Carbonitride nano two-dimensional material enhanced structural ceramic and preparation method thereof

A nano-two-dimensional, carbonitride technology, applied in the field of materials, can solve problems such as limitations, and achieve the effect of improving thermal, excellent mechanical properties, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

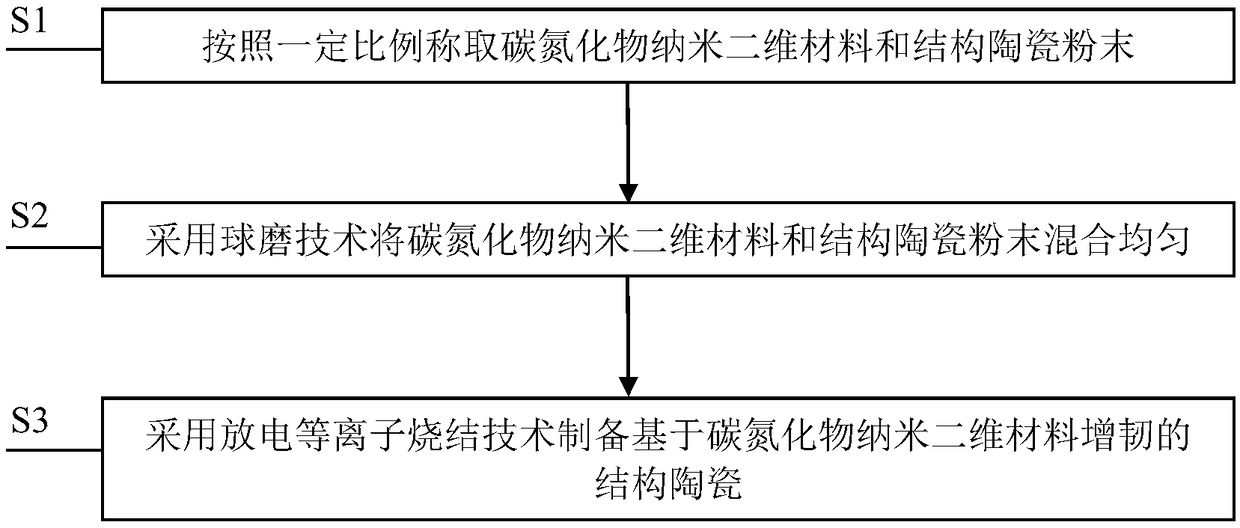

[0026] like figure 1 , the preferred embodiment of the present invention discloses a method for preparing structural ceramics toughened based on carbonitride nano-two-dimensional materials, comprising the following steps:

[0027] S1: Weigh carbonitride nanometer two-dimensional material and structural ceramic powder according to a certain ratio;

[0028] Among them, carbonitride nano two-dimensional materials include but not limited to hexagonal boron nitride (h-BN), graphitic carbon nitride (g-C 3 N 4 ), MXene;

[0029] The chemical formula of MXene is MX y T x , where M is Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and other early transition metals, X is C, N; T is -OH, -O, -H, -F and other M n+1 x n surface terminal functional groups), including but not limited to Ti 3 C 2 T x 、Cr 3 C 2 T x 、Ti 2 CT x 、Ti 2 NT x 、 Ta 4 C 3 T x , (Ti 0.5 ,Nb 0.5 ) 2 CT x 、Ti 2 (C 0.5 ,N0.5 ) T x 、Zr 3 C 5 T x 、Hf 2 C 5 T x 、Mo 2 TiC 2 T x , (Ti 1-z ,V z ) 3 C 2 T ...

Embodiment approach 1

[0040] This embodiment specifically includes the following steps: referring to patent application 201310625253.3, adopting mechanical alloying technology to prepare Si-B-C-N ceramic powder, weighing Ti respectively according to the mass ratio of 1:99 3 C 2 T x and Si-B-C-N ceramic powder; use dry ball milling technology to mix and mill the two material powders for 24 hours, in which the mass of silicon nitride grinding balls is 20 times the total mass of the two material powders; use spark plasma sintering technology at 1800 ° C, nitrogen Under the condition of atmosphere protection, heat preservation and sintering for 5 minutes to obtain Ti 3 C 2 T x / Si-B-C-N bulk ceramics.

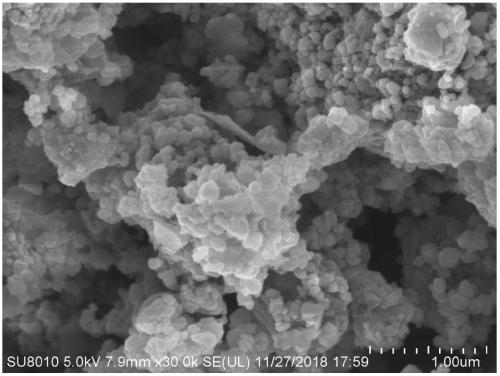

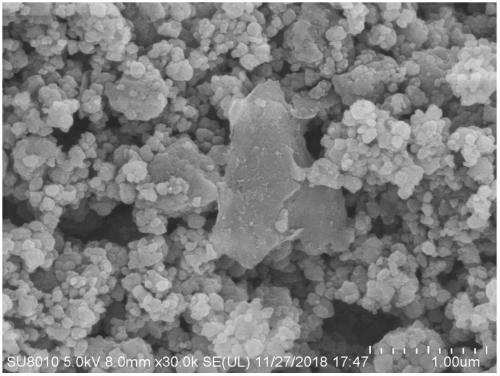

[0041] figure 2 is the Ti obtained in Embodiment 1 3 C 2 T x Scanning electron microscope picture of mixed powder with Si-B-C-N, it can be seen that Ti 3 C 2 T x The nano two-dimensional material is well dispersed in the Si-B-C-N ceramic powder, and the uniformly dispersed mixed powder is h...

Embodiment approach 2

[0043] This embodiment specifically includes the following steps: referring to patent application 201310625253.3, adopting mechanical alloying technology to prepare Si-B-C-N ceramic powder, weighing Ti respectively according to the mass ratio of 1:99 2 NT x and Si-B-C-N ceramic powder; use wet ball milling technology to mix and mill the two material powders for 24 hours, wherein the quality of the silicon nitride grinding ball is 20 times the total mass of the two material powders, and the grinding medium is a water / alcohol mixture; mix The ball-milled slurry was dried in a vacuum oven at 60°C for 12 hours; using spark plasma sintering technology at 1900°C under nitrogen atmosphere protection conditions, heat preservation and sintering for 3 minutes to obtain Ti 2 NT x / Si-B-C-N bulk ceramics.

[0044] For the Ti obtained in Embodiment 2 2 NT x / Si-B-C-N bulk ceramics can be known through analysis and testing, the Ti obtained in the second embodiment 2 NT x The fracture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com