Large-area functional microstructure array current-assisted roll forming device

A microstructure array and roll forming technology, which is applied in the driving devices, manufacturing tools, metal rolling, etc. of metal rolling mills, can solve the problems of difficulty in forming large-area functional microstructure arrays, and achieve breakthroughs in forming size limits, The effect of saving fuel and reducing the forming load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

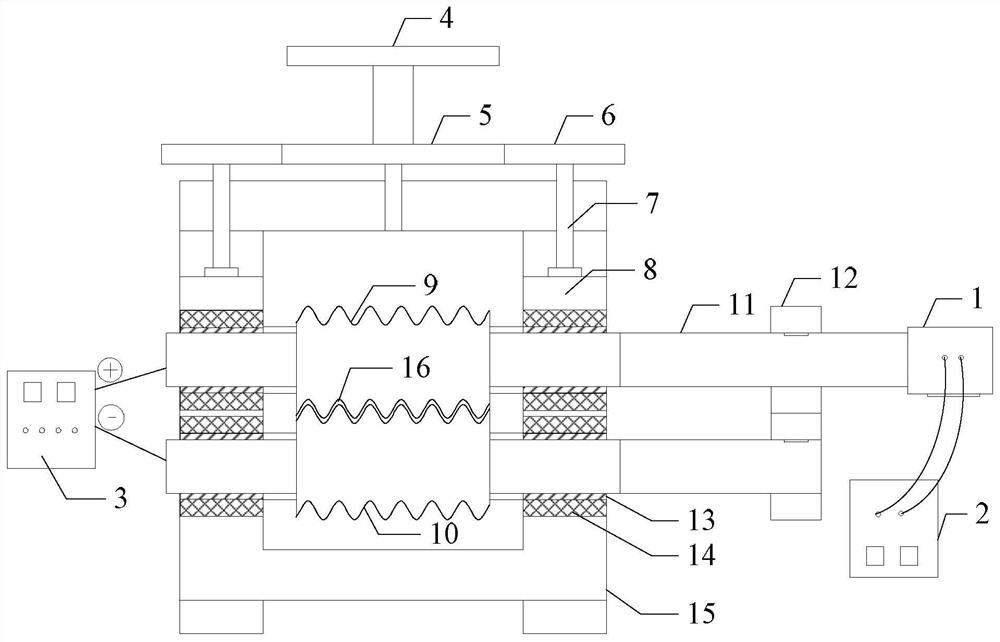

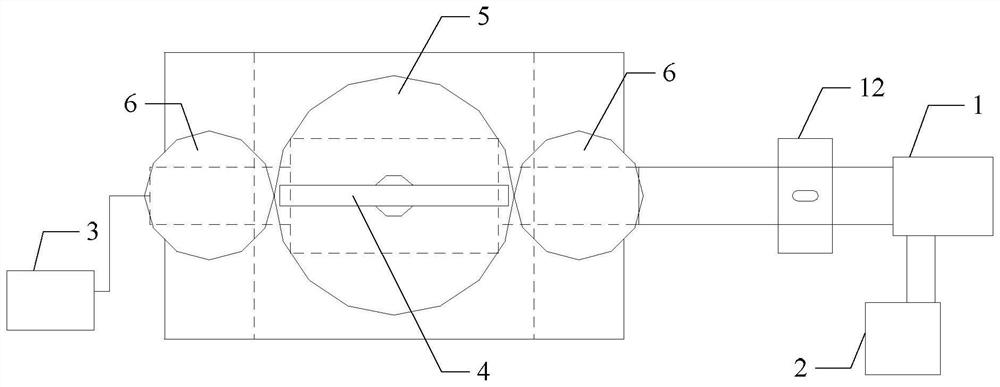

[0010] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the large-area functional microstructure array current-assisted rolling forming device described in this embodiment includes a precision microstructure array rolling machine, a driving motor 1, a control cabinet 2, and an auxiliary forming power supply 3;

[0011] The control cabinet 2 is used to control the driving motor 1 to drive the precision microstructure array rolling machine to complete the forming of the microstructure array of the formed part 16;

[0012] The auxiliary forming power supply 3 is used to output pulsed direct current, and the pulsed direct current passes through the precision microstructure array rolling machine and the forming part 16 to realize a closed loop of current.

[0013] In this embodiment, according to the needs of different surface functions, the structure and size of the precision microstructure array rolling machine are different.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com