Method and device for maintaining seal integrity of cement sheath

A cement sheath and integrity technology, used in sealing/isolation, earthwork drilling, special data processing applications, etc., to improve the interface bonding strength, maintain integrity, and improve the stress state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

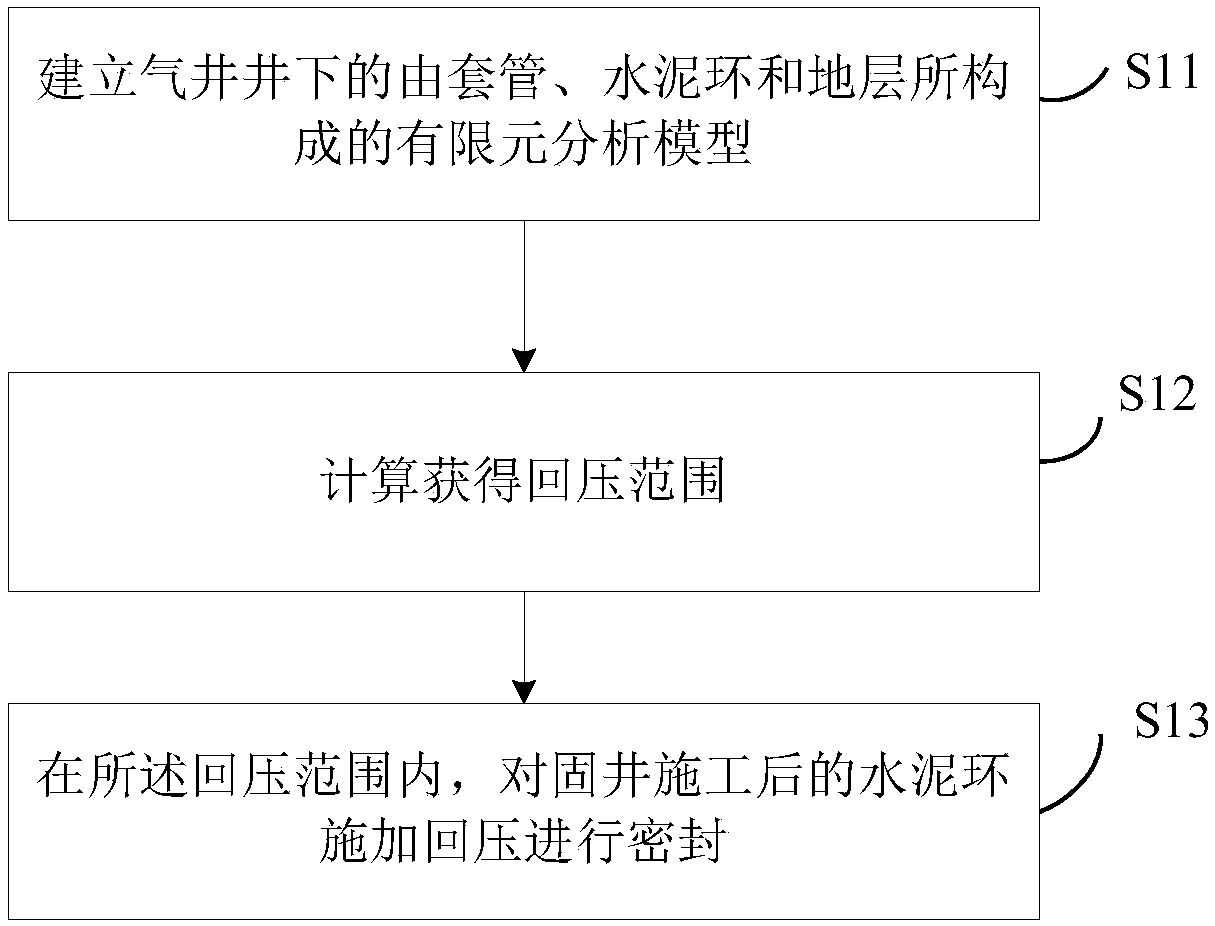

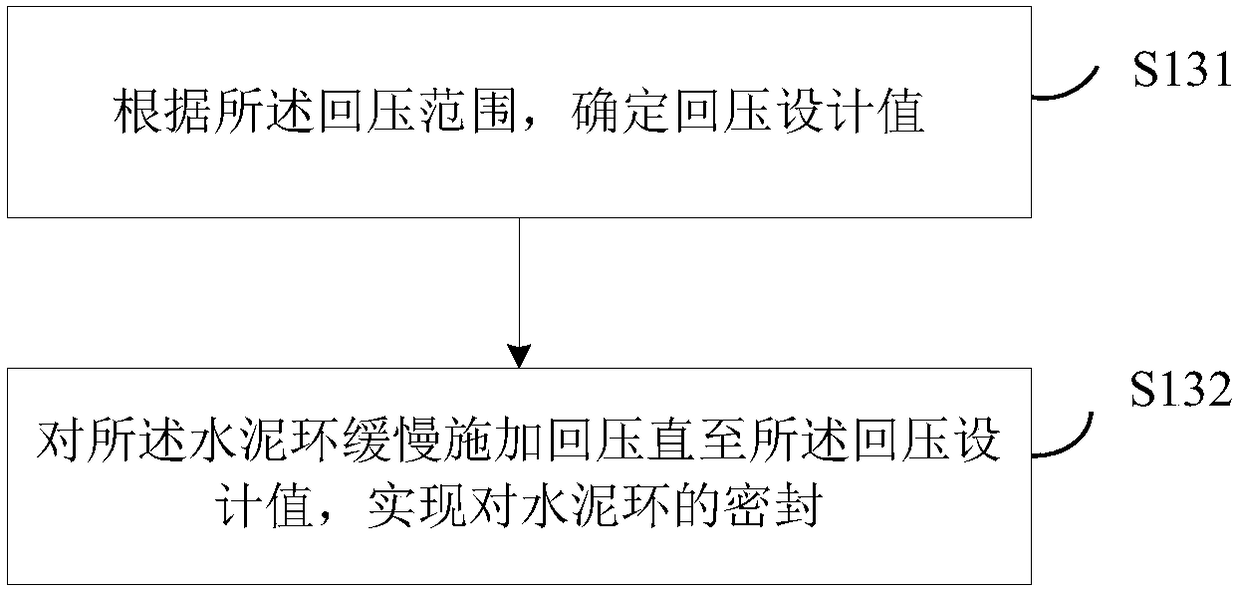

[0057] see figure 1 A schematic flow chart of a method for maintaining the sealing integrity of the cement sheath provided by Embodiment 1 of the present invention, the method includes the following steps:

[0058] S11. Establish a finite element analysis model composed of casing, cement sheath and formation downhole of the gas well, wherein, in the gas well, the cement sheath is located between the casing and the formation;

[0059] Specifically, the main purpose of gas well cementing and cementing operations is to effectively isolate the outer annulus of the casing to prevent formation fluid channeling during gas well drilling, stimulation operations, and production; and to form a complete cement sheath to effectively support and protect casing. During the drilling and development of gas wells, the cement sheath is subject to such effects as casing internal pressure, formation rock confining pressure, temperature stress, etc. These loads often have an adverse effect on the ...

Embodiment 2

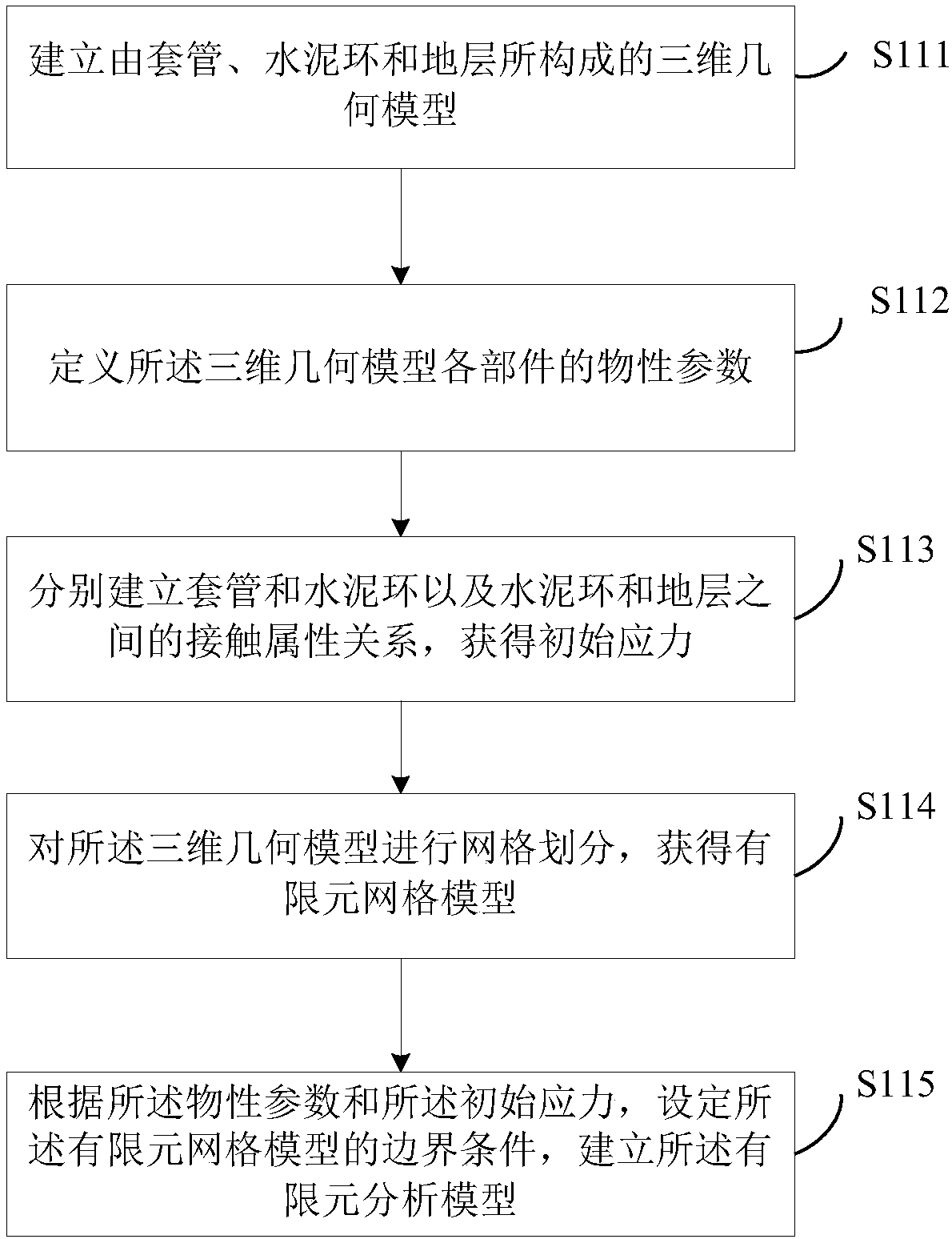

[0066] Referring to embodiment one of the present invention and figure 1 For the specific process of steps S11 to S13 described in , see figure 2 Corresponding to the second embodiment of the present invention figure 1 The schematic flow chart of the specific establishment of the finite element analysis model in the shown S11 step, figure 1 Step S11 specifically includes:

[0067] S111. Establish a three-dimensional geometric model composed of casing, cement sheath and formation according to the casing size actually used and the measured borehole expansion rate;

[0068] Specifically, it is preferable in the second embodiment, according to the size of the oil reservoir casing actually used on site and the measured diameter enlargement rate, while considering the elimination of the influence of the wellbore stress on the far-field stress and the end effect, through the ABAQUS finite element The software builds a three-dimensional geometric model of the casing-cement sheath-...

Embodiment 3

[0094] Corresponding to the methods for maintaining the sealing integrity of the cement sheath disclosed in Embodiments 1 and 2 of the present invention, Embodiment 3 of the present invention also provides a device for maintaining the sealing integrity of the cement sheath, see Figure 5 A schematic structural diagram of a device for maintaining the sealing integrity of the cement sheath provided in the third embodiment of the present invention, the device includes:

[0095] Model building module 1, used to build a finite element analysis model composed of casing, cement sheath and formation downhole in the gas well, wherein, in the gas well, the cement sheath is located between the casing and the formation ;

[0096] The calculation module 2 is used to analyze the parameters related to the stress characteristics of the cement sheath in the finite element analysis model, and calculate and obtain the back pressure range. Injected, the pressure range capable of maintaining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com