Patents

Literature

48results about How to "No folding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

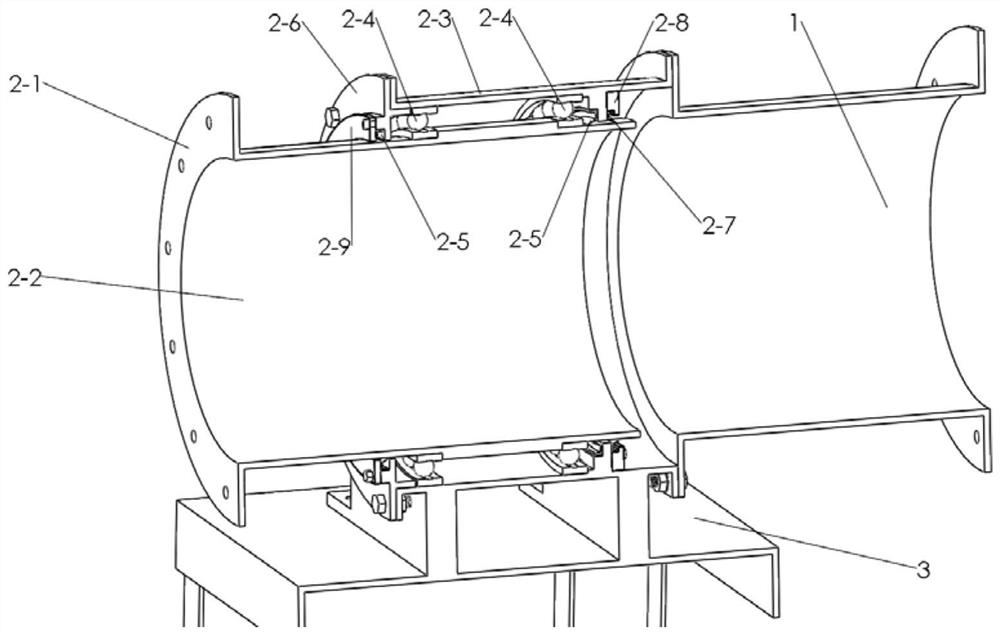

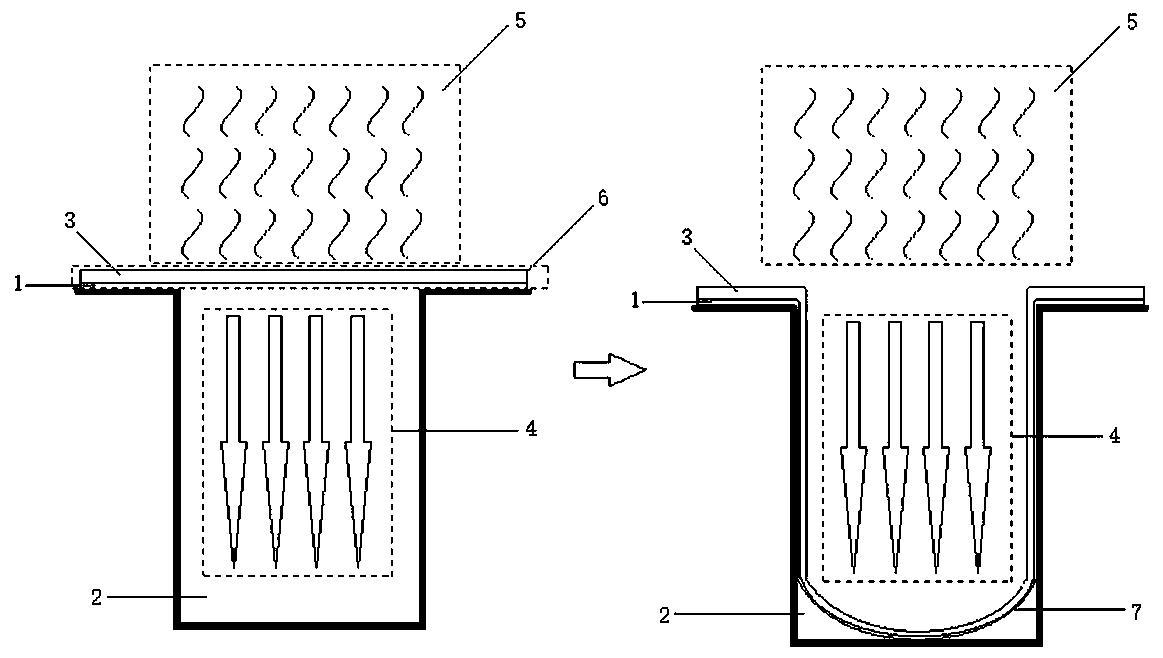

Continuous tapered upsetting die and upsetting method for bar material with superhigh height-diameter ratio

ActiveCN106623718AAspect ratioNo foldingForging/hammering/pressing machinesInstabilityDiameter ratio

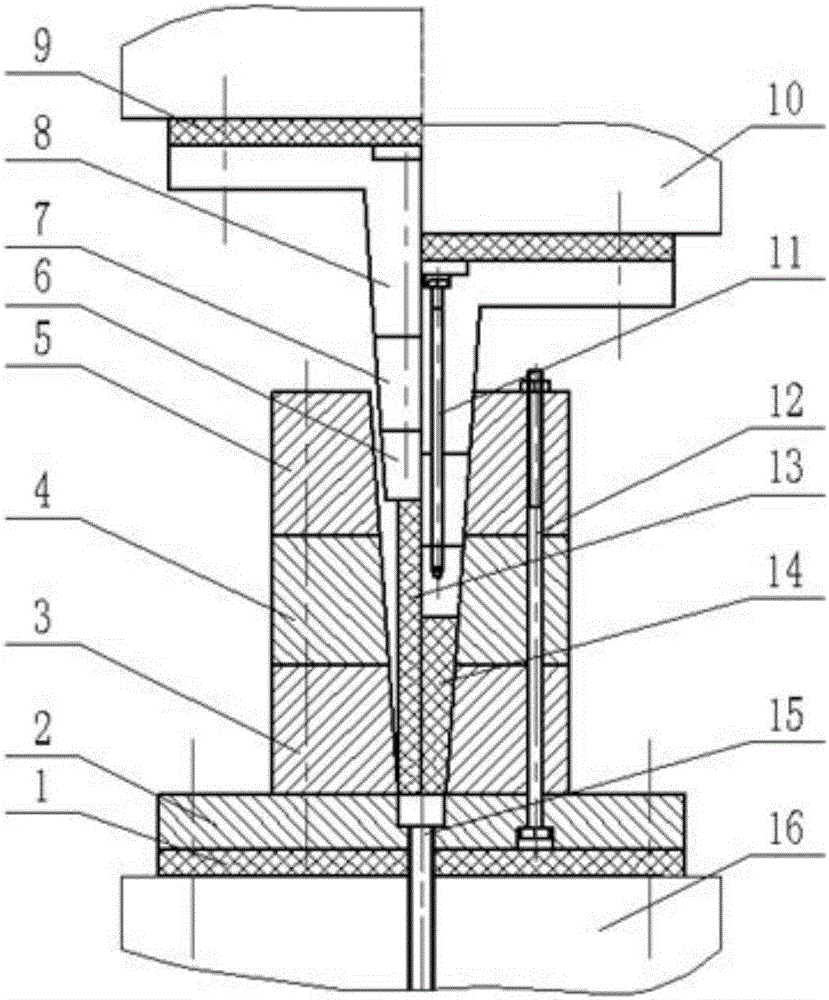

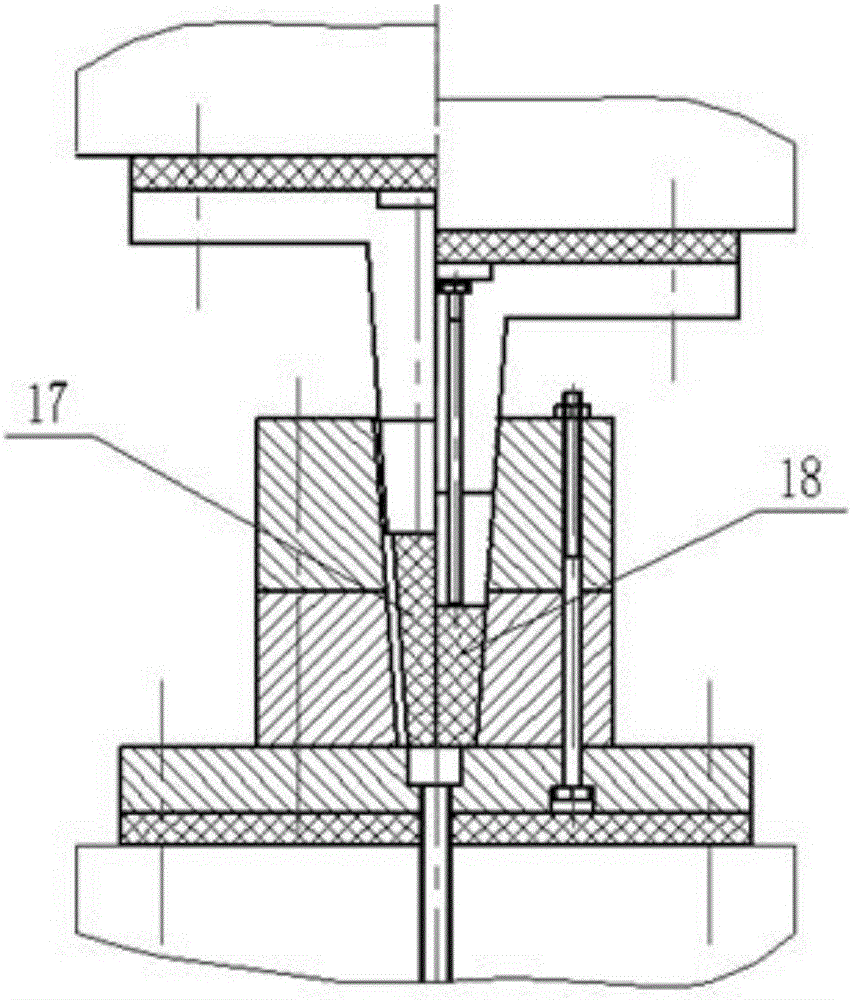

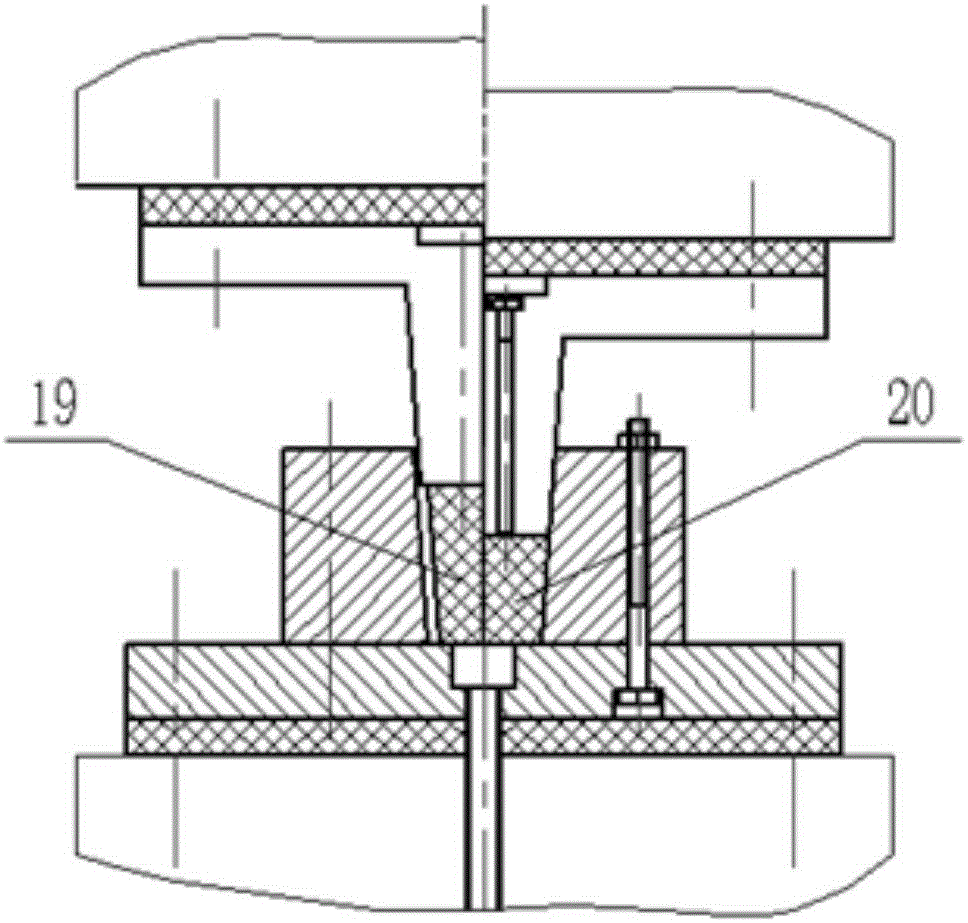

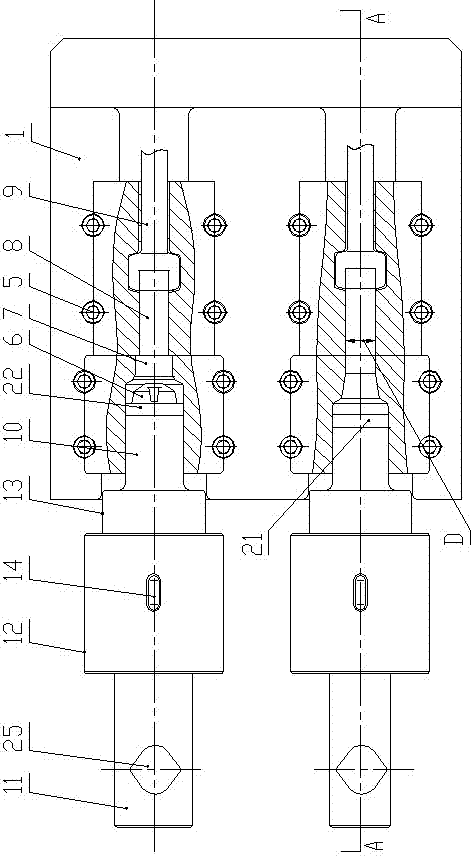

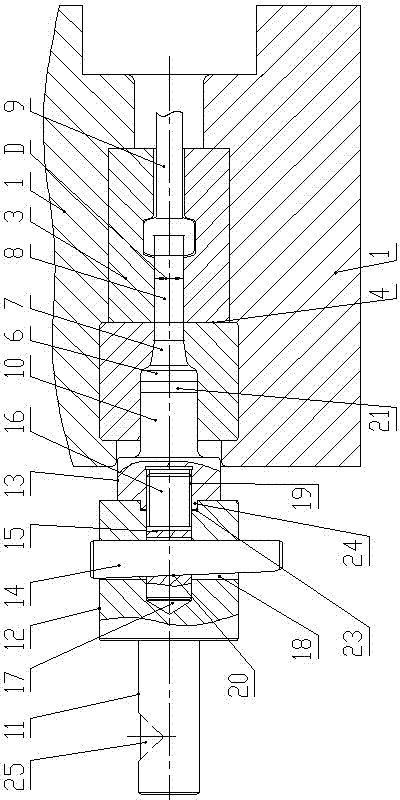

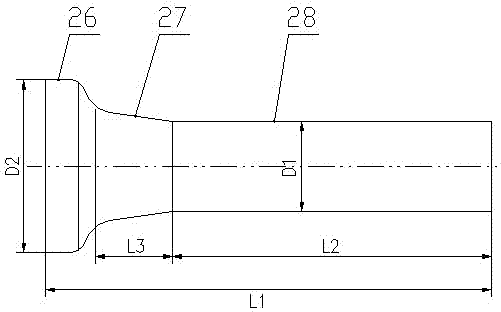

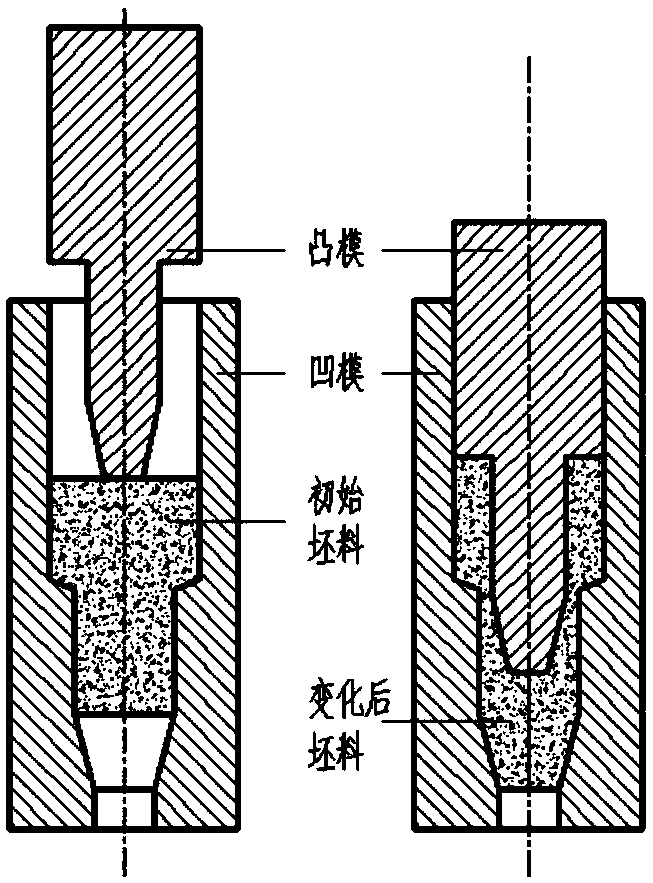

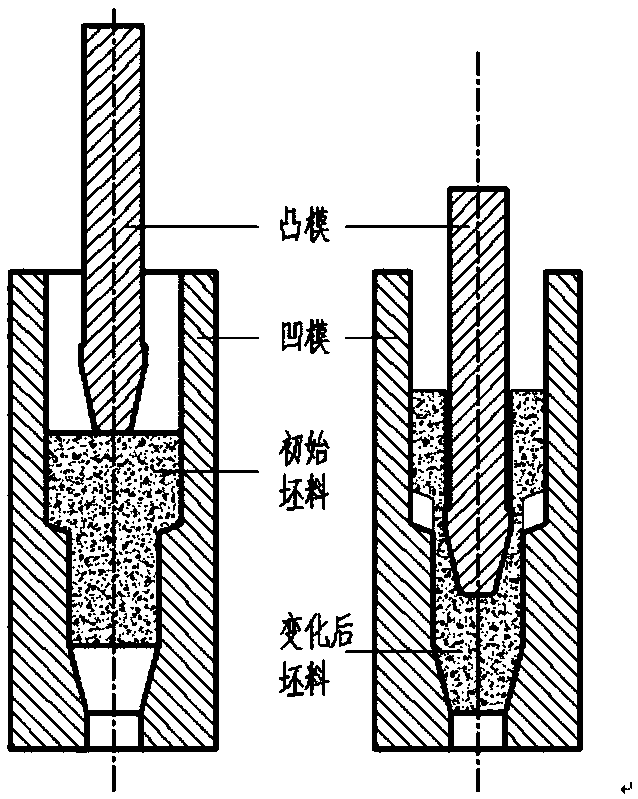

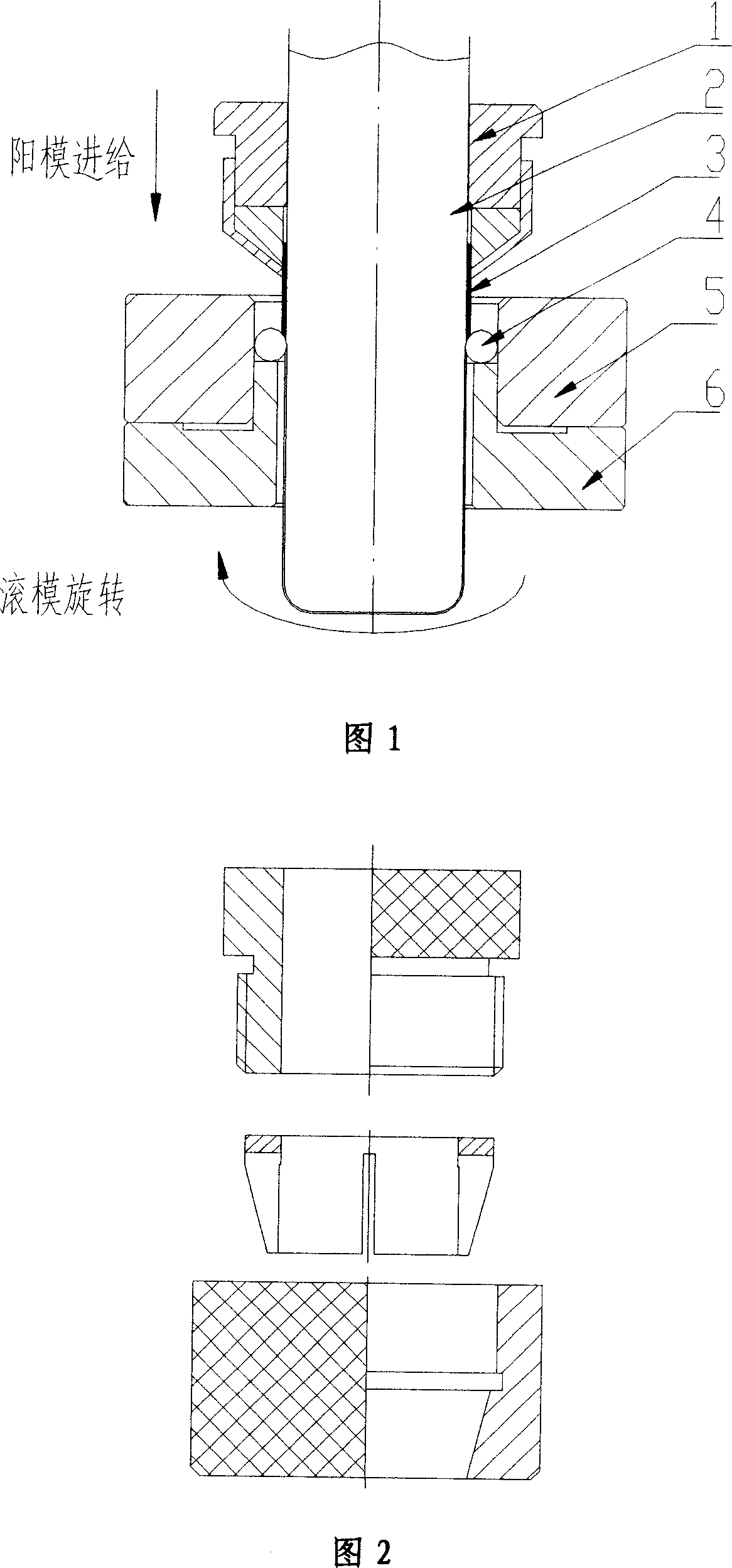

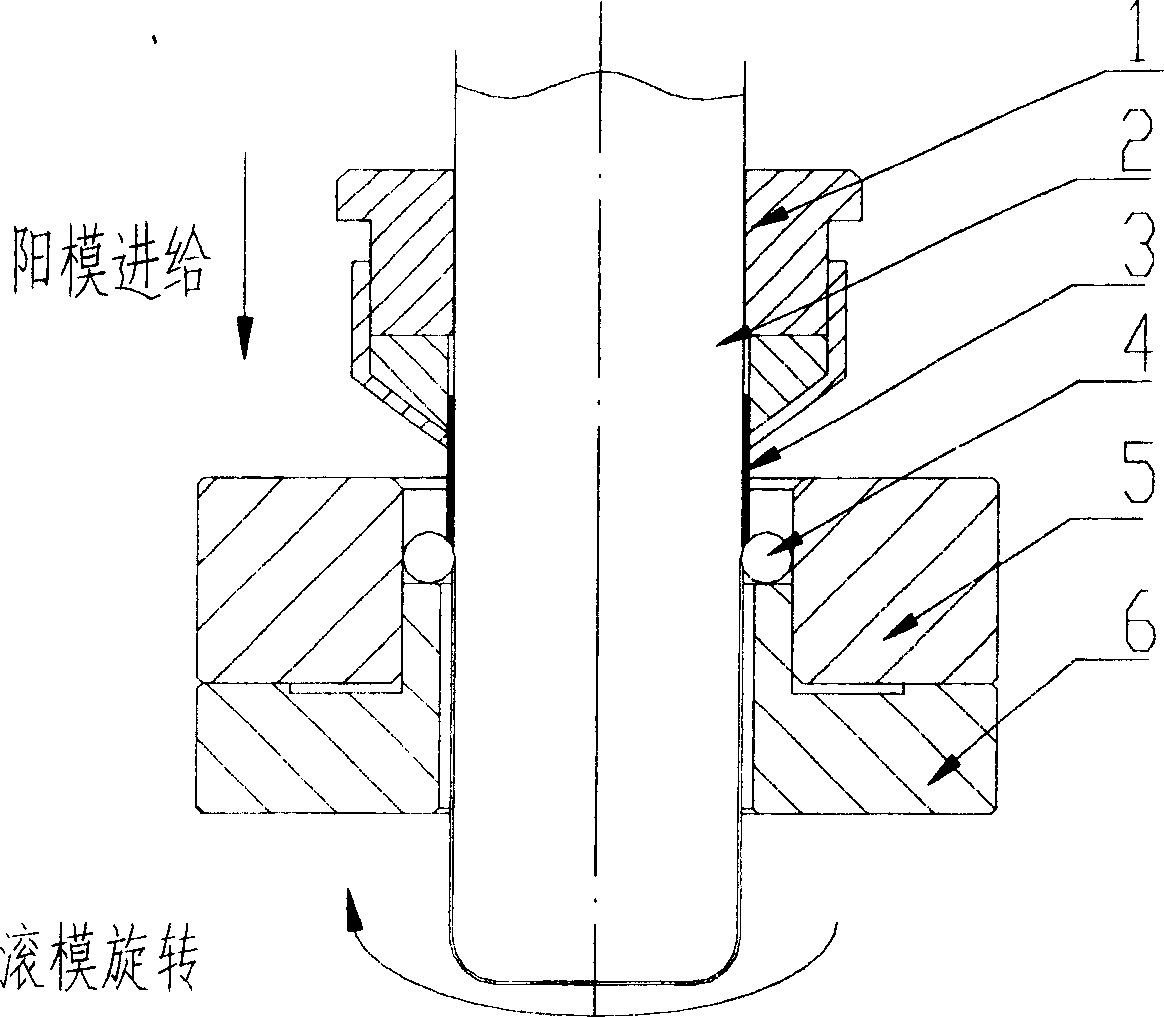

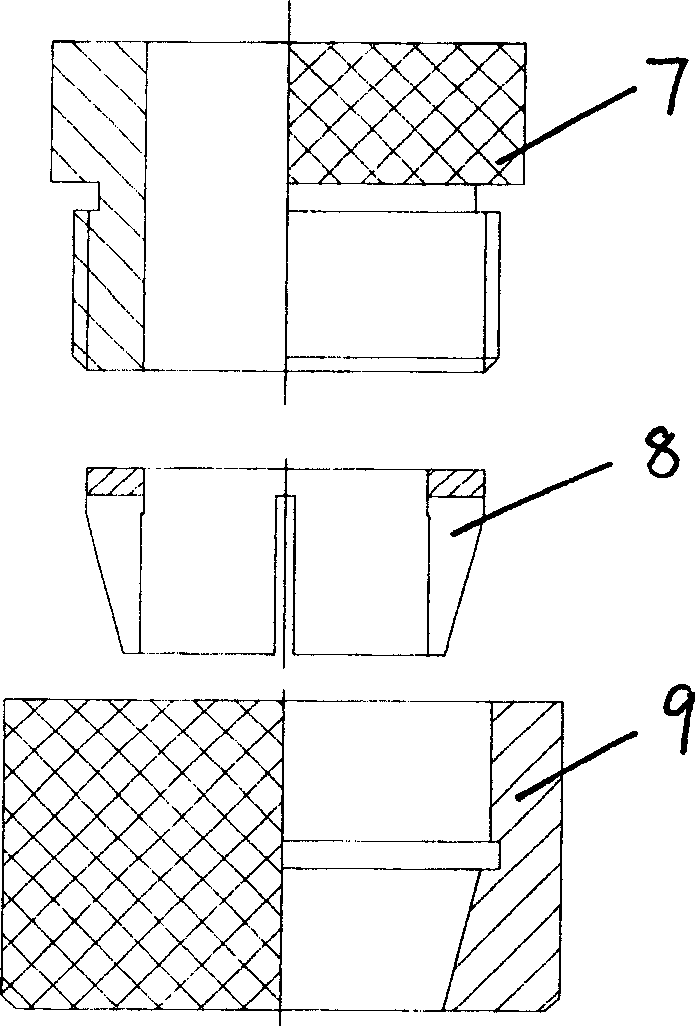

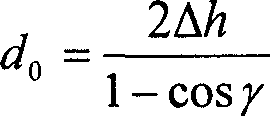

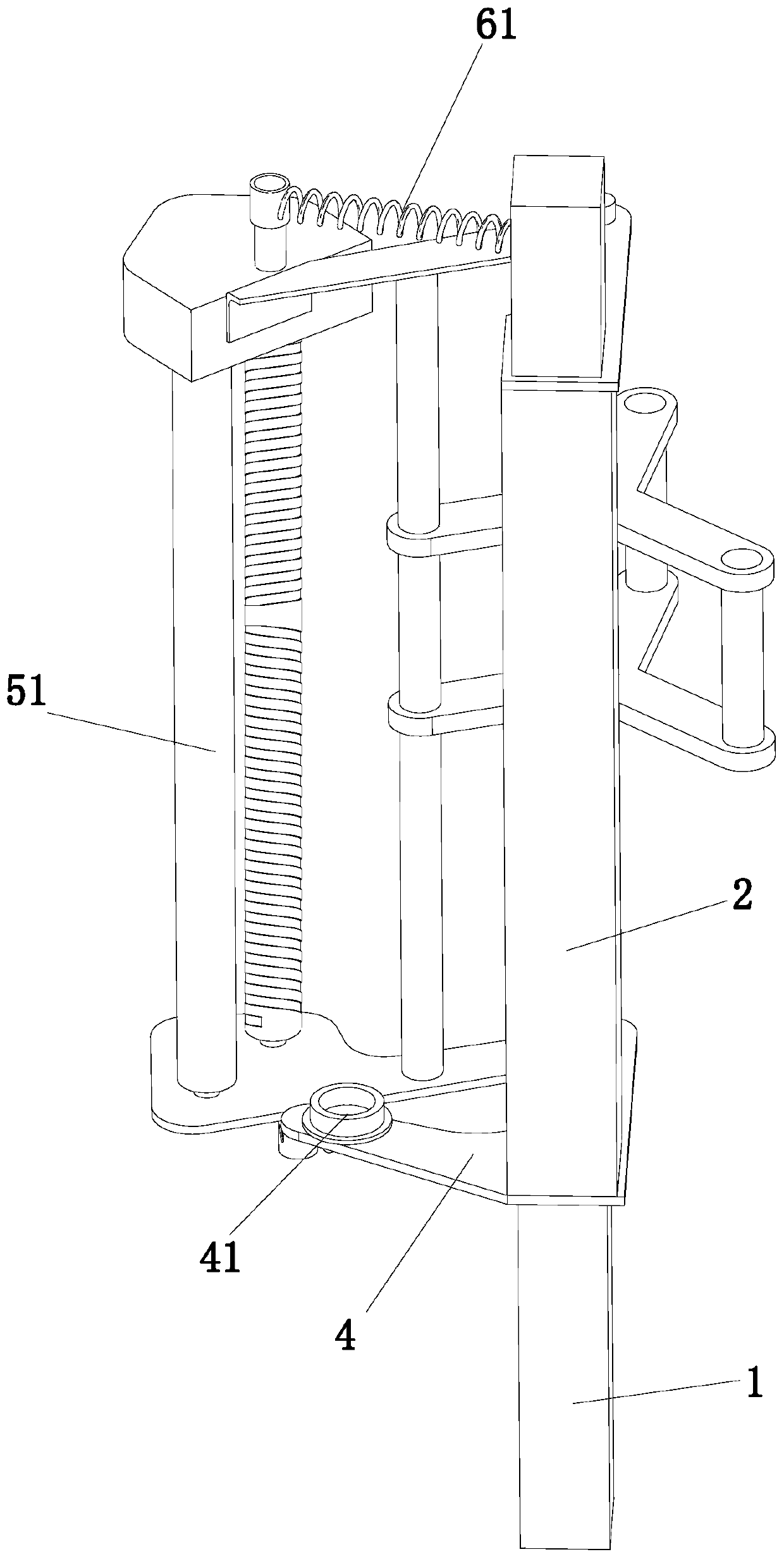

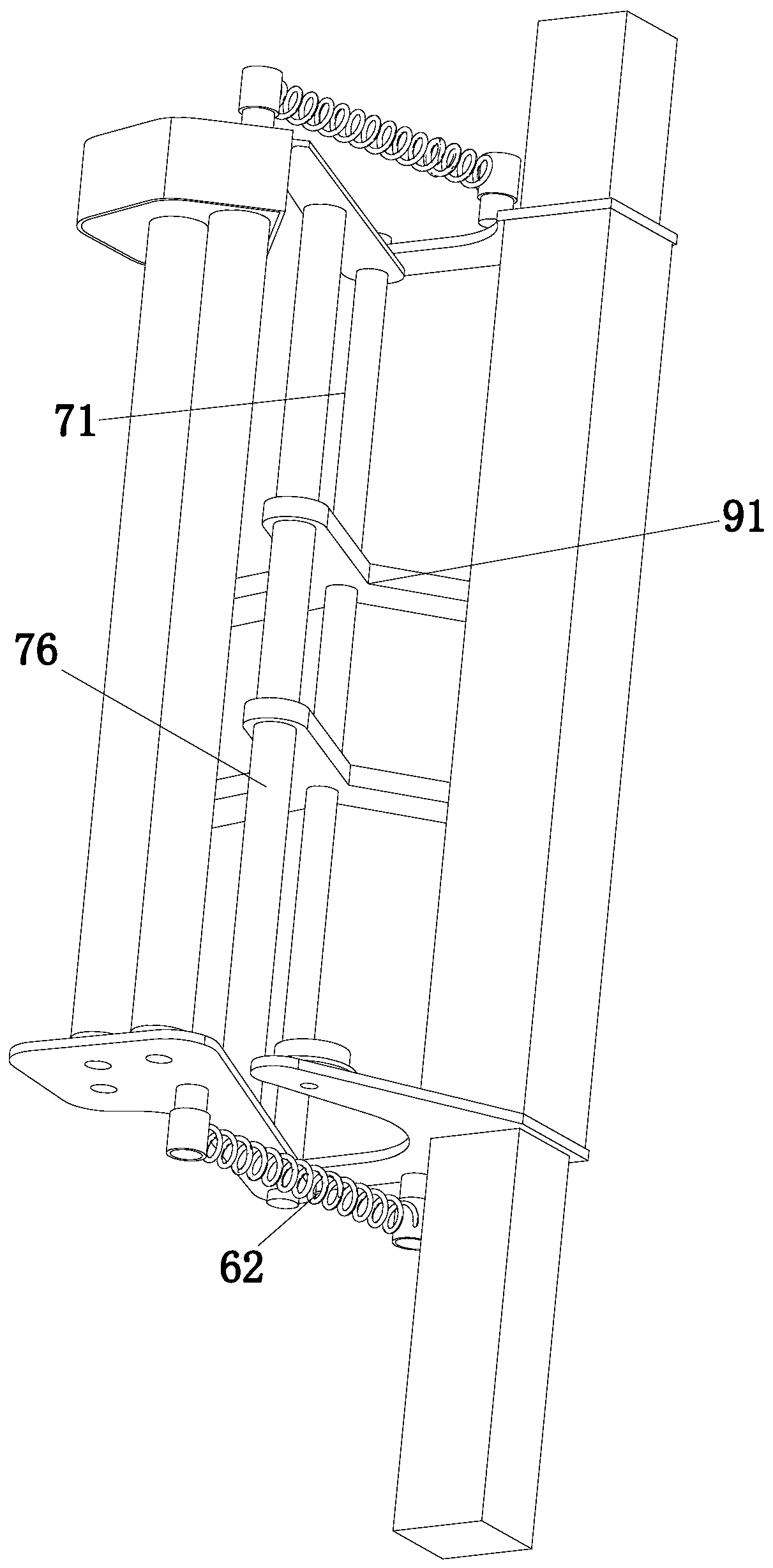

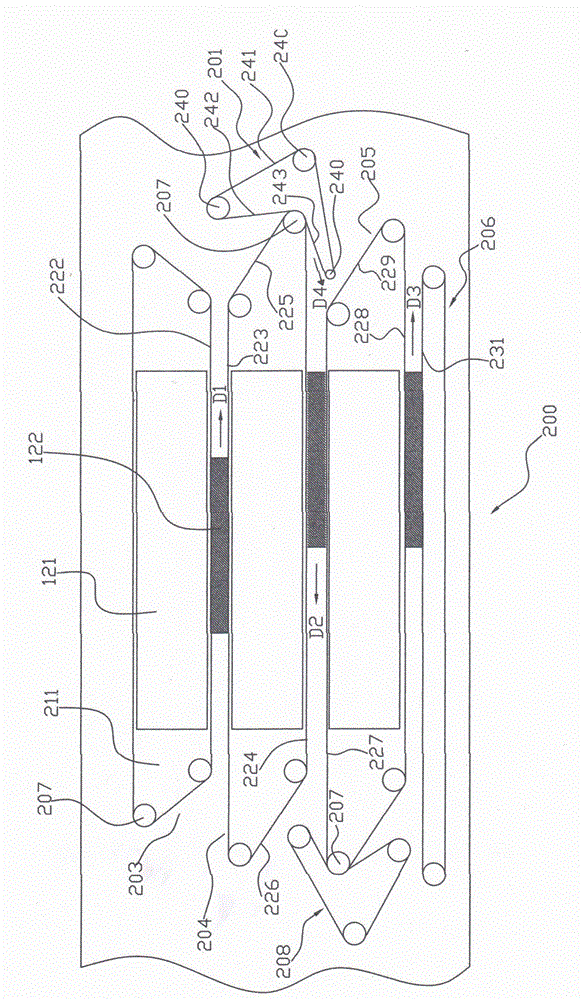

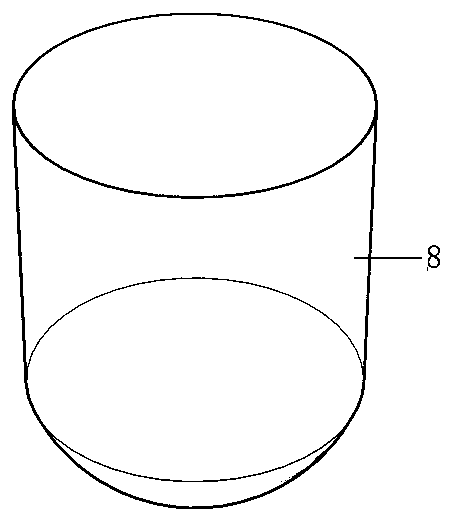

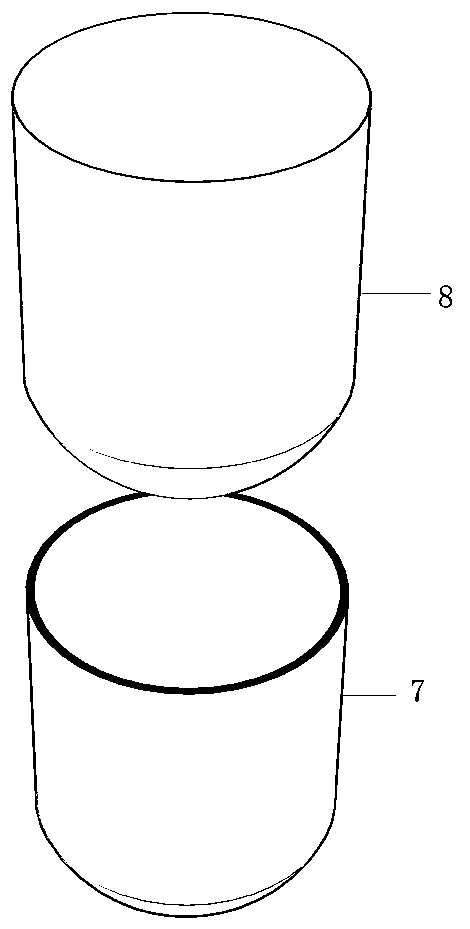

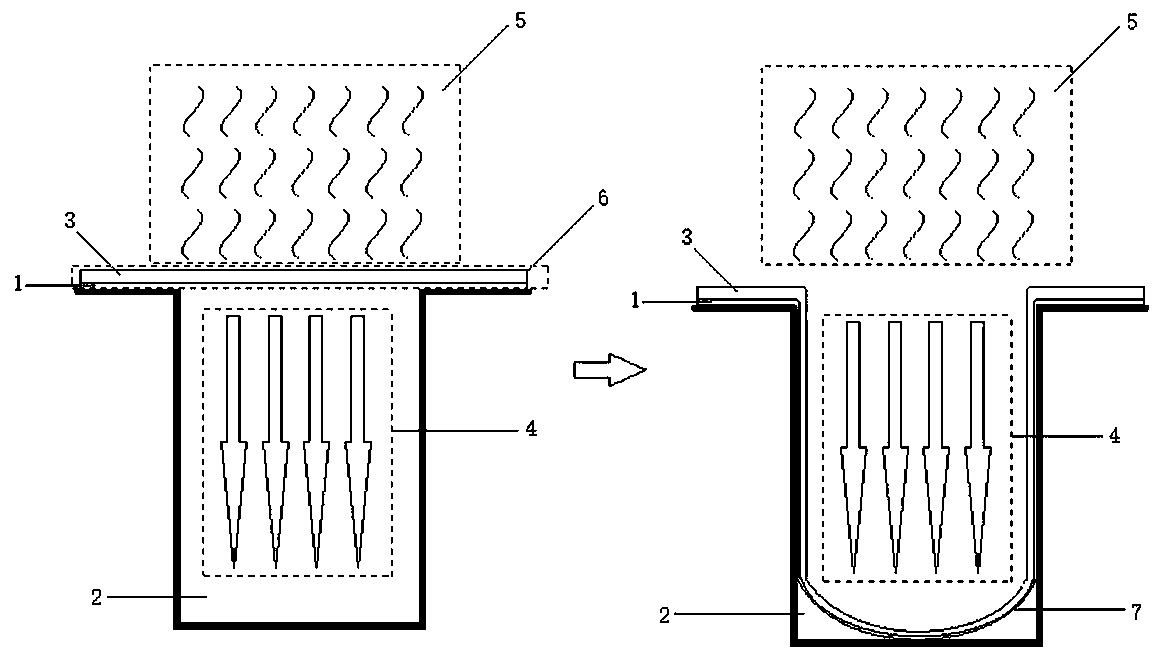

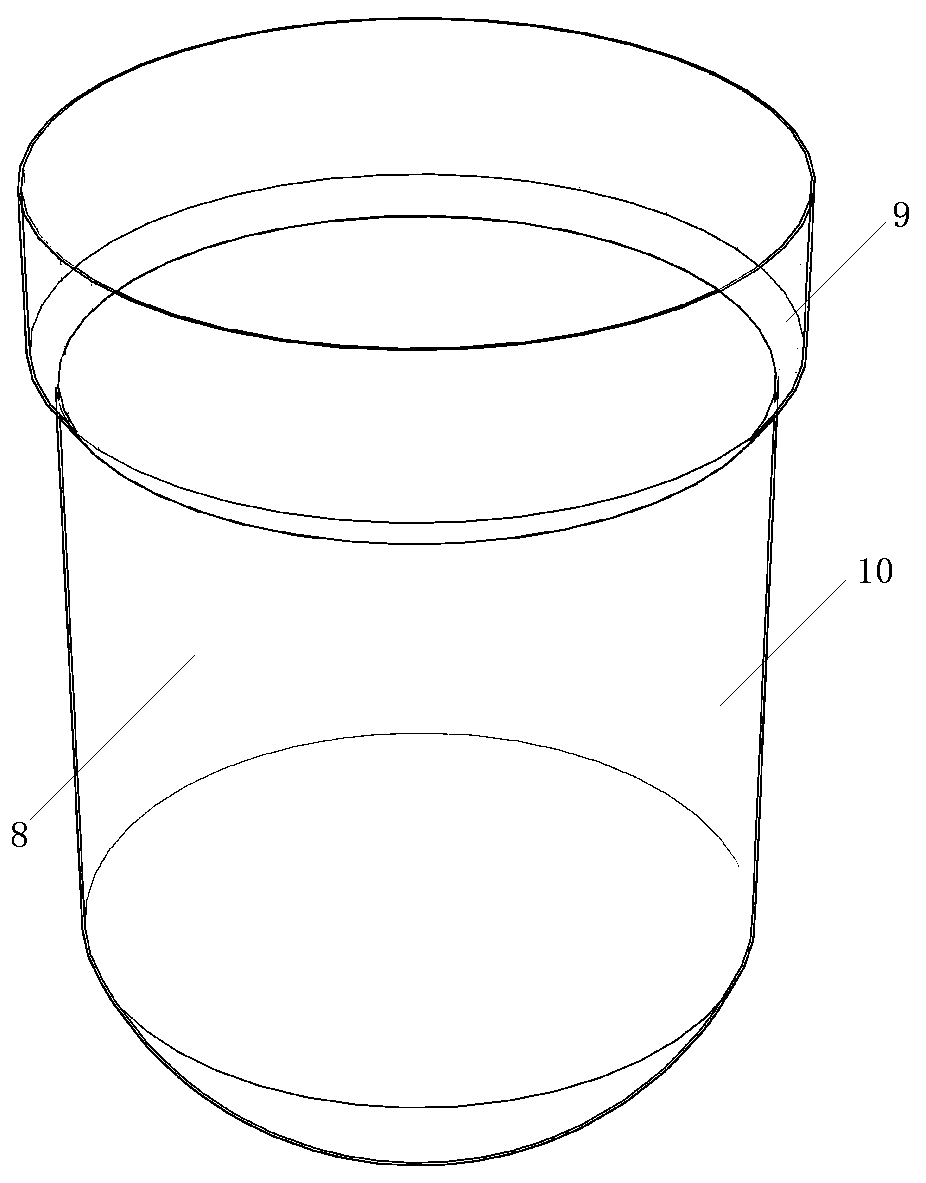

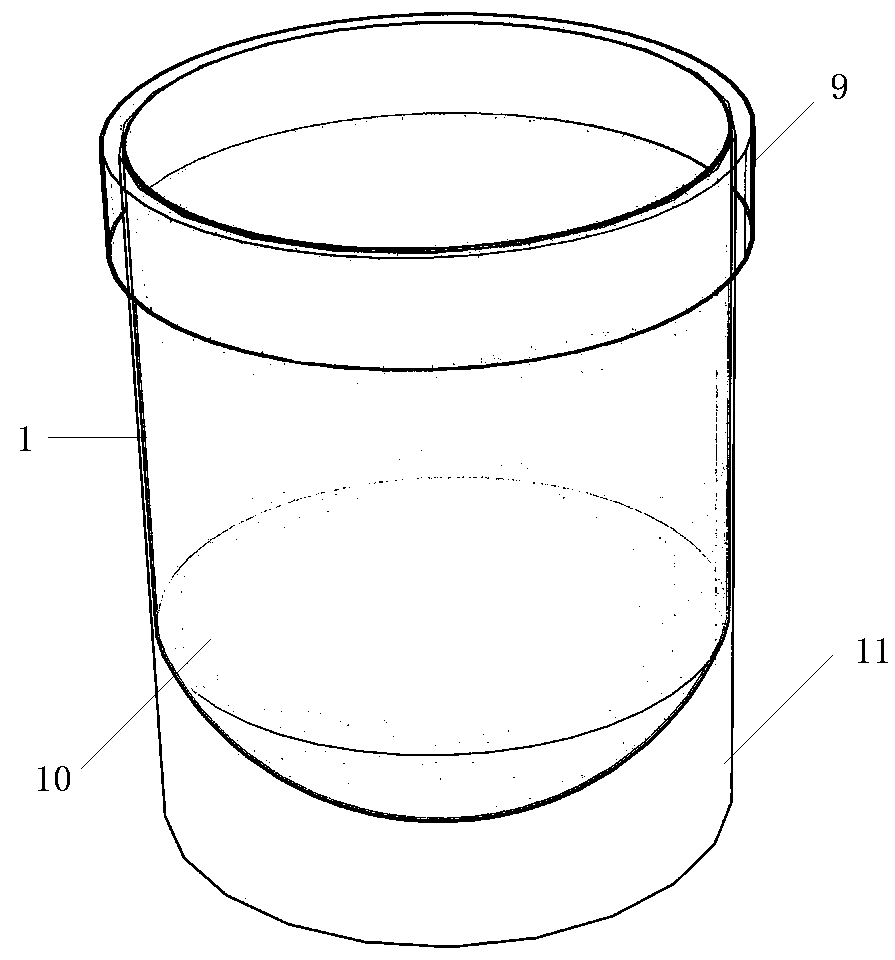

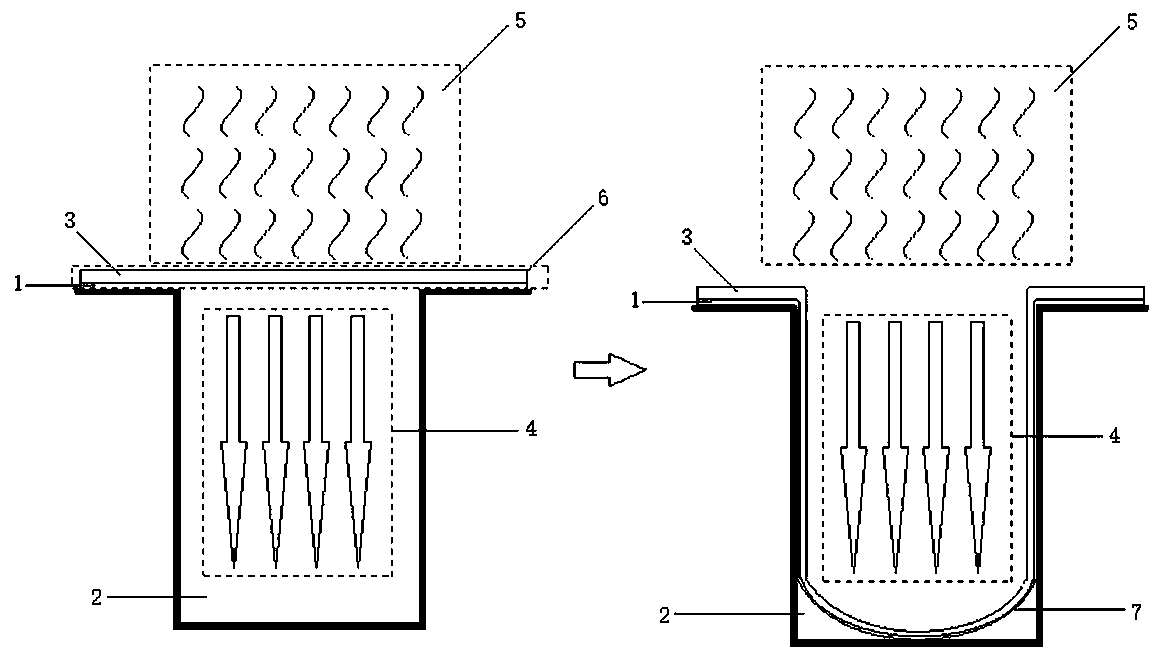

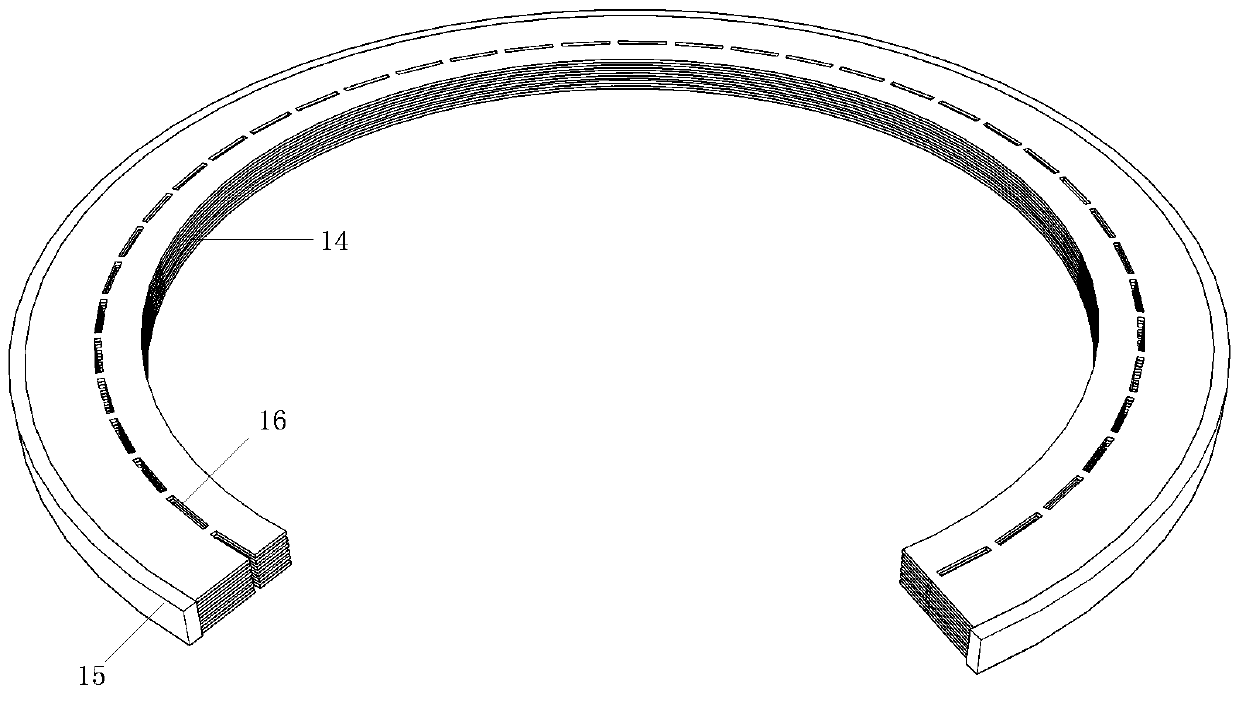

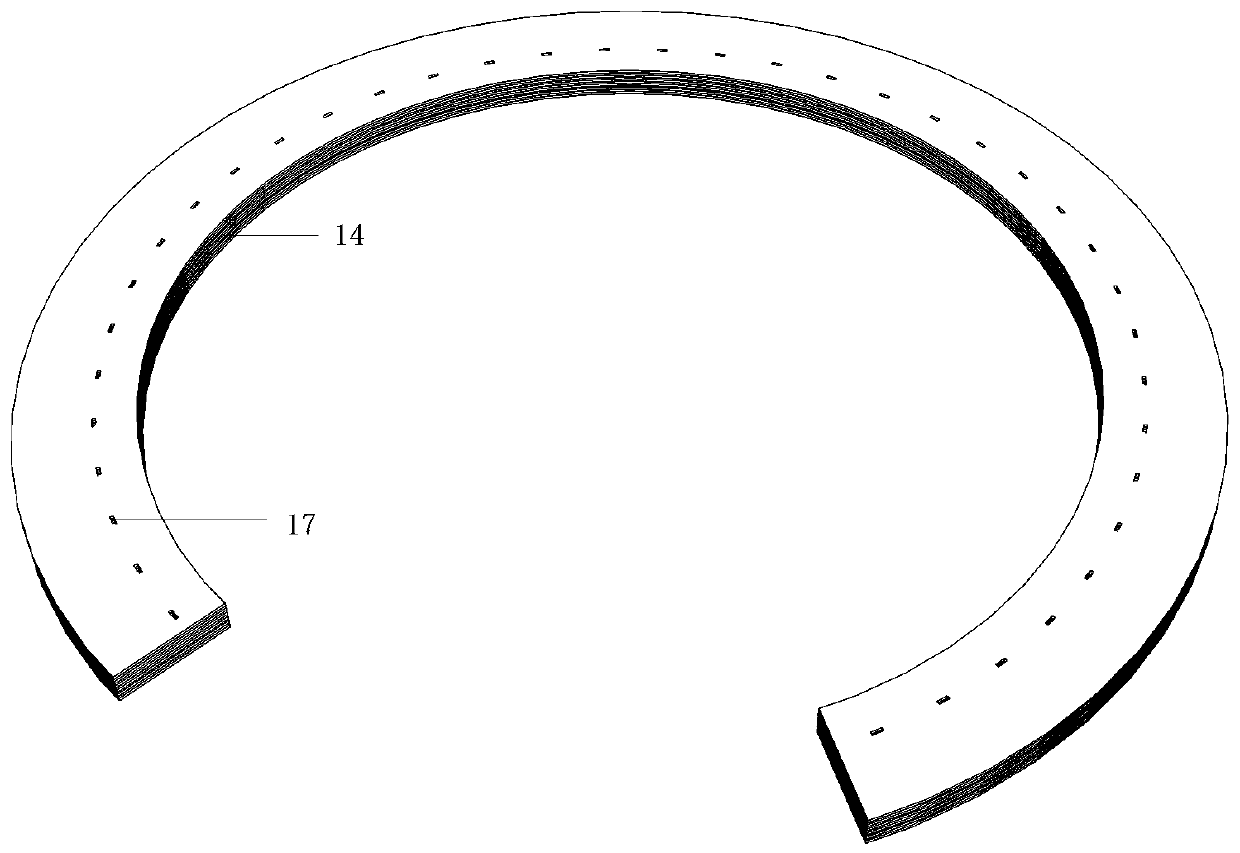

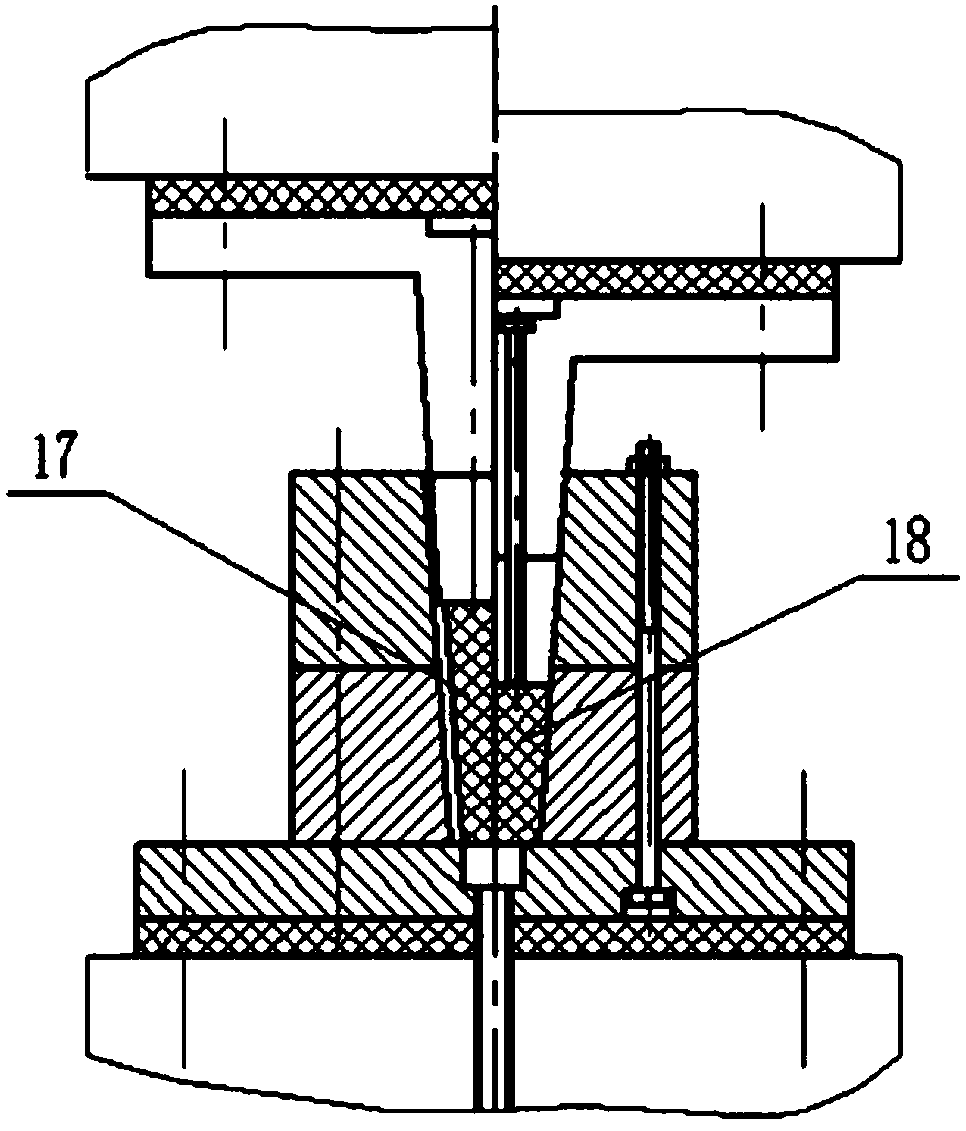

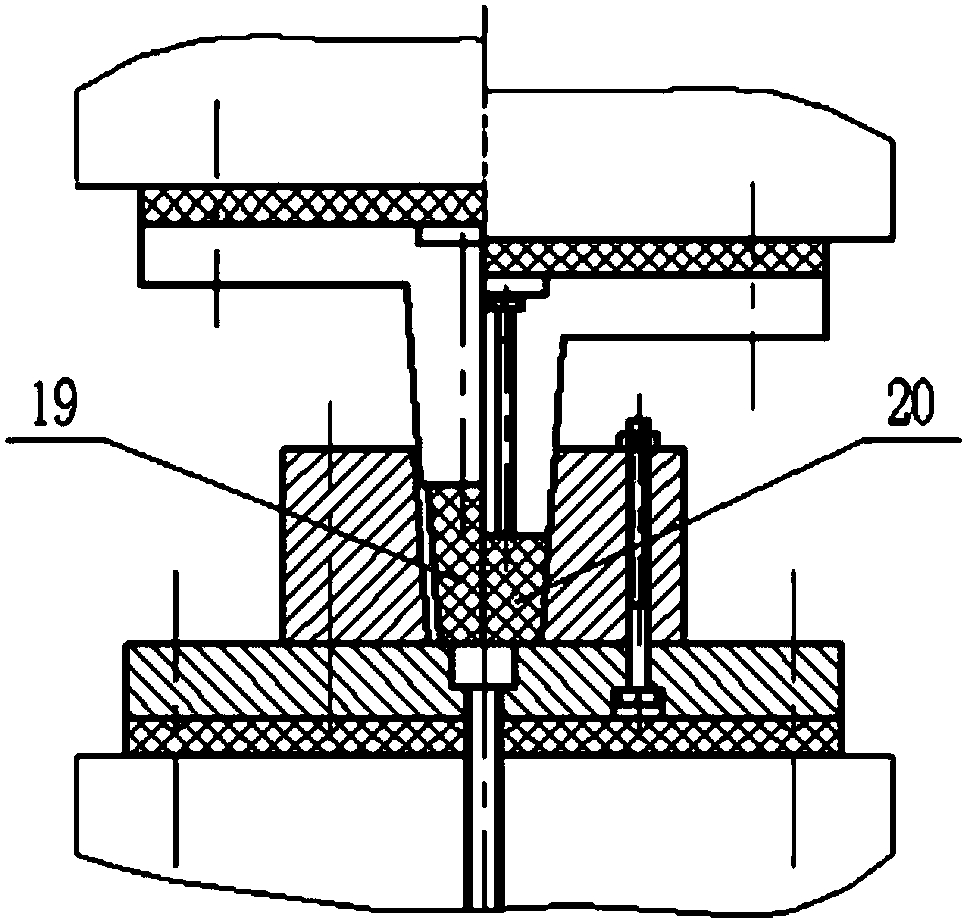

The invention discloses a continuous tapered upsetting die and upsetting method for a bar material with the superhigh height-diameter ratio. The method comprises the steps that 1, the height of the bar material is obtained according to the diameter of the bar material and the size of a forge piece; 2, the taper degree of a forming wall surface of a male die and the taper degree of a forming wall surface of a female die are selected, and the upsetting frequency, the layer number of the male die, the layer number of the female die, the height of each layer of male die modules and the height of each layer of female die modules are determined according to the taper angles of the forming wall surfaces, the height of the bar material and the upsetting ratio every time; 3, after the bar material, the female die and the male die are heated, first-time upsetting forming is conducted; 4, after first-time upsetting forming is completed, the male die module with the minimum average outer diameter and the female die module with the minimum average inner diameter are removed, second-time upsetting is conducted, and in this way, the steps are conducted till the height-diameter ratio of an upsetting part is smaller than the maximum height-diameter ratio of non-instable upsetting. According to the die, the female die is designed into multiple layered modules of which the inner walls have the certain taper degree, instability of blanks is constrained through the oblique wall of the female die, and then a folding phenomenon cannot be generated.

Owner:SHANDONG UNIV +1

Novel technology for forging spline shaft of transmission shaft

ActiveCN103537595AReduce consumptionReduce energy consumptionForging/hammering/pressing machinesDrive shaftMedium frequency

The invention relates to a novel technology for forging a spline shaft of a transmission shaft. The novel technology includes following steps: (1), blanking; (2), medium-frequency heating; (3), pre-forging: after the medium-frequency heating, a blank material is placed in a cavity of a pre-forging die body of a spline shaft hammer forging die on a hammer forging machine, the hammer forging machine is controlled, a power drive end drives the pre-forging die body to stamp the blank material, and the blank material is stamped into a pre-forging piece of the spline shaft; (4), finish-forging: the pre-forging piece is placed in a cavity of a finish-forging die body of the spline shaft hammer forging die on the hammer forging machine, the hammer forging machine is controlled, the power drive end drives the finish-forging die body to stamp the pre-forging piece, and the pre-forging is stamped into a finish-forging piece. The novel technology is reasonable in design and simple in structure, forging pieces are easy to be formed, and rejection rate of the forging pieces is greatly lowered. Gathering process is eliminated, production efficiency is improved, and production cost and die making cost are lowered. Inner diameters of shaft body cavities of a pre-forging cavity and a finish-forging cavity are reduced, and processing amount of a machine is reduced and raw material is saved.

Owner:XUCHANG ZHONGXING FORGING +1

Hyperpure alloy wire or semi-tandem rolling wing-shaped holes for bar material and semi-tandem rolling technology of using hyperpure alloy wire or semi-tandem rolling wing-shaped holes for bar material

InactiveCN103286130AQuality improvementNo crackMetal rolling arrangementsCorrosion resistant alloyStrip mill

The invention discloses a set of hyperpure alloy wire or semi-tandem rolling wing-shaped holes for a bar material. The hyperpure alloy wire or semi-tandem rolling wing-shaped holes for the bar material comprises 1-7 wing-shaped holes of a roughing mill, 8-13 wing-shaped holes of an intermediate mill and 14-19 wing-shaped holes of a finishing mill. In addition, the invention further discloses a technology for carrying out the semi-tandem rolling by adopting the hyperpure alloy wire or the semi-tandem rolling wing-shaped holes for the bar material. Compared with the prior art, the technology provided by the invention can produce high quality heat-resisting alloy 40Cr25Ni35W2Nb2MnSi, corrosion resistant alloy Cr16Mo16W4Fe6Ni, and hot rolled wire rod, and the qualification rate is 98 percent. After surface inspection, the defects of crack, folding, cicatrization and scratch do not exist, the requirements of GB / T15008-2008 are met, and the regulations specified by GB / T14981-2009 to size, appearance and allowable deviation are met.

Owner:CHAOYANG TIANYI GUOJI NEW MATERIAL

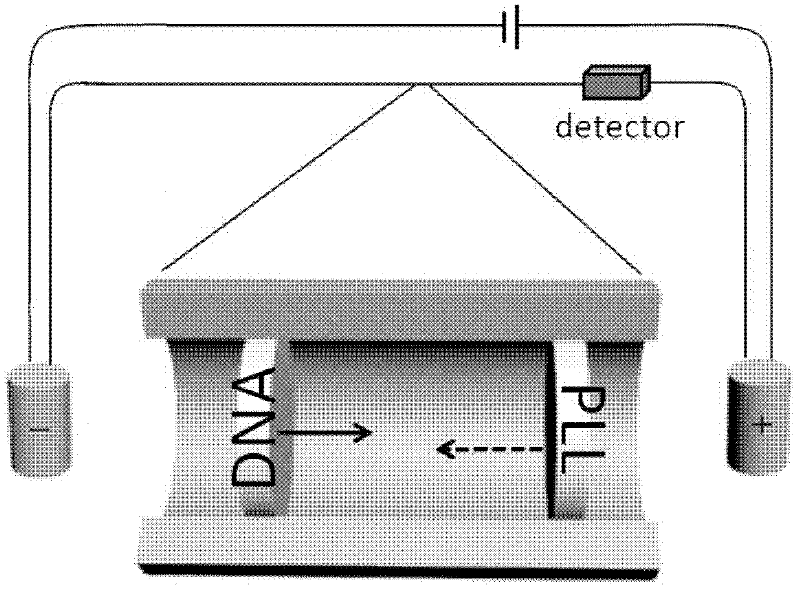

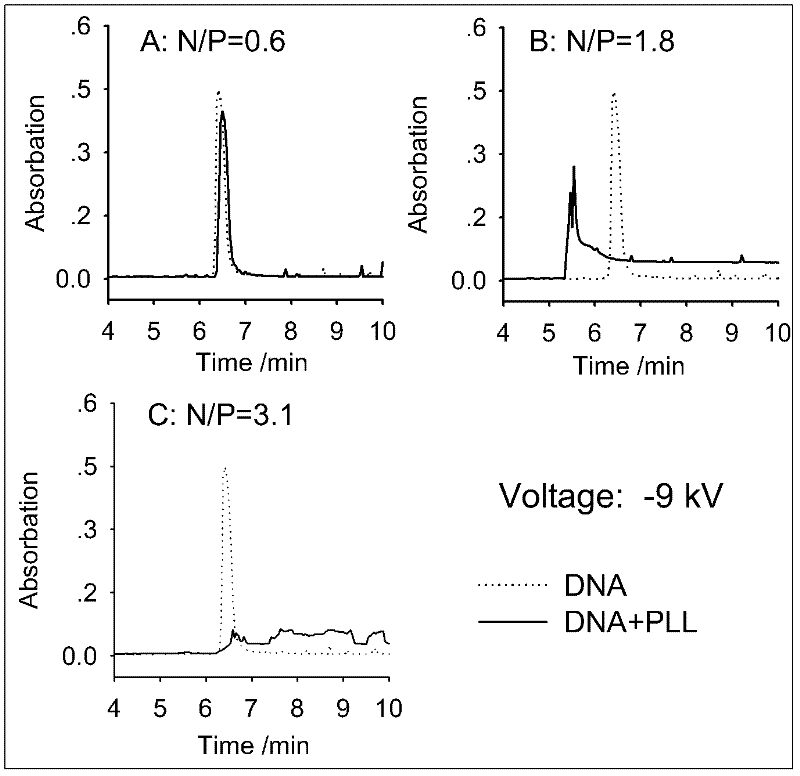

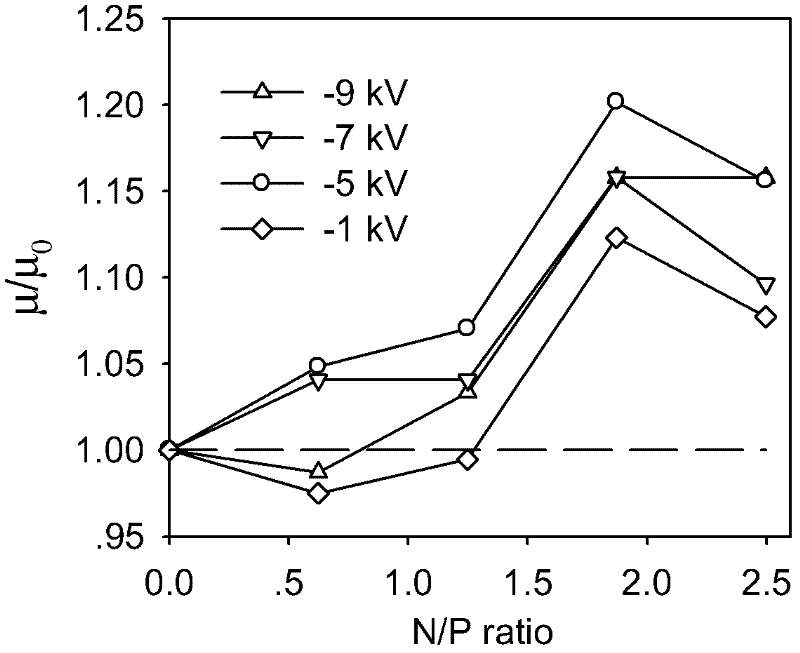

A kind of preparation method of dna or rna complex

InactiveCN102268459ASmall sizeUniform sizeOther foreign material introduction processesA-DNAPolymer solution

The invention discloses a method for preparing a DNA (Deoxyribonucleic Acid) or RNA (Ribonucleic Acid) complex, belonging to the field of biological medicinal materials. In the method, by applying an external direct current electric field, a cationic polymer solution and a DNA or RNA solution meet each other in the electric field and are compounded to form a complex of DNA or RNA and cationic polymer. The DNA or RNA complex prepared by the method has a controllable structure and a small and uniform size and contributes to transfer of DNA or RNA and gene therapy.

Owner:PEKING UNIV

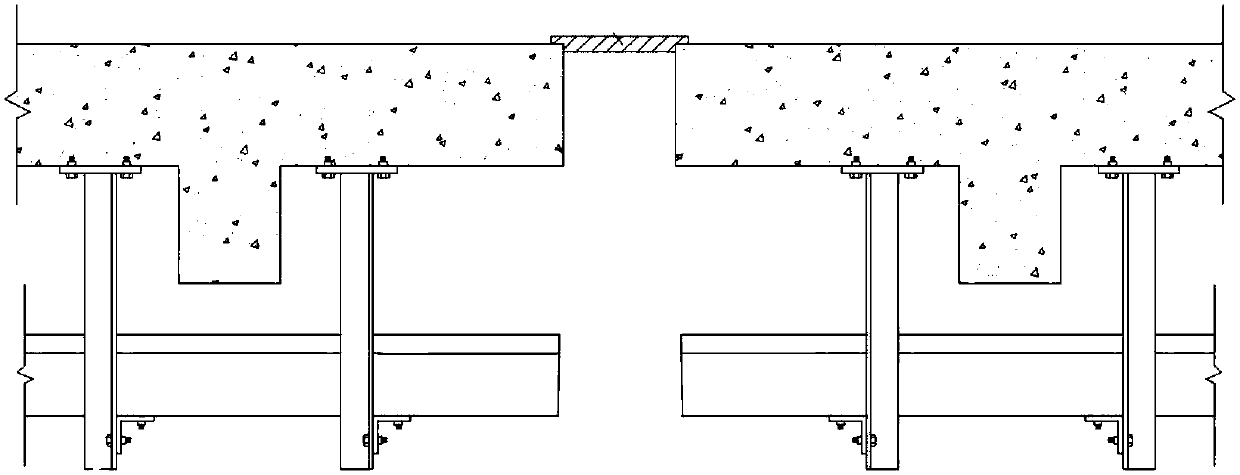

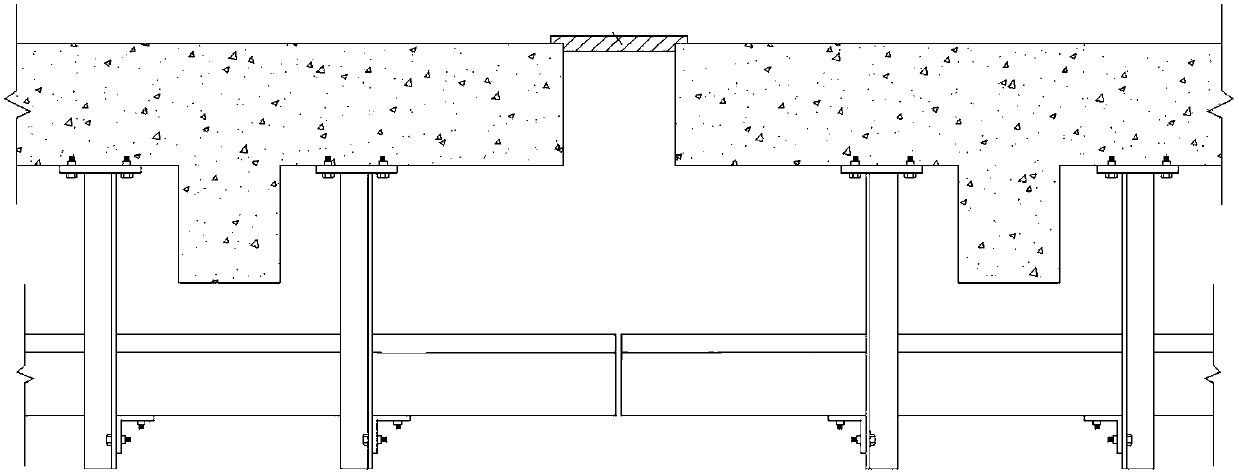

Novel connection device for telescopic and settlement seam of cable bridge frame

InactiveCN110391621AImprove integrityProtect electricity safetyElectrical apparatusButt jointCable tray

The invention discloses a novel connection device for a telescopic and settlement seam of a cable bridge frame. The device includes two sets of connection mechanisms, a U-shaped telescopic mechanism is disposed between the connection mechanisms, two ends of the U-shaped telescopic mechanism are respectively connected with the corresponding connection mechanisms, a supporting mechanism is disposedinside the U-shaped telescopic mechanism, and the supporting mechanism is connected with the inside of the U-shaped telescopic mechanism. In a present bridge frame system, through a treatment manner of structure telescopic settlement seams, the bridge frame mainly utilizes a reserved butt joint seam, an expansion joint is easy to make the cable bridge frame ventilate and make dust enter, and the cable life is affected.

Owner:陈磊

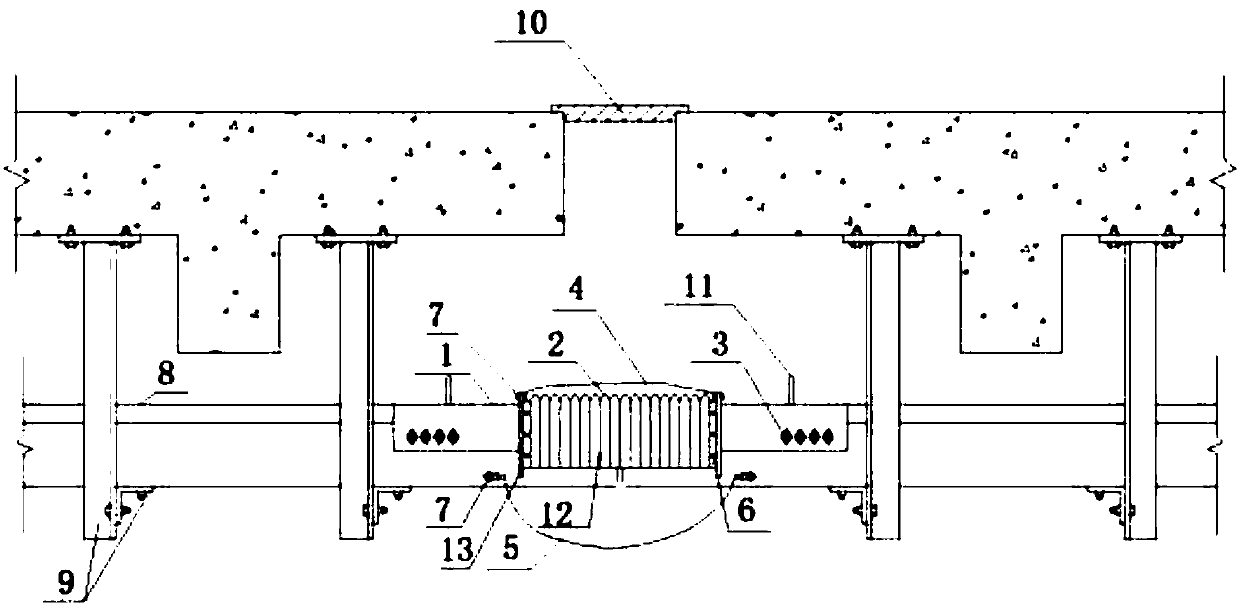

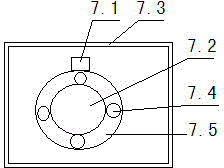

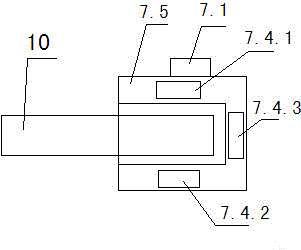

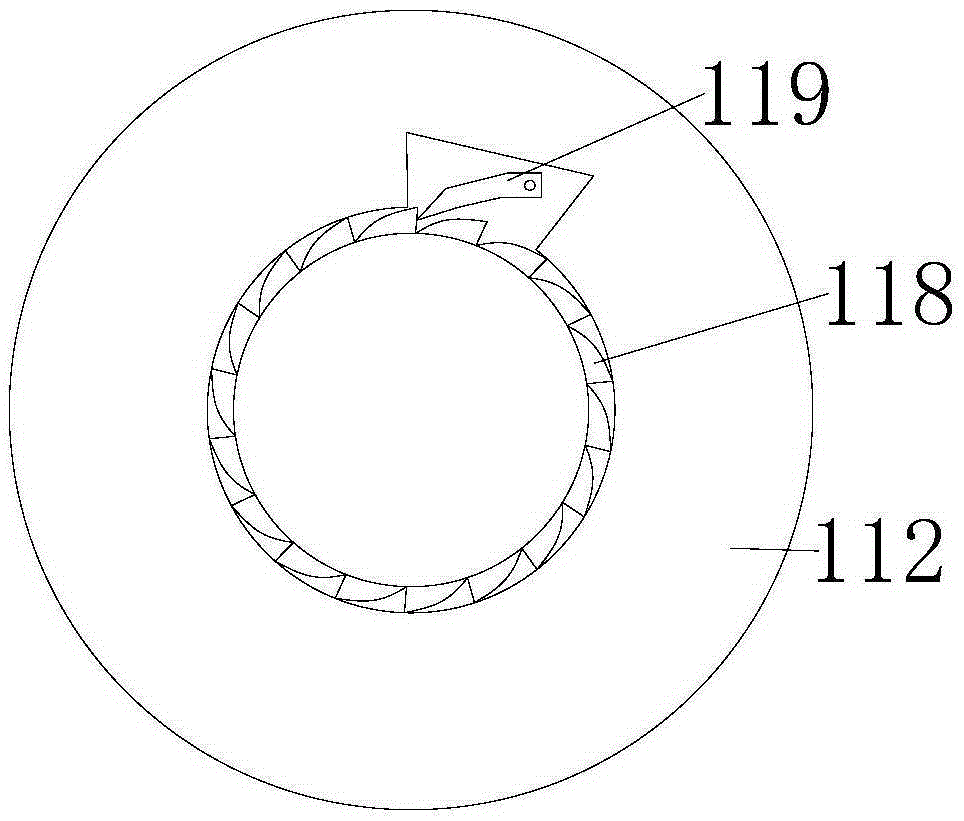

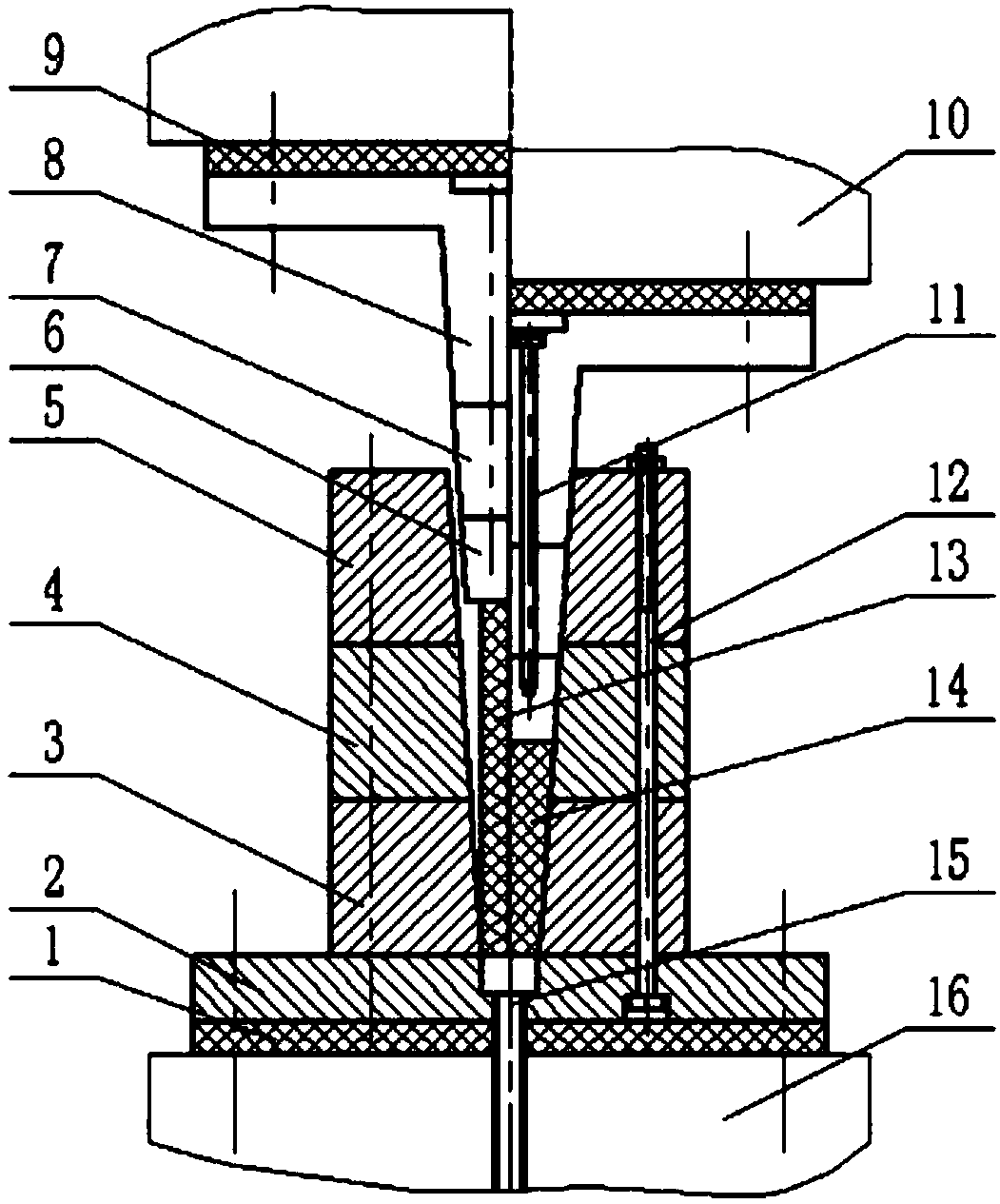

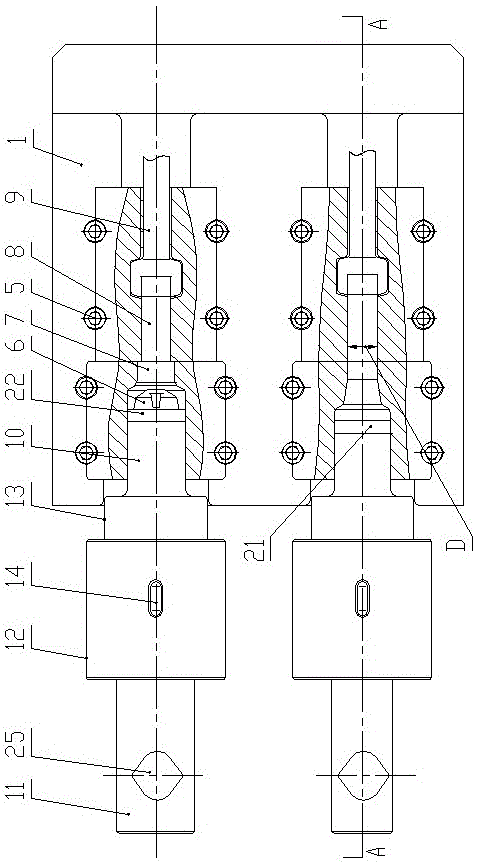

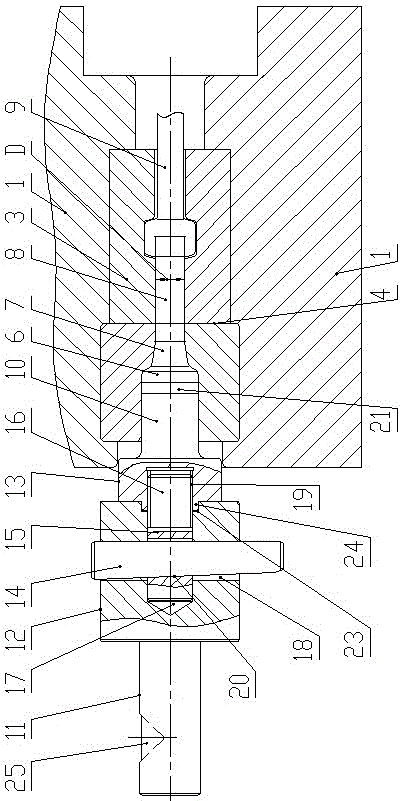

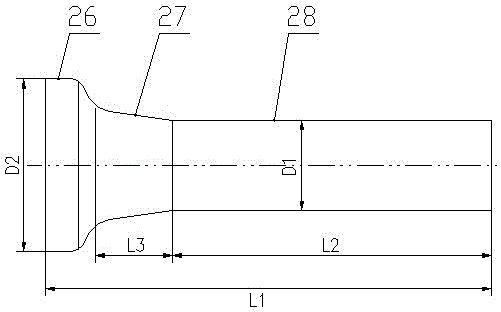

Compression die

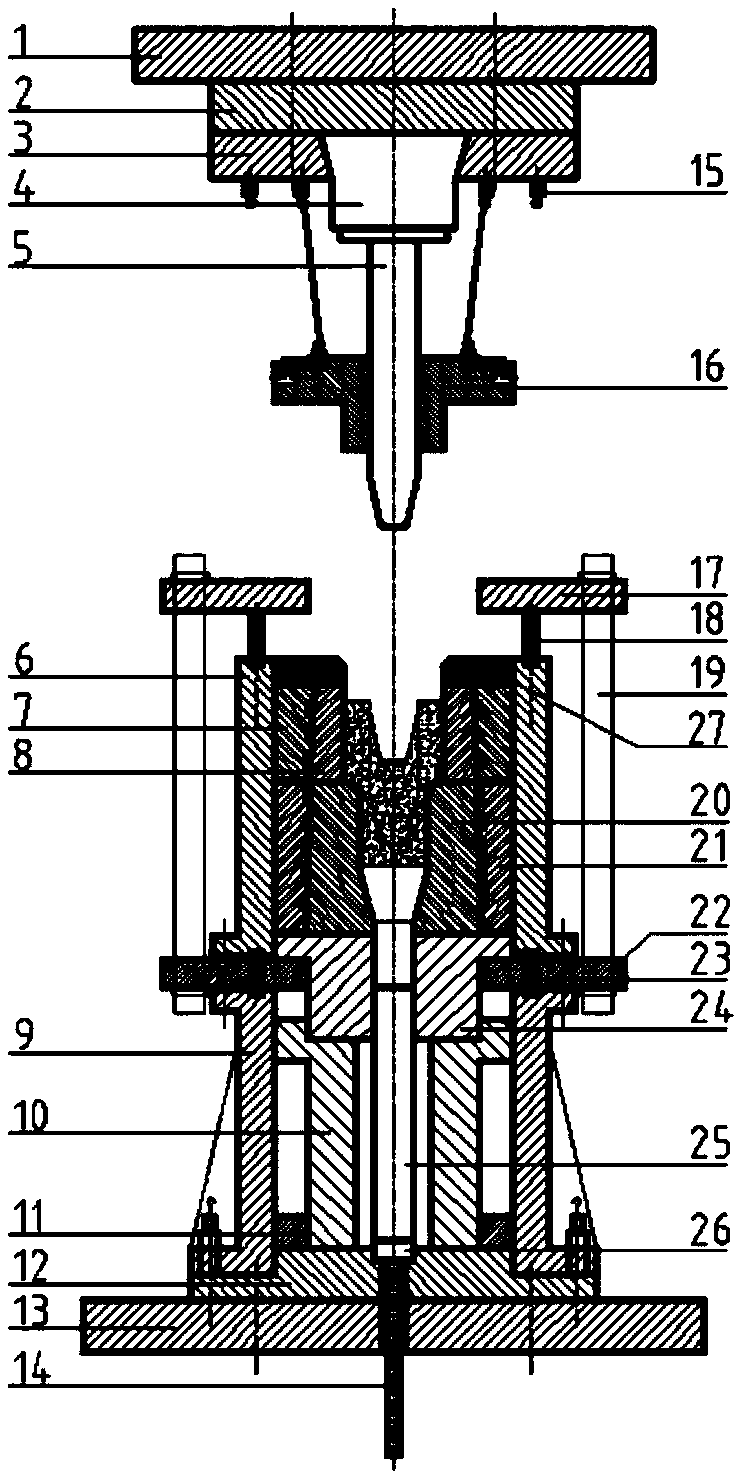

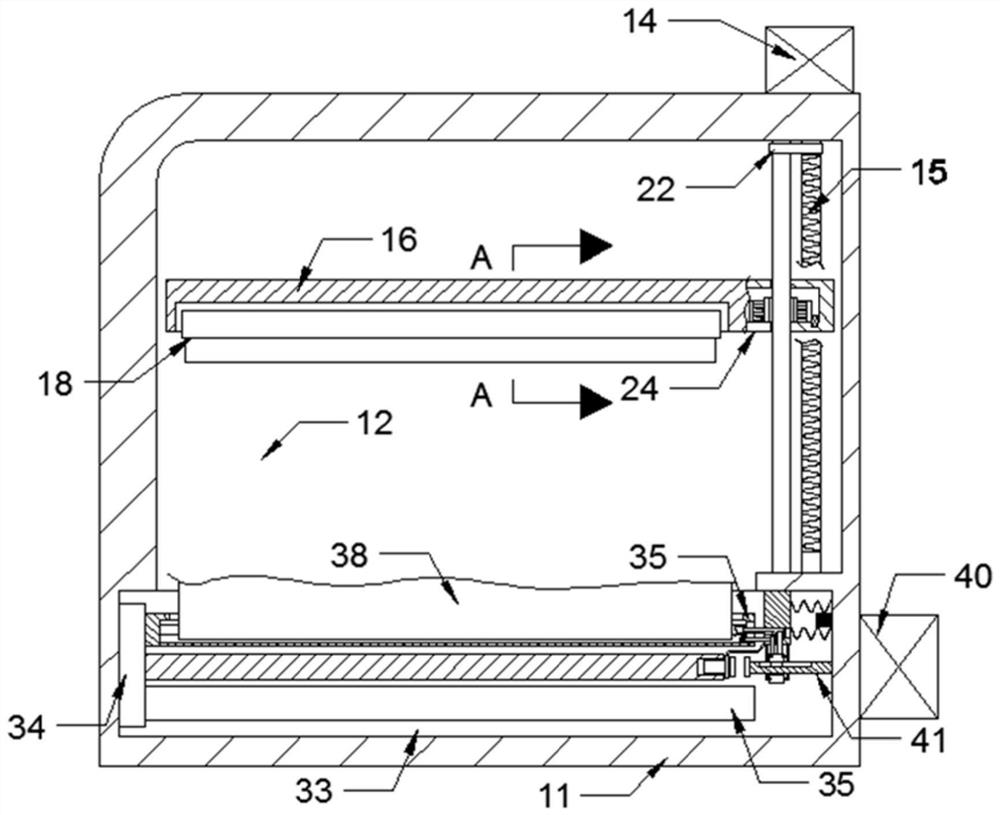

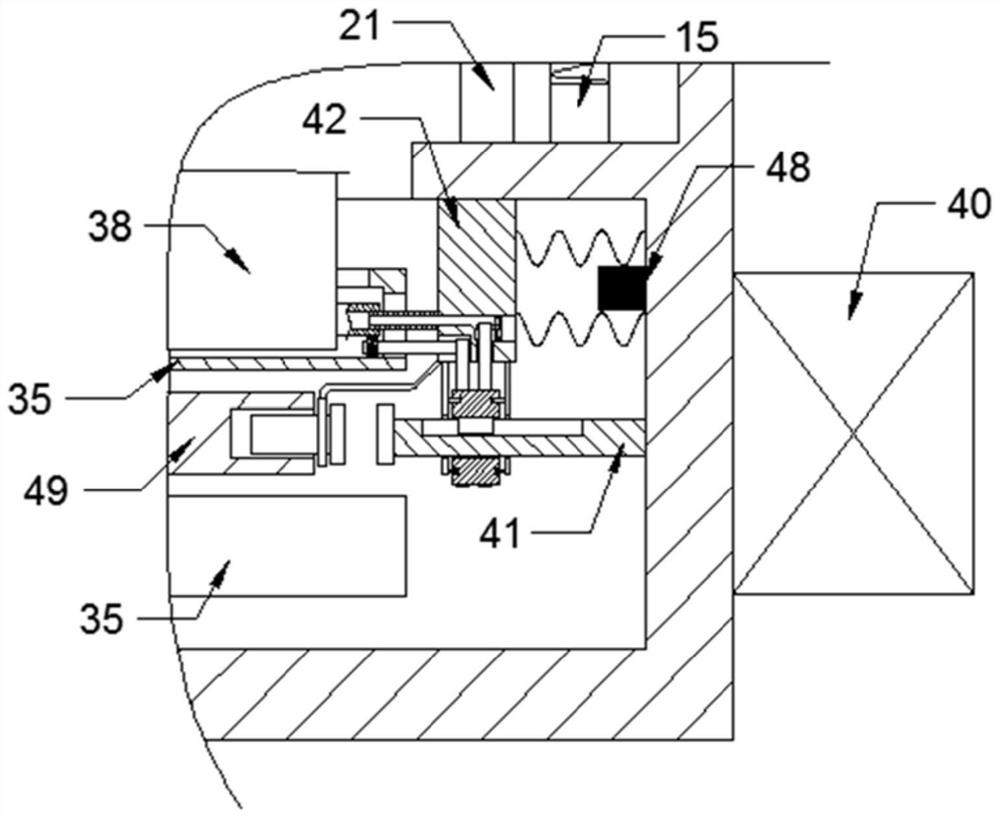

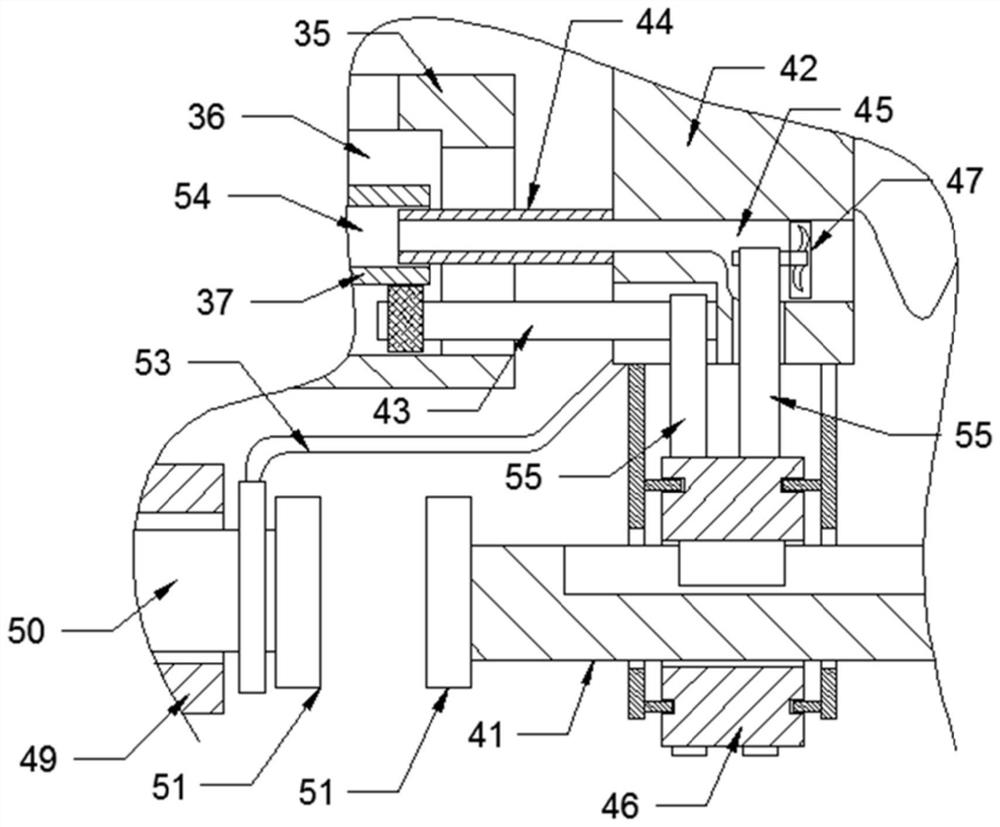

ActiveCN108941232AReduce deformation resistanceImprove stabilityExtrusion diesShape changeEngineering

The invention discloses a compression die. The compression die is mainly composed of an upper die body and a lower die body, wherein the upper die body comprises an upper die plate 1, an upper base plate 2, an upper fixing plate 3, a male die seat 4, a first male die 5, hanging rings 15, a second male die 16 and the like; and the lower die body comprises an upper sleeve 6, a first prestress ring 7, a first female die 8, a lower sleeve 9, a first supporting barrel 10, an annular plate 11, a lower base plate 12, a lower die plate 13, an ejector rod 14, an upper pressing ring 17, upper cushion blocks 18, pull rods 19, a second female die 20, a second prestress ring 21, a lower pressing ring 22, lower cushion blocks 23, a second supporting barrel 24, a transition rod 25, ejector blocks 26, a cover plate 27, rolling sector rings 28 and the like. By means of the compression die, the problems that shape changing, difficult unloading and folding are caused by the compression reverse acting force can be solved, and the compression die can be applied to forming of a blind hole member which is locally wall-thickened.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

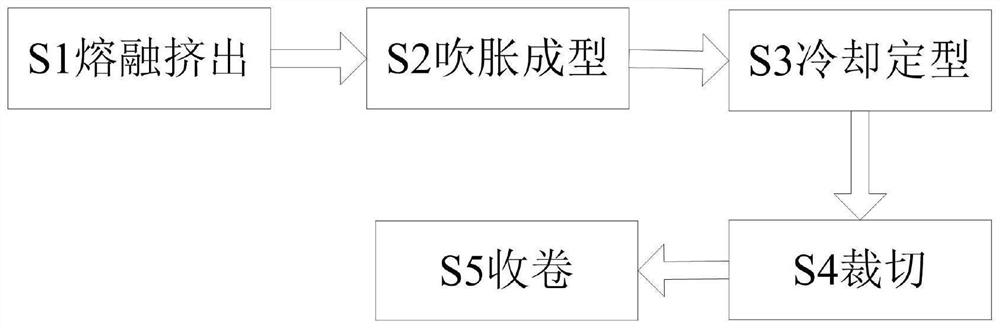

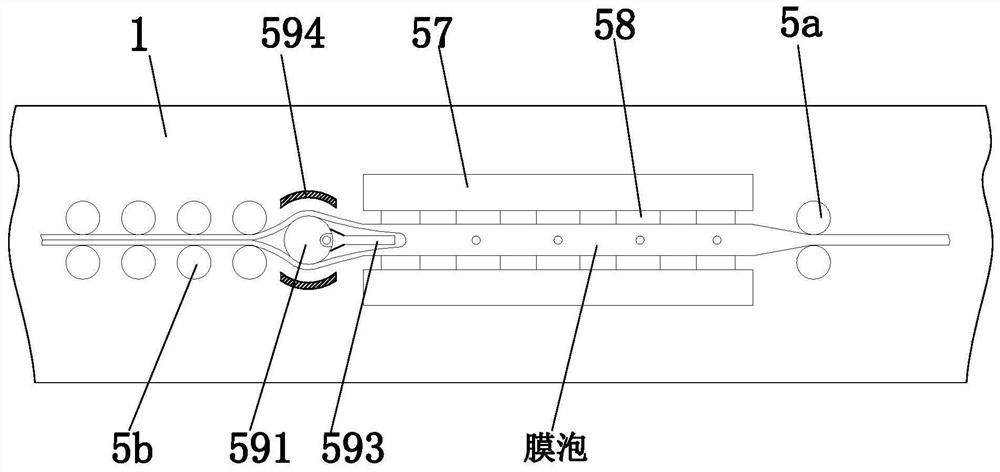

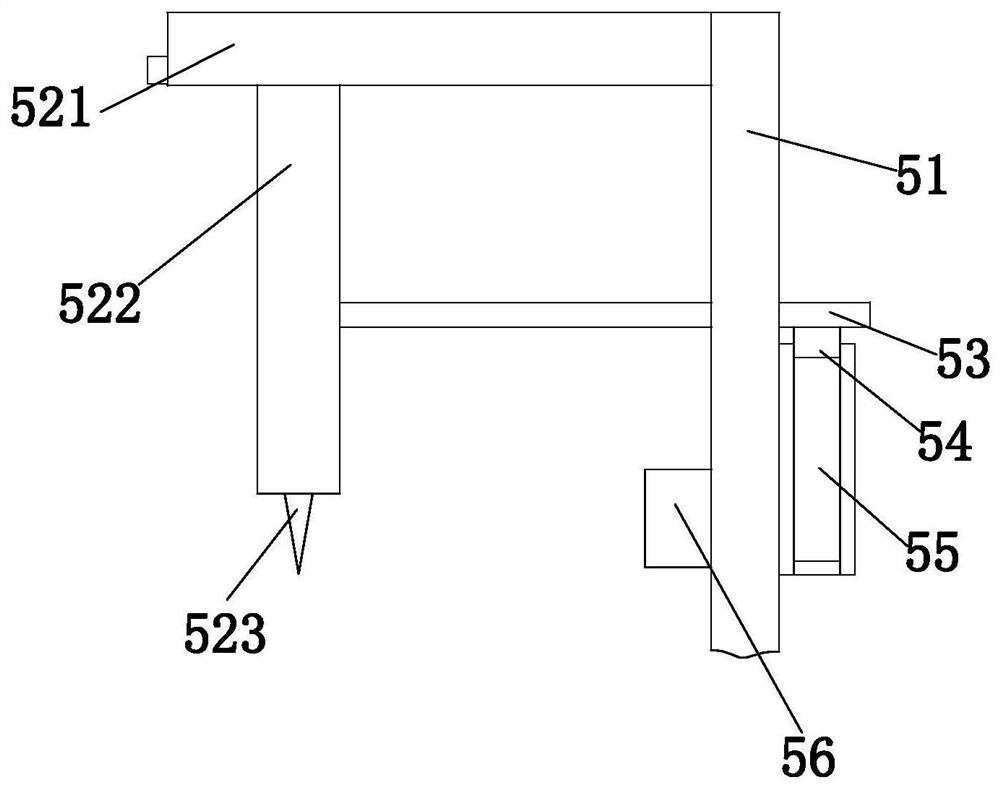

Preparation process of biodegradable plastic film

InactiveCN111923360AAvoid irregularitiesPrevent retractionMetal working apparatusSuction forcePunching

The invention relates to a preparation process of a biodegradable plastic film, which uses cutting equipment. The cutting equipment comprises a bottom plate, a winding roller, an unwinding roller, a winding motor and a cutting device. The preparation process of the plastic film by adopting the cutting equipment specifically comprises the following process flow of melt extrusion, huffing and molding, cooling and shaping, cutting and winding; and the cutting device comprises a mounting frame, a punching mechanism, a connecting frame, a connecting sliding block, a rotating cam, a rotating motor,a workboard, a stretching sucking disc and a cutting mechanism. According to the preparation process, after bubbles are stretched outwards, a plurality of round holes are formed in the upper ends of the bubbles by the punching mechanism, and then the upper ends of the bubbles are cut by the cutting mechanism. Compared with a bubble cutting method which directly uses a blade, the resistance of a cutting blade is obviously reduced during operation, the condition of irregular cut edges due to pulling can be prevented, and in addition, the cut edges can be prevented from being retracted inwards byapplying suction force to the edge of the film after cutting is performed.

Owner:仇芳

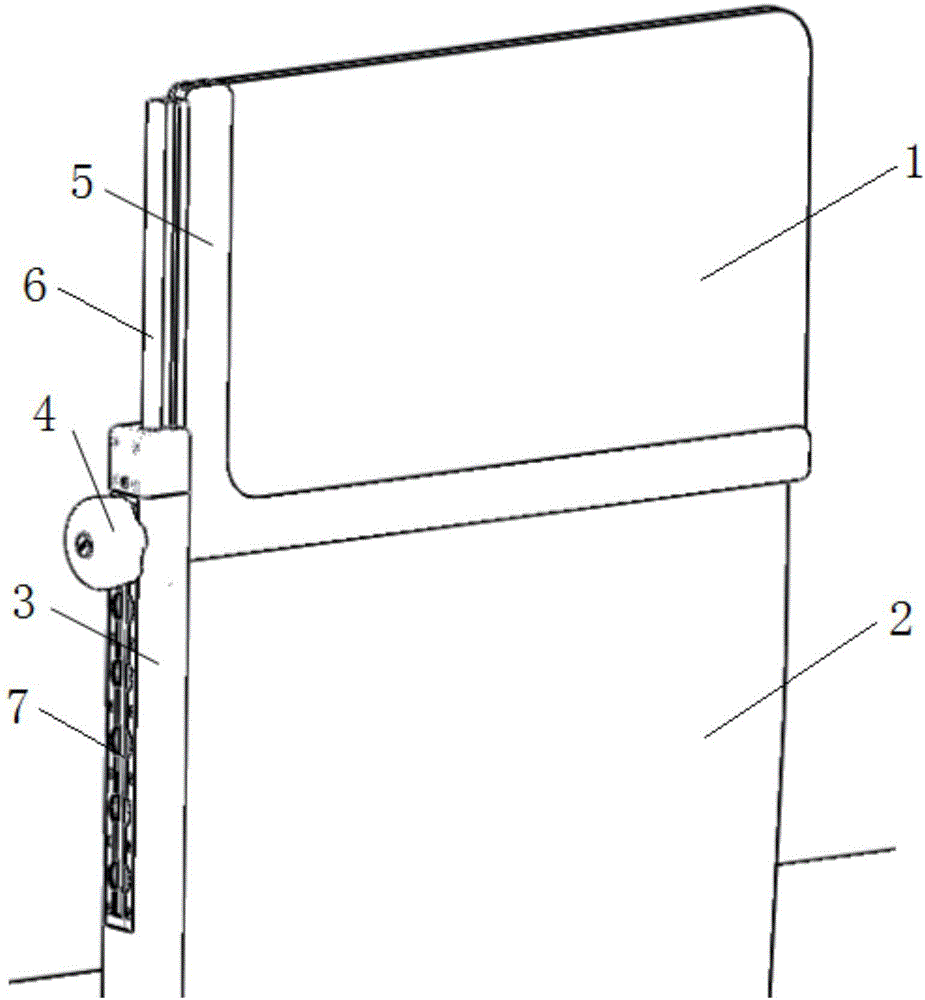

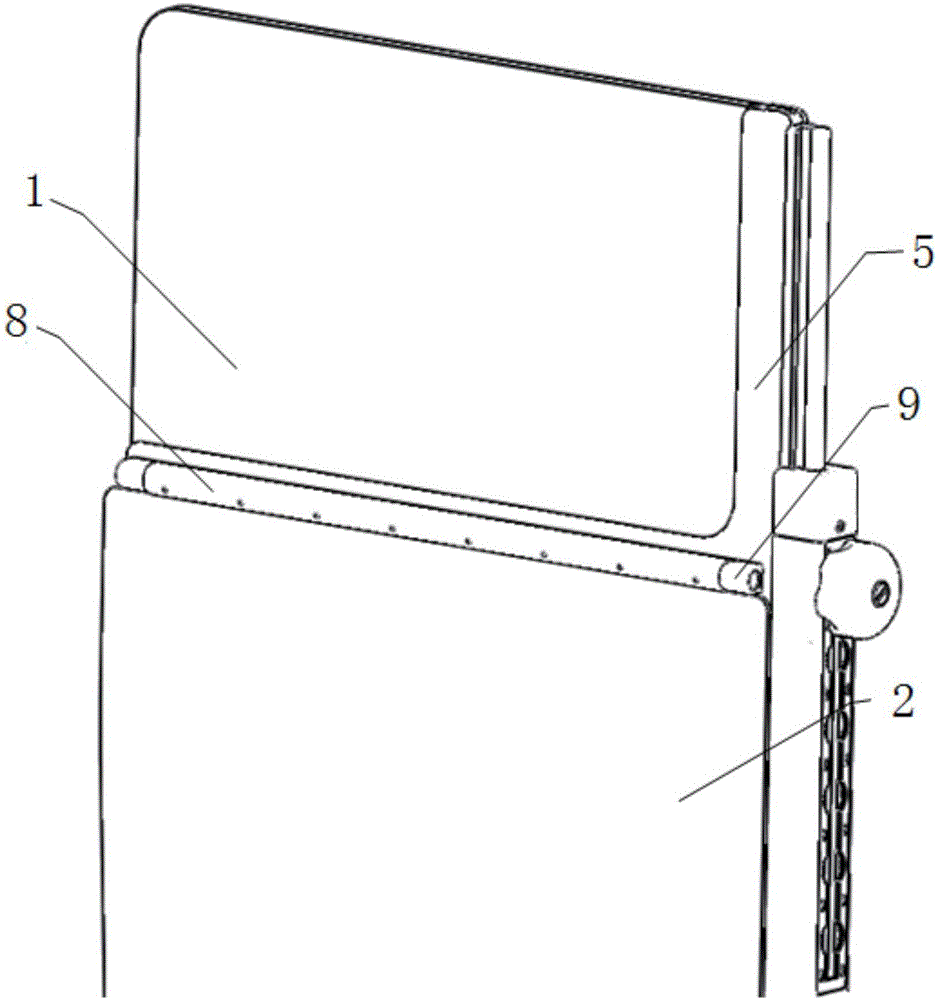

Protective curtain device

The invention relates to the technical field of medical apparatuses and discloses a protective curtain device. The protective curtain device comprises a protective screen, a protective curtain, a lifting rod and a handle. The protective curtain is arranged below the protective screen, the protective curtain and the protective screen are connected through a supporting plate, a connection rod is fixedly connected to the upper end of the protective curtain, sleeves corresponding to the two ends of the connection rod are arranged on the side faces of the supporting plate, and the two ends of the connection rod are sleeved with the sleeves and can rotate up and down around the sleeves. Sliding rails are arranged on the side edges of the protective screen, a sliding groove is formed in one side of the lifting rod, and the protective screen can drive the protective curtain to slide up and down along the lifting rod. On one hand, a lead curtain can be prevented from being frequently folded and damaged due to fatigue; on the other hand, the height requirement of operators in different heights for a protective device is met.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

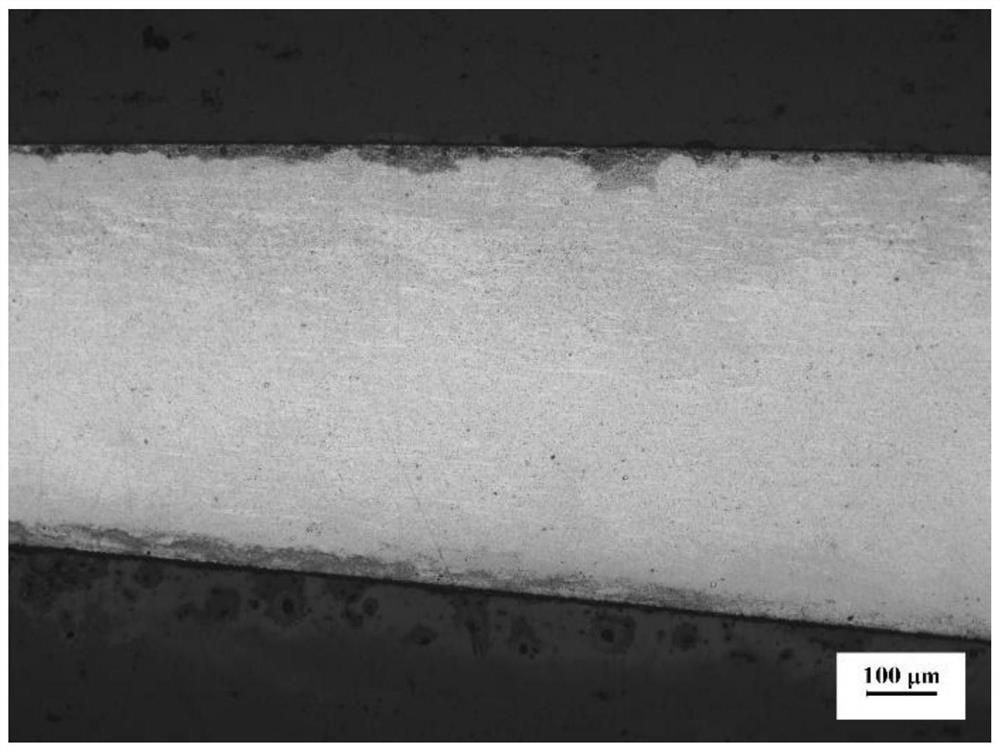

Spinning and drawing process of fixing metal film casing for printer and duplicator and the locking fixture therefor

The present invention belongs to the field of precise machining technology, is improved machining process of fixing metal film casing for printer and duplicator, and features that the stainless steel pipe blank after pre-treatment is spun and stretched in a spinning and stretching machine with stretching mold to form high accuracy seamless stainless steel casing. The stainless steel casing may be used in making fixing metal film with high surface roughness, no pit, no crease, no cracking, long service life and high heat resistance.

Owner:HEFEI JIANGHANG AIRCRAFT EQUIP CORP LTD

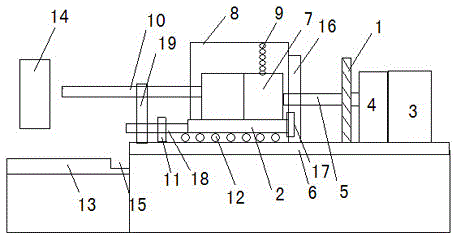

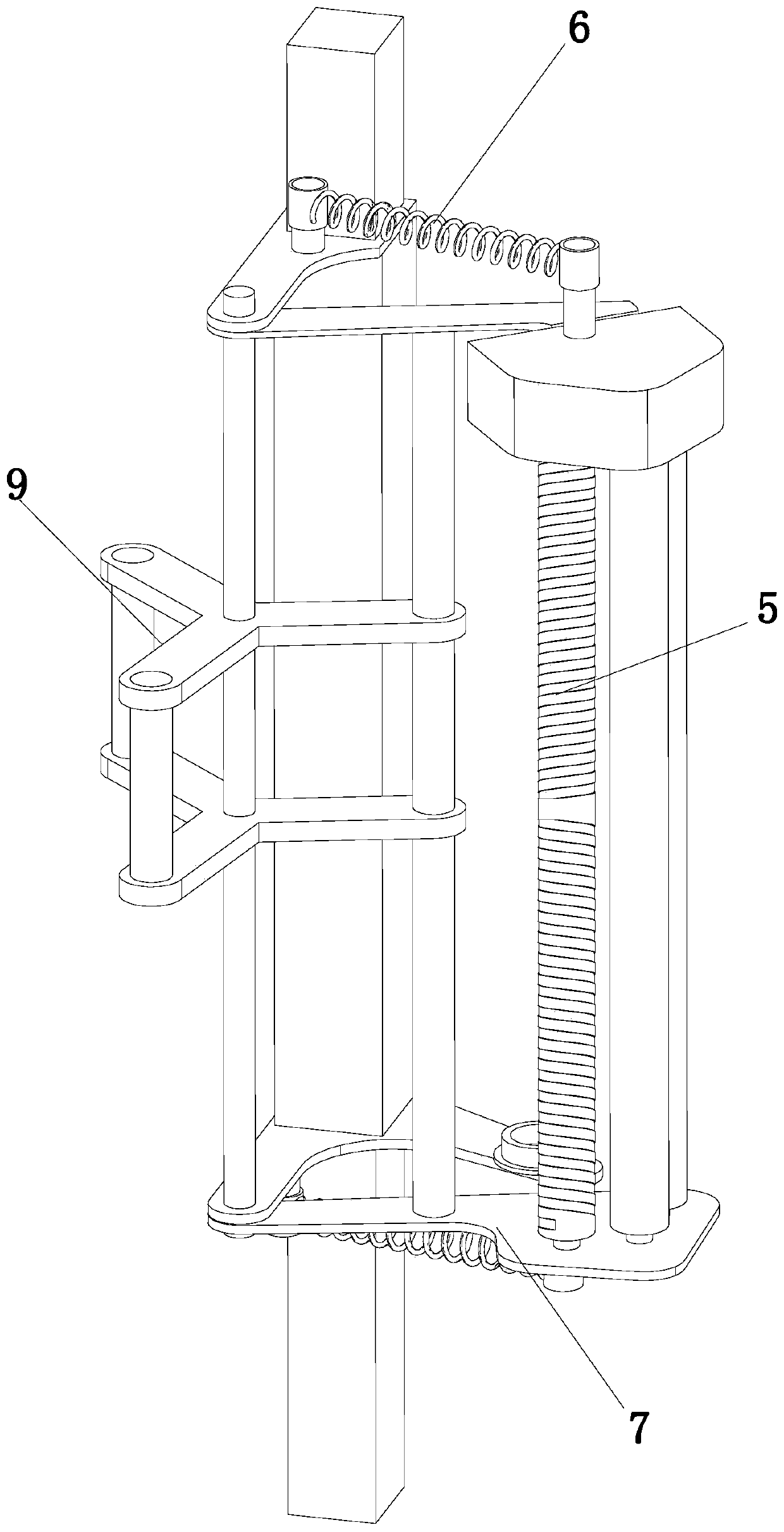

Steel pipe end vibration upsetting joint device and method

InactiveCN104525812AEasy to achieve the purpose of thermal processingDislocation increaseForging/hammering/pressing machinesThermal deformationGraphite

The invention relates to a steel pipe end vibration upsetting joint device and method. The method includes the following steps that (1) a steel pipe end is heated through a coil heating device; (2) the steel pipe end is put at a station of a machine tool, and a non-heated portion is fixed on a base of one end of a machine tool platform; (3) colloidal graphite or a high-temperature lubricating agent is applied in a mold cavity of a vibration device; (4) a push plate device at the other end of the operation platform is started, the platform is linearly pushed by means of a pushing force of a push rod to approach the workpiece end, and the mold cavity of the vibration device is matched with the steel pipe end; (5) an auxiliary vibration exciter and a vibration exciter of the vibration device are started so that the vibration device can perform X and Z direction vibration and upsetting is achieved after multi-time extrusion vibration. The steel pipe end vibration upsetting joint device and method has the advantages that the vibration device is applied to upset-extruding of the steel pipe end in stead of traditional large hydraulic devices, the purpose of hot working of the steel material end can be easily achieved, and the thermal deformation effect of the steel pipe end is excellent by means of vibration and impact of hot forging force.

Owner:崔连义

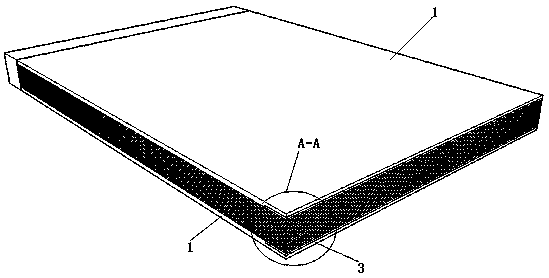

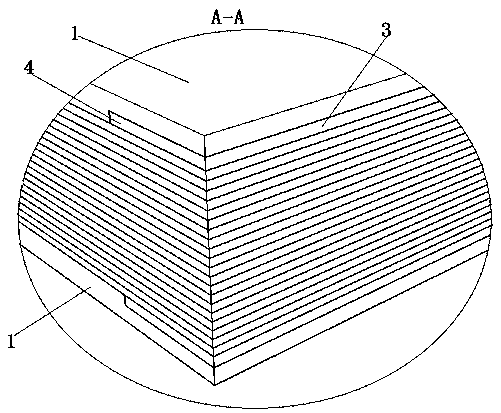

Exercise book capable of preventing shortsightedness

InactiveCN110091646APrevent corners from foldingIncrease roughnessBook keepingToysAdhesiveEngineering

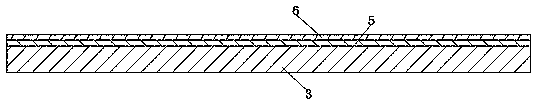

The invention relates to the technical field of school supplies and discloses an exercise book capable of preventing shortsightedness. The exercise book comprises a plurality of inner pages, magneticpowder, first ink coatings and second ink coatings, wherein the inner pages are disposed between two symmetrical covers, and the inner pages are in color capable of preventing shortsightedness; the magnetic powder is disposed on the two covers through adhesives, and the two covers can be mutually attracted through the magnetic powder; each first ink coating is disposed on the corresponding inner page, and the colors of the first ink coatings are different from those of the inner pages; and the second ink coatings are disposed on the first ink coatings or the inner pages. Under the condition ofno influence on normal use, the roughness of printed surfaces of the inner pages can be improved, the reflection factor of reflected light of the pages is lowered, thus stimulus of the page reflectedlight to eyes is reduced, the shortsightedness is prevented more effectively, corners of the exercise book are prevented from being folded when the exercise book is not in use, meanwhile students canbe reminded of making the exercise book moving upwards, and thus the a certain distance between the eyes and the exercise book can be kept.

Owner:李向军

Locking clamp for spinning and drawing process of fixing metal film casing for printer and duplicator and the

The present invention belongs to the field of precise machining technology, is improved machining process of fixing metal film casing for printer and duplicator, and features that the stainless steel pipe blank after pre-treatment is spun and stretched in a spinning and stretching machine with stretching mold to form high accuracy seamless stainless steel casing. The stainless steel casing may be used in making fixing metal film with high surface roughness, no pit, no crease, no cracking, long service life and high heat resistance.

Owner:HEFEI JIANGHANG AIRCRAFT EQUIP CORP LTD

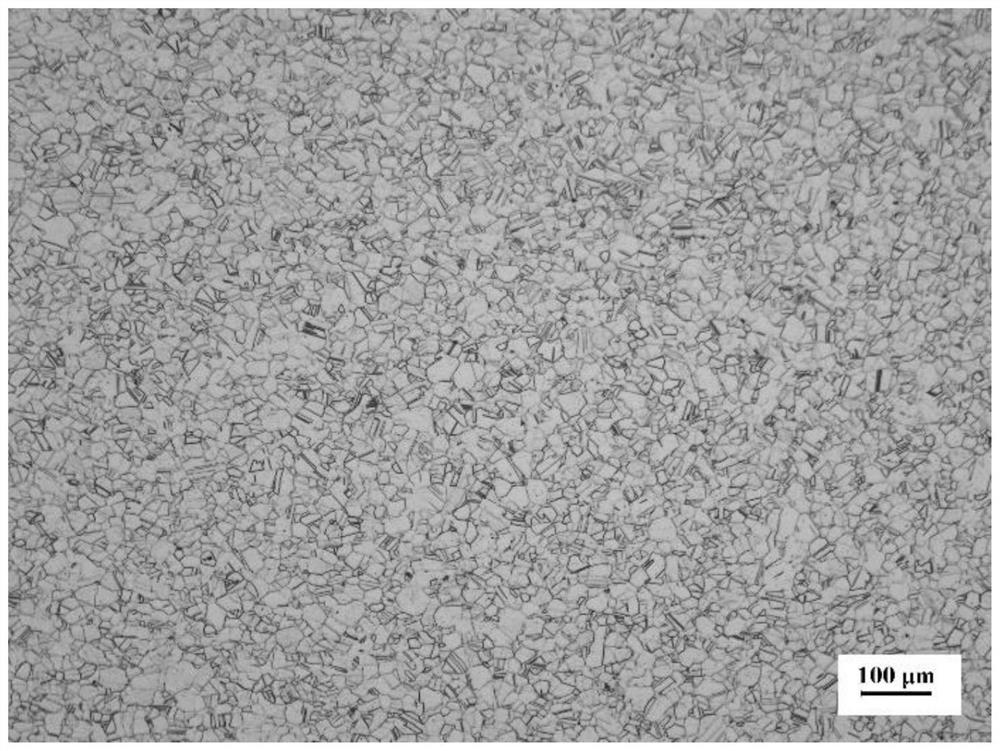

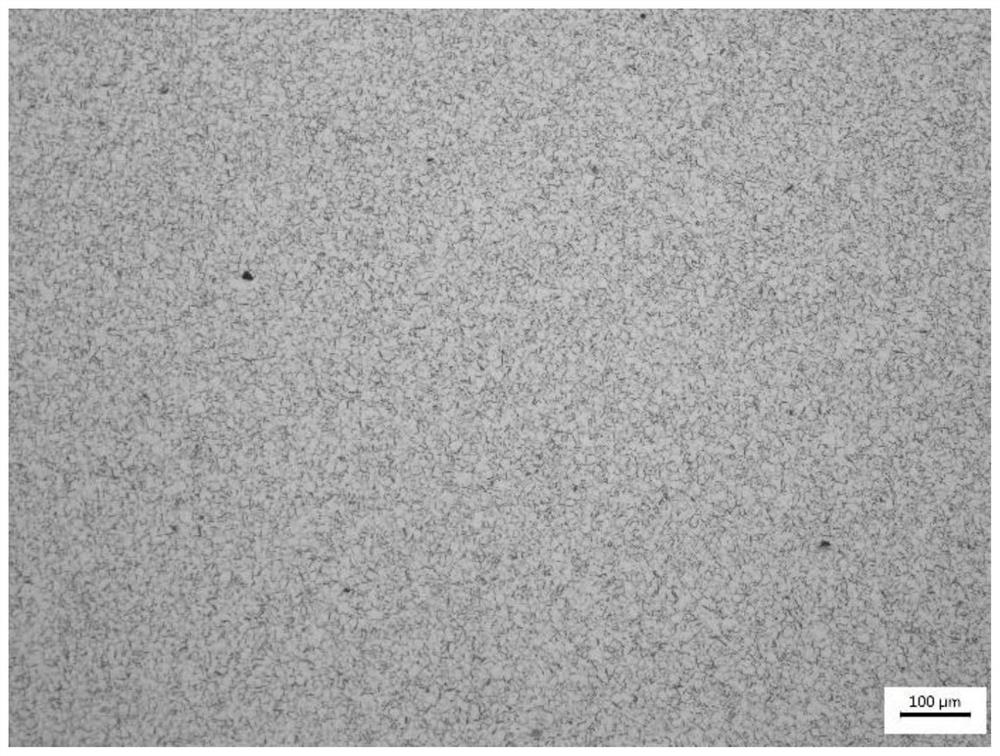

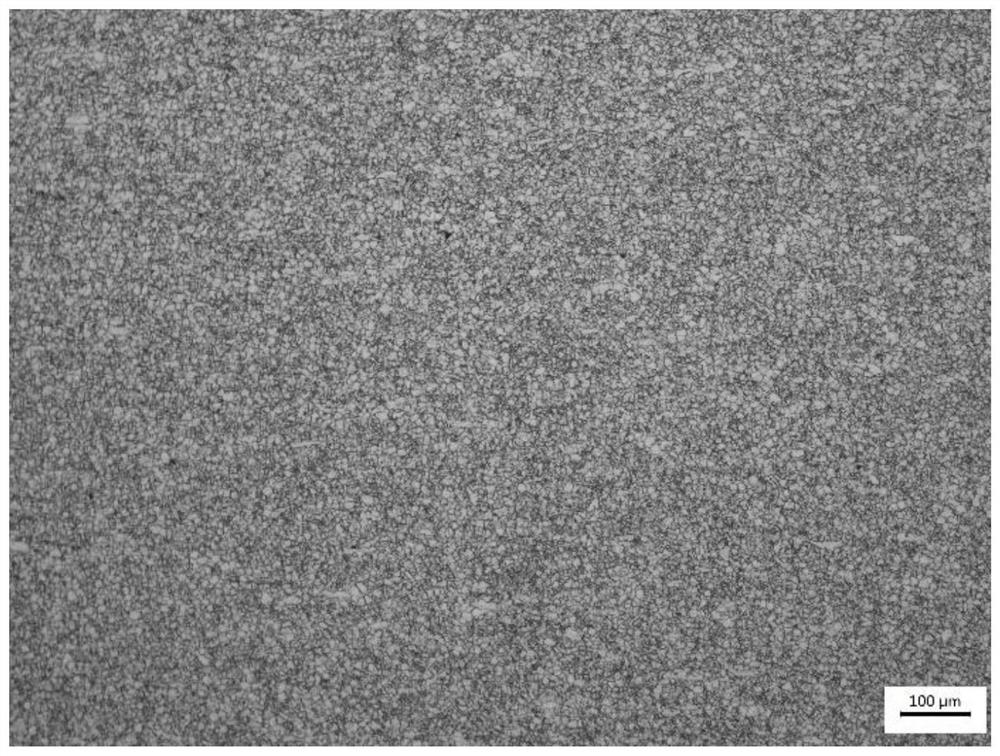

Deformation high-temperature alloy blade forged piece and precision forging method thereof

ActiveCN112108597AHomogeneous tissue stateGood mechanical propertiesExtrusion control devicesPretreated surfacesSuperalloyAero engine

The invention discloses a deformation high-temperature alloy blade forged piece and a precision forging method thereof. The precision forging method comprises the following steps that S1, a high-temperature alloy bar material is subjected to heat preservation for 8-60 min at the temperature of 950-1150 DEG C, and extrusion is conducted; S2, heating is conducted for 8-60 min at the temperature of 910-1060 DEG C, and head upsetting is conducted; S3, heating is conducted for 6-60 min at the temperature of 910-1060 DEG C, and pre-forging is conducted; and S4, heating is conducted for 4-60 min at the temperature of 910-1060 DEG C, finish forging is conducted, and a finish forged piece is obtained. The invention further discloses the deformation high-temperature alloy blade forged piece obtainedthrough the precision forging method. The precision forging method and the deformation high-temperature alloy blade forged piece have the beneficial effects that precision forging forming of the blade forged piece based on a novel nickel-based high-temperature alloy GH4169D material is achieved, an obtained GH4169D alloy blade can meet the requirements for the shape and size of an aero-engine blade and for the performance at the high temperature of 650 DEG C to 750 DEG C, and the requirement for the temperature bearing capacity of a blade material due to the fact that the performance and theuse requirement of an aero-engine are continuously improved is met.

Owner:BEIJING CISRI GAONA TECH +1

Aluminum alloy steering joint machining process

InactiveCN112222770AEasy to shapeLess prone to fatigue crackingMaintainance and safety accessoriesIndustrial manipulatorMachining process

The invention relates to an aluminum alloy steering joint machining process. The aluminum alloy steering joint machining process is characterized by comprising the following steps that S1, blanking isconducted, wherein a 6082 aluminum alloy is used as a raw material, and an extrusion aluminum bar sawing machine is adopted for sawing according to phi 26-125; S2, heating is conducted for the firsttime; S3, a blank is prepared; S4, heating conducted for the second time; S5, rough forging is performed; S6, heating is performed for the third time; S7, finish forging is conducted; S8, trimming isconducted, wherein a steering joint blank final forge piece obtained after S7 is transferred into a forging press through an industrial mechanical arm to be forged and pressed, and waste edges of thesteering joint blank final forge piece are cut off; S9, initial inspection is conducted, wherein the final forging piece of the steering joint blank subjected to S8 is inspected according to a drawing; S10, heat treatment is conducted; S11, final inspection is conducted, wherein appearance and size inspection is conducted on the steering joint blank final forge piece subjected to heat treatment inthe step S10; and S12, packaging is conducted, wherein the steering joint blank final forge piece qualified through final inspection in the step S11 is packaged. The method has the beneficial effectsthat the integrally forged and pressed steering joint is good in forming; fatigue cracking is not likely to happen; and the defects of folding, hole shrinkage and the like are avoided.

Owner:RUIAN LIANZHONG AUTO PARTS

Paper board producing unit

ActiveCN105328974ANo foldingWill not print lighter, etc.Lamination ancillary operationsLaminationCardboardPulp and paper industry

The invention provides a paper board producing unit, and belongs to the field of paper board production devices. The paper board producing unit comprises a machine frame, an upper half piece, a lower half piece, a squeezing mechanism and four linkage mechanisms. The squeezing mechanism comprises a pressing cylinder, a first slide block and a first reset spring. A positioning slide way is arranged on the machine frame. The first slide block is arranged in the positioning slide way in a sliding mode. The pressing cylinder is arranged at the top end of the first slide block in a rotating mode. The linkage mechanisms are arranged between the pressing cylinder and a gauge roller and between the gauge roller and a front guide roller and used for making the pressing cylinder, the gauge roller and the front guide roller synchronously move. The pressing cylinder, the gauge roller and the front guide roller are made to synchronously move through the linkage mechanisms, the pressing cylinder presses surface paper of a surface paper cylinder, the pressing cylinder drives the surface paper cylinder to rotate synchronously while rotating, the surface paper between the pressing cylinder and the gauge roller and the surface paper between the gauge roller and the front guide roller are both kept tensioned, pattern printing incompleteness caused by surface paper looseness is avoided, and meanwhile the quality of paper boards is prevented from being influenced by surface paper overlapping.

Owner:惠州市展华实业有限公司

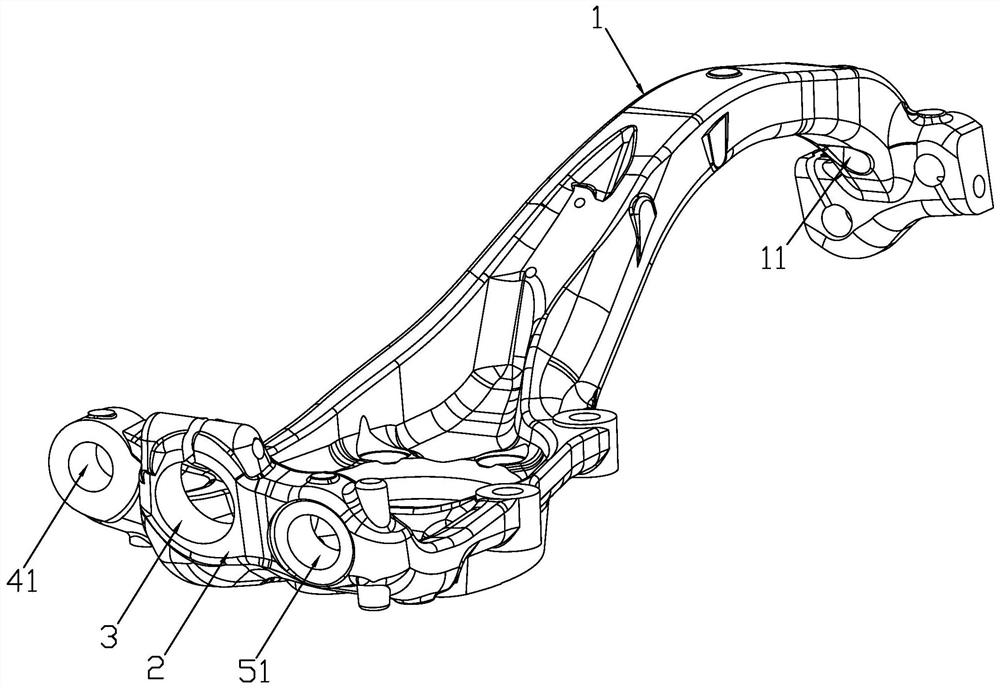

Aluminum alloy steering knuckle and processing process thereof

InactiveCN112222769AEasy to shapeLess prone to fatigue crackingMaintainance and safety accessoriesStructural engineeringMachining process

The invention relates to an aluminum alloy steering knuckle which comprises a steering knuckle body. The aluminum alloy steering knuckle is characterized in that the steering knuckle body is equippedwith a damping pull rod, wherein a damping hole, a steering pull rod conical hole and a lower swing arm pull rod conical hole are formed in the damping pull rod; one side of the damping pull rod is equipped with a clamp head; and a bearing hole is formed in the clamp head. The aluminum alloy steering knuckle has the beneficial effects that: the integrated forced and processed steering knuckle is good in formation, is not liable to have fatigue crack, and is free of defects such as folding and hole shrinking.

Owner:RUIAN LIANZHONG AUTO PARTS

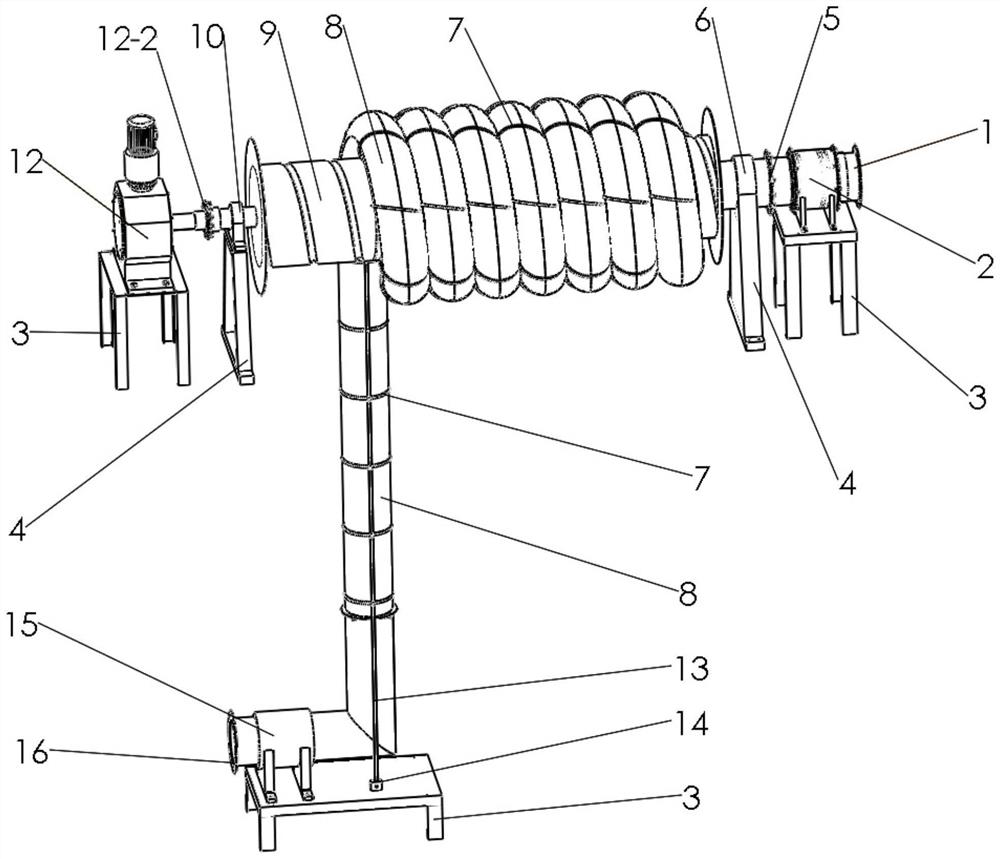

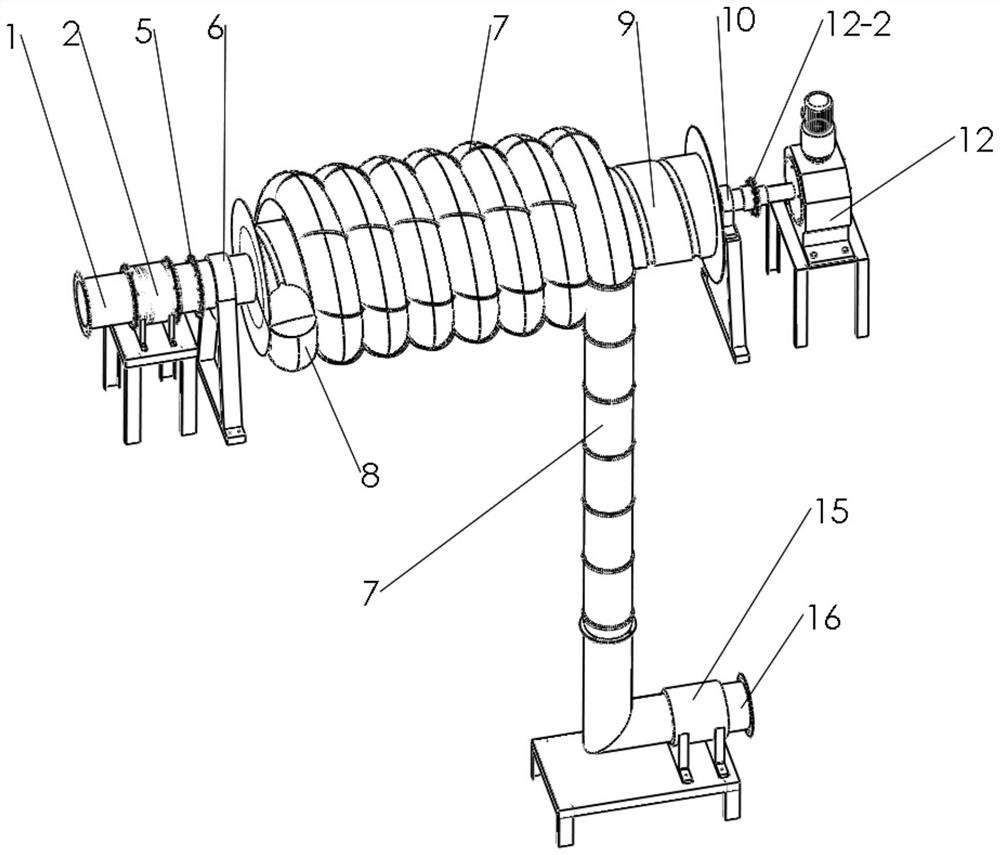

Flexible air pipe winding and unwinding device for air supply

ActiveCN113247713ARealize automatic retractionMeet the requirements of mobile air supplyMechanical apparatusSpace heating and ventilation safety systemsStructural engineeringMechanical engineering

The invention relates to a flexible air pipe winding and unwinding device for air supply. The device comprises an air pipe winding drum assembly, a flexible air pipe, two winding drum seats, a rotary air inlet assembly and a rotary driving assembly for driving the air pipe winding drum assembly to rotate, the air pipe winding drum assembly comprises a winding drum main body, a winding drum air pipe shaft and a winding drum rotating shaft, the rotary air inlet assembly comprises an air inlet pipe, a fixed air pipe and a rotary air pipe rotatably inserted into the fixed air pipe, the air outlet end of the air inlet pipe is connected with the air inlet end of the fixed air pipe, the air outlet end of the rotary air pipe is fixedly connected with the winding drum air pipe shaft, and an output shaft of the rotary driving assembly is fixedly connected with the winding drum rotating shaft. Compared with the prior art, automatic winding and unwinding of the flexible air pipe on the winding drum main body can be achieved, the requirement for movable air supply is effectively met, and the device is safe and reliable in structure and long in service life.

Owner:HUANENG POWER INT INC

Deformation high-temperature alloy blade forged piece and die forging method thereof

ActiveCN112108598APrevent coarse grainPrevent mixed crystalsPretreated surfacesExtrusion control devicesSuperalloyAero engine

The invention discloses a deformation high-temperature alloy blade forged piece and a die forging method thereof. The die forging method comprises the following steps: extrusion heating, specifically,the heating temperature is 950-1100 DEG C, and the heat preservation time is 10-60 min; extrusion forming; finish forging heating, specifically, the heating temperature is 910-1060 DEG C, and the heat preservation time is 5-60 min; and finish forging for obtaining a finish forged piece. The provided method can effectively realize the consistency of the quality of the forged pieces, increases thequalification rate of the finished forge piece and improve the quality of the finished forge piece. The invention further discloses a deformation high-temperature alloy blade forged piece obtained through the die forging method. The deformation high-temperature alloy blade forged piece has the advantages that the surface is free of cracks, and the internal structure meets the design requirement, the requirements for the shape and size of an aero-engine blade and for the performance at the high temperature of 650 DEG C to 750 DEG C can be met, and the requirement for the temperature bearing capacity of a blade material due to the fact that the performance and the use requirement of an aero-engine are continuously improved is met.

Owner:BEIJING CISRI GAONA TECH +1

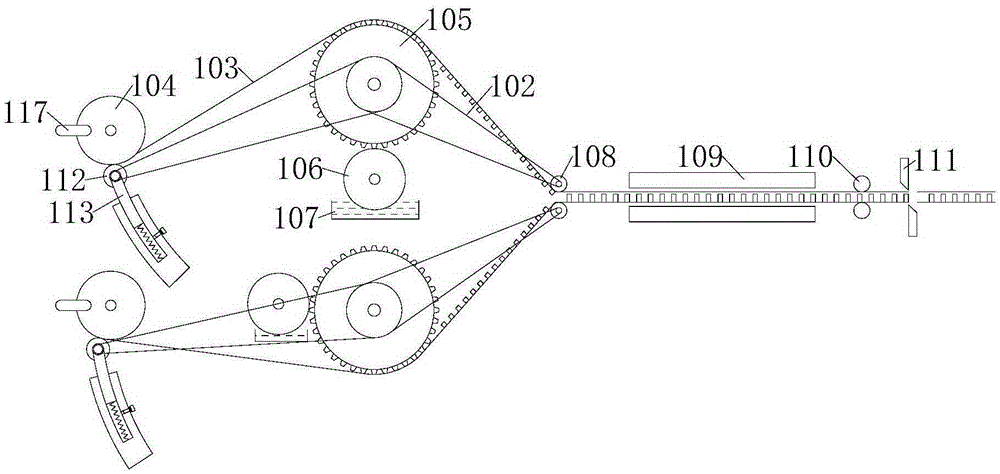

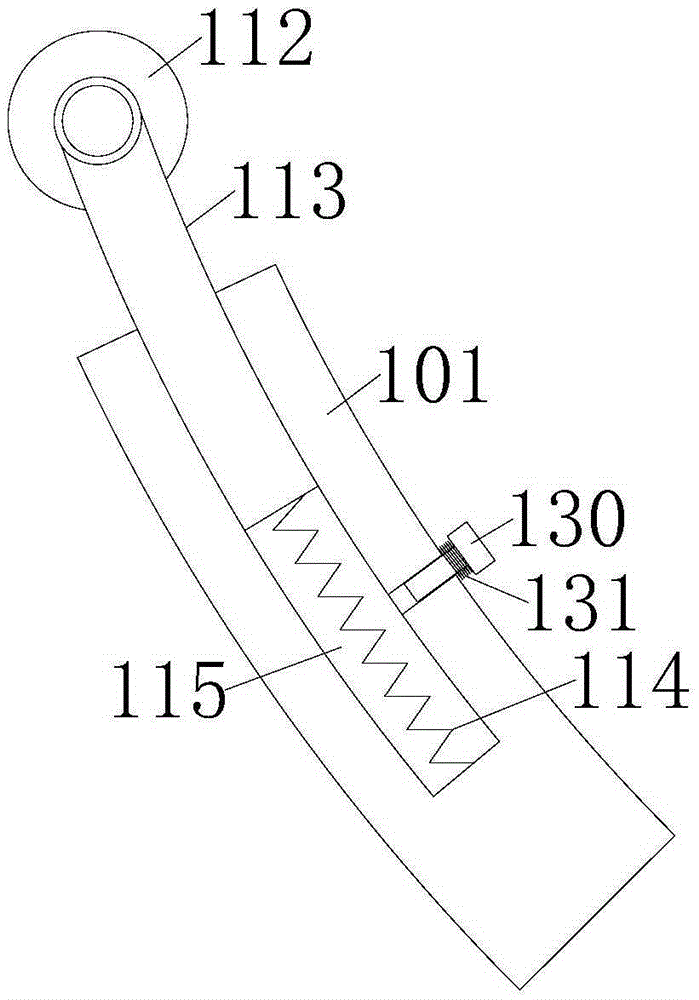

Film supply mechanism of bale wrapping machine

The invention relates to the technical field of agricultural machinery operation, in particular to a film supply mechanism of a bale wrapping machine. The film supply mechanism comprises a support rod, a guide sleeve and a clamping device and is characterized in that the support rod is vertically mounted on the bale wrapping machine, the guide sleeve sleeves the support rod, the clamping device isused for clamping a film winding roller and comprises a support platform, a guide mechanism and a pull mechanism, the support platform can support the film winding roller, the film winding roller canrotate on the support platform, the guide mechanism can constantly attach to the surface of the film winding roller, the pull mechanism is used for changing the distance between the guide mechanism and the support platform, the support platform is horizontally fixedly mounted at the bottom of the guide sleeve, the guide mechanism is in running fit with the guide sleeve through a hinge rack, the pull mechanism is arranged on the hinge rack, and the guide mechanism comprises a plurality of vertical guide rollers which are in running fit with the hinge rack. The film supply mechanism has the advantages that film folding during film discharge can be avoided by the guide mechanism, film winding roller loosening can be prevented, the film winding roller can be prevented from getting stuck, andhand pinching or excessively large pulling strength can be avoided.

Owner:德邦大为(芜湖)农机有限公司

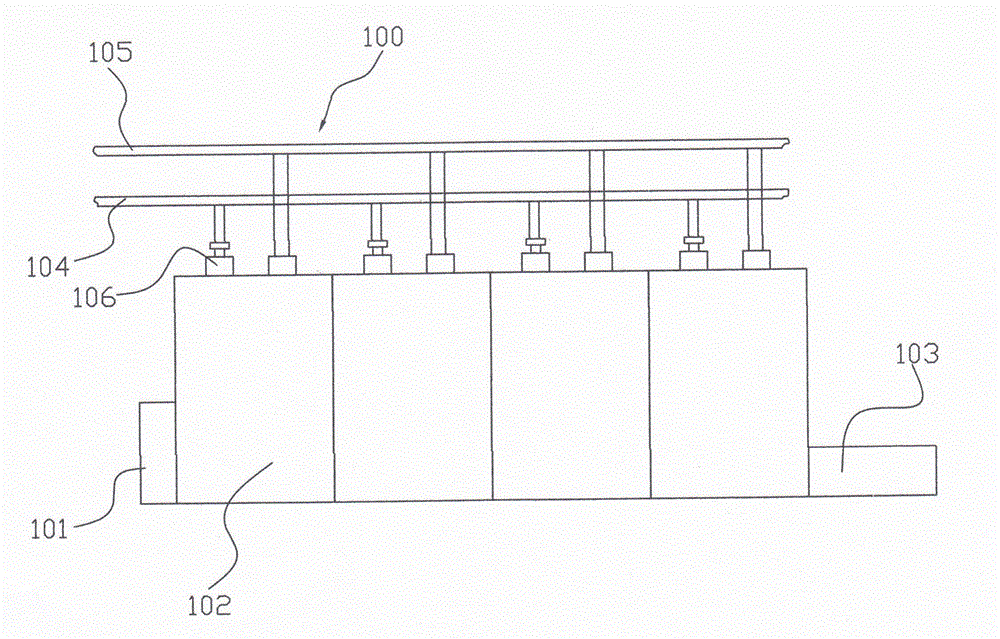

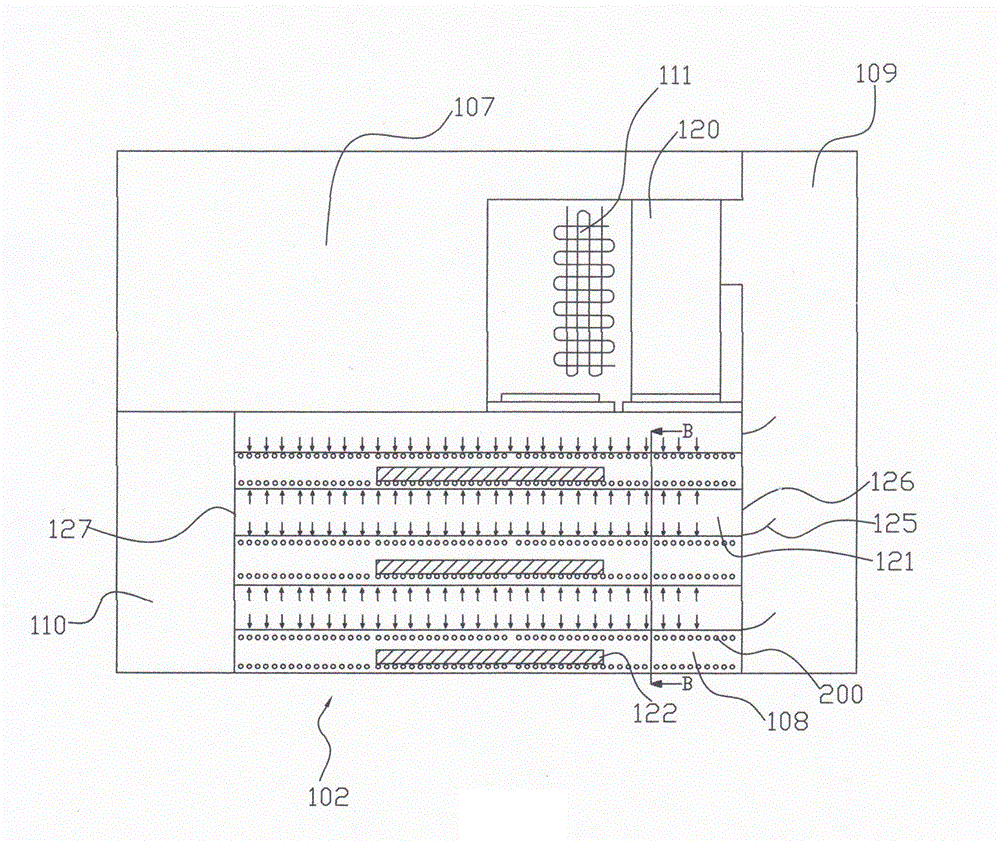

Intelligent natural leather automatic processing device provided with constant temperature and humidity control system

InactiveCN105806066AAvoid foldingAvoid wrinklesDrying gas arrangementsDrying machines with progressive movementsInlet channelControl system

The invention discloses an intelligent natural leather automatic processing device provided with a constant temperature and humidity control system. The intelligent natural leather automatic processing device comprises at least one equipment body, wherein the equipment body comprises a temperature and humidity regulator, a conveyor belt conveying device used for moving leather products, and an air inlet channel and an air return channel which communicate with the temperature and humidity regulator and the conveyer belt conveying device. By adopting the intelligent natural leather automatic processing device, folding and wrinkling of the leather products during a conveying process can be prevented; and furthermore, the conveying direction of the leather products can be safely and reliably changed, and hot air blasted over the leather products is not affected.

Owner:肖斌

Property fire safety propaganda device

PendingCN114783319ANo foldingGuaranteed display effectIdentification meansDisplay deviceElectric machinery

The property fire safety propaganda device comprises a propaganda column main body, a display cavity with a forward opening is formed in the main body, the display cavity is sealed by a transparent plate, a lifting motor is arranged in the main body, a threaded shaft extending into the display cavity is installed in the lifting motor, and the threaded shaft extends into the display cavity. A lifting plate in threaded connection with the threaded shaft is connected in the display cavity in an up-down sliding mode, multiple leaflets can be stored in the display device, the leaflets cannot be folded in the storage process, and the display effect of the leaflets is guaranteed; according to the method, the propaganda content can be automatically replaced so as to achieve the purpose of propagandizing different contents at different times, the propaganda content is updated by replacing the leaflet, and compared with an electronic display screen type propaganda method, the method has the advantages that the stability is high, and the maintenance cost is low.

Owner:尤晓敏

Integrated plastic bag multilayer combination

The invention discloses an integrated plastic bag multilayer combination, and relates to the technical field of plastic bags. The integrated plastic bag multilayer combination comprises a plurality oflayers of integrated plastic bags which are distributed in a jacket layer structure, wherein each layer of the integrated plastic bags is of an integrated structure, fillers for preventing interlayeradhesion fill the space between every two adjacent layers of the integrated plastic bags, and every two adjacent layers of the integrated plastic bags are concentrically aligned and closely attachedand sealed. The integrated plastic bag multilayer combination has the beneficial effects that raw materials are saved, the damage rate is low, the volume utilization rate is high, and the occupied space for storing and carrying is small.

Owner:JIAXING YOUYIKE SMART HOME CO LTD

A kind of processing method of high precision U-shaped titanium nail

The invention relates to a processing method for a high-precision U-shaped titanium nail. The method comprises the following steps that a straightening mechanism is manufactured by utilizing cork materials; titanium wires are conveyed in the straightening mechanism, the rotating speed of a straightening raw is controlled to be 2800-3200 revolutions / min, the wire discharging speed is 2-3.5 circles / min, the wire winding speed of a wire winding mechanism is controlled to be 6-7circles / min for wire winding; and the titanium wires wound by the wire winding mechanism are convoyed into a cutter die,a die core is attached to cutters, after a forming mechanism presses down, a pressure spring and a pre-pressing block press the titanium wires tightly, then double cutters on the two sides act to cuttitanium wires on the two sides of the cutter die at the same time, the titanium wires are bent and formed, and a titanium nail with a U-shaped structure is formed. Compared with the prior art, the process of one-time punching forming has the advantages that the process is greatly simplified, the production efficiency is improved, and the processing mode is unique, so that products are greatly improved in terms of quality, performance and processing flexibility.

Owner:上海亚尔精密零件制造有限公司

Integrated plastic bag multilayer combination

The invention discloses an integrated plastic bag multilayer combination, and relates to the technical field of plastic bags. The integrated plastic bag multilayer combination comprises a plurality oflayers of integrated plastic bags which are distributed in a nested structure; each layer of integrated plastic bag is of an integrated structure; the portion between every two adjacent layers of integrated plastic bags is filled with a filler for preventing interlayer adhesion; every two adjacent layers of integrated plastic bags are concentrically aligned and are tightly attached to each other;the side wall of the integrated plastic bag multilayer combination is divided into an upper folding spare area and a lower in-barrel loading area in the vertical direction; the perimeter of the sidewall of the folding spare area is larger than the perimeter of the in-barrel loading area; when the integrated plastic bag multilayer combination is combined with a storage barrel, the folding spare area is folded outside an opening of a storage cavity of the storage barrel; and the in-barrel loading area is positioned in the storage cavity of the storage barrel. The integrated plastic bag multilayer combination has the beneficial effects that raw materials are saved, the damage rate is low, the volume utilization rate is high, the occupied area of the space for storage is small.

Owner:JIAXING YOUYIKE SMART HOME CO LTD

Integrated plastic bag multilayer combination

The invention discloses an integrated plastic bag multilayer combination, and relates to the technical field of plastic bags. The integrated plastic bag multilayer combination comprises a plurality oflayers of integrated plastic bags which are distributed in a jacket layer mode, each layer of the integrated plastic bags is of an integrated structure, fillers for preventing interlayer adhesion fill the space between every two adjacent layer of the integrated plastic bags, every two adjacent layers of the integrated plastic bags are concentrically aligned and closely attached and sealed, the side wall or the bottom of an accommodating cavity of an integrated plastic bag multilayer combination body is provided with a volume standby area, the volume standby area is used for releasing the available volume when the integrated plastic bag is lifted away from a storage barrel, the edge area of the integrated plastic bag multilayer combination body is provided with a sealing mechanism, and theedge area of the integrated plastic bag multilayer combination body is provided with a lifting handle mechanism. The integrated plastic bag multilayer combination has the beneficial effects that rawmaterials are saved, the damage rate is low, the volume utilization rate is high, and the occupied space for storing and carrying is low.

Owner:JIAXING YOUYIKE SMART HOME CO LTD

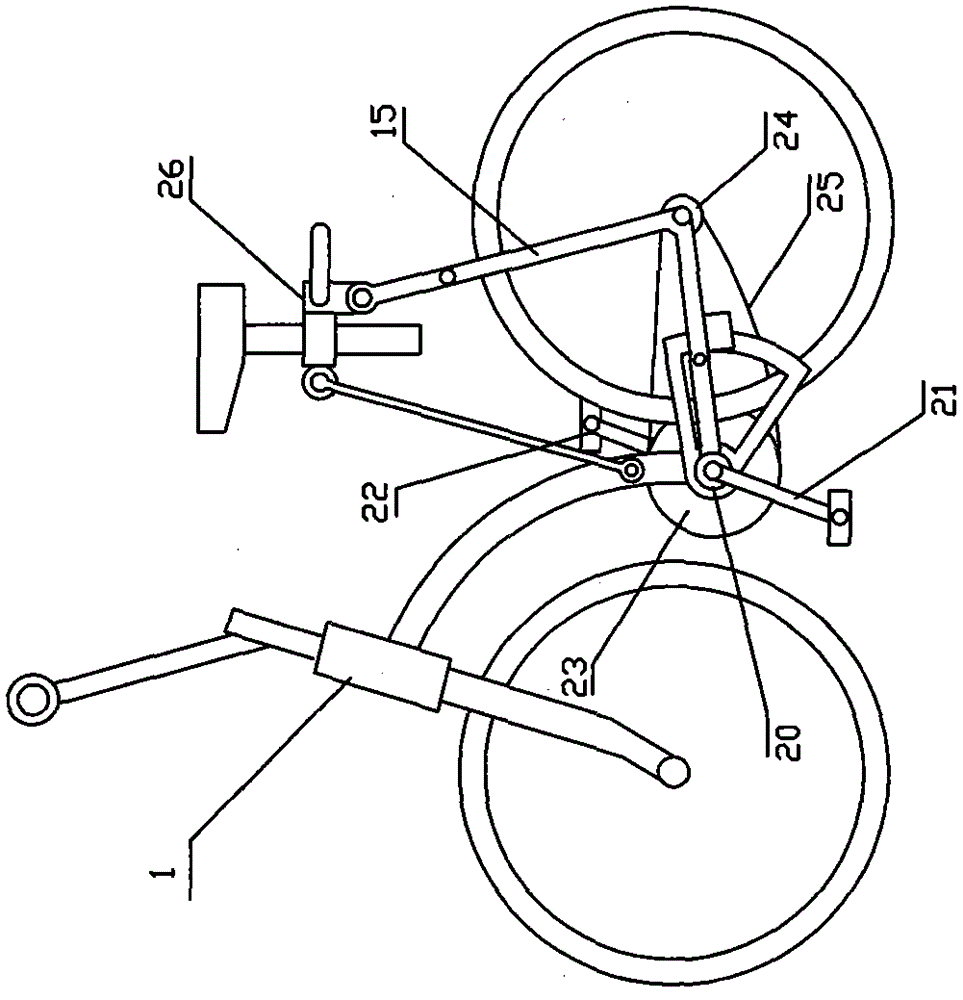

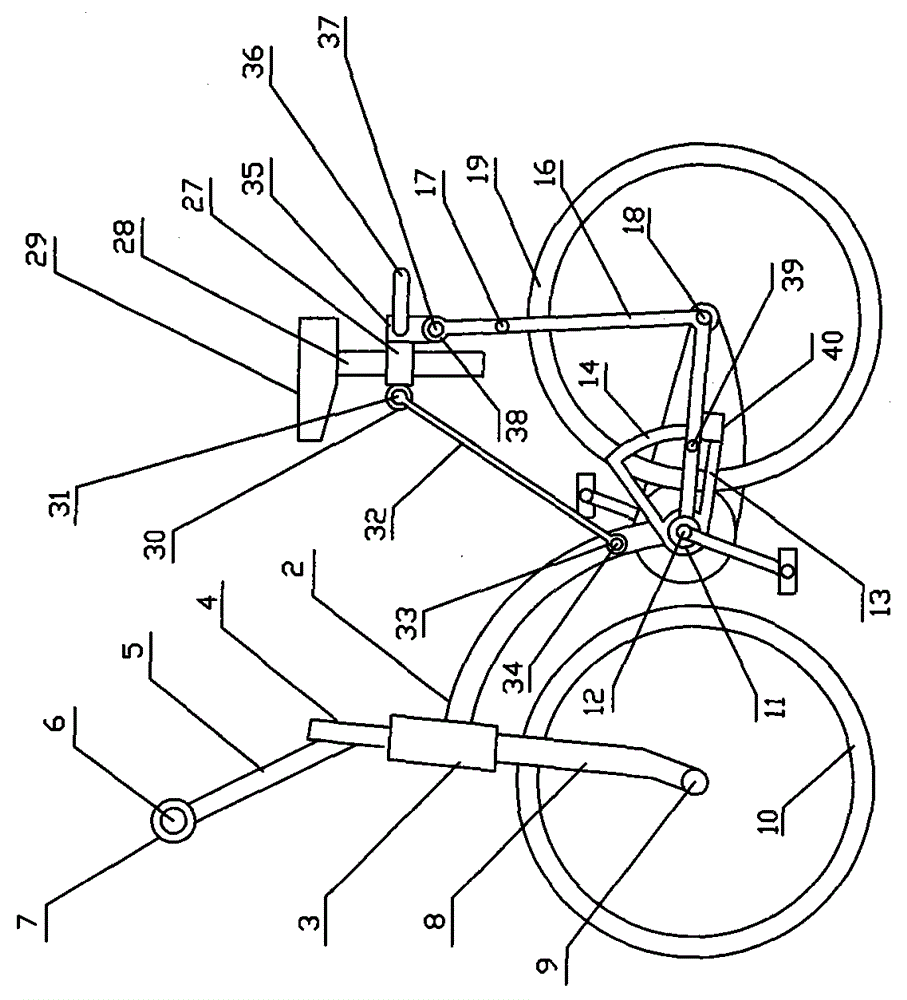

semi-automatic deformation bike

InactiveCN104260809BWithout compromising comfortHeight adjustableConvertible cyclesVehicle frameSemi automatic

Disclosed is a semi-automatic deformation bicycle. A steering frame and a rear wheel fork frame of the semi-automatic deformation bicycle are connected into an integral frame through a center shaft, a linkage rod and an automatic horizontal saddle. The large range opening and retraction deformation function of the integral frame is achieved and the deformation is locked in a manual handle turning to implement the semi-automatic deformation of the integral frame. The front and back distance between a head and the saddle is controlled by a rider freely, the integral frame deformation can be rapidly achieved in the stopping static state or in the driving dynamic state, and accordingly the rider can bend down to ride and can be straight up to ride and the use is convenient and rapid. In addition, the structure is simple, the size is small, the weight is light, the folding is avoided, and the like.

Owner:赵祖悦

A continuous tapered upsetting die and upsetting method for a bar with a super large aspect ratio

ActiveCN106623718BAspect ratioNo foldingForging/hammering/pressing machinesDiameter ratioInstability

The invention discloses a continuous tapered upsetting die and upsetting method for a bar material with the superhigh height-diameter ratio. The method comprises the steps that 1, the height of the bar material is obtained according to the diameter of the bar material and the size of a forge piece; 2, the taper degree of a forming wall surface of a male die and the taper degree of a forming wall surface of a female die are selected, and the upsetting frequency, the layer number of the male die, the layer number of the female die, the height of each layer of male die modules and the height of each layer of female die modules are determined according to the taper angles of the forming wall surfaces, the height of the bar material and the upsetting ratio every time; 3, after the bar material, the female die and the male die are heated, first-time upsetting forming is conducted; 4, after first-time upsetting forming is completed, the male die module with the minimum average outer diameter and the female die module with the minimum average inner diameter are removed, second-time upsetting is conducted, and in this way, the steps are conducted till the height-diameter ratio of an upsetting part is smaller than the maximum height-diameter ratio of non-instable upsetting. According to the die, the female die is designed into multiple layered modules of which the inner walls have the certain taper degree, instability of blanks is constrained through the oblique wall of the female die, and then a folding phenomenon cannot be generated.

Owner:SHANDONG UNIV +1

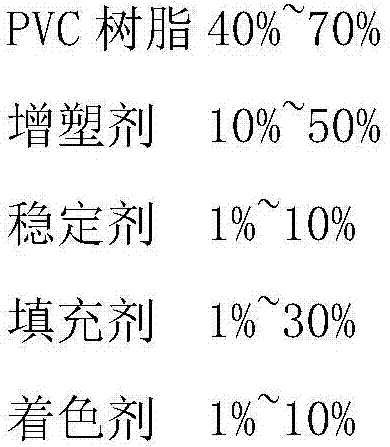

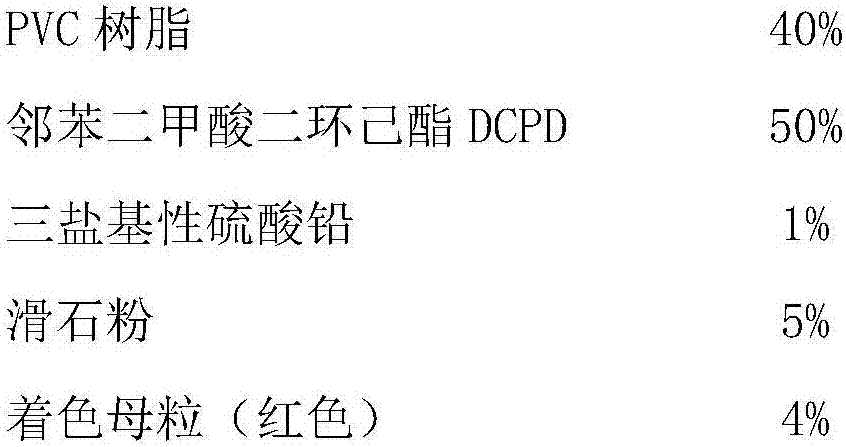

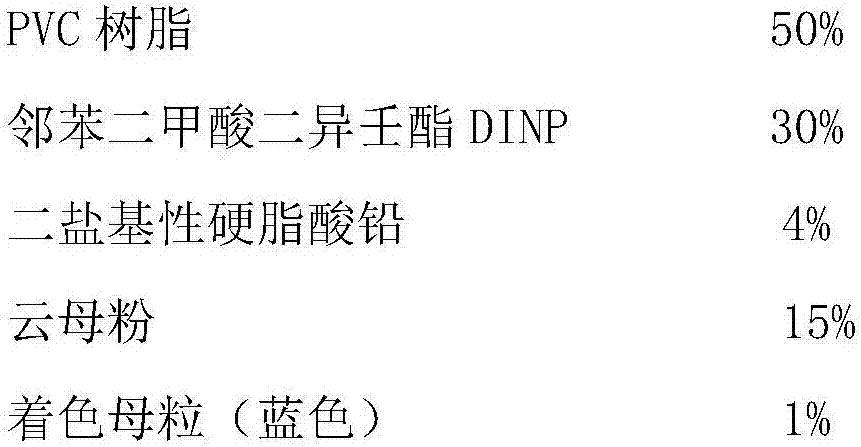

Durable cable PVC film

The invention discloses durable cable PVC film. The durable cable PVC film is prepared from, by weight, 40%-70% of PVC resin, 10%-50% of plasticizer, 1%-10% of stabilizer, 1%-30% of filling agent, and 1%-10% of colorant. According to the durable cable PVC film, because of the mutual coordination of PVC resin, the plasticizer, the stabilizer and the filling agent, the prepared thin film is smooth in surface, uniform in thickness, free of obvious spots and free of oil stains, impurities and creases, the stretch rate of the thin film is 250%-300%, the water absorption rate is smaller than or equal to 0.5%, the natural shrinking percentage is smaller than or equal to 0.5%, smog during combustion is small, and the combustion cannot last.

Owner:中山市华子电缆有限公司

Spline Shaft Forging Process of Drive Shaft

ActiveCN103537595BReduce manufacturing difficultyReduce manufacturing costForging/hammering/pressing machinesDrive shaftMedium frequency

Owner:XUCHANG ZHONGXING FORGING +1

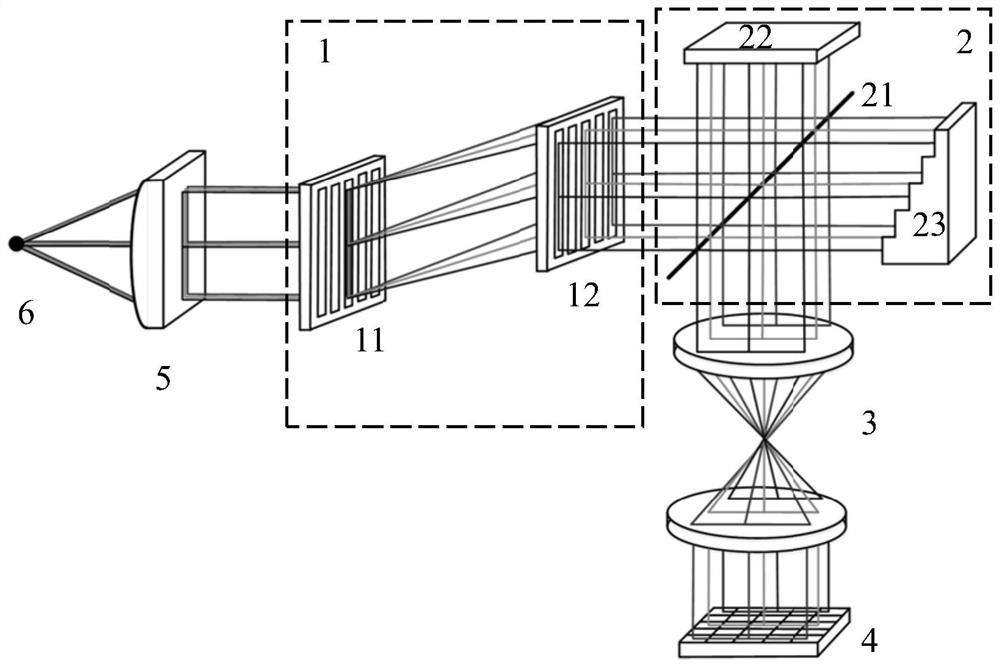

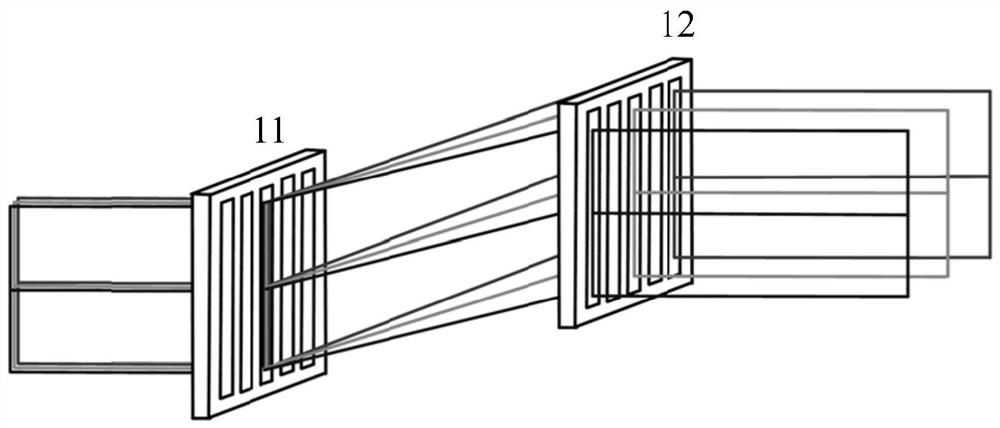

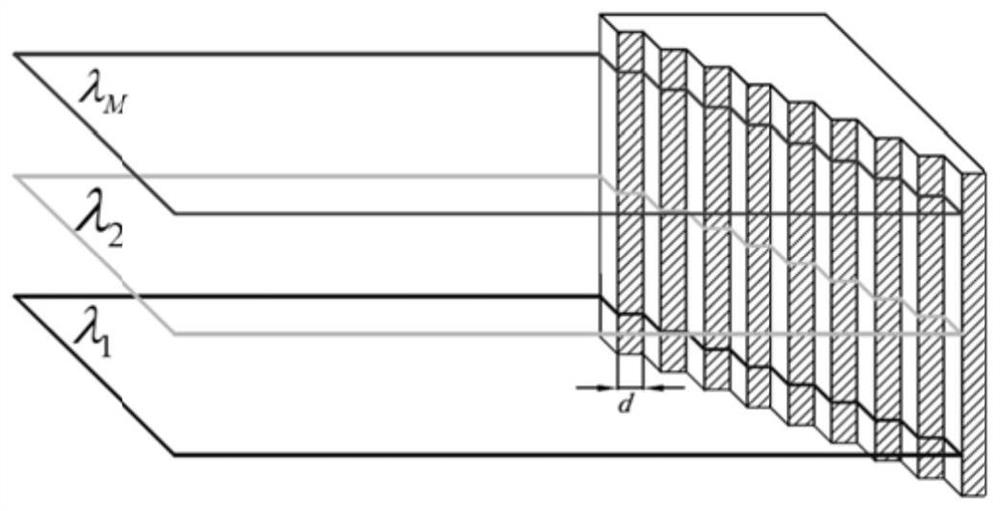

Fourier transform spectrometer

ActiveCN113280916AReduce the difficulty of adjustment and correctionEasy to makeRadiation pyrometryInterferometric spectrometryOptical spectrometerImage resolution

The invention provides a Fourier transform spectrometer. Spectrum segmentation is realized by utilizing a double-grating system in one dimension, so that an optical axis is not folded, the adjustment and correction difficulty of each element of the system is reduced, and the complexity of the system is reduced. In another dimension, band-pass sampling is realized by utilizing a spatial modulation interference system, so that the cross coupling modulation of chromatic dispersion and interference of an incident light field is realized in two orthogonal directions. A narrow slit and a large array refrigeration detector which need to be adopted by a chromatic dispersion spectrometer for realizing infrared high spectral resolution are avoided, the limitation of a core device is eliminated, and relatively high luminous flux and signal-to-noise ratio are achieved; meanwhile, a static structure is adopted, manufacturing and control difficulties caused by moving parts are avoided, and the reliability, the stability and the real-time performance are better; and a measurement mechanism of spectrum segmentation and band-pass sampling is adopted, so that the contradiction of mutual restriction between the spectrum bandwidth and the spectrum resolution is solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com