Patents

Literature

116results about How to "Improve the interface bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

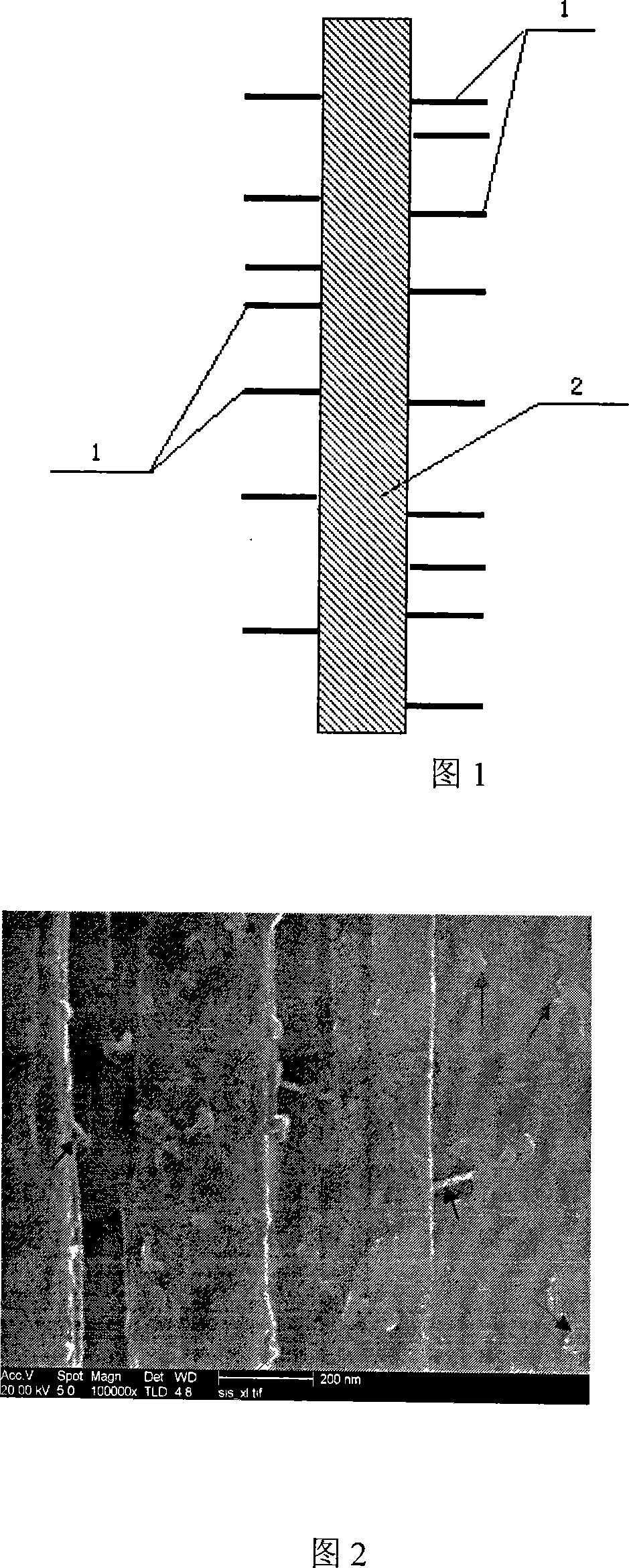

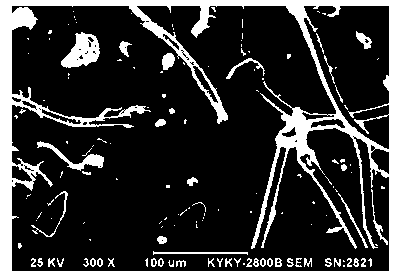

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

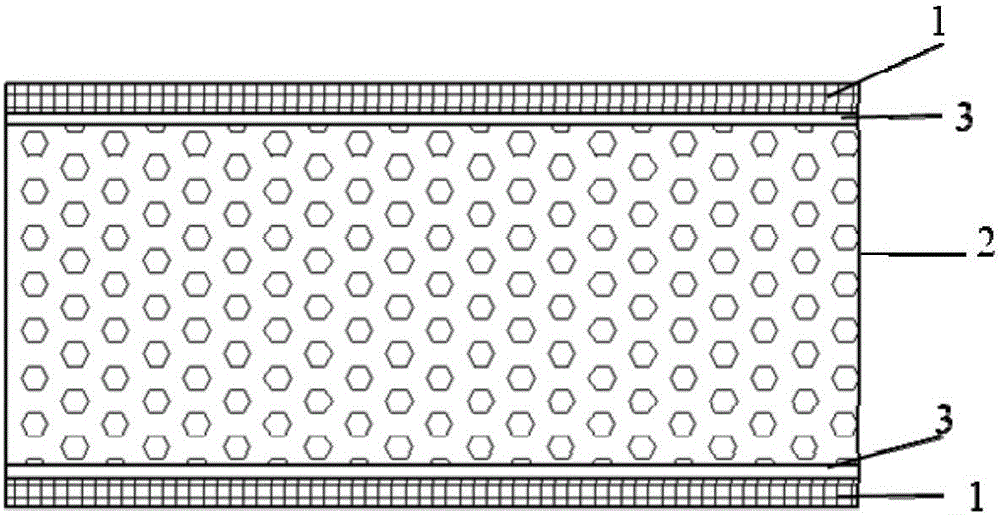

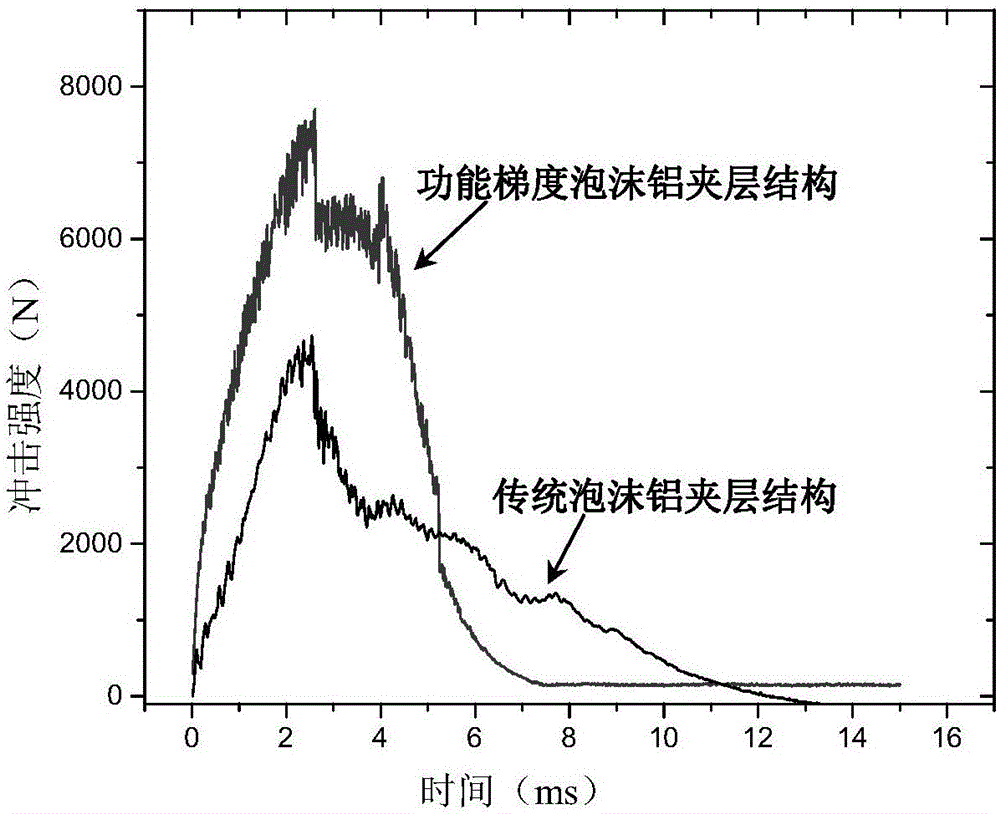

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

Surface modification method of aramid, and reinforced natural rubber material and preparation method thereof

The invention discloses a surface modification method of aramid, a reinforced natural rubber material and a preparation method thereof. The surface modification method of aramid comprises the following steps of: dipping aramid fibre for 0.5-3h by using phosphoric acid solution at 20-50 DEG C, after cleaning and drying, dipping aramid fibre for 1-2h by using acetone solution of epoxy resin with the mass percentage concentration of 5-20% at normal temperature, and then modifying the surface of aramid after drying. According to the invention, active groups of surface modified aramid and terminated hydroxyl of epoxy resin and liquid rubber are chemically reacted simultaneously at mixing temperature, so that the interfacial bonding strength is improved; liquid rubber and matrix rubber are vulcanized together in the subsequent vulcanizing process of mixing rubber, so that a cross-linked network tightly combined with aramid fibre is formed; the problem that the matrix rubber in an original physical manner forms a self cross-linked network while being vulcanized is overcome, and therefore, negative phenomena of a rubber and aramid fibre interface can be reduced; and the aramid reinforced rubber composite material having good interfacial bonding and fibre dispersion can be formed.

Owner:GUIZHOU UNIV

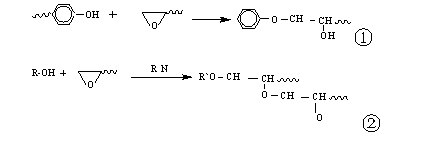

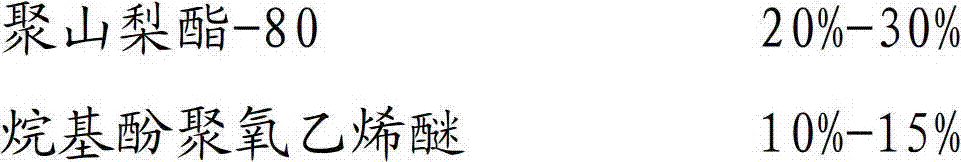

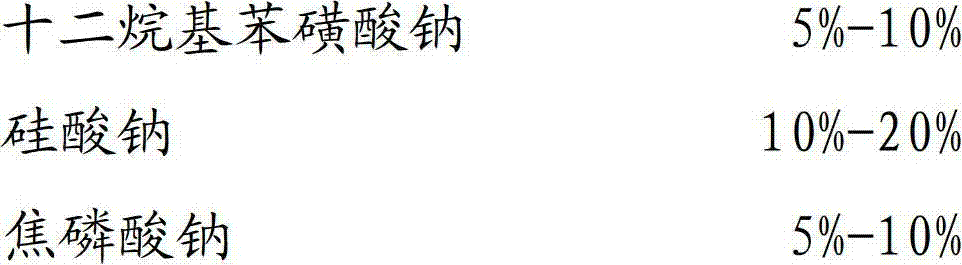

Organic and inorganic composite flushing liquid as well as preparation method and applications thereof

ActiveCN102732239AImprove the interface bonding strengthImprove flushing efficiencyDrilling compositionWater basedPolyethylene glycol

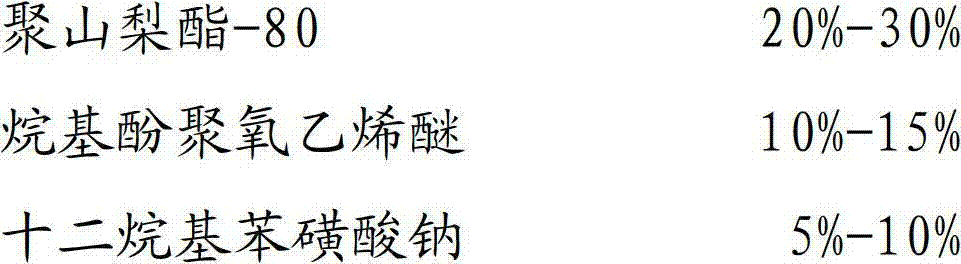

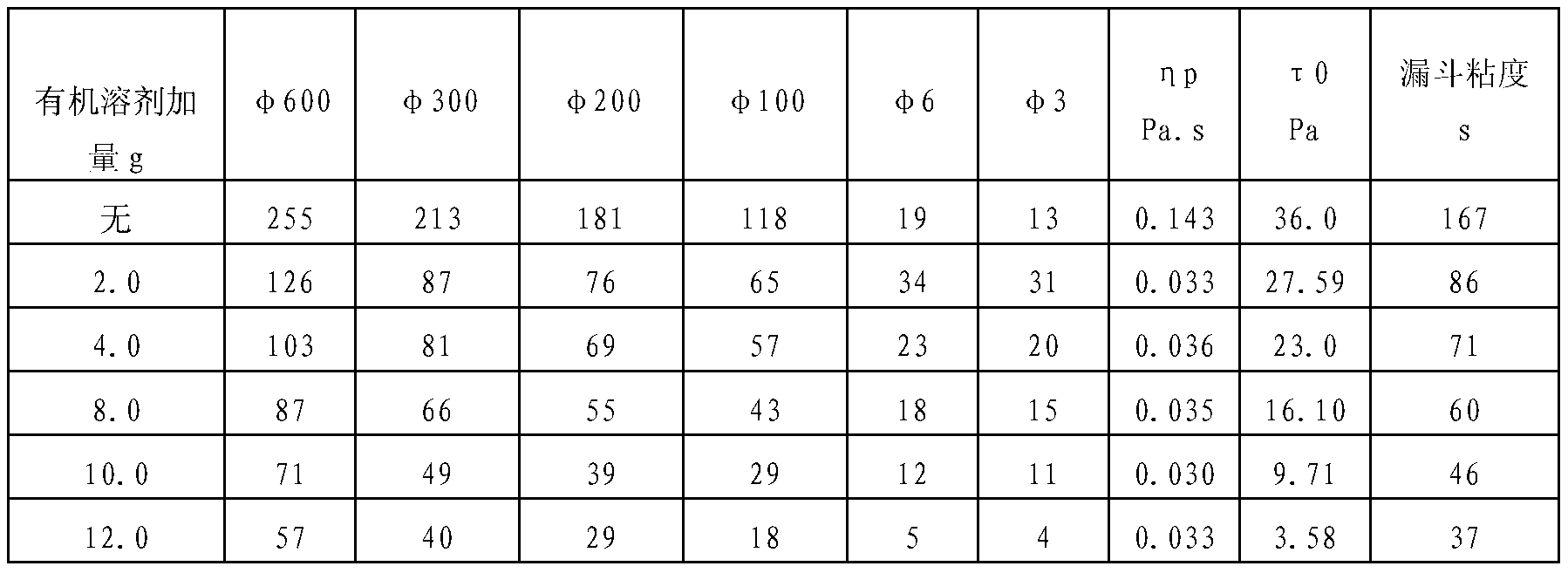

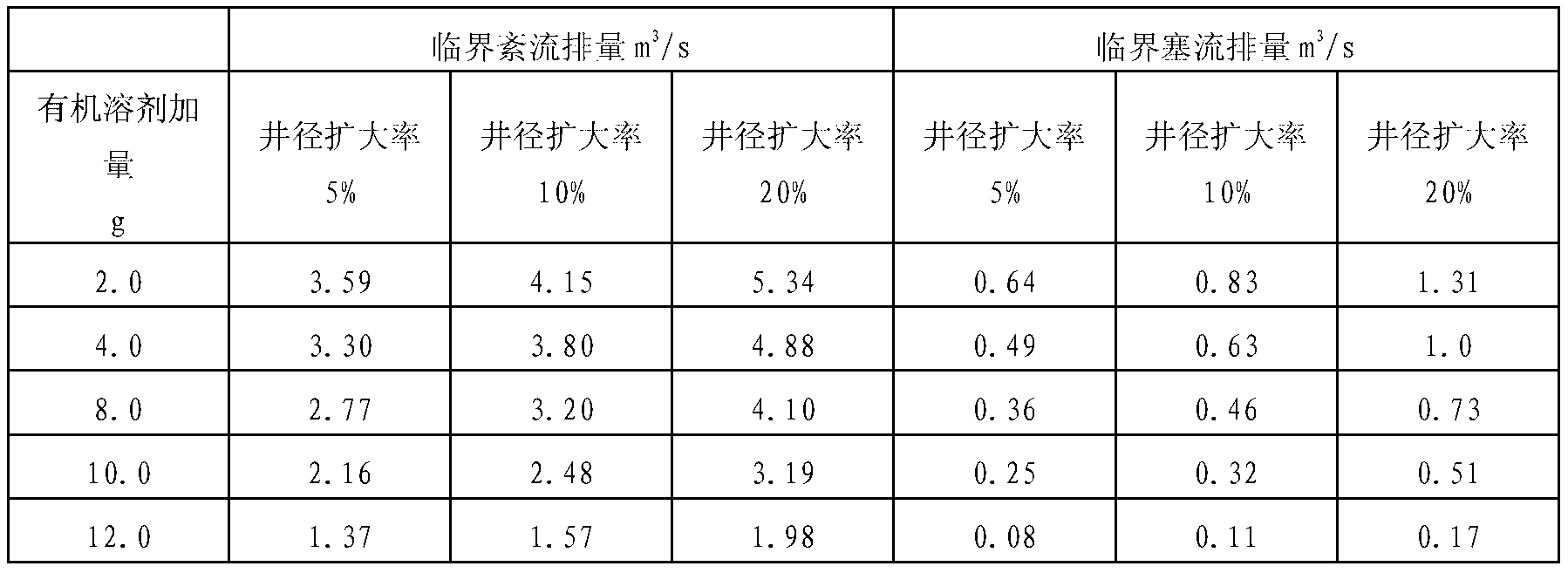

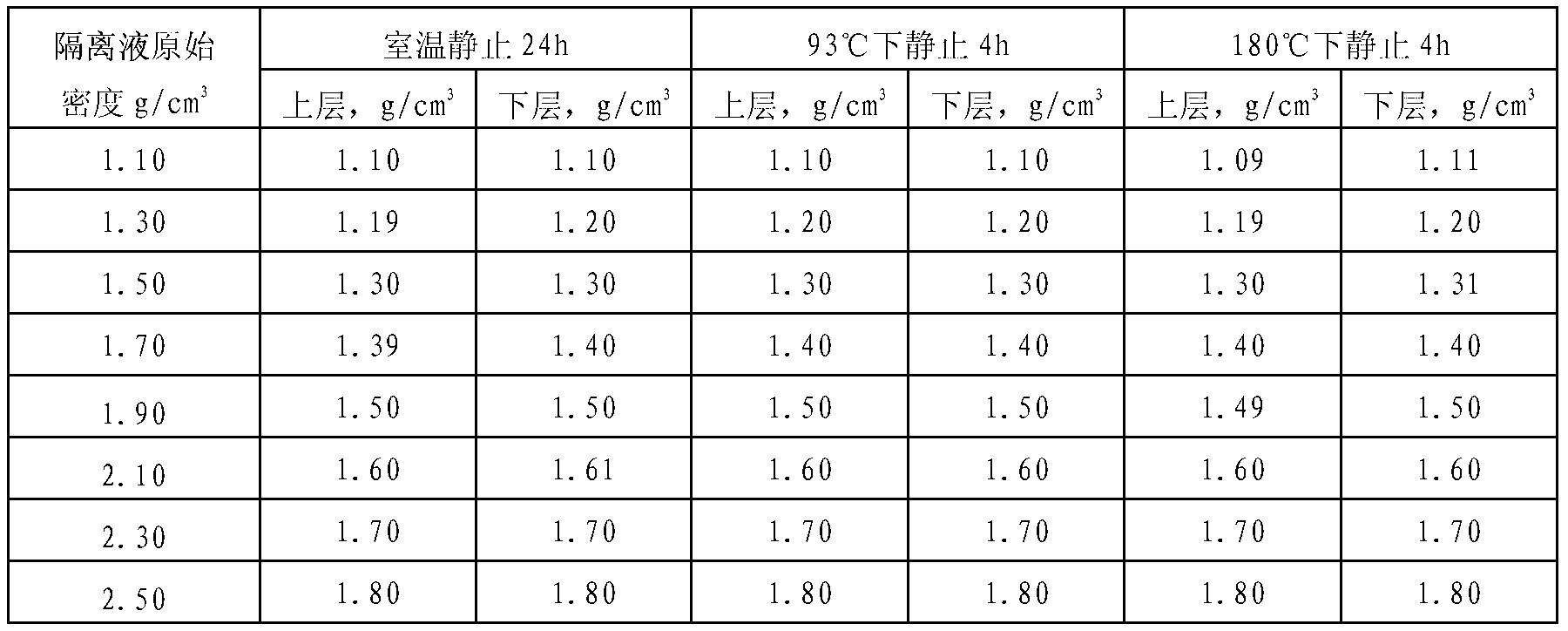

The invention discloses a preparation method of an organic and inorganic composite flushing liquid, and belongs to the technique of oil well cement well cementation. The flushing liquid comprises the following components: polysorbate-80, alkyl phenol polyethylene glycol ether, dodecyl benzene sulfonic acid sodium, sodium silicate, sodium pyrophosphate and water, wherein the mass ratio of each component is as follows: 20%-30% of polysorbate-80, 10%-15% of alkyl phenol polyethylene glycol ether, 5%-10% of dodecyl benzene sulfonic acid sodium, 10%-20% of sodium silicate, 5%-10% of sodium pyrophosphate and the balance of water. The flushing liquid is suitable for both the oil-based mud and water-based mud, has high flushing efficiency, improves the replacement efficiency of a well drilling liquid and cement sheath interfacial cementation quality, and can be used under the condition of 50 DEG C-200 DEG C.

Owner:天津科力奥尔工程材料技术有限公司

Dual-effect well cementing pad fluid using suspending agent as surfactant

ActiveCN103224774AWide range of density adaptationImprove cleanlinessDrilling compositionActive agentDual effect

The invention relates to a dual-effect well-cementing pad fluid using a suspending agent as a surfactant, and mainly solves problems that present well-cementing pad fluid is added with high-molecular polymer grade inorganic suspending agent which can influence compatibility and cement sheath cementation and thus influence sealing effect of well cementing and exploitation operation in a later stage. The dual-effect well-cementing pad fluid comprises the following components by weight parts: 12-20 parts of a flushing suspending agent, 0.2-1 part of an antifoaming agent, 0-420 parts of a weighting agent and 100 parts of water. The dual-effect well-cementing pad fluid using a suspending agent as a surfactant can eliminate adverse influences of inorganic soil and the high-molecular polymer in the well-cementing pad fluid on the compatibility and the cement sheath cementation, improve flushing and displacing effects on a drilling fluid, and guarantee quality of well cementing and the exploitation operation in the later stage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Application of novel epoxy modified heat-resisting liquid silicon rubber

PendingCN108977066AHigh strengthHigh elongation at breakMacromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceUltimate tensile strength

The invention provides application of novel epoxy modified heat-resisting liquid silicon rubber. Specifically, the invention provides application of heat-resisting type liquid silicon rubber with improved strength and interface bonding performance to a preparation of a coating, a binding agent and a composite material. The epoxy modified heat-resisting liquid silicon rubber is prepared from the following raw materials in parts by weight: 100 parts of liquid silicon rubber, 10 parts of a bisphenol A type epoxy resin-silane coupling agent pre-polymer, 3 parts of a curing agent and 0.2 part of acatalyst A. To sum up, the strength and elongation at break of modified liquid silicon rubber are greatly improved (the tensile strength is improved to reach 0.83MPa and is improved by 162 percent when being compared with that of a pure sample, the bonding performance is 0.81MPa and is improved by 160 percent when being compared with that of the pure sample, and the elongation at break reaches 268percent and is improved by about 2 times when being compared with that of the pure sample); the rigidity and toughness of a material matrix are improved at the same time, and the interface bonding strength with filler and the matrix is remarkably increased when the liquid silicon rubber is used for a coating, a bonding agent and a composite material; the application field of the liquid silicon rubber is expanded and the service life of the liquid silicon rubber is prolonged. Meanwhile, the heat resisting performance still can keep a relatively high level, and the heat residual weight at 800 DEG C reaches 53.53 percent; a synthesis process has the advantages of simplicity, easiness for processing, short time and few steps and has a wide market application prospect.

Owner:SICHUAN UNIV

PBT composite material reinforced by modified flat glass fibers, and preparation method of PBT composite material

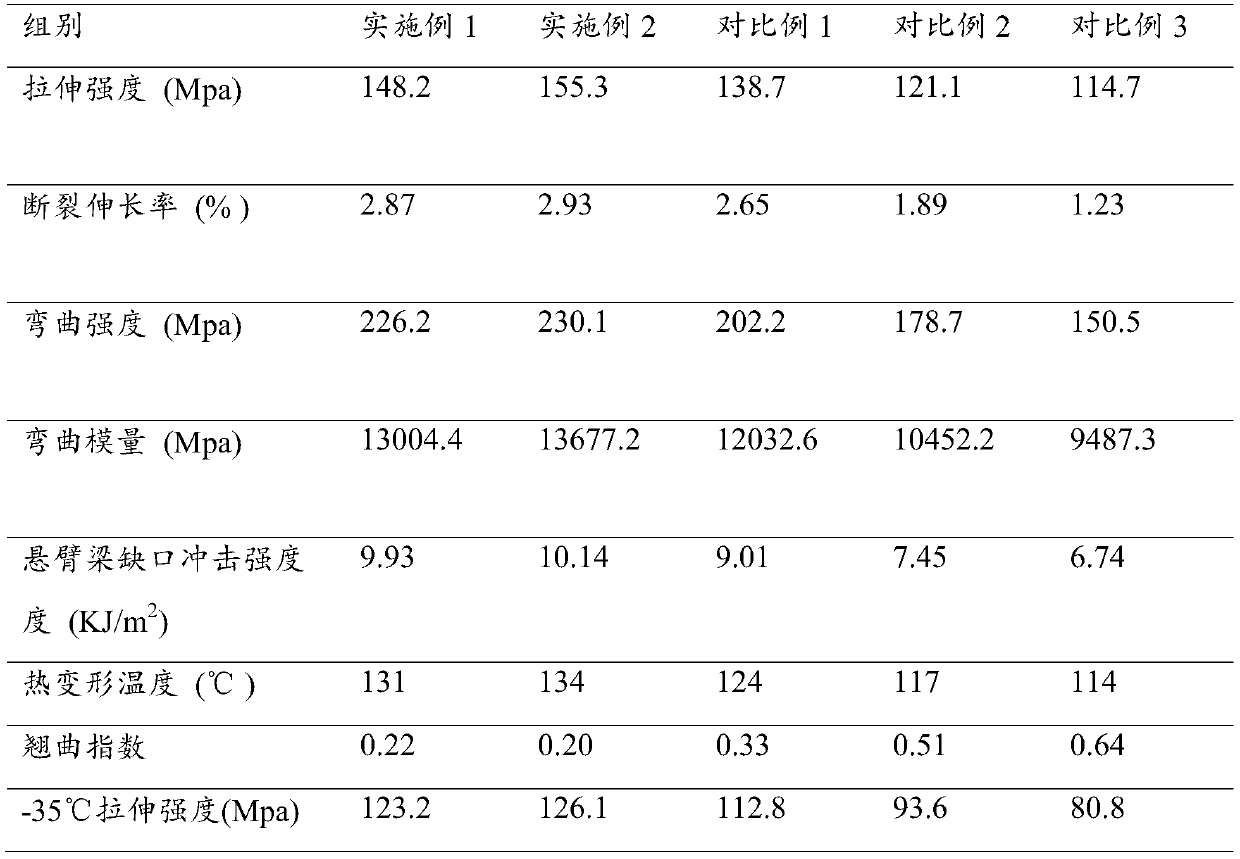

ActiveCN110804282AOvercoming Floating Fiber ProblemsMeet the requirements of parts with high heat resistance requirementsThermal deformationMesoporous silica

The invention discloses a PBT composite material. The composite material comprises the following preparation raw materials in parts by weight: 70-80 parts of PBT composite resin, 10-30 parts of a PET-ABS mixed material composition, 20-30 parts of composite glass fibers, 5-20 parts of a compatible toughening agent, 3-5 parts of surface-treated hollow glass micro-beads, 1-5 parts of mesoporous silica nanoparticles treated by a silane coupling agent and 0-3 parts of an auxiliary agent. According to the prepared PBT composite material, the defect of poor compatibility of an inorganic material andan organic polymer is effectively improved, and the composite material can obtain balanced mechanical properties on the basis of good notch impact strength, thermal deformation temperature and shrinkage rate.

Owner:福建华塑新材料有限公司

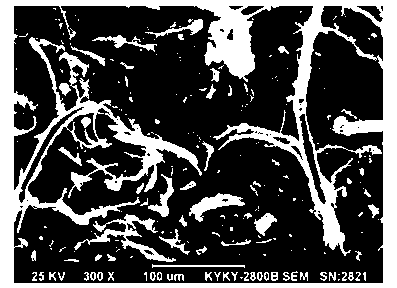

Preparation method of hybrid size for improving basalt fiber performance and modification method

A process for improving the performance of basalt fibers features that an ultrasonic forced continuous coating technique is used for coating hybridized slurry on the surface of each basalt fiber to improve its tension strength and the resistance to high temp. A process for preparing said hybridized slurry is also disclosed.

Owner:哈尔滨工业大学深圳研究院

Display apparatus and process for producing the same

InactiveUS20120183721A1Avoid breakingInhibits bubble formationOther chemical processesFilm/foil adhesivesDisplay deviceEngineering

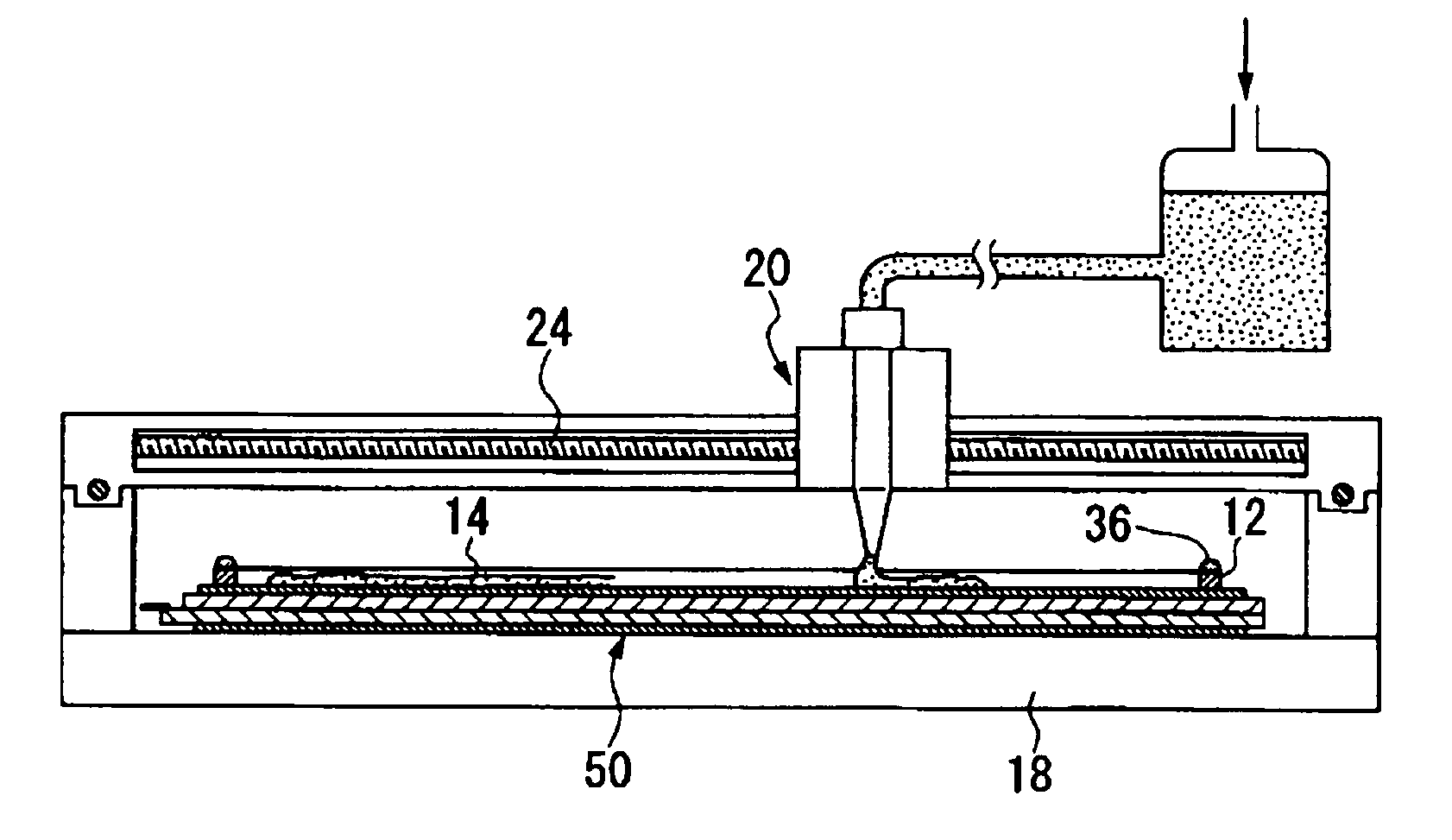

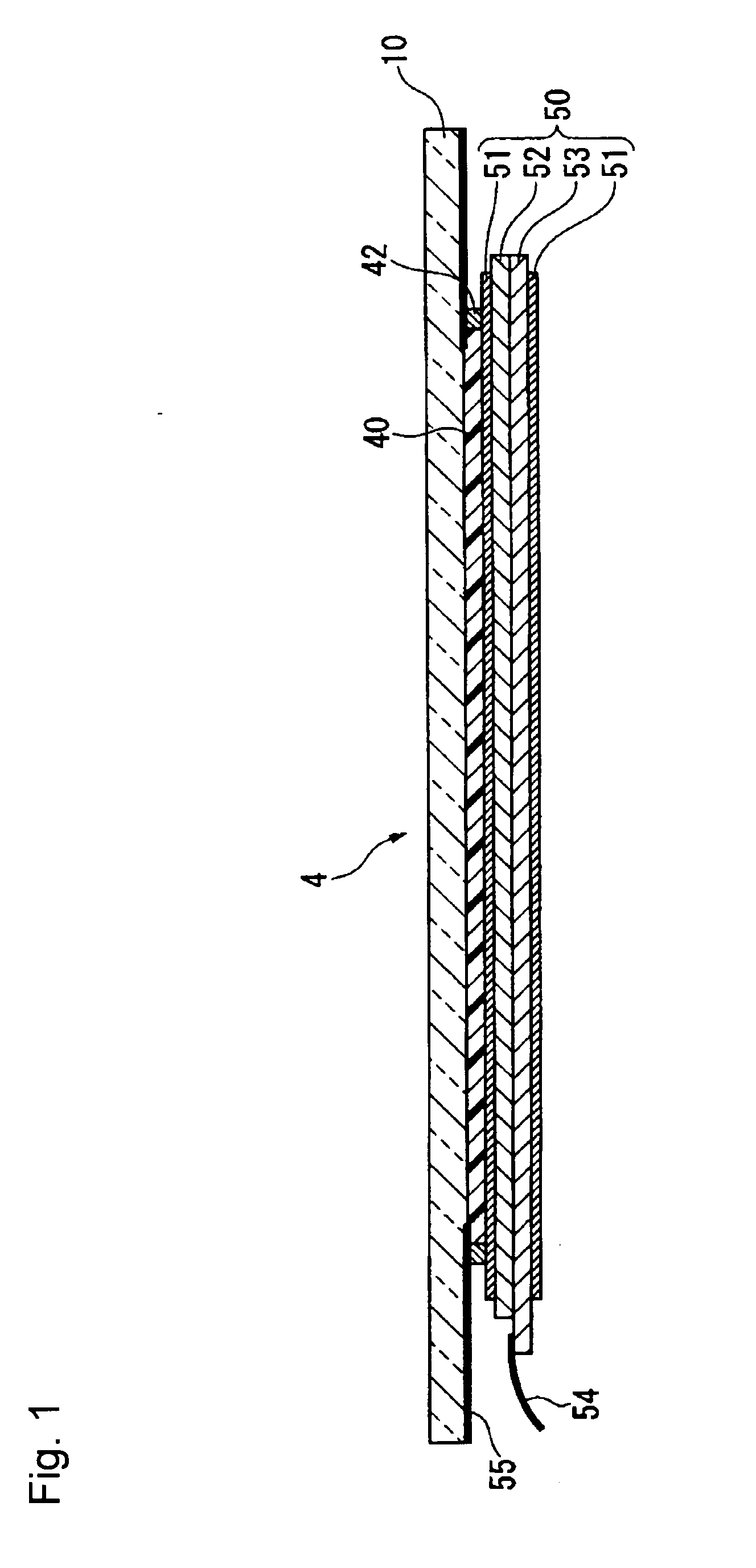

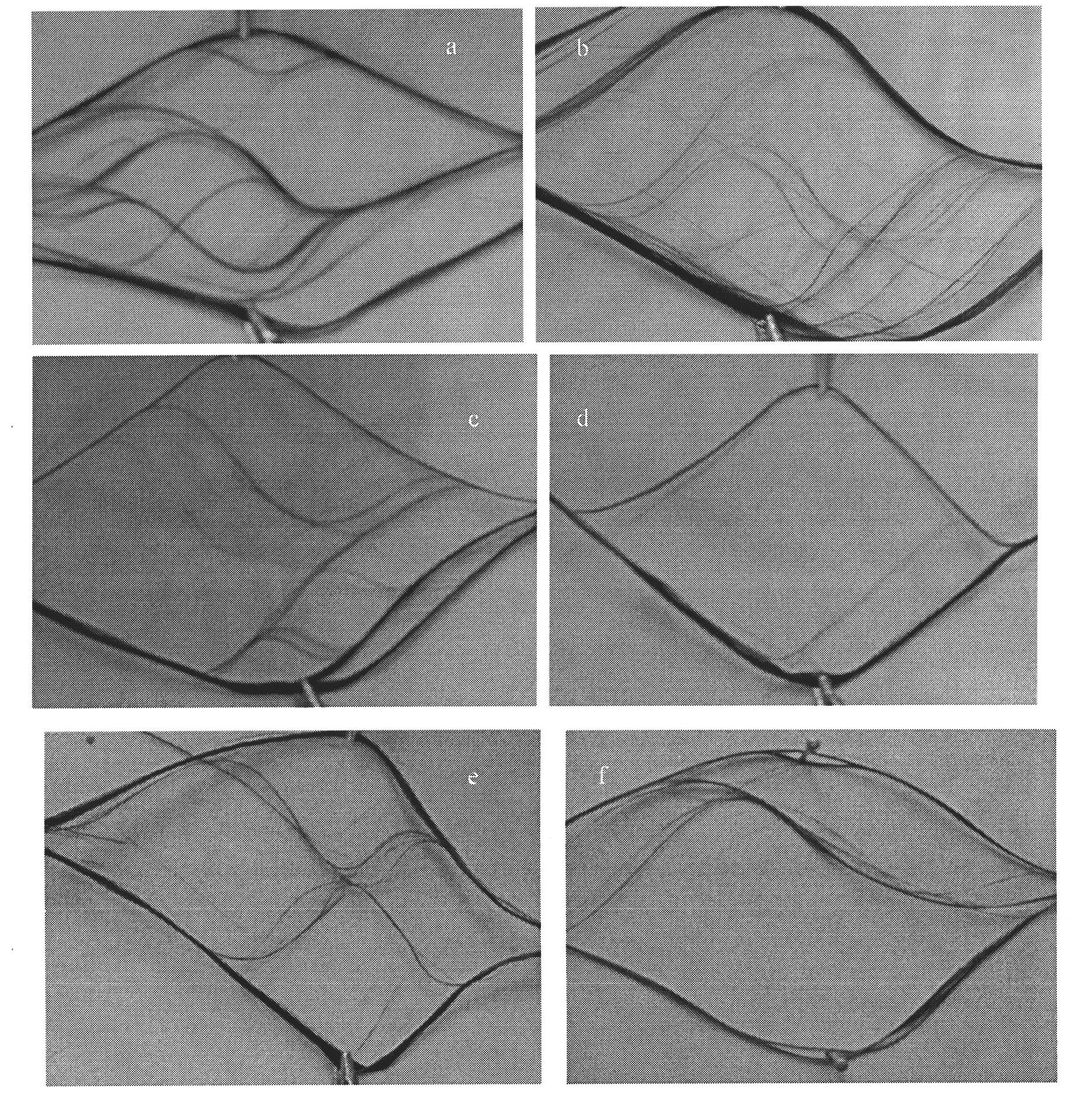

Provided is a process for producing a display apparatus, which comprises (a) a step of forming a seal part made of e.g. a double-sided adhesive tape 12 on the edge of a surface of a display device 50 (a first plate), (b) a step of supplying a liquid photocurable resin composition 14 to a region enclosed by the seal part, (c) a step of laminating, in a reduced-pressure atmosphere of not more than 100 Pa, a transparent plate 10 (a second plate) on the photocurable resin composition 14 thereby to obtain a laminated precursor having the photocurable resin composition 14 hermetically sealed, and (d) a step of curing the photocurable resin composition 14 in such a state that the laminated precursor is placed in a pressure atmosphere of not less than 50 kPa to form a resin layer.

Owner:ASAHI GLASS CO LTD

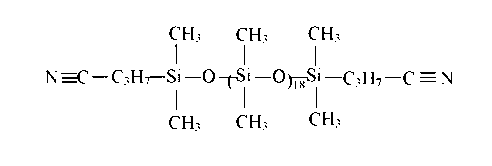

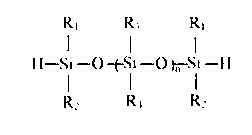

Silane coupling agent containing cyanogen group and preparation method of silane coupling agent

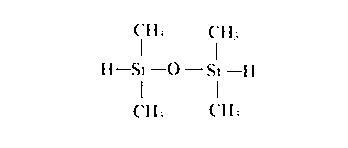

ActiveCN103122008AHigh bonding strengthGroup richGroup 4/14 element organic compoundsHydrogenSilanes

The invention relates to the field of silane coupling agents and particularly discloses a silane coupling agent containing a cyanogen group and a preparation method of the silane coupling agent. The silane coupling agent containing the cyanogen group is synthesized from oligosiloxane (A) containing a hydrogen group and a compound (C) containing a cyanogen group and an allyl group through hydrosilylation, or synthesized from oligosiloxane (A) containing the hydrogen group, siloxane (B) containing an allyl group, and the compound (C) containing the cyanogen group and the allyl group through hydrosilylation. The silane coupling agent containing the cyanogen group is capable of improving the bonding strength of silica gel to various base materials; and in additional, the preparation process is easy to control, the production efficiency is high and the yield of products is high.

Owner:埃肯有机硅材料(中山)有限公司

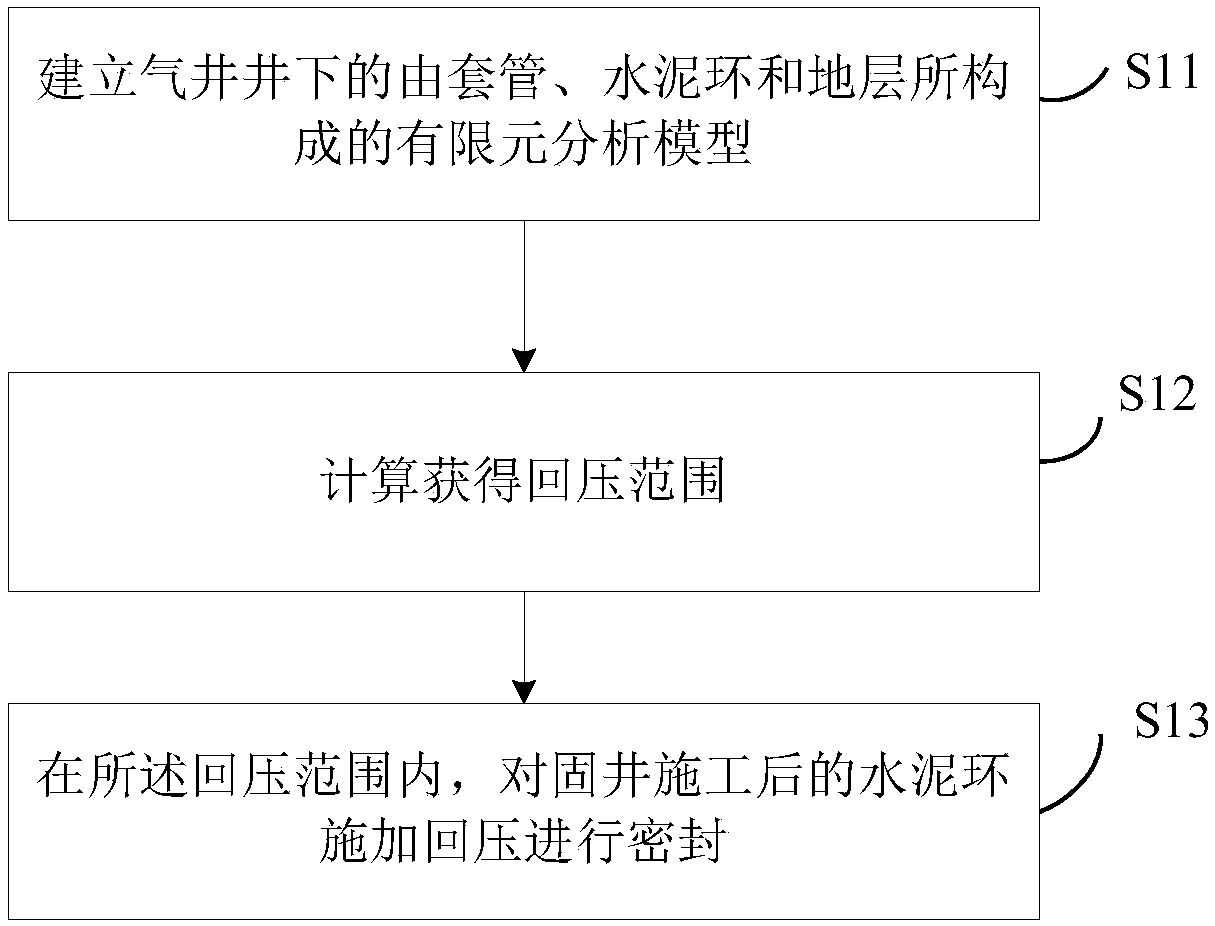

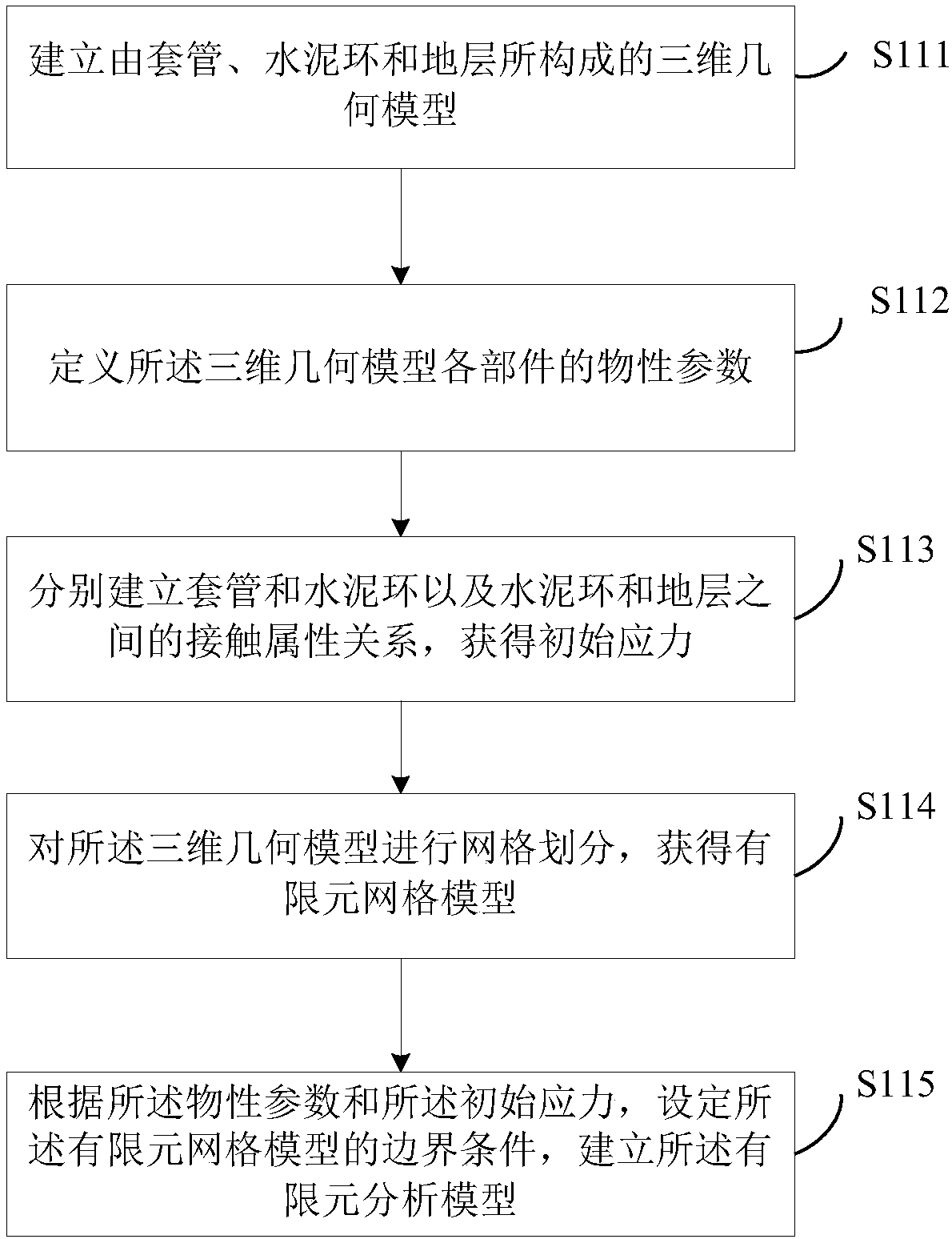

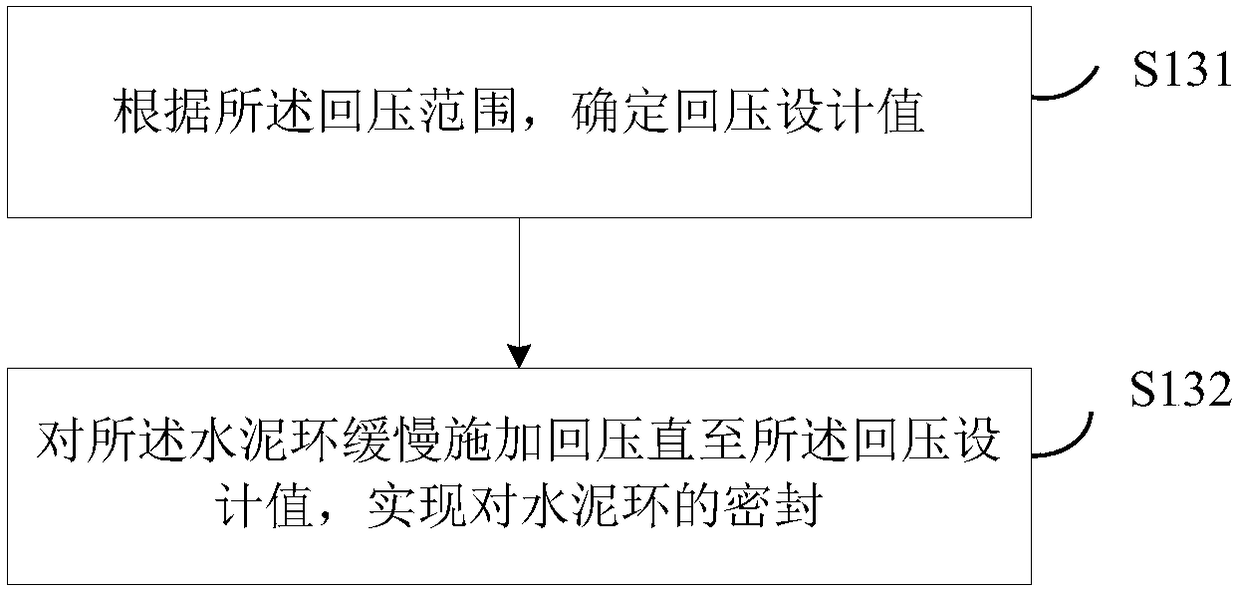

Method and device for maintaining seal integrity of cement sheath

ActiveCN108729901AImprove the state of stressIntegrity guaranteedConstructionsDesign optimisation/simulationElement analysisWell cementing

The invention discloses a method and device for maintaining seal integrity of a cement sheath. The method comprises the steps of building a finite element analysis model which is under a gas well andis composed of a casing pipe, the cement sheath and a stratum; analyzing parameters related to stress features of the cement sheath in the finite element analysis model, and calculating to obtain a return pressure range; within the return pressure range, applying return pressure to the cement sheath which is subjected to well cementation construction for sealing. By means of the method and device,by maintaining the seal integrity of the cement sheath and reducing micro-annuli, the purpose of inhibiting the annulus belt pressure of a wellhead of the gas well is achieved.

Owner:中石化石油工程技术服务有限公司 +1

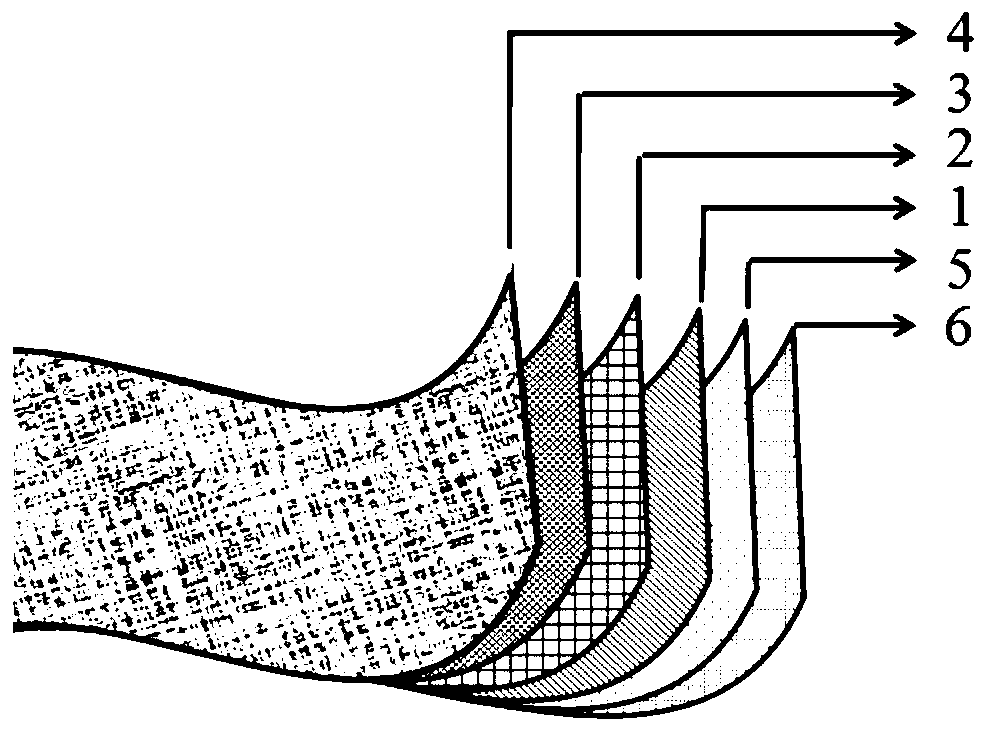

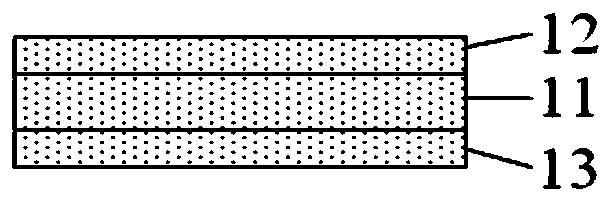

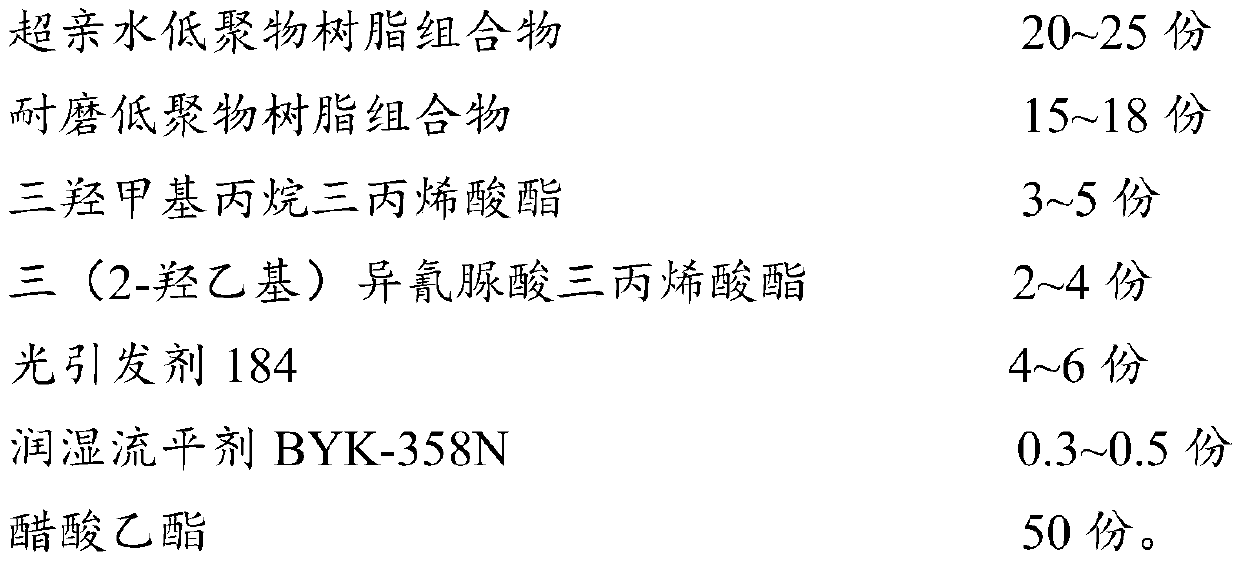

High-wear-resistance glass explosion-proof film adhesive with anti-fog effect, and preparation method thereof

ActiveCN111040653AReduce surface tensionHigh hardnessPolyurea/polyurethane coatingsPolyether coatingsPolymer scienceMeth-

The invention provides a high-wear-resistance glass explosion-proof film with an anti-fog effect. The high-wear-resistance glass explosion-proof film comprises a PET protective film (4), an anti-fog and wear-resistant resin coating (3), a polyacrylate pre-coating (2), a high-hardness transparent modified PET film (1), a mounting adhesive layer (5) and a PET release film (6). The anti-fog and wear-resistant resin coating comprises, by mass, 20 to 25 parts of a super-hydrophilic oligomer resin composition, 15 to 18 parts of a wear-resistant oligomer resin composition, 3 to 5 parts of trimethylolpropane triacrylate, 2 to 4 parts of tri(2-hydroxyethyl)isocyanurate triacrylate, 4 to 6 parts of a photoinitiator 184, 0.3 to 0.5 part of a wetting leveling agent BYK-358N and 50 parts of ethyl acetate. The high-hardness transparent modified PET film is a composite film prepared from three layers of different mass components through melt co-extrusion and two-way stretching. The product provided by the invention has good antifogging effect and excellent wear resistance, and can be used for explosion-proof films on various glass surfaces.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

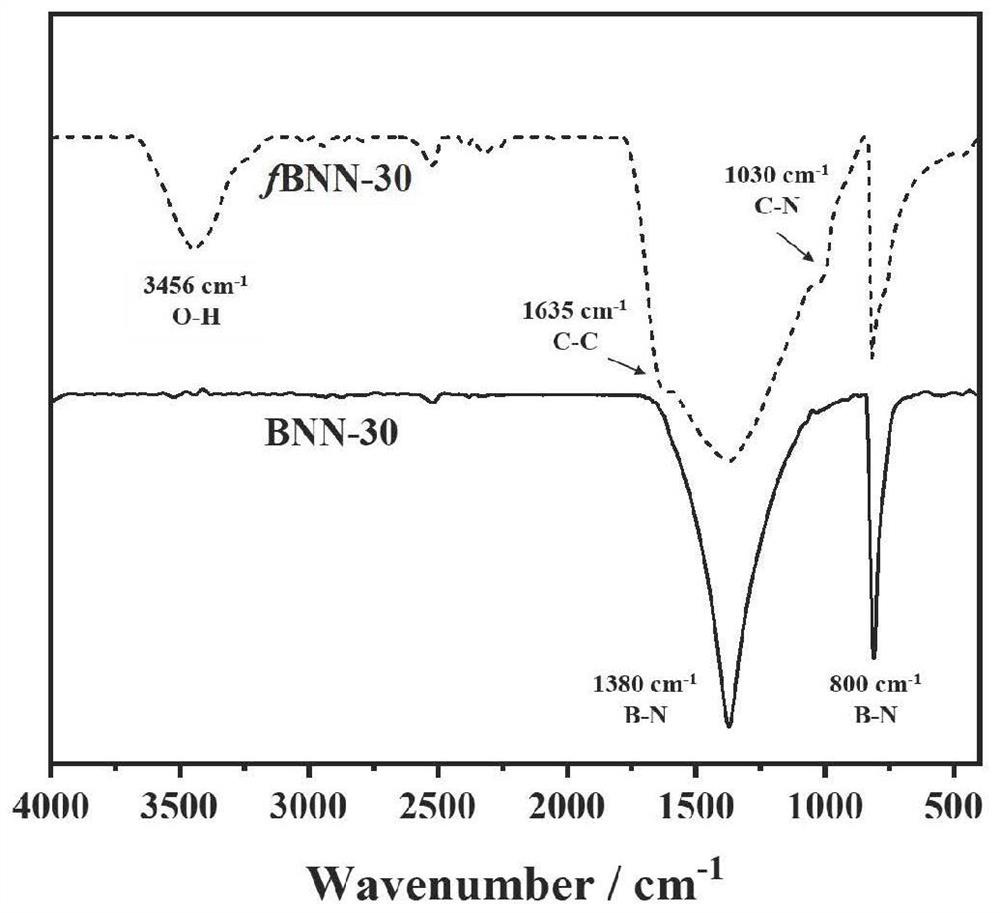

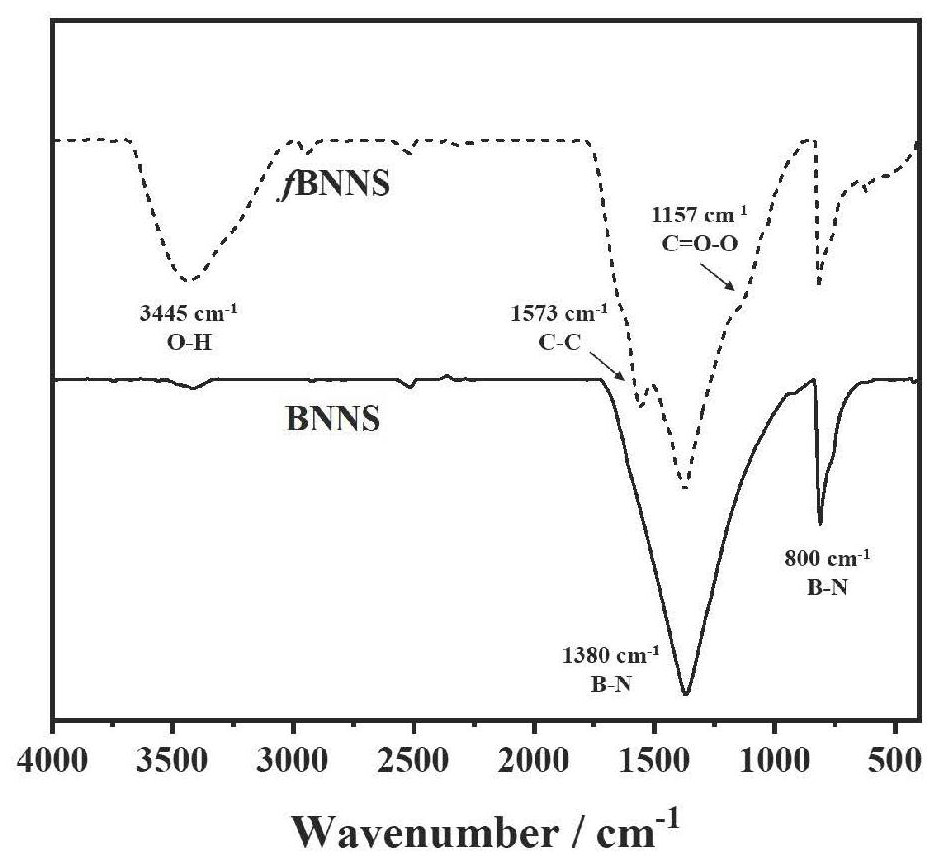

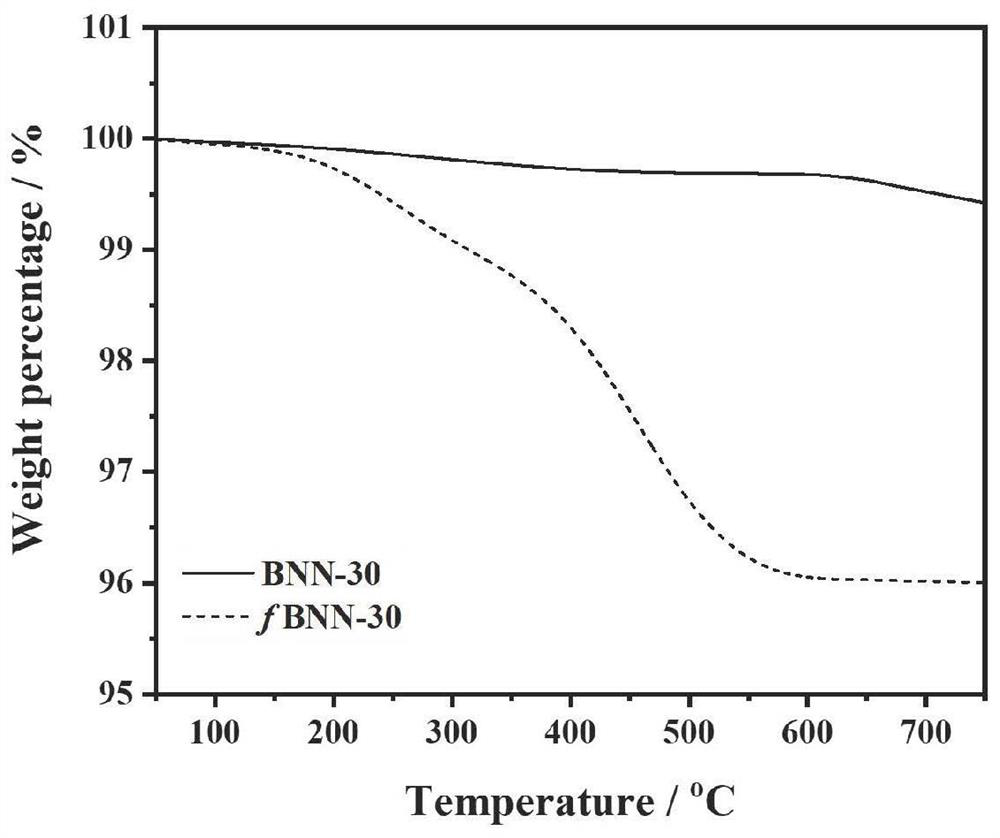

Boron nitride heterogeneous filler and preparation method thereof, and fiber-reinforced epoxy resin heat-conducting composite material, preparation method and application thereof

ActiveCN112876741AImprove mechanical propertiesImprove the interface bonding strengthHeat-exchange elementsBoron nitrideGlass fabric

The invention belongs to the technical field of composite materials, particularly relates to a boron nitride heterogeneous filler and a preparation method thereof, and a fiber-reinforced epoxy resin heat-conducting composite material, a preparation method and application thereof, and provides a boron nitride heterogeneous filler, which comprises modified spherical micron boron nitride and modified boron nitride nanosheets, wherein the modified spherical micron boron nitride and the modified boron nitride nanosheet have different charges, and the modified boron nitride nanosheet is electrostatically adsorbed on the surface of the modified spherical micron boron nitride. According to the invention, the boron nitride heterostructure provided by the invention is used as a heat-conducting filler, the modified glass cloth is used as a reinforcing material, and the epoxy resin is used as a matrix to prepare the epoxy resin heat-conducting composite material, so that the heat-conducting property, the electrical insulation property and the mechanical property of the epoxy resin heat-conducting composite material are further improved under the condition of lower filler consumption.

Owner:HUNAN KOSEN NEW MATERIAL

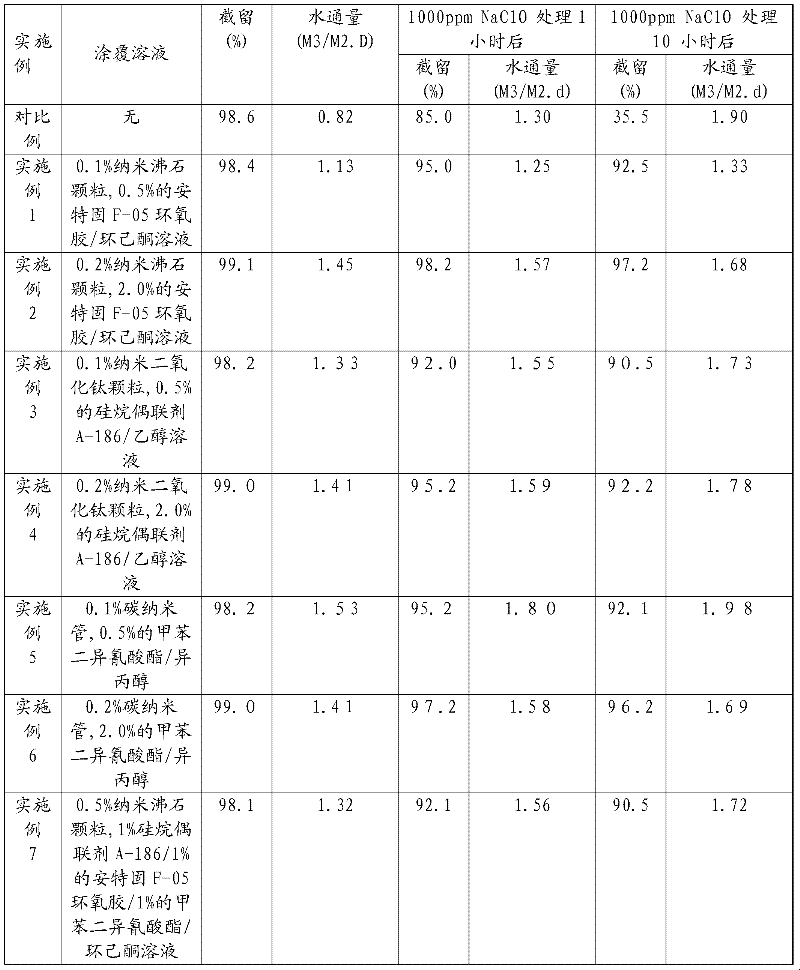

A kind of method for manufacturing polyamide reverse osmosis composite membrane

ActiveCN102258948AGood adhesionImprove chemical resistance and stabilitySemi-permeable membranesReverse osmosisPolyamide

The invention belongs to a method for preparing a polyamide reverse osmosis compound membrane. The method comprises the following steps of: coating a layer of epoxy compounds containing nanoparticles, silica compounds containing naoparticles, or isocyanate compounds containing nanoparticles on the surface of a support bottom membrane, immersing the coated support bottom membrane in aqueous solution of diamine or polyamine by a general polyamide reverse osmosis membrane compounding process, taking out and when the coated support bottom membrane is half-dried, immersing in solution of multi acyl chloride, performing interfacial polymerization reaction to form the polyamide reverse osmosis compound membrane, finally performing heat treatment and completely cleaning. The compound membrane hasthe chlorine resistance performance which is greater than 10,000 ppm.h, and water flux is also improved.

Owner:NANJING DELNAMEM TECH CO LTD

Hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe

The invention relates to a material special for a hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe. The material special for the hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe is prepared from, by mass, 80-120 parts of PPR, 0.5-10 parts of hindered-phenol-quaternary-ammonium-salt-modified imvite and 1-30 parts of a compatilizer, wherein the compatilizer is one or more of maleic anhydride (MAH) grafted by elastomer, HDPE, LDPE and PP or acrylonitrile (SAN) or glycidyl methacrylate (GMA). According to the material, the hindered-phenol-quaternary-ammonium-salt-modified imvite and the compatilizer are compounded, then the mixture and the PPR resin are blended and modified, and the material special for the PPR pipe is prepared; the material special for the PPR pipe has the advantages of being excellent in low-temperature performance, stable in size and good in antibacterial performance and weather resistance.

Owner:LIANSU TECH DEV GUIYANG

Plugging agent, preparing method thereof and oil well casing leakage stopping and channeling blocking method

InactiveCN106479462AImprove retentionReduce dosageDrilling compositionBlock effectUltimate tensile strength

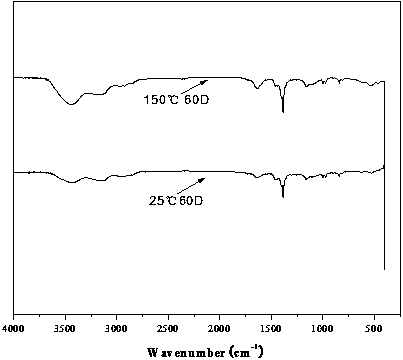

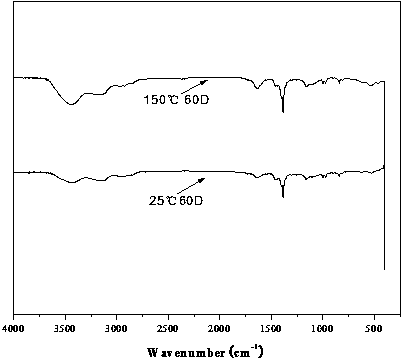

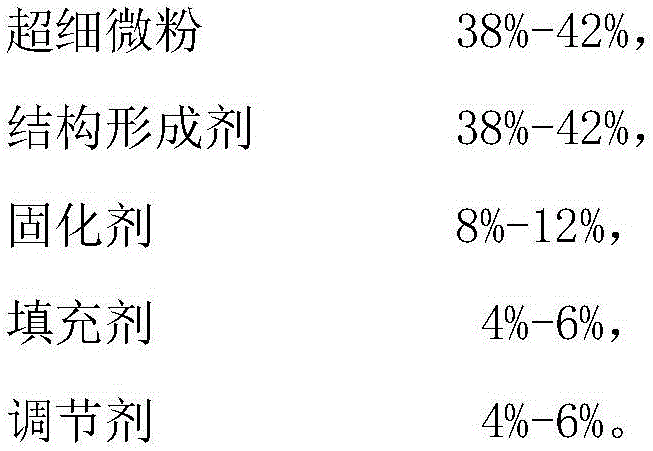

The invention discloses a plugging agent, a preparing method thereof and an oil well casing leakage stopping and channeling blocking method, and relates to the field of oil field construction. The problem that an oil well casing is poor in casing leakage stopping and channeling blocking effect is effectively solved. Raw materials of the plugging agent include a drying agent and water by the mass ratio of (0.8-1.6):(0.8-1.2), wherein the drying agent is prepared from, by mass, 30-50% of ultrafine micropowder, 30-50% of structure formation agent, 4-16% of curing agent, 2-8%of filler and 2-8% of modifier. The plugging agent has the advantages of being high in residing performance, interface bonding strength and channeling resisting strength, small in usage amount and short in construction period in oil well casing leakage stopping and channeling blocking construction.

Owner:BEIJING HUAYOU LUHAI SCI & TECH

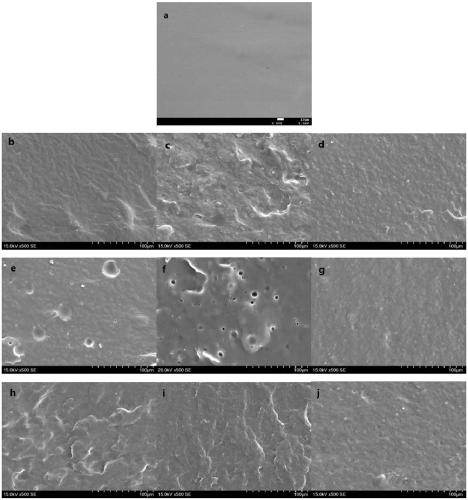

Modified rubber concrete and preparation method thereof

InactiveCN107602016AImprove the interface bonding strengthSlow growth rateSolid waste managementUreaDouble bond

Owner:汪逸凡

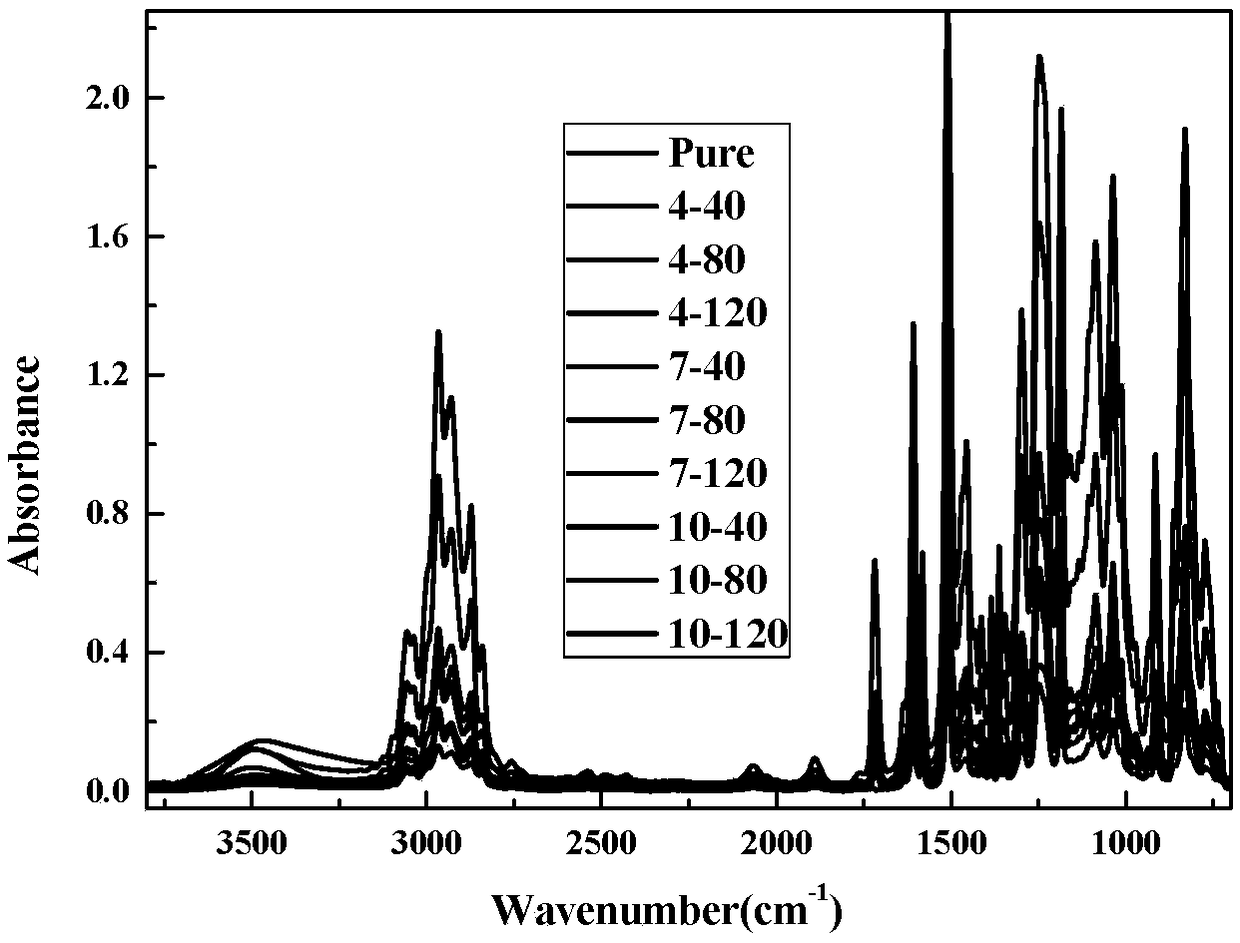

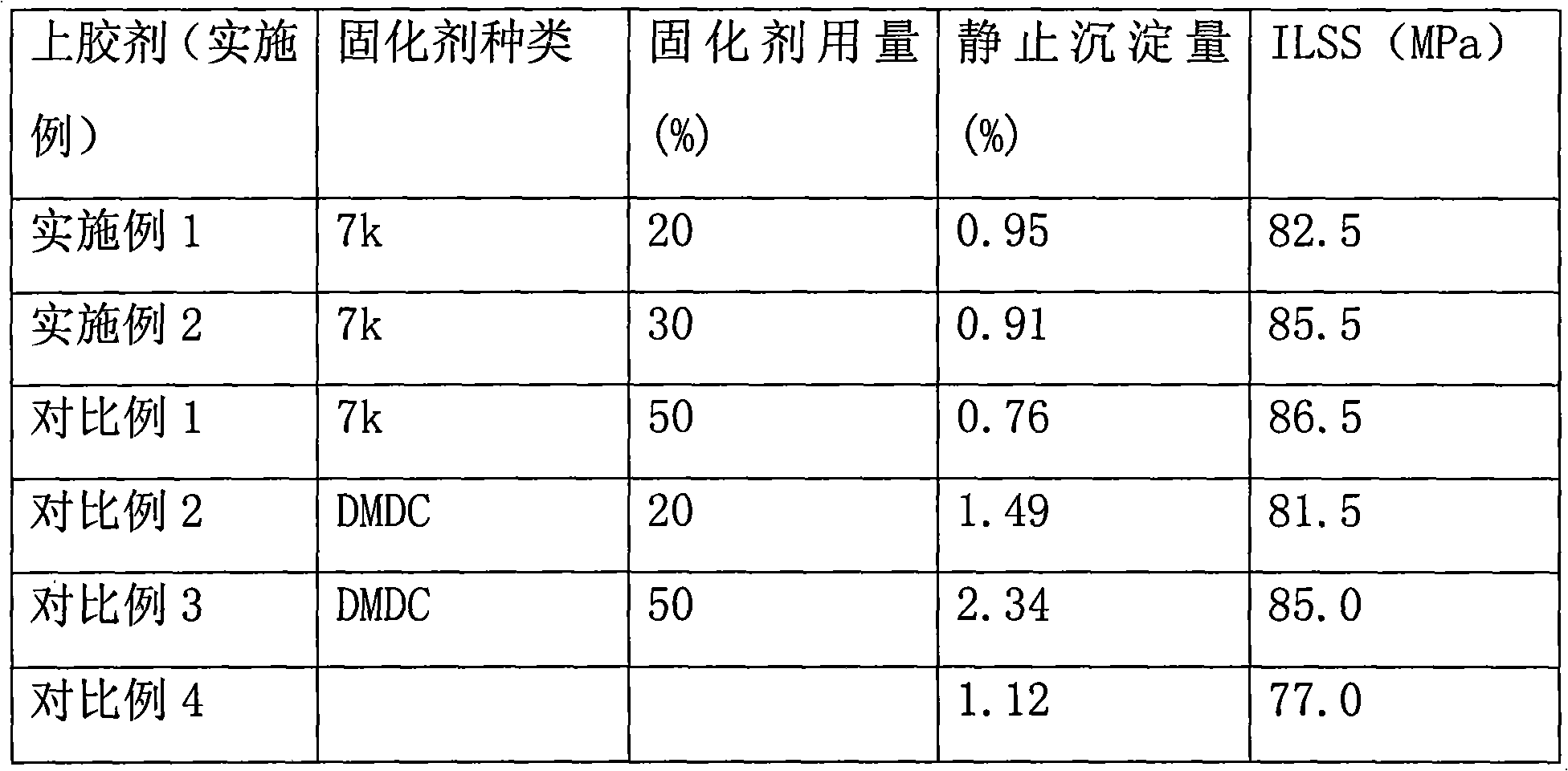

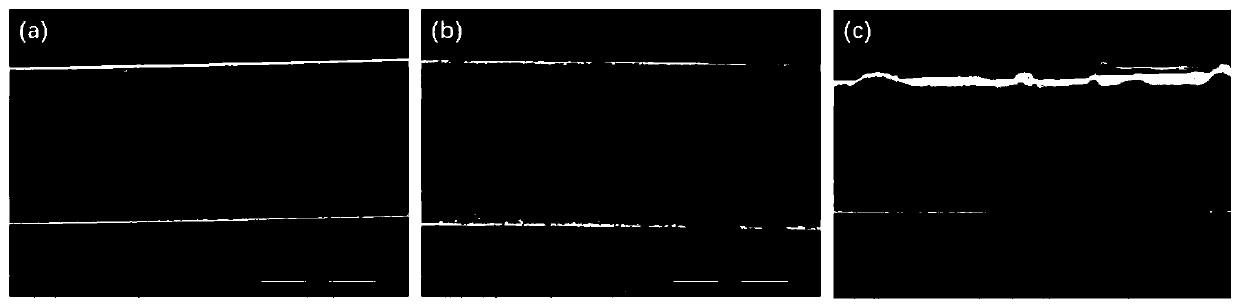

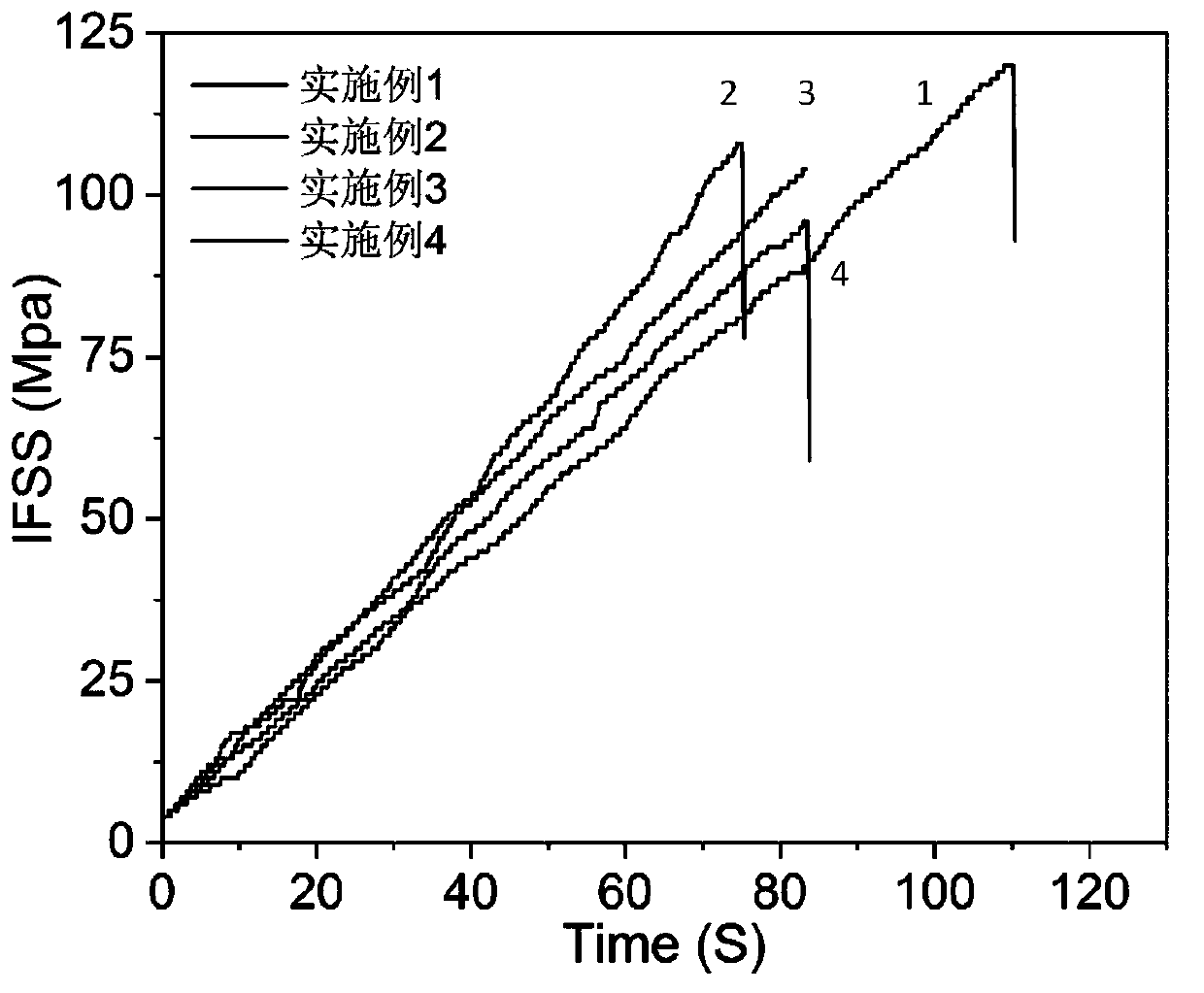

Sizing agent for carbon fiber

InactiveCN101982602AIncrease cross-linking pointImprove the interface bonding strengthCarbon fibresFiberCarbon fibers

The invention discloses a sizing agent for a carbon fiber, belonging to the fields of organic chemistry and fiber materials. The sizing agent is an epoxy water emulsion added with an aqueous curing agent, wherein the aqueous curing agent is modified epoxy amine curing agent, namely an amidated amine curing agent obtained by a reaction between a mono-fatty acid and an epoxy amine curing agent, a polyamide curing agent obtained by a reaction between a dimer acid and an epoxy amine curing agent and a curing agent obtained by a reaction between an epoxy amine curing agent and epoxy resin; the epoxy emulsion uses bisphenol A epoxy resin as the main body, and the epoxy equivalent is 200-500; the amount of the aqueous curing agent is 10% to 40% of theoretical one, and the theoretical amount should be calculated as follows: W=(Namine / NEP)*100, wherein Namine is the amine hydrogen equivalent of the curing agent, NEP is the epoxy equivalent of the epoxy resin, and W is the theoretical amount of the curing agent required by 100 grams of epoxy resin. The sizing agent is safe and healthy, the stability and the bundling performance are further improved, and the interface bonding strength of the composite material is enhanced.

Owner:BEIJING UNIV OF CHEM TECH

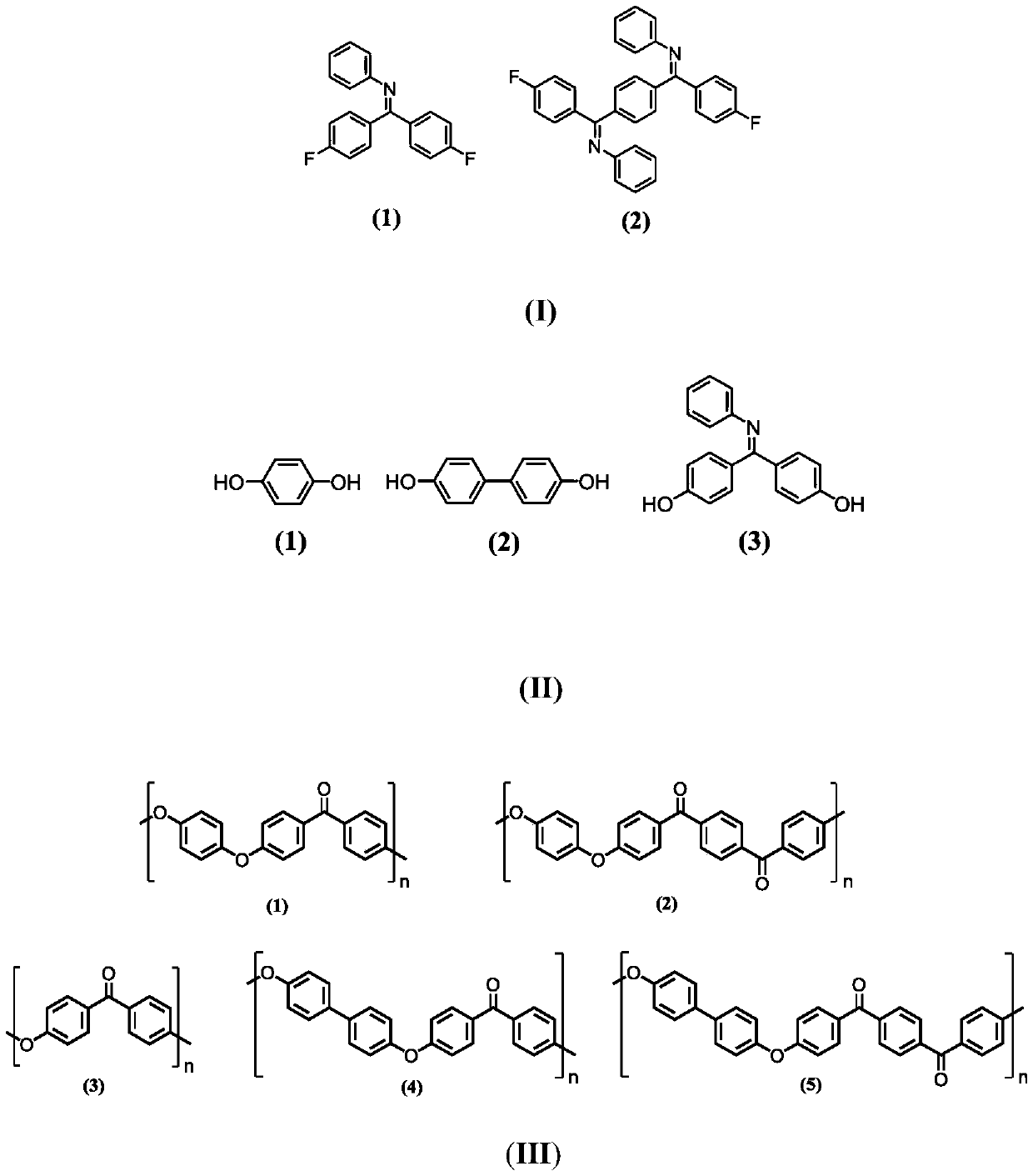

Carbon fiber modified with crystalized crosslinkable polyaryletherketone sizing agent and preparation method of carbon fiber

ActiveCN110820315ASimple structureImprove bondingPhysical treatmentCarbon fibresPolymer scienceCarbon fibers

The invention discloses a carbon fiber modified with a crystalized crosslinkable polyaryletherketone sizing agent and a preparation method of the carbon fiber and belongs to technical field of carbonfiber surface treatment. The preparation method includes subjecting double-fluorine monomer containing aniline side groups and bisphenol monomers to polymerization, or modifying crystalized polyaryletherketone, so as to obtain soluble amorphous polyaryletherketone polymer, and blocking thermotropic crosslinking groups to two terminals of the polymer; meanwhile, subjecting the carbon fiber to surface electrochemical reduction, and grafting the crosslinking groups which are the same as the mentioned to the surface of the carbon fiber; further, drafting the carbon fiber which is subjected to thesurface electrochemical reduction to pass through a sizing agent solution to size the carbon fiber, and performing acidification to recover the crystallinity of the polyaryletherketone sizing agent; finally, finishing the carbon fiber. The carbon fiber can be used for preparing a composite material, the composite material is subjected to high-heat treatment, so that the crosslinking reaction is initiated, the crystallinity of the polyaryletherketone polymer is improved, the sizing agent is allowed to have a crystalline texture and can form a chemical bonding with the surface of the carbon fiber, and further, the interference shear strength is improved, and the composite material has high temperature resistance and corrosion resistance performance.

Owner:JILIN UNIV

High weather-resistance PE film for solar battery backboard

ActiveCN107841029AReduce crystallinityGood flexibilitySynthetic resin layered productsElectrical equipmentLow-density polyethyleneLinear low-density polyethylene

The invention discloses a high weather-resistance PE film for a solar battery backboard. The high weather-resistance PE film is prepared from inner, middle and outer layers through melting co-extrusion blowing. The inner layer has thickness 20-40% that of the composite film and is prepared from 100 parts by weight of linear low density polyethylene, 5 to 20 parts by weight of ethylene-vinyl acetate copolymer resin, 6 to 15 parts by weight of white master batch and 4 to 10 parts by weight of anti-UV anti-aging master batch. The middle layer has thickness 20-40% that of the composite film and isprepared from 100 parts by weight of linear low density polyethylene, 6 to 15 parts by weight of white master batch and 4 to 10 parts by weight of anti-UV anti-aging master batch. The outer layer hasthickness 20-40% that of the composite film and is prepared from 100 parts by weight of linear low density polyethylene, 3 to 15 parts by weight of ethylene-vinyl acetate copolymer resin, 6 to 15 parts by weight of white master batch and 4 to 10 parts by weight of anti-UV anti-aging master batch. The PE film has high weather resistance and excellent dimensional stability, can meet the requirements on the durability and stability of solar battery backboards and can prolong the service life of the solar battery.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

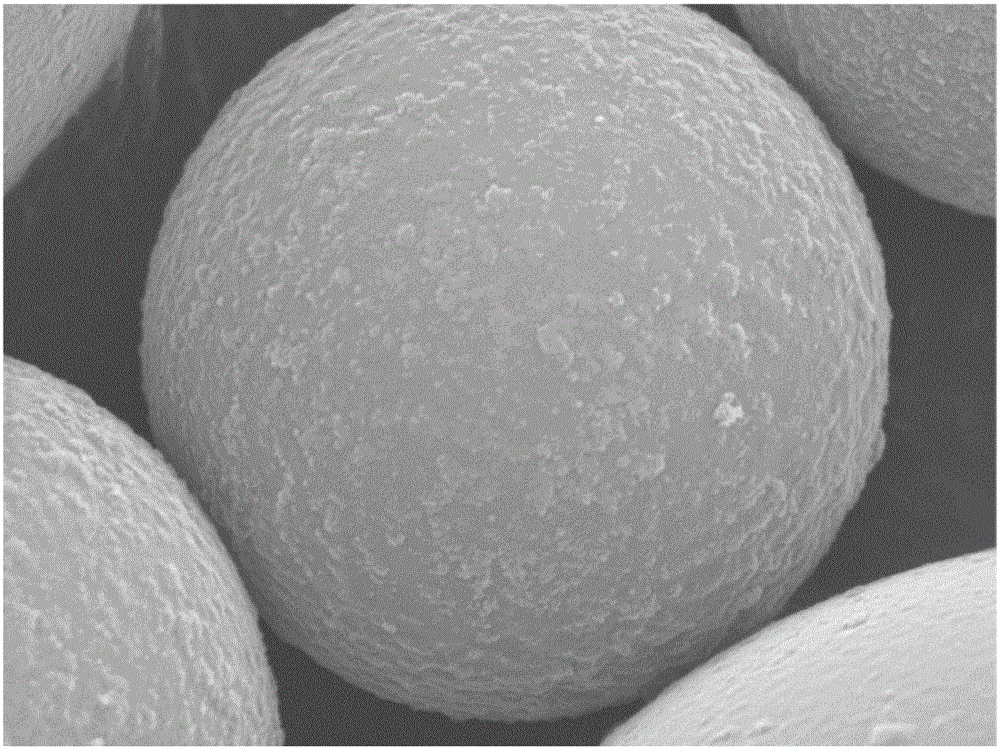

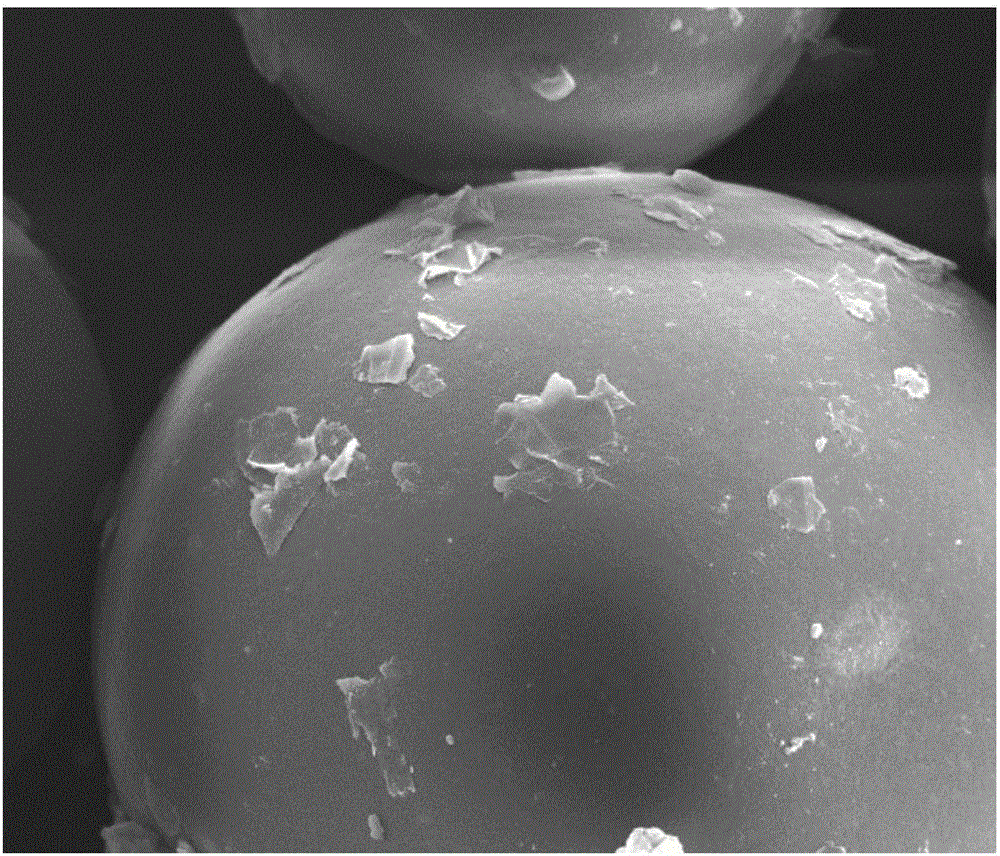

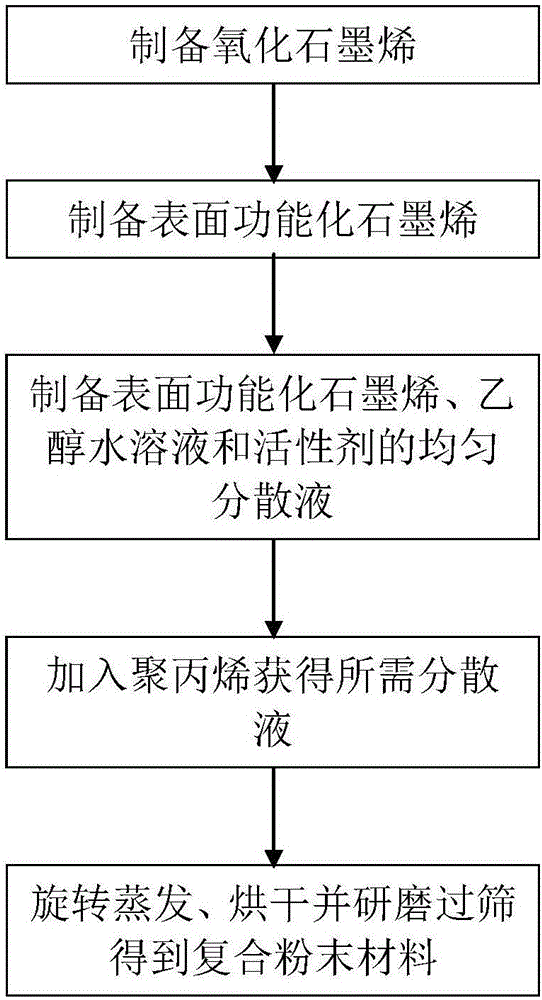

Graphene/polypropylene composite powder material for SLS and preparation method

ActiveCN106146864AImprove the interface bonding strengthHigh precisionAdditive manufacturing apparatusPolypropylene compositesEvaporation

The invention provides a graphene / polypropylene composite powder material for SLS and a preparation method. The preparation method of the composite powder material comprises the following steps: performing oxidation and surface functionalization of graphene; uniformly dispersing the graphene after the surface functionalization into an aqueous solution; adding polypropylene powder, and stirring vigorously; performing rotary heating for evaporation; and drying, grinding and sieving to obtain the composite powder material. According to the invention, the graphene is uniformly dispersed into the solution by adopting a liquid-phase dispersion method, and then the graphene is uniformly dispersed into high-molecular matrix polypropylene in later solution volatilization process; and the prepared composite material has the advantages of uniform form, appropriate particle size and good fluidity and facilitates the powder laying and laser sintering process of the SLS technology.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

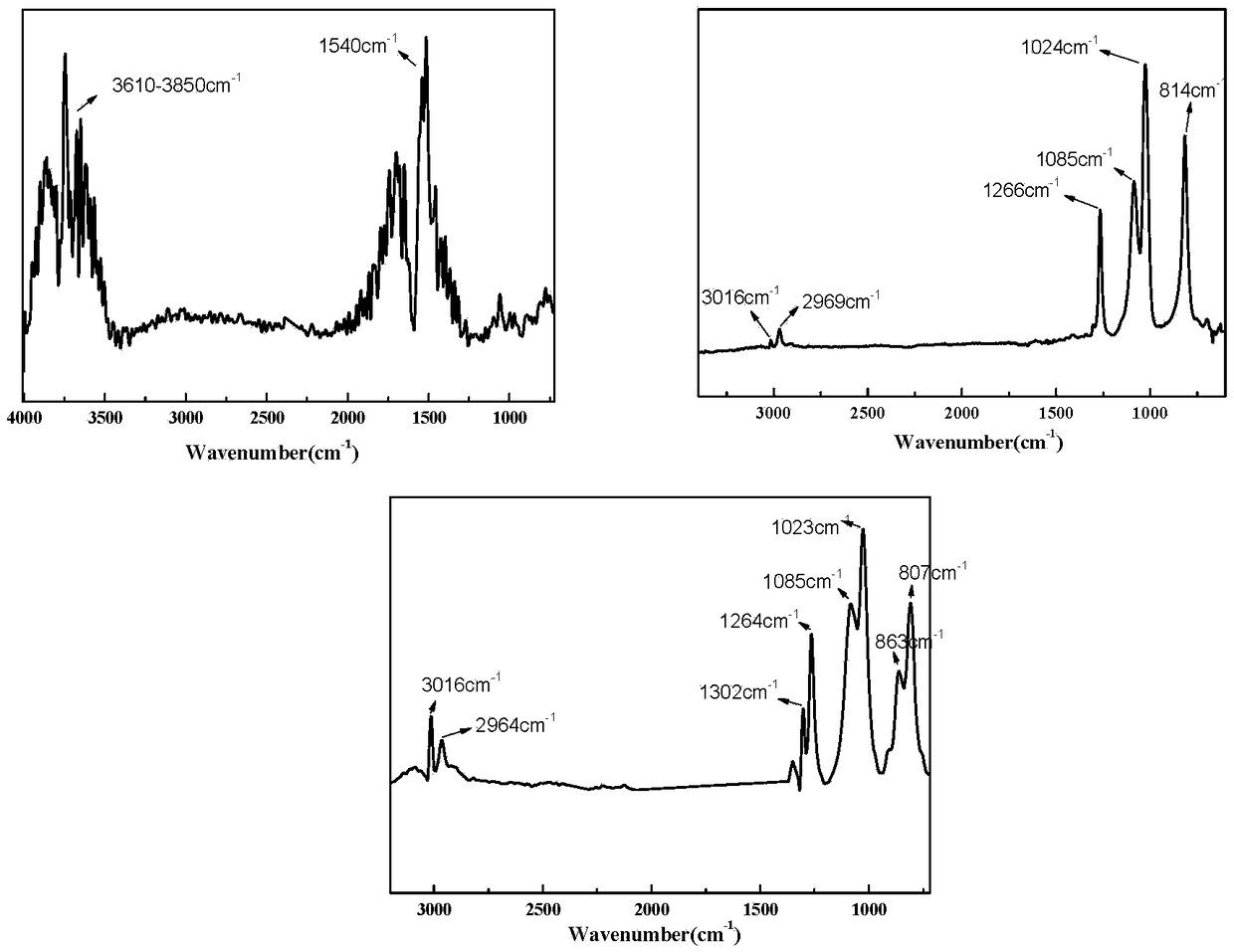

Aramid fiber (AF) surface modification method, product and preparation method of product

InactiveCN105986465AImprove surface propertiesImprove the interface bonding strengthFibre typesLight/infra-red/X-rays fibre treatmentPolymer scienceChemical reaction

The invention discloses a method for modifying the surface of an aramid fiber, a product thereof and a preparation method of the product. The present invention uses ultraviolet light as the radiation source to irradiate aramid fibers in the air to improve the surface properties of aramid fibers, thereby increasing the interface bonding strength between aramid fibers and natural rubber, and maximizing the use of aramid fibers. Reinforcement effect; radiation modification can stimulate the activity of functional groups on the surface of aramid fibers, and these active functional groups can physically cross-link or chemically react with the natural rubber matrix, thereby increasing interfacial adhesion; and radiation modification can also affect the aramid fibers The surface is etched to increase the roughness of the surface of the aramid fiber, thereby increasing the surface area of the fiber, enhancing the mechanical interlocking of the aramid fiber and natural rubber, and increasing the interface bonding strength between the two. The invention has the advantages of safety, high efficiency, little pollution, low energy consumption, simple equipment and suitable for industrial production, etc., and has good development prospects in the modification of aramid fibers. The preparation method of the invention has simple process and easy operation, and is very suitable for industrial production.

Owner:GUIZHOU UNIV

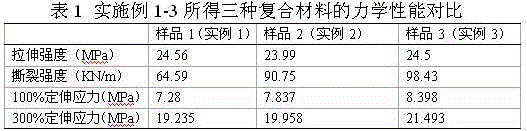

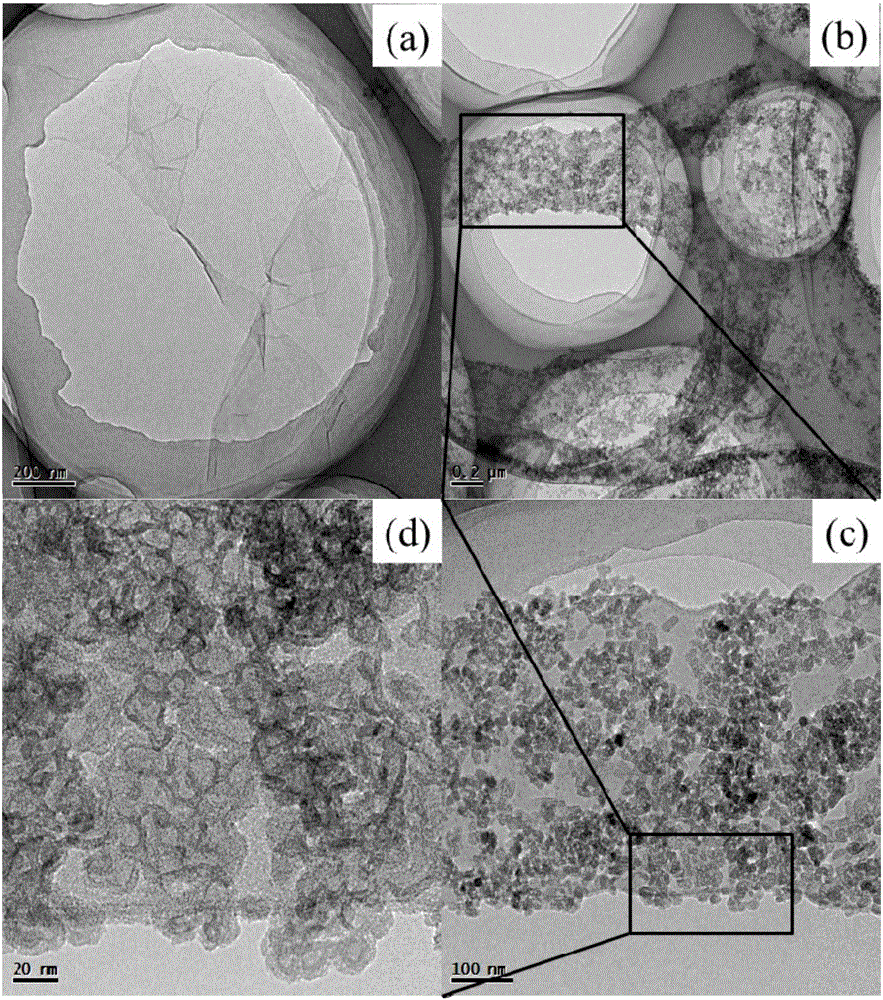

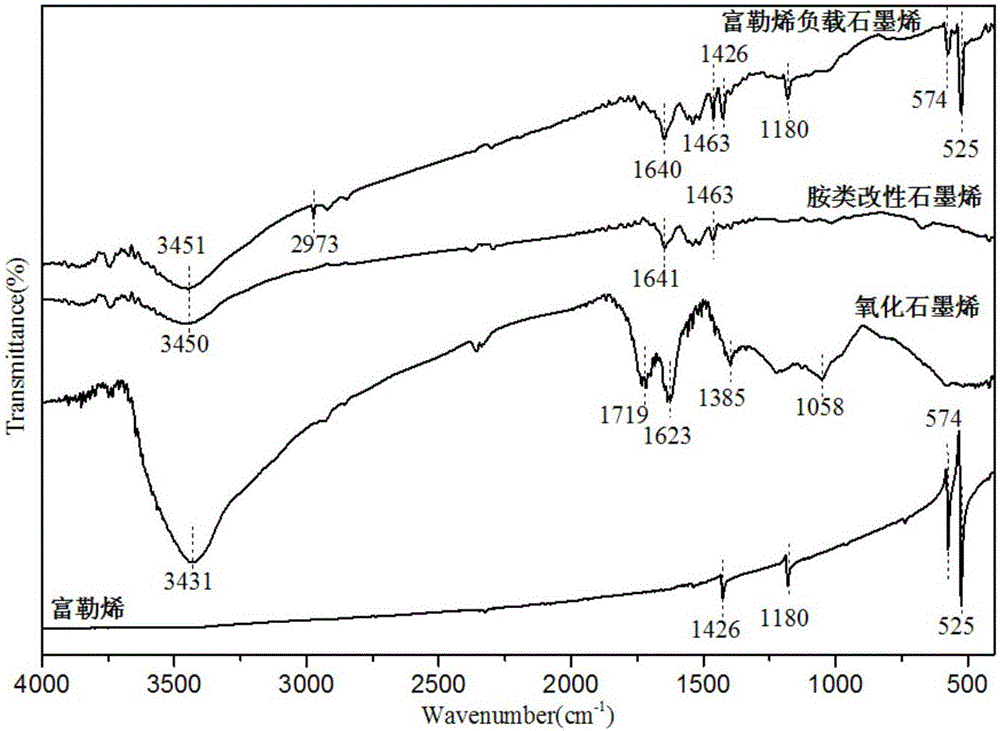

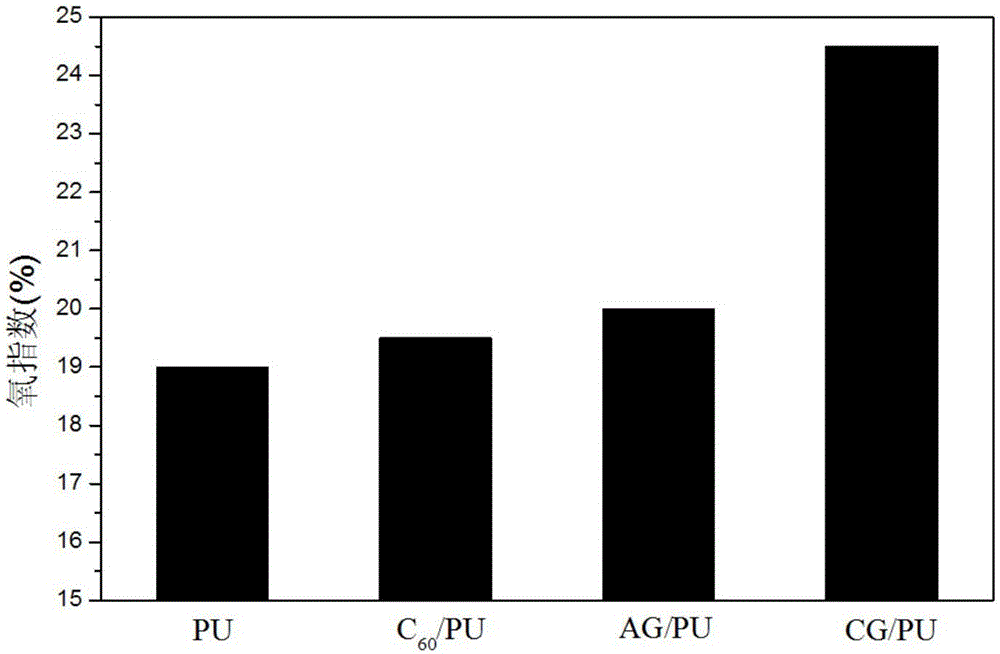

Preparation of graphene supported fullerene hybrid and polymer flame retardation application

The invention discloses a preparation method of a graphene supported fullerene hybrid material and an application of the hybrid material in polymer flame retardation. Through amine compounds, fullerene is load on the surface of graphene oxide through chemical bonds to prepare the graphene supported fullerene hybrid material. At the same time, the hybrid material is compounded with polymers through solution blending and direct blending; the flame retardant performance of polymers is obviously enhanced by the sheet obstruction effect and enhancing effect of graphite and the free radical absorption effect of fullerene; and the mechanical properties of polymers are strengthened at the same time.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

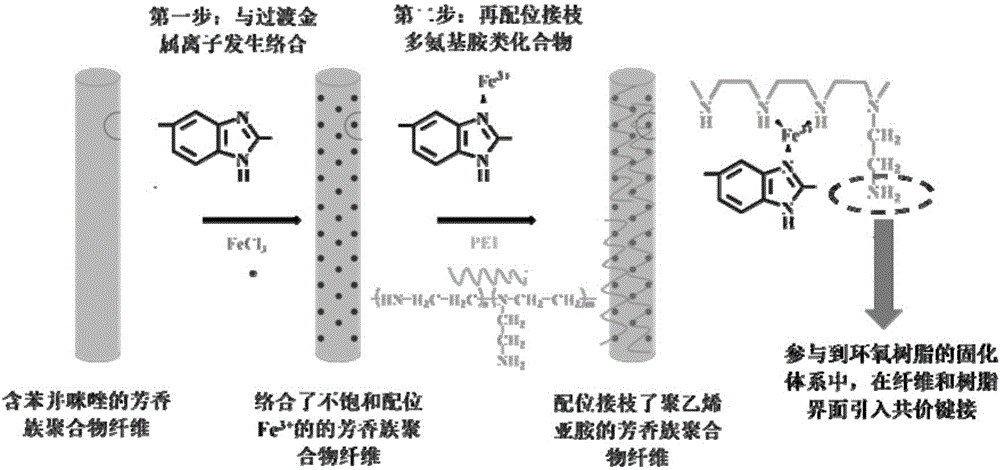

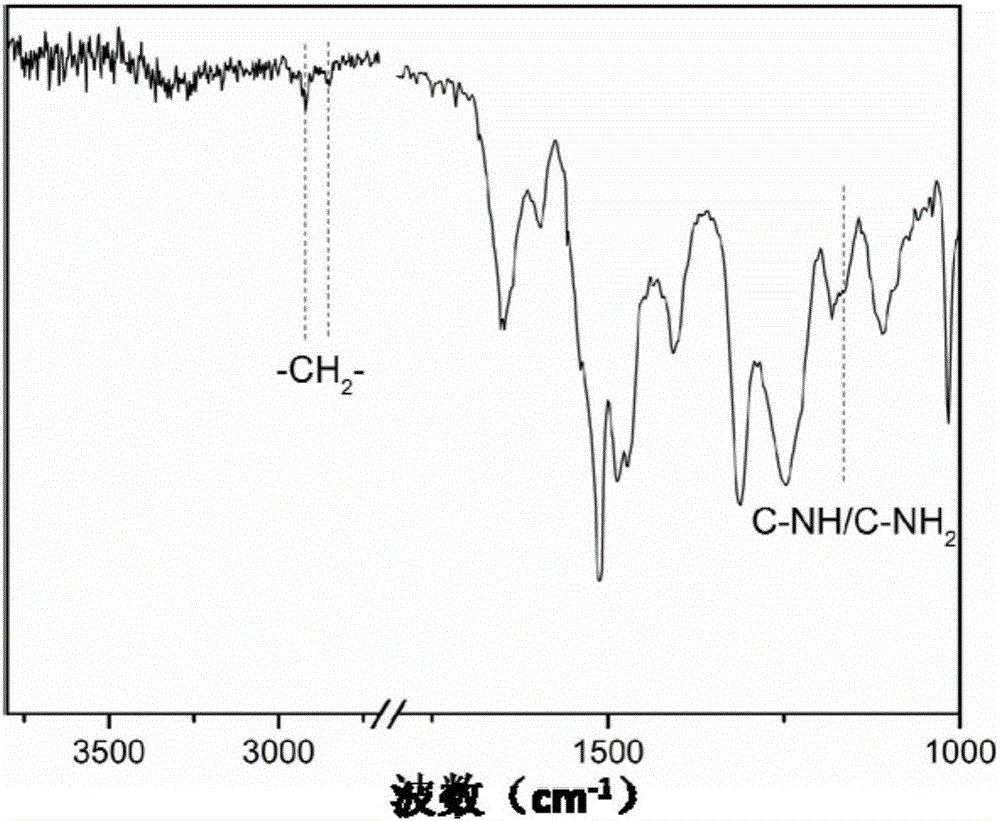

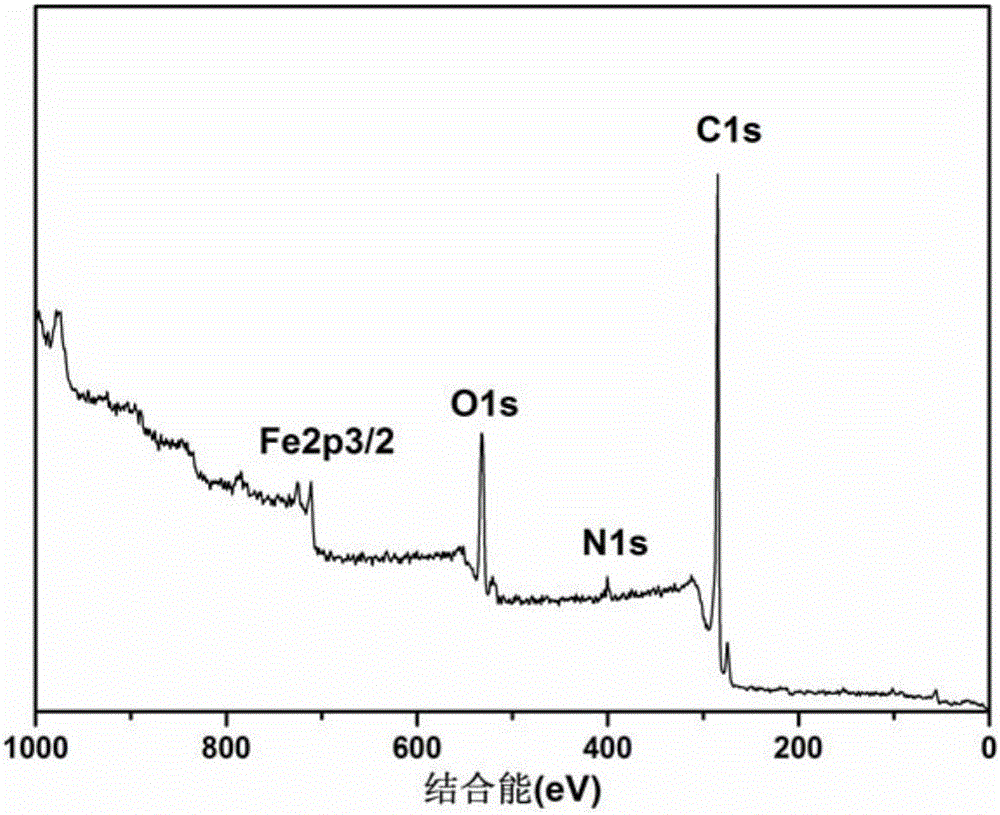

High-composite performance benzimidazole-containing aromatic polymer fiber and preparation method thereof

High-composite performance benzimidazole-containing aromatic polymer fiber disclosed by the invention is prepared according to the following steps: first statically or dynamically and continuously soaking the fiber into a mixed solution of a transition metal ion-containing organic polar solvent and water for reacting, drying, then statically or dynamically and continuously soaking the fiber into a polyamino amine compound-containing ethanol solution for reacting, and performing vacuum drying to obtain the fiber having active amino groups reactive with resin on the surface; a composite material formed by the prepared aramid III fiber and epoxy resin has the interlayer shear strength of 52-58MPa and the impregnated filament strength of 5.5-5.8GPa; a composite material formed by the prepared polyimide fiber and epoxy resin has the interlayer shear strength of 35-40MPa and the impregnated filament strength of 3.3-3.5GPa. Due to adoption of a first-complexing and then-coordinating grafting method, the physical and chemical structures of a fiber body are not destroyed, the mechanical properties of the fiber body are reduced, and non-damage modification can be achieved to obtain high-composite performance aromatic polymer fiber.

Owner:SICHUAN UNIV

Waste rubber particle surface treatment method

ActiveCN104710119AGood compatibilityImprove the interface bonding strengthSolid waste managementEpoxyEmulsion

The invention discloses a waste rubber particle surface treatment method, and belongs to the high molecular material technical field. The method includes the following steps: (1) treating the surface of waste rubber particles with clean water; (2) treating the surface of the waste rubber particles with an acid solution; (3) treating the surface of the waste rubber particles with an epoxy emulsion; (4) curing the surface of the waste rubber particles; and (5) crushing and screening of waste rubber particle aggregates. The epoxy emulsion is composed of a component A and a component B, the component A is an oily epoxy resin solution, the component B is a waterborne epoxy curing agent GCA01 or GCA02, the component A and the component B are mixed and stirred according to the mass ratio of 1:(1-2) until uniform milky white emulsion is formed, and then the emulsion is diluted by clean water. The method can effectively improve the compatibility of the waste rubber particles and a cementing material, and significantly improves the interfacial bonding strength between the waste rubber particles and the cementing material.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

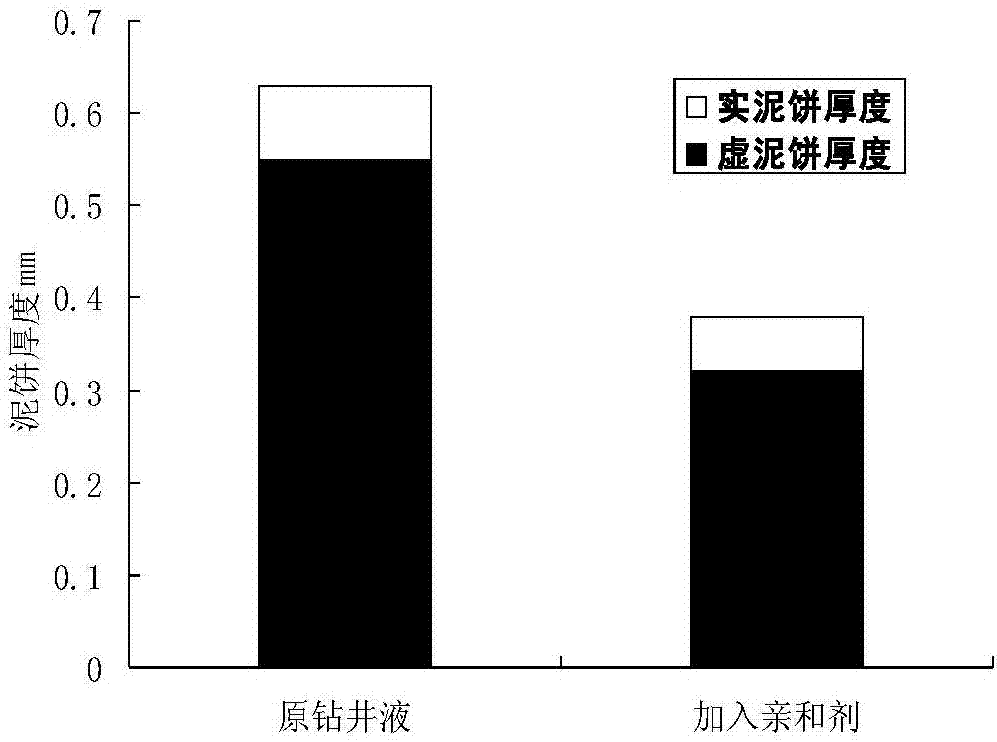

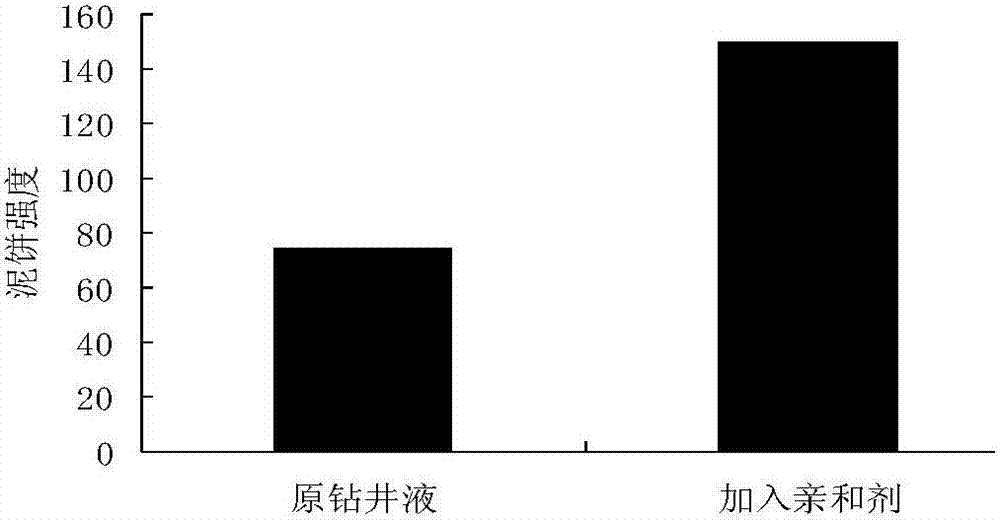

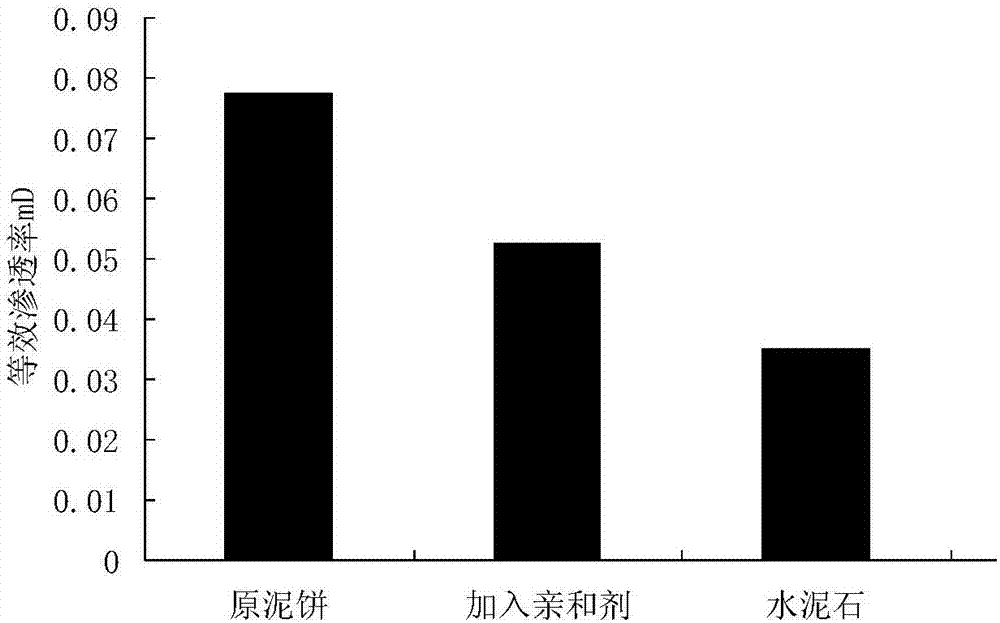

Interface affinity agent used for well cementation by water-based drilling fluid for horizontal well

ActiveCN107353884AReduce thicknessImprove mud cake strengthDrilling compositionPoor qualityCalcium carbonate

The invention discloses an interface affinity agent used for well cementation by water-based drilling fluid for a horizontal well, which solves the problem of poor quality of a mud cake after leak-off of the water-based drilling fluid for the horizontal well. The interface affinity agent is composed of a mud cake structure conditioning agent, a mud cake reinforcing agent, an interface adhesive and an interface cleaning compound; wherein the weight part of the mud cake structure conditioning agent to the mud cake reinforcing agent to the interface adhesive to the interface cleaning compound is 1: 0.5: 1.2: 0.5; the above mud cake structure conditioning agent is the calcium carbonate whisker with the diameter between 0.5-10 [mu]m, the mud cake reinforcing agent is ploysilicate aluminium ferric sulphate, the interface adhesive is adhesive polystyrene particles, and the interface cleaning compound is dodecyl glucuronide. The interface affinity agent can effectively reduce the original mud cake thickness, increases the mud cake intensity, reduces the equivalent permeability, increases the interface cementation intensity, and is in favor of increasing the well cementation quality for the horizontal well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

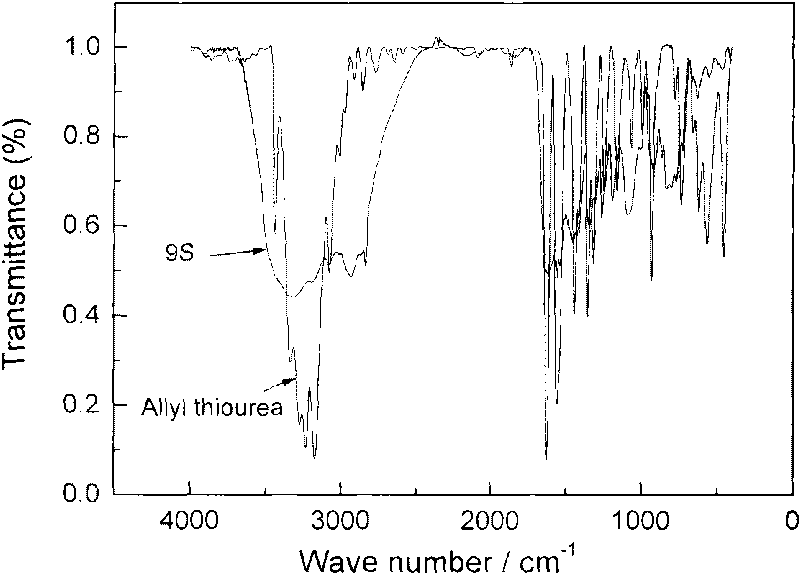

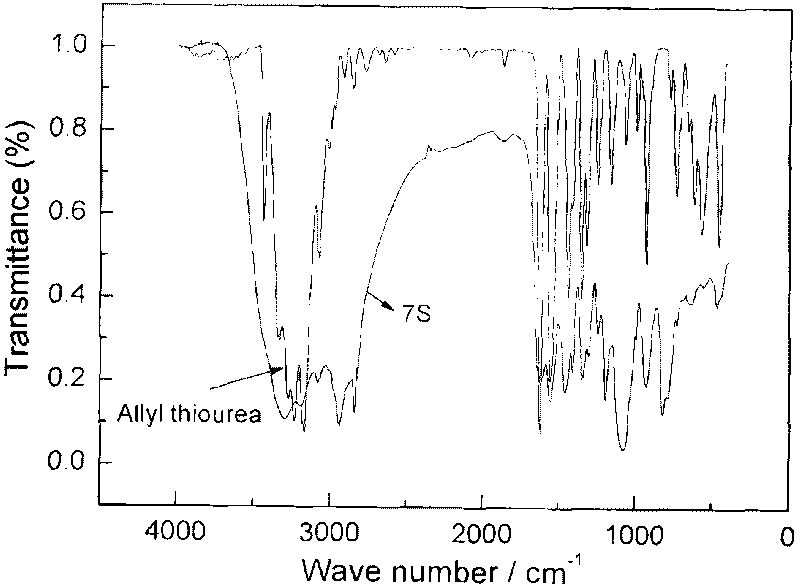

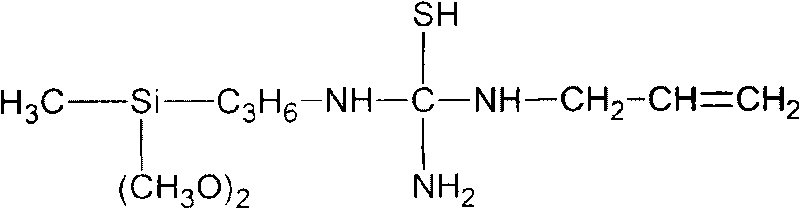

Preparation method of silane coupling agent containing allyl sulfydryl and amino and usage thereof

InactiveCN101747532AAct as modifierReduce and inhibit oxygen inhibitionGroup 4/14 element organic compoundsNon-macromolecular adhesive additivesPrepolymerAddition reaction

The invention discloses a preparation method of a silane coupling agent containing allyl sulfydryl and amino and a usage thereof. The molecular structural formula of the silane coupling agent is (R1O)3-xSiR2xR3(NHR4)yNHz(SHCNH2NHCH2CH=CH2)m. The silane coupling agent is obtained through addition reaction of 1-2 mole allylthiourea and 1 mole silane coupling agent with the molecular formula of (R1O)3-xSiR2xR3(NHR4)yNH2, wherein R1 and R2 are straight chain or branched alkyl of same or different 1-6 carbon atoms, R3 is alkylidene and aryl of 1-6 carbon atoms or aryl alkylidene and alkyl arylene of 6-10 carbon atoms, and R4 is alkylidene of 1-6 carbon atoms, x is 0 or 1, y is 0, 1 or 2, z is 0 or 1, and m is 2-z. Compared with the traditional allyl monomer, the silane coupling agent can be used as active diluent monomer of ultraviolet curing prepolymer, the sulfydryl is contained in the molecule, the inhibition of the oxygen to the ultraviolet curing process can be effectively reduced, the ultraviolet curing speed is improved, the function of the silane coupling agent can be brought into play, and the adhesion function of the coating adhesive and the matrix is improved.

Owner:浙江凌志新材料有限公司

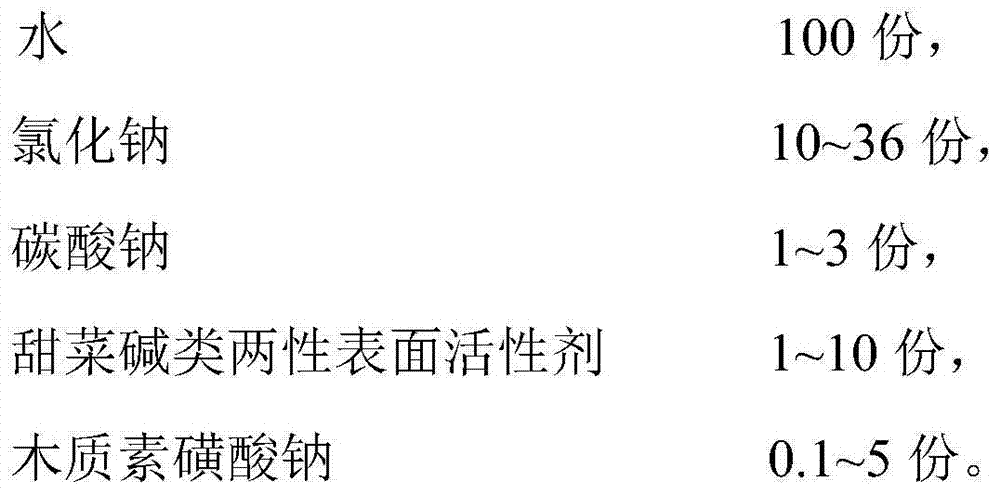

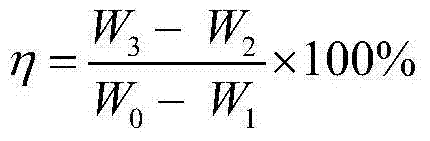

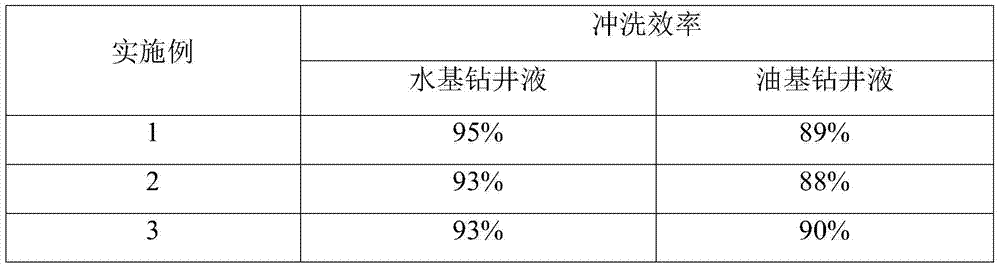

Salty flushing fluid for well cementation and preparation method thereof

ActiveCN104745165AReduce or prevent dissolutionPrevent collapseDrilling compositionWater basedChemistry

The invention discloses a salty flushing fluid for well cementation. The formula of the salty flushing fluid comprises 100 parts of water, 10-36 parts of sodium chloride, 1-3 parts of sodium carbonate, 1-10 parts of betaine-type amphoteric surfactant and 0.1-5 parts of sodium lignin sulfonate; the invention further discloses a preparation method of the salty flushing fluid for well cementation. The method comprises the following steps: completely dissolving sodium chloride, sodium carbonate and sodium lignin sulfonate in water, and then adding the betaine-type amphoteric surfactant, further stirring for 10-20min to obtain the salty flushing fluid for well cementation. The salty flushing fluid for well cementation is used for reducing or preventing the dissolving to an salt gypsum bed when the well cementation is performed on the salt gypsum bed, and avoiding the hole-wall collapsing caused when the salt gypsum bed is excessively dissolved by the flushing fluid, and a sleeve wall can be effectively flushed, the interface bonding strength of the cement slurry and the sleeve is improved, the well cementation quality is improved, and the salty flushing fluid is suitable for oil-based drilling fluid or water-based drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com