Carbon fiber modified with crystalized crosslinkable polyaryletherketone sizing agent and preparation method of carbon fiber

A polyaryletherketone, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of easy oxidation of hydroquinone, affecting mechanical properties, affecting interface properties, etc., to improve the interface bonding strength, interface Improved shear performance and enhanced interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

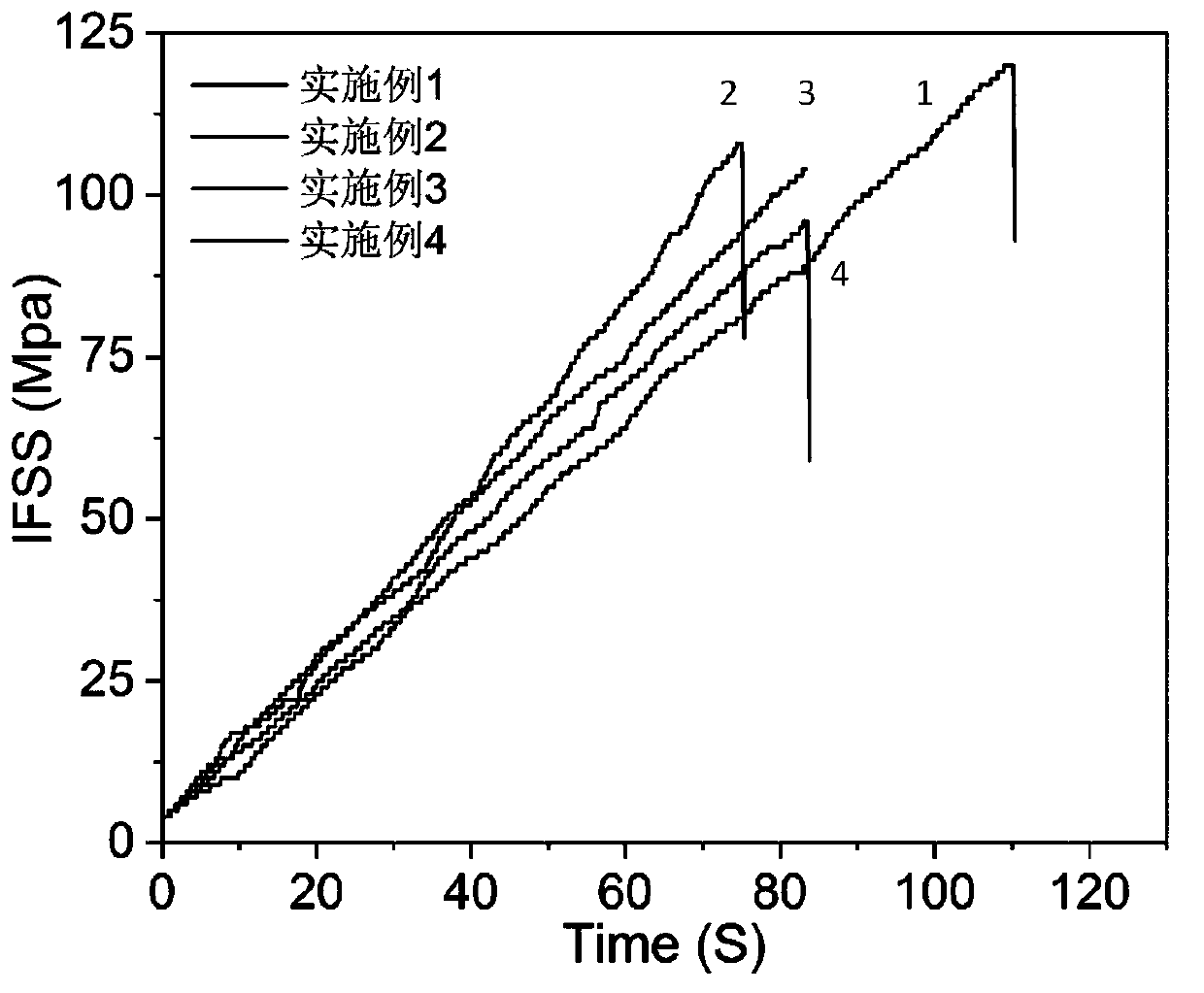

Embodiment 1

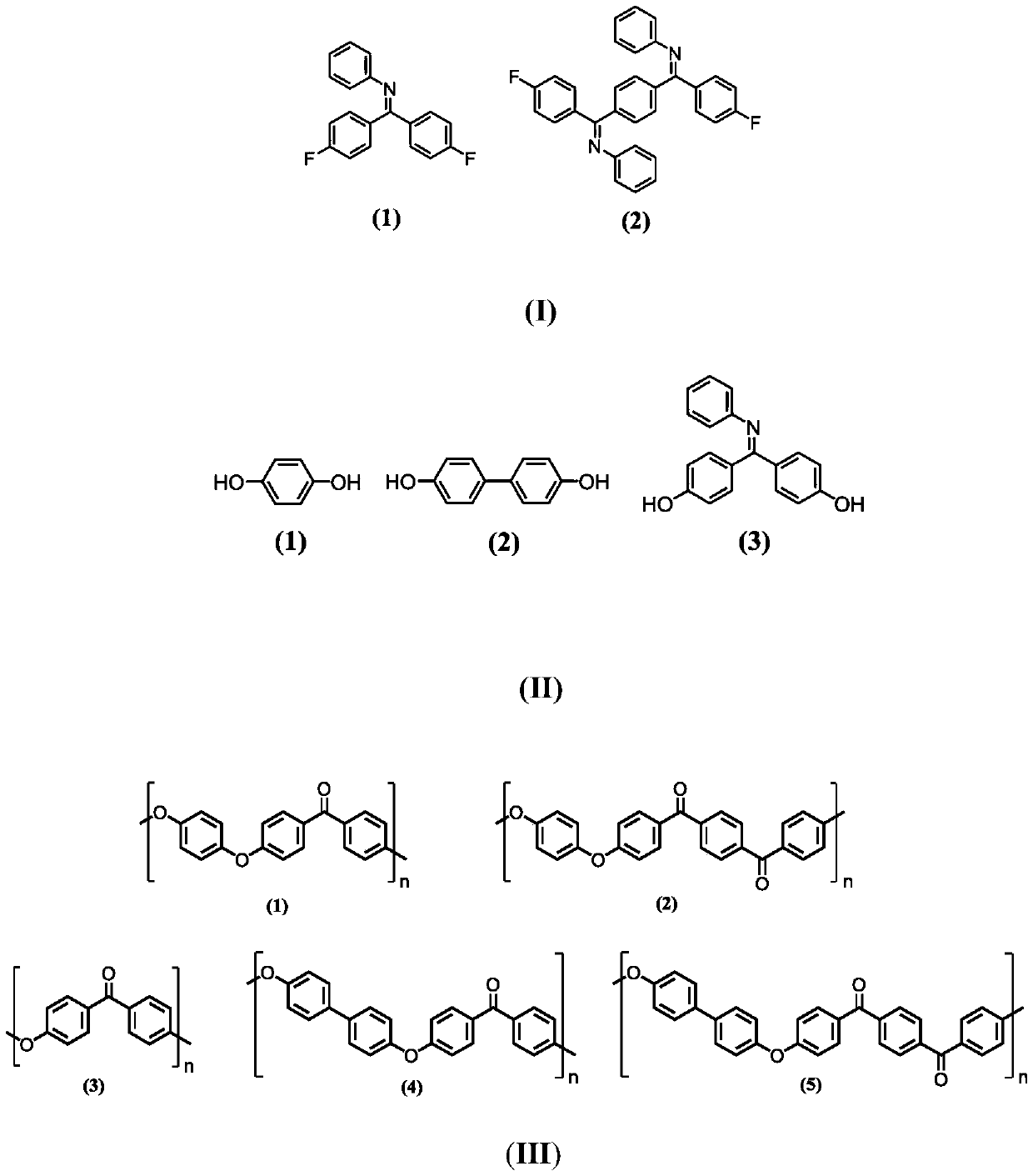

[0047] Put 20mmol of ketimine fluoroketone and 20mmol of hydroquinone into sulfolane, polymerize at reflux temperature for 10h, reduce the temperature of the polymer solution to 120°C after the polymerization is completed, and directly add 1mmol of phenylethynyl fluoroketone for capping. After the reaction is completed, the material is discharged in methanol and washed three times to obtain phenylacetylene-capped soluble crosslinkable ketimine polyetheretherketone (the number average molecular weight is 20000g / mol);

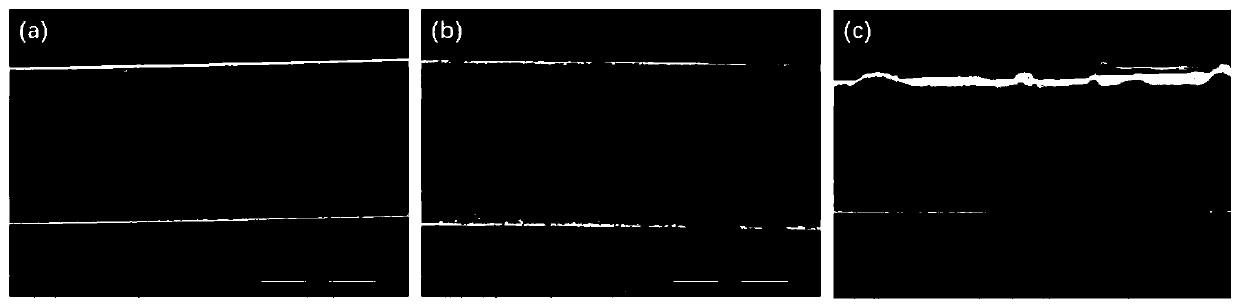

[0048] Add 10 g of p-anilinophenylacetylene to 100 mL of an aqueous solution containing 15 g of sodium nitrite and 0.1 mol of hydrochloric acid at zero temperature, and then undergo recrystallization to obtain phenylacetylene diazonium salt. Pull the carbon fiber into the acetonitrile solution with a concentration of 1mmol / L phenylacetylene diazonium salt, and use a brush to feed a current of 0.5A to carry out the grafting reaction, so that the crosslinking group ...

Embodiment 2

[0057] Put 20mmol of ketimine fluoroketone and 20mmol of hydroquinone into sulfolane, carry out polymerization at reflux temperature for 5h, reduce the temperature of the polymer solution to 120°C after polymerization, and directly add 1mmol of distyryl fluoroketone for capping. After the reaction is completed, the material is discharged in methanol and washed three times to obtain a soluble crosslinkable ketimine polyether ether ketone (number average molecular weight: 4000 g / mol) terminated by phenylmaleimide;

[0058] Add 10 g of phenylmaleamide aniline to 100 mL of an aqueous solution containing 15 g of sodium nitrite and 0.1 mol of hydrochloric acid at zero temperature, and then undergo recrystallization to obtain phenylmaleamide diazonium salt. Pull the carbon fiber into the acetonitrile solution with a concentration of 1mmol / L phenylmaleamide diazonium salt, and use a brush to feed a 0.5A current to carry out the grafting reaction, so that the crosslinking group is graft...

Embodiment 3

[0066] Put 20mmol of ketimine fluoroketone and 20mmol of biphenyldiphenol into sulfolane, carry out polymerization at reflux temperature for 24h, after the polymerization is completed, lower the temperature of the polymer solution to 120°C, and directly put in 1mmol of phenylethynyl fluoroketone for capping. After the reaction is completed, the material is discharged in methanol and washed three times to obtain phenylacetylene-capped soluble crosslinkable ketimine polyetheretherketone (number average molecular weight 20000g / mol);

[0067] Add 10 g of phenylethynyl aniline to 100 mL of an aqueous solution containing 15 g of sodium nitrite and 1 mol of hydrochloric acid at zero temperature, and then undergo recrystallization to obtain phenylethynyl diazonium salt. Pull the carbon fiber into the acetonitrile solution with a concentration of 1mmol / L phenylethynyl diazonium salt, and use a brush to feed a 0.5A current to carry out the grafting reaction, so that the crosslinking grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com