Paper board producing unit

A unit and cardboard technology, applied in the field of cardboard production units, can solve the problems affecting the quality of cardboard, poor water resistance of finished cardboard, loose surface paper, etc., and achieve the effect of avoiding incomplete pattern printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The domestic invention patent application with the application number of 201210140498.2 provides a paperboard production equipment with many problems, among which the more prominent problem is that the rotation speed of the front guide roller or the rear guide roller changes as When it slows down, especially at the moment when the knife board cuts the cardboard, the movement of the cardboard will stagnate to a certain extent. The surface paper between the pattern roller and the leading guide roller is loose, so that the surface paper cannot form a complete pattern under the action of the pattern roller, and it may also cause the accumulation and deformation of the surface paper passing the leading roller, thus affecting the quality of the cardboard after production .

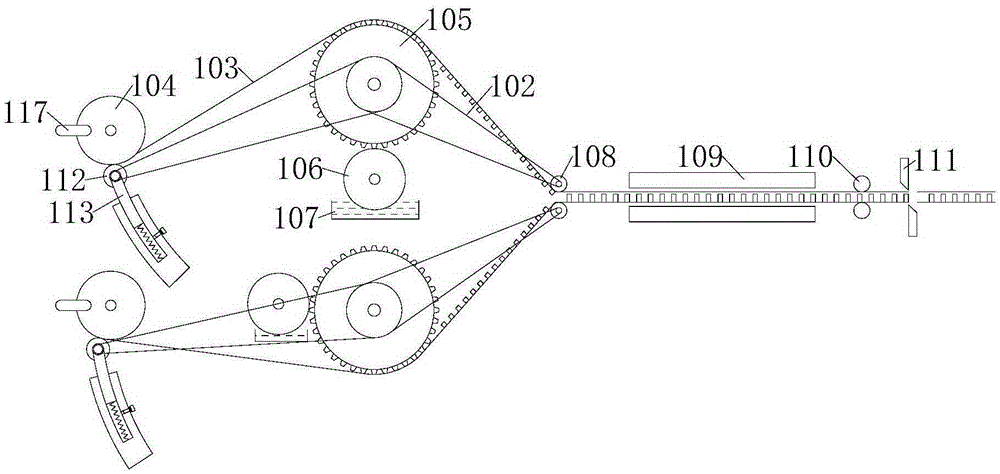

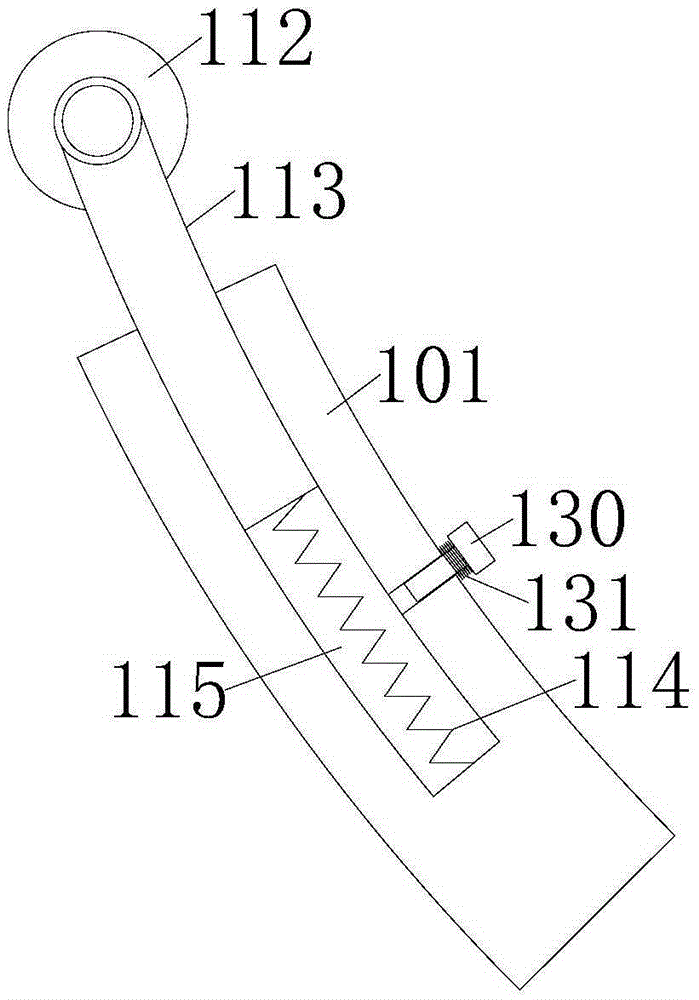

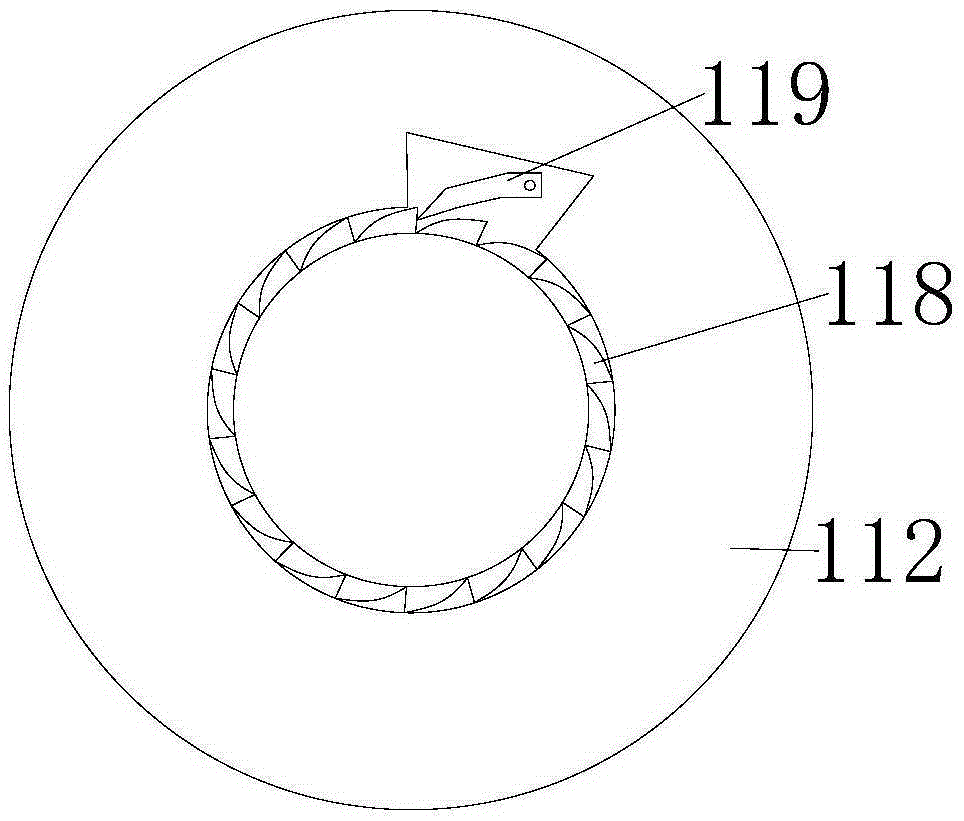

[0036] In order to improve the above problems, the present invention provides a cardboard production unit, which includes a frame, an upper half, a lower half, an extrusion mechanism and four linkage mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com