowly moves downwards, a part with the required small-end appearance is extruded through upsetting, and then the floating mold core is pushed upwards by the press machine to eject the part out; secondly, the other end of the part is placed on a female die base plate, a forming male die slowly descends, and ejection and demolding are conducted after reaming is completed; and thirdly, the part subjected to broaching in the last step is placed in the female die, then the male die moves downwards slowly, the inner portion of the upper end of the part is thickened, and then the part is ejected out through an ejector device below the press machine. And fourthly, the part formed in the last step is placed in the female die, the male die moves downwards slowly, the thickened part is necked towards the middle, and then the part is ejected out through an ejection device below the press.

Owner:XIANGTAN UNIV

Ultra-thin-walled tube roll forming method and device

The invention discloses a method and a device for rolling forming ultra-thin wall tubes. The device comprises a spindle, a limiting bracket, and a power device, and further comprises a roll wave device and a shaping device. The roll wave device comprises a plurality of roll wave brackets and variable diameter mandrels. Roll wave dies are arranged on the roll wave brackets. The shaping device comprises a plurality of shaping brackets, and roll flat dies are arranged on the shaping brackets. The spindle, the roll wave brackets and the shaping brackets are connected with the power device. According the method and the device, in the preforming stage of tube blanks, a stepping rolling method is adopted for machining, so that the problem of difficulties of a traditional rolling forming mode is solved, and the problem of excessive thinning of traditional rolling tube blanks caused by that materials cannot flow into wave troughs when multiple waves are rolled synchronously is solved; and in the shaping stage of the tube blanks, the stepping rolling method is adopted for machining, so that the flow resistance of the materials in the deformation process is reduced, and the situation that thematerials are evenly distributed around tube walls after shaping is ensured.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Method and device for forming parts of conical rubber tube

ActiveCN111558645ASolving Form Sealing ProblemsSolve forming difficultiesConical tubeStructural engineering

The invention relates to a method for forming parts of a conical rubber tube. The method comprises the following steps that 1, a conical pipe blank sleeves a sealing assembly of the conical rubber tube, the sealing assembly with the conical pipe blank is placed in a floating block body of a lower die tire, so that the axes of the two ends of the conical pipe blank are parallel to a working table of equipment, the equipment drives an upper die tire to move downward, so that a floating block body of the upper die tire is in contact with the floating block body of the lower die tire; and 2, forming stage is conducted, specifically, the upper die tire continues to move downward, so as to make the axes of the two ends of the conical pipe blank drop to a preset position and maintain the preset tonnage, a liquid inlet is formed in the sealing assembly, and liquid finally enters the conical rubber tube through the liquid inlet. The invention further provides a device for forming the parts of the conical rubber tube.

Owner:天津天锻航空科技有限公司 +1

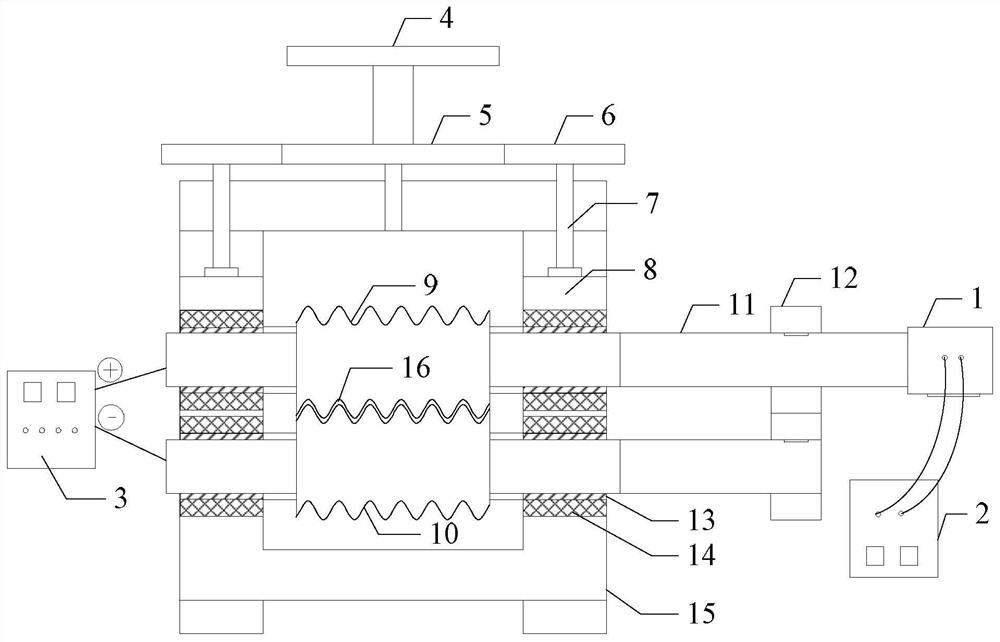

An Electromagnetic Progressive Flexible Composite Forming Method

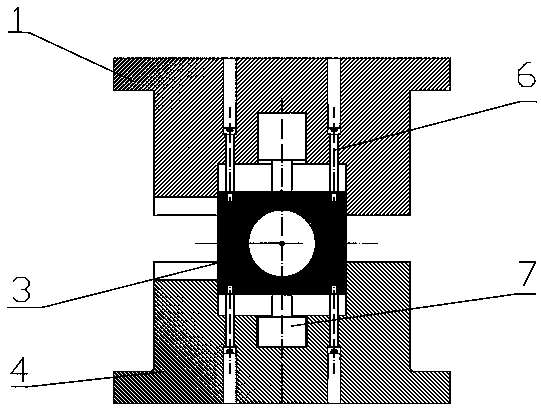

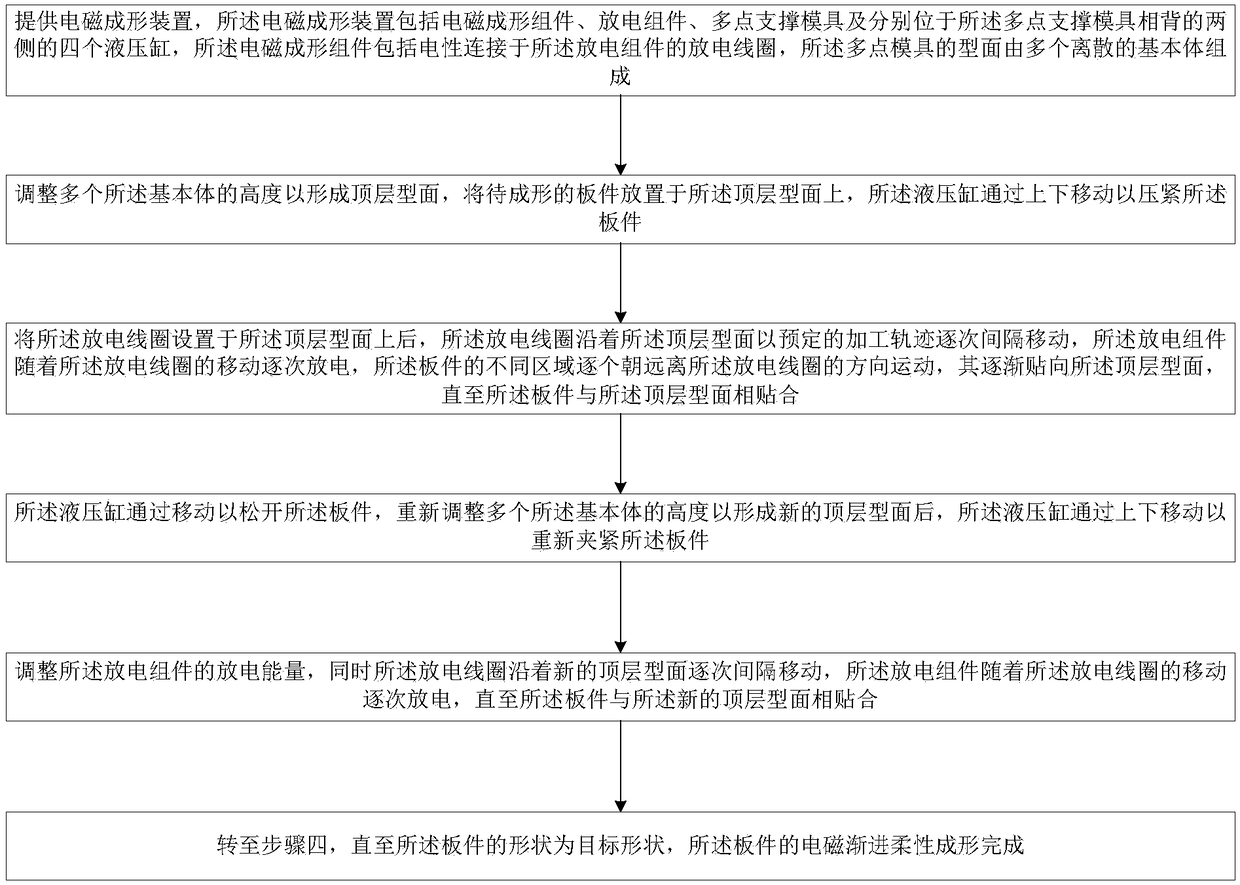

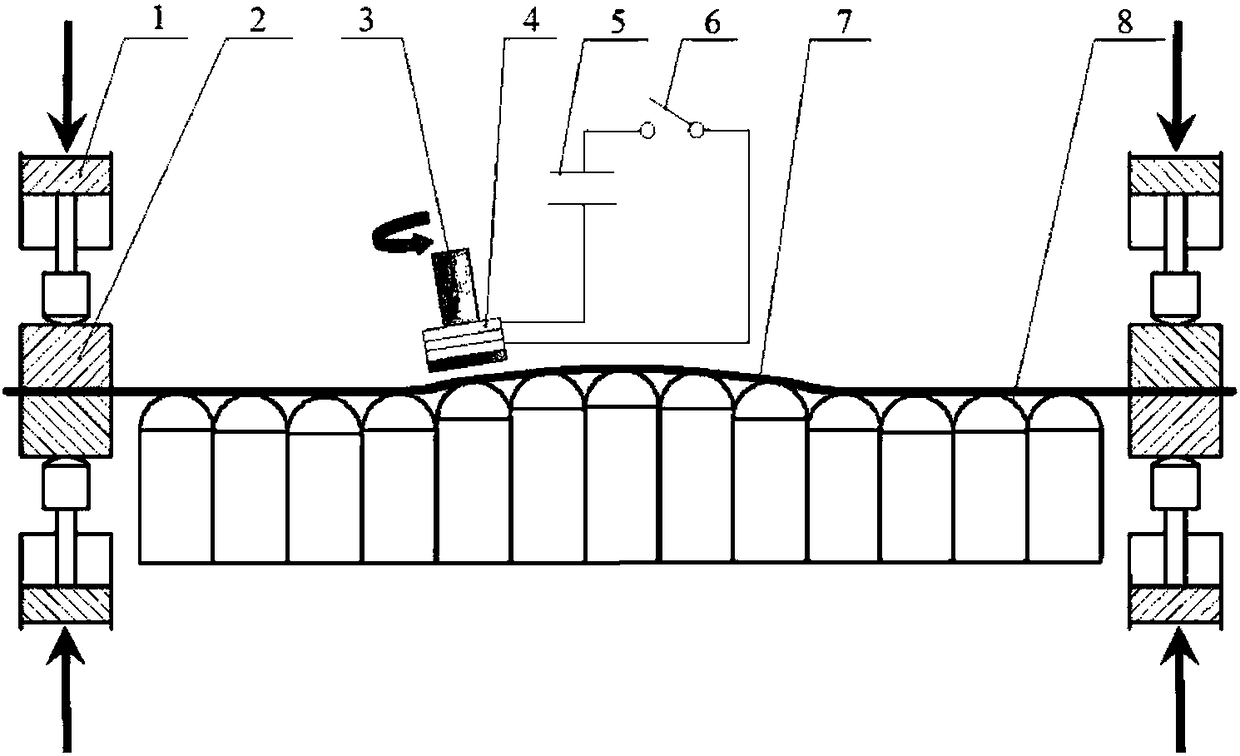

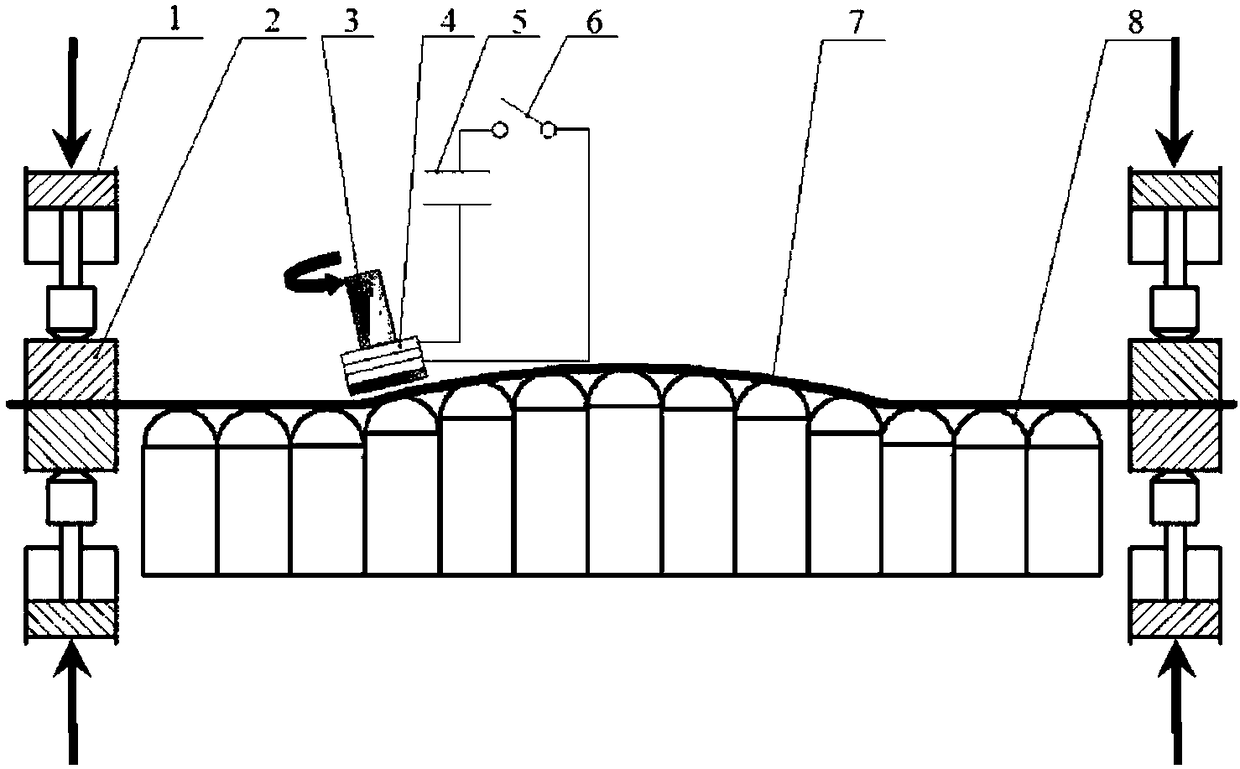

ActiveCN106807825BReduce manufacturing costSolve forming difficultiesShaping toolsHydraulic cylinderThinning

The invention belongs to the related technical field of component forming manufacturing, and discloses an electromagnetic gradual flexible composite forming method. The electromagnetic gradual flexible composite forming method comprises the following steps: providing an electromagnetic forming device, wherein the electromagnetic forming device comprises a discharge assembly, a multi-point supporting mould and four hydraulic cylinders, and the mould surface of the multi-point supporting mould consists of multiple discrete basic bodies; adjusting the basic bodies to form a top mould surface, and moving the hydraulic cylinders to tightly press a plate component; gradually moving a discharge coil along the top mould surface, gradually discharging the discharge assembly along with movement of the discharge coil, and gradually moving the plate component towards a direction away from the discharge coil till the plate component is fitted with the top mould surface; readjusting the heights of the basic bodies to form a new top mould surface, and reclamping the plate component; re-moving the discharge coil, and gradually discharging the discharge assembly till the plate component is fitted with the new top mould surface; repeating the steps till the plate component has a target shape. By the electromagnetic gradual flexible composite forming method, wrinkling is avoided, the thinning amount and the resilience are reduced, and uniform deformation of the plate component is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

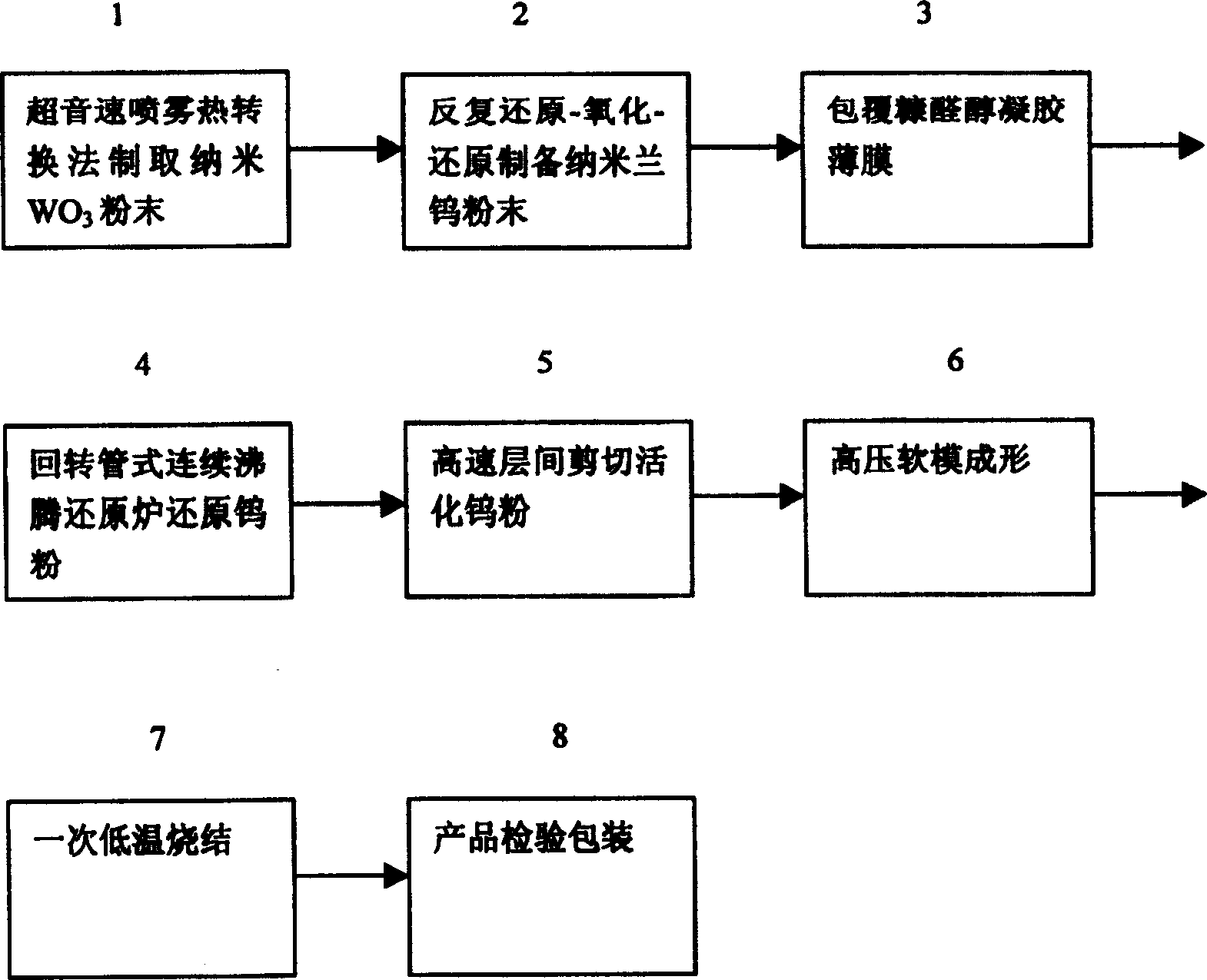

Preparation of low-temperature primary sintering high-density superfine crystal particle pure tungsten material

InactiveCN100340365CFiner and more uniform particle sizeUniform particle sizeOrganic filmInterlaminar shear

The invention was involved in producing pure tungsten with high-density ultra-fine grain at low temperature for one time. The temperature was 350-400deg.C and pressure was 5-6.5Mpa. Supersonic spray heat change was used to produce nano-WO3 powder, the diameter was lower than 40nm. Blue tungsten powder was formed in nanometer grade by deoxidation-oxidation-deoxidation reaction. Then adding furfural- phenolic aldehyde-ethyl carbinol solution, blue tungsten powder was coverd by furfural organic film after mixing by twin-screw agitator. Blue tungsten powder was deacidize in tungsten powder whose diameter was lower than 70nm in the continuous rotary furnace in fluid bed and the nano-tungsten powder was sheared and activated in dry-type high-speed interlaminar shearing machine. Tungsten powder pressed blocks were produced with high-pressure soft dies. Pure tungsten ultra-fine grain with 95%-96% relative density was produced at low temperature for one time and the tungsten crystal grain was smaller than 8-12um.

Owner:UNIV OF SCI & TECH BEIJING

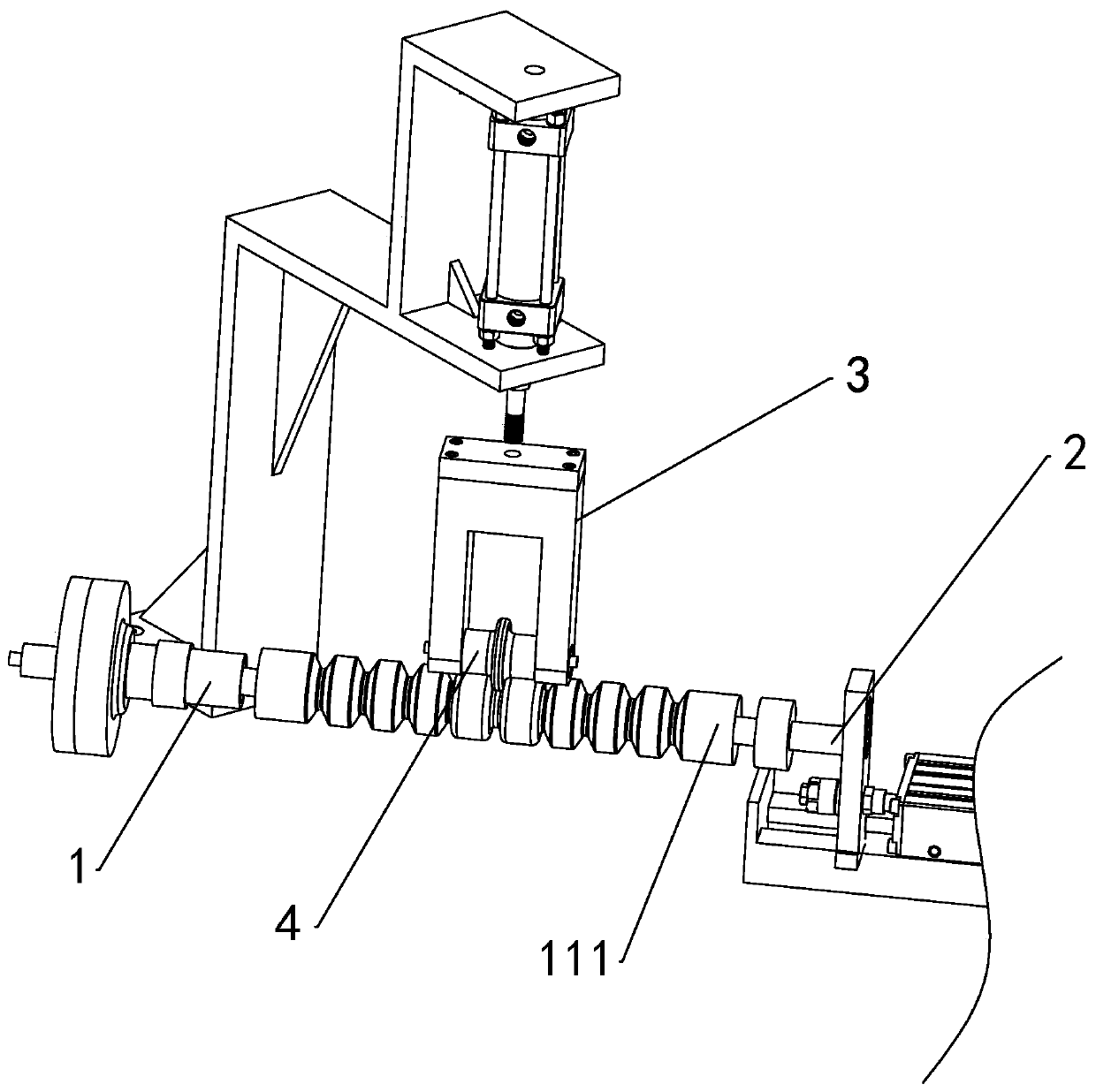

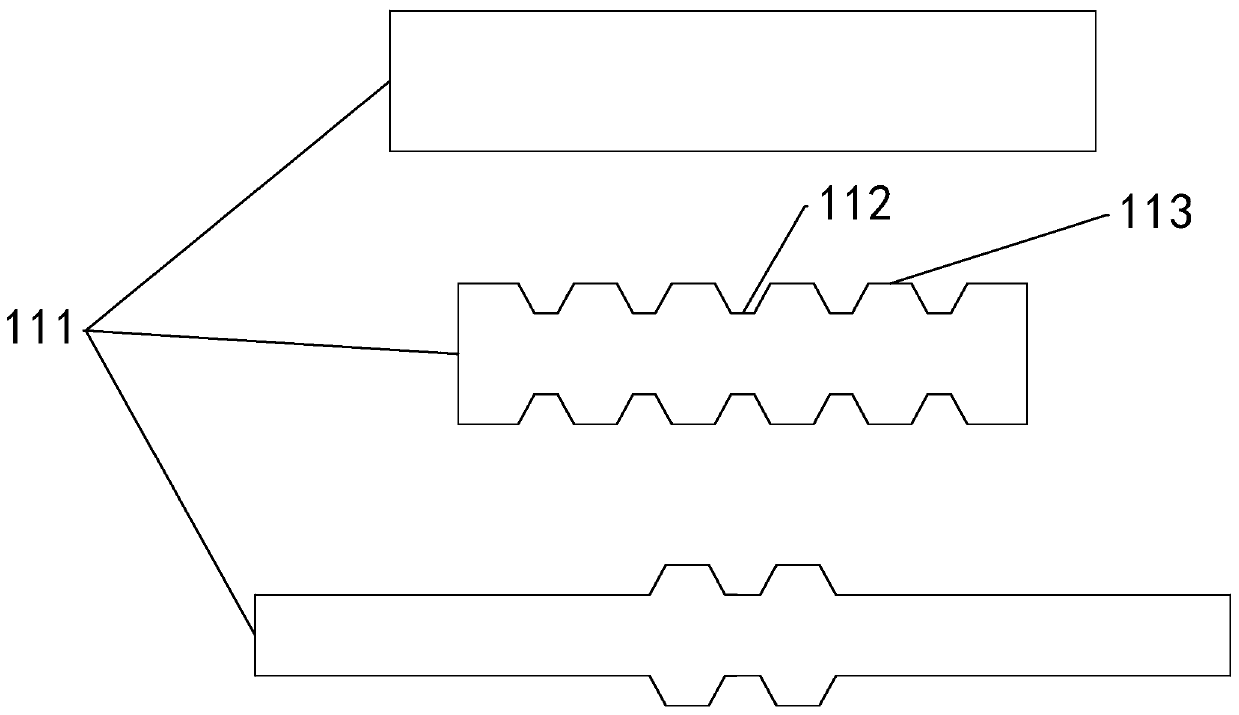

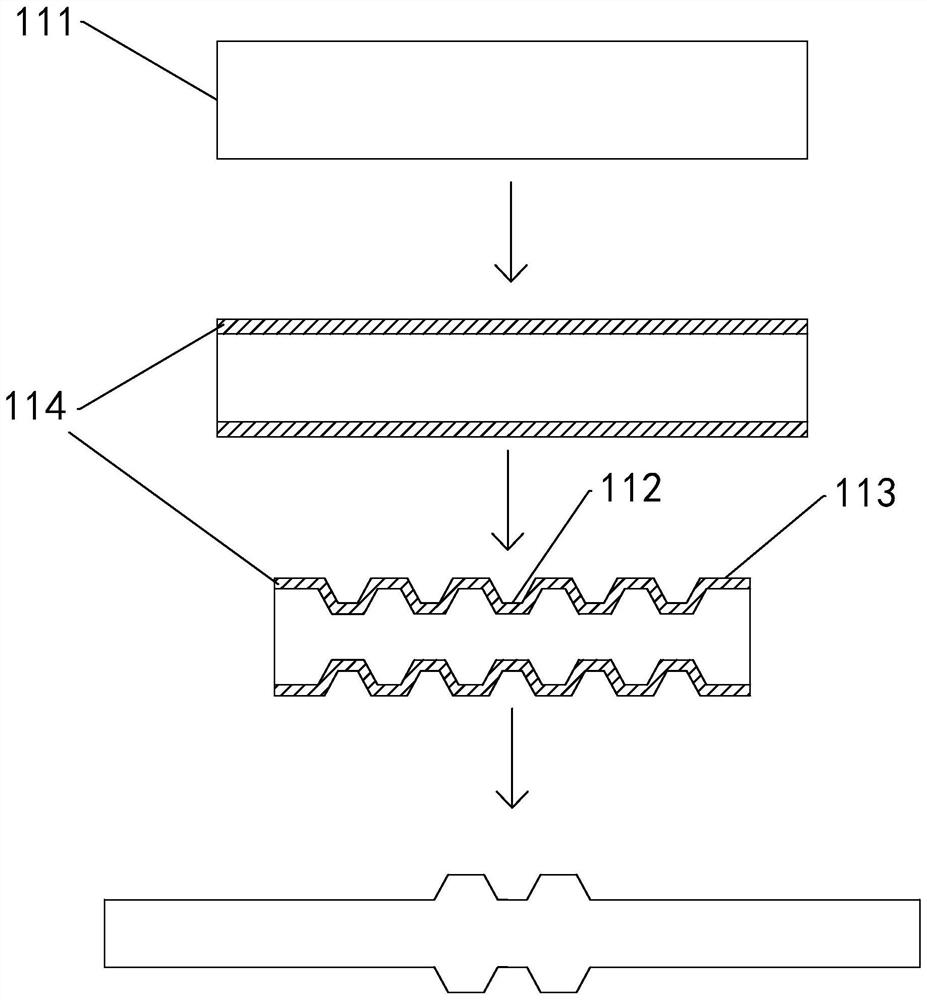

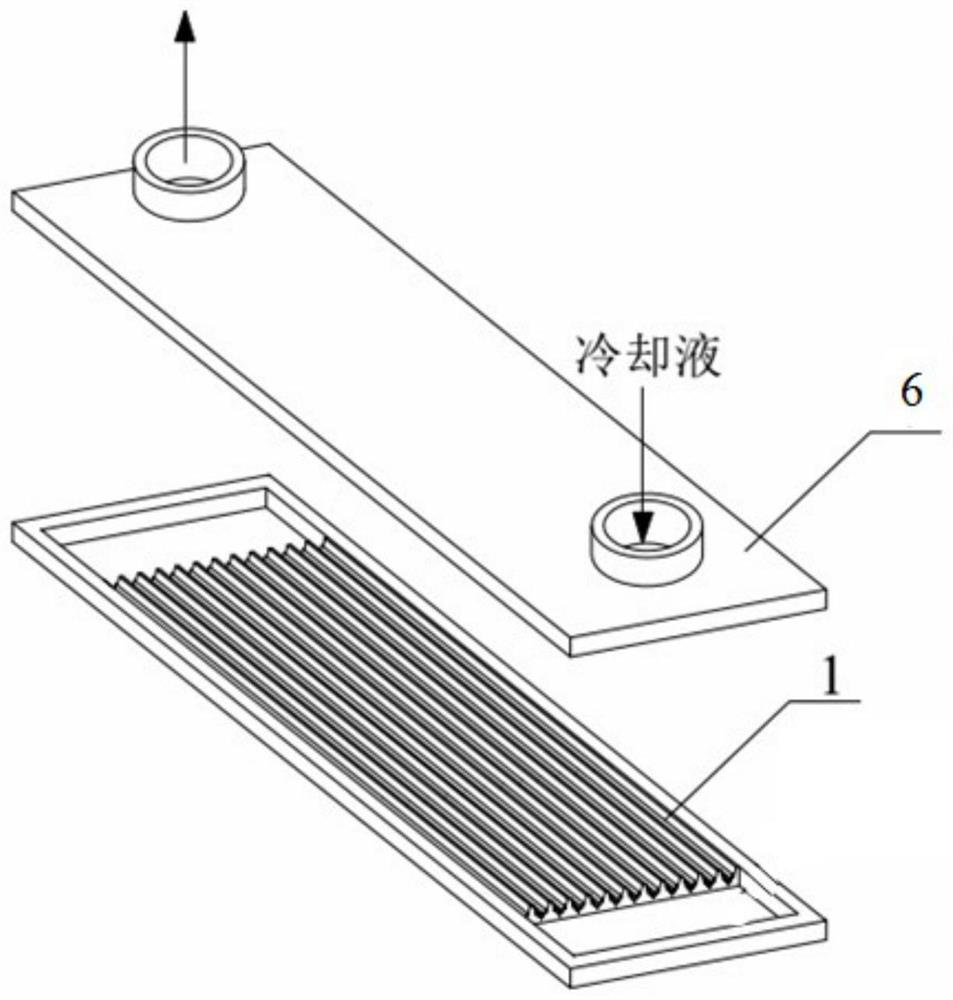

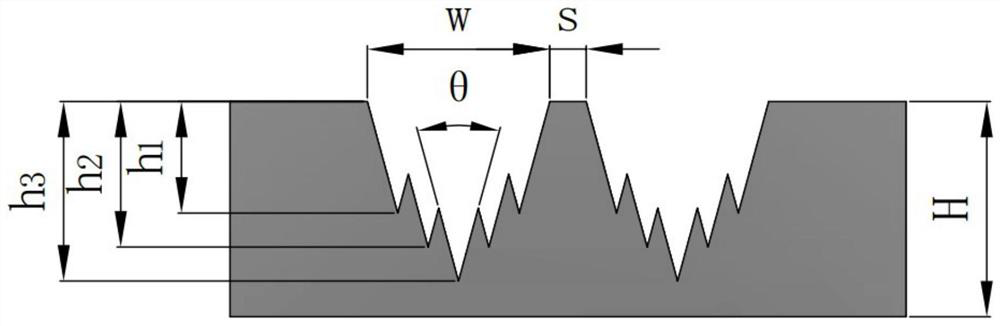

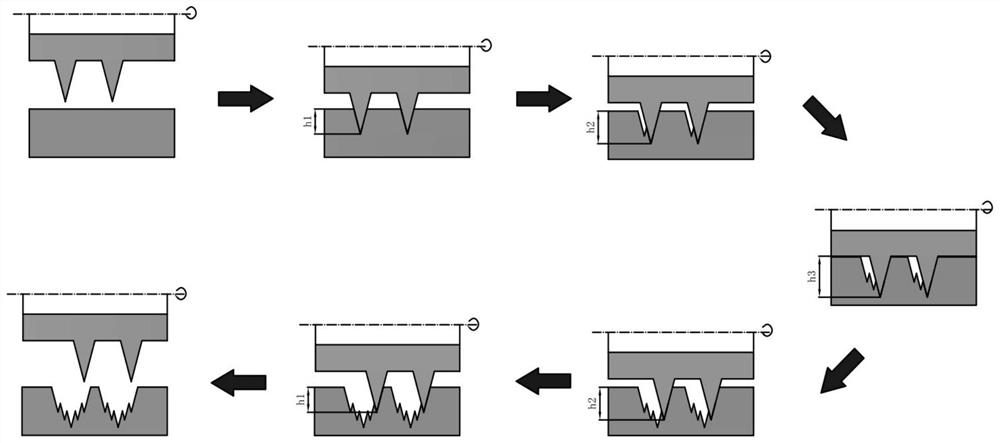

A micro-channel heat exchanger with multi-stage micro-channels and its manufacturing method

ActiveCN111707116BIncrease contact areaDisruption of normal flowIndirect heat exchangersModifications by conduction heat transferMicrowaveEngineering

The invention discloses a microchannel heat exchanger with multistage microchannels and a manufacturing method thereof. The microchannel heat exchanger is composed of an upper cover plate, a lower cover plate and a metal microchannel base body. The metal microchannel matrix includes a number of microchannels arranged in parallel and spaced arrays, and the two side walls of the microchannels respectively have a raised secondary microchannel structure in an array, and the secondary microchannels are symmetrically distributed in the microchannels, It can significantly increase the heat exchange area, enhance the turbulence, and realize enhanced heat exchange. The preparation method is as follows: firstly process trapezoidal grooves with an array on the work roll to form a V-shaped boss; change the axial translation amount and pressing depth of the work roll with grooves, and perform multi-pass rolling processing to obtain a multi-pass rolling process. A metal microchannel substrate with level microgrooves; finally, it is sealed and packaged to obtain a new type of microchannel heat exchanger. The invention solves the difficult problem of processing and forming the multi-level micro channel structure in the array micro channel, and has the advantages of simple process, low cost, high efficiency and the like.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Tea rolling machine with good rolling effect

PendingCN114365780AChange down speedControl pressurePre-extraction tea treatmentRubber membraneEngineering

The invention relates to the technical field of tea leaf production and processing, and discloses a tea leaf rolling machine with a good rolling effect, the tea leaf rolling machine comprises a rolling disc, a rolling barrel is placed at the top end of the rolling disc, the top end of the interior of the rolling barrel is movably sleeved with a pressurizing cover assembly, and the pressurizing cover assembly is composed of a lower cover, an upper cover and rubber; the lower cover is the bottom end of the pressurizing cover assembly, the upper cover is the top end of the pressurizing cover assembly, and the edge of the top end of the lower cover is fixedly connected with the edge of the bottom end of the upper cover through a rubber film. The pressurizing cover assembly composed of the lower cover, the upper cover and the rubber film is arranged, and the change speed of the pressure intensity in the pressurizing cover assembly is changed by controlling the speed of gas introduced into the pressurizing cover assembly, so that the downward moving speed of the lower cover is effectively controlled, and the pressure applied to tea by the pressurizing cover assembly in the rolling process is changed; the pressure applied to the tea leaves by the pressurizing cover assembly is controlled, so that the pressure rhythm of the pressurizing cover assembly is light pressure-heavy pressure-light pressure, and uniform rolling of the tea leaves is promoted.

Owner:夏颖

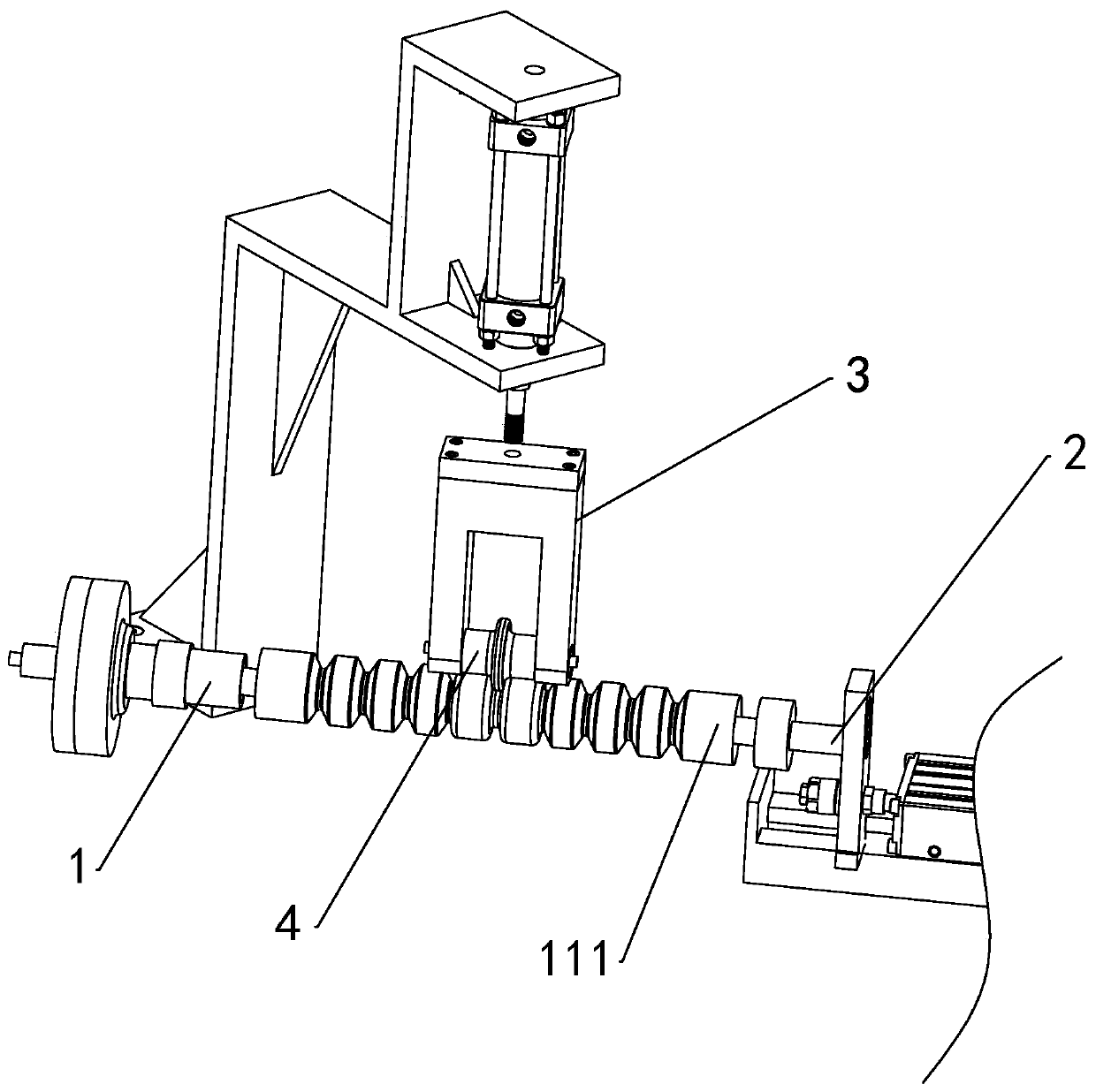

Large-area functional microstructure array current-assisted roll forming device

ActiveCN108906891BSolve forming difficultiesReduce drag reductionMetal rolling stand detailsRolling equipment maintainencePulsed DCEngineering

A current-assisted roll forming device for a large area functional microstructure array relates to a roll forming technology, and is designed to solve the problem that large area functional microstructure array is not easy to be formed. A control cabinet of the device is used to control a driving motor to drive a roller press of the precise microstructure array to complete the forming process of the microstructure array of formed parts; an auxiliary forming power supply is used to output pulsed DC, and the current closed loop is realized by the pulsed DC passing though the roller press of theprecise microstructure array and the formed parts. The current-assisted roll forming device for the large area functional microstructure array has the advantages that the forming load can be reduced,and the device is more suitable for continuous production. By using the Joule heating effect and the electroplastic effect formed by assisted current, plastic forming ability of materials can be improved, the minimum forming size can make a breakthrough, and the problem that the large area functional microstructure array is not easy to be formed can be solved.

Owner:HARBIN INST OF TECH

Quasi pressure adjusting casting machine and casting method thereof

Owner:SHENYANG LIGONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com