Patents

Literature

115results about How to "Improve the strengthening and toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

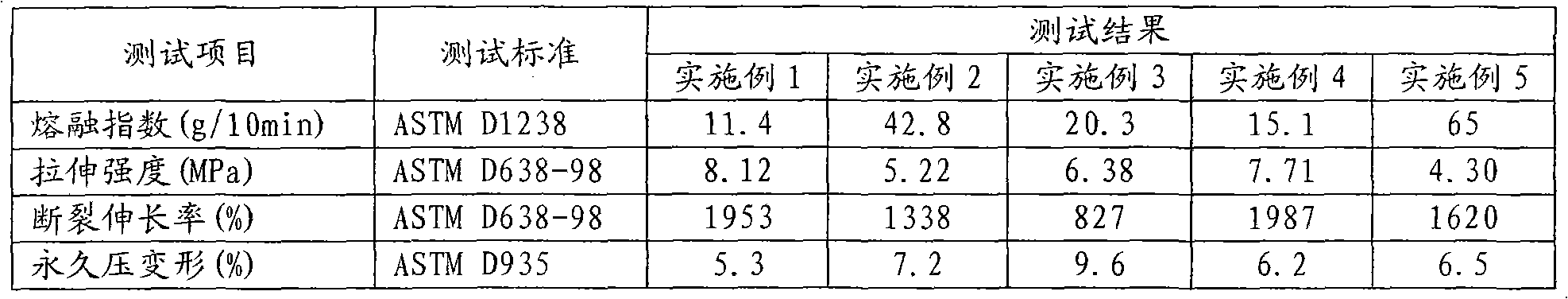

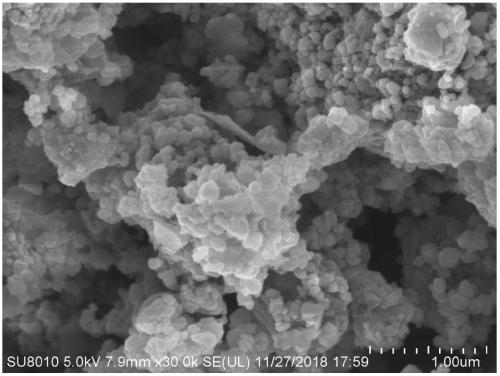

Cross-linked rubber composition, application thereof, rubber grains prepared by cross-linked rubber composition, preparation method and injection method of rubber grains

InactiveCN101624461ASmall molecular weightImprove liquiditySolesOvergarmentsCross-linkPolymer science

The invention relates to a cross-linked rubber composition, the application thereof, rubber grains prepared by the cross-linked rubber composition, a preparation method and an injection molding method of the rubber grains. The cross-linked rubber composition at least comprises a styrene-butadiene copolymer, a rubber softening agent, a flow modifying agent and a peroxide vulcanizing agent; the cross-linked rubber composition is suitable for preparing rubber products and can be prepared into non-cross-linked rubber grains below the temperature of 80 DEG C; and the rubber grains are formed by banburying, milling, extruding and granulating. The rubber composition and the rubber grains can be directly molded by injection, have good flow property, can be vulcanized in a later period and can be preserved at room temperature. Compared with the prior art, the rubber grains can be directly molded by injection, rubber particles are not easy to self-vulcanize, the vulcanization speed is easy to control, the rubber grains have no need to be stored at low temperature, and the like.

Owner:陈友明

Self-repairing anti-shrink cement based composite material

The invention discloses a self-repairing anti-shrink cement based composite material which comprises the following components in parts by weight: 400-800 parts of cement, 200-600 parts of waste, 400-1000 parts of sand, 264-528 parts of water, 10-70 parts of fiber, 4-10 parts of additive and polymer emulsion which accounts for 5%-10% of the gross weight of the cement. The self-repairing anti-shrink cement based composite material has good anti-shrink performance, impermeability and durability. When having a crack, the material can realize a self-repairing function under field conditions, and can be used as restorative materials for retaining walls, road mat coats, concrete pipelines, oil and gas pipelines, dams and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Fiber reinforced modified foam cement thermal insulation board and preparation process thereof

InactiveCN107226657ALow water absorptionHigh strengthHeat proofingCeramicwarePolymer scienceThermal insulation

The invention discloses a fiber reinforced modified foam cement thermal insulation board and a preparation process thereof. The fiber reinforced modified foam cement thermal insulation board uses a modified foam cement thermal insulation board as a thermal insulation core material, wherein alkali-resistant fiberglass cloth is attached to the upper surface and the lower surface of the modified foam cement thermal insulation board, polymer glue is applied onto the upper surface and the lower surface of the foam cement thermal insulation board through spray coating, roller coating, dip coating or scraping so as to integrate the alkali fiberglass cloth with the modified foam cement thermal insulation board to prepare a novel light cement-based inorganic thermal insulation board. The novel light cement-based inorganic thermal insulation board has the advantages of high strength, high toughness, low water absorption rate, low heat conduction coefficient, good thermal insulation effect, small drying shrinkage value, high adhesiveness, high integrity, good anti-vibration and anti-impact performance, A-level fire-proof performance, long service life as a building and the like. A used polycarboxylate superplasticizer modified graphene can disperse in cement paste uniformly and steadily, so that the problems of agglomeration, non-thorough disperse and the like in an existing graphene adding manner are solved.

Owner:CHONGQING CITY HUTH BUILDING MATERIALS LIMITED

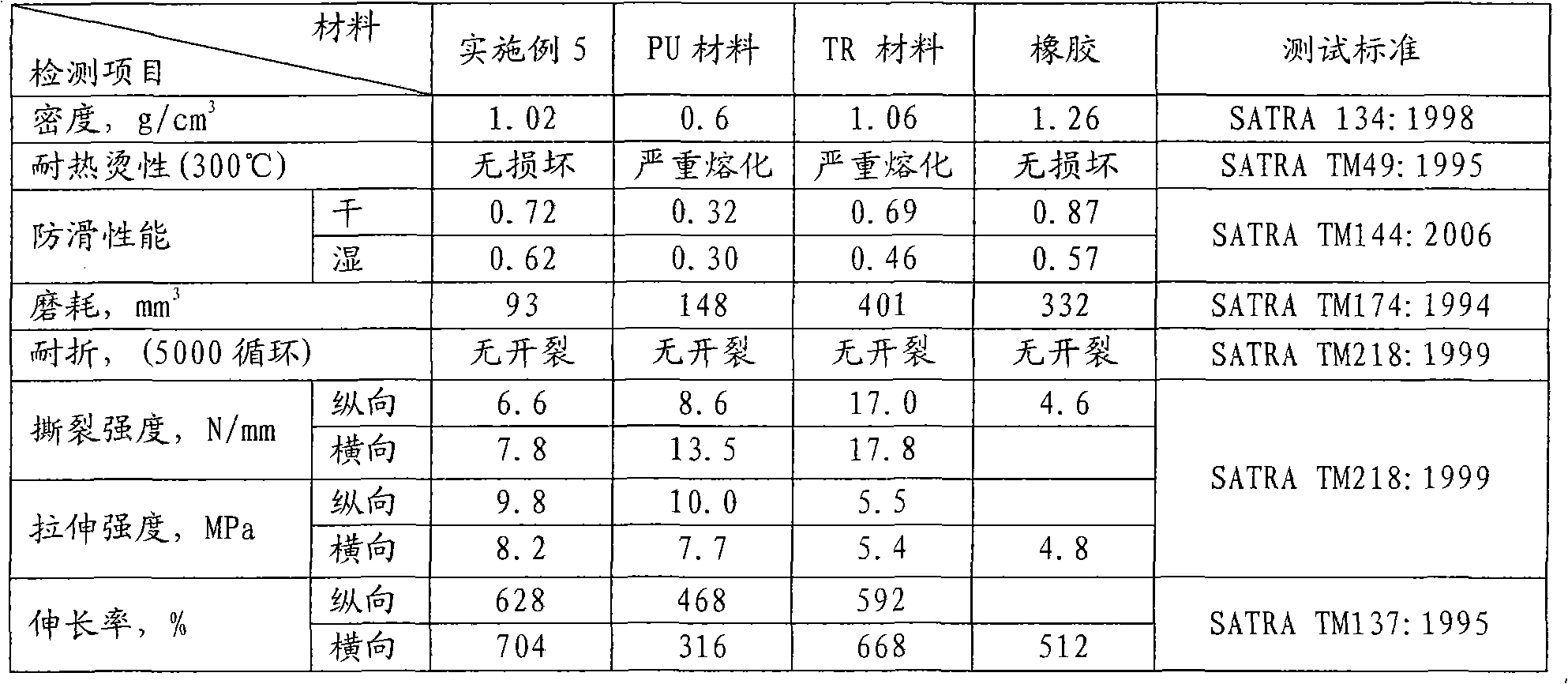

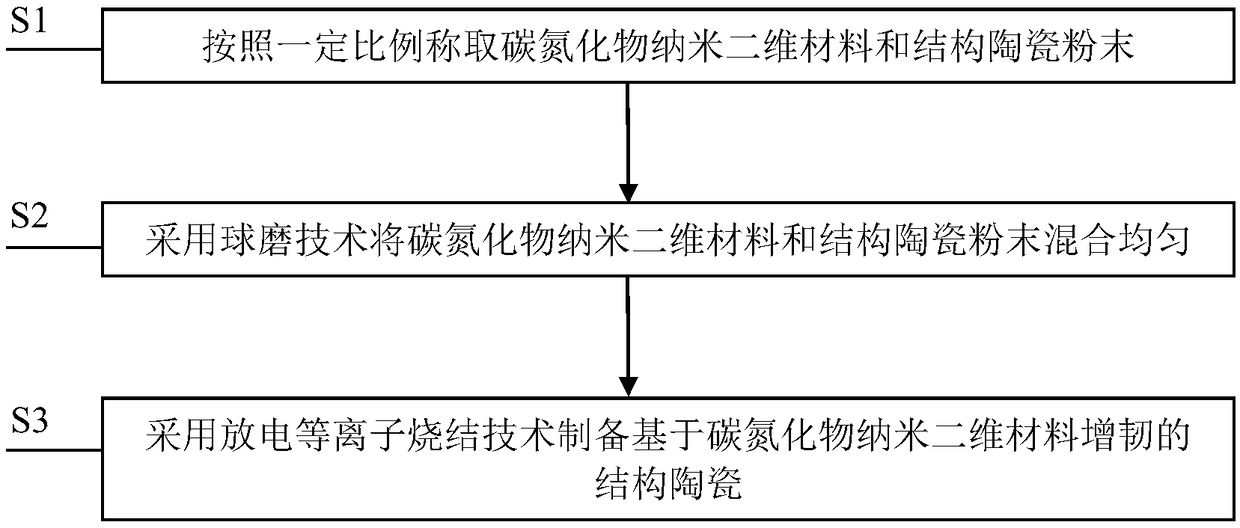

Carbonitride nano two-dimensional material enhanced structural ceramic and preparation method thereof

The invention discloses a carbonitride nano two-dimensional material enhanced structural ceramic and a preparation method thereof. The preparation method comprises the following steps: S1, weighing carbonitride nano two-dimensional material powder and structural ceramic powder in a preset proportion; S2, uniformly mixing the carbonitride nano two-dimensional material powder with the structural ceramic powder; and S3, sintering the power uniformly mixed in the S2 to obtain the carbonitride nano two-dimensional material enhanced structural ceramic. The carbonitride nano two-dimensional materialenhanced structural ceramic and the preparations method thereof are simple and rapid and green and environment-friendly. The research range of a novel structure-function integrated ceramic and ceramic-based composite material is expanded.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Fiber-reinforced composite refractory castable for molten iron desulphurization lance and preparation method of fiber-reinforced composite refractory castable

The invention relates to a fiber-reinforced composite refractory castable for a molten iron desulphurization lance and a preparation method of the fiber-reinforced composite refractory castable. According to the technical scheme, the method comprises the steps of dispersing the following raw materials in parts by weight: 1-4 parts of mullite powder, 3-5 parts of kyanite, 5-8 parts of fused dense corundum powder, 5-8 parts of alpha-Al2O3 micro powder, 4-7 parts of silica powder, 1-4 parts of silicon carbide powder and 5-7 parts of pure aluminum silicate cement and an additive into a flat container and mixing evenly by using a rake; adding the following raw materials in parts by weight: 10-15 parts of first-level bauxite chamotte, 30-38 parts of natural fused mullite, 20-25 parts of andalusite and 1-2 parts of high-purity fused mullite particles; and pouring the mixed materials into a stirrer for stirring to obtain the fiber-reinforced composite refractory castable for the molten iron desulphurization lance. The fiber-reinforced composite refractory castable is low in cost and wide in raw material source, the obtained product is good in mechanical property and thermal shock resistance, the service life of the molten iron desulphurization lance can be prolonged, and the desulphurization cost can be reduced.

Owner:WUHAN UNIV OF SCI & TECH

Corn starch composite membrane as well as preparation method and applications thereof

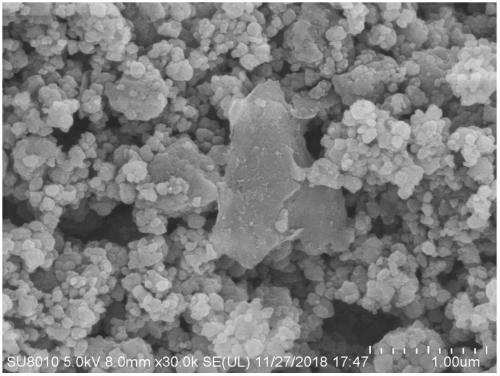

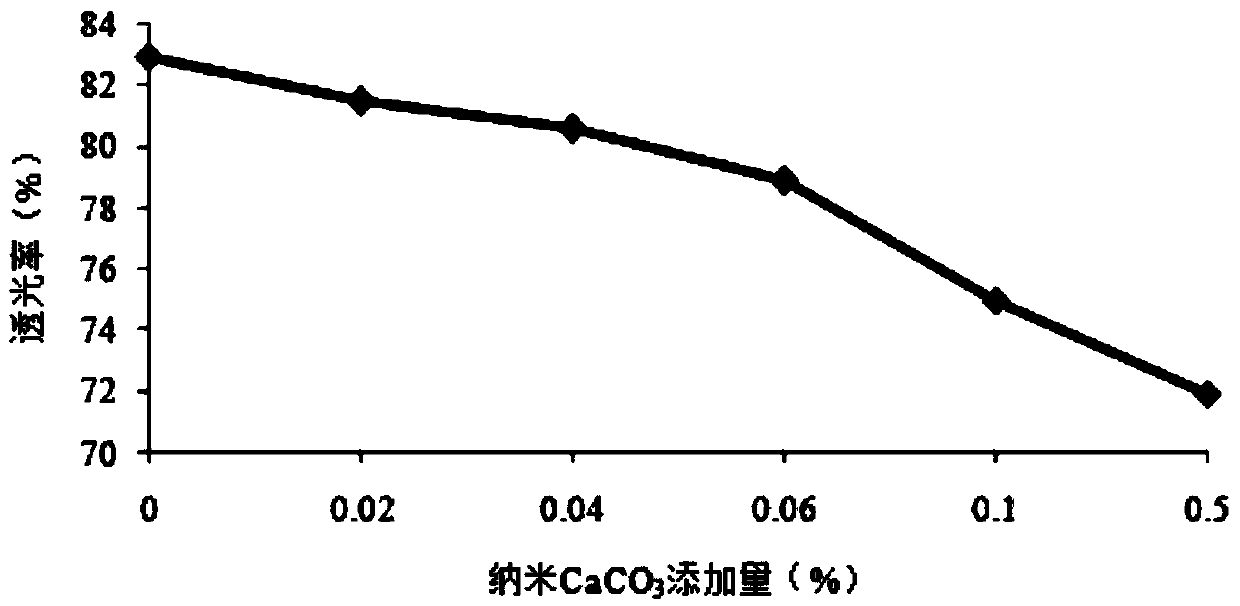

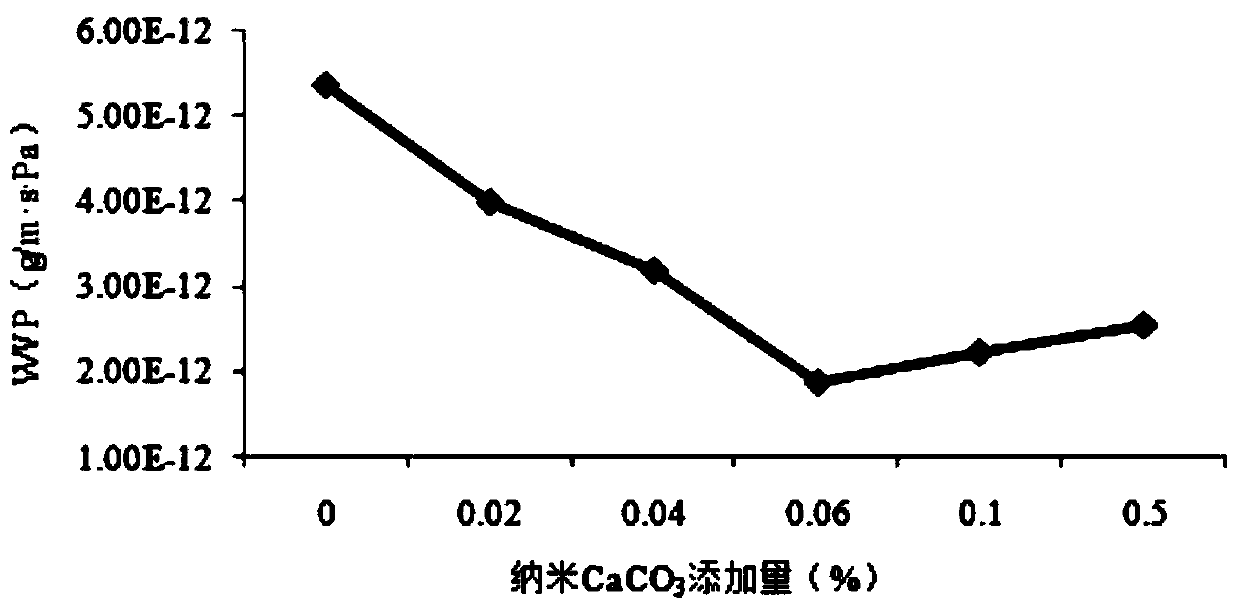

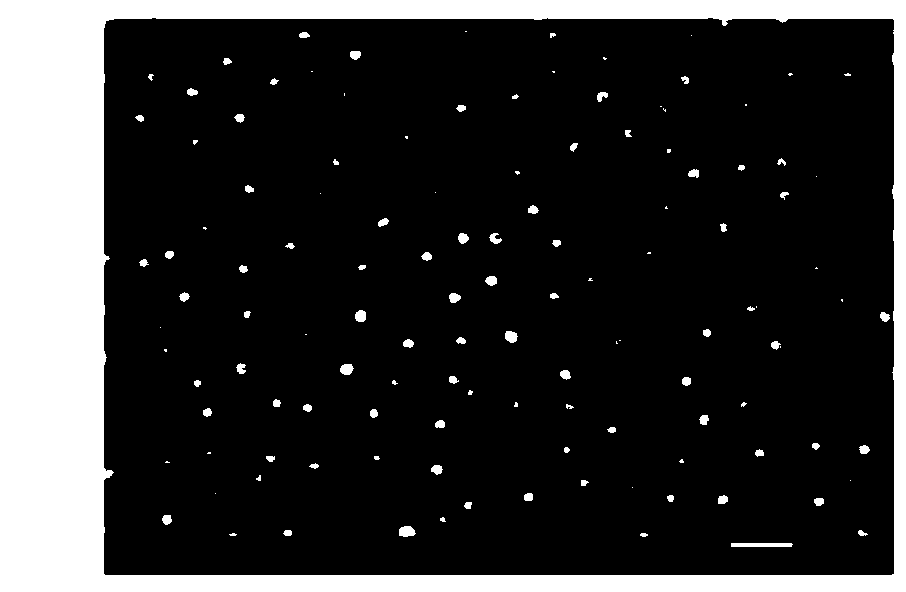

ActiveCN104194064AReduce light transmittanceLow moisture permeabilityFlexible coversWrappersWaxy cornNanoparticle

The invention discloses a corn starch composite membrane as well as a preparation method and applications thereof. The corn starch composite membrane comprises corn starch, glycerol and an enhancer, wherein the enhancer is nano CaCO3, waxy corn starch nanoparticles or chitosan, the mass ratio of the corn starch to glycerol is equal to (6.5-8.0):(1.5-3.0), when the enhancer is nano CaCO3 and waxy corn starch nanoparticles, the masses of the enhancer / corn starch are respectively 0.02-0.5, and 1-25; when the enhancer is nano CaCO3 or chitosan, the mass ratio of nano CaCO3 and corn starch is 0.06, and the mass ratio of chitosan and corn starch is 10-50; the size of the nano CaCO3 ranges from 30nm to 50nm; and the size of the waxy corn starch nanoparticles is 70-120nm. The mechanical performance of the composite membrane is obviously improved; the light transmittance and moisture penetrability of the membrane can be reduced; the thermal characteristic is better; the thermal stability of the composite membrane is higher than that of the corn starch membrane; and the corn starch and the nano CaCO3 particles have better compatibility.

Owner:QINGDAO AGRI UNIV

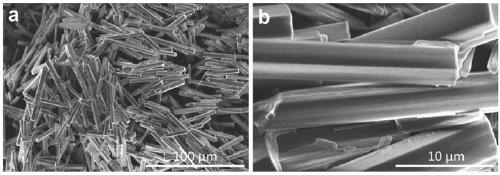

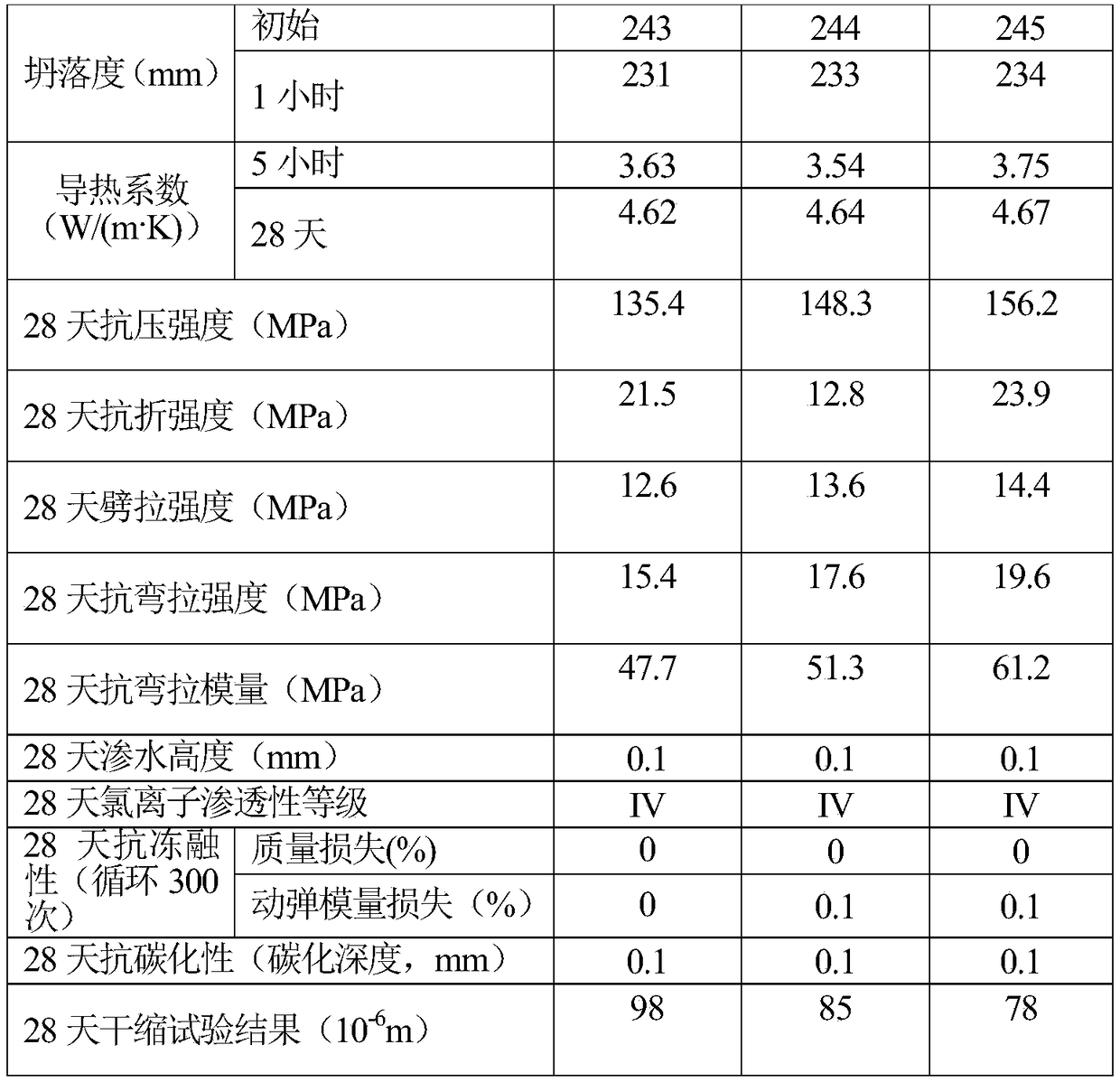

Calcium sulfate whisker reinforced and toughened polylactic acid composite and preparation method thereof

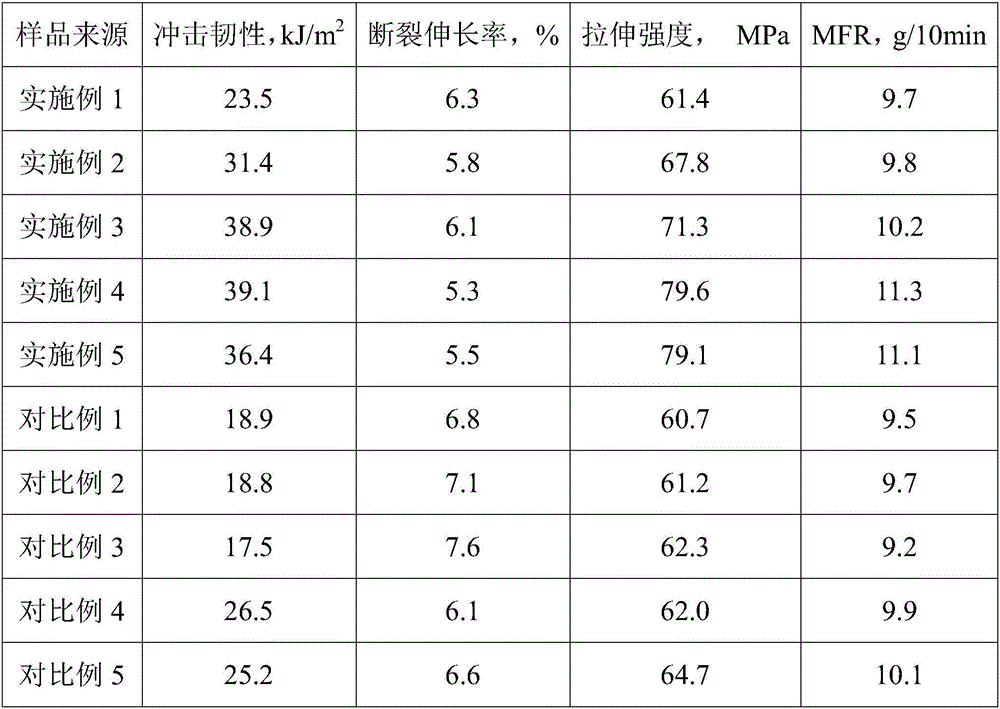

ActiveCN105820522AImprove the strengthening and toughening effectDoes not significantly reduce melt flow rateMasterbatchSulfate

The invention discloses a calcium sulfate whisker reinforced and toughened polylactic acid composite. The composite comprises the following raw materials in percent by weight: 49 to 89.9 percent of polylactic acid, 10 to 50 percent of composite masterbatch, and 0.1 to 2 percent of an antioxidant, wherein the composite masterbatch adopts polylactic acid modified by calcium sulfate whisker which is subjected to surface treatment. The invention further discloses a preparation method of the calcium sulfate whisker reinforced and toughened polylactic acid composite. The composite adopts calcium sulfate whisker reinforced and toughened polylactic acid, wherein the calcium sulfate whisker is subjected to proper surface pretreatment, so as to ensure that calcium sulfate whisker is uniformly dispersed in a polylactic acid matrix, therefore the impact toughness and the tensile strength of the polylactic acid are improved, and the processability is improved.

Owner:苏州苏湖新材料科技有限公司

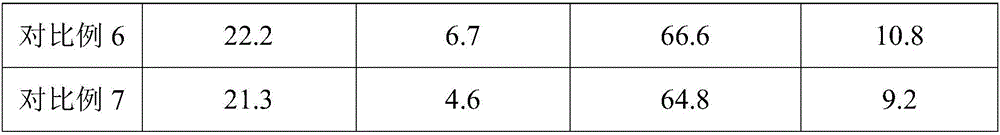

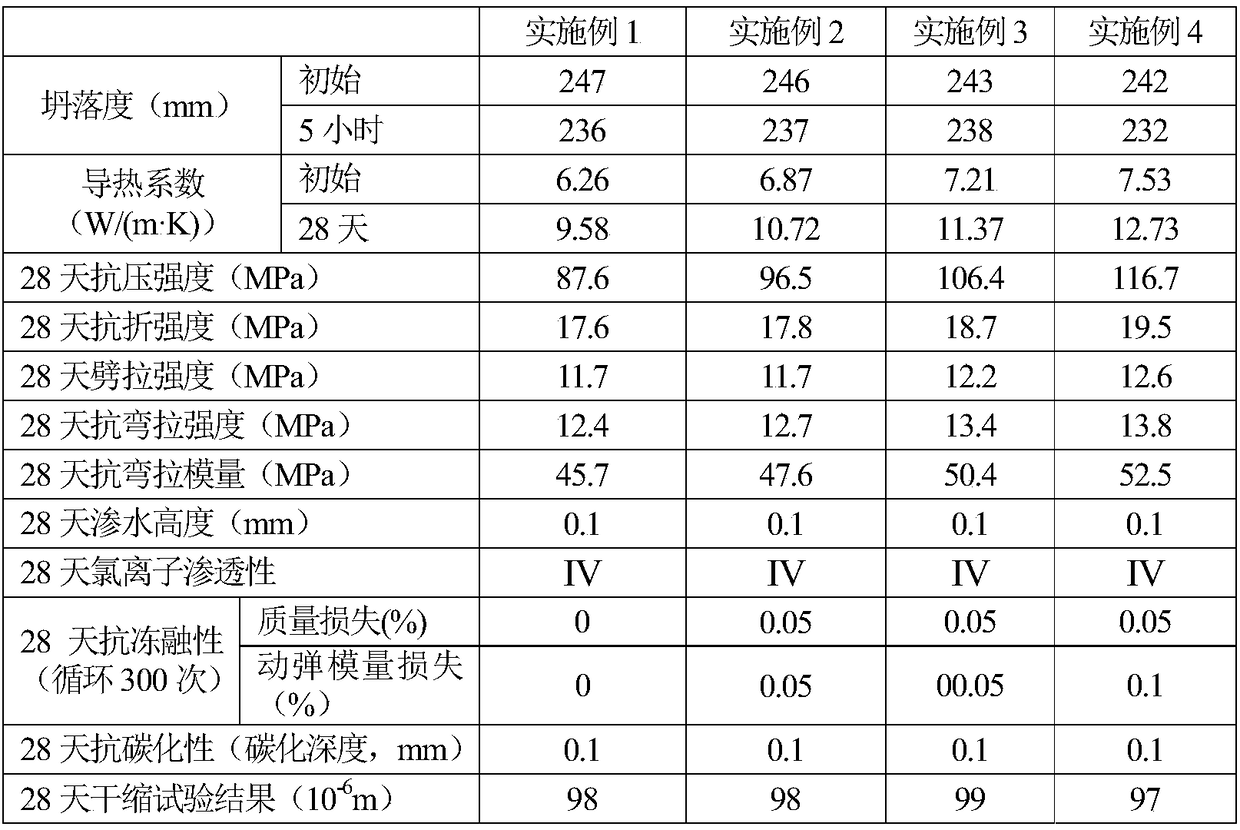

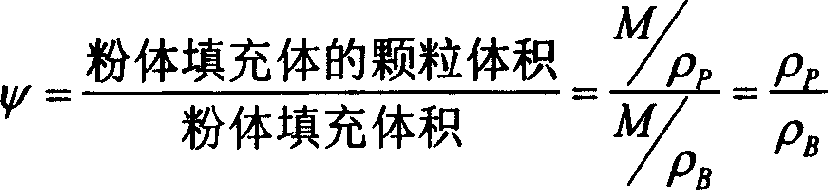

High-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and preparation method thereof

The invention discloses high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and a preparation method thereof. The high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete comprises cement, fly ash, silicon powder, steel slag powder, boron nitride, graphene oxide flake powder, sand, gravel, high-strength polyvinyl alcohol fiber, a polycarboxylic acid water reducing agent, a dispersion activator, a modified graphene oxide dispersion and water. The obtained concrete has the initial and 28-day-old heat conductivity of 6.26-7.53W / (m.K) and 9.58-12.73W / (m.K) respectively and has the capability of dispersing and conducting cement hydration heat and resisting temperature cracks caused by environment temperature change; 28-day-old concrete has the compressive strength of 87.6-116.7MPa, the rupture strength of 17.6-19.5MPa, the splitting tensile strength of 11.7-12.6MPa, the bending tensile strength of 12.4-13.8MPa and the bending tensile modulus of 45.7-52.5GPa; the water permeability resistance, the chloride ion permeability resistance, the freeze-thaw resistance and the carbonation resistance reachthe highest levels; and the prepared concrete has good social and economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

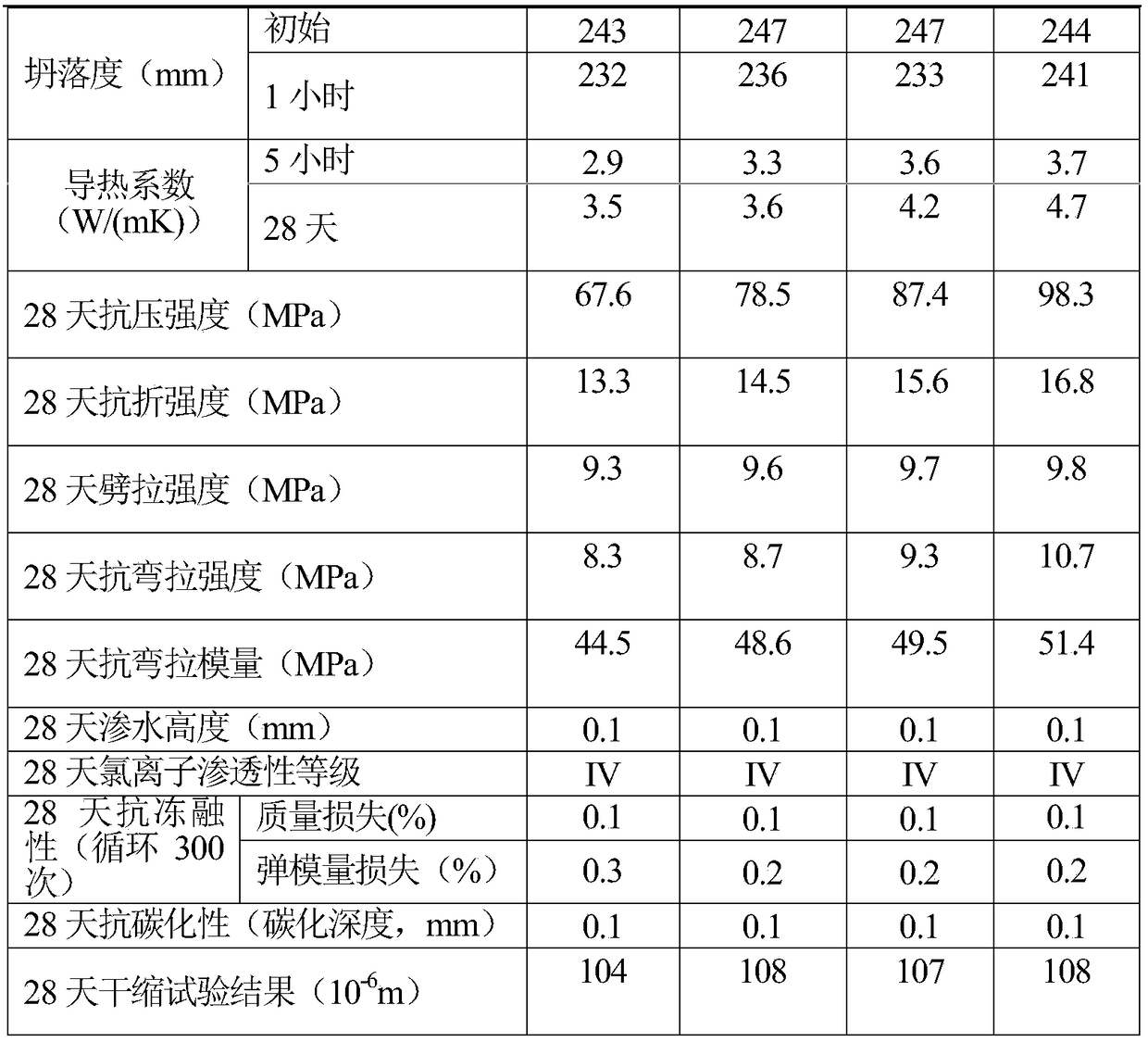

Concrete with anti-cracking, anti-seepage and high-durability effects and preparation method thereof

The invention relates to a concrete with anti-cracking, anti-seepage and high-durability effects and a preparation method thereof. The concrete is prepared from the following components of cement, flyash, silicon powder, coal gangue powder, boron nitride, phosphor residue powder, sand, crushed stone, high-strength polyvinyl alcohol fiber, a water reduction agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The concrete has the advantages that the heat conduction coefficient in the 1h age period is 2.9 to 3.7W / (m.K), the heat conduction coefficient in the 28-day age period is 3.5 to 4.7W / (m.K), the compressive strength is 67.6 to 98.3MPa, the break strength is 13.3 to 16.8MPa, the split strength is 9.3 to 9.8MPa, the tensile strength is 8.3 to 10.7MPa, and the tensile elastic modulus is 44.5 to 51.4GPa; the anti-water permeation property, anti-chlorine ion permeation property, anti-freezing and thawing property, and anti-carbonizing property can reachthe highest level; the working property is high, the volume stability is high, the durability is high, the toughness is high, the anti-cracking ability is high, and the anti-seepage ability is high.

Owner:CHONGQING YABO BUILDING MATERIALS CO LTD

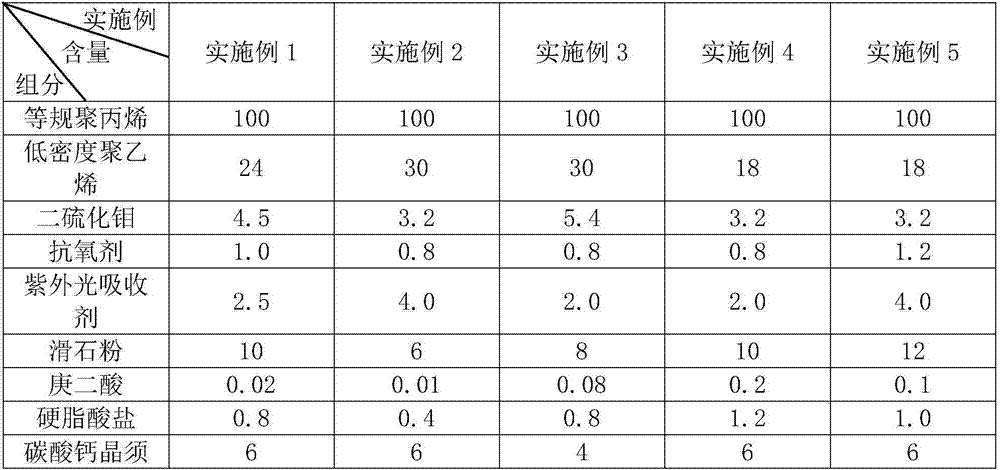

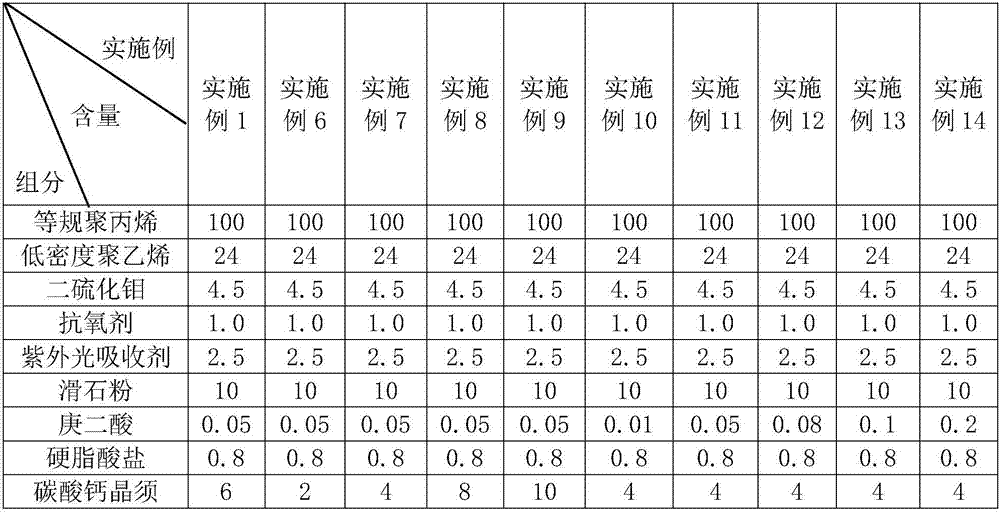

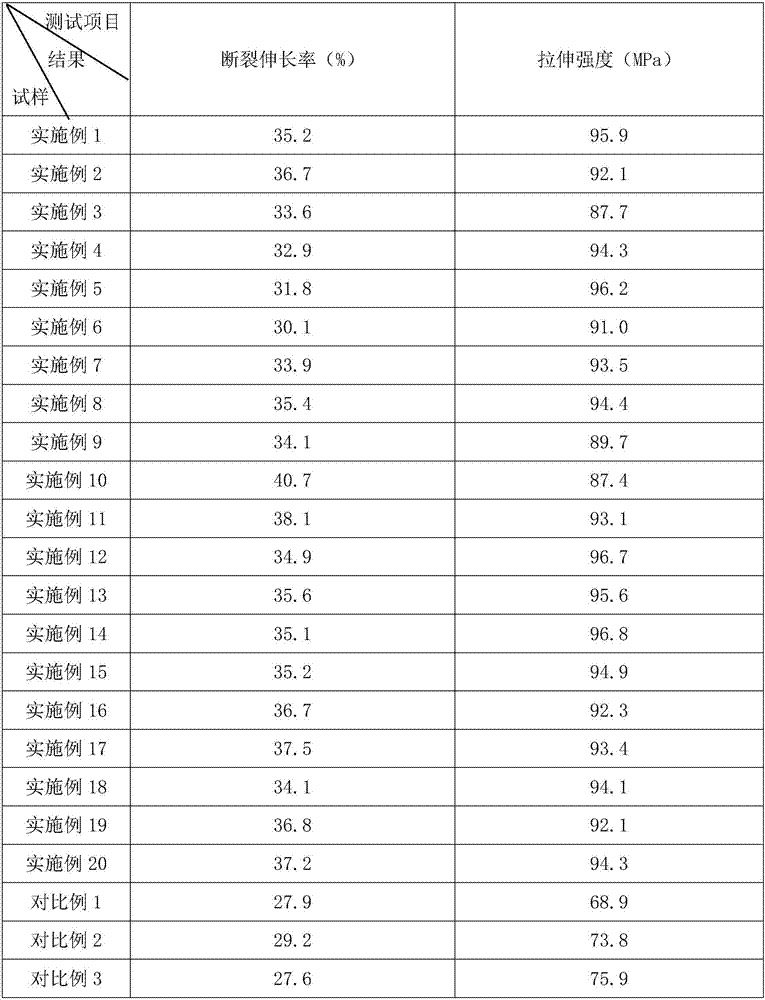

Material for reinforced plastic woven bag

The invention discloses a material for a reinforced plastic woven bag. The material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of isotactic polypropylene, 18 to 30 parts of low density polyethylene, 3.2 to 5.4 parts of molybdenum disulfide, 0.8 to 1.2 parts of an antioxidant, 2 to 4 parts of an ultraviolet absorbent, 6 to 12 parts of talcum powder, 0.01 to 0.2 part of pimelic acid, 0.4 to 1.2 parts of stearate and 2 to 10 parts of calcium carbonate whiskers, wherein stearate comprises calcium stearate. The material has the advantages of high tensile strength and high toughness.

Owner:浙江海威包装有限公司

Modified calcium carbonate and application thereof to preparation of silicon rubber

InactiveCN108752981AGood compatibilityGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentBulk fillPalmitates

The invention discloses modified calcium carbonate and the application thereof to preparation of silicon rubber. The modified calcium carbonate is subjected to twice surface modification by a surfacetreating agent consisting of pentaerythritol palmitate and sodium polysiloxane succinate amide sulfonate as well as polyurethane methyl sesquisiloxane and vegetable oil fatty acid alkanolamide borate.The modified calcium carbonate has the advantages of high dispersibility, high toughness, weather resistance, high-temperature and low-temperature resistance and the like, can be filled with a largeamount of silicon rubber, and gives high strength, high toughness, high-temperature and low-temperature resistance, high impact resistance, high flame resistance, corrosion resistance, tensile strength and high breaking elongation to the silicon rubber after filling.

Owner:贺州钟山县双文碳酸钙新材料有限公司

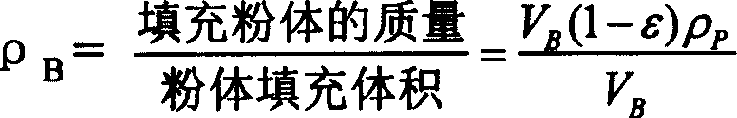

Size distribution method for micro powder

InactiveCN1600519AGood effect of dispersion modificationLow costMixing methodsDistribution methodPeak value

A graded dispersion method of superfine powder uses a numbers of superfine powders in different peak value sizes to carry out mixing preparation in order to obtain optimum dispersion result of powder with peak value of 300 micron to 15 nanometre. The superfine powder material can be organic material, inorganic material or mixture of the two and the mixing-preparation can be single organic material, single inorganic material, or mixed both, two or above organic with two or above inorganic materials.

Owner:DEHAO TECH DEV TIANJIN CITY

Soy protein adhesive and preparation method thereof

ActiveCN109181631AImprove surface hydrophobicityImprove the strengthening and toughening effectNon-macromolecular adhesive additivesProtein adhesivesSulfateGraphene

The invention discloses a soy protein adhesive which comprises the following raw materials in parts by weight: 20-50 parts of soy protein powder, 200-600 parts of water, 5-15 parts of urea, 5-10 partsof calcium sulfate, 3-5 parts of graphene, 3-5 parts of manganese dioxide and 5-15 parts of an anionic surfactant. The invention further provides a preparation method of the soy protein adhesive. According to the method, by virtue of hydrophobic modification, high-temperature treatment, ultrasonic treatment and the like of the soy protein powder, an enhancer is added, so that the prepared soy protein adhesive is excellent in water resistance and high in bonding strength. Therefore, the quality of plywood is ensured.

Owner:南京泓莉沃材料科技有限公司

Two-component epoxy resin pouring sealant and preparation method thereof

InactiveCN105368362AStrong UV Absorbing PropertiesReduce in quantityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyDiluent

The invention provides a two-component epoxy resin pouring sealant. The two-component epoxy resin pouring sealant is composed of a component A and a component B, wherein, the component A comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 10-15 parts of diluents, 1-3 parts of an antifoaming agent, 50-70 parts of a filler, 5-8 parts of a fire retardant, 1-1.5 parts of color paste, 20-30 parts of nano iron oxide, and 10-15 parts of LIR; the component B comprises the following raw materials in parts by weight: 100 parts of a curing agent and 2-4 parts of a promoter; wherein a weight ratio of the component A to the component B is 2:1. The invention also provides a preparation method of the two-component epoxy resin pouring sealant. The two-component epoxy resin pouring sealant has the advantages of good mechanical property and strong toughness.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

Preparation method of sodium calcium silicate glass bottles

ActiveCN108117267AImprove the strengthening and toughening effectImproved high thermal shock resistanceGlass blowing apparatus50SMagnesium

The invention relates to a preparation method of sodium calcium silicate glass bottles. The preparation method specifically comprises the following steps: (1) weighing quartz sand, crushed glass, limestones, sodium carbonate, sodium nitrate, borax, barium carbonate, magnesium carbonate, mullite crystal whiskers, silicon nitride crystal whiskers, cerium oxide powder and selenium powder; and ball-milling and mixing the components to obtain a mixed material; (2) feeding the mixed material into a smelting furnace, wherein the temperature of the mixed material reaches 1570-1600 DEG C, and keeping the temperature for 9-11h; and (3) cooling a glass stock solution to 1320-1350 DEG C, and blowing and forming the glass bottles; converting the glass bottles to an annealing furnace at 420-430 DEG C, keeping the temperature for 80-130min first, then heating the glass bottles to 500-520 DEG C, keeping the temperature for 80-120min, taking out the glass bottles, cooling the glass bottles for 6-9s with a air flow at 35-40 DEG C, and then cooling the glass bottles for 30-50s with a air flow at 9-15 DEG C. The internal stresses in the glass bottles can be removed effectively, and the glass bottles keep relatively good strength, and are good in impact resistance, breakage-proof and stable in chemical property.

Owner:安徽钦同瓶业有限公司

Modified alkali-resistant glass fiber reinforced concrete and preparation method thereof

The invention discloses modified alkali-resistant glass fiber reinforced concrete and a preparation method thereof and belongs to the technical field of building materials. The preparation method comprises steps as follows: alkali-resistant glass fibers and a peach gum liquid are stirred, mixed, soaked and filtered, a filtered product is washed, and soaked alkali-resistant glass fibers are obtained; the soaked alkali-resistant glass fibers are placed in a muffle furnace, nitrogen is introduced into the muffle furnace, the temperature is increased step by step for carbonization, heating reaction is continued, cooling is performed, and pretreated alkali-resistant glass fibers are obtained; the pretreated alkali-resistant glass fibers and a potassium permanganate solution are subjected to a stirred and mixed reaction, a product is filtered, a filtered product is washed and dried, and modified alkali-resistant glass fibers are obtained; river sand, cement, fly ash, silica fume, slag, waterand a silane coupling agent are stirred and mixed, the modified alkali-resistant glass fibers are added for stirring and mixing, and the modified alkali-resistant glass fiber reinforced concrete is obtained. The modified alkali-resistant glass fiber reinforced concrete has excellent impervious performance and mechanical property.

Owner:郦璋

Polyester/carbon nano tube-nucleating agent composite material and preparation method thereof

InactiveCN102532817AImprove performanceReduced spherulite sizeMaterials preparationDimethyl terephthalate

The invention belongs to the technical field of high polymer material preparation, and in particular relates to a polyester / carbon nano tube-nucleating agent composite material and a preparation method thereof. The composite material provided by the invention comprises the following components in parts by weight: 78 parts of dimethyl terephthalate, 61-100 parts of 1,3-propylene glycol, 0.0078-0.78 part of ester exchange catalyst, 0.0078-0.78 part of polymerization catalyst, 0.05-5 parts of carbon nano tube and 0.02-2 parts of nucleating agent. The invention also provides the preparation method of the polyester / carbon nano tube-nucleating agent composite material. The preparation method comprises two steps, namely ester exchange and polymerization. For the composite material provided by the invention, the addition of the nucleating agent enhances the heterogeneous nucleation crystallization capability, improves the crystallization speed, reduces the sphaerocrystal size of dimethyl terephthalate and improves mechanical property; at the moment, the strength-increasing and toughening capabilities are mainly exerted by the addition of the carbon nano tube so that the great improvement of the property of the composite material can be realized only by less filling, thus the application field of the composite material is greatly expanded.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Calcium carbonate enhanced silicone rubber composite material and preparation method

The invention discloses a calcium carbonate enhanced silicone rubber composite material and preparation method. The calcium carbonate enhanced silicone rubber composite material comprises the following raw materials in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 10-30 parts of methyl vinyl silicone rubber, 30-60 parts of modified calcium carbonate, 5-10 parts of aramid fiber, 5-15 parts of white carbon black, 4-8 parts of cross-linking agent, 1-3 parts of stabilizer, 2-4 parts of coupling reagent, 0.1-1 part of catalyst, 3-6 parts of processing agent and 0.5-1.5parts of antioxidant. According to the invention, the silicone rubber composite material prepared by adopting a unique raw material formula and the coordination of all the components has the advantages of high strength, high toughness, high impact resistance, high and low temperature resistance, high stability, ageing resistance, fire resistance, and the like, the processing process is simple, thecost is lower and the market prospect is wide.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Insert-buckled bullet-proof ceramic wafer and preparation method thereof

The invention discloses an insert-buckled bullet-proof ceramic wafer and a preparation method thereof. The bullet-proof ceramic wafer is composed of 40-50% of silicon carbide powder, 20-25% of siliconpowder, 18-22% of short carbon fibers and 10-16% of phenolic resin powder, and the bullet-proof ceramic wafer is in butt joint in a concave-convex or top-bottom insert-buckled manner, so that the bonding area and bonding strength of the adhesive in the insert-buckled structure are increased, and the joint strength and rigidity between the ceramic wafers are enhanced. Moreover, the raw materials are subjected to cold-pressing and hot-pressing molding, a sintered composite ceramic material which has high strength, hardness and good wear resistance and is nearly completely dense can be obtained,the service life is long, and the processibility is high.

Owner:LUOYANG INST OF SCI & TECH

Nano molybdenum disilicide-enhanced high-thermal-conductivity silicon carbide-based ceramic circuit board substrate material and preparation method thereof

The invention discloses a nano molybdenum disilicide-enhanced high-thermal-conductivity silicon carbide-based ceramic circuit board substrate material. According to a silicon carbide-based ceramic circuit board substrate, micron-sized silicon carbide powder and nano-sized aluminum oxide powder are compounded for use, so that a blank body is higher in density and better in sintering stability. The sintering temperature can be effectively decreased through added pyrophyllite. Nano molybdenum disilicide has the good reinforcement and toughening effect, can promote the thermal conductivity and does not damage the insulativity of the substrate. A polyethylene glycol complex solvent containing nano-ceramic powder transparent liquid has the high wettability and bonding capability for powder, the various materials can be evenly scattered and coated to form the blank body of a uniform structure, and the composite ceramic substrate with the high density, strength and thermal conductivity can be obtained at the relatively low temperature. The production process is safe and environmentally friendly, and the application potential is great.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

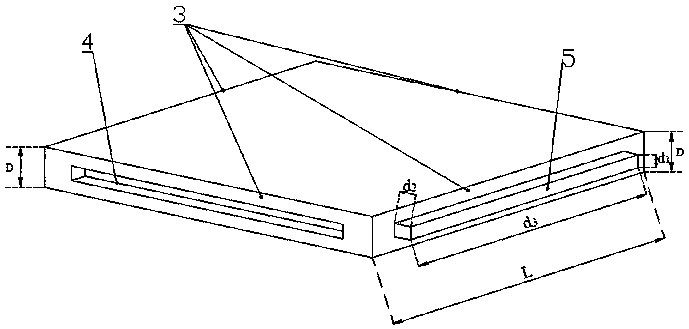

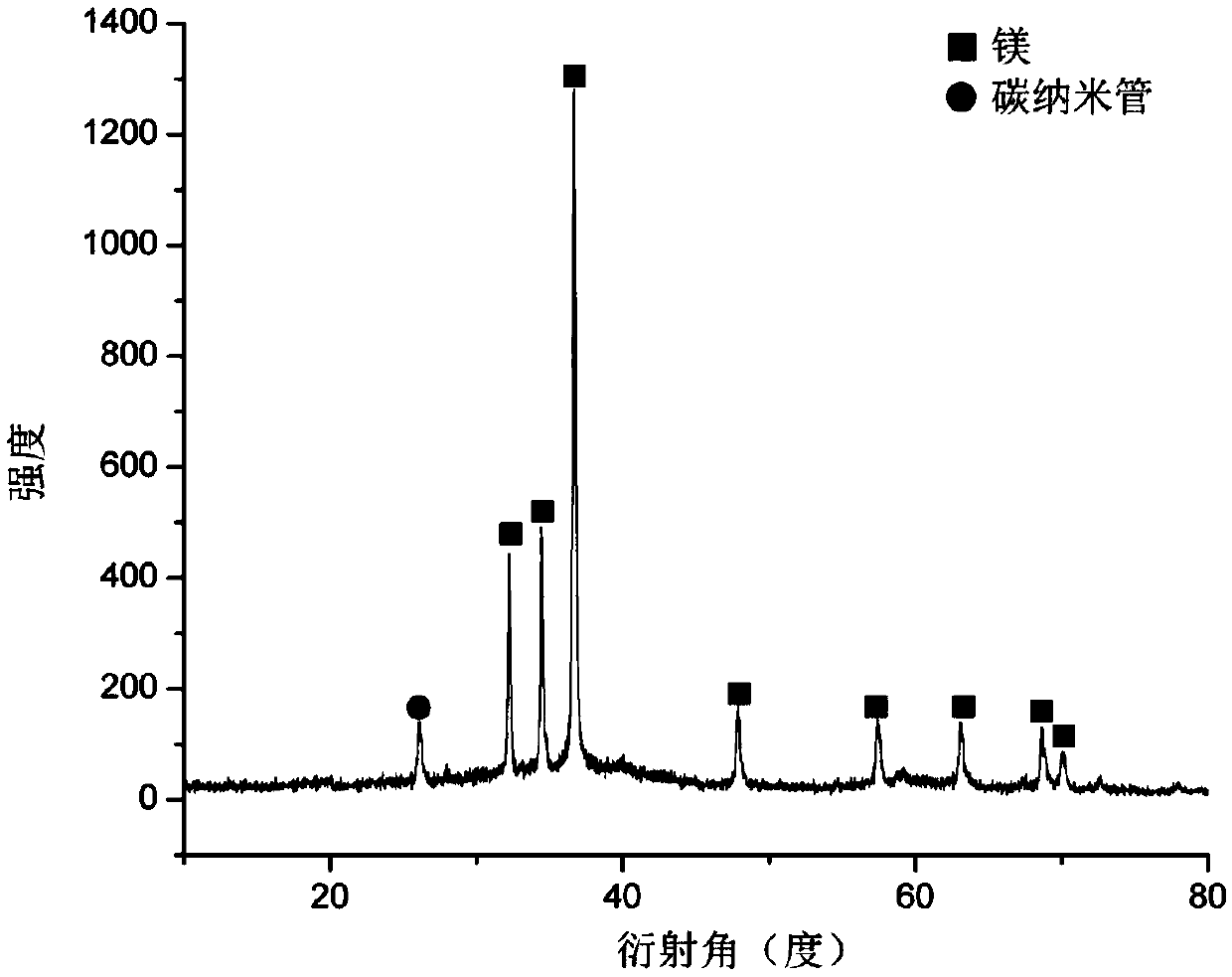

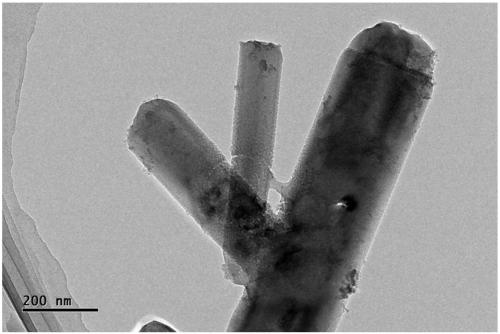

Preparation method of carbon-nanotube-reinforced magnesium-based composite material

ActiveCN109666816AThe interface is tightly combinedGood comprehensive mechanical propertiesNanometer sizeCarbon nanotube

The invention discloses a preparation method of a carbon-nanotube-reinforced magnesium-based composite material and relates to a non-metal fiber-containing alloy characterized by a matrix material. According to the method, nanometer-sized magnesium particles are synthesized on the surface of a carbon nanotube in situ so as to obtain a magnesium-coated carbon nanotube composite powder; and then themagnesium-coated carbon nanotube composite powder is subjected to an ultrasonic extrusion casting process to form the carbon-nanotube-reinforced magnesium-based composite material. The defects of a method for preparing the carbon-nanotube-reinforced magnesium-based composite material in the prior art that the carbon nanotube agglomeration results in uneven dispersion of the carbon nanotube in a magnesium matrix, the preparation process results in structural damage of the carbon nanotube, consequently, the reinforcing effect is reduced, different degrees of oxidation of the magnesium matrix are difficult to avoid, the carbon nanotube and magnesium interface in the composite material has poor wettability, and only weak interface bonding is formed, so that the carbon-nanotube-reinforced magnesium-based composite material has poor comprehensive mechanical properties are overcome.

Owner:HEBEI UNIV OF TECH +1

Strengthened and toughened PVC composition and preparation method thereof

InactiveCN106317670ASolving Dispersion ProblemsSolve associativityCarbon nanotubeUltimate tensile strength

A strengthened and toughened PVC composition and a preparation method thereof belongs to the technical field of plastic processing. The strengthened and toughened PVC composition comprises, by weight, 100 parts of PVC, 1.5-2.5 parts of an organic tin stabilizer, 4-8 parts of PVC / surfactant coated carbon nanotubes, 1.5-2.5 parts of a processing assistant ACR, 1.0-1.5 parts of a lubricant, 1.5-2.5 parts of titanium dioxide and 7-12 parts of fine calcium carbonate. The preparation method comprises the following steps: weighing above materials, putting the materials in a mixer, blending the materials, and discharging the obtained material to prepare the strengthened and toughened PVC composition. The PVC material is modified with the PVC / surfactant coated carbon nanotubes, so the agglomeration phenomenon of the carbon nanotubes is eliminated, the PVC material has high strength and toughness, and the strength decrease problem brought by a general toughening modifier is avoided.

Owner:CHINA PETROLEUM & CHEM CORP

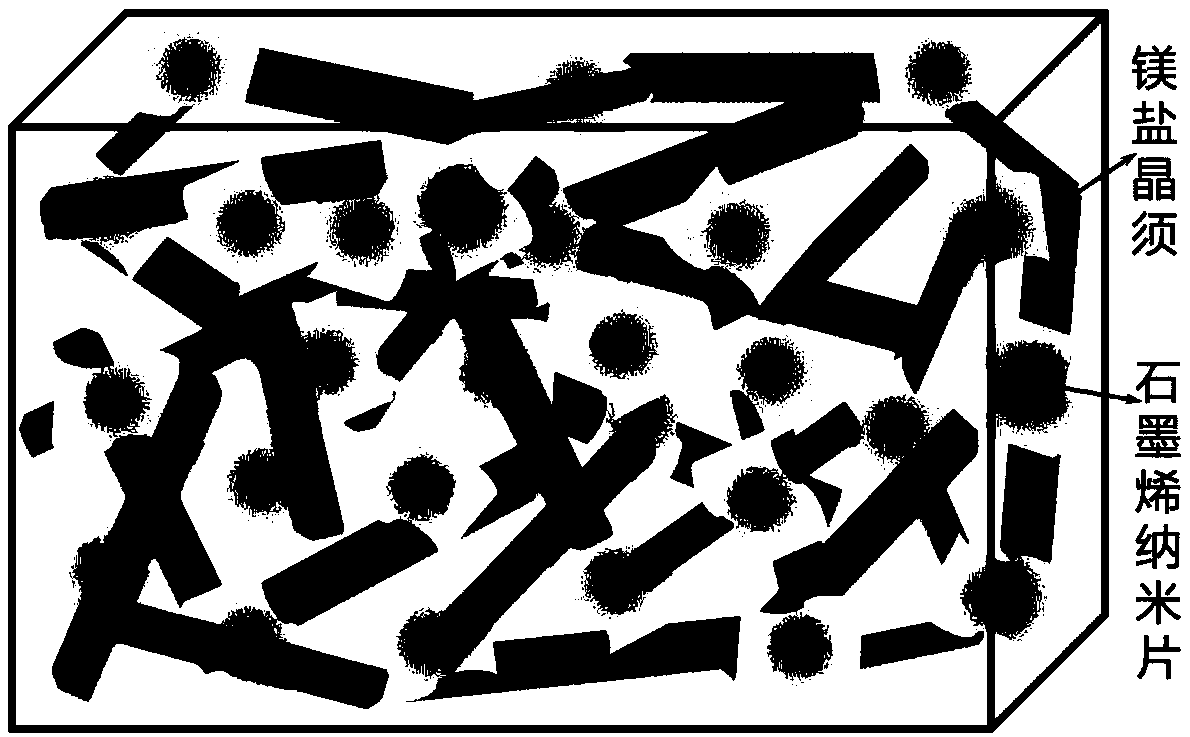

Polymer composite material containing micro-nano hybrid structure filler, and preparation method thereof

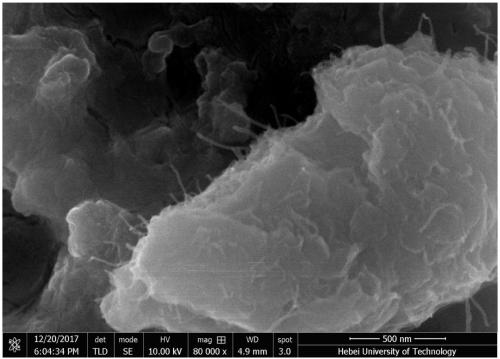

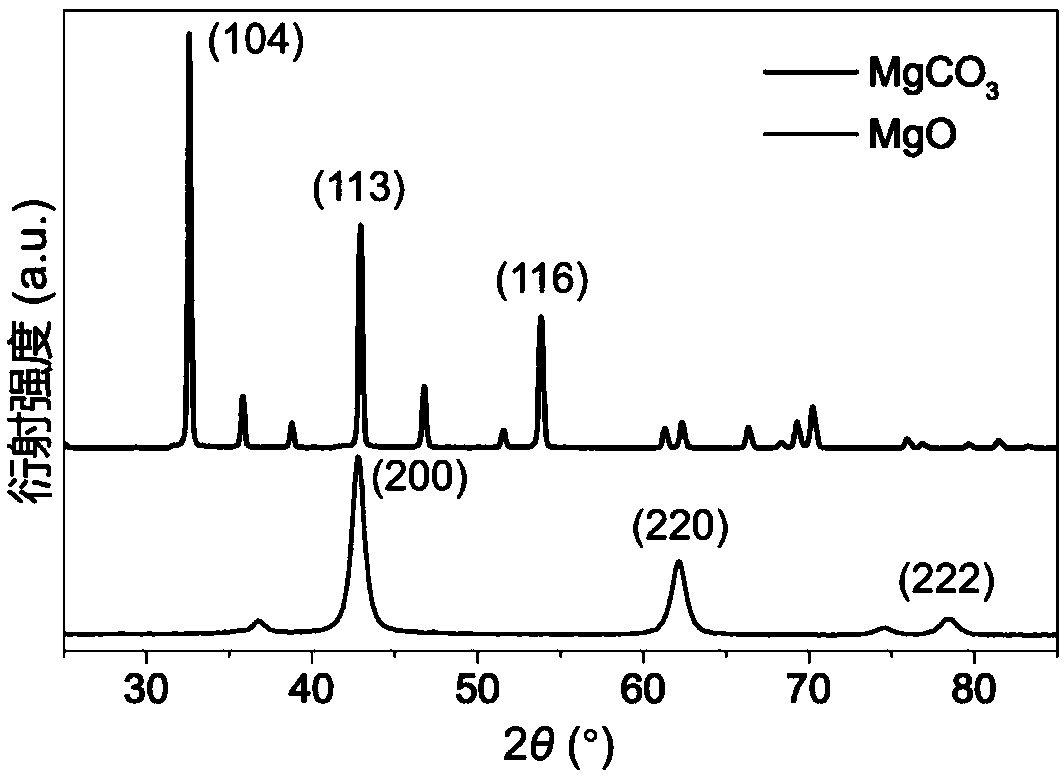

InactiveCN111303511AHigh crystallinityLarge specific surface areaPolycrystalline material growthFrom normal temperature solutionsMagnesium saltNano hybrid

The invention discloses a polymer composite material containing a micro-nano hybrid structure filler, and a preparation method thereof, wherein the composite material is composed of graphene nanosheets, magnesium salt whiskers and a polymer matrix. According to the invention, a stable, perfect and efficient heat-conducting network chain is constructed in a polymer matrix by adopting an organic-inorganic hybrid composed of multi-scale and multi-dimensional graphene nanosheets and magnesium salt whiskers, so that the heat-conducting property of the composite material is greatly improved under the condition of low filler addition amount while good melt processability is ensured; the hybrid structure filler also has good reinforcing and toughening effects on the composite material, and significantly improves the comprehensive mechanical properties of the composite material; and the method is simple in production process, easy to implement, rich in raw material source, safe, environment-friendly and low in production cost.

Owner:ENN GRAPHENE TECH CO LTD

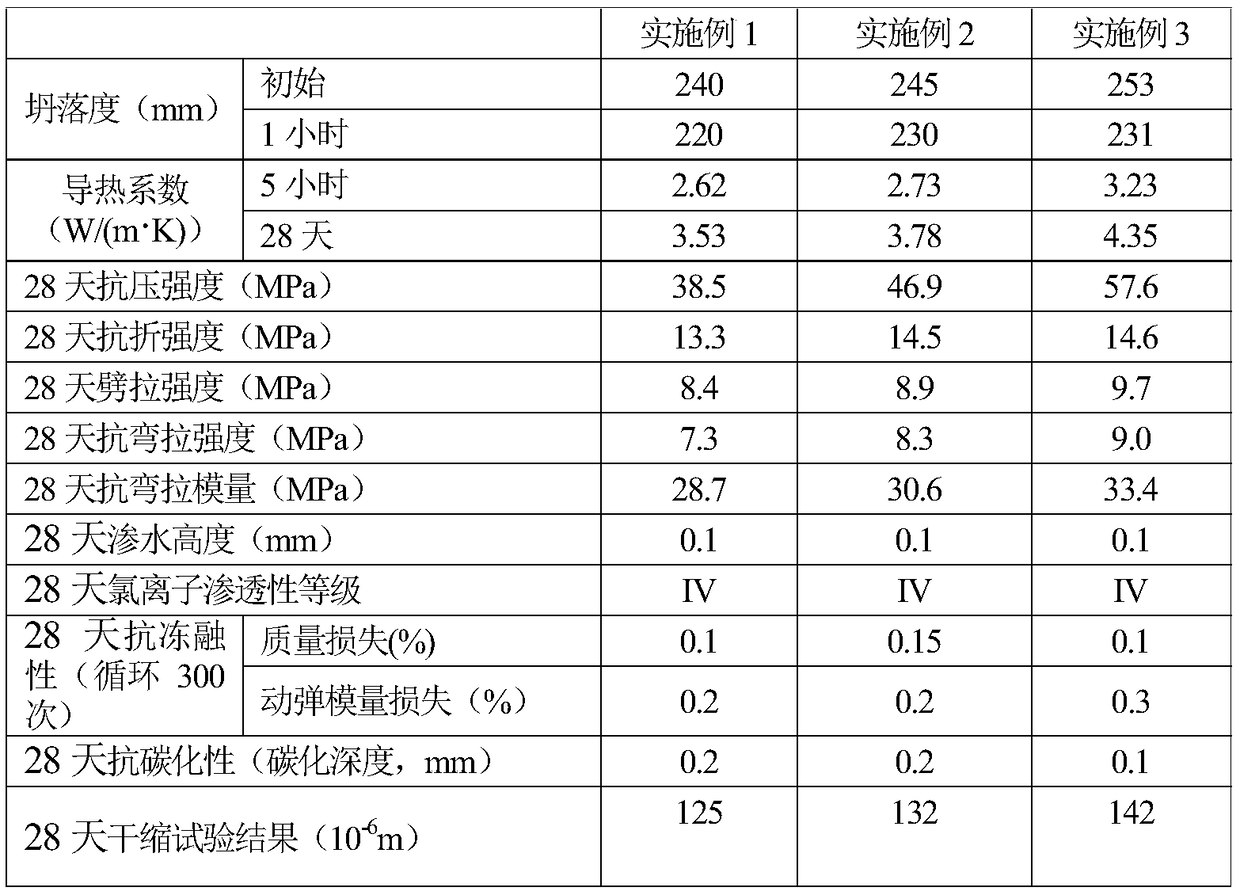

Anti-crack, anti-permeability and high-durability concrete and preparation method thereof

ActiveCN109293303AImprove toughnessImprove penetration resistanceSolid waste managementFiberCrack resistance

Provided are anti-crack, anti-permeability and high-durability concrete and a preparation method thereof; the concrete is prepared from cement, silica powder, boron nitride powder, sand, polyvinyl alcohol fibers, crushed stone, fly ash, coal gangue powder, phosphorus slag powder, a water reducing agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The thermal conductivity coefficients of the obtained concrete at 1 h and 28 days of age is 2.62-3.23 W / (m*K) and 3.53-4.35 W / (m*K) respectively, the compressive strength at 28 days of age is 38.7-57.6 MPa, the breaking strength is 13.3-14.6 MPa, the splitting tensile strength is 8.4-9.7 MPa, the bending-tensile strength is 7.3-9.0 MPa and the bending-tensile elasticity modulus is 28.7-33.4 GPa. Meanwhile, all the water permeability resistance, chloride ion permeability resistance, freeze-thaw resistance and carbonization resistance reach the best level. The concrete has high workability, high volume stability and abilities of high durability, high toughness, high crack resistance and high permeability resistance, and is suitable for the requirements of ordinary high performance concrete under various complex environmental conditions.

Owner:衢州鑫业建材有限公司

Nano composite hydrogel and preparation method thereof

InactiveCN108409901AGood dispersionImprove the strengthening and toughening effectIn situ polymerizationSilicon dioxide

Owner:SOUTHEAST UNIV

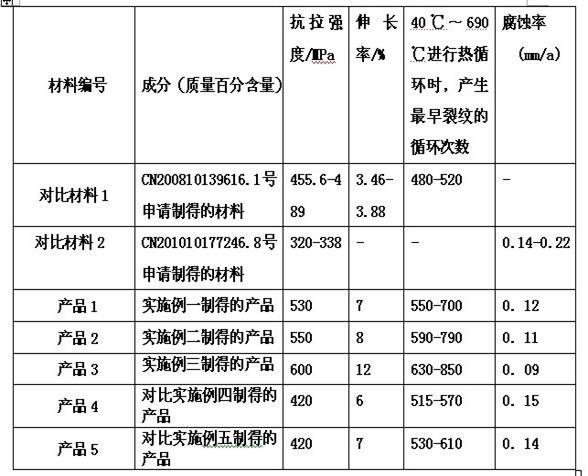

Heat resistant and corrosion resistant vermicular cast iron material and preparation method thereof

InactiveCN102071371AImprove the strengthening and toughening effectImprove toughnessCorrosion resistantMetal

The invention provides a heat resistant and corrosion resistant vermicular cast iron material and a preparation method thereof. The material has good performances. The preparation method has simple process and low production cost and is suitable for industrial production. The material uses vermicular cast iron as matrix and metal wire balls formed by steel wires are distributed in the matrix, wherein the diameter of the steel wires is 1-2mm, the diameter of the metal wire balls is 10-15cm and the volume percentage of the steel wires to the material of the invention is 5-40%.

Owner:金湖中博物联网科技有限公司

Damping wear-resistant aluminum alloy material and preparation method thereof

InactiveCN102051554AEasy to enhance and toughenImprove the strengthening and toughening effectFiberCarbon fibers

The invention discloses a damping wear-resistant aluminum alloy material and a preparation method thereof. In the damping wear-resistant aluminum alloy material, aluminum alloy serves as a matrix; steel wire rolls and carbon fibers are distributed in the matrix; the diameter of each steel wire roll is 10 to 15 centimeters; each steel wire has a rectangular section and the section size is 0.1-0.4 mm*0.5-1.5 mm; the weight ratio of the steel wires to the carbon fibers is 25-30:1; and the steel wires and the carbon fibers account for 20 to 40 percent of the volume of the material. The damping wear-resistant aluminum alloy material prepared by the method has high toughness, wear resistance, a simple process and low production cost.

Owner:金湖中博物联网科技有限公司

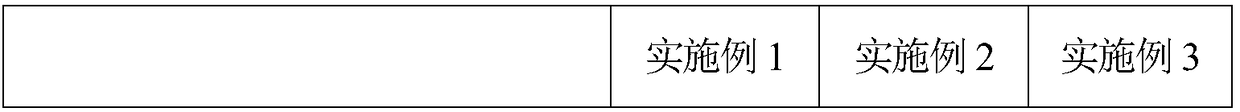

High-tenacity high-anti-permeability high-durability concrete and preparation method thereof

ActiveCN109231918AImprove crack resistanceHigh compressive strengthSolid waste managementFiberCrack resistance

The invention discloses high-tenacity high-anti-permeability high-durability concrete and a preparation method thereof. The high-tenacity high-anti-permeability high-durability concrete comprises cement, coal ash, silica powder, steel slag powder, boron nitride, low-concentration oxidized graphene slice layer powder, phosphorus slag powder, sand, gravels, high-strength polyvinyl alcohol fibers, awater reducing agent, a dispersing excitant, modified oxidized graphene dispersion liquid and water. The prepared concrete has high-strength, high-tenacity, high-crack-resistance, high-anti-permeability and high-durability. A heat conductivity coefficient of the concrete is 3.63-3.75 W / (mK), a heat conductivity coefficient of 28 days of aged concrete is 4.62-4.67 W / (mK), compressive strength is 135.4-156.2 MPa, breaking strength is 21.5-23.9 MPa, splitting strength is 12.6-14.4 MPa, flexural strength is 15.4-19.6 MPa, and an anti-bending elastic modulus is 47.7-61.2 GPa. The prepared concreteis in comply with requirements of the C130-C150 high-performance long-durability concrete.

Owner:广州天达混凝土有限公司

Preparation method of reinforcing and toughening lubricant specially used for ABS

The invention belongs to the technical field of lubricants, and in particular relates to a preparation method of a reinforcing and toughening lubricant specially used for ABS. The method comprises thefollowing steps: firstly nano powder is added into ethanol, a treating agent is added to modify the surface of the powder, the obtained treated nano powder is added into ethylenediamine to obtain aminated nano powder, the aminated nano powder and stearic acid are subjected to a reaction at high temperature to obtain a waxy substance, glass cellulose modified by glyceryl monostearate can be addedinto the waxy substance, extrusion granulation is performed, and therefore the reinforcing and toughening lubricant specially used for the ABS can be obtained. According to the method provided by theinvention, the prepared lubricant is added into the ABS resin, and the lubricant has good compatibility with the ABS resin, and improves the impact strength and bending strength of the ABS resin whileimproving the fluidity of the ABS resin.

Owner:常州可赛成功塑胶材料有限公司

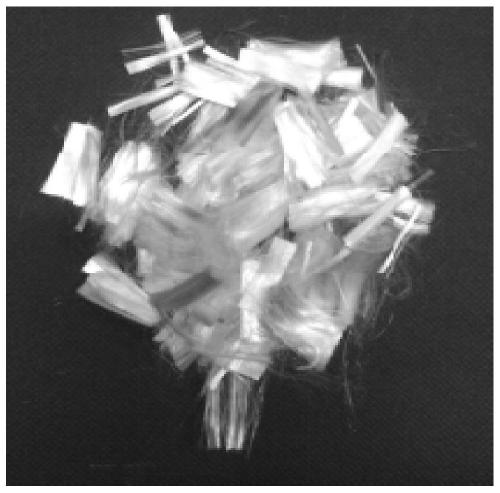

Polyvinyl alcohol fiber dispersion technology and application thereof

The invention discloses a polyvinyl alcohol fiber dispersion technology, comprising the following steps: (1) placing polyvinyl alcohol fiber in a container and conducting stirring, so as to convert the polyvinyl alcohol fiber from bundle fiber to bulky fiber; (2) adding a powder having a particle size of a micrometer order to the system of the step (1), and then stirring the mixture in a ball milluntil the bulky fiber is dispersed into monofilaments to achieve dispersion of the polyvinyl alcohol fiber, so as to finally obtain monofilament polyethylene alcohol fiber. The invention also discloses application of the dispersion technology to preparation of concrete materials. The dispersion technology can disperse the polyvinyl alcohol fiber well, and the added powder does not affect variousmechanical properties of the concrete material, but improves the dispersion uniformity of the polyvinyl alcohol fiber in the concrete, and better improves the reinforcement toughening performance of the concrete. The dispersion technology has the advantages of simpleness, short process, easy control, low cost and easy industrial production.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com