Patents

Literature

109results about How to "Reduce forming load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

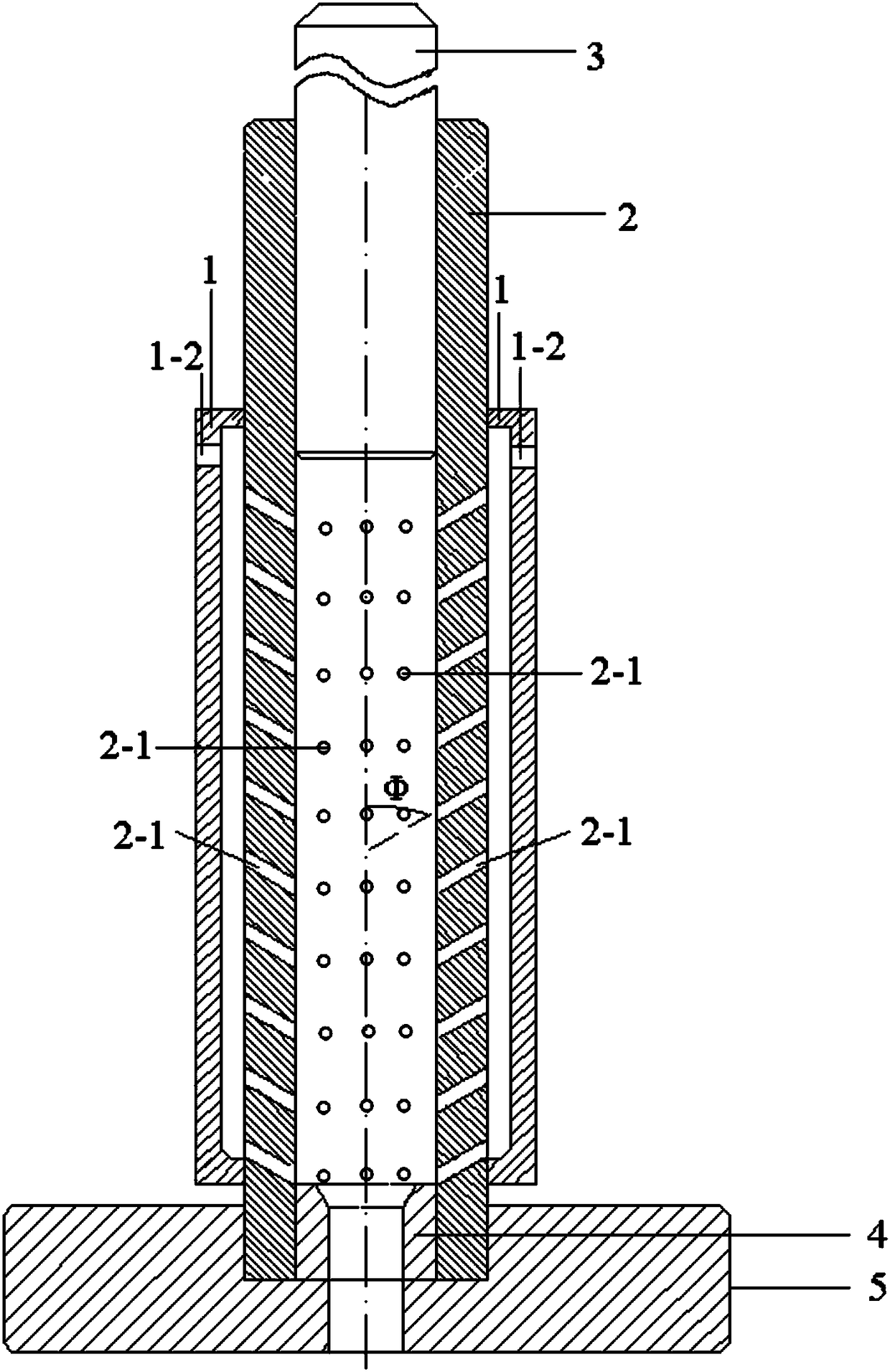

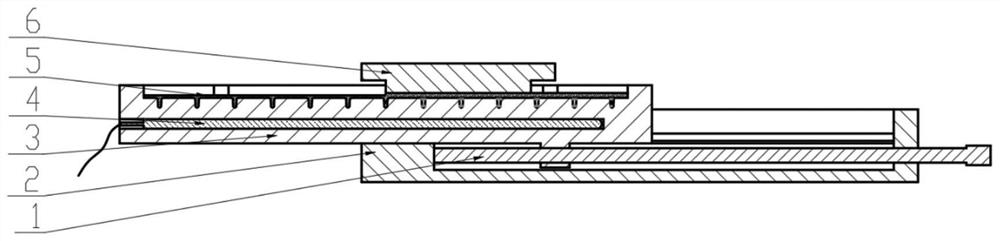

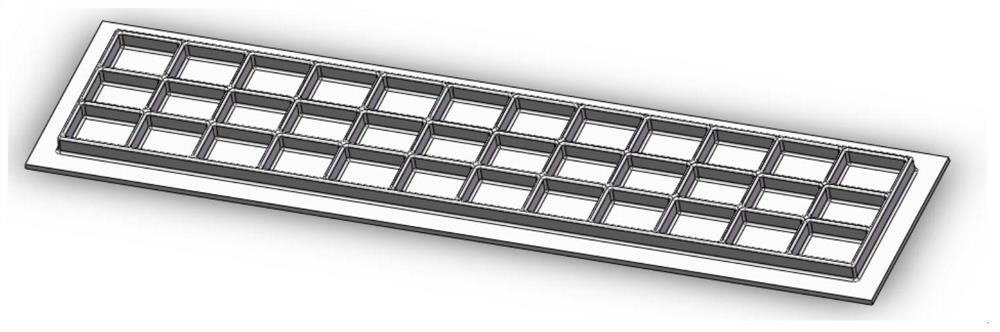

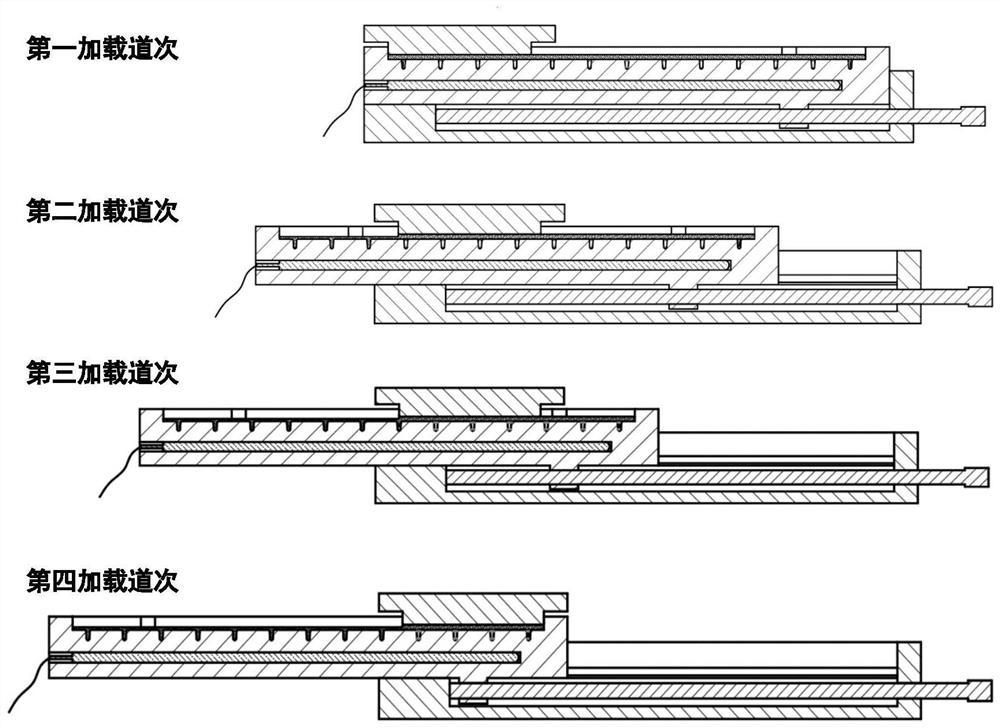

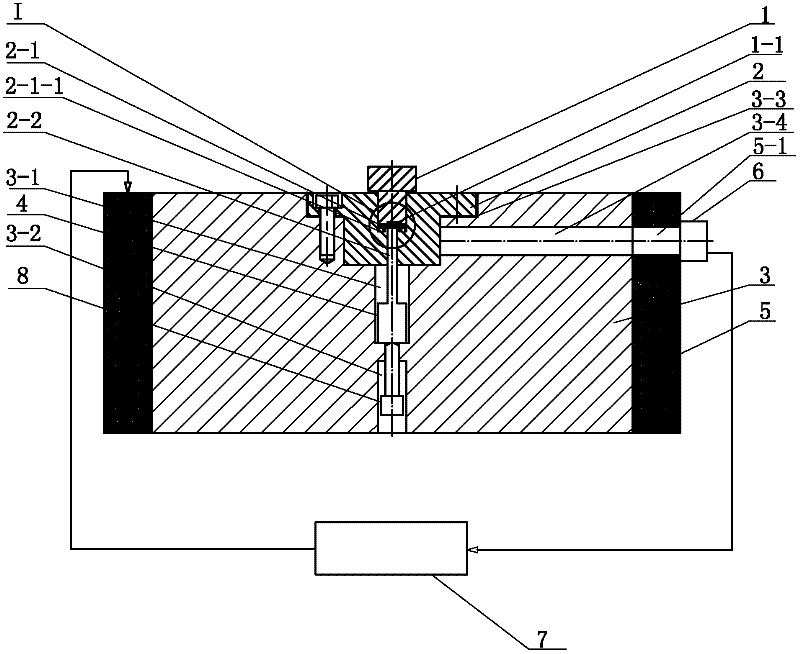

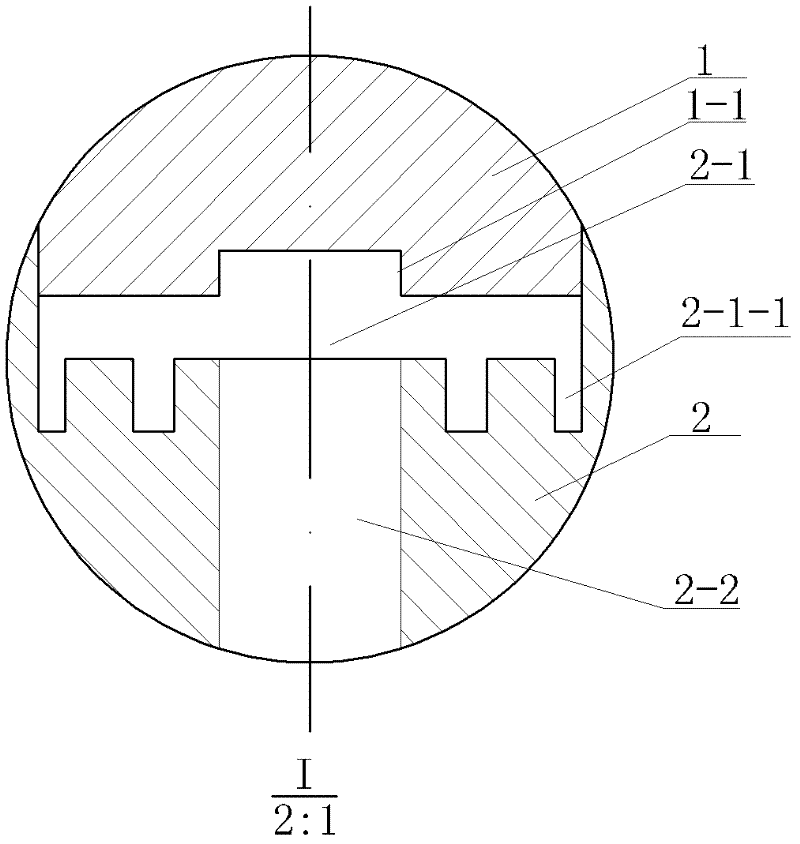

Multi-point male die liquid-filling drawing forming device and method for plate

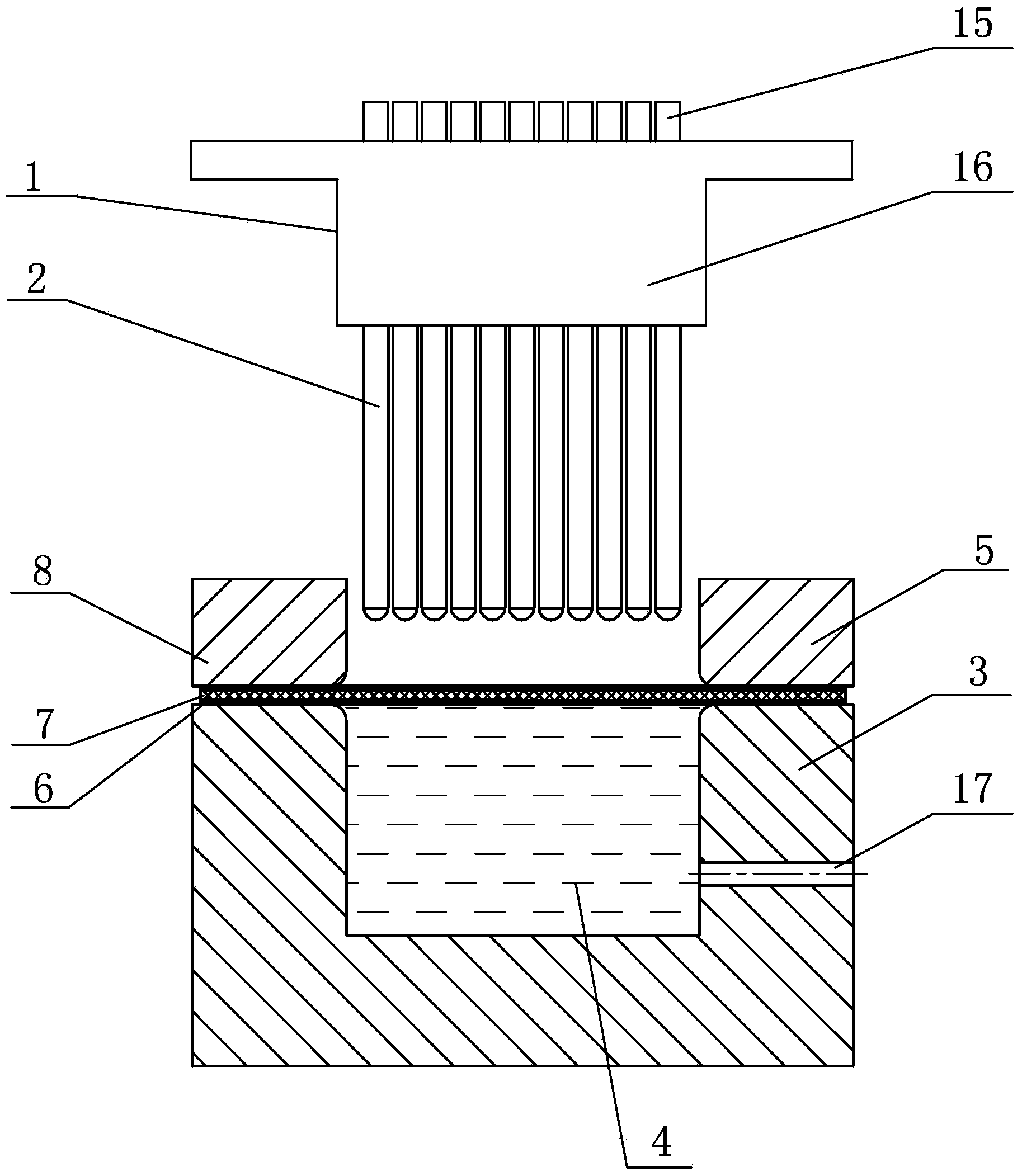

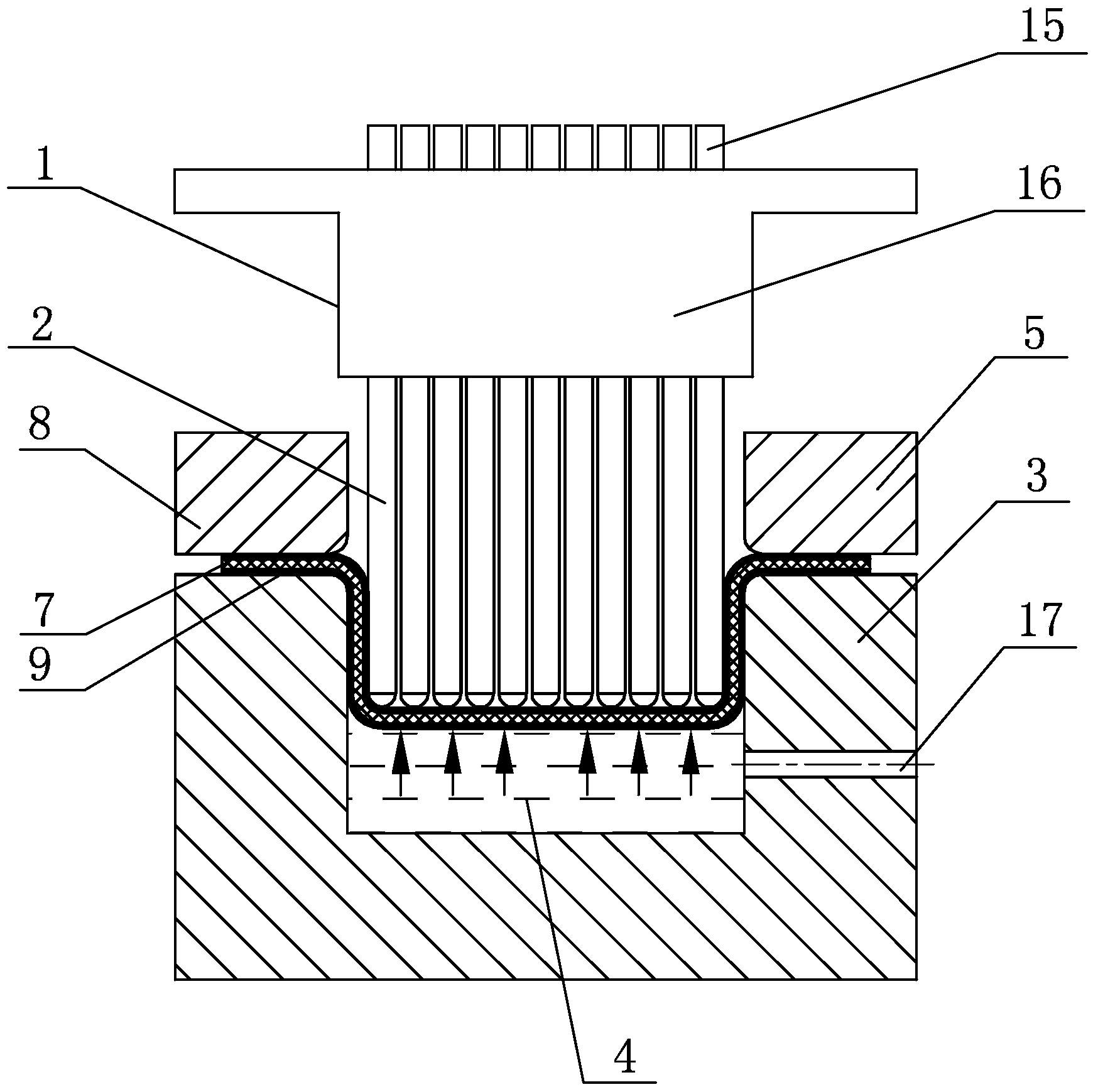

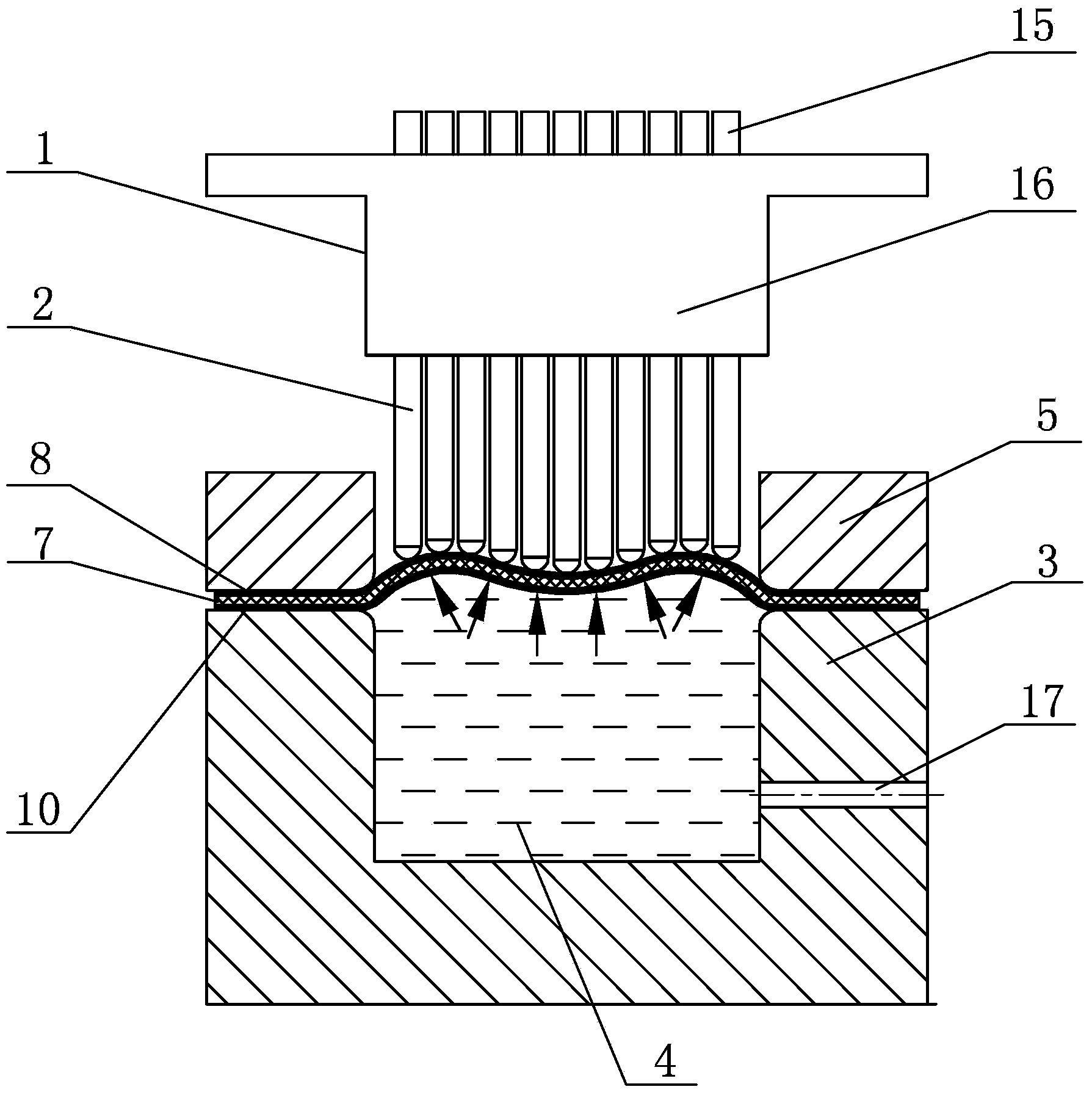

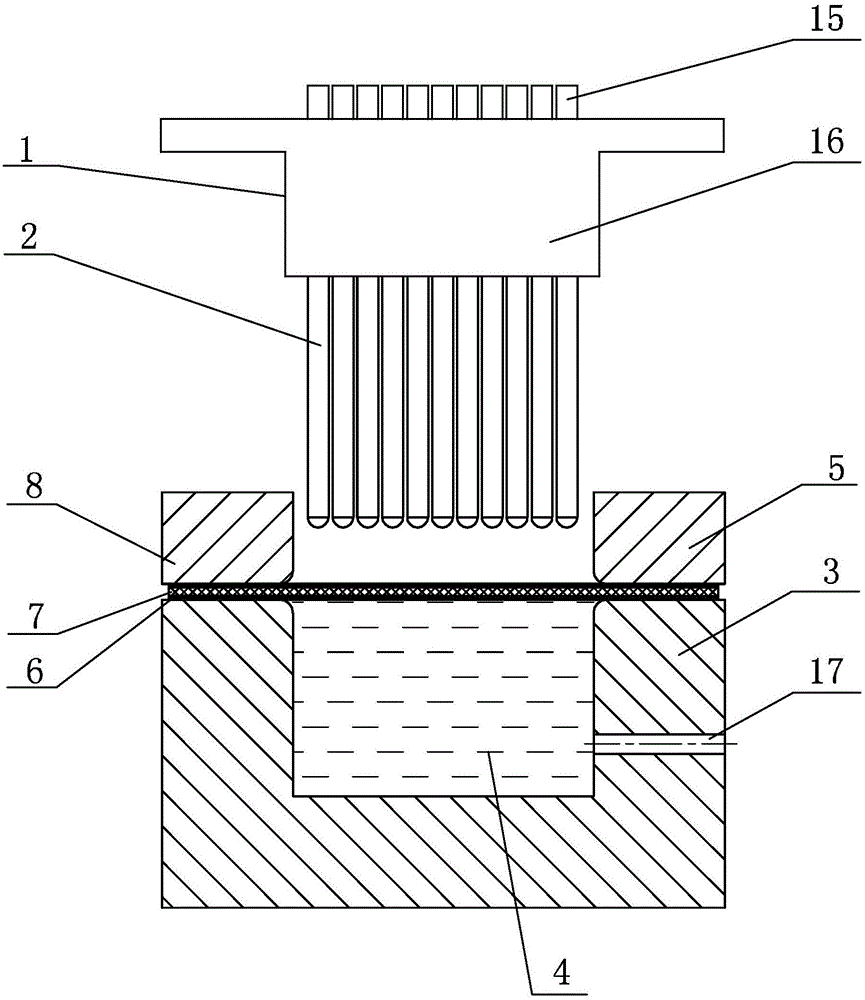

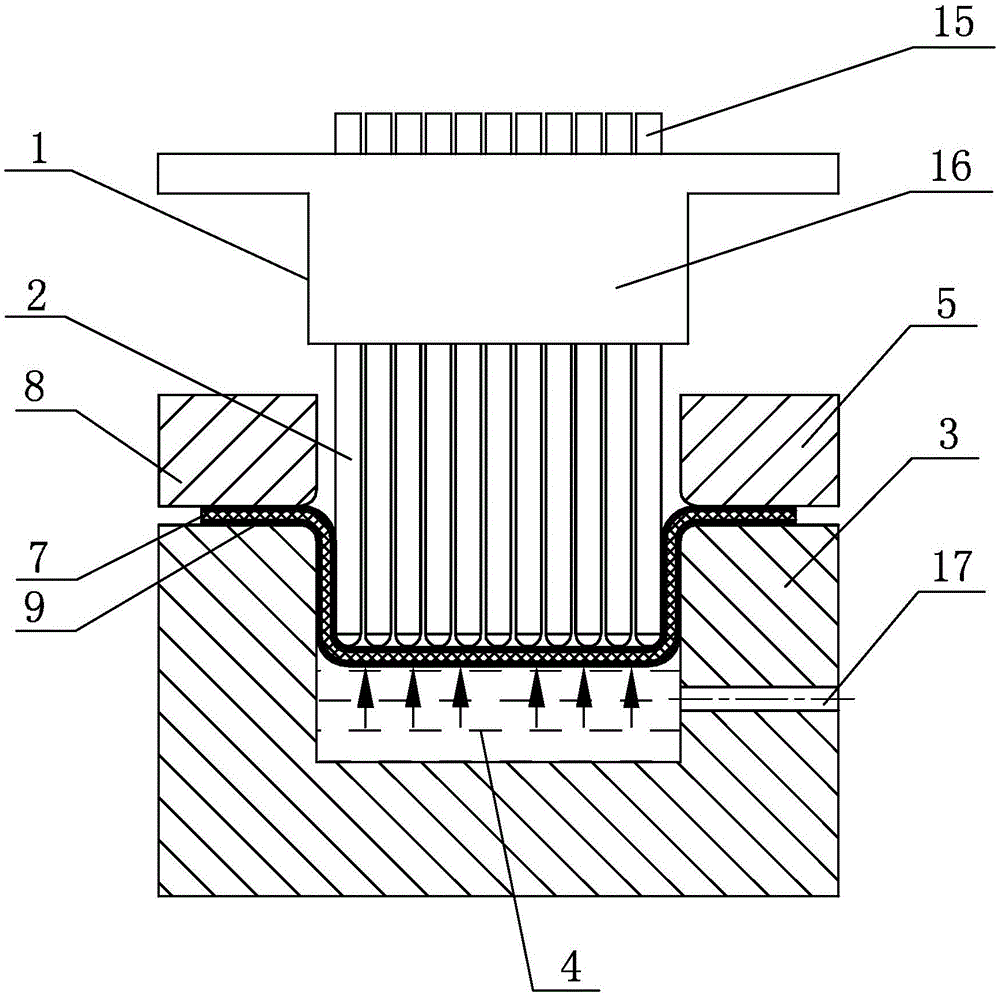

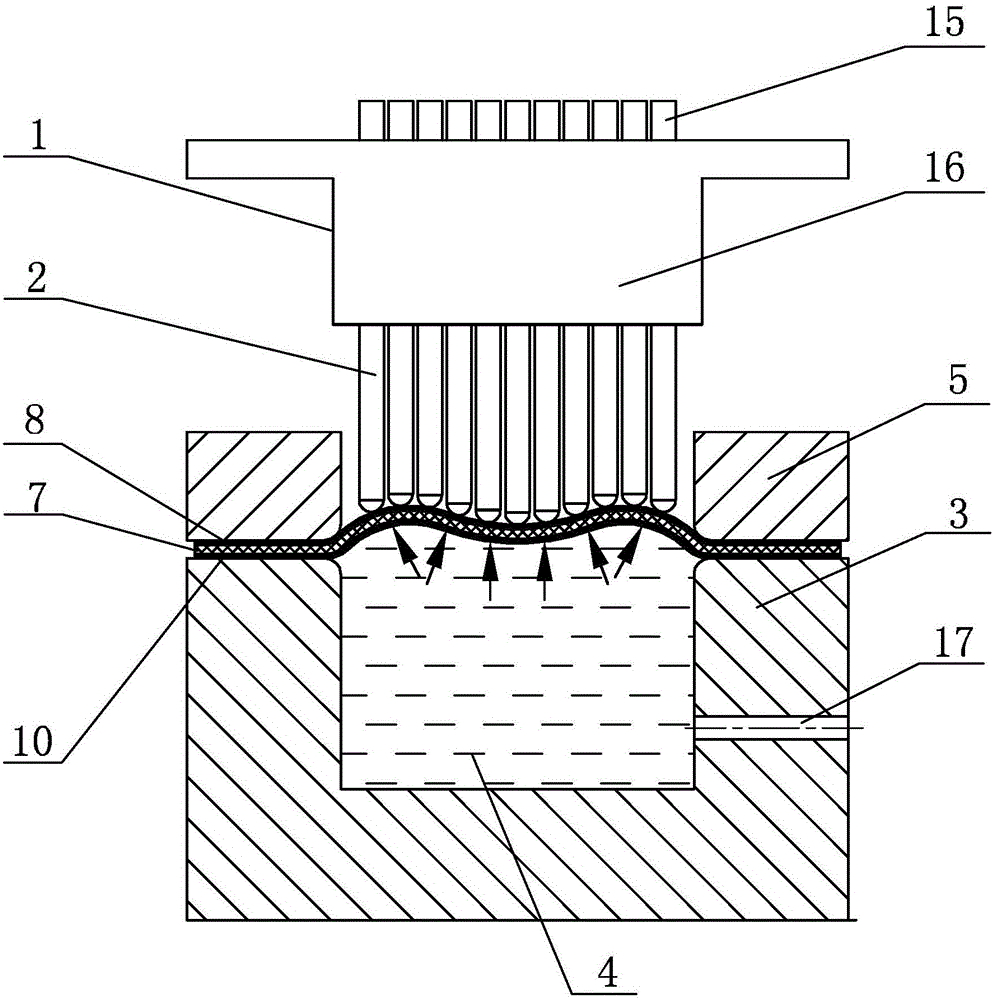

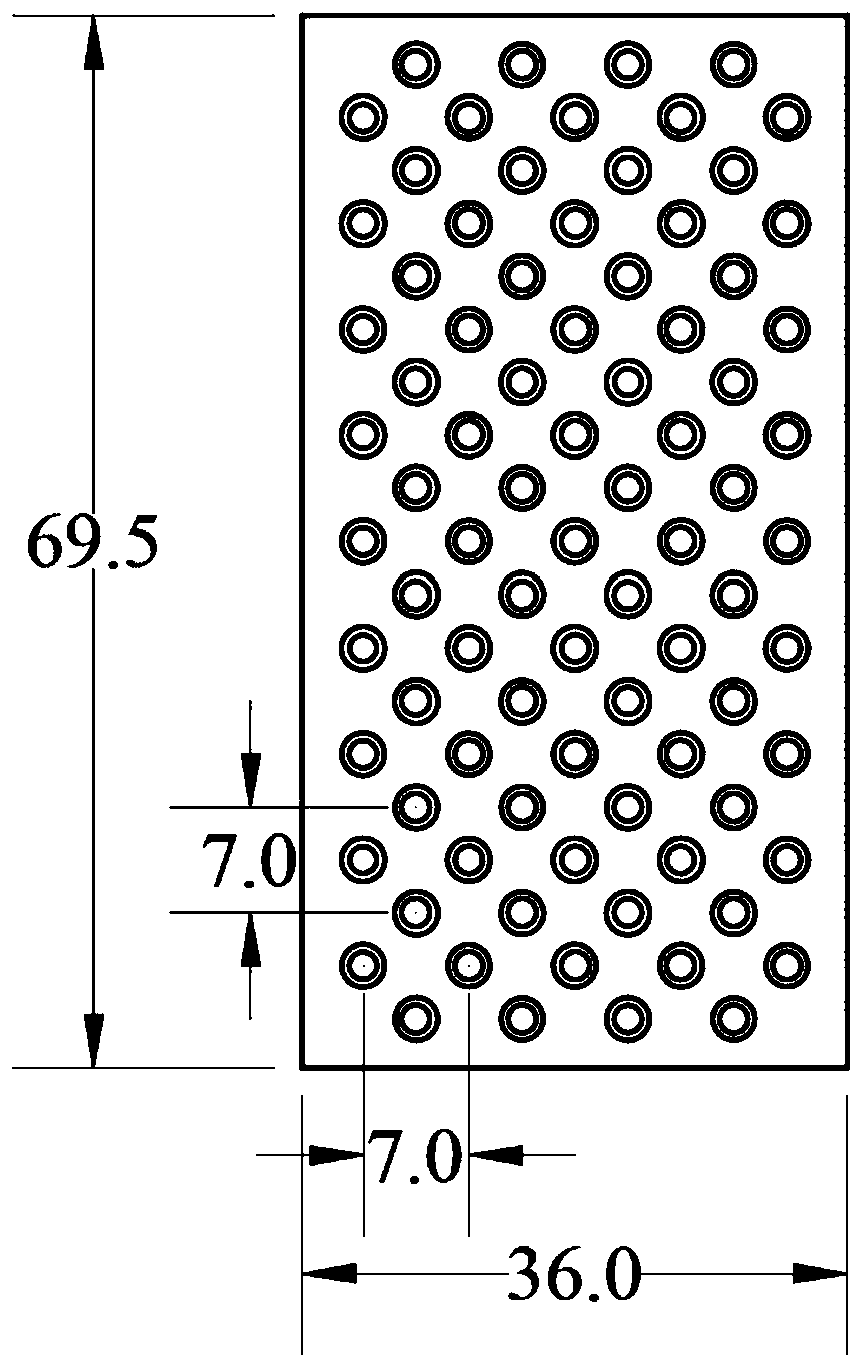

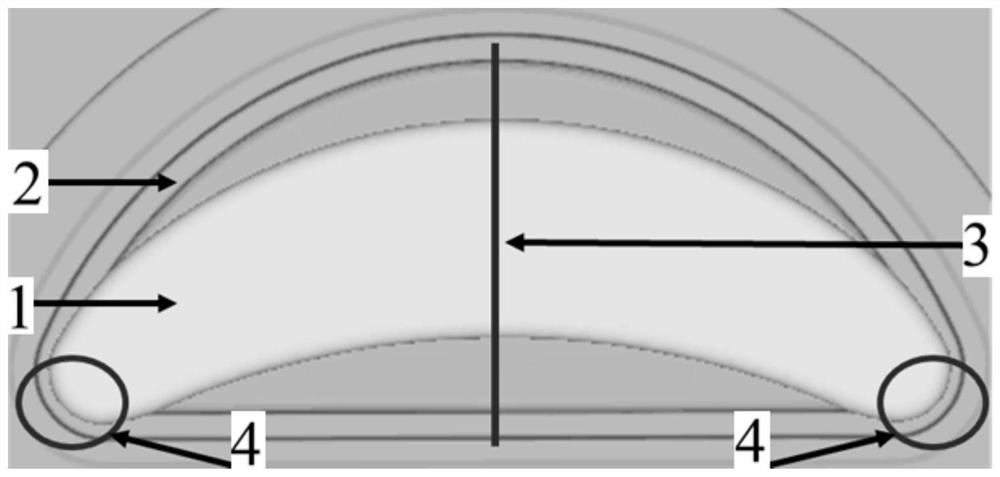

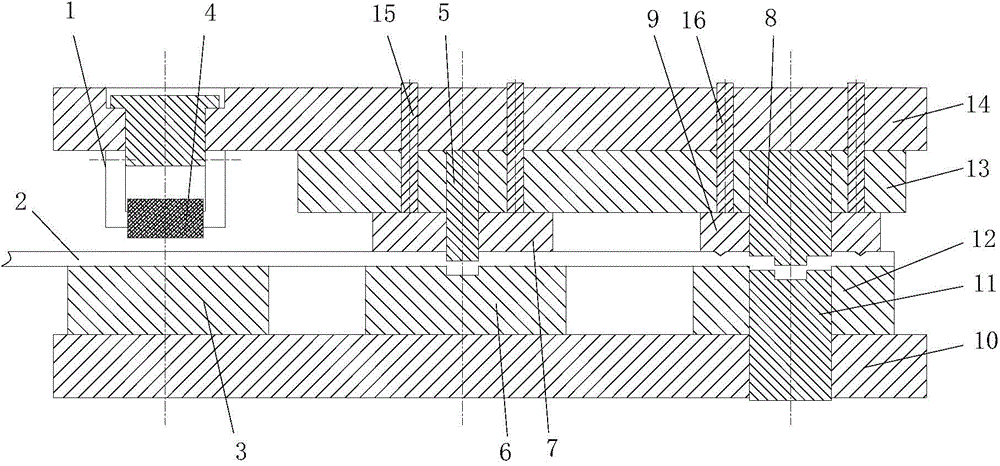

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

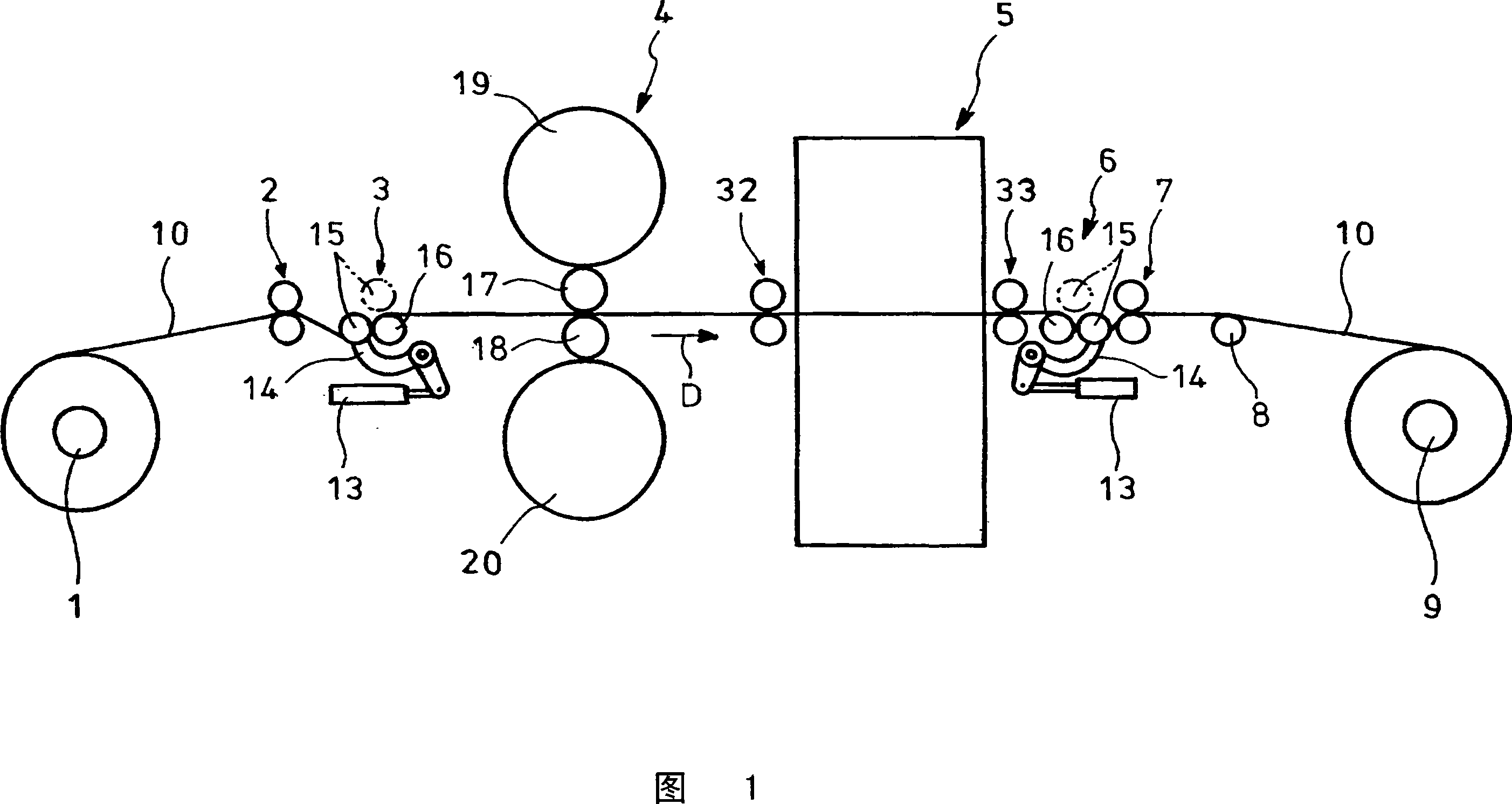

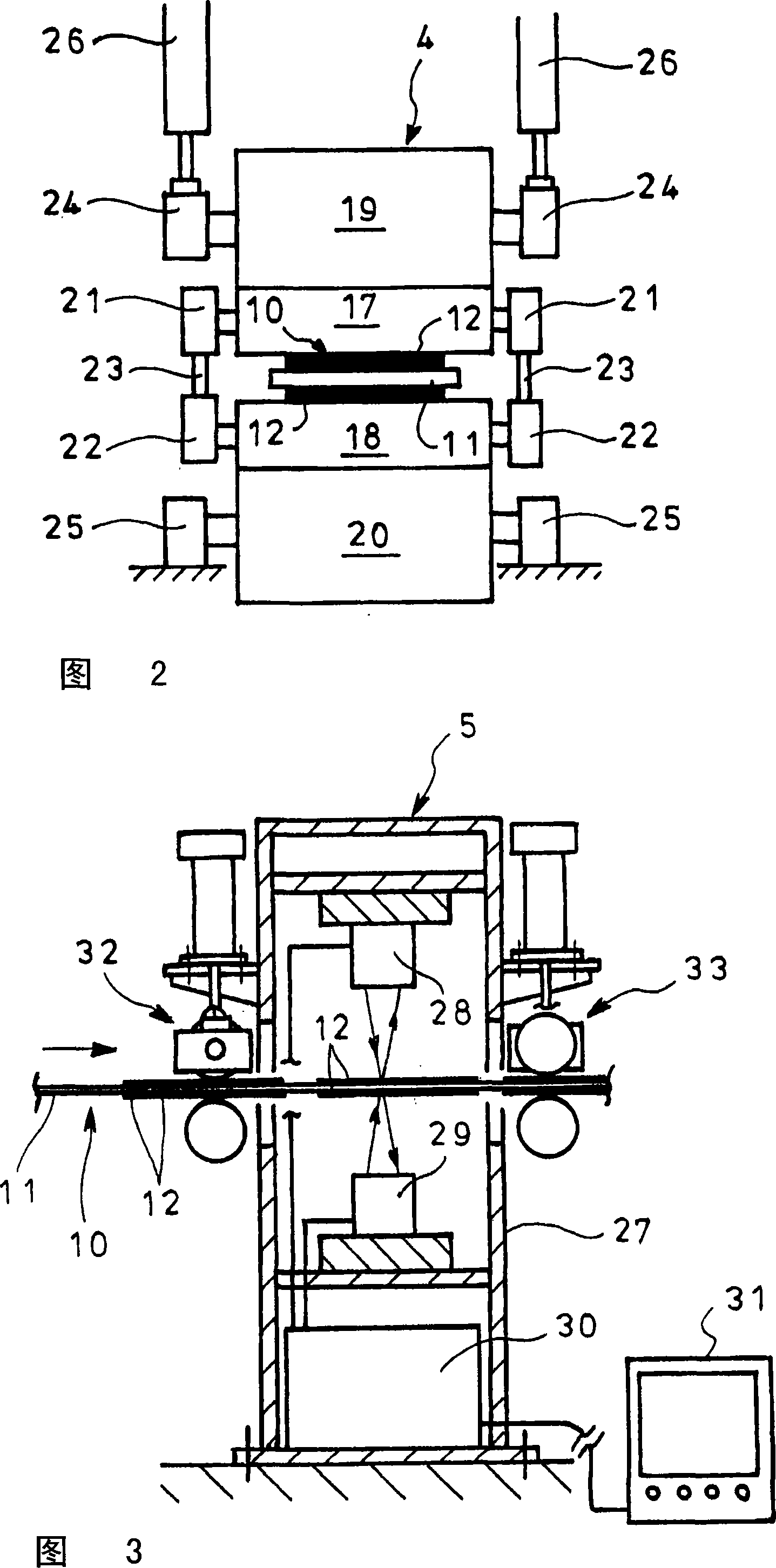

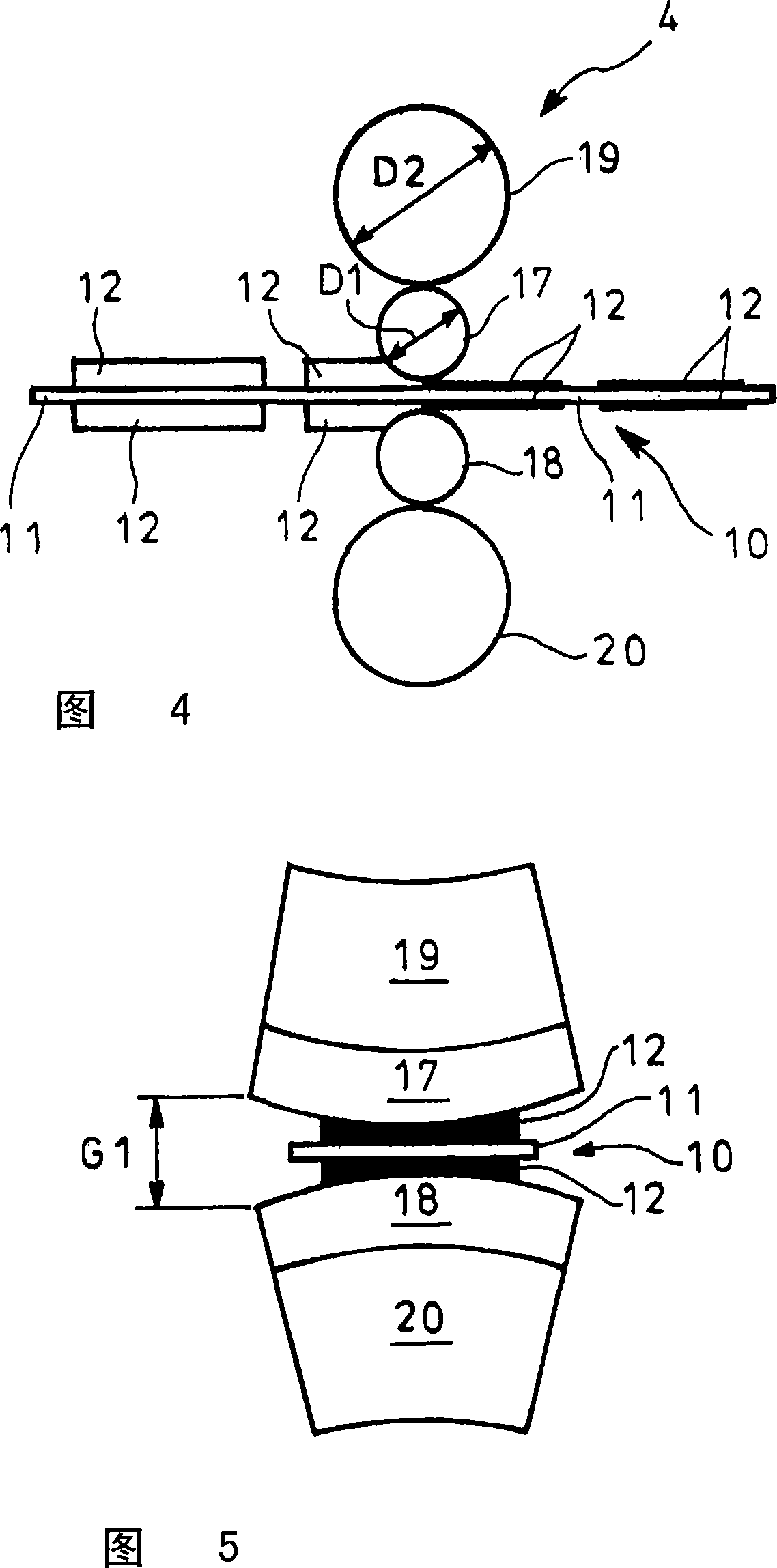

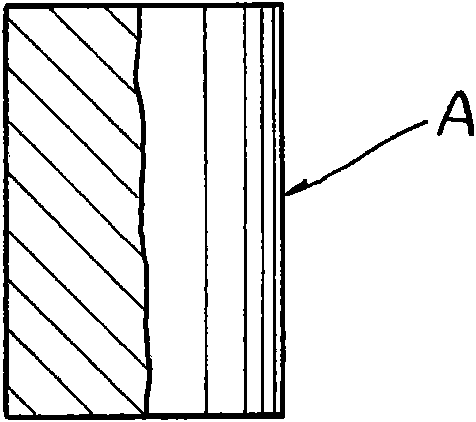

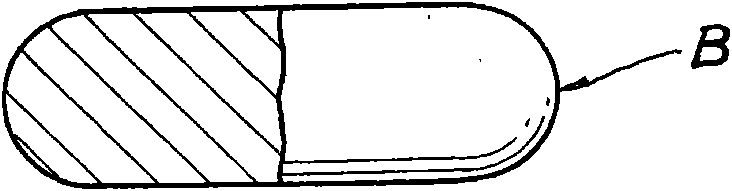

Facility for forming battery electrode plate

InactiveCN101095252AReduce forming loadAvoid bendingElectrode manufacturing processesProduction rateCoated electrodes

A battery electrode board figuration device, in the running direction (D) of the battery electrode board (10) which core is coated electrode active material, setting a decoiling machine (1), a tension endowing device (3), a four-high roller device (4), a thickness detecting device (5), a tension endowing device (6) and a winder (9) from upstream to downstream. Thus, under the state of pressing figuration to the battery electrode board with wide extent so as to improve the volume density of the electrode active material, to produce battery electrode board with high quality reliably and stably.

Owner:IHI CORP

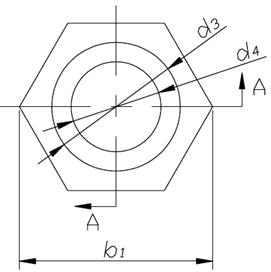

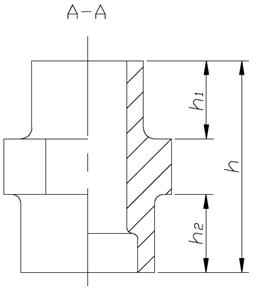

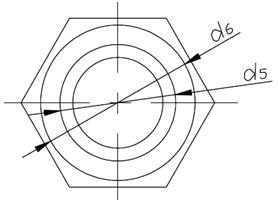

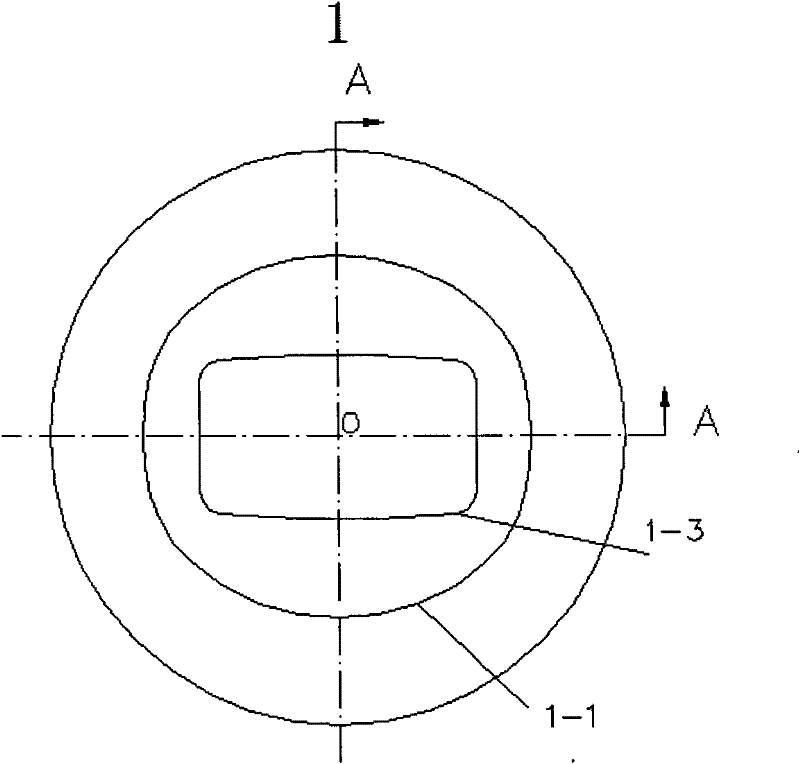

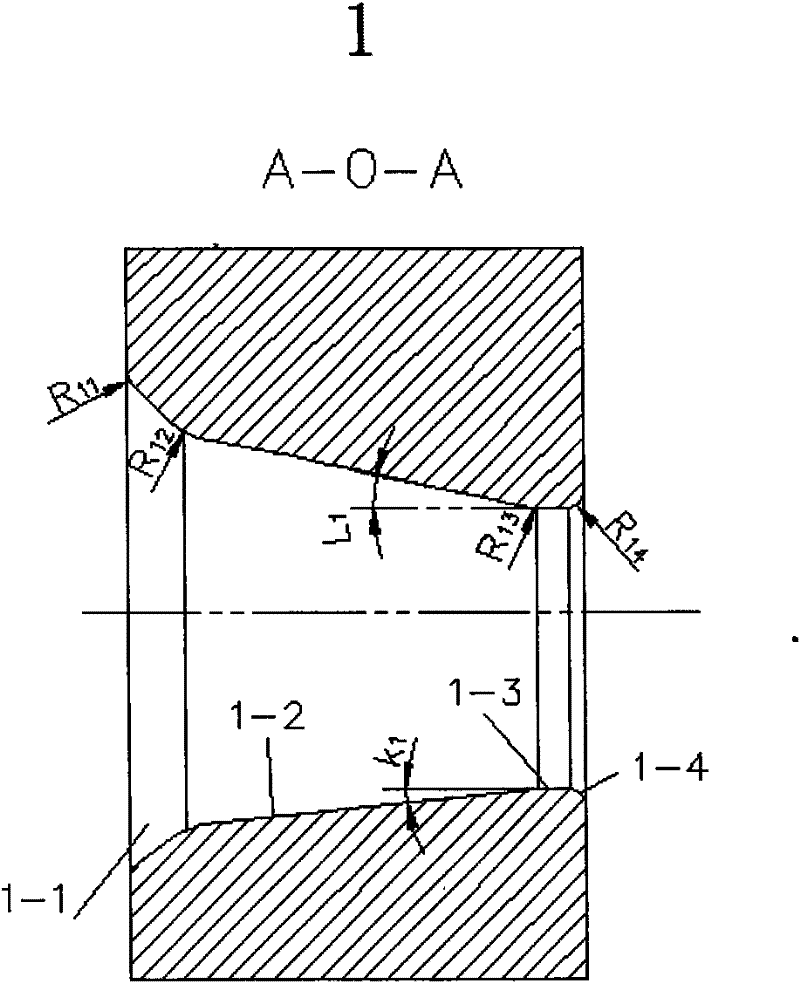

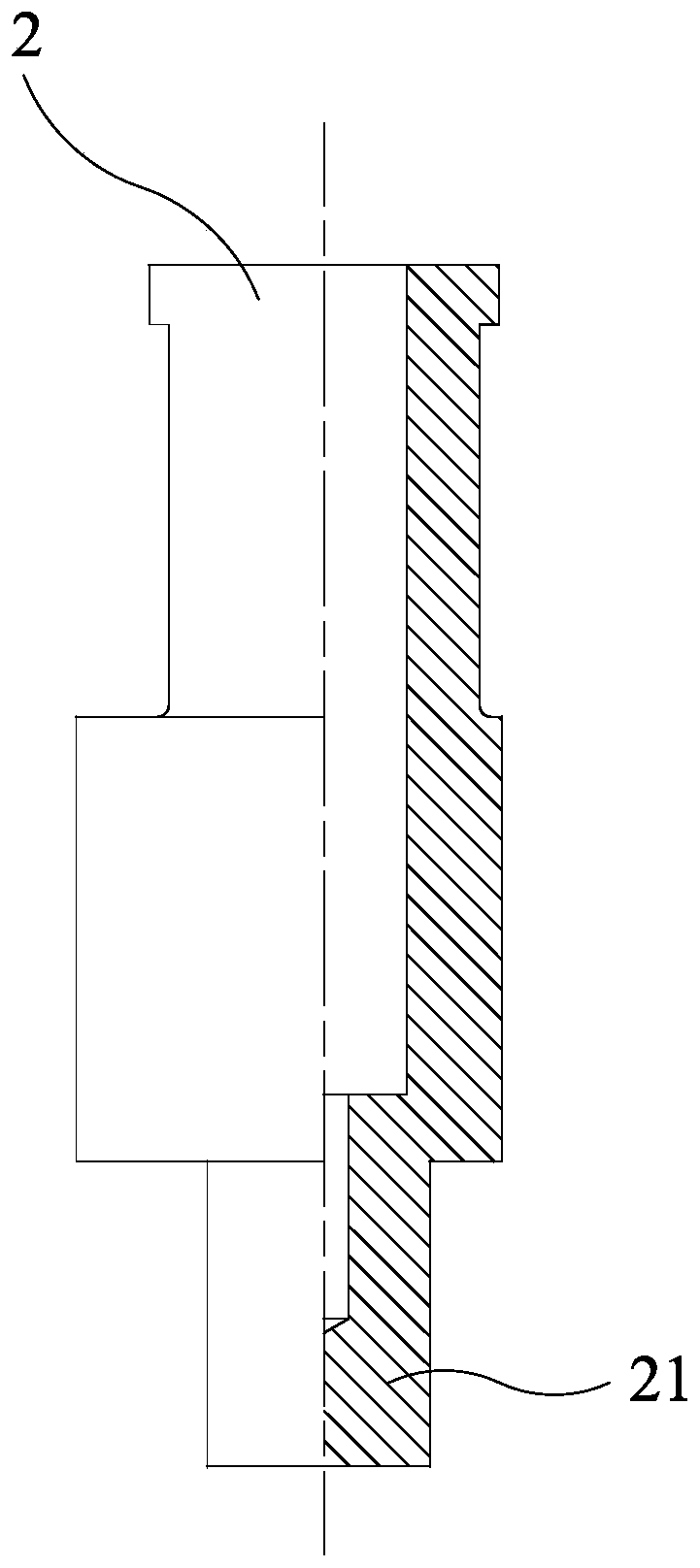

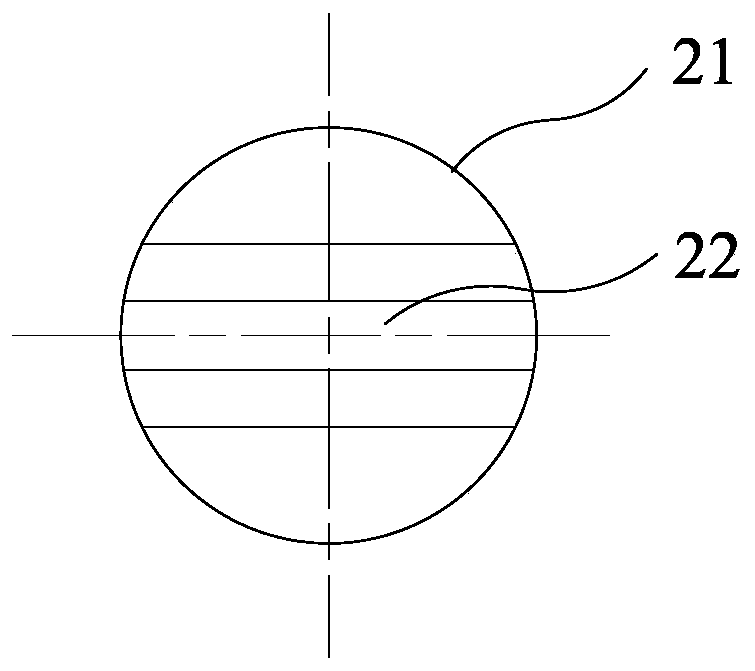

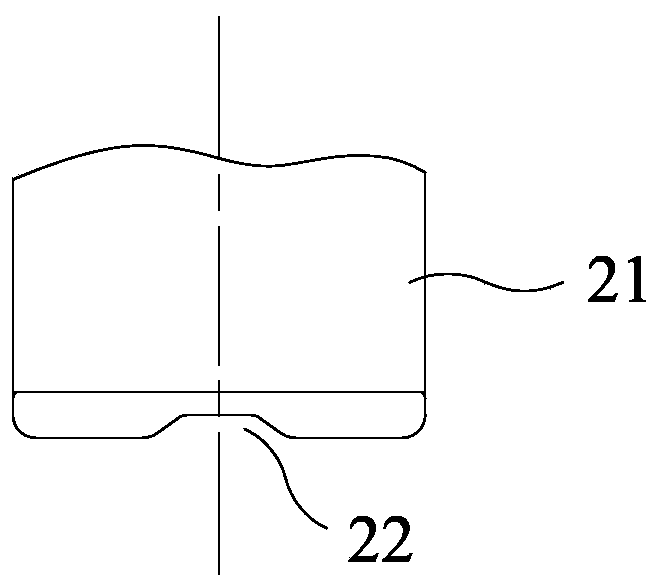

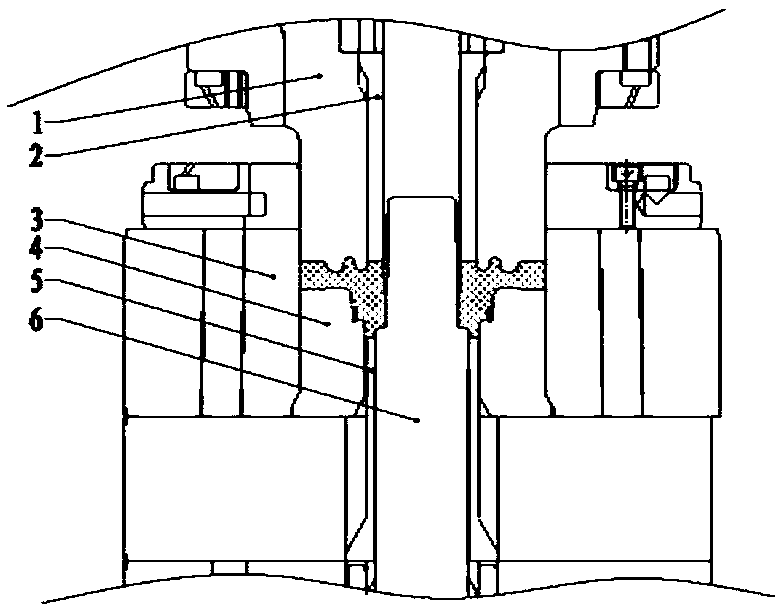

Method and apparatus for manufacturing inner ring and outer ring

The present invention provides a method for easily manufacturing an inner ring and an outer ring, capable of improving a rate of finished products and reducing material cost. Firstly, forging heated disk-shaped raw produce to form so as to form a first shaping produce which is provided with a tapered dent that the diameter of the tapered inner surface is shortened gradually toward the inner side on the center of one end face, the bottom face of the tapered dent is provided with a circular hole which diameter is less than that of the inner ring to be manufactured and having a thin-wall bottom on the center. Subsequently, stamping the thin-wall bottom of the first shaping produce so as to form a second shaping produce with a circular through hole. Subsequently, protruding the perimeter of the circular through hole of the second shaping produce towards, simultaneously expanding the through hole so as to form a third shaping produce having an outer ring part, a middle ring part and an inner ring part. Finally, stamping the third shaping produce secondarily by inner / outer forging dies and inner / outer press heads so as to form the inner ring, the outer ring and the middle ring which is used as the stamping residual material.

Owner:SAKAMURA THERMAL TREATMENT TECH

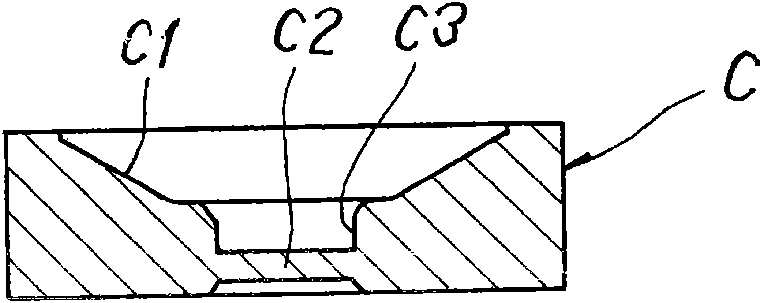

Device and method for compounding and forming central flange pipe joint from pipe blank in single-step and multi-directional way

ActiveCN102303090AReduce forming loadGood metal fluidityExtrusion diesExtrusion mandrelsExtrusion mouldingForming force

The invention discloses a device and a method for compounding and forming a central flange pipe joint from a pipe blank in a single-step and multi-directional way. The method comprises the following steps of: applying enough pressure on an appropriate pipe billet serving as a blank to make the whole pipe billet plastically deformed; forming a central flange of the pipe joint by upsetting; and inversely extruding to form a small head end part of the pipe joint and positively extruding to form a large head end part of the pipe joint, so metal upwards, downwards and radially flows, the forming force is small, and the number of stations is small. Compared with a cutting pipe joint, the invention has the advantages of high material utilization ratio and production efficiency and good metal flow structure, and is particularly applicable for production of high-pressure pipe joints.

Owner:JIANGSU UNIV

High-precision aluminum alloy rectangular tube forming method

The invention discloses a high-precision aluminum alloy rectangular tube forming method which comprises the following steps: a) heating the prepared No.6061 aluminum alloy ingot over uniform fire to 415+ / -5 DEG C, and keeping for 1-2 hours; b) performing hot extrusion on an extrusion shunting mould with a preheating temperature of 400 DEG C to obtain an initial tube blank; c) performing annealingtreatment in salt bath; d) performing cold rolling on the tube blank obtained in the step c) to obtain a round tube; e) soaking the round tube obtained in the step d) in a 38# cylinder oil for 24 hours; f) performing non-mandrel drawing on the tube blank obtained in the step e) to obtain an approximately rectangular tube; g) performing mandrel drawing on the approximately rectangular tube obtained in the step f) through a rectangular correction mould to obtain a rectangular tube; and h) performing mandrel drawing of the rectangular tube obtained in the step g) to obtain the finished tube. Through the invention, the size precision and surface quality of the finished tube are improved, the problems that the tube blank is drawn apart in the drawing process and obvious transverse cracks appear at the corner are solved, and the operational performance and service life of the product are remarkably improved.

Owner:CHONGQING UNIV

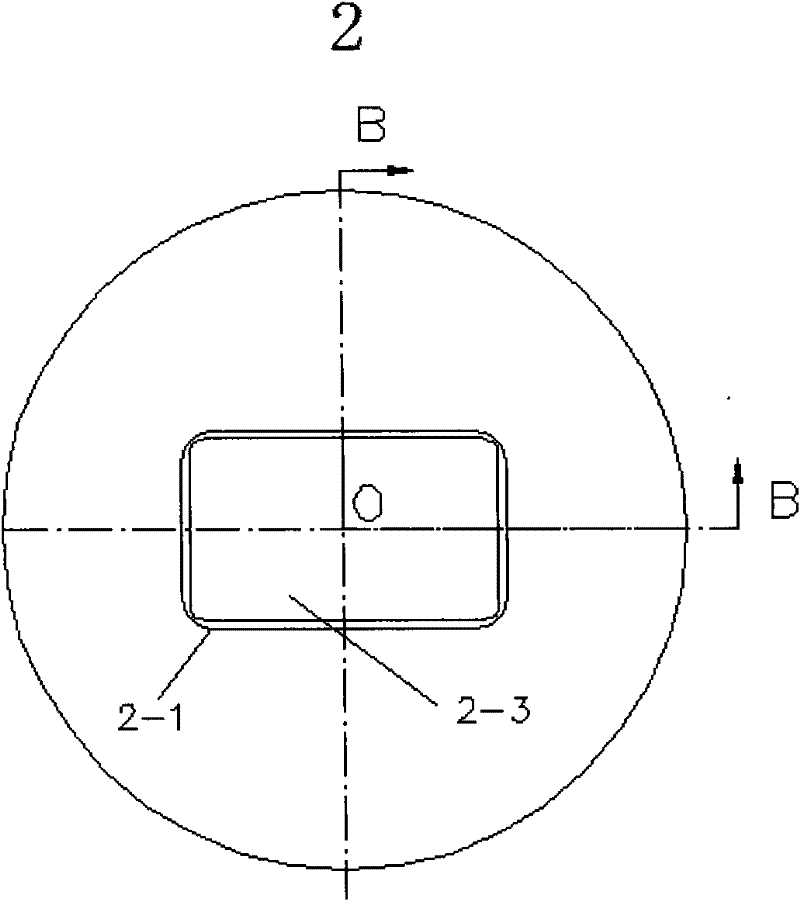

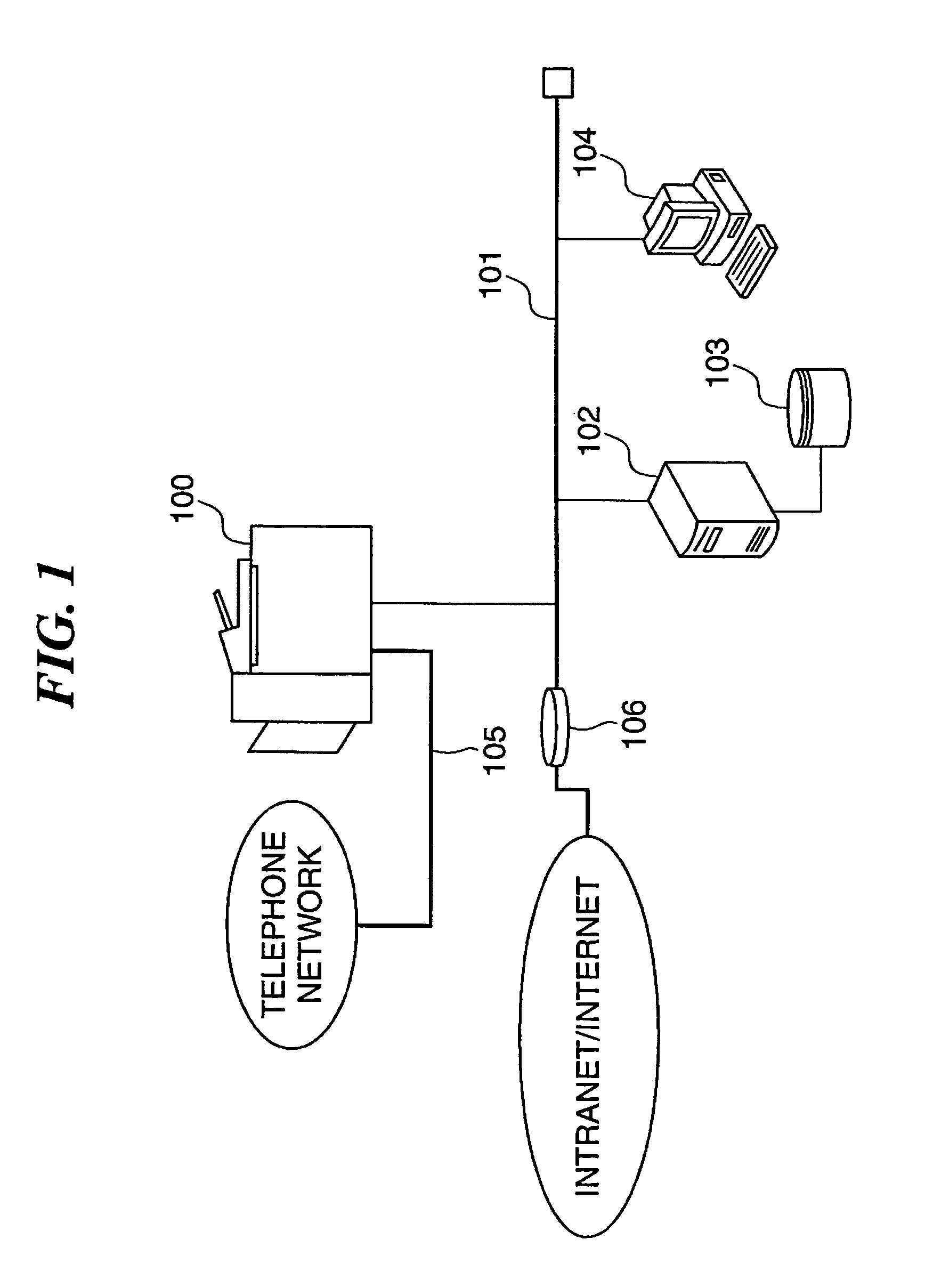

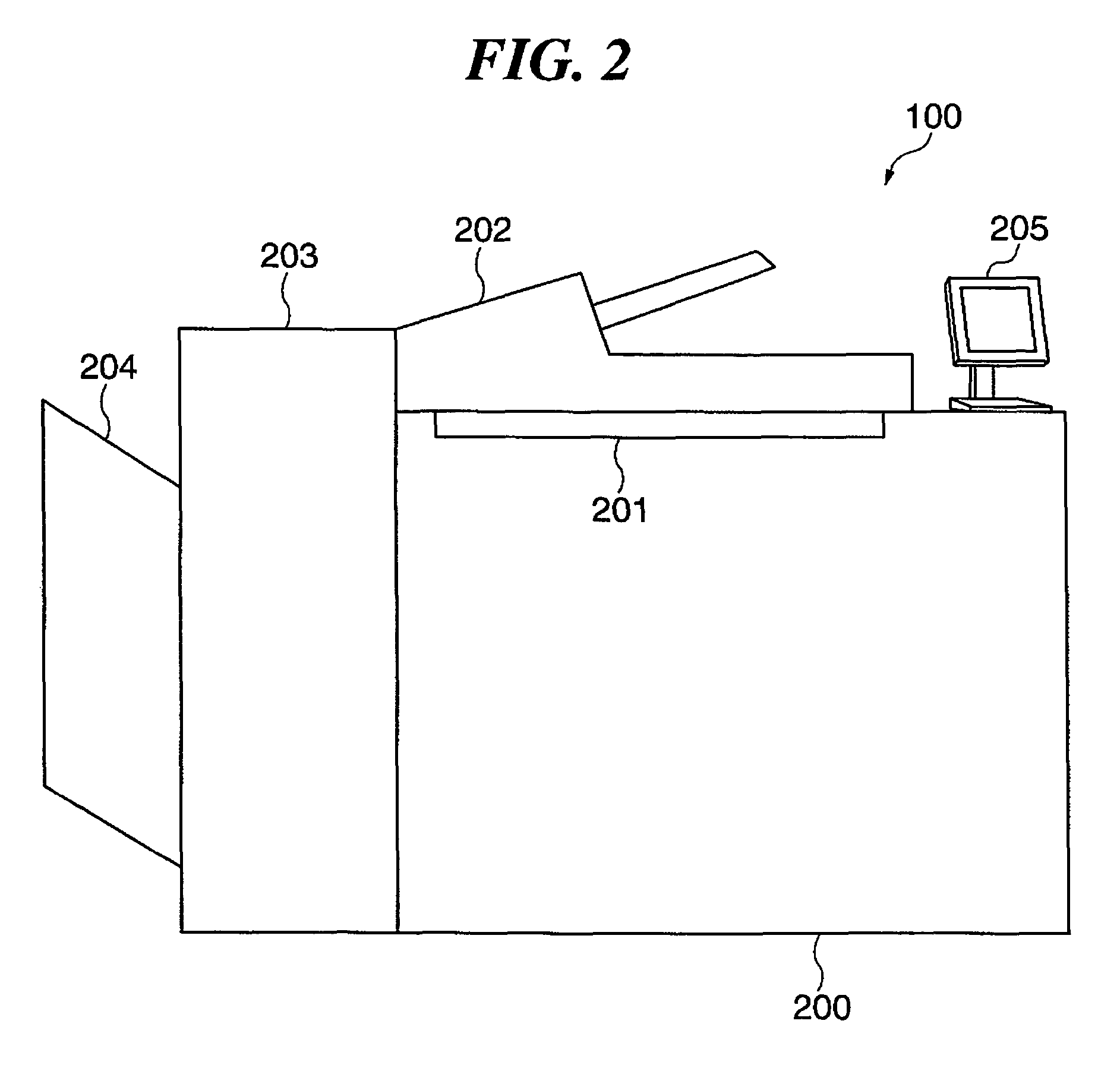

Data processing apparatus, image processing apparatus, data processing method, image processing method, and programs for implementing the methods

InactiveUS7787158B2Reduce forming loadImprove accuracyCharacter recognitionPictoral communicationImaging processingCharacter recognition

A data processing apparatus that is capable of improving the accuracy with which form types can be identified. An image file of a form and an additional file including a form type ID of the form are inputted. A character recognition process on the image file is carried out based on the form type ID. The image file and a result obtained in the character recognition process are stored in a storage device 103.

Owner:CANON KK

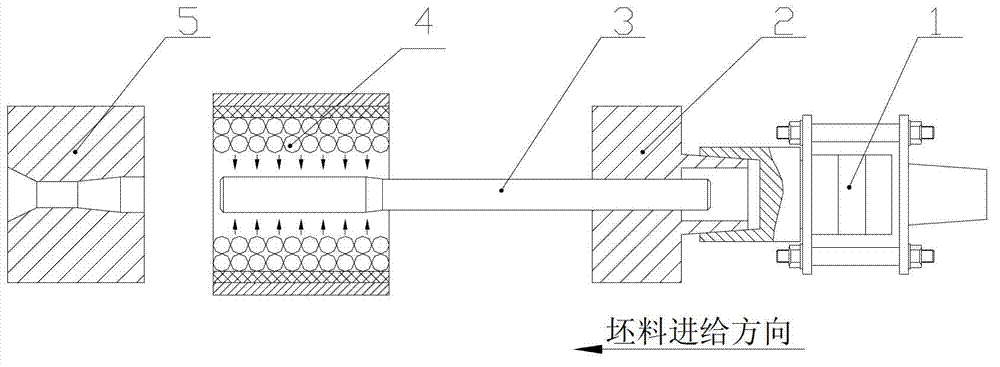

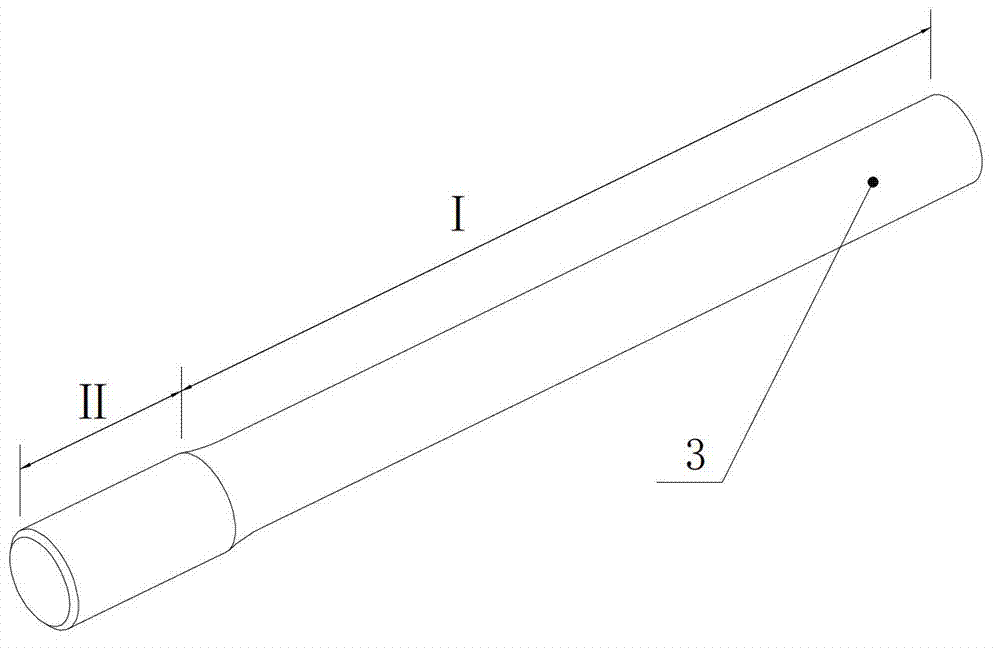

Device for compositely extruding spline shaft by means of medium-high frequency induction heating and vibrating and technology therefor

The invention provides a device for compositely extruding a spline shaft by means of medium-high frequency induction heating and vibrating and a technology for compositely extruding the spline shaft by means of medium-high frequency induction heating and vibrating. The device comprises a vibrator and a medium-high frequency induction heater, wherein the vibrator is axially connected with a blank in series by a clamp, and the medium-high frequency induction heater and an extrusion die are distributed at the front of a blank feed direction. The technology comprises the following steps of: firstly, clamping a blank, wherein the clamp drives the blank to move to a spline tooth-shaped section of the blank along the feed direction to completely enter into an inner chamber of the medium-high frequency induction heater, quickly heating the surface metal of the spline tooth-shaped section on the blank to a preset temperature, continuously feeding the blank, applying axial vibration to the blank by the vibrator, forming the spline shaft in an extruding way due to the action of the extrusion die, reversely withdrawing the blank, and quickly quenching. The device has the advantages of being less in forming load, low in energy consumption, high in efficiency, good in forming quality, wide in machining range and the like.

Owner:XI AN JIAOTONG UNIV

Surface micro-morphology processing method of gear composite plastic forming die

ActiveCN109158523AExtend your lifeImprove mechanical propertiesForging/hammering/pressing machinesMicro textureMachining process

The invention relates to a surface micro-morphology processing method of a gear composite plastic forming die. The surface micro-morphology processing method comprises the following step that S1, a large area of the forming pressure of the mold in the machining process is determined, and a micro-pit is machined in the area where the forming pressure is larger; S2, the micro-pit with nanometer molybdenum disulfide is filled. The micro-pit morphology is based on the forming mechanism of the mold, the surface micro-textures processed by the maximum forming pressure area are selected, a lubricantcan be effectively provided under the condition of boundary lubrication and lean oil, the mechanical performance and the friction lubricating performance of the precision forging gear in the forming process are improved, the abrasion amount of the precision forging die is reduced, so that the service life of the die is prolonged; the micro-morphology processing method is efficient, precise and controllable, pollution-free to the environment, low in cost and the like.

Owner:南京江峰新能源科技有限公司 +2

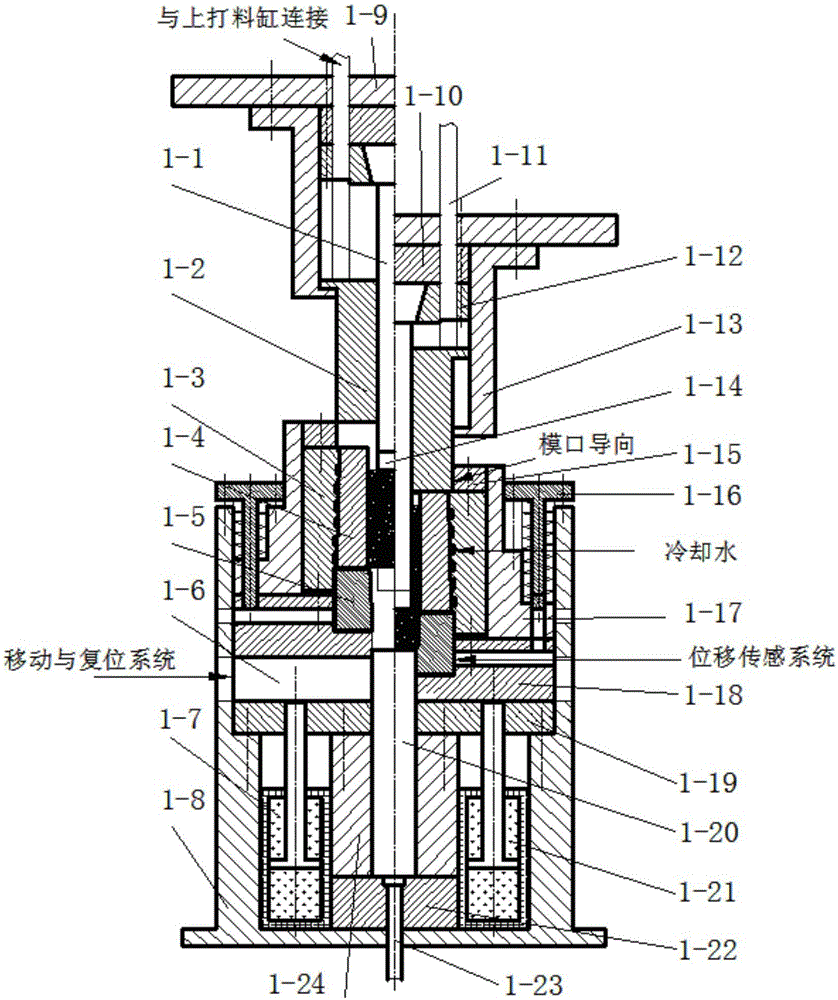

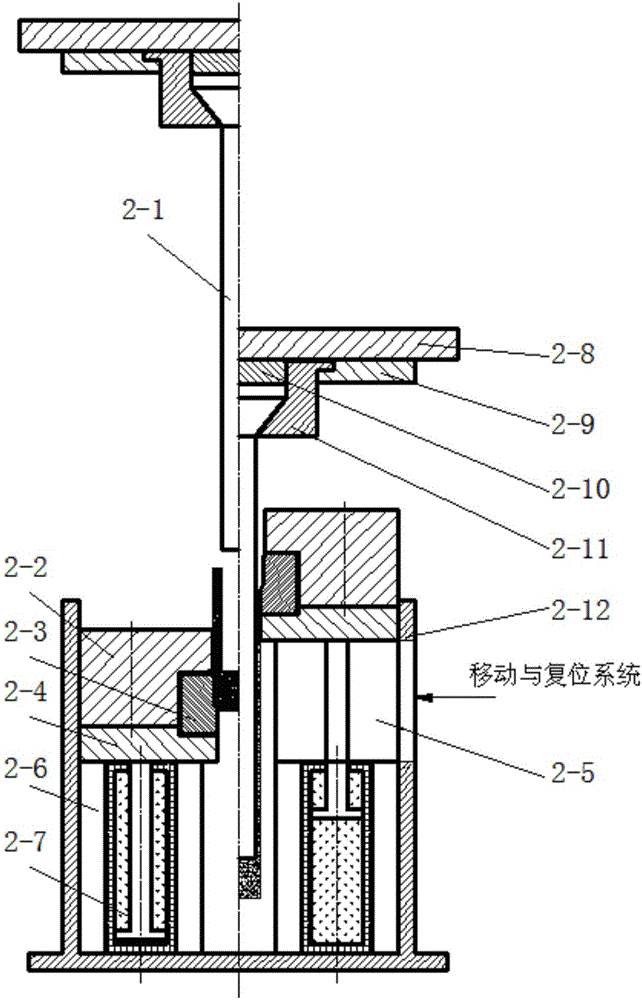

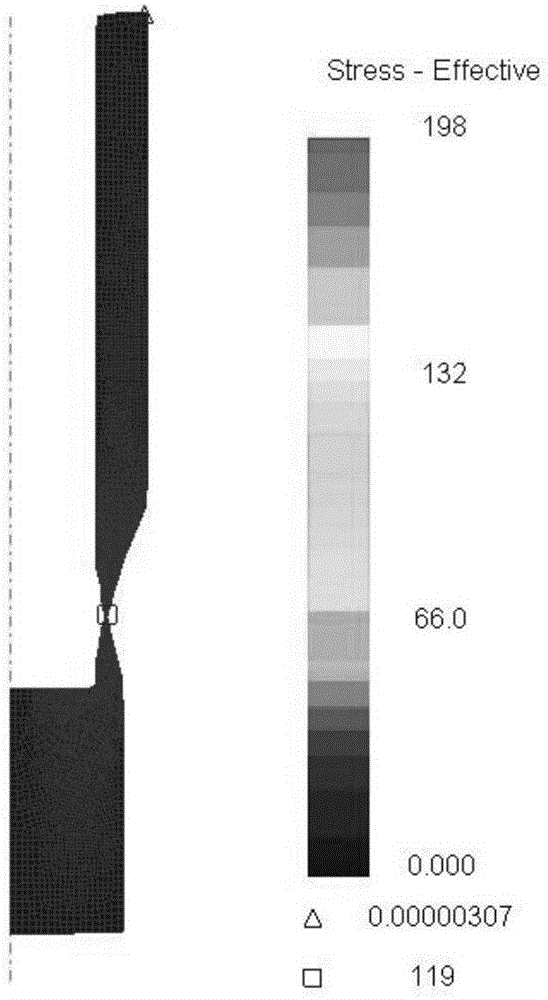

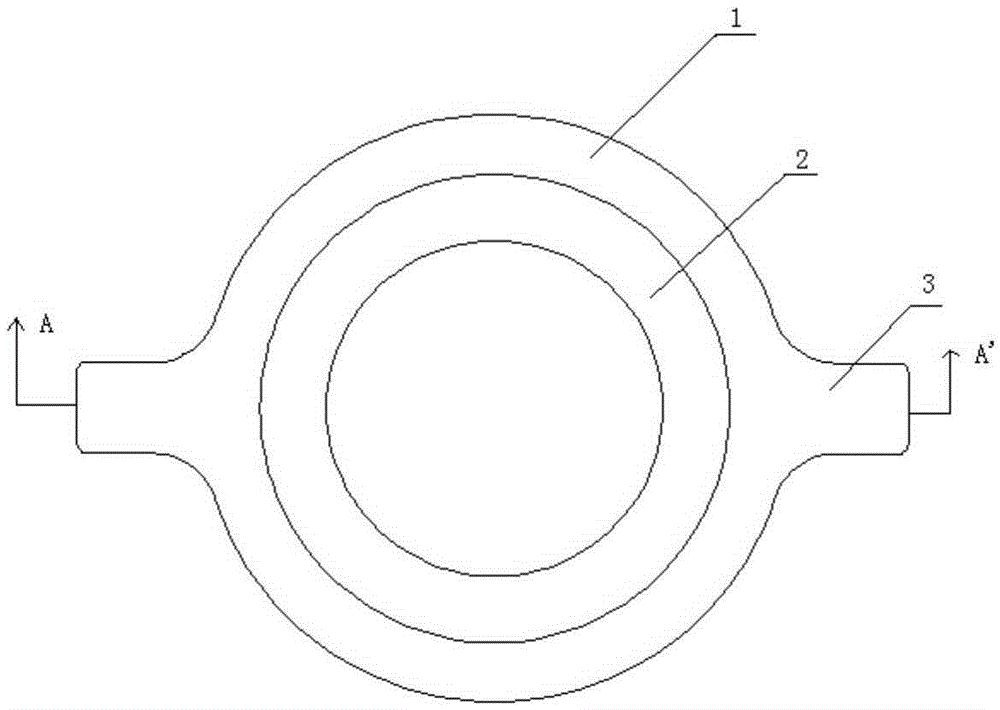

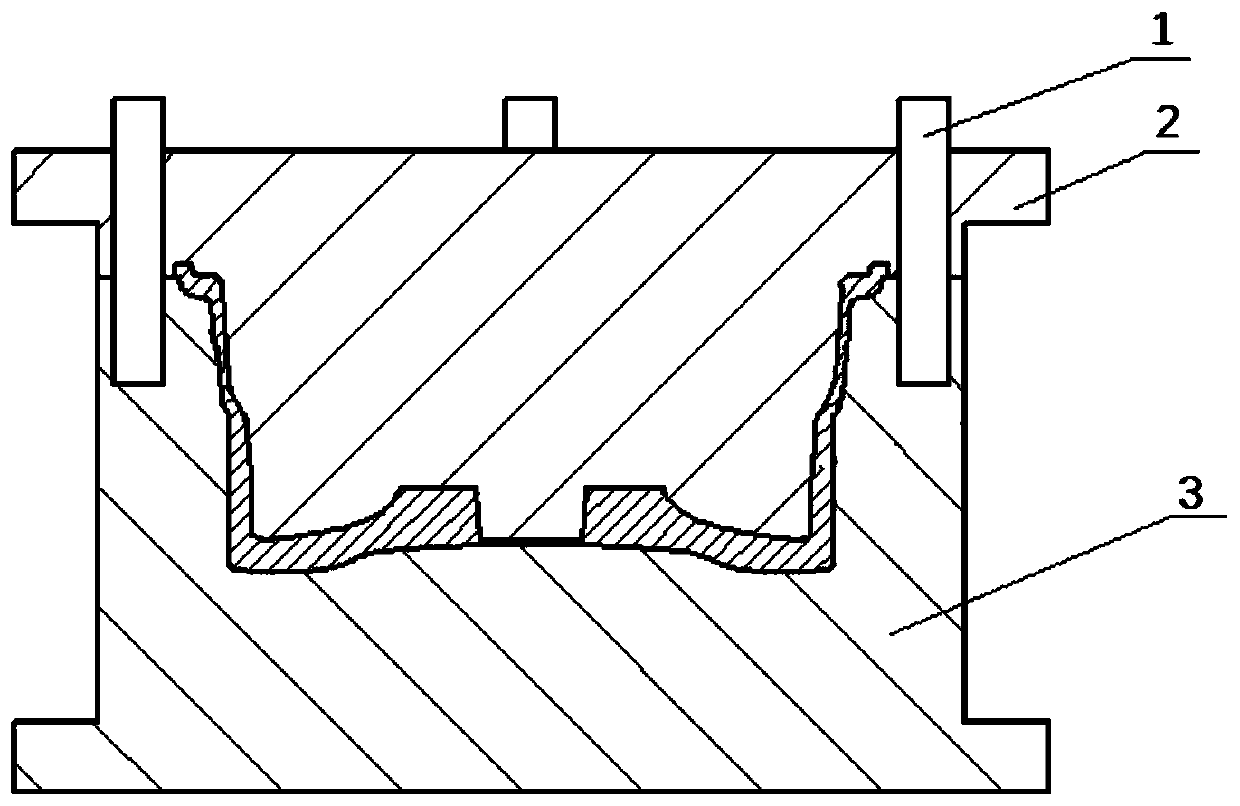

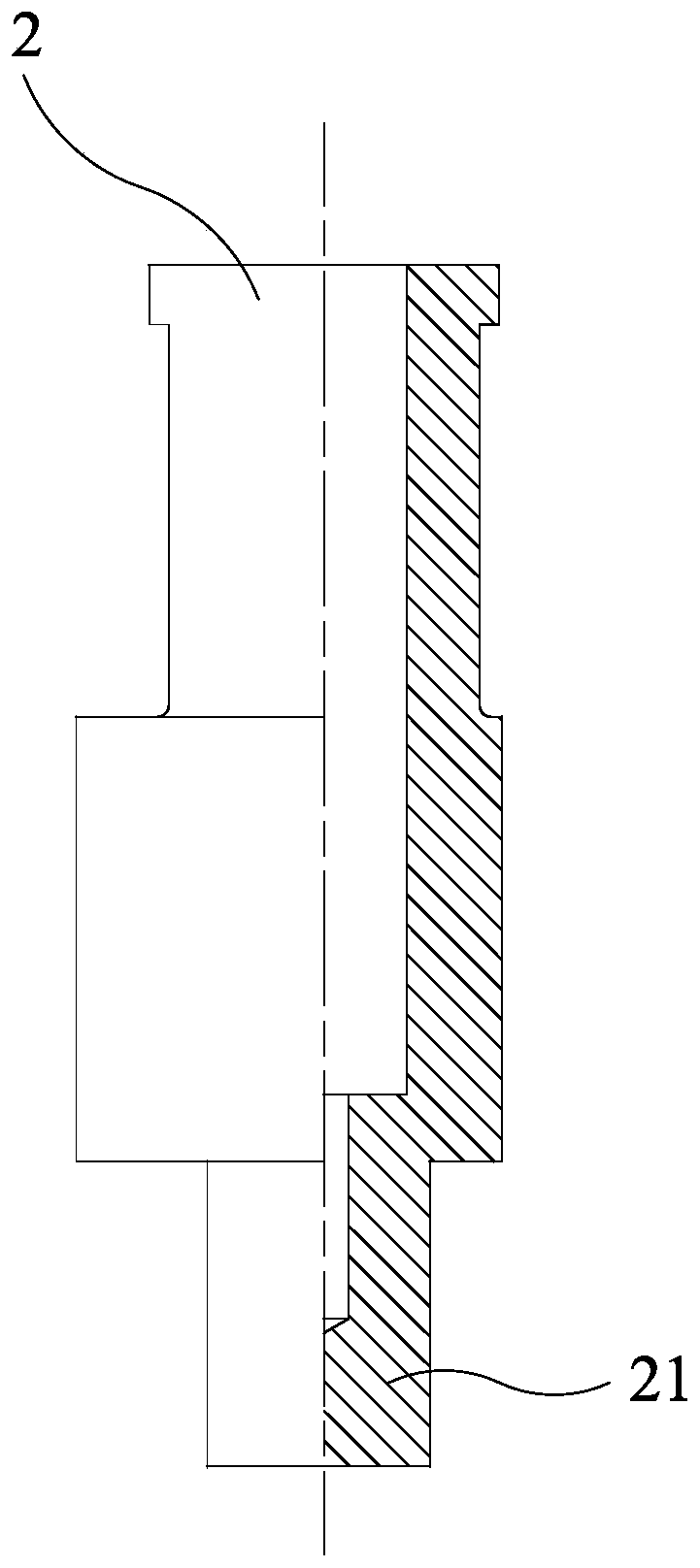

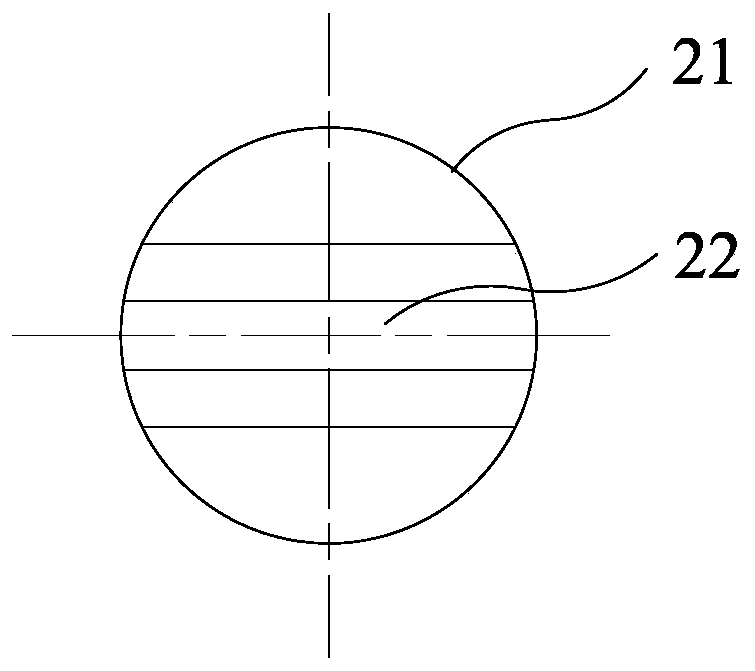

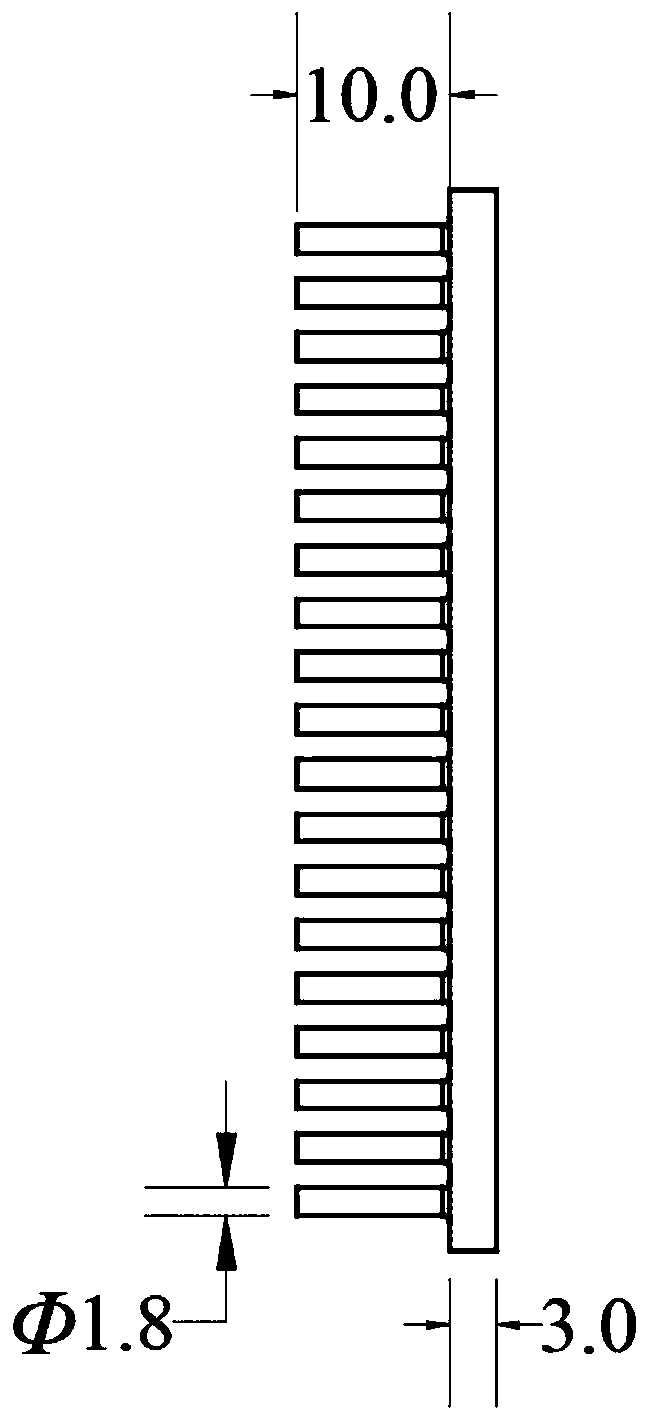

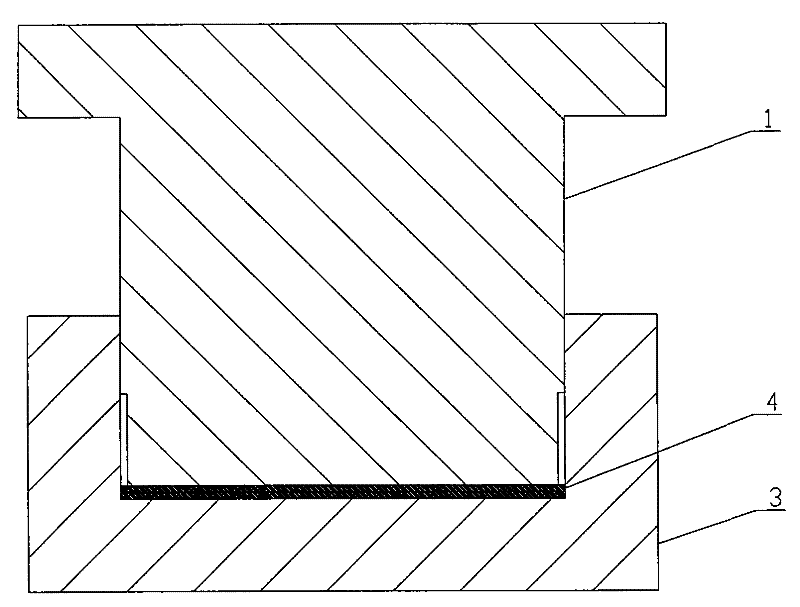

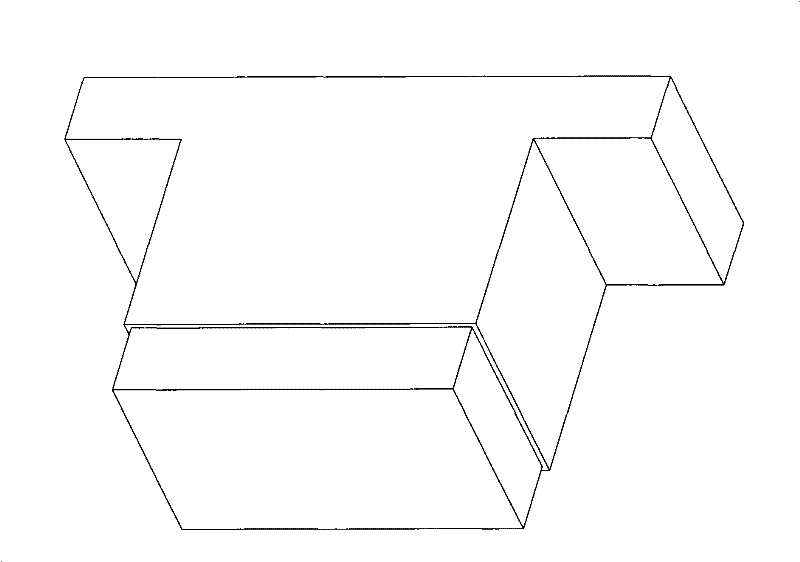

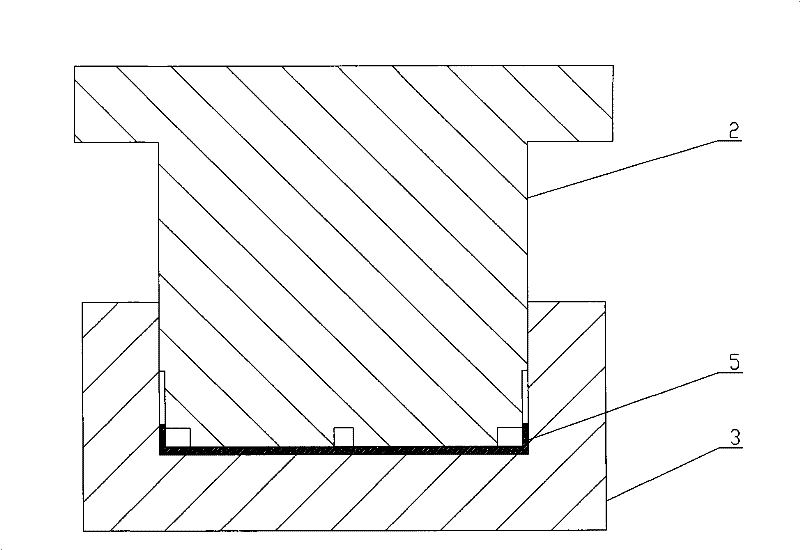

Extrusion forming die for open mold cavity

ActiveCN107433300AReduce forming loadIncrease the aspect ratio of the inner holeShaping toolsPistonThin walled

The invention discloses an extrusion forming die for an open mold cavity. The extrusion forming die mainly comprises an extrusion punching die body and an extrusion pulling die body. In the extrusion punching stage, the open mold cavity is formed by a first female die and a second female die. The second female punching die is of a floating structure and moves downwards along an upper die, the forming load is reduced, and the bend resistance bearing capability of a male die is improved. After a blank makes contact with a first jacking rod, the upper die and an upper ramming cylinder are depressurized; piston rods of a left piston cylinder and a right piston cylinder move upwards to support a female die supporting ring; a left movable supporting block and a right movable supporting block are pulled out horizontally under the effect of a moving and resetting system; a lower die sleeve and the female die supporting ring overall move downwards under the effects of the resilience force of a spring and the pressing force of the upper ramming cylinder in the return stroke process of the left piston cylinder and the right piston cylinder; and when the blank makes complete contact with a lower fixed plate, the open mold cavity is formed again at the moment. The thinning pulling times can be effectively decreased, forming defects such as pull cracks and pull fractures are prevented, and the extrusion forming die for the open mold cavity can be applied to forming of various deep blind hole thin wall products.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

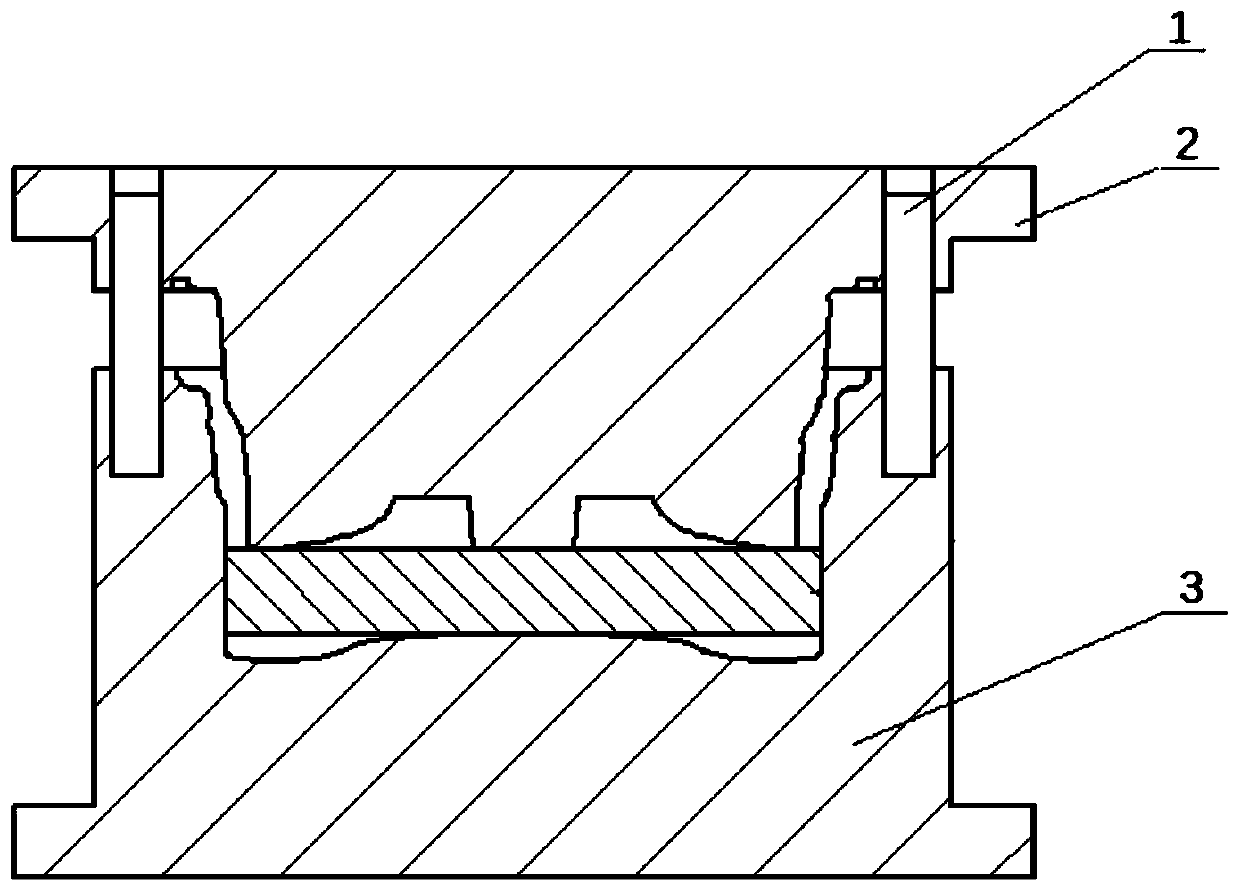

Forming method of die forging clamps made of titanium alloy

ActiveCN105328096AReduce forming loadReduce consumptionMetal-working apparatusPunchingHeating furnace

The invention aims at solving problems in the prior art, and provides a forming method of die forging clamps made of titanium alloy. The method belongs to the field of forging of titanium alloy materials. The method comprises the following steps of: cleaning up surface flaws of a rhombic blank made of the titanium alloy, heating the cleaned rhombic blank in a heating furnace till the temperature reaches 930-950 DEG C, and keeping the temperature for 0.5-2h; performing punching by an open die forging machine so as to obtain a rhombic blank with a through hole in the center; placing the rhombic blank with the through hole in the center in a forging die, and forging the rhombic blank into a die forging clamp by a die forging machine; and performing a trimming working procedure and a punching working procedure so as to obtain a finished product. According to the method disclosed by the invention, the forming load needed by die forging is greatly reduced, and the service life of a die is prolonged; besides, the consumption of precious raw materials is reduced, and the quality of titanium alloy forgings is guaranteed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

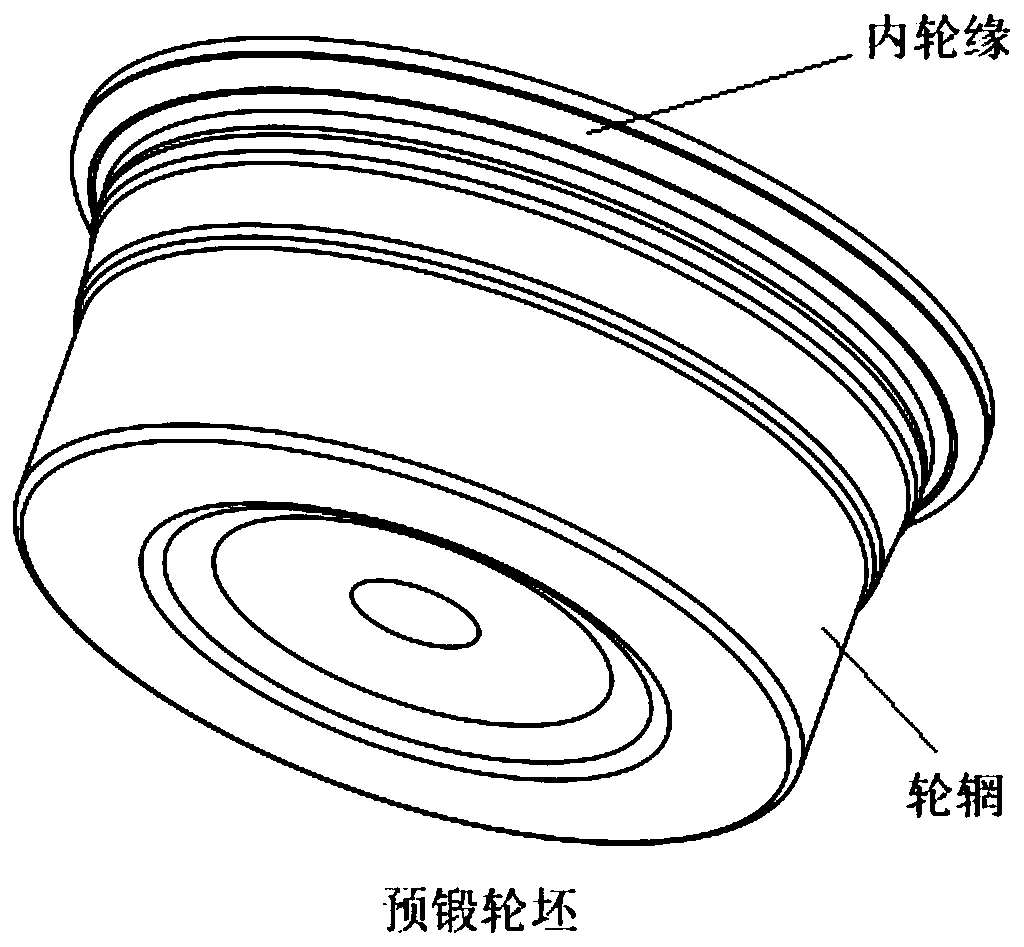

Hub extrusion forming method

ActiveCN110508737ASimple and easy forming processComplete formMetal-working apparatusWheelsEngineeringMechanical property

The invention discloses a hub extrusion forming method. A hub is produced and manufactured in a pre-forging and final forging two-step extrusion forming mode. In the pre-forging stage, a rim and an inner rim portion of the hub are extruded and formed through downward reverse extrusion motion of a pre-forging upper male die, and an outer rim and wheel arm parts of the hub are extruded and formed through the downward extruding motion of a final forging upper die in the final forging forming stage. The hub producing and manufacturing process by adopting the forming method is simple, the production efficiency is high, the forming pressure is smaller, the near-net forming material utilization rate is high, and the hub mechanical performance is more excellent.

Owner:NANJING UNIV OF SCI & TECH

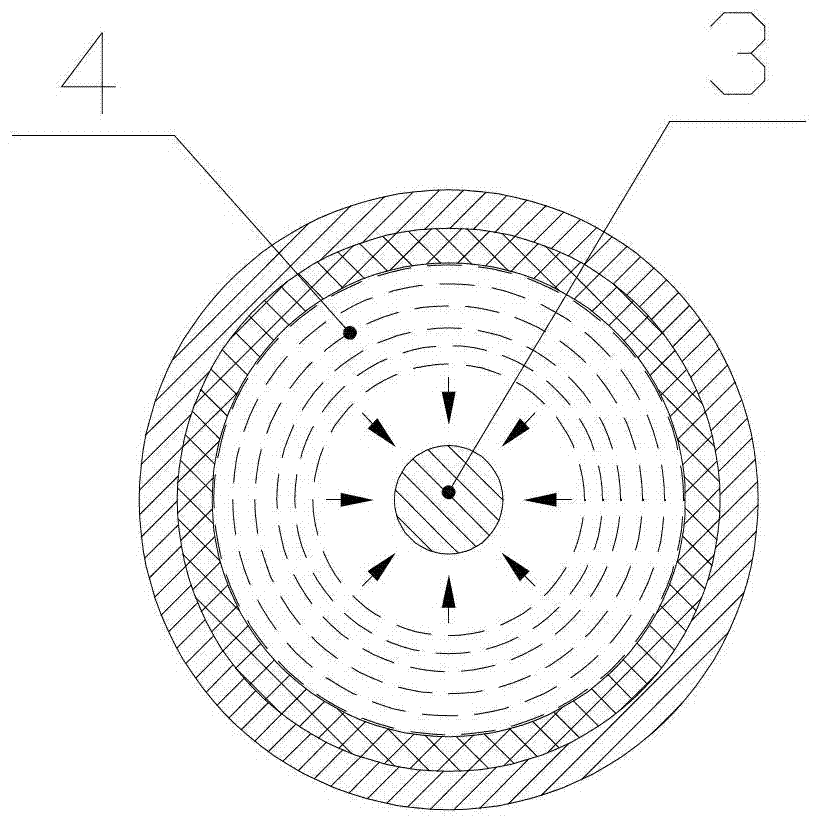

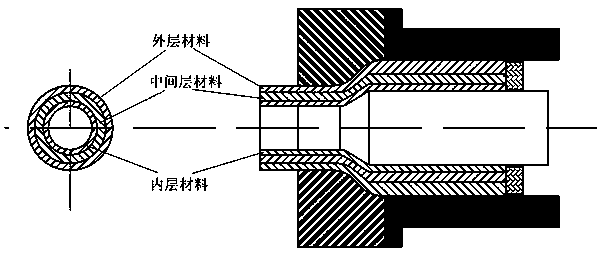

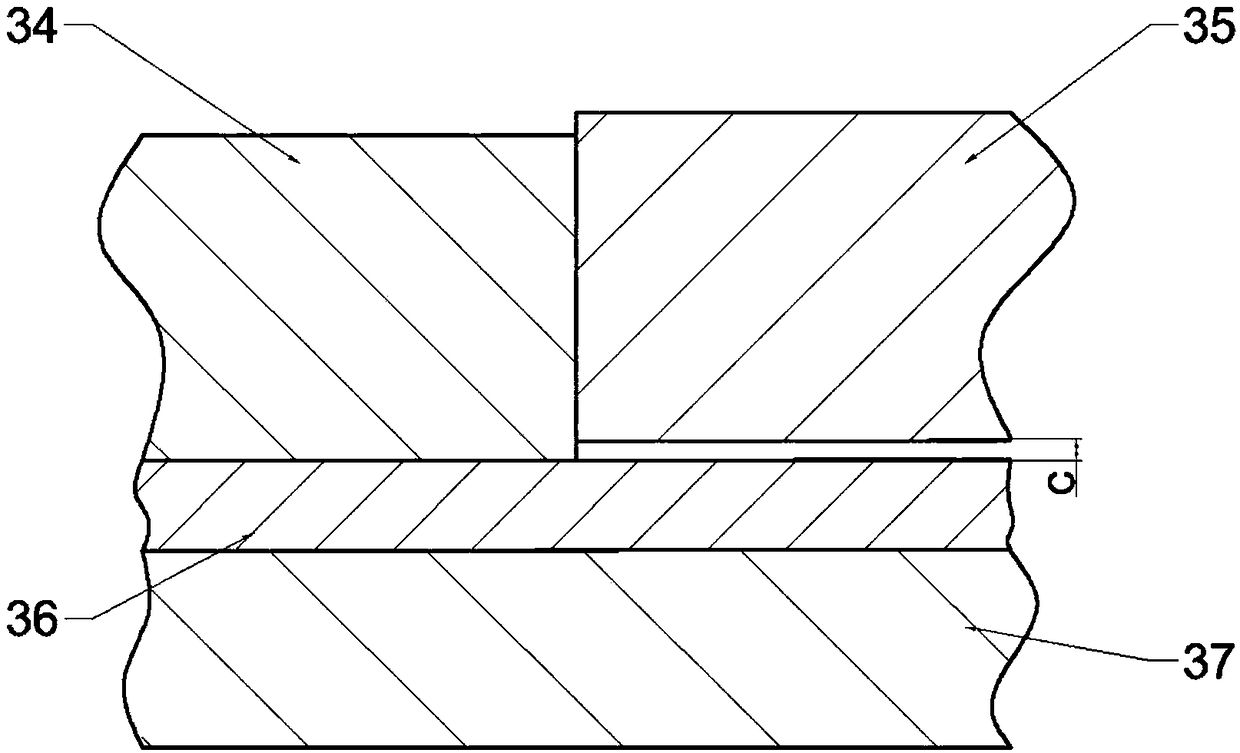

Semi-solid forming method of composite pipe

The invention relates to a semi-solid forming method of a composite pipe, and belongs to the technical field of semi-solid forming of metal. The semi-solid forming method comprises the following steps: at first, pouring a three-layered material by a centrifugal casting machine to obtain a composite pipe blank (at first, pouring an outer-layer easy-to-plastic deformation material, then pouring the middle-layer difficult-to-plastic deformation material, and at last, pouring an inner-layer easy-to-plastic deformation material); then, heating the composite pipe blank to the solid-liquid temperature interval of the difficult-to-plastic deformation material to enable the composite pipe blank to be in the semi-solid state, and reducing the diameter and the wall thickness of the composite pipe blank through high-speed extrusion, so as to obtain a pipe with a certain length; and at last, heating the hot extrusion pipe, so as to obtain a composite pipe with different mechanical properties. The semi-solid forming method solves the problem that a difficult-to-deformation pipe is difficult to process and manufacture, long in forming cycle, and high in product cost, and expands the application field of a semi-solid forming technology.

Owner:KUNMING UNIV OF SCI & TECH

Extrusion forming method for no-anisotropy magnesium alloy rods

ActiveCN110665984AImprove mechanical propertiesIncrease torsional deformationExtrusion diesEconomic benefitsInternal stress

The invention discloses an extrusion forming method for no-anisotropy magnesium alloy rods. The method relates to an extrusion forming mold for the no-anisotropy magnesium alloy rods; the mold comprises an insert, a convex mold connected with a press, a concave mold connected with a rotating mechanism, and an ejecting mechanism; a molding cavity is formed in the concave mold, and is provided witha feed port; an extrusion working belt is arranged in the molding cavity; and the insert is mounted on the extrusion working belt. The torque is applied based on traditional extrusion; the rotating lap number can be increased through change of the rotating speed, so that the gradient structure is improved under rotating formation, and the uniform deformation of the structure is realized; the higher shearing strain is generated through change of internal stress and strain states of a deformation body to form a fine crystal structure with large-angle grain boundary, so that the anisotropy of components is reduced; and insert can be timely replaced after wear to prevent the cost increment of the scrapped concave mold, so that the mold life is prolonged, and the popularization and economical benefit in the forging industry is prominent.

Owner:ZHONGBEI UNIV

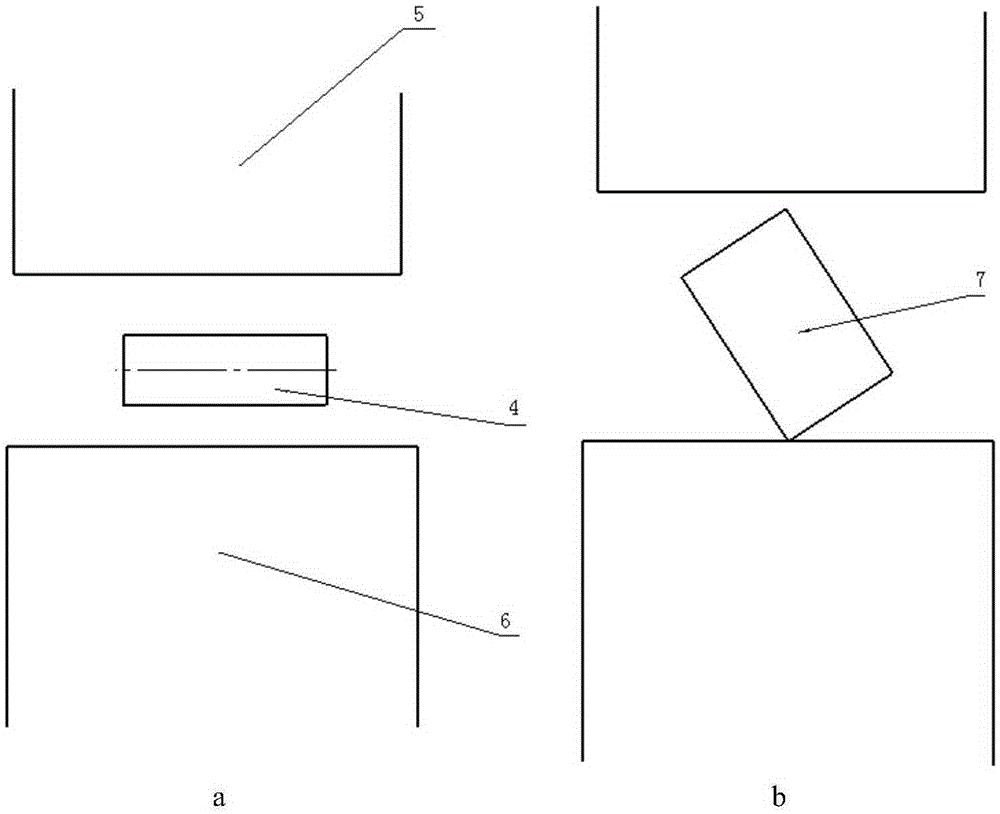

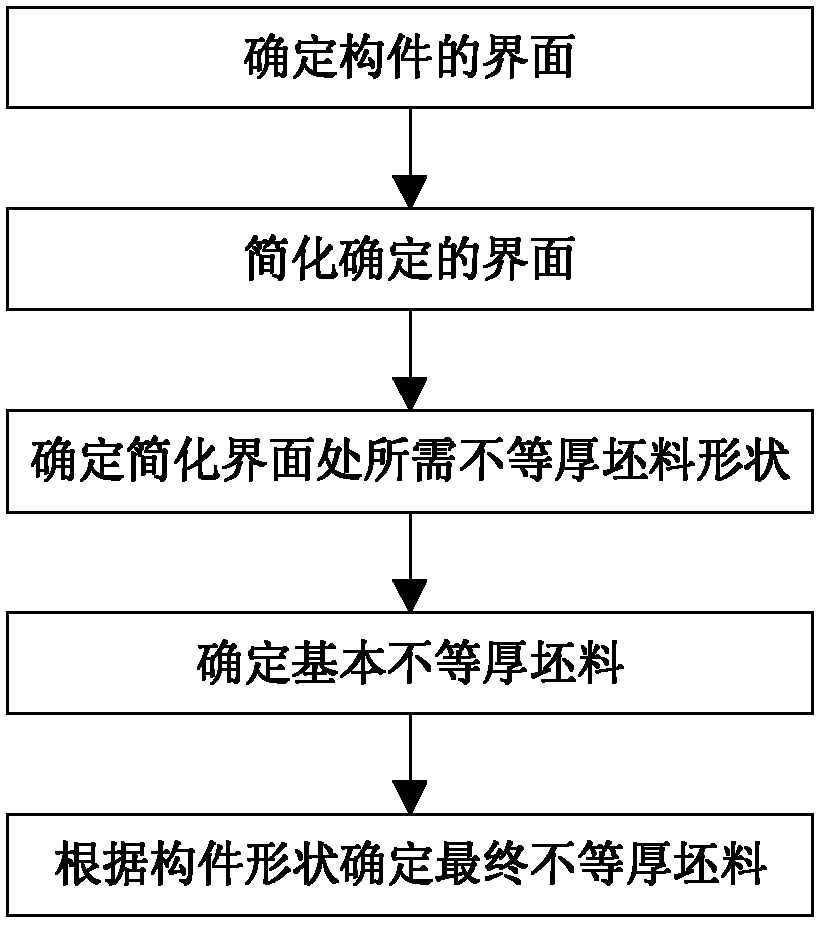

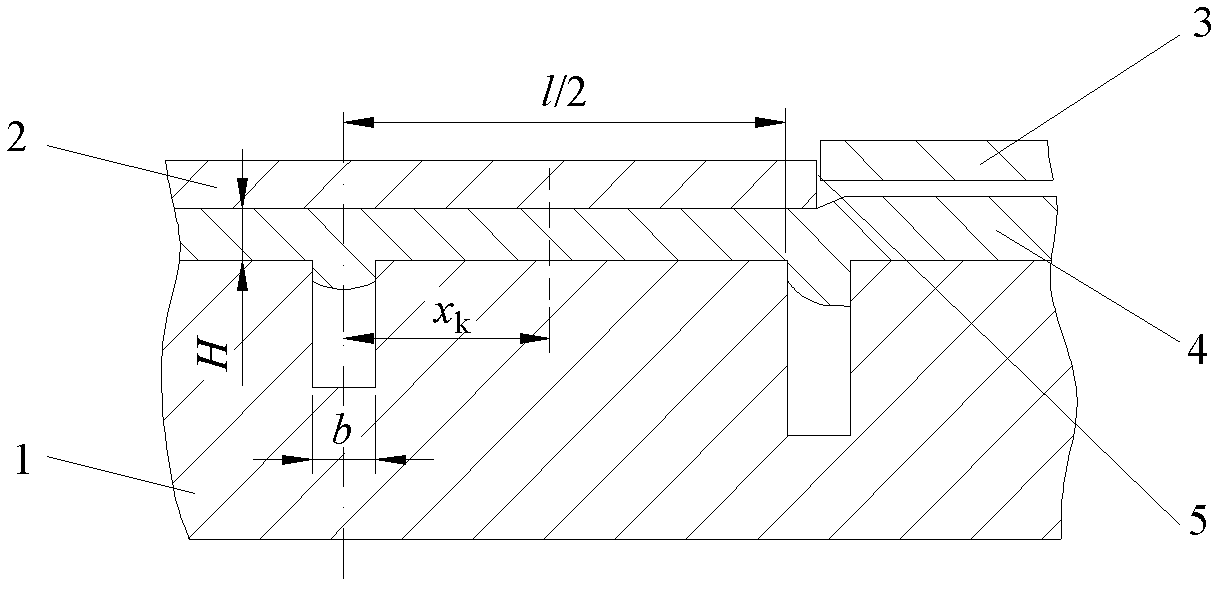

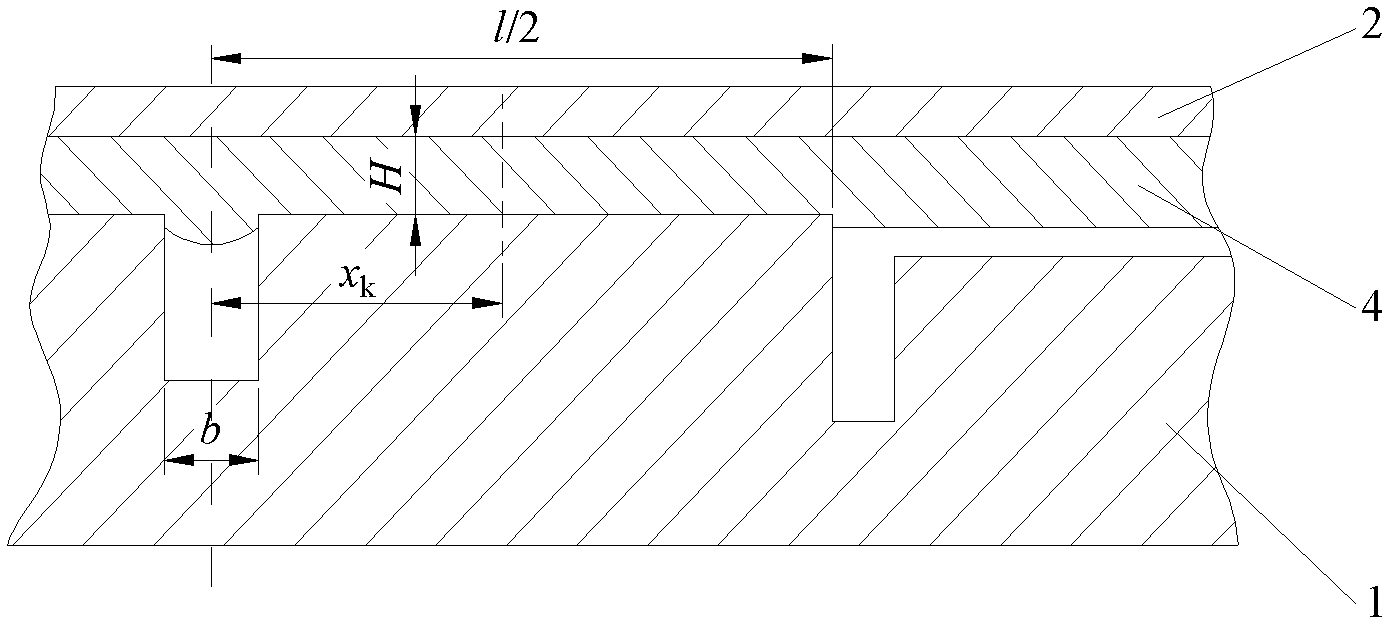

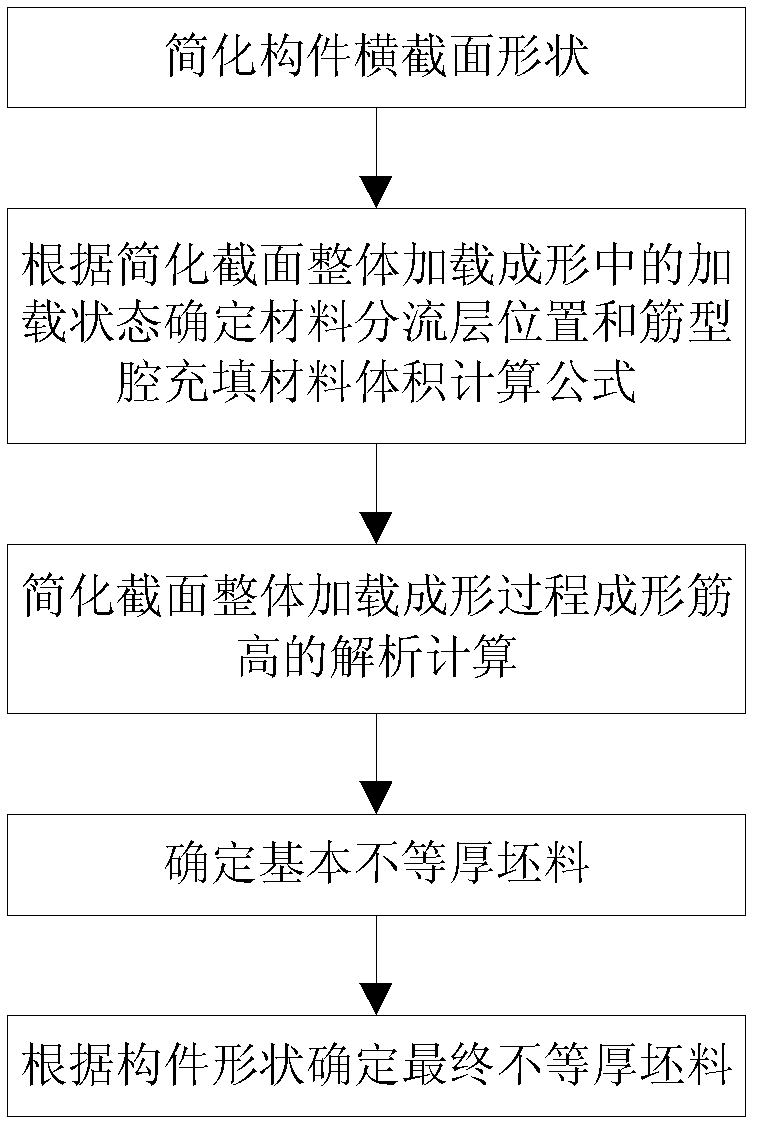

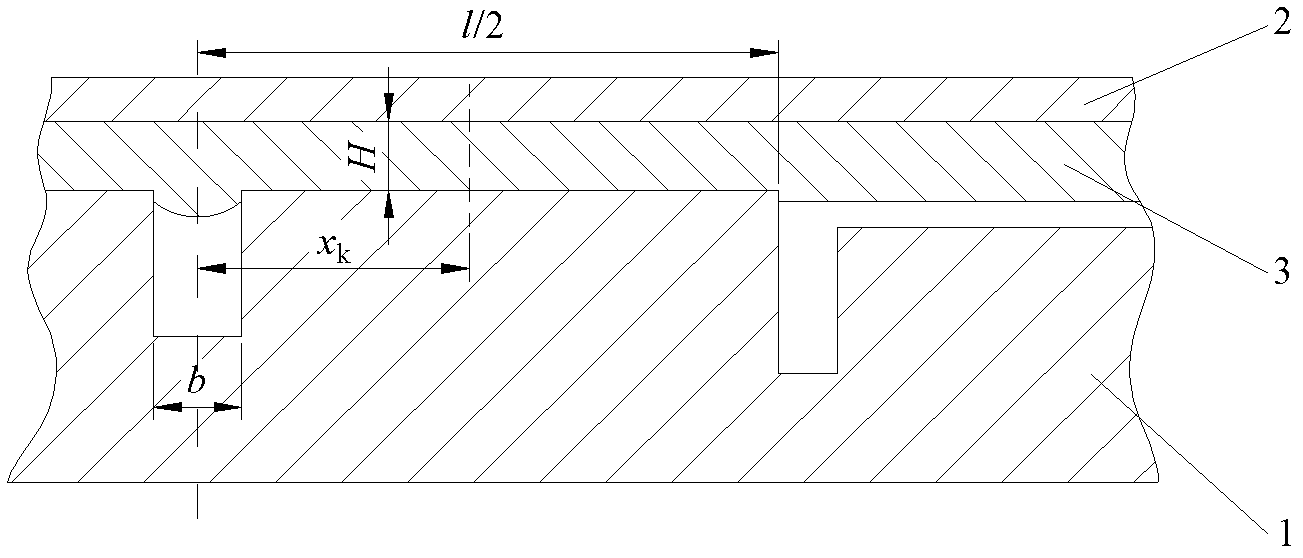

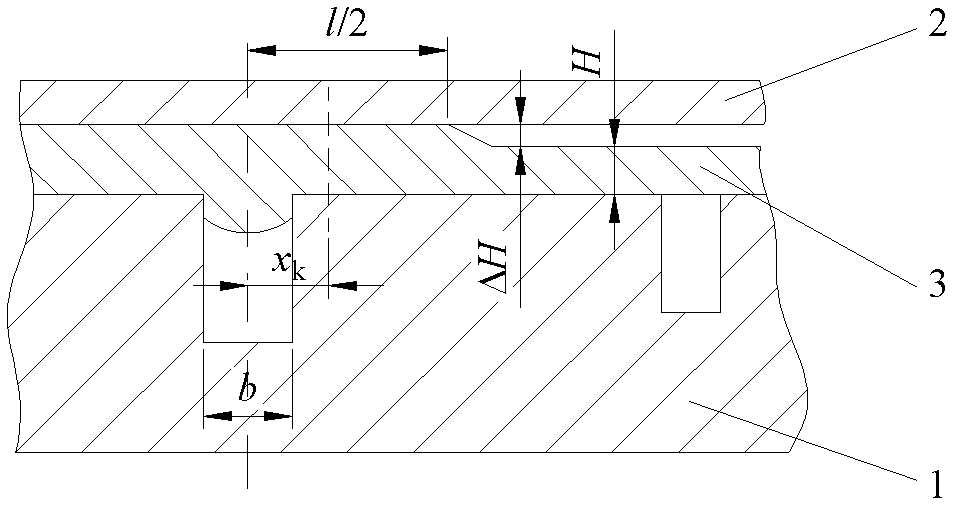

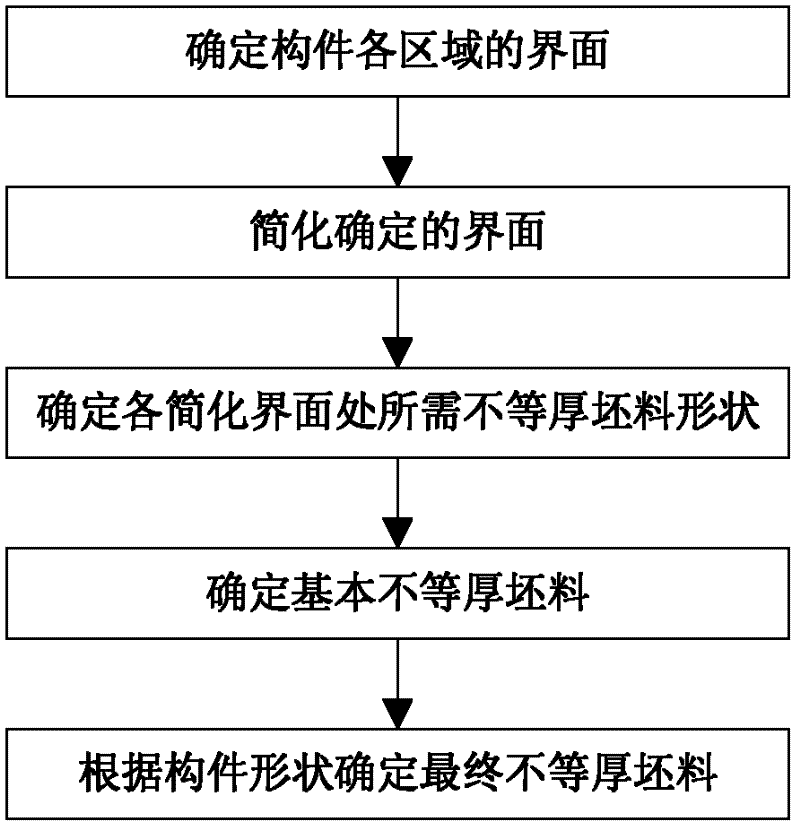

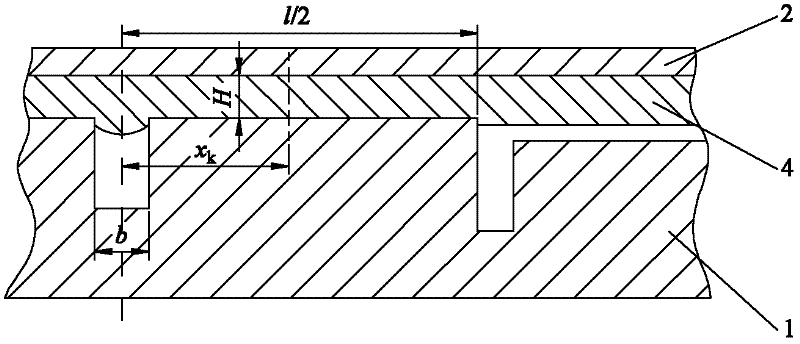

Method for determining blanks of different thickness for local loading forming of three-dimensional frame-shaped member

InactiveCN102601281AEasy to analyzeQuick analysisMetal-working apparatusEngineeringForming processes

Disclosed is a method for determining blanks of different thickness for local loading forming of a three-dimensional frame-shaped member. The method includes steps of determining a calculating formula for sizes of inflow ribbed cavity materials according to various loading states in a forming process to realize fast analysis of a simplified interface and shortening time for determining blank shapes, and modifying blank shapes according to numerical simulation results, and determining the blanks of different thickness which meet the filling demands so as to reduce cost. By the method, the determined size distribution of the blanks of different thickness is reasonable, the flaws such as insufficient filling, folding and the like in the forming process are eliminated, machining allowance and forming load are reduced, and the blanking is easy due to the simple blank shapes.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

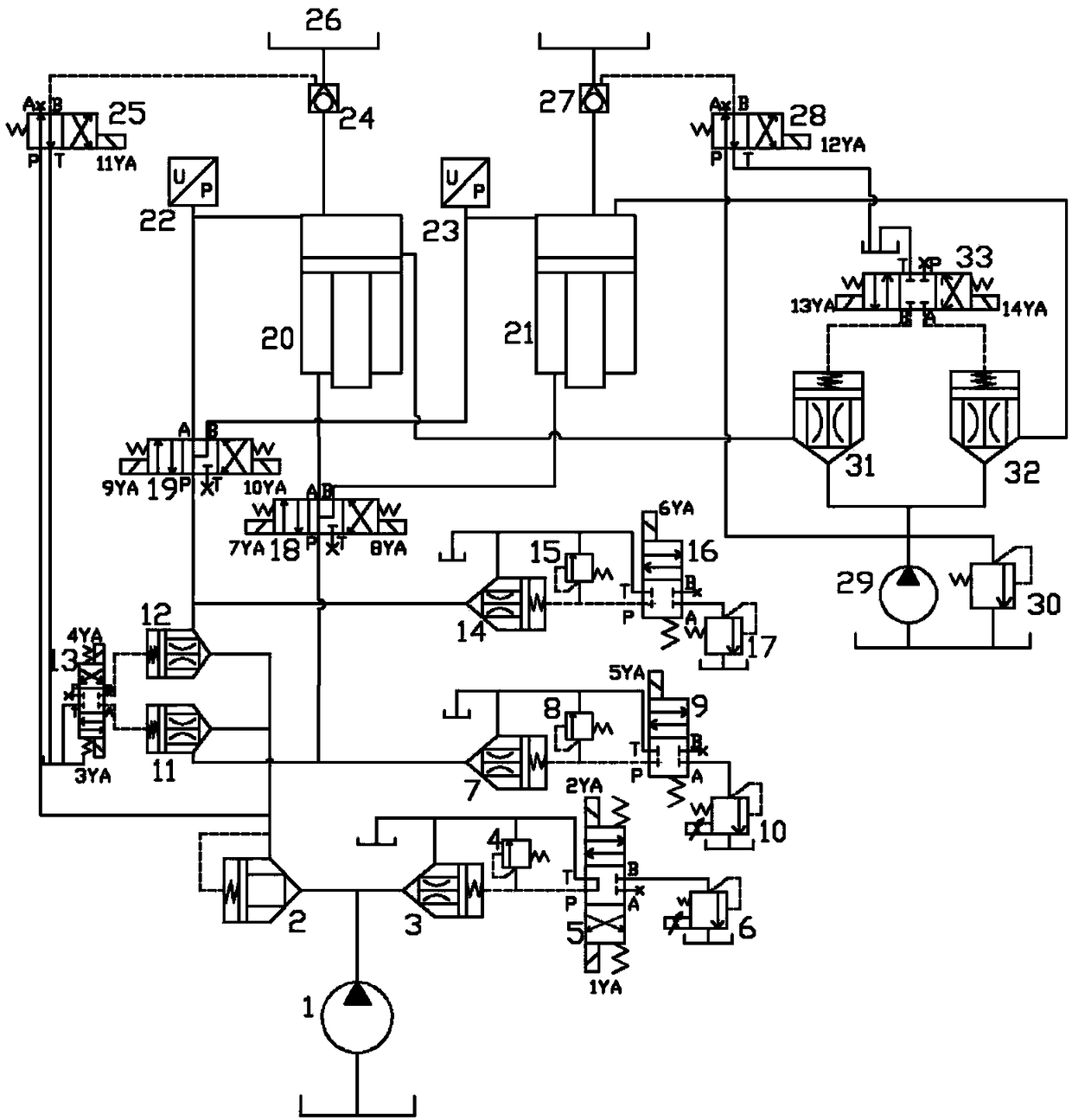

Hydraulic machine hydraulic system capable of realizing local loading rapidly and stably

ActiveCN108150468ALarge forming loadReduce forming loadServomotorsServometer circuitsHydraulic cylinderControl system

The invention provides a hydraulic machine hydraulic system capable of realizing local loading rapidly and stably. The hydraulic machine hydraulic system comprises a power output system, a pressure control system and a loading system. Formation is achieved through multiple passes and multiple local loading steps. A loading zone can be transformed continuously through a low-pressure high-flow pumpand a high-pressure low-flow pump. It is guaranteed that a large forming load can be exerted on a loaded deformation zone rapidly, and a small restraint load is exerted on an unloaded zone in the forming process. Hydraulic cylinders obtain high-flow hydraulic oil in stages of descending and return stroke, and rapid descending and rapid return stroke are realized. An integrated cartridge valve adopted by the hydraulic system is rapid in response and sensitive in action. A charging valve adopted not only can assists in realizing rapid descending and rapid return stroke, but also can enable the hydraulic cylinders to rapidly reduce pressure after a loading step is completed, meanwhile energy consumption is reduced, and energy is saved. The local loading zone can be transformed multiple timeswithin primary-fire heating in the forming process, and the forming capacity larger than that of overall loading forming under the same installed power is obtained.

Owner:XI AN JIAOTONG UNIV

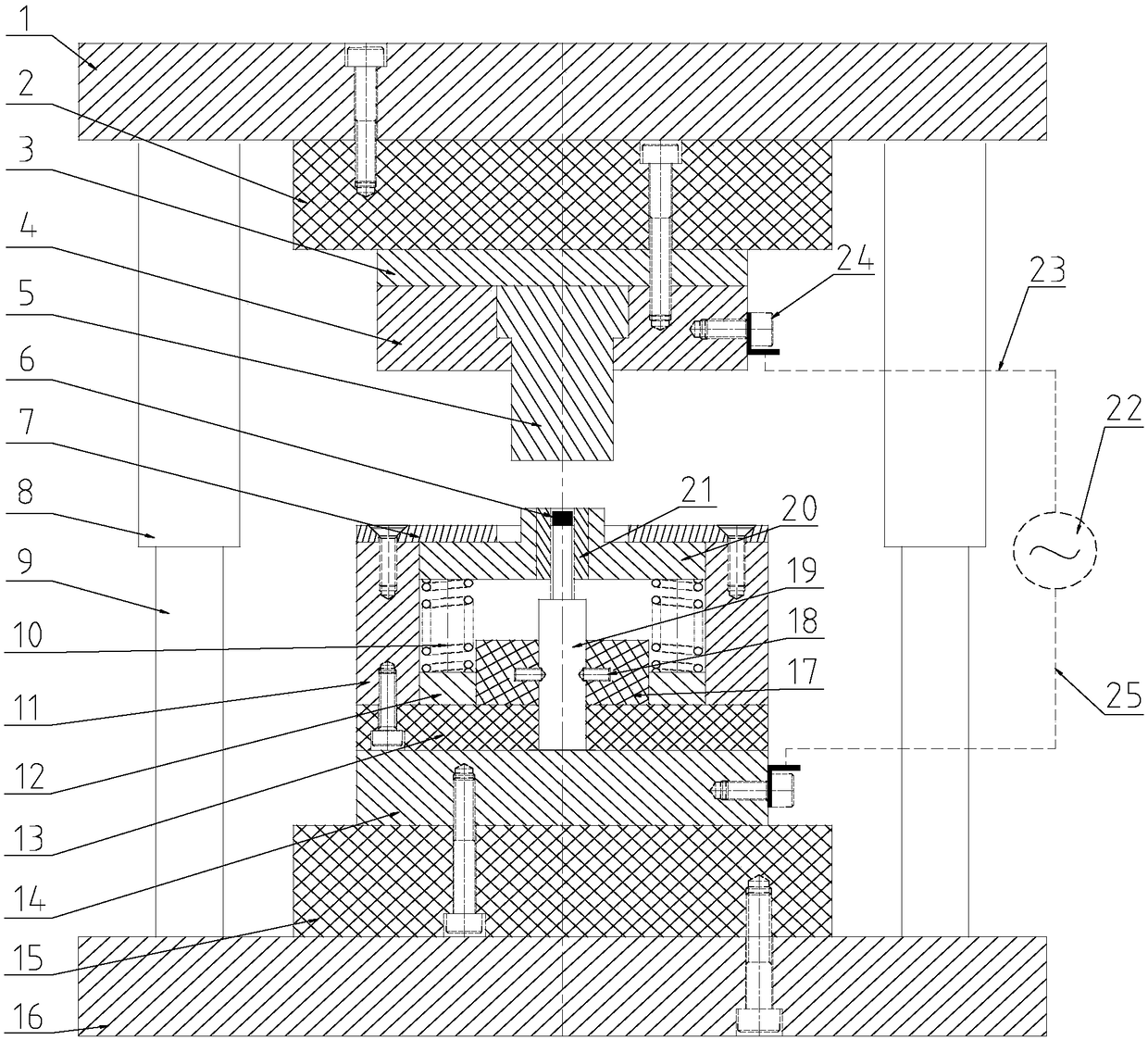

Titanium alloy micro gear pulse current auxiliary microforming floating die

InactiveCN109047610AHeating fastShorten the timeForging/hammering/pressing machinesTitanium alloyMaterials science

The invention relates to a microforming floating die, in particular to a titanium alloy micro gear pulse current auxiliary microforming floating die, and belongs to the technical field of mechanicalmanufacturing and plastic micro forming. The problems that an existing titanium alloy micro gear die forging micro blank is low in heating efficiency, the micro die is large in stress, a lower cornerof a micro gear is difficult to fill, and the service life of the die is short are solved. A punch is arranged on the lower surface of an upper mold assembly, a male mold is arranged on the upper surface of a lower mold assembly, a male mold is sleeved with a female mold, a mold cavity is formed under the punch, a titanium alloy forging blank is arranged in the mold cavity, one end of a first wireis connected with the upper mold assembly through a wire joint, the other end of the first wire is connected with a pulse power source, one end of a second wire is connected with the lower mold assembly through the other wire joint, and the other end of the second wire is connected with a pulse power source.

Owner:HARBIN INST OF TECH

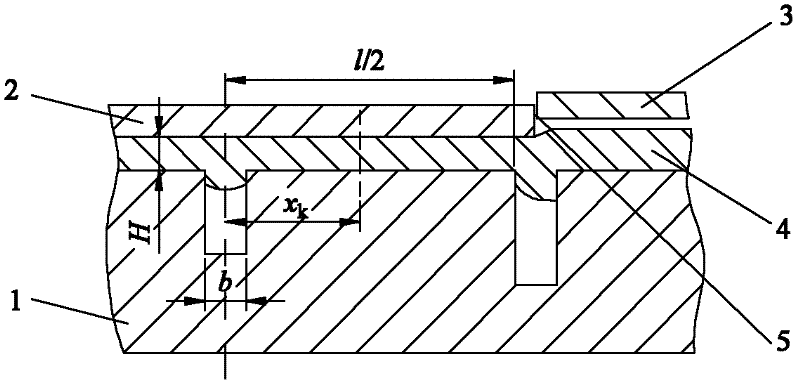

Method for determining blank with different thicknesses for two-dimensional integrated loading and forming

InactiveCN102581183AEasy to shapeReasonable volume distributionMetal-working apparatusEngineeringMechanical engineering

The invention discloses a method for determining a blank with different thicknesses for two-dimensional integrated loading and forming. The method comprises the following steps of: quickly forecasting material flowability and cavity filling of a multi-rib structural member during two-dimensional forming based on partial loading characteristics according to a resolving analysis calculation formula; quickly determining the shape of the blank with different thicknesses of a two-dimensional base body by quickly analyzing the material flowability and the cavity filling on a cross section; performing value simulation; modifying the shape of the blank with different thicknesses according to a value simulation result by considering the partial loading flow characteristics; and obtaining the final shape of the blank with different thicknesses by adjusting and modifying for zero or a plurality of times. According to the determined blank with different thicknesses, the problem that the cavity cannot be filled fully during forming can be solved completely, and the optimized design time is shortened. The determined of the blank with different thicknesses is distributed rationally; shortcomings that the cavity cannot be filled fully, the blank is folded and the like during forming are overcome; the machining allowance and the forming load are reduced; the shape of the blank is simple; and the blank is easy to make.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

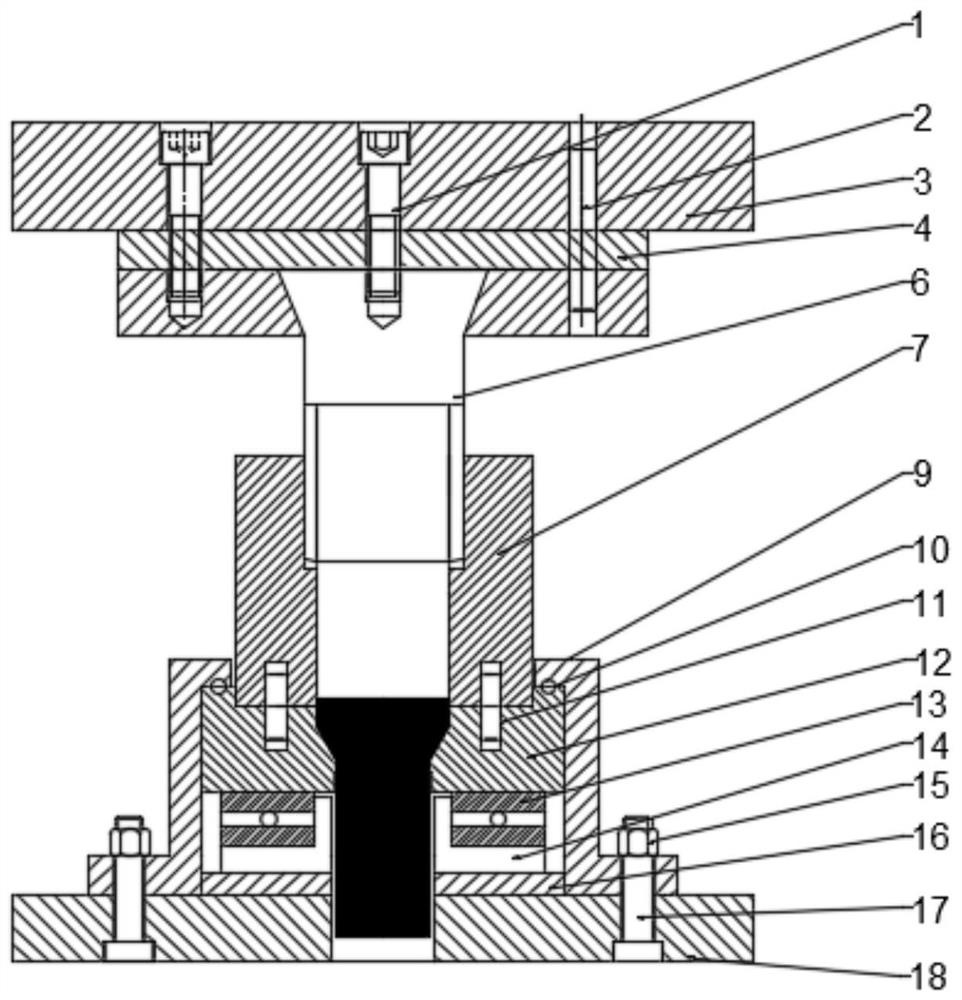

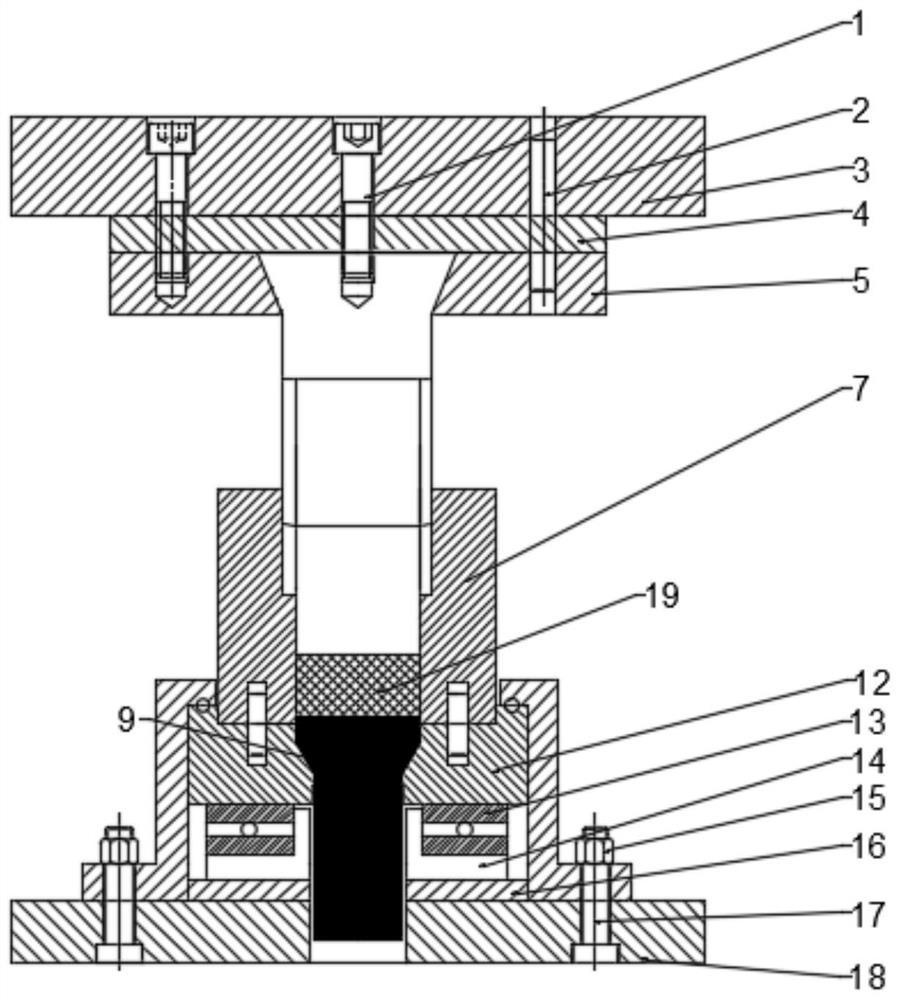

A device and method for sheet metal multi-point punch liquid-filled deep drawing

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

Space envelope forming manufacturing method of thin-wall high-rib heat dissipation component

ActiveCN110918843AIncrease productivityImprove liquidityHandling devicesEngineeringShearing (manufacturing)

The invention relates to a space envelope forming manufacturing method of a thin-wall high-rib heat dissipation component. The method comprises the following steps that S1, a forging is designed, specifically, a forging parting surface of the thin-wall high-rib heat dissipation component is a plane where a bottom plate is located, and an oblique flash edge is arranged at the top of the side face of a bottom plate of the forging; S2, a blank is designed, specifically, the blank is a slab, and the shape of the cross section contour line of the slab is the same as the shape of the cross section contour line of the bottom plate; S3, space envelope forming is carried out; S4, envelope finishing is carried out; S5, the forging is ejected; and S6, trimming is carried out, specifically, high ribsof the forging obtained in the S5 are inserted into hole type cavities of a lower die of a trimming die, an upper die of the trimming die makes contact with the bottom plate of the forging, the forging and the lower die of the trimming die are pushed to move downwards at the same time, and the flash edge of the forging is cut off under the shearing action of the upper die and a fixing die of the trimming die; and S7, the end surfaces of the high ribs are orderly cut. According to the space envelope forming manufacturing method of the thin-wall high-rib heat dissipation component, not only canthe integral forming of the thin-wall high-rib heat dissipation component be realized, but also the material utilization rate can be improved, the forming limit of the thin wall and the high ribs canbe improved, and the loaded state of a die can be improved.

Owner:WUHAN UNIV OF TECH

Continuous-lubrication extrusion mold

InactiveCN108213104AContinuous and stable lubricationImprove deformation uniformityExtrusion diesMachining processMaterials science

The invention discloses a continuous-lubrication extrusion mold, relates to an extrusion mold, aims to solve the technical problems of undesirable lubrication effect since the surfaces of the mold andblank materials are coated with a lubrication agent, increase of the mold manufacturing cost and difficulty caused by adopting a method of surface coating treatment, and gradual abrasion and separation of the coating on the surface of the mold in a forming process. The continuous-lubrication extrusion mold consists of a lubrication agent storage tank and an extrusion mold, an upper part of the side wall of the lubrication agent storage tank is provided with at least one lubrication agent injection hole; at least on lubrication agent hole is formed on the side wall of the extrusion mold; and the lubrication agent storage tank is sleeved outside the extrusion mold. The continuous-lubrication extrusion mold has the advantages that: the blank and the extrusion mold can keep a good and continuous stable lubrication state in a machining process, the abrasion on the mold is lowered, and the service life of the mold is prolonged. The continuous-lubrication extrusion rod can be applied to themachining field of materials.

Owner:HARBIN INST OF TECH

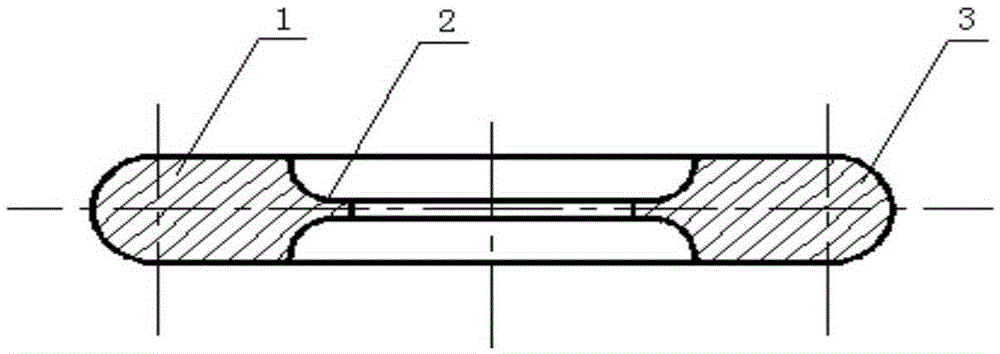

Two-stage press forging and forming method of metal thin shell piece with inward convex micro-structure

InactiveCN101850396BComplex shapeHigh dimensional accuracyMetal-working apparatusMicro structureThin shells

The invention relates to a metal plastic processing production technology, in particular to a two-stage press forging and pressing method of a metal thin shell piece with the complex geometric shape (with an inward convex micro-structure such as a stud bolt, a buckle and a hinged flange), which is applicable to metal materials such as magnesium alloy and aluminum alloy. A metal plate is taken as a blank, a die needs to be heated to 200 DEG C-400 DEG C for the magnesium alloy (the die does not need to be heated for the aluminum alloy), the magnesium alloy blank is heated to 250 DEG C-450 DEG C(the blank does not need to be heated for the aluminum alloy), a lubricant is uniformly coated on the blank, then the blank is placed in a female die cavity, a first-stage male die is used for forming an outer shell piece with the partial side wall, and a second-stage male die is used for forming the complete side wall and the inward convex micro-structure such as the stud bolt, the buckle, the hinged flange and the like. The method can solve the problems of slow production speed, low excellent rate, holes on the surface of a casting and poor mechanical properties in the prior art, and form the side wall of the metal thin shell piece with high dimensional precision and the inward convex micro-structure with the complex shape, and the forming quality of the inward convex micro-structure isgood.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

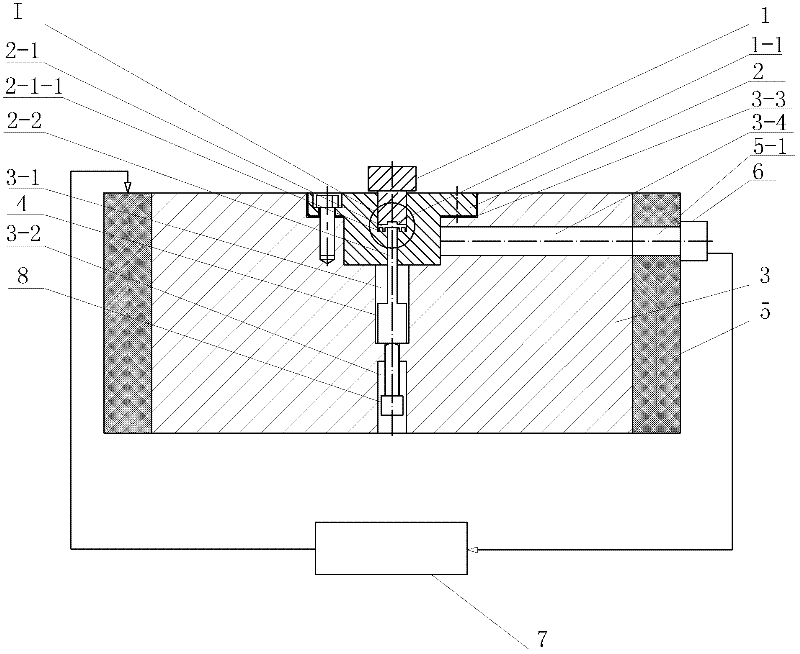

Die for achieving continuous local loading forming of large-size rib plate and forming method of die

PendingCN111804858ARealize continuous productionIncrease productivityForging/hammering/pressing machinesHeating/cooling devicesHeater RodEngineering

The invention provides a die for achieving continuous local loading forming of a large-size rib plate and a forming method of the die, and belongs to the field of plastic processing. The continuous local loading die comprises an upper male die connected with an upper working platform of a press, and a lower die assembly connected with a lower working platform of an extruder. The upper male die isconnected with an upper working table of the press through a fastening bolt. The lower die assembly comprises a lower die body, a lower die base with a lead screw and sliding groove structure, and a heating rod used for heating the die. The heating rod is arranged in a heating rod groove in the lower die body, and the lower die body is matched with the lower die base through a dovetail groove andconnected with the lower die base through a lead screw structure on the lower die base. Die cavity design is carried out according to the structure of a formed part, the continuous local loading combined die is used, a lower die cavity is moved in the loading process, the assembling relation of an upper die body and the lower die body is changed, and forming of the large-size rib plate is achievedthrough continuous local loading of different loading areas. The forming load can be effectively reduced, and the problem that complex large-size rib plate forming is limited by the area of the working platform of the extruder and the load of the press is solved.

Owner:UNIV OF SCI & TECH BEIJING

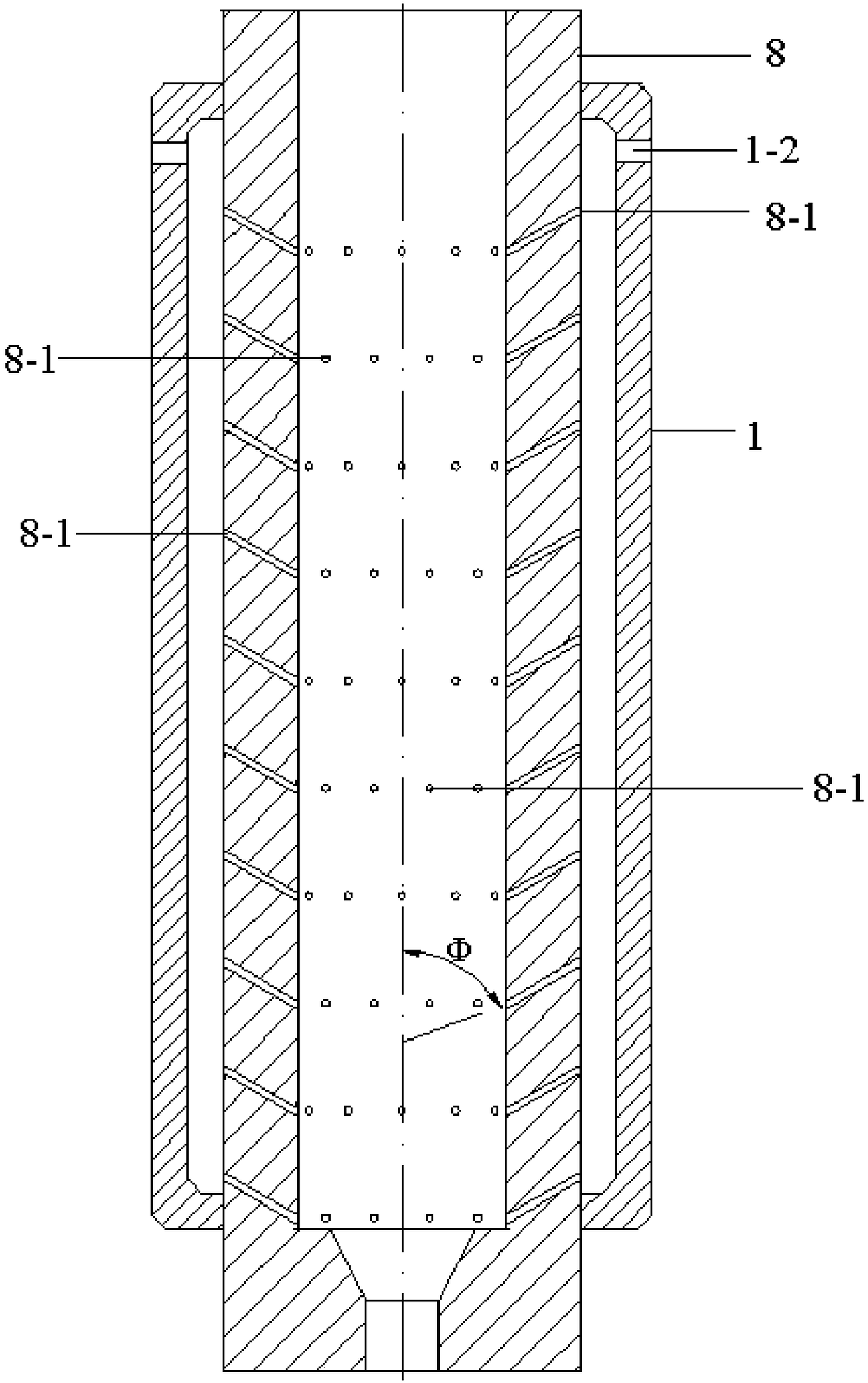

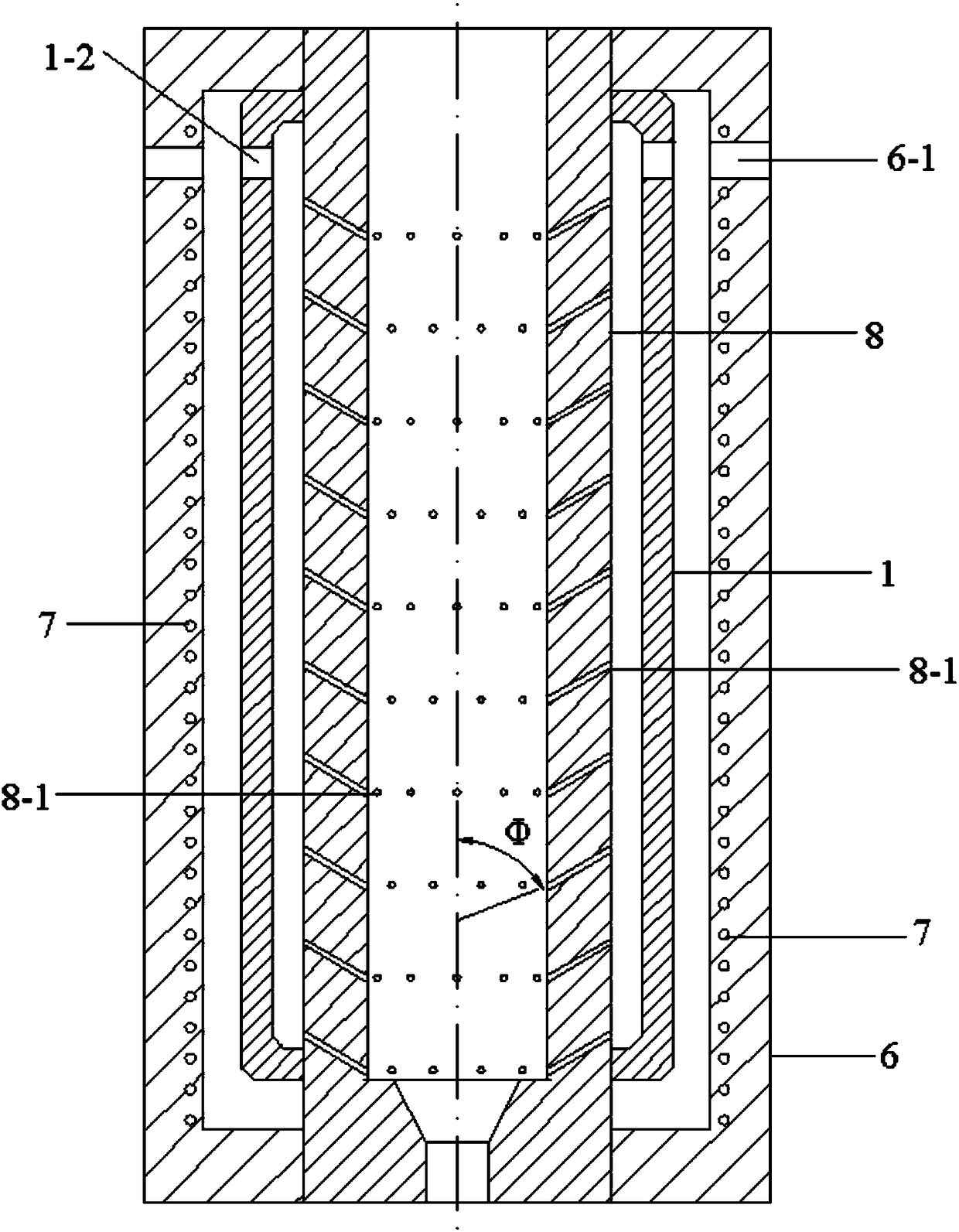

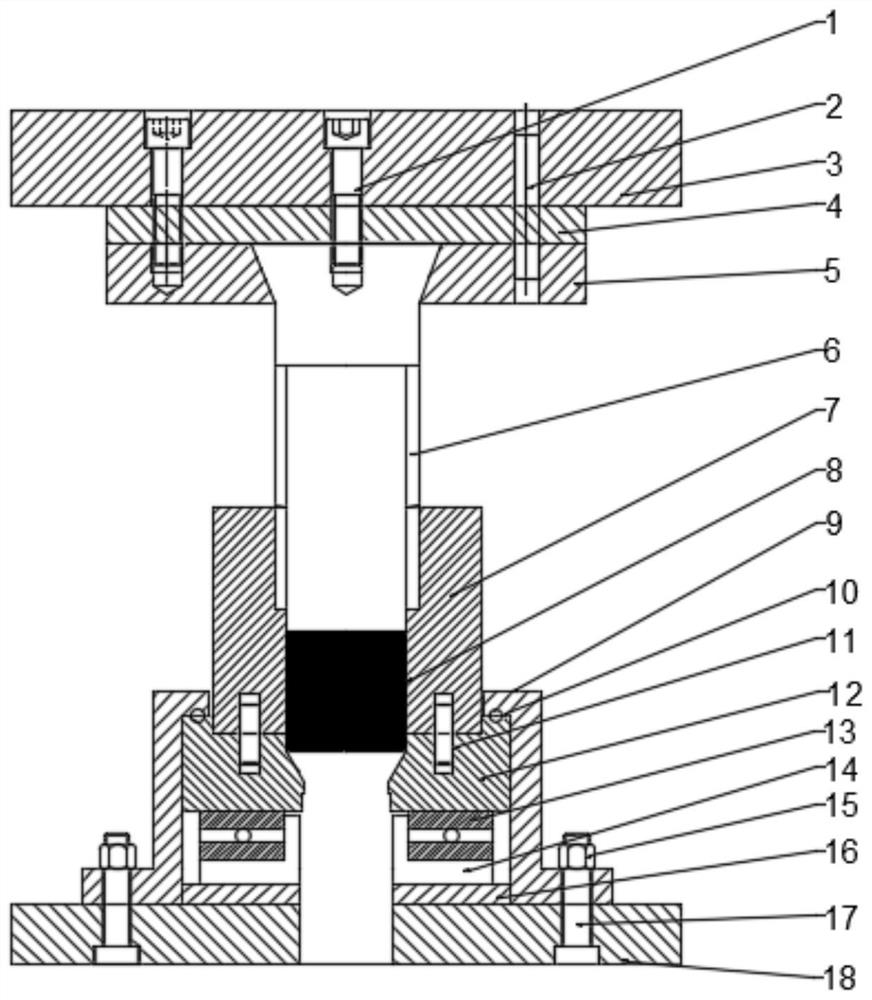

Device and method for moulding and forming micro-turbine

ActiveCN102240755AQuality improvementImprove interchangeabilityShaping toolsElectricityTemperature control

The invention discloses a device and method for moulding and forming a micro-turbine, and relates to a device and method for forming a micro-turbine, for solving the problems in the prior art having low material utilization rate, low processing efficiency, high processing cost and unsuitable batch production in the event of manufacturing the micro-turbine. The device comprises a male mould, a female mould, a female mould holder, an ejector rod, an electrically heated component, a temperature sensor, a temperature control meter and a first screw. A groove is arranged in the middle of the upperhead face of the female mould holder. The female mould is in the groove of the female mould holder. The female mould and the female mould holder are detachably connected. A formed groove is arranged in the middle of the upper head face of the female mould. A blade groove is arranged on the lower head face of the formed groove. The male mould is in the formed groove of the female mould. The femalemould holder is in the electrically heated component. The electrically heated component and the female mould holder are glidingly connected. A probe of the temperature sensor is contacted with the female mould. A signal output end of the temperature sensor is connected with a signal input end of the temperature control meter. A signal output end of the temperature control meter is connected with the electrically heated component. The device is used for forming the micro-turbine.

Owner:HARBIN INST OF TECH

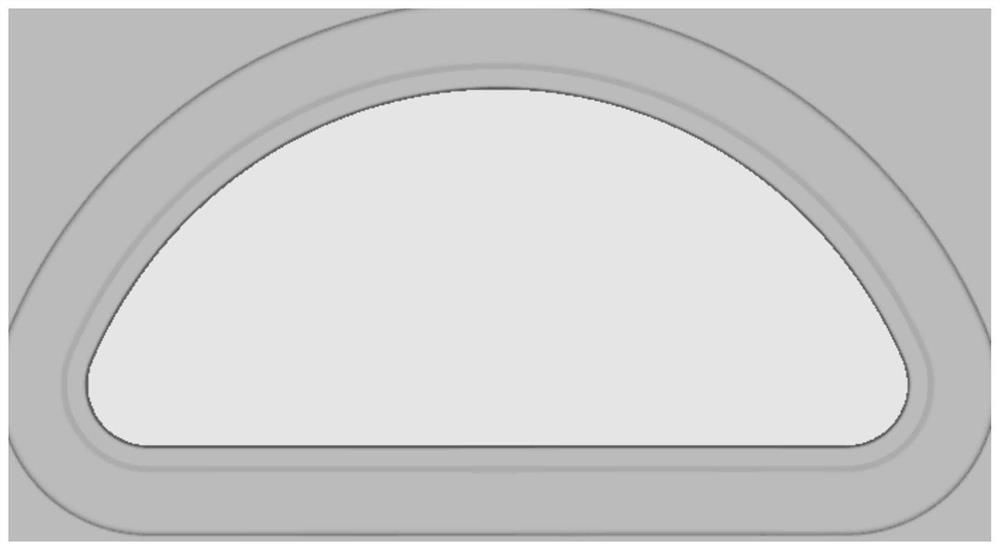

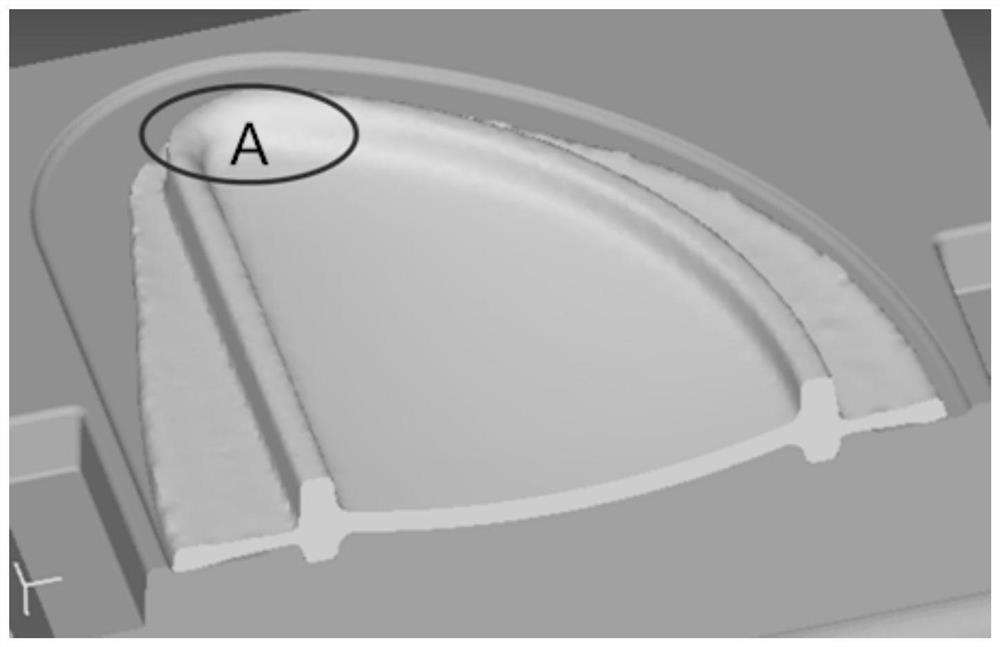

Precise hot forming method for metal forge piece with nearly-semi-oval thin web and large rib spacing

ActiveCN112974699AAppropriate shape and sizeNo foldingMetal-working apparatusFurnace typesStructural engineeringIsothermal forging

The invention discloses a precise hot forming method for a metal forge piece with a nearly-semi-oval thin web and a large rib spacing, belongs to the field of isothermal forging, and aims to solve the problems that an existing special-shaped contour web large-rib-spacing metal component cannot be partially filled, ribs are folded, the production cost is high, and the service life of a mold is short. The method comprises the steps: 1, preparing a preformed blank; 2, preforming; 3, drawing and repairing damage; 4, final forming; and 5, heat treatment after forging. The method is used for precise hot forming of the metal forge piece with the nearly-semi-oval thin web and the large rib spacing.

Owner:HARBIN INST OF TECH

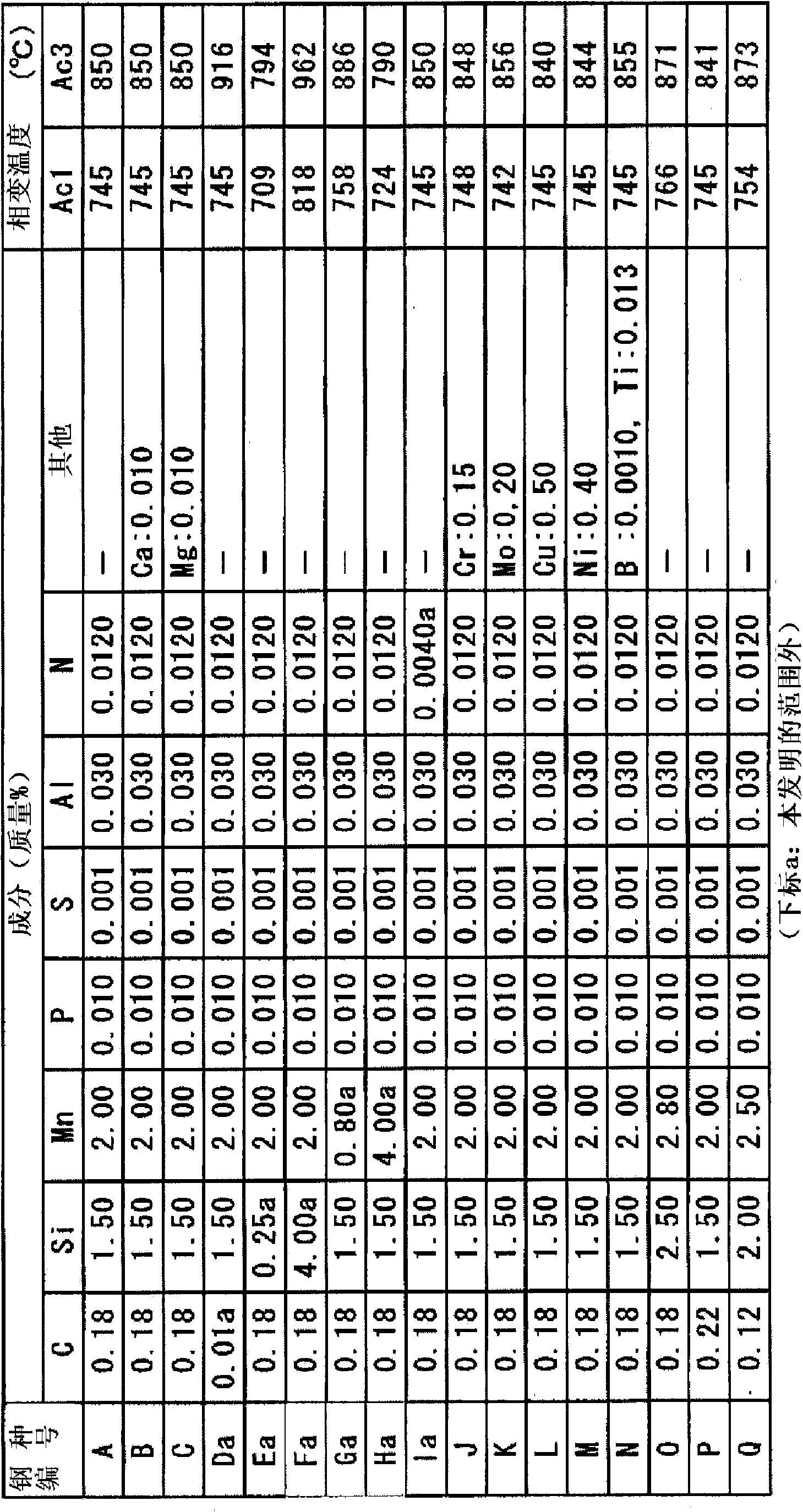

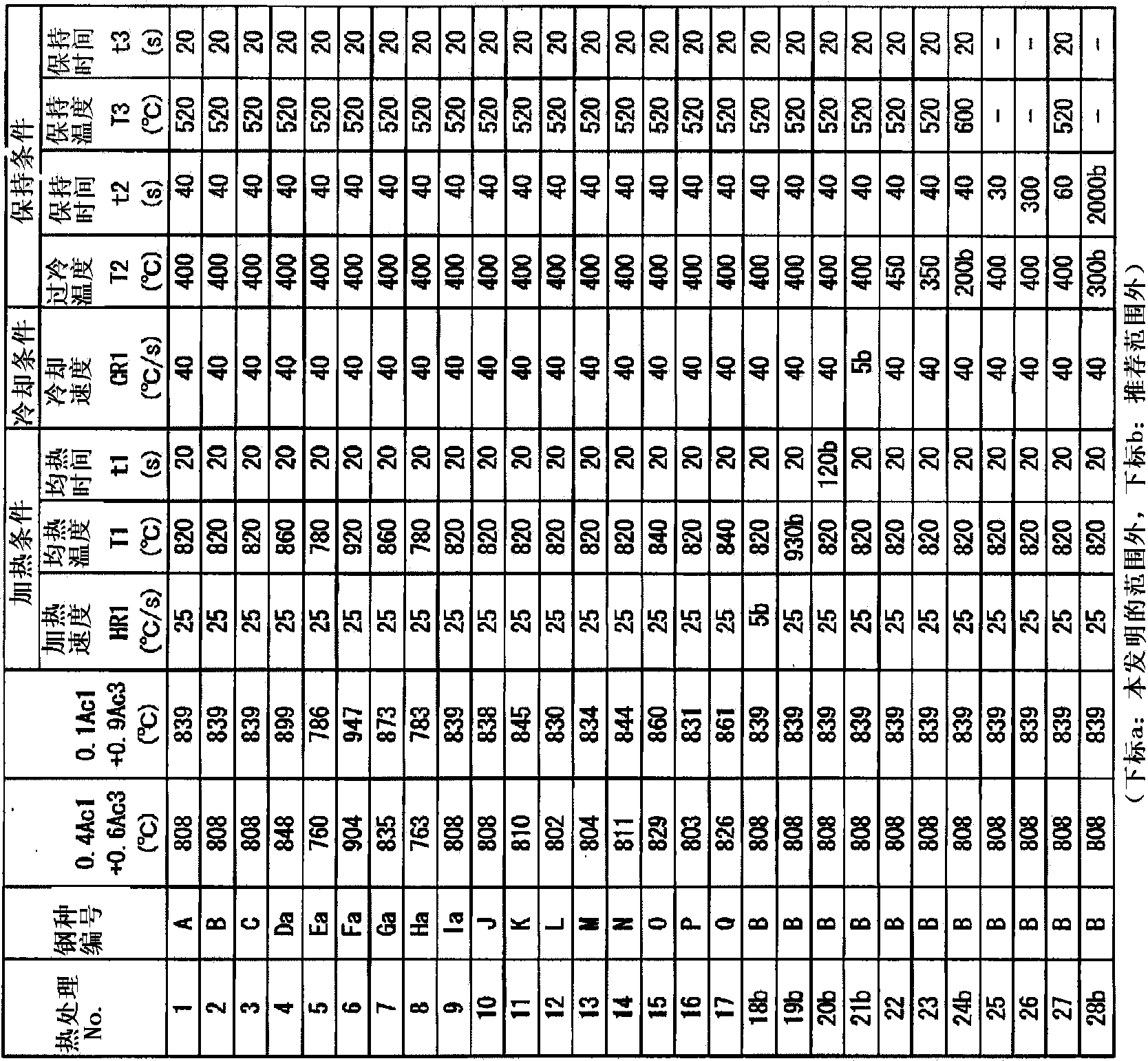

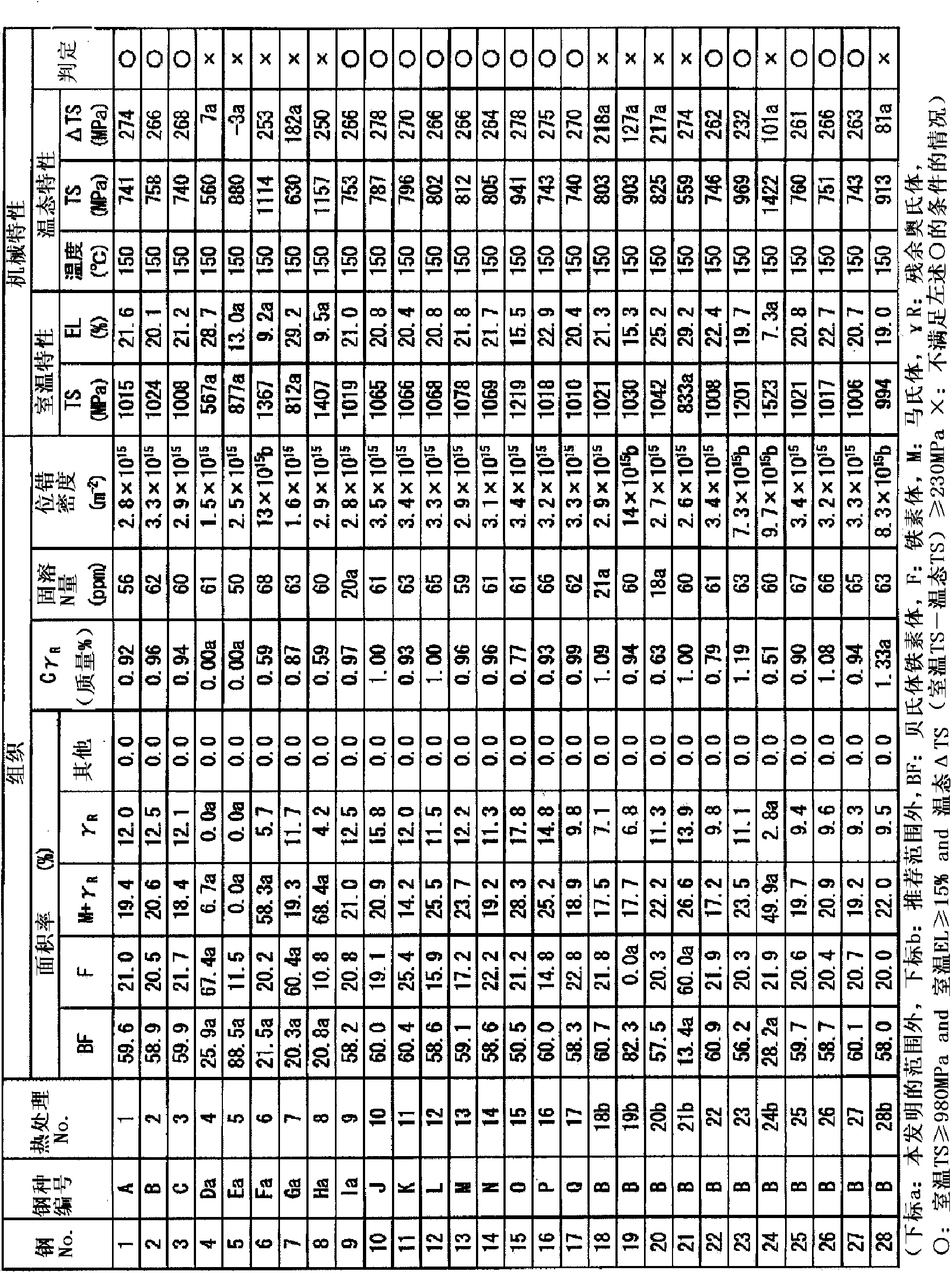

High strength steel plate with excellent warm and room-temperature formability and warm forming method thereof

ActiveCN103732778AEnsure room temperature strengthFormableFurnace typesHeat treatment furnacesSheet steelRoom temperature

A high-strength steel plate has a component composition including, in mass%, C: 0.02-0.3%, Si: 1-3%, Mn: 1.8-3%, P: 0.1% or less, S: 0.01% or less, Al: 0.001-0.1%, N: 0.002-0.03%, the rest consisting of iron and impurities. The steel plate has a structure including, in terms of area ratio relative to the entire structure, each of the following phases: bainitic ferrite: 50-85%; retained gamma: 3% or greater; martensite + the aforementioned retained gamma: 10-45%; and ferrite: 5-40%. The C concentration (C[gamma]R) in the aforementioned retained austenite is 0.3-1.2 mass%, part or all of the N in the aforementioned component composition is solid solution N, and the amount of the solid solution N is 30-100 ppm.

Owner:KOBE STEEL LTD

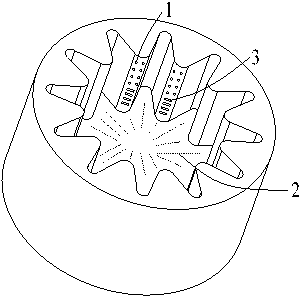

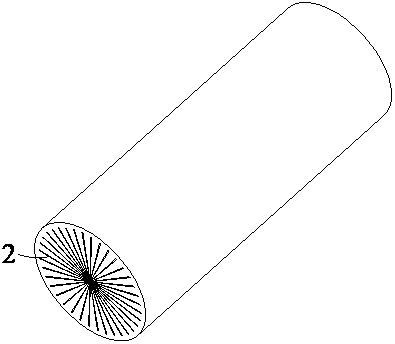

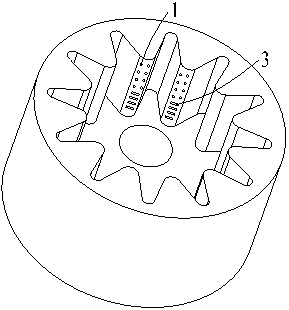

Nonanisotropic magnesium alloy bar extrusion forming mold

ActiveCN110665987AImprove mechanical propertiesIncrease torsional deformationExtrusion diesHomogeneous deformationFine grain

The invention discloses a nonanisotropic magnesium alloy bar extrusion forming mold. The nonanisotropic magnesium alloy bar extrusion forming mold comprises an insert, amale mold and a female mold. The male mold is connected with a press for axial movement, the female mold is connected with a rotating mechanism for circumferential rotating movement, a cavity is formed in the female mold, a feed port is formed in the cavity, an extrusion working tape is further arranged in the cavity, the insert, a bar and the male mold are arranged in the feed port, and the insert is mounted at the position ofthe extrusion working tape. Torque is applied on the basis of traditional extrusion, a gradient structure generated under rotating forming can be improved by changing the rotating speed and increasing the rotating circle number, uniform deformation of the structure is achieved, the large shearing strain capacity is generated by changing the stress-strain state in a deformation body, grains can berefined, a fine grain structure with a large angle grain boundary is formed, the anisotropy of the components is reduced, the insert can be replaced in time after being abraded due to the structuralmanner of the insert, the situation that the cost is increased as the female mold is scrapped is avoided, thus, the service life of the mold is prolonged, and economic benefits are remarkable when thenonanisotropic magnesium alloy bar extrusion forming mold is popularized to the forging and pressing industry.

Owner:ZHONGBEI UNIV

Self-rotating forward extrusion forming die and method

ActiveCN112620376AReduce investmentChange the direction of frictionExtrusion diesBall bearingElectric machinery

The invention discloses a self-rotating forward extrusion forming die and a method. The self-rotating forward extrusion forming die comprises a first fixing assembly, a male die body, a female die body, an extrusion die body, a thrust ball bearing, a second fixing assembly and a fixing sleeve; the first fixing assembly comprises an upper die plate, an upper base plate and a fixing plate, and after the male die body is placed in the center of the fixing plate, and the upper base plate and the upper die plate are positioned through positioning pins, and fixedly connected through hexagon socket bolts; and the extrusion die mold is arranged below the female die body and fixedly connected with the female die body through pins, the thrust ball bearing is fixedly assembled between the extrusion die body and the lower base plate through a middle ring, and the middle ring is fixedly connected with the lower base plate. According to the self-rotating forward extrusion forming die, self-rotation of the female die body and the extrusion die body is achieved through die structure design without driving of a motor; and a blank is violently twisted and deformed in a rotating die body, so that the forming load is reduced, structure refining and performance improving are facilitated, and a high-performance profile is prepared.

Owner:北方材料科学与工程研究院有限公司

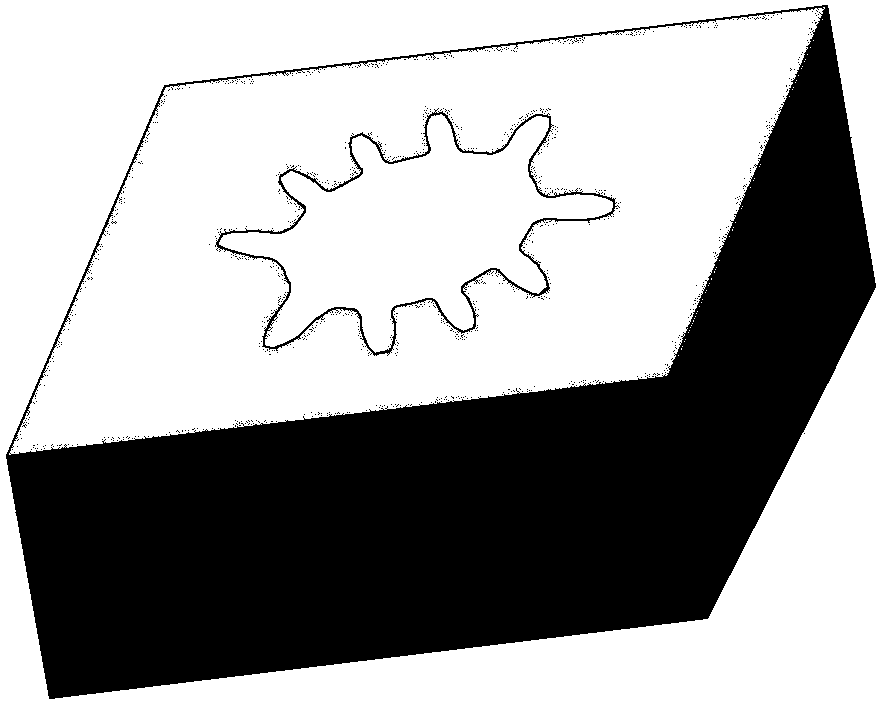

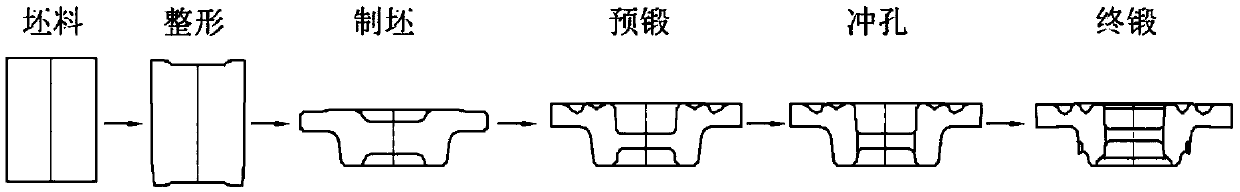

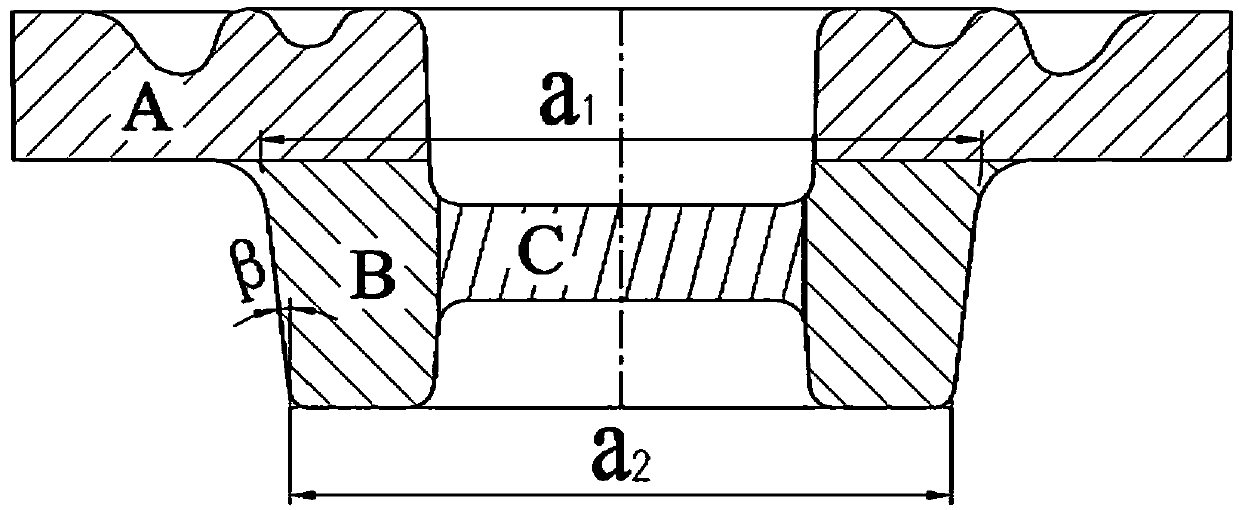

Integral combined tooth gear forging process with punching performed before combined tooth forming

InactiveCN110216232AReduce forming loadLow equipment requirementsForging/hammering/pressing machinesWheelsCombined methodEngineering

The invention relates to an integral combined tooth gear forging process with punching performed before combined tooth forming. The integral combined tooth gear forging process is characterized in that a blank is shaped, then blank making and pre-forging are sequentially performed, a middle connected sheet of a pre-forged piece is removed through punching, and finally final forging forming is performed. According to the integral combined tooth gear forging process, the combined tooth portion is formed by using an upsetting and extruding combined method so that a gear forge piece with qualifiedsize precision and performance can be obtained under the conditions of relatively low forming load and relatively long mold service life.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Method for determining uneven-thickness blank for realizing local loading forming of rib-plate-shaped three-dimensional component

InactiveCN102632172AEasy to analyzeQuick analysisMetal-working apparatusEngineeringMechanical engineering

The invention discloses a method for determining an uneven-thickness blank for realizing local loading forming of a rib-plate-shaped three-dimensional component. A computational formula for the volume of materials flowing into a rib cavity is determined according to various loading states in a forming process, a simplified interface is fast analyzed, and the time for determining the shape of the blank is shortened; the shape of the blank is corrected according to a numerical value simulated result, the uneven-thickness blank meeting the requirement of filling is determined, and cost is reduced; and the volume distribution of the determined uneven-thickness blank is reasonable, shortcomings that the blank cannot fully filled, is folded and the like in the forming process are eliminated, allowance for machining is reduced, forming loads are reduced, the shape of the blank is simple, and the blank is easy to be manufactured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Medium-thick plate differential thermal volume forming device and process

The invention discloses a medium-thick plate differential thermal volume forming device and process. Positions with forming characteristics on plates are subjected to local sensing heating, and the heating temperature does not exceed the recrystallization temperature; the locally heated plates are graded to a next process to be subjected to local volume forming. By means of the device and the process, the plate volume forming load can be reduced effectively, and the die service life is prolonged.

Owner:FOSHAN NUODI PRECISION MOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com