A high-strength toughness deformed aluminum-lithium alloy compounded with multiple rare earth elements and its preparation method

A high-strength toughness, rare earth element technology, applied in the field of deformed aluminum-lithium alloy, high-strength toughness deformed aluminum-lithium alloy and its preparation, can solve the limited effect of alloy strength and toughness, no obvious improvement in alloy strength, no strength, etc. problems, to achieve the effect of stable performance, uniform microstructure, strength and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

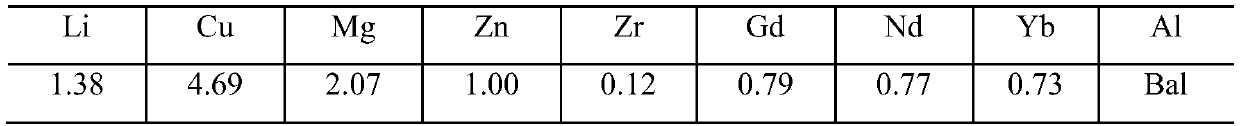

[0044] This example relates to a method for preparing a high-strength toughness deformed aluminum-lithium alloy compounded with multiple rare earth elements. Pure Al, Al-50Cu master alloy, Al-30Gd master alloy, Al-10Nd master alloy, Al-10Yb master alloy, pure Zn, pure Mg and pure Li and preheat the mold used for casting to 180-220°C; the melting process is carried out in sequence as follows: ①After melting pure Al, heat it at 800-820°C Add Al-Zr, Al-Gd, Al-Yb and Al-Nd and other intermediate alloys and stir evenly, then keep warm at 780-820°C for 8-10 minutes and then stir again; ②Add Al-Cu intermediate at 780-800°C Alloy and stir evenly, keep warm at 740-800°C for 10-15 minutes after stirring; ③Add Zn at 740-760°C and stir evenly, keep warm at 730-760°C for 8-10 minutes after stirring; ④Add Zn at 730-750°C Mg and stir evenly, after stirring, keep warm at 710-750°C for 8-10 minutes; then refine at 710-730°C (the refining agent used is hexachloroethane) twice, and sprinkle the ...

Embodiment 2

[0056] This example relates to a high-strength toughness deformed aluminum-lithium alloy compounded with multiple rare earth elements. The preparation method of this example is the same as that of Example 1, and the only difference is that the content of the alloy ratio in this example is different from that of Example 1.

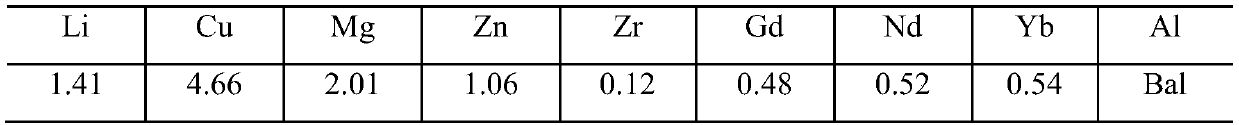

[0057] Gained alloy ingot is (wt%) through chemical analysis alloy composition:

[0058]

[0059] The aging elastic modulus and room temperature mechanical properties of the deformed aluminum-lithium alloy are:

[0060] Elastic modulus: 81GPa. Yield strength: 677MPa, tensile strength: 731MPA, elongation: 11.2%.

Embodiment 3

[0062] This example relates to a high-strength toughness deformed aluminum-lithium alloy compounded with multiple rare earth elements. The preparation method of this example is the same as that of Example 1, and the only difference is that the content of the alloy ratio in this example is different from that of Example 1.

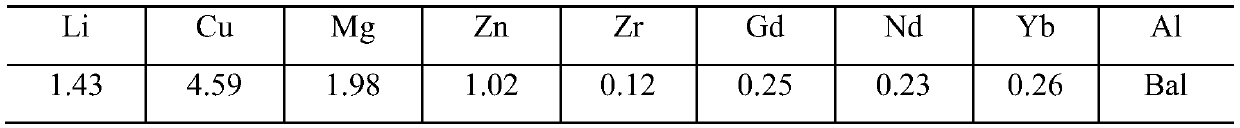

[0063] Gained alloy ingot is (wt%) through chemical analysis alloy composition:

[0064]

[0065] The aging elastic modulus and room temperature mechanical properties of the deformed aluminum-lithium alloy are:

[0066] Elastic modulus: 83GPa. Yield strength: 678MPa, tensile strength: 735MPA, elongation: 11.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com