Durable cable PVC film

A cable, durable technology, applied in the field of PVC film preparation, can solve the problems of poor tensile and abrasion resistance of PVC film, cable wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

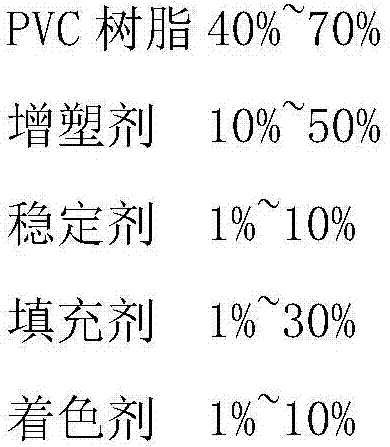

Method used

Image

Examples

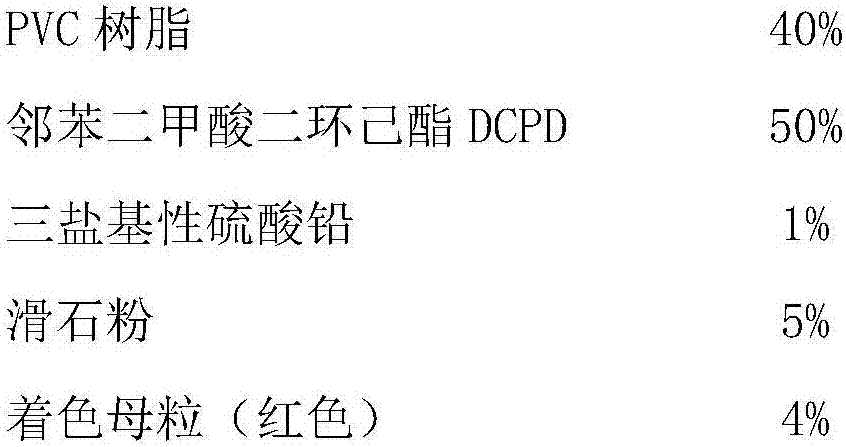

Embodiment 1

[0018]

[0019] Its preparation method is:

[0020] Add the material components in the above proportions into the PVC resin, and then stir and mix uniformly with a high-speed mixer to form a mixture A, then plasticize and knead the mixture A through an internal mixer, and then carry out the mixture A through an open mixer. Heat smelting, molding, and then the rollers of the calender press and stretch the molded material into a film of a certain thickness, and finally peel off the formed film, cool and shape it, thereby forming a PVC film. The thickness of the film in this embodiment is 0.3mm.

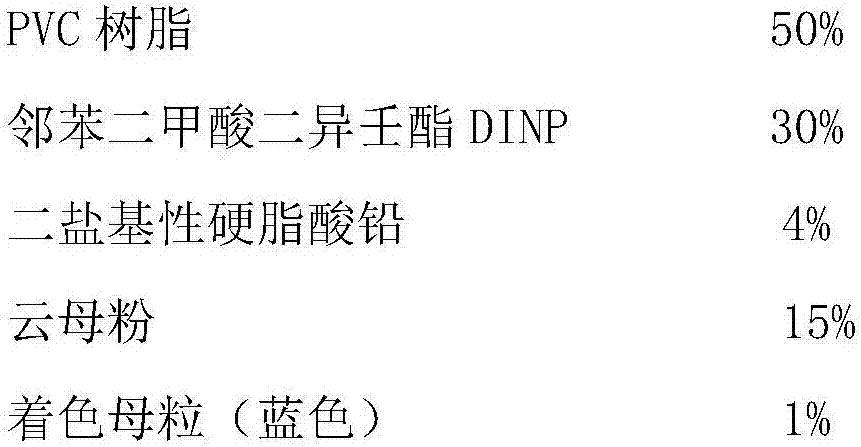

Embodiment 2

[0022]

[0023] The preparation method is the same as in Example 1, and the thickness of the prepared film is 0.4mm.

Embodiment 3

[0025]

[0026] The preparation method is the same as in Example 1, and the thickness of the prepared film is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com