Steel pipe end vibration upsetting joint device and method

A joint device and vibration device technology, which is applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve problems such as difficulty, high production cost, and failure to use, and achieve easy operation, The effect of low production cost and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

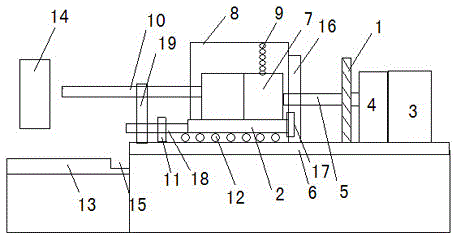

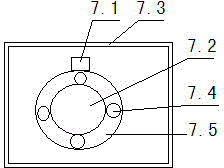

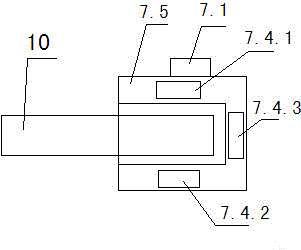

[0030] combined with Figure 1-4 , to further describe the present invention:

[0031] A vibration upsetting joint device at the end of a steel pipe, the technical solution of which is: an operating platform 6 is installed on the upper part of the main body of the machine tool, and a push plate 1, a lifting platform 2, a motor 3, a reducer 4, and a push rod 5 are installed on the operating platform 6 , vibration support frame 8, controller 16, push rod guide rail 18, one side of described push plate 1 is provided with push rod 5, and the other side connects reducer 4 and motor 3, and the outside of described push rod 5 is connected Vibration device 7, and the vibration support frame 8 of rectangular structure is installed on the outside of vibration device 7, the two ends of vibration support frame 8 are fixed on the operating platform 6, and the top of vibration support frame 8 is connected to vibration device 7 by elastic element 9 The bottom of the vibrating device 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com