Preparation method of reinforcing and toughening lubricant specially used for ABS

A technology of strengthening and toughening and lubricants, applied in the field of lubricants, can solve the problems of obvious impact strength and bending strength, and achieve the effect of reducing resistance, conducive to stress transfer, and reducing chemical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

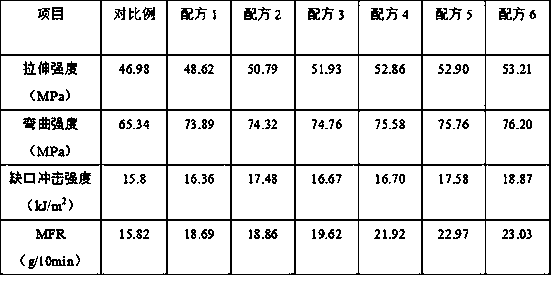

Examples

example 1

[0035] According to the mass ratio of 1:10, weigh nano-calcium carbonate and add it to ethanol, use a high-speed emulsifier, disperse at a speed of 1000r / min for 20min to obtain a nano-calcium carbonate dispersion, add 1% of the nano-carbonic acid dispersion to the nano-carbonic acid dispersion KH550, heated to 60°C, then kept stirring and reacted for 40 minutes, cooled to room temperature after the reaction, filtered, collected the filter residue, put it in an oven, and dried at 60°C for 8 hours to obtain the treated nano-calcium carbonate; the treated nano-calcium carbonate Calcium is added to ethylenediamine, so that the mass fraction of the treated nano-calcium carbonate in the ethylenediamine solution is 2%, and a high-speed emulsifier is used to disperse at a speed of 1500r / min for 20min, and after dispersion, nano-calcium carbonate ethylenedi Amine solution; add stearic acid into the reaction kettle, and feed nitrogen gas into the reaction kettle at a rate of 10mL / min, w...

example 2

[0038] According to the mass ratio of 1:10, weigh nano-calcium carbonate and add it to ethanol, use a high-speed emulsifier, disperse at a speed of 1500r / min for 25 minutes to obtain a nano-calcium carbonate dispersion, add 1.5% of the quality of the nano-carbonic acid dispersion to the nano-carbonic acid dispersion KH560, heated to 65°C, then kept stirring and reacted for 60 minutes, cooled to room temperature after the reaction, filtered, collected the filter residue, put it in an oven, and dried at 70°C for 9 hours to obtain the treated nano-calcium carbonate; the treated nano-calcium carbonate Calcium is added to ethylenediamine, so that the mass fraction of the treated nano-calcium carbonate in the ethylenediamine solution is 5%, and a high-speed emulsifier is used to disperse at a speed of 2000r / min for 25min, and after dispersion, nano-calcium carbonate ethylenedi Amine solution; add stearic acid into the reaction kettle, and feed nitrogen gas into the reaction kettle at...

example 3

[0041] According to the mass ratio of 1:10, weigh nano-silicon carbide and add it to ethanol, use a high-speed emulsifier, disperse at a speed of 2000r / min for 30 minutes to obtain a nano-calcium carbonate dispersion, add 1% of the nano-carbonic acid dispersion to the nano-carbonic acid dispersion KH570, heated to 70°C, then kept stirring and reacted for 80 minutes, cooled to room temperature after the reaction, filtered, collected the filter residue, put it in an oven, and dried at 80°C for 10 hours to obtain the treated nano-calcium carbonate; the treated nano-calcium carbonate Calcium is added to ethylenediamine, so that the mass fraction of the treated nano-calcium carbonate in the ethylenediamine solution is 10%, and a high-speed emulsifier is used to disperse at a speed of 2500r / min for 30min, and the dispersed nano-calcium carbonate ethylenedi Amine solution; add stearic acid into the reaction kettle, and feed nitrogen gas into the reaction kettle at a rate of 30mL / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com